Flow and Heat Transfer on the Surface of Molten Steel Slag Layer in Continuous Casting Mold

Abstract

:1. Introduction

2. Model Description

2.1. Assumptions

- (1)

- The flow of molten steel and protective slag is an incompressible steady-state flow.

- (2)

- Due to the small calculation area of the model, the thickness of the slag film remains unchanged.

2.2. Governing Equation

- (2)

- (3)

2.3. Initial and Boundary Conditions

- (1)

- For the top boundary, the upper surface is the sintering slag, it is regarded as a wall, so the top boundary is set to no slip boundary, the interface temperature is the solidification temperature of the protective slag.

- (2)

- For the bottom of the liquid slag layer, the interface temperature is set to the pouring temperature of steel liquid.

- (3)

- For the right boundary of the liquid slag layer, it is considered adiabatic and set as a symmetric boundary, with a zero normal velocity and zero normal gradient for other variables.

- (4)

- The left boundary of the liquid slag layer is adjacent to the mold wall, and there is cooling water on the back of the mold. Therefore, the protective slag next to the mold wall will solidify, the temperature on the left boundary is set to the solidification temperature. To fully consider the influence of the meniscus behavior of the mold, the liquid slag temperature is set as a linear function of the change in slag layer thickness from the slag/steel interface to the 1/2 slag layer height.

2.4. Calculated Method

3. Results and Discussion

3.1. Subsection

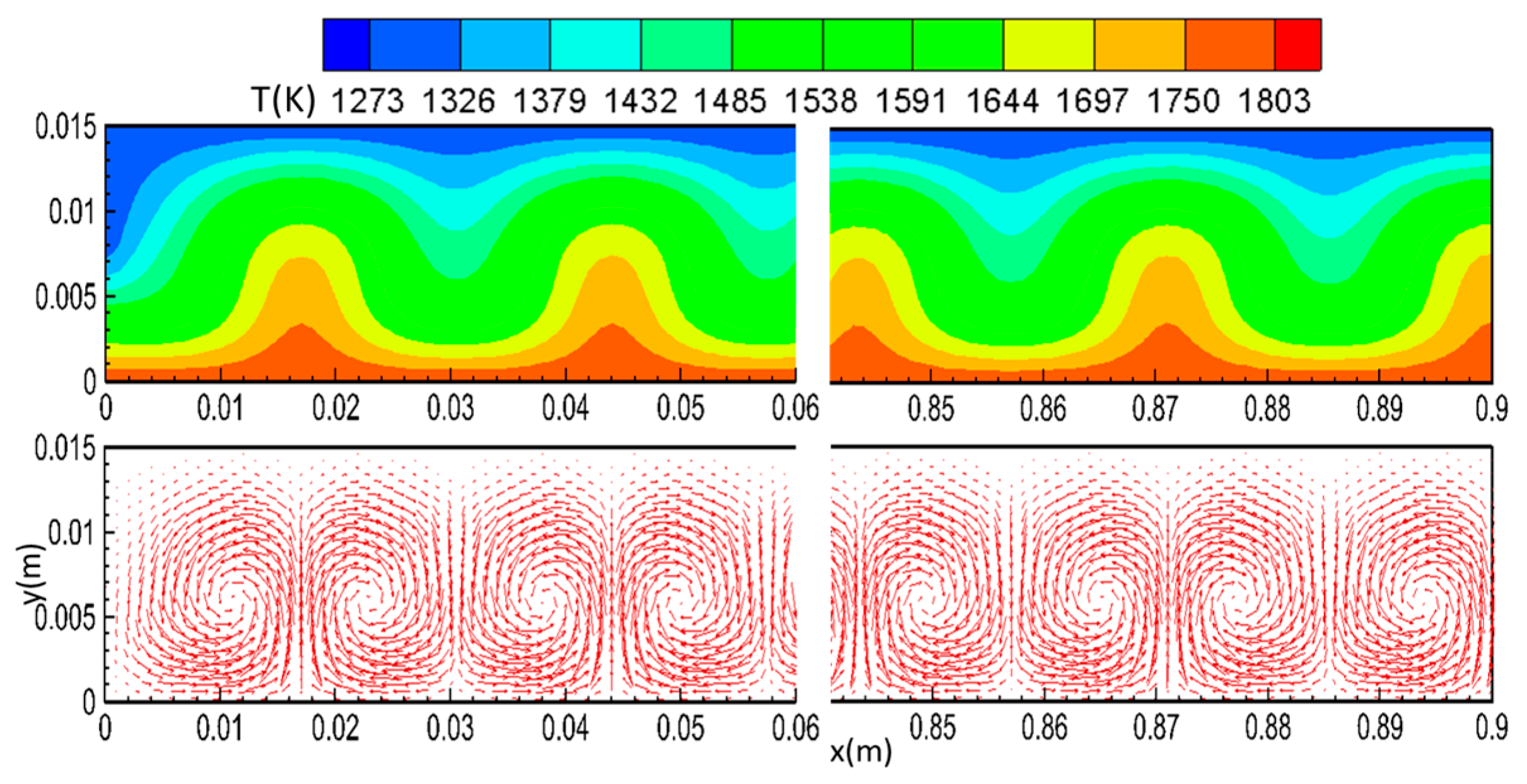

3.2. Rayleigh Number

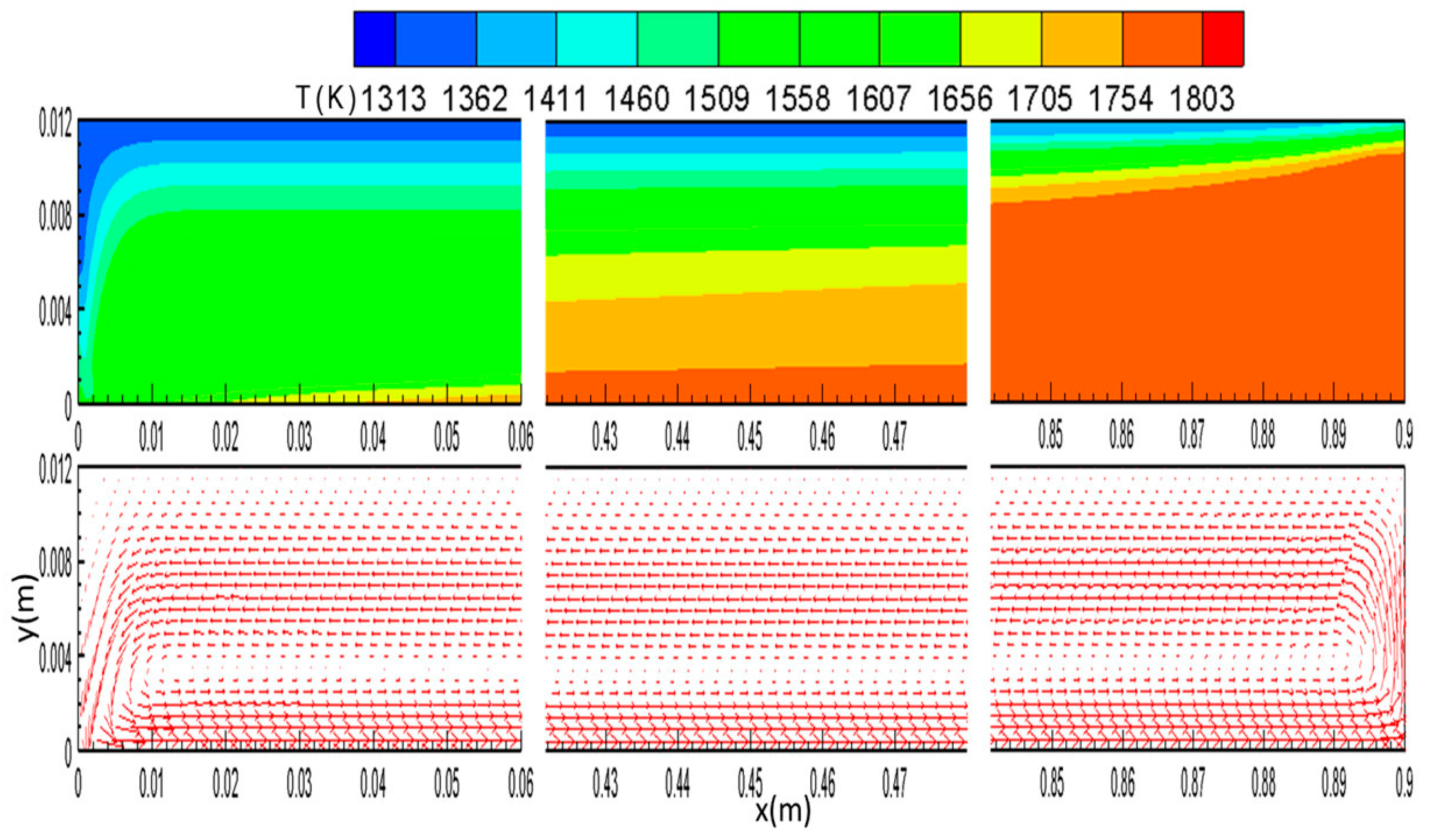

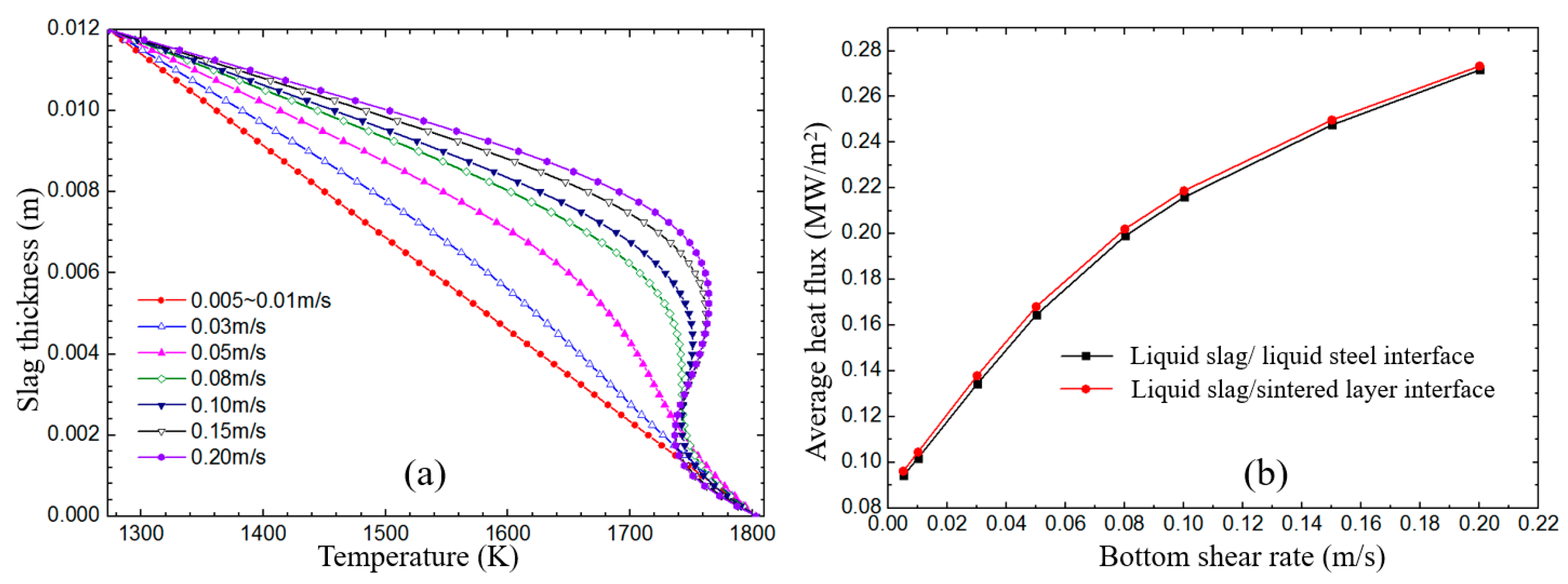

3.3. The Effect of Bottom Shear Velocity on Liquid Slag Flow and Heat Transfer

4. Discussion

- (1)

- When the shear speed of the slag steel interface is not considered, with the increase of the thickness of the liquid slag layer, the driving of the internal buoyancy flow will lead to the natural convection vortex in the liquid slag layer, and the heat transfer effect of natural convection is also strong. When considering the effect of bottom shear velocity, the flow inside the liquid slag layer is basically laminar, and the heat transfer inside the liquid slag layer will mainly be heat conduction.

- (2)

- The shear stress formed at the bottom of the slag layer due to the flow of molten steel will promote the formation of a counterclockwise circulation zone within the slag layer. The heat transfer rate near the nozzle along the casting direction is relatively high, which can provide heat to the sintering layer in a shorter time and promote the melting of protective slag. Therefore, the amount of protective slag added in the nozzle area can be moderately increased in production to optimize the slag adding process and promote slag consumption.

- (3)

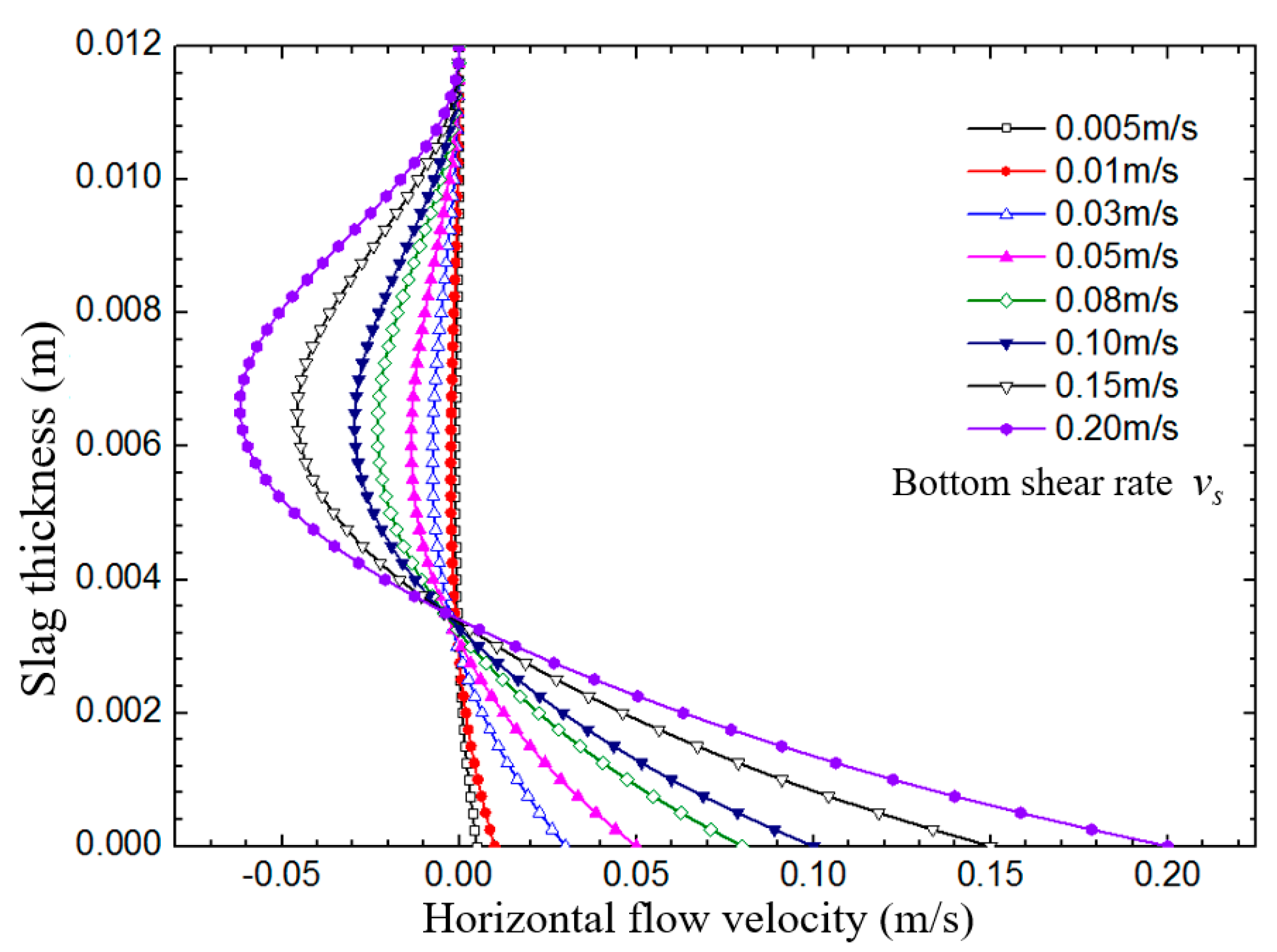

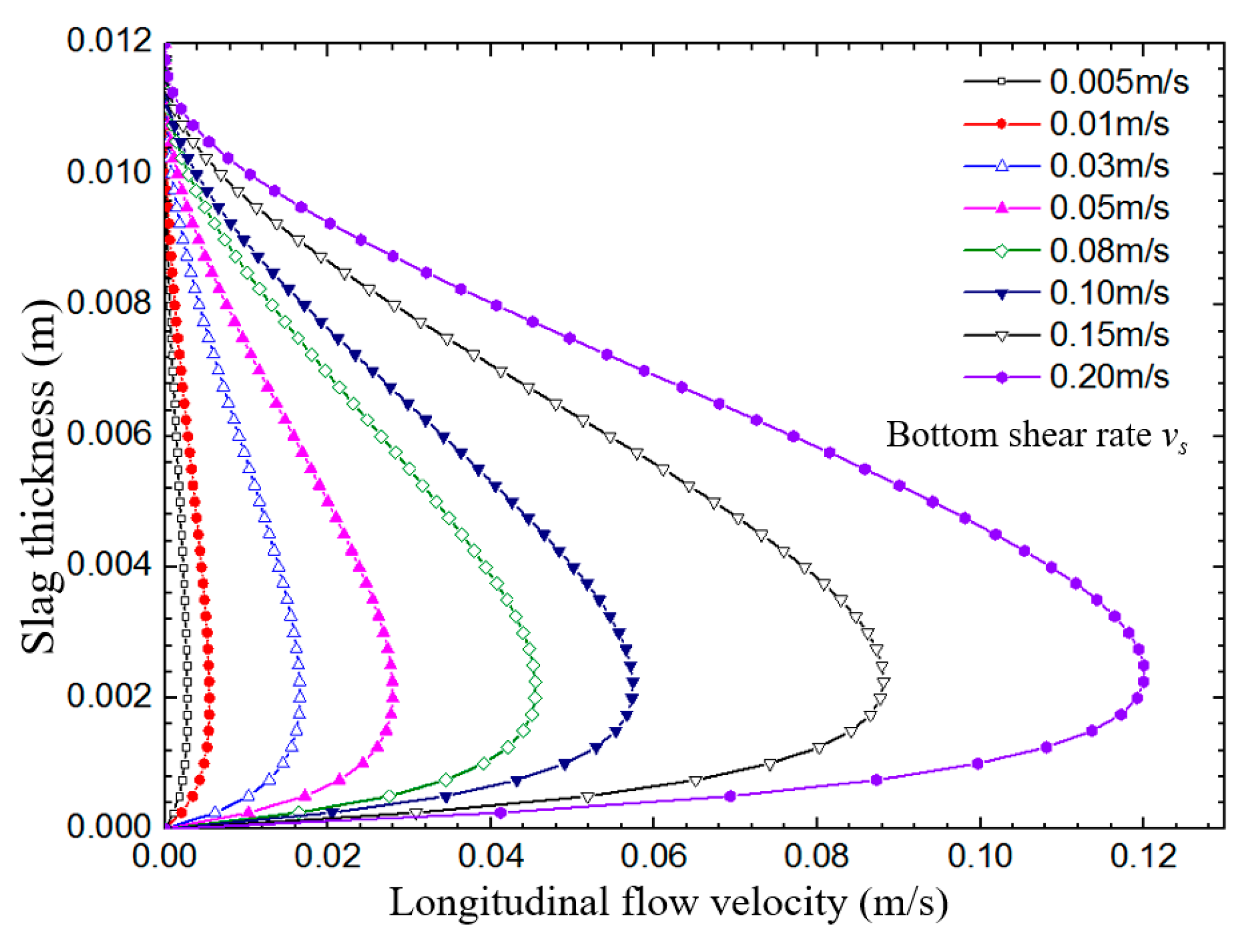

- The shear velocity formed at the steel/slag interface due to the flow of molten steel has a significant impact on the flow state of the protective slag. As the bottom shear velocity increases, the flow and heat transfer of the liquid slag layer will undergo significant changes, which cannot be ignored in numerical calculations and analysis. When the bottom shear velocity increases from 0.005 m/s to 0.2 m/s, the maximum flow velocity of liquid slag from the nozzle to the narrow surface in the center area of the model increases from 0.0012 m/s to 0.0617 m/s, and the average longitudinal flow velocity of liquid slag near the nozzle increases from 0.0012 m/s to 0.0627 m/s. The heat conduction and heat convection in the liquid slag layer significantly enhance with the increase of shear velocity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Furumai, K.; Aramaki, N.; Oikawa, K. Influence of heat flux different between wide and narrow face in continuous casting mould on unevenness of hypo-peritectic steel solidification at off-corner. Ironmak. Steelmak. 2022, 49, 845–859. [Google Scholar] [CrossRef]

- Long, Q.; Wang, W.L.; Dou, K. Investigation on carbonizing from mold flux into ultra-low-carbon steel during continuous casting. Metal. Mater. Trans. B 2022, 54, 263–274. [Google Scholar] [CrossRef]

- Irie, S.; Tsuzumi, K.; Matsui, A.; Kikuchi, N. Estimation of changes in content and characteristics of mold flux during continuous casting. ISIJ Int. 2023, 63, 516–524. [Google Scholar] [CrossRef]

- Yang, J.; Wang, L.J.; Li, Y.; Wang, T.J.; Kong, L.Z.; Zhang, X.M. Modeling of Flux Reaction and Mixing in Continuous Casting Mold of Medium Mn Steel. Metal. Mater. Trans. B 2022, 53, 1516–1525. [Google Scholar] [CrossRef]

- Dozhdikov, V.I.; Cherkasov, N.V.; Vasyutin, A.Y.; Ganul, A.O. Simulation of the Heat-Transfer Conditions in a CCM Mold. Metallurgist 2022, 66, 610–616. [Google Scholar] [CrossRef]

- Meng, Y.; Thomas, B.G. Heat-transfer and solidification model of continuous slab casting: CON1D. Metal. Mater. Trans. B. 2003, 34, 685–705. [Google Scholar] [CrossRef]

- Han, F.N.; Wen, G.H.; Zhang, F.; Wang, Z.; Yu, L. Effect of Microstructure on the Granule Strength of Hollow Granulated Mold Fluxes for Continuous Casting. Steel Res. Int. 2023, 94, 2200480. [Google Scholar] [CrossRef]

- Neelakantan, V.N.; Sridhar, S.; Mills, K.C.; Sichen, D. Mathematical model to simulate the temperature and composition distribution inside the flux layer of a continuous casting mould. Scand. J. Metall. 2002, 31, 191–200. [Google Scholar] [CrossRef]

- Mcdavid, R.M.; Thomas, B.G. Flow and thermal behavior of the top surface flux/powder layers in continuous casting molds. Metall. Mater. Trans. B. 1996, 27, 672–685. [Google Scholar] [CrossRef]

- Macias, A.E.; Castillejos, E.A.H.; Acosta, G.F.A.; Herrera, M.; Neumann, F. Modelling molten flux layer thickness profiles in compact strip process moulds for continuous thin slab casting. Ironmak. Steelmak. 2002, 29, 347–358. [Google Scholar] [CrossRef]

- Xu, L.; Pei, Q.W.; Han, Z.F.; Wang, E.A.; Wang, J.Y.; Karcher, C. Modeling study of EMBr effects on molten steel flow, heat transfer and solidification in a continuous casting mold. Metall. Res. Technol. 2023, 120, 218. [Google Scholar] [CrossRef]

- Swain, A.N.S.S.; Ganguly, S.; Sengupta, A.; Chacko, E.Z.; Dhakate, S.; Pandey, P.K. Investigation of corner cracks in continuous casting billet using thermomechanical model and plant measurements. Met. Mater. Int. 2022, 28, 2434–2447. [Google Scholar] [CrossRef]

- Thaps, S.; Wang, M.Q.; Silaen, A.K.; Ferreira, M.E.; RollingS, W.; Zhou, C. Application of electromagnetic braking to minimize a surface wave in a continuous caster. Materials 2023, 16, 1042. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Vanka, S.P.; Thomas, B.G. Numerical study of flow and heat transfer in a molten flux layer. Int. J. Heat Fluid Flow 2005, 26, 105–118. [Google Scholar] [CrossRef]

| Number of Grid | Maximum Velocity | Deviation |

|---|---|---|

| 39,600 | 0.114 | - |

| 49,500 | 0.159 | 0.045 |

| 66,000 | 0.196 | 0.027 |

| 79,200 | 0.213 | 0.017 |

| 98,000 | 0.214 | 0.001 |

| Item | Value |

|---|---|

| Length, L | 900 mm |

| Density of liquidus slag, ρ0 | 2500 kg/m3 |

| Specific heat, Cp | 3000 J/kg·°C |

| Effective thermal conductivity, k | 2 W/m·°C |

| Thermal expansion coefficient, β | 2.4 × 10−5 °C−1 |

| Viscosity temperature coefficient, n | 1.3 |

| Viscosity of slag at 1300 °C, u0 | 0.87 Pa·s |

| Solidification temperature of slag, Ts | 1000.6 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Wang, S.; Zheng, G. Flow and Heat Transfer on the Surface of Molten Steel Slag Layer in Continuous Casting Mold. Coatings 2023, 13, 1551. https://doi.org/10.3390/coatings13091551

Li G, Wang S, Zheng G. Flow and Heat Transfer on the Surface of Molten Steel Slag Layer in Continuous Casting Mold. Coatings. 2023; 13(9):1551. https://doi.org/10.3390/coatings13091551

Chicago/Turabian StyleLi, Guohui, Shanjiao Wang, and Gengtao Zheng. 2023. "Flow and Heat Transfer on the Surface of Molten Steel Slag Layer in Continuous Casting Mold" Coatings 13, no. 9: 1551. https://doi.org/10.3390/coatings13091551

APA StyleLi, G., Wang, S., & Zheng, G. (2023). Flow and Heat Transfer on the Surface of Molten Steel Slag Layer in Continuous Casting Mold. Coatings, 13(9), 1551. https://doi.org/10.3390/coatings13091551