Optimization of Large-Area PM6:D18-CL:Y6 Ternary Organic Solar Cells: The Influence of Film Thickness, Annealing Temperature, and Connection Configuration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Cleaning of ITO Glass Substrates

2.3. UV-Light Cleaning

2.4. Transport Layer Film Preparation

2.5. Active Layer Film Preparation

2.6. Electrode Preparation

3. Results and Discussion

3.1. Effect of Film Thickness and Annealing Temperature on the Performance of Large-Area Devices

3.1.1. Effect of Film Thickness on the Photovoltaic Performance of Large-Area Devices

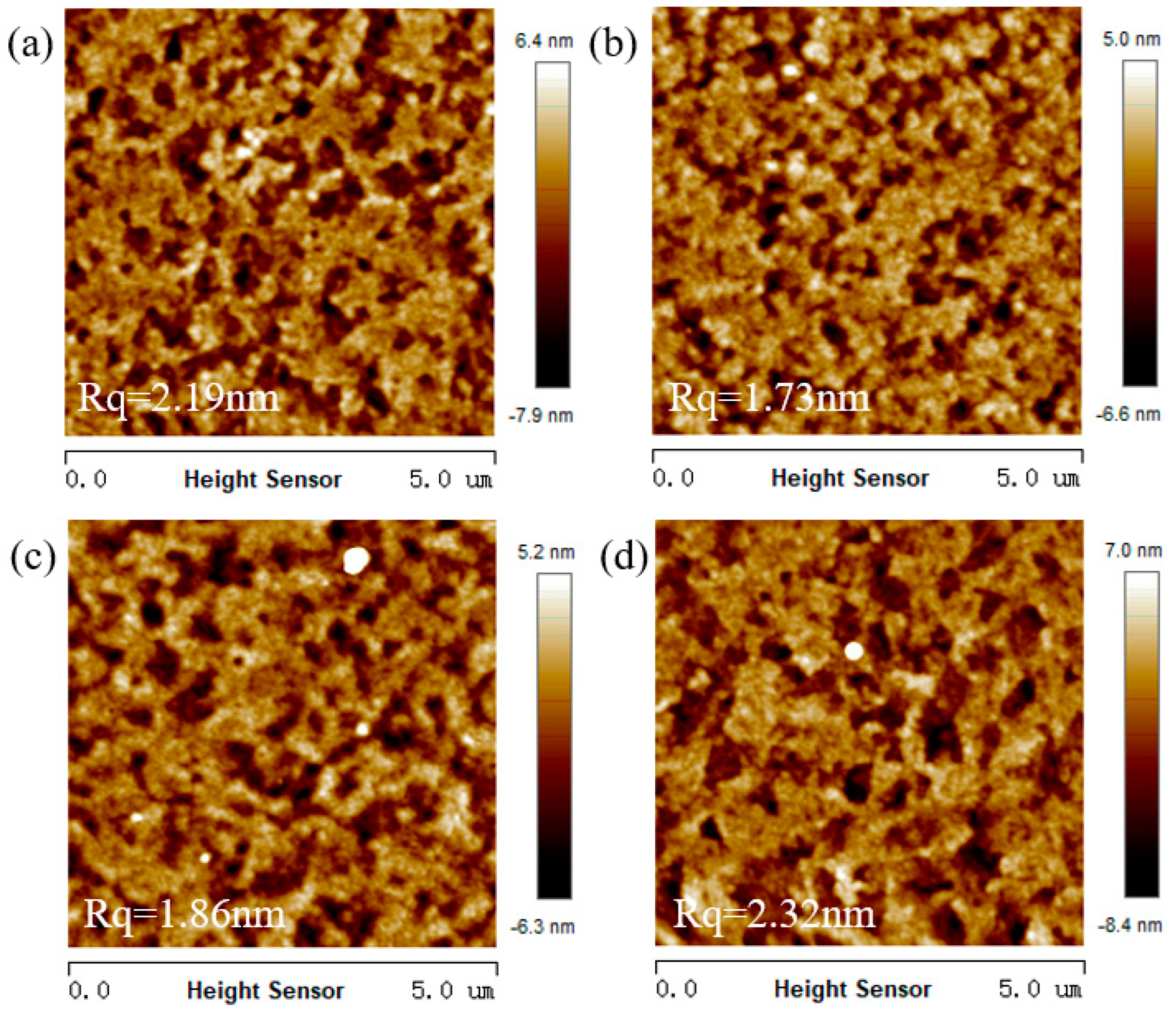

3.1.2. Effect of Film Thickness on the Morphology of the Active Layer in Large-Area Devices

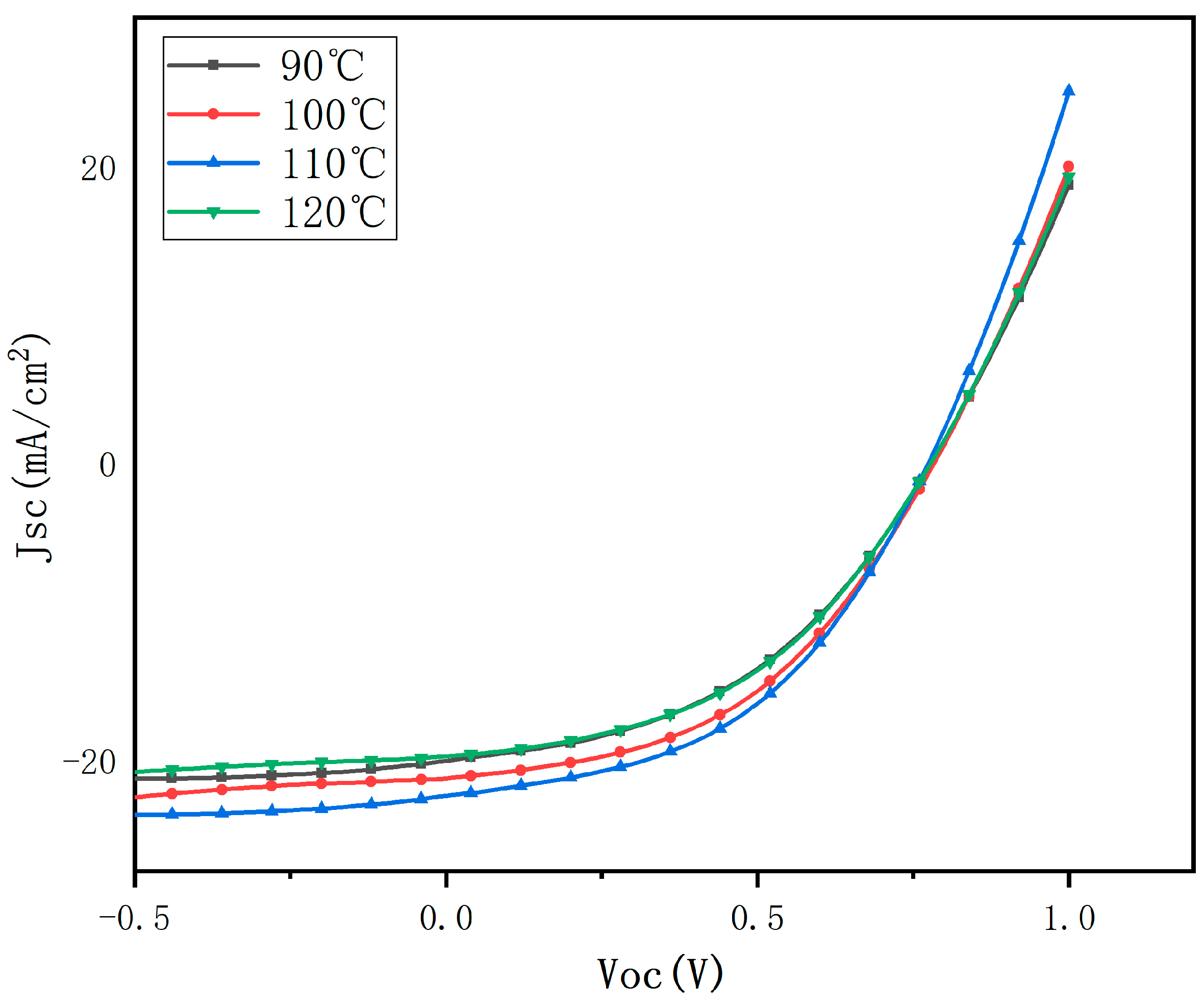

3.1.3. Effect of Annealing Temperature on the Photovoltaic Performance of Large-Area Devices

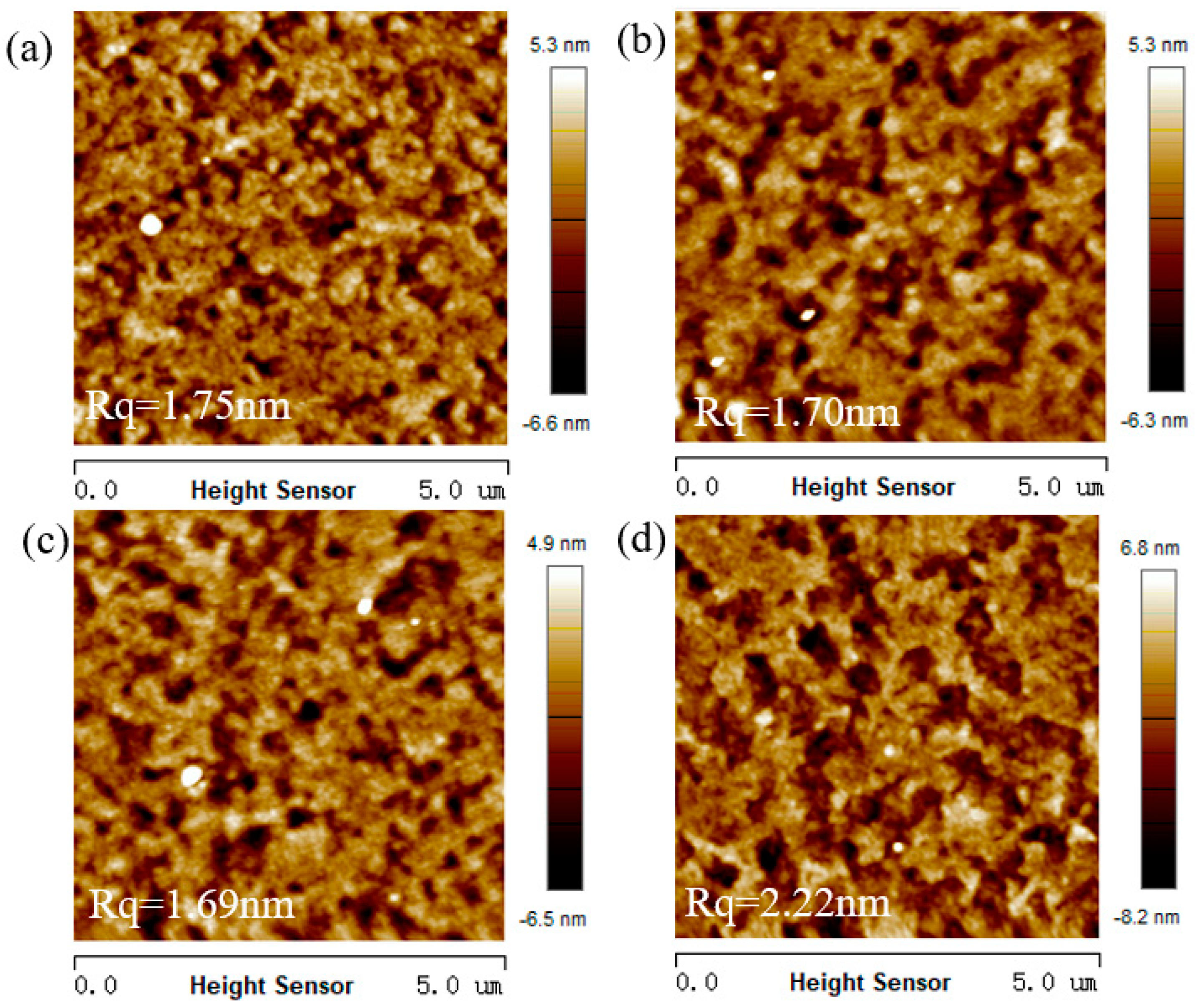

3.1.4. Effect of Annealing Temperature on the Morphology of Active Films

3.2. Series–Parallel Simulations of Battery Modules Based on Large-Area Devices

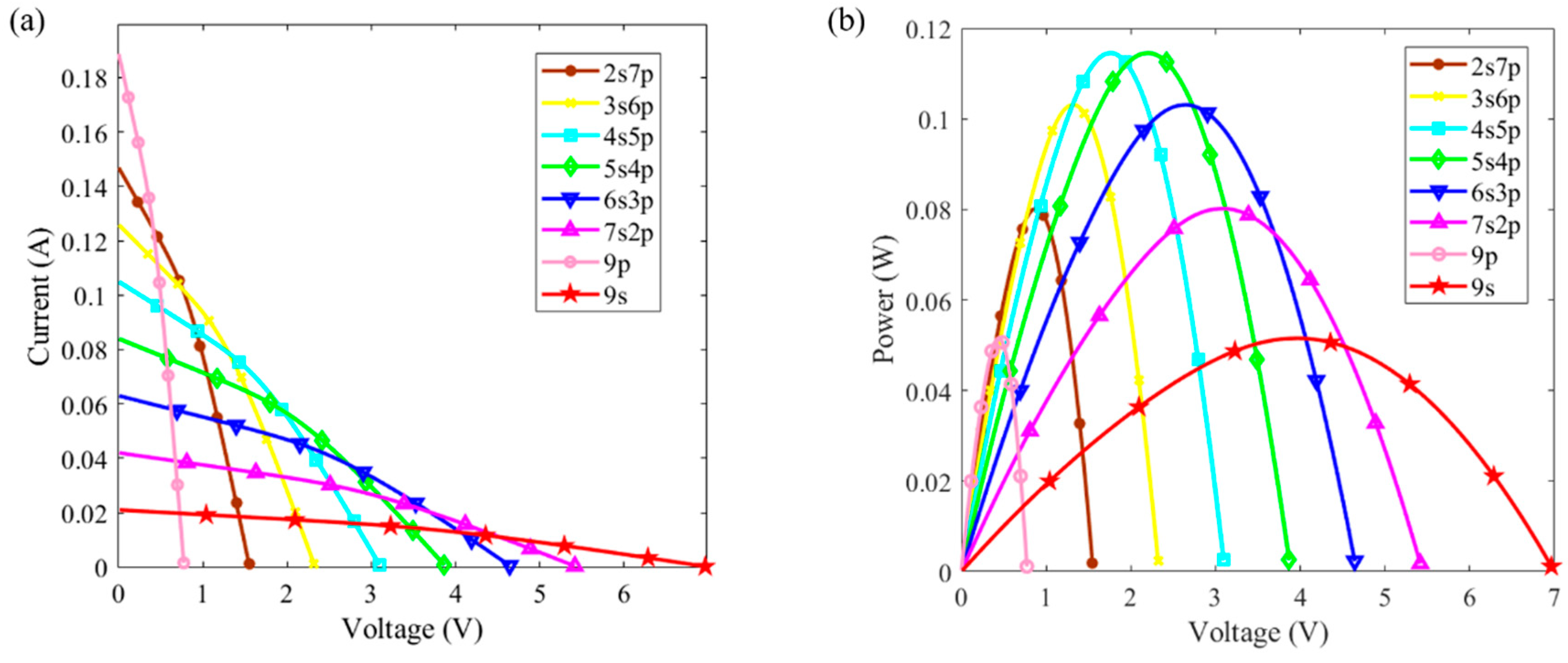

3.2.1. Simulation and Analysis of the Series–Parallel Connections of Battery Components

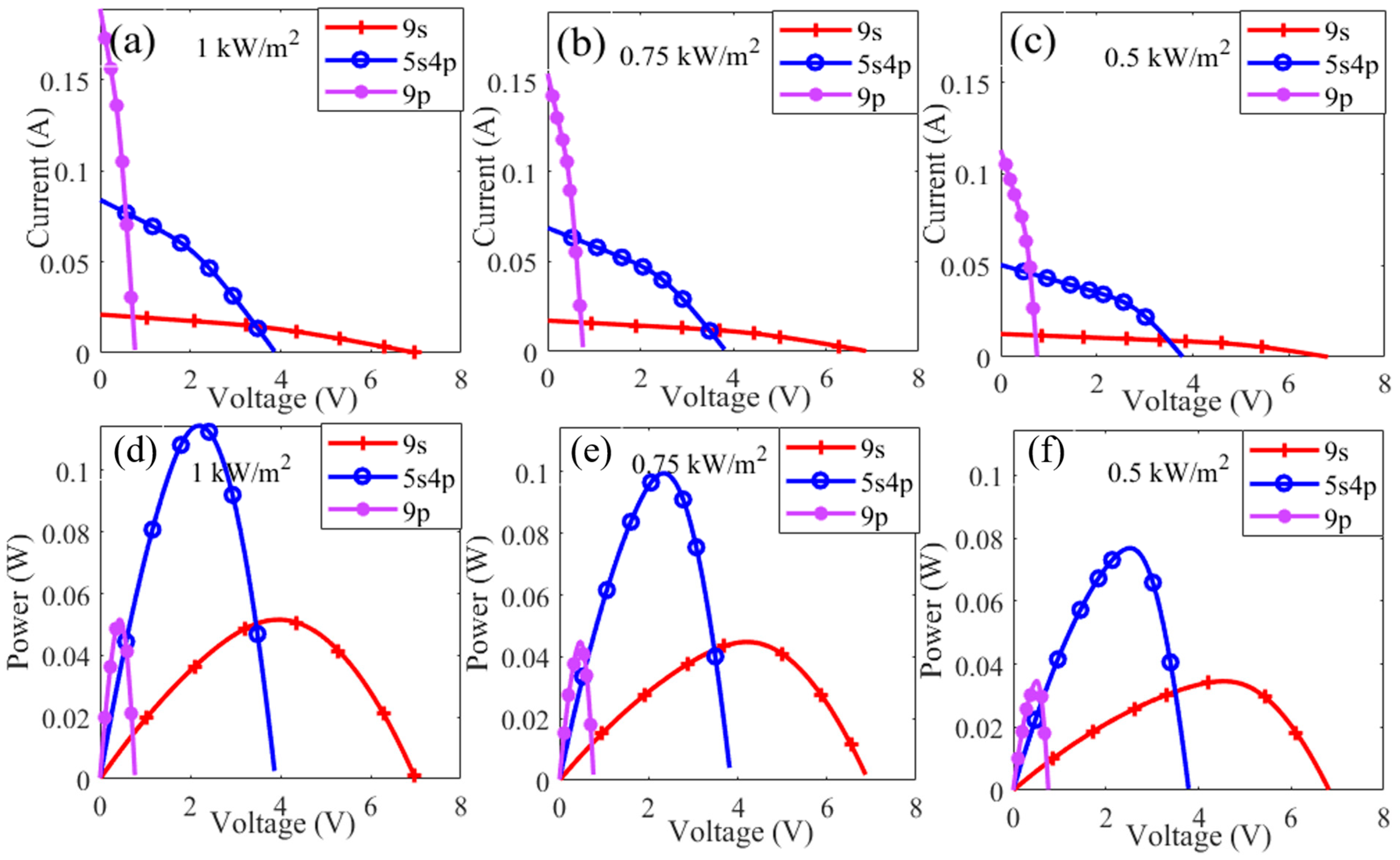

3.2.2. Simulation Analysis of Battery Modules with Different Light Intensities

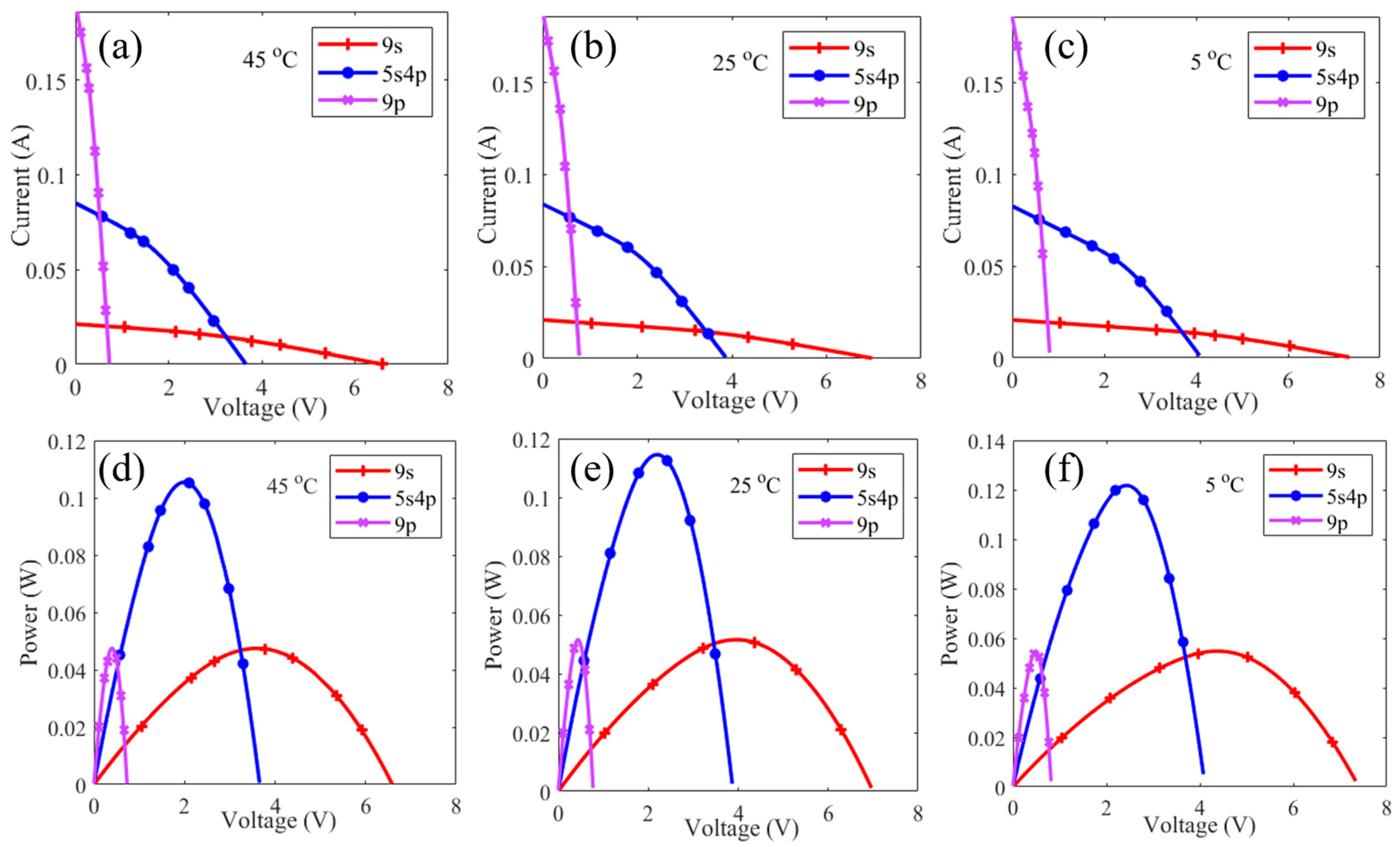

3.2.3. Simulation and Analysis of Battery Components at Different Temperatures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, C.H.; Xiao, C.Y.; Xie, C.C.; Li, W.W. Flexible organic solar cells: Materials, large-area fabrication techniques and potential applications. Nano Energy 2021, 89, 106399. [Google Scholar] [CrossRef]

- Xiao, Y.F.; Zuo, C.T.; Zhong, J.X.; Wu, W.Q.; Shen, L.; Ding, L.M. Large-Area Blade-Coated Solar Cells: Advances and Perspectives. Adv. Energy Mater. 2021, 11, 2100378. [Google Scholar] [CrossRef]

- Xue, P.Y.; Cheng, P.; Han, R.P.S.; Zhan, X.W. Printing fabrication of large-area non-fullerene organic solar cells. Mater. Horiz. 2022, 9, 194–219. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Kang, H.; Kim, G.; Lee, S.; Kim, S.; Lee, J.H.; Lee, J.; Yi, M.; Kim, J.; Back, H.; et al. A series connection architecture for large-area organic photovoltaic modules with a 7.5% module efficiency. Nat. Commun. 2016, 7, 10279. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.D.; Adil, M.A.; Zhang, J.Q.; Wei, Z.X. Large-Area Organic Solar Cells: Material Requirements, Modular Designs, and Printing Methods. Adv. Mater. 2019, 31, e1805089. [Google Scholar] [CrossRef] [PubMed]

- Jeong, S.; Park, B.; Hong, S.; Kim, S.; Kim, J.; Kwon, S.; Lee, J.H.; Lee, M.S.; Park, J.C.; Kang, H.; et al. Large-Area Nonfullerene Organic Solar Cell Modules Fabricated by a Temperature-Independent Printing Method. ACS Appl. Mater. Interfaces 2020, 12, 41877–41885. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, F.; Meng, X.C.; Yang, S.Z.; Ke, L.L.; Zhou, C.H.; Yan, H.P.; Hu, X.T.; Zhang, S.H.; Ma, W.; et al. Regulating crystallization to maintain balanced carrier mobility via ternary strategy in blade-coated flexible organic solar cells. Org. Electron. 2021, 89, 106027. [Google Scholar] [CrossRef]

- Pan, W.; Han, Y.F.; Wang, Z.G.; Gong, C.; Guo, J.B.; Lin, J.; Luo, Q.; Yang, S.F.; Ma, C.Q. An efficiency of 14.29% and 13.08% for 1 cm2 and 4 cm2 flexible organic solar cells enabled by sol-gel ZnO and ZnO nanoparticle bilayer electron transporting layers. J. Mater. Chem. A 2021, 9, 16889–16897. [Google Scholar] [CrossRef]

- Zheng, X.J.; Zuo, L.J.; Zhao, F.; Li, Y.K.; Chen, T.Y.; Shan, S.Q.; Yan, K.R.; Pan, Y.W.; Xu, B.W.; Li, C.Z.; et al. High-Efficiency ITO-Free Organic Photovoltaics with Superior Flexibility and Upscalability. Adv. Mater. 2022, 34, e2200044. [Google Scholar] [CrossRef]

- Song, J.L.; Zhu, L.; Li, C.; Xu, J.Q.; Wu, H.B.; Zhang, X.N.; Zhang, Y.; Tang, Z.; Liu, F.; Sun, Y.M. High-efficiency organic solar cells with low voltage loss induced by solvent additive strategy. Matter 2021, 4, 2542–2552. [Google Scholar] [CrossRef]

- Wang, G.D.; Zhang, J.Q.; Yang, C.; Wang, Y.H.; Xing, Y.; Adil, M.A.; Yang, Y.; Tian, L.J.; Su, M.; Shang, W.Q.; et al. Synergistic Optimization Enables Large-Area Flexible Organic Solar Cells to Maintain over 98% PCE of the Small-Area Rigid Devices. Adv. Mater. 2020, 32, e2005153. [Google Scholar] [CrossRef]

- Zhang, S.C.; Chen, H.B.; Wang, P.R.; Li, S.T.; Li, Z.X.; Huang, Y.Z.; Liu, J.; Yao, Z.Y.; Li, C.X.; Wan, X.J.; et al. A Large Area Organic Solar Module with Non-Halogen Solvent Treatment, High Efficiency, and Decent Stability. Sol. RRL 2023, 7, 2300029. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, J.Q.; Bi, P.Q.; Ren, J.Z.; Wang, Y.F.; Yang, Y.; Liu, X.Y.; Zhang, S.Q.; Hou, J.H. Tandem Organic Solar Cell with 20.2% Efficiency. Joule 2022, 6, 171–184. [Google Scholar] [CrossRef]

- Andersen, T.R.; Dam, H.F.; Hosel, M.; Helgesen, M.; Carle, J.E.; Larsen-Olsen, T.T.; Gevorgyan, S.A.; Andreasen, J.W.; Adams, J.; Li, N.; et al. Scalable, ambient atmosphere roll-to-roll manufacture of encapsulated large area, flexible organic tandem solar cell modules. Energy Environ. Sci. 2014, 7, 2925–2933. [Google Scholar] [CrossRef]

- Haldar, A.; Liao, K.S.; Curran, S.A. Effect of printing parameters and annealing on organic photovoltaics performance. J. Mater. Res. 2012, 27, 2079–2087. [Google Scholar] [CrossRef]

- Kubis, P.; Lucera, L.; Machui, F.; Spyropoulos, G.; Cordero, J.; Frey, A.; Kaschta, J.; Voigt, M.M.; Matt, G.J.; Zeira, E.; et al. High precision processing of flexible P3HT/PCBM modules with geometric fill factor over 95%. Org. Electron. 2014, 15, 2256–2263. [Google Scholar] [CrossRef]

- Agrawal, N.; Ansari, M.Z.; Majumdar, A.; Gahlet, R.; Khare, N. Efficient up-scaling of organic solar cells. Sol. Energy Mater. Sol. Cells 2016, 157, 960–965. [Google Scholar] [CrossRef]

- Chan, M.Y.; Lai, S.L.; Fung, M.K.; Lee, C.S.; Lee, S.T. Doping-induced efficiency enhancement in organic photovoltaic devices. Appl. Phys. Lett. 2007, 91, 089902, Erratum in Appl. Phys. Lett. 2007, 90, 023504. [Google Scholar] [CrossRef]

- Choi, S.; Potscavage, W.J.; Kippelen, B. Area-scaling of organic solar cells. J. Appl. Phys. 2009, 106, 054507. [Google Scholar] [CrossRef]

- Jin, W.Y.; Ginting, R.T.; Ko, K.J.; Kang, J.W. Ultra-Smooth, Fully Solution-Processed Large-Area Transparent Conducting Electrodes for Organic Devices. Sci. Rep. 2016, 6, 36475. [Google Scholar] [CrossRef]

- Kopola, P.; Aernouts, T.; Sliz, R.; Guillerez, S.; Ylikunnari, M.; Cheyns, D.; Valimaki, M.; Tuomikoski, M.; Hast, J.; Jabbour, G.; et al. Gravure printed flexible organic photovoltaic modules. Sol. Energy Mater. Sol. Cells 2011, 95, 1344–1347. [Google Scholar] [CrossRef]

- Yu, J.S.; Jung, G.H.; Jo, J.; Kim, J.S.; Kim, J.W.; Kwak, S.W.; Lee, J.L.; Kim, I.; Kim, D. Transparent conductive film with printable embedded patterns for organic solar cells. Sol. Energy Mater. Sol. Cells 2013, 109, 142–147. [Google Scholar] [CrossRef]

- Li, H.J.; Liu, S.Q.; Wu, X.T.; Qi, Q.C.; Zhang, H.Y.; Meng, X.C.; Hu, X.T.; Ye, L.; Chen, Y.W. A general enlarging shear impulse approach to green printing large-area and efficient organic photovoltaics. Energy Environ. Sci. 2022, 15, 2130–2138. [Google Scholar] [CrossRef]

- Ramos-Hernandez, R.; Calvo, F.D.; Perez-Gutierrez, E.; Percino, M.J. Large area small-molecule thin films deposited by the doctor blade technique implemented with computer numerical control machine. Thin Solid Films 2023, 771, 139787. [Google Scholar] [CrossRef]

- Xie, K.C. Reviews of clean coal conversion technology in China: Situations & challenges. Chin. J. Chem. Eng. 2021, 35, 62–69. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Li, S.L.; Xiao, L.E.; Zhang, S.W.; Han, B.; Kang, J.J.; Zhou, H.Q. Development and application of blade-coating technique in organic solar cells. Nano Res. 2023, 1–18. [Google Scholar] [CrossRef]

- Dam, H.F.; Krebs, F.C. Simple roll coater with variable coating and temperature control for printed polymer solar cells. Sol. Energy Mater. Sol. Cells 2012, 97, 191–196. [Google Scholar] [CrossRef]

- Dehaj, M.S.; Ahmadi, M.; Ghazanfarpour, S. Inverted bulk heterojunction organic solar cells using optimization of active layer deposition via controlling of doctor blade parameters. Surf. Interfaces 2020, 21, 100694. [Google Scholar] [CrossRef]

- Fan, J.Y.; Liu, Z.X.; Rao, J.; Yan, K.R.; Chen, Z.; Ran, Y.X.; Yan, B.Y.; Yao, J.Z.; Lu, G.H.; Zhu, H.M.; et al. High-Performance Organic Solar Modules via Bilayer-Merged-Annealing Assisted Blade Coating. Adv. Mater. 2022, 34, e2110569. [Google Scholar] [CrossRef]

- Fukuda, K.; Yu, K.; Someya, T. The Future of Flexible Organic Solar Cells. Adv. Energy Mater. 2020, 10, 2000765. [Google Scholar] [CrossRef]

- Hu, X.T.; Liu, S.Q.; Song, Y.L.; Chen, Y.W. New Thin-film Solar Cells: Flexible Design and Printing Manufacturing. Acta Polym. Sin. 2023, 54, 910–926. [Google Scholar]

- Ajayan, J.; Nirmal, D.; Mohankumar, P.; Saravanan, M.; Jagadesh, M.; Arivazhagan, L. A review of photovoltaic performance of organic/inorganic solar cells for future renewable and sustainable energy technologies. Superlattices Microstruct. 2020, 143, 106549. [Google Scholar] [CrossRef]

- Bai, Y.M.; Zhao, C.Y.; Zhang, S.; Zhang, S.Q.; Yu, R.N.; Hou, J.H.; Tan, Z.A.; Li, Y.F. Printable SnO2 cathode interlayer with up to 500 nm thickness-tolerance for high-performance and large-area organic solar cells. Sci. China-Chem. 2020, 63, 957–965. [Google Scholar] [CrossRef]

- Bernardo, G.; Lopes, T.; Lidzey, D.G.; Mendes, A. Progress in Upscaling Organic Photovoltaic Devices. Adv. Energy Mater. 2021, 11, 29. [Google Scholar] [CrossRef]

- Chen, D.; Liu, S.Q.; Huang, B.; Oh, J.; Wu, F.Y.; Liu, J.B.; Yang, C.; Chen, L.; Chen, Y.W. Rational Regulation of the Molecular Aggregation Enables A Facile Blade-Coating Process of Large-area All-Polymer Solar Cells with Record Efficiency. Small 2022, 18, e2200734. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Huang, W.; Zhao, D.J.; Wang, L.; Jiao, Z.Q.; Huang, Q.Y.; Wang, P.; Sun, M.N.; Yuan, G.C. Recent Progress in Organic Solar Cells: A Review on Materials from Acceptor to Donor. Molecules 2022, 27, 1800. [Google Scholar] [CrossRef]

- Liao, Y.J.; Hsieh, Y.C.; Chen, J.T.; Yang, L.S.; Jian, X.Z.; Lin, S.H.; Lin, Y.R.; Chen, L.M.; Li, F.H.; Hsiao, Y.T.; et al. Large-Area Nonfullerene Organic Photovoltaic Modules with a High Certified Power Conversion Efficiency. ACS Appl. Mater. Interfaces 2023, 15, 7911–7918. [Google Scholar] [CrossRef]

- McDowell, C.; Abdelsamie, M.; Toney, M.F.; Bazan, G.C. Solvent Additives: Key Morphology-Directing Agents for Solution-Processed Organic Solar Cells. Adv. Mater. 2018, 30, e1707114. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Haris, M.; Ryu, S.U.; Jahankhan, M.; Song, C.E.; Lee, H.K.; Lee, S.K.; Shin, W.S.; Park, T.; Lee, J.C. Trifluoromethyl-Substituted Conjugated Random Terpolymers Enable High-Performance Small and Large-Area Organic Solar Cells Using Halogen-Free Solvent. Adv. Sci. 2023, 10, e2302376. [Google Scholar] [CrossRef]

- Shen, Y.F.; Zhang, H.; Zhang, J.Q.; Tian, C.Y.; Shi, Y.A.; Qiu, D.D.; Zhang, Z.Q.; Lu, K.; Wei, Z.X. In Situ Absorption Characterization Guided Slot-Die-Coated High-Performance Large-Area Flexible Organic Solar Cells and Modules. Adv. Mater. 2023, 35, e2209030. [Google Scholar] [CrossRef]

- Campoy-Quiles, M.; Kanai, Y.; El-Basaty, A.; Sakai, H.; Murata, H. Ternary mixing: A simple method to tailor the morphology of organic solar cells. Org. Electron. 2009, 10, 1120–1132. [Google Scholar] [CrossRef]

- Khan, M.U.; Khalid, M.; Arshad, M.N.; Khan, M.N.; Usman, M.; Ali, A.; Saifullah, B. Designing Star-Shaped Subphthalocyanine-Based Acceptor Materials with Promising Photovoltaic Parameters for Non-fullerene Solar Cells. ACS Omega 2020, 5, 23039–23052. [Google Scholar] [CrossRef] [PubMed]

- ul Ain, Q.; Shehzad, R.A.; Yaqoob, U.; Sharif, A.; Sajid, Z.; Rafiq, S.; Iqbal, S.; Khalid, M.; Iqbal, J. Designing of benzodithiophene acridine based Donor materials with favorable photovoltaic parameters for efficient organic solar cell. Comput. Theor. Chem. 2021, 1200, 113238. [Google Scholar] [CrossRef]

- Khalid, M.; Khan, M.U.; Razia, E.T.; Shafiq, Z.; Alam, M.M.; Imran, M.; Akram, M.S. Exploration of efficient electron acceptors for organic solar cells: Rational design of indacenodithiophene based non-fullerene compounds. Sci. Rep. 2021, 11, 19931. [Google Scholar] [CrossRef] [PubMed]

| Speed (rpm) | Thickness (nm) | VOC (V) | JSC (mA/cm2) | FF (%) | PCE (%) |

|---|---|---|---|---|---|

| 4000 | 90 | 0.75 | 19.70 | 41.8 | 6.2 |

| 3500 | 105 | 0.75 | 20.52 | 46.2 | 7.2 |

| 3000 | 120 | 0.77 | 19.89 | 45.2 | 6.97 |

| 2500 | 135 | 0.74 | 18.53 | 40.6 | 5.54 |

| Annealing Temperature (°C) | VOC (V) | JSC (mA/cm2) | FF (%) | PCE (%) |

|---|---|---|---|---|

| 90 | 0.76 | 20.52 | 45.2 | 6.98 |

| 100 | 0.78 | 21.26 | 46.2 | 7.68 |

| 110 | 0.77 | 22.56 | 46.6 | 8.15 |

| 120 | 0.77 | 20.01 | 45.1 | 7.00 |

| Connection Method | Isc (A) | Voc (V) | Pmpp (V, W) |

|---|---|---|---|

| 9s | 0.021 | 7.02 | (3.96, 0.05) |

| 7s2p | 0.042 | 5.46 | (3.08, 0.08) |

| 6s3p | 0.063 | 4.68 | (2.64, 0.10) |

| 5s4p | 0.084 | 3.9 | (2.20, 0.11) |

| 4s5p | 0.105 | 3.12 | (1.76, 0.11) |

| 3s6p | 0.126 | 2.34 | (1.32, 0.10) |

| 2s7p | 0.147 | 1.56 | (0.88, 0.08) |

| 9p | 0.189 | 0.78 | (0.78, 0.05) |

| Light Intensity (kW/m2) | Series Pmpp (V, W) | Series–Parallel Pmpp (V, W) | Parallel Pmpp (V, W) |

|---|---|---|---|

| 0.5 | (4.54, 0.03) | (2.52, 0.07) | (0.50, 0.03) |

| 0.75 | (4.20, 0.04) | (2.33, 0.09) | (0.46, 0.04) |

| 1 | (3.96, 0.05) | (2.20, 0.11) | (0.44, 0.05) |

| Ambient Temperature (°C) | Series Pmpp (V, W) | Series–Parallel Pmpp (V, W) | Parallel Pmpp (V, W) |

|---|---|---|---|

| 5 | (4.37, 0.05) | (2.43, 0.12) | (0.48, 0.05) |

| 25 | (3.96, 0.05) | (2.20, 0.11) | (0.44, 0.05) |

| 45 | (3.58, 0.04) | (1.98, 0.10) | (0.40, 0.04) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Wang, X.; Yu, X.; Liu, J.; Zhang, Z.; Zhong, J. Optimization of Large-Area PM6:D18-CL:Y6 Ternary Organic Solar Cells: The Influence of Film Thickness, Annealing Temperature, and Connection Configuration. Coatings 2023, 13, 1561. https://doi.org/10.3390/coatings13091561

Yang J, Wang X, Yu X, Liu J, Zhang Z, Zhong J. Optimization of Large-Area PM6:D18-CL:Y6 Ternary Organic Solar Cells: The Influence of Film Thickness, Annealing Temperature, and Connection Configuration. Coatings. 2023; 13(9):1561. https://doi.org/10.3390/coatings13091561

Chicago/Turabian StyleYang, Jianjun, Xiansheng Wang, Xiaobao Yu, Jiaxuan Liu, Zhi Zhang, and Jian Zhong. 2023. "Optimization of Large-Area PM6:D18-CL:Y6 Ternary Organic Solar Cells: The Influence of Film Thickness, Annealing Temperature, and Connection Configuration" Coatings 13, no. 9: 1561. https://doi.org/10.3390/coatings13091561

APA StyleYang, J., Wang, X., Yu, X., Liu, J., Zhang, Z., & Zhong, J. (2023). Optimization of Large-Area PM6:D18-CL:Y6 Ternary Organic Solar Cells: The Influence of Film Thickness, Annealing Temperature, and Connection Configuration. Coatings, 13(9), 1561. https://doi.org/10.3390/coatings13091561