The Use of Natural Zeolites in Cement-Based Construction Materials—A State of the Art Review

Abstract

:1. Introduction

2. Fresh-State Properties

3. Mechanical Properties

3.1. Cement Paste

3.2. Mortar

3.3. Concrete

4. Durability

4.1. Freeze–Thaw Resistance

4.2. Chloride Diffusion Resistance

4.3. Acid Attack Resistance

4.4. Water Transport Properties

4.5. Carbonation Resistance

4.6. Electrical Resistivity

4.7. Drying Shrinkage

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iijima, A. Geology of natural zeolites and zeolitic rocks. Pure Appl. Chem. 1980, 52, 2115–2130. [Google Scholar] [CrossRef]

- Ahmadi, B.; Shekarchi, M. Use of natural zeolite as a supplementary cementitious material. Cem. Concr. Compos. 2010, 32, 134–141. [Google Scholar] [CrossRef]

- Islam, M.S.; Mohr, B.J.; VandenBerge, D. Performance of natural clinoptilolite zeolite in the cementitious materials: A comparative study with metakaolin, fly ash, and blast furnace slag. J. Build. Eng. 2022, 53, 104535. [Google Scholar] [CrossRef]

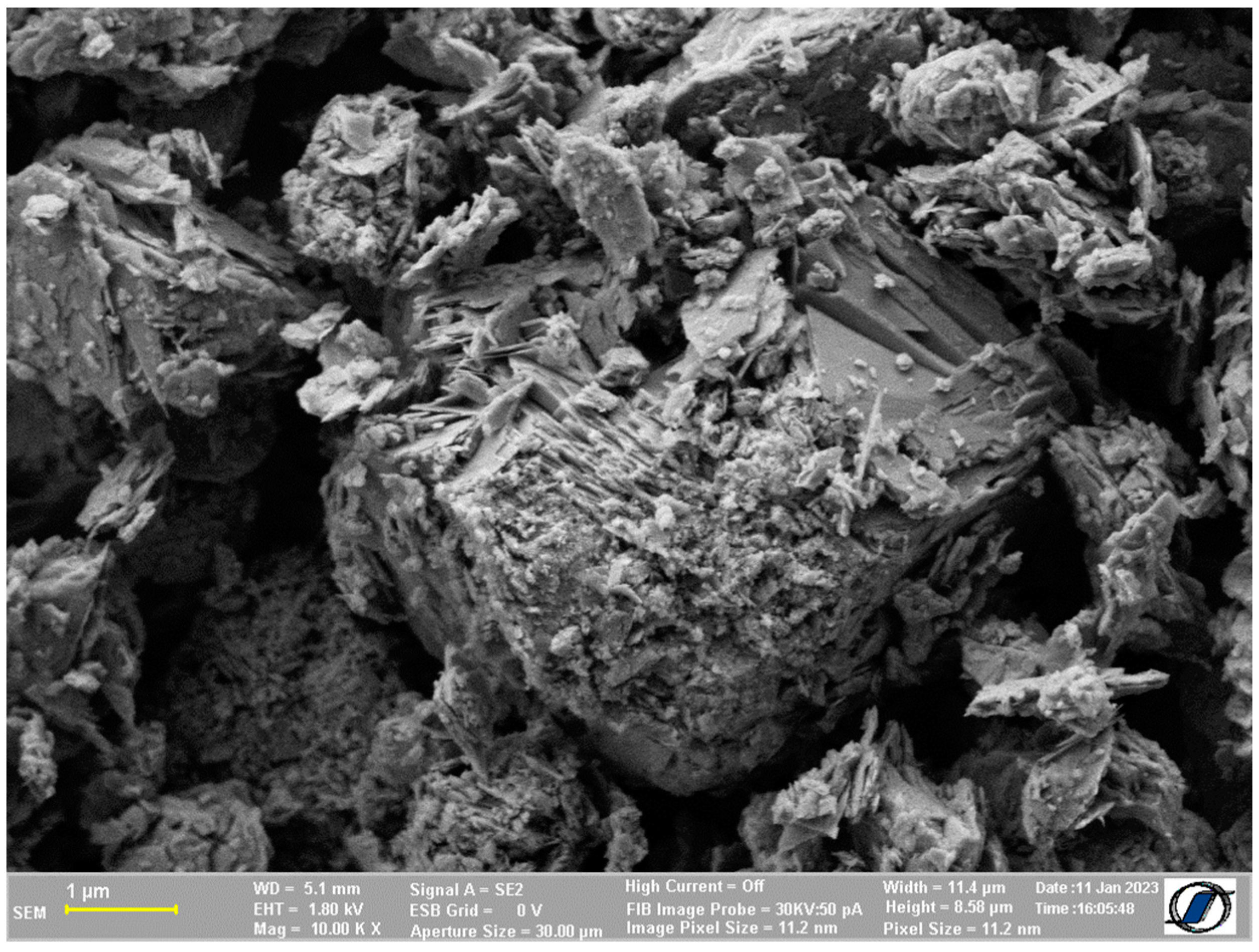

- Toma, I.-O.; Stoian, G.; Rusu, M.-M.; Ardelean, I.; Cimpoeşu, N.; Alexa-Stratulat, S.-M. Analysis of Pore Structure in Cement Pastes with Micronized Natural Zeolite. Materials 2023, 16, 4500. [Google Scholar] [CrossRef] [PubMed]

- Kazemian, M.; Shafei, B. Internal curing capabilities of natural zeolite to improve the hydration of ultra-high performance concrete. Constr. Build. Mater. 2022, 340, 127452. [Google Scholar] [CrossRef]

- Gottardi, G.; Galli, E. Natural Zeolites; Springer: Berlin/Heidelberg, Germany, 1985; Volume 18, ISBN 978-3-642-46520-8. [Google Scholar]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and durability properties of concretes incorporating natural zeolite. Arch. Civ. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Xuan, Z.; Jun, Z. Influence of zeolite addition on mechanical performance and shrinkage of high strength Engineered Cementitious Composites. J. Build. Eng. 2021, 36, 102124. [Google Scholar] [CrossRef]

- Kriptavičius, D.; Girskas, G.; Skripkiūnas, G. Use of Natural Zeolite and Glass Powder Mixture as Partial Replacement of Portland Cement: The Effect on Hydration, Properties and Porosity. Materials 2022, 15, 4219. [Google Scholar] [CrossRef]

- Kocak, Y.; Tascı, E.; Kaya, U. The effect of using natural zeolite on the properties and hydration characteristics of blended cements. Constr. Build. Mater. 2013, 47, 720–727. [Google Scholar] [CrossRef]

- Najimi, M.; Sobhani, J.; Ahmadi, B.; Shekarchi, M. An experimental study on durability properties of concrete containing zeolite as a highly reactive natural pozzolan. Constr. Build. Mater. 2012, 35, 1023–1033. [Google Scholar] [CrossRef]

- Tran, Y.T.; Lee, J.; Kumar, P.; Kim, K.-H.; Lee, S.S. Natural zeolite and its application in concrete composite production. Compos. Part B Eng. 2019, 165, 354–364. [Google Scholar] [CrossRef]

- Kaplan, G.; Coskan, U.; Benli, A.; Bayraktar, O.Y.; Kucukbaltacı, A.B. The impact of natural and calcined zeolites on the mechanical and durability characteristics of glass fiber reinforced cement composites. Constr. Build. Mater. 2021, 311, 125336. [Google Scholar] [CrossRef]

- Burris, L.E.; Juenger, M.C.G. Effect of calcination on the reactivity of natural clinoptilolite zeolites used as supplementary cementitious materials. Constr. Build. Mater. 2020, 258, 119988. [Google Scholar] [CrossRef]

- Faheem, A.; Rizwan, S.A.; Bier, T.A. Properties of self-compacting mortars using blends of limestone powder, fly ash, and zeolite powder. Constr. Build. Mater. 2021, 286, 122788. [Google Scholar] [CrossRef]

- Rahhal, V.F.; Pavlík, Z.; Tironi, A.; Castellano, C.C.; Trezza, M.A.; Černý, R.; Irassar, E.F. Effect of cement composition on the early hydration of blended cements with natural zeolite. J. Therm. Anal. Calorim. 2017, 128, 721–733. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Mousavi, R.; Kalhori, M.; Sobhani, J.; Najimi, M. Micro and macro level properties of natural zeolite contained concretes. Constr. Build. Mater. 2015, 101, 347–358. [Google Scholar] [CrossRef]

- Chen, J.J.; Li, L.G.; Ng, P.L.; Kwan, A.K.H. Effects of superfine zeolite on strength, flowability and cohesiveness of cementitious paste. Cem. Concr. Compos. 2017, 83, 101–110. [Google Scholar] [CrossRef]

- Jokar, F.; Khorram, M.; Karimi, G.; Hataf, N. Experimental investigation of mechanical properties of crumbed rubber concrete containing natural zeolite. Constr. Build. Mater. 2019, 208, 651–658. [Google Scholar] [CrossRef]

- Abdi Moghadam, M.; Izadifard, R.A. Effects of zeolite and silica fume substitution on the microstructure and mechanical properties of mortar at high temperatures. Constr. Build. Mater. 2020, 253, 119206. [Google Scholar] [CrossRef]

- Florez, C.; Restrepo-Baena, O.; Tobon, J.I. Effects of calcination and milling pre-treatments on natural zeolites as a supplementary cementitious material. Constr. Build. Mater. 2021, 310, 125220. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Mortezaei, M.; Mirvalad, S. Synergic effect of nano-silica and natural pozzolans on transport and mechanical properties of blended cement mortars. J. Build. Eng. 2021, 44, 102667. [Google Scholar] [CrossRef]

- Sobolev, K.; Flores, I.; Torres-Martinez, L.M.; Valdez, P.L.; Zarazua, E.; Cuellar, E.L. Engineering of SiO2 Nanoparticles for Optimal Performance in Nano Cement-Based Materials. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 139–148. [Google Scholar]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Q.; Zhang, J. Shrinkage of internal cured high strength engineered cementitious composite with pre-wetted sand-like zeolite. Constr. Build. Mater. 2017, 134, 664–672. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, J.; Ho, J.C.M. Zeolite to improve strength-shrinkage performance of high-strength engineered cementitious composite. Constr. Build. Mater. 2020, 234, 117335. [Google Scholar] [CrossRef]

- Thang, N.C.; Van Tuan, N.; Yang, K.-H.; Phung, Q.T. Effect of Zeolite on Shrinkage and Crack Resistance of High-Performance Cement-Based Concrete. Materials 2020, 13, 3773. [Google Scholar] [CrossRef] [PubMed]

- Ranjbar, M.M.; Madandoust, R.; Mousavi, S.Y.; Yosefi, S. Effects of natural zeolite on the fresh and hardened properties of self-compacted concrete. Constr. Build. Mater. 2013, 47, 806–813. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Kou, S.C.; Lin, Z.S. A study on the hydration rate of natural zeolite blended cement pastes. Constr. Build. Mater. 1999, 13, 427–432. [Google Scholar] [CrossRef]

- Nagrockiene, D.; Girskas, G. Research into the properties of concrete modified with natural zeolite addition. Constr. Build. Mater. 2016, 113, 964–969. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, W.; Zhan, P.; Liu, X.; Chen, D. Strengths, Microstructure and Nanomechanical Properties of Concrete Containing High Volume of Zeolite Powder. Materials 2020, 13, 4191. [Google Scholar] [CrossRef]

- Zolghadri, A.; Ahmadi, B.; Taherkhani, H. Influence of natural zeolite on fresh properties, compressive strength, flexural strength, abrasion resistance, Cantabro-loss and microstructure of self-consolidating concrete. Constr. Build. Mater. 2022, 334, 127440. [Google Scholar] [CrossRef]

- Raggiotti, B.B.; Positieri, M.J.; Oshiro, Á. Natural zeolite, a pozzolan for structural concrete. Procedia Struct. Integr. 2018, 11, 36–43. [Google Scholar] [CrossRef]

- Mohseni, E.; Tang, W.; Cui, H. Chloride Diffusion and Acid Resistance of Concrete Containing Zeolite and Tuff as Partial Replacements of Cement and Sand. Materials 2017, 10, 372. [Google Scholar] [CrossRef] [PubMed]

- Valipour, M.; Yekkalar, M.; Shekarchi, M.; Panahi, S. Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Ganji, S.; Sharabiani, H.E.; Zeinali, F. Laboratory investigation on abrasion resistance and mechanical properties of concretes containing zeolite powder and polyamide tire cord waste as fiber. Constr. Build. Mater. 2021, 308, 125053. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M. Effect of pozzolanic materials on mechanical properties and water absorption of autoclaved aerated concrete. J. Build. Eng. 2019, 26, 100856. [Google Scholar] [CrossRef]

- Zhang, G.-Z.; Wang, X.-Y. Effect of Pre-Wetted Zeolite Sands on the Autogenous Shrinkage and Strength of Ultra-High-Performance Concrete. Materials 2020, 13, 2356. [Google Scholar] [CrossRef] [PubMed]

- Sobuś, N.; Czekaj, I.; Diichuk, V.; Kobasa, I.M. Characteristics of the structure of natural zeolites and their potential application in catalysis and adsorption processes. Tech. Trans. 2020, 117, e2020043. [Google Scholar] [CrossRef]

- Zhang, H. Concrete. In Building Materials in Civil Engineering; Zhang, H., Ed.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 81–423. ISBN 9781845699550. [Google Scholar]

- Powers, T.C. A Working Hypothesis for Further Studies of Frost Resistance of Concrete. ACI J. Proc. 1945, 41, 245–272. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Keppert, M.; Žumár, J.; Rovnaníková, P.; Keršner, Z.; Sedlmajer, M.; Černý, R. Engineering properties of concrete containing natural zeolite as supplementary cementitious material: Strength, toughness, durability, and hygrothermal performance. Cem. Concr. Compos. 2015, 55, 259–267. [Google Scholar] [CrossRef]

- Ebrahimi Besheli, A.; Samimi, K.; Moghadas Nejad, F.; Darvishan, E. Improving concrete pavement performance in relation to combined effects of freeze–thaw cycles and de-icing salt. Constr. Build. Mater. 2021, 277, 122273. [Google Scholar] [CrossRef]

- Bilim, C. Properties of cement mortars containing clinoptilolite as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 3175–3180. [Google Scholar] [CrossRef]

- Milović, T.; Šupić, S.; Malešev, M.; Radonjanin, V. The Effects of Natural Zeolite as Fly Ash Alternative on Frost Resistance and Shrinkage of Blended Cement Mortars. Sustainability 2022, 14, 2736. [Google Scholar] [CrossRef]

- Chakraborty, S.; Mandal, R.; Chakraborty, S.; Guadagnini, M.; Pilakoutas, K. Chemical attack and corrosion resistance of concrete prepared with electrolyzed water. J. Mater. Res. Technol. 2021, 11, 1193–1205. [Google Scholar] [CrossRef]

- Valipour, M.; Shekarchi, M.; Arezoumandi, M. Chlorine diffusion resistivity of sustainable green concrete in harsh marine environments. J. Clean. Prod. 2017, 142, 4092–4100. [Google Scholar] [CrossRef]

- Valipour, M.; Pargar, F.; Shekarchi, M.; Khani, S. Comparing a natural pozzolan, zeolite, to metakaolin and silica fume in terms of their effect on the durability characteristics of concrete: A laboratory study. Constr. Build. Mater. 2013, 41, 879–888. [Google Scholar] [CrossRef]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and durability properties of self consolidating high performance concrete incorporating natural zeolite, silica fume and fly ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Madhuri, P.V.; Kameswara Rao, B.; Chaitanya, A. Improved performance of concrete incorporated with natural zeolite powder as supplementary cementitious material. Mater. Today Proc. 2021, 47, 5369–5378. [Google Scholar] [CrossRef]

- Samimi, K.; Kamali-Bernard, S.; Akbar Maghsoudi, A.; Maghsoudi, M.; Siad, H. Influence of pumice and zeolite on compressive strength, transport properties and resistance to chloride penetration of high strength self-compacting concretes. Constr. Build. Mater. 2017, 151, 292–311. [Google Scholar] [CrossRef]

- Dousti, A.; Rashetnia, R.; Ahmadi, B.; Shekarchi, M. Influence of exposure temperature on chloride diffusion in concretes incorporating silica fume or natural zeolite. Constr. Build. Mater. 2013, 49, 393–399. [Google Scholar] [CrossRef]

- Oueslati, O.; Duchesne, J. Resistance of blended cement pastes subjected to organic acids: Quantification of anhydrous and hydrated phases. Cem. Concr. Compos. 2014, 45, 89–101. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Pannem, R.M.R. Enhanced chemical resistance to sulphuric acid attack by reinforcing Graphene Oxide in Ordinary and Portland Pozzolana cement mortars. Case Stud. Constr. Mater. 2022, 17, e01452. [Google Scholar] [CrossRef]

- Irico, S.; De Meyst, L.; Qvaeschning, D.; Alonso, M.C.; Villar, K.; De Belie, N. Severe Sulfuric Acid Attack on Self-Compacting Concrete with Granulometrically Optimized Blast-Furnace Slag-Comparison of Different Test Methods. Materials 2020, 13, 1431. [Google Scholar] [CrossRef] [PubMed]

- Samimi, K.; Kamali-Bernard, S.; Maghsoudi, A.A. Durability of self-compacting concrete containing pumice and zeolite against acid attack, carbonation and marine environment. Constr. Build. Mater. 2018, 165, 247–263. [Google Scholar] [CrossRef]

- Gerengi, H.; Kocak, Y.; Jazdzewska, A.; Kurtay, M.; Durgun, H. Electrochemical investigations on the corrosion behaviour of reinforcing steel in diatomite- and zeolite-containing concrete exposed to sulphuric acid. Constr. Build. Mater. 2013, 49, 471–477. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M. Carbonation of cement paste: Understanding, challenges, and opportunities. Constr. Build. Mater. 2016, 117, 285–301. [Google Scholar] [CrossRef]

- Thiery, M.; Villain, G.; Dangla, P.; Platret, G. Investigation of the carbonation front shape on cementitious materials: Effects of the chemical kinetics. Cem. Concr. Res. 2007, 37, 1047–1058. [Google Scholar] [CrossRef]

- Azarsa, P.; Gupta, R. Electrical Resistivity of Concrete for Durability Evaluation: A Review. Adv. Mater. Sci. Eng. 2017, 2017, 8453095. [Google Scholar] [CrossRef]

- Idiart, A.E.; López, C.M.; Carol, I. Modeling of drying shrinkage of concrete specimens at the meso-level. Mater. Struct. 2011, 44, 415–435. [Google Scholar] [CrossRef]

- Lv, Y.; Ye, G.; De Schutter, G. Investigation on the potential utilization of zeolite as an internal curing agent for autogenous shrinkage mitigation and the effect of modification. Constr. Build. Mater. 2019, 198, 669–676. [Google Scholar] [CrossRef]

- Shekarchi, M.; Ahmadi, B.; Azarhomayun, F.; Shafei, B.; Kioumarsi, M. Natural zeolite as a supplementary cementitious material—A holistic review of main properties and applications. Constr. Build. Mater. 2023, 409, 133766. [Google Scholar] [CrossRef]

- Wang, Q.; Xiong, Z.; He, J.; Lai, M.; Ho, J. Effective solution for improving rheological properties of cement paste containing zeolite. Constr. Build. Mater. 2022, 351, 128780. [Google Scholar] [CrossRef]

- Thomas, M.; Osińska, M.; Ślosarczyk, A. Long-Term Behavior of Cement Mortars Based on Municipal Solid Waste Slag and Natural Zeolite—A Comprehensive Physico-Mechanical, Structural and Chemical Assessment. Materials 2022, 15, 1001. [Google Scholar] [CrossRef] [PubMed]

| Material | Water/Binder Ratio | Replacement Percentage | Findings | Ref. |

|---|---|---|---|---|

| Paste | 0.4 | 5%, 10% by mass | The initial and final setting time decreased by 20–35 min and 15–35 min, respectively, compared to the control mix. | [3] |

| Paste | 0.45, 0.5, 0.55, 0.6, 0.65, 0.7 | 5%, 10%, 15%, 20% by mass | flow spread increased with increase in w/b but decreased with increase in zeolite content; packing density increased with increase in zeolite content; water film thickness increased with increase in w/b but decreased with increase in zeolite content. | [18] |

| Paste | 0.5 | 5%, 10%, 15%, 20% not specified | water demand increased with zeolite content; volume expansion was halved with more than 5% zeolite; initial/final setting time showed little variations. | [10] |

| Paste | 0.6 | 10%, 20%, 30% by mass | initial setting time decreased and final setting time increased when using zeolite; flow of cement paste decreased with increase in zeolite content. | [4] |

| Mortar | 0.33 | 15%, 30% by mass | higher dosage of superplasticizer required when using zeolite; slump increased after zeolite calcination. | [13] |

| Mortar | 0.336 | 10% by mass | higher water-reducing admixture content. highest times for mortar to reach spread diameters of 250 mm and 300 mm. | [15] |

| Mortar | 0.485 | 5%, 10% by mass | the use of up to 10% zeolite decreased the workability by approximately 25% compared to the control mix. | [3] |

| Mortar | 0.5 | 5%, 10%, 15%, 20% by volume | the flowability increased up to 10% replacement and then decreased; porosity was higher than control mix and highest for 10% replacement. | [9] |

| Concrete | 0.4 | 5%, 10%, 15%, 20% by mass | Increased dosage of superplasticizer to obtain a similar slump to the control mix; air content increased with the increase in the replacement percentage. | [2] |

| Concrete | 0.35, 0.4, 0.45, 0.5 | 10%, 15% by mass | higher dosage of water-reducing admixture was required with the increase in the zeolite content in order obtain similar slump values with the control mix; increasing the w/b ratio resulted in lower dosages of water-reducing admixture. | [17] |

| Concrete | 0.48 | 5%, 10%, 15% by mass | slump decreased with an increase in zeolite percentage; The increase in the crumb rubber content resulted in a further decrease in the slump. | [19] |

| Water/Binder Ratio | Replacement Percentage | Age [Days] | Findings | Ref. |

|---|---|---|---|---|

| 0.45, 0.5, 0.55, 0.6, 0.65, 0.7 | 5%, 10%, 15%, 20% by mass | 7, 28, 70 | Increasing the w/b ratio decreases the compressive strength irrespective of age or replacement percentage; The compressive strength decreases with the increase in zeolite content compared to reference mix; At the age of 70 days, all zeolites containing pastes showed higher values compared to the reference mix, irrespective of w/b ratio. | [18] |

| Water/Binder Ratio | Replacement Percentage | Age [Days] | Findings | Ref. |

|---|---|---|---|---|

| 0.5 | 5%, 10%, 15%, 20% not specified replaces cement | 2, 7, 28, 56 | early age (2 and 7 days) flexural strength decreased with increase in zeolite content; at 28 and 56 days, flexural strength of mortars with 5% and 10% zeolite was similar to the reference; higher percentages resulted in lower values; compressive strength followed a similar trend. | [10] |

| 0.5 | 30%, 40%, 50% by mass of cement | 1, 3, 7, 28 | lower compressive strength for all mortar mixes with zeolite; increase in replacement percentages resulted in lower values; compressive strength was slightly improved by calcination of zeolite; compressive strength was significantly improved by milling of zeolite; milling and calcination did not show improvements in compressive strength over milling alone. | [21] |

| 0.485 | 15% by mass of cement | 3, 7, 28, 90 | compressive strength of mortar with zeolite increased with the curing age; early age compressive strength is lower for zeolite mortars compared to the reference; at 28 and 90 days, compressive strength is higher for zeolite mortars; when used together with nano-silica (3%, 4%), compressive strength is consistently higher than the one obtained for control. | [22] |

| 0.4 | 5%, 10%, 15%, 20% by volume of cement | 90 | flexural tensile strength decreased when zeolite was used; smallest decrease recorded for 10% zeolite; compressive strength marginally higher for 10% and 15% zeolite use compared to control; the other two mixes showed up to 12% decrease. | [9] |

| 0.336 | 10% by mass of cement | 7, 28 | compressive strength increased for both ages compared to control (additionally, 10% of cement was replaced by limestone powder); highest increase, of 26%, obtained at 28 days. | [15] |

| Not specified | 10%, 20% by mass of cement | 28 | compressive strength at room temperature was 5% lower, on average, when using zeolite; with increasing temperature, the decrease was up to 10.53%; flexural tensile strength at room temperature was similar to the reference for the 10% zeolite mix and 12.57% lower for the 20% mix; exposure to temperatures up to 800 °C resulted in an average decrease of 3.45%. | [20] |

| 0.2 | 15%, 20%, 30% by mass of sand | 28 | compressive strength was lower at 28 days when using zeolite, both natural and calcined; compressive strength reduced by 2.24% for 15% zeolite use (either natural or calcined) and by 5% for 20% calcined zeolite use; increasing zeolite content resulted in 10% decrease in compressive strength. | [26] |

| Water/Binder Ratio | Replacement Percentage | Age [Days] | Investigated Properties: f′c, ft, E | Findings | Ref. |

|---|---|---|---|---|---|

| 0.48 | 5%, 10%, 15% by mass of cement | 7, 28 | f′c, ft, E | compressive strength and splitting tensile strength at 28 days increased with increasing zeolite content for all crumb rubber percentages; modulus of elasticity was influenced by the crumb rubber content rather than zeolite. | [19] |

| 0.45 | 2.5%, 5%, 7.5%, 10% by mass of cement | 7, 28 | f′c | compressive strength of all zeolite mixes was higher than the reference; increasing zeolite percentage resulted in a lower increase in compressive strength during curing. | [30] |

| 0.42, 0.46 | 5%, 10%, 15% by mass of cement | 7, 28, 90 | f′c, ft | higher w/b resulted in lower values of mechanical properties; early age compressive strength was lower with increasing zeolite content; compressive strength at 90 days was higher for zeolite concrete for all w/b; 10% zeolite use resulted in highest compressive strength, irrespective of w/b; similar results were obtained for flexural tensile strength. | [32] |

| 0.41 | 5%, 10%, 15%, 20% by mass of cement | 7, 28, 90, 180 | f′c, ft, E | compressive strength was lower for all concrete mixes containing zeolite at all ages; mechanical properties were highly affected by cement type; tensile splitting strength was lowest for 10% zeolite use, irrespective of cement type; tensile strength was higher for higher replacement percentages; modulus of elasticity was not significantly influenced by zeolite or cement type. | [33] |

| 0.4 | 5%, 10%, 15%, 20% by mass of cement | 3, 7, 28, 90 | f′c | compressive strength was higher for all zeolite concrete at all ages; compressive strength decreased with increasing zeolite content, up to 28 days; significantly higher compressive strength was obtained at 90 days compared to the reference. | [2] |

| 0.4 | 10%, 15% by mass of cement | 28, 90, 236 | f′c | compressive strength was higher for all zeolite concrete at all ages; increasing volcanic tuff content improved the compressive strength values; concrete with 10% zeolite performed slightly better than the 15% mix. | [34] |

| 0.4 | 10%, 20%, 30% by mass of cement | 7, 28 | f′c | compressive strength decreased with increase in zeolite content; at 7 days, the 10% zeolite concrete mix showed higher compressive strength than the control; at 28 days, both 10% and 15% zeolite concrete mixes showed higher compressive strength than the control. | [35] |

| 0.38, 0.45 | 5%, 10%, 15%, 20% by mass of cement | 3, 7, 14, 28, 90 | f′c, ft | compressive strength increased with the age of concrete and with reduction in w/b; higher rate of compressive strength development with age was recorded for zeolites containing self-compacting concrete; splitting tensile strength at 28 days decreased with increasing zeolite content. | [28] |

| 0.35 | 5%, 7.5%, 10% by mass of cement | 7, 28, 90 | f′c, ft | compressive and splitting tensile strength at all ages were improved by increasing the zeolite percentage; mechanical properties were further improved by adding fibers. | [36] |

| 0.3 | 20%, 40%, 60% by mass of cement | 7, 28, 90 | f′c | compressive strength of zeolite concrete was lower than the reference at 7 and 28 days; 20% zeolite use resulted in the highest compressive strength at 90 days; higher percentages resulted in lower compressive strength compared to the control. | [31] |

| 0.18 | 5%, 10%, 15% by mass of cement | 3, 7, 28, 90 | f′c | compressive strength increased for all zeolite concrete at all ages, compared to the reference; early age (3 and 7 days) compressive strength was highest for the 5% zeolite mix; at 28 days and later, the 10% zeolite mix exhibited the highest compressive strength. | [27] |

| - | 7%, 14%, 21% by mass of cement | N.A. | f′c, ft | compressive strength of autoclave aerated concrete was significantly improved by zeolite; compressive and splitting tensile strength increased with increasing the zeolite content. | [37] |

| 0.2 | 15%, 30% by mass of sand | 3, 7, 28 | f′c | compressive strength decreased with increasing the zeolite content at all ages; zeolite calcination had a positive effect after 90 days, though compressive strength was slightly lower than the reference; calcination pre-treatment was not effective at early ages. | [38] |

| Material | Replacement Percentage | Measurement | Findings | Ref. |

|---|---|---|---|---|

| Concrete | 10% by mass of cement | strength loss | lower strength loss percentage (25.6 vs. 37.9 after 150 cycles). | [7] |

| Concrete | 10%, 20%, 40%, 60% by mass of cement | strength loss | 10% and 20% zeolite use resulted in better results when compared to reference, in both compression and bending. | [42] |

| Concrete | 10%, 20%, 40%, 60% by mass of cement | mass loss (de-icing salts) | mass loss was reduced by 50% for 10% and 20% zeolite use, compared to control; mass loss was increased 2–3 times by 40% and 60% zeolite use. | [42] |

| Concrete | 15% by mass of cement | mass loss (de-icing salts) | four times less mass loss when using zeolite; obs.: lime was also used in all mixes. | [43] |

| Mortar | 5%, 10%, 15%, 20%, 30% by mass of cement | mechanical properties | increase in zeolite content resulted in better mechanical properties compared to the reference before freeze–thaw cycles; after 50 freeze–thaw cycles, 5% zeolite use resulted in better values of mechanical properties. | [44] |

| Mortar | 10%, 20%, 30% by mass of cement | Compressive strength | compressive strength for all mixes decreased after 50 freeze–thaw cycles; 10% zeolite use resulted in the highest freeze–thaw performance. | [45] |

| Material | Replacement Percentage | Measurement | Findings | Ref. |

|---|---|---|---|---|

| Concrete | 15%, 30% by mass of cement | rapid chloride penetration test | values were lowered by up to 85% and 93% for 15% and 30%, respectively, after 90 days of curing. | [11] |

| Concrete | 30%, 40% by mass of cement | rapid chloride penetration test | zeolite mixes showed low chloride permeability for low w/b (0.3), while reference had a moderate one; zeolite had no impact at higher w/b (0.4). | [50] |

| Concrete | 10%, 15% by mass of cement | rapid chloride penetration test | higher w/b resulted in higher chloride penetration for the reference; similar behavior was observed for zeolite concrete for w/b ratios of 0.35, 0.4 and 0.45; 10% zeolite reduced chloride permeability by 43%, 57%, 59% and 54% for w/b of 0.35, 0.4, 0.45 and 0.5; 15% zeolite reduced chloride permeability by 51%, 58%, 65% and 70% for w/b of 0.35, 0.4, 0.45 and 0.5. | [17] |

| Concrete | 10%, 20%, 30% by mass of cement | accelerated chloride penetration test | zeolite use increased resistance to chloride diffusion; 20% zeolite presented the best results in splash conditions. | [47] |

| Concrete | 10%, 20%, 30% by mass of cement | accelerated chloride penetration test | chloride penetration was lower in zeolite specimens and it reduced with zeolite percentage. | [48] |

| Concrete | 10%, 20% by mass of cement | accelerated chloride penetration test | diffusion coefficient decreased more than 2 times compared to control | [49] |

| Concrete | 15% by mass of cement | non-steady-state chloride migration | the diffusion coefficient value at day 7 is the same for reference and zeolite-containing mix; during aging, zeolite mix showed a more pronounced reduction; after 365 days, zeolite mix showed a value 3 times lower than the control. | [43] |

| Concrete | 10%, 15% by mass of cement | non-steady-state chloride migration | migration coefficient decreased more abruptly during curing to 365 days when zeolite was used; values were 2.3 and 2.9 times lower than control; penetration depth decreased by ~30% for zeolite mixes when tested after 230 days of saline solution immersion; diffusion coefficient was reduced to half for zeolite mixes. | [51] |

| Concrete | 10%, 20%, 30% by mass of cement | apparent diffusion coefficient | diffusion coefficient decreased ~2 times when zeolite was used; exposure temperature (22, 35, 50 °C) increased the diffusion coefficient, but growth rate was slower for zeolite concrete. | [52] |

| Concrete | 5%, 10%, 15%, 30% by mass of cement | apparent diffusion coefficient | diffusion coefficient decreased with zeolite percentage; 5% zeolite mix was similar to control, while 30% zeolite resulted in ~66% reduction. | [2] |

| Concrete | 10%, 15% by mass of cement | standard chloride diffusion test | zeolite use decreased the diffusion coefficient, proportional to zeolite percentage. | [34] |

| Material | Replacement Percentage | Measurement | Findings | Ref. |

|---|---|---|---|---|

| Concrete | 15%, 30% by mass of cement | strength loss | after H2SO4 immersion for 300 days, zeolite concrete showed a higher strength loss (20.8% and 23.3%) than control (5.5%). | [11] |

| Concrete | 10%, 15% by mass of cement | strength loss | after 180 days immersion in H2SO4, strength loss increased with zeolite content. | [34] |

| Concrete | 10%, 15% by mass of cement | strength loss | after H2SO4 immersion for 8 weeks, zeolite concrete behaved better compared to the reference; 10% zeolite use resulted in minor improvement of strength loss, and 15% zeolite use reduced strength loss by over 70%. | [56] |

| Concrete | 30%, 40% by mass of cement | strength loss | after H2SO4 immersion, zeolite concrete exhibited a higher strength loss. | [50] |

| Concrete | 15%, 30% by mass of cement | mass loss | reference concrete mass increased during immersion; zeolite modified concrete mass firstly decreased and then increased, almost reaching the initial value. | [11] |

| Concrete | 10%, 15% by mass of cement | mass loss | after 180 days immersion in either HCl or H2SO4, mass loss increased with zeolite content. | [34] |

| Concrete | 10%, 15% by mass of cement | mass loss | after 8 weeks immersion in H2SO4, specimens with 10% zeolite were very similar to the control; 15% zeolite use reduced mass loss by over 37%. | [56] |

| Concrete | 30%, 40% by mass of cement | mass loss | after H2SO4 immersion for 56 days, 30% zeolite mix reduced mass loss for w/b = 0.3 and w/b = 0.4; for higher w/b, mass loss is lower; mass loss was higher than the reference for 40% zeolite mix, irrespective of w/b. | [50] |

| Concrete | 20% not specified | electrochemical impedance spectroscopy | resistance was higher for zeolite specimens during exposure to H2SO4, indicating a lower corrosion potential. | [57] |

| Material | Replacement Percentage | Measurement | Findings | Ref. |

|---|---|---|---|---|

| Concrete | 15%, 30% by mass of cement | water penetration | water penetration decreased with increasing zeolite content; the effect of zeolite percentage is more pronounced at the age of 90 days. | [11] |

| Concrete | 10%, 15% by mass of cement | water penetration | penetration depth was decreased by 55% and 65% for 10% and 15% zeolite use, respectively. | [51] |

| Concrete | 10% by mass of cement | water penetration | 15% decrease in water penetration compared to reference mix | [7] |

| Concrete | 10%, 15% by mass of cement | water penetration | 28 days: 10% (15%) zeolite use reduced the maximum permeability by 18% (30%), 15% (42%), 16% (29%) and 28% (44%) for w/b ratios of 0.35, 0.4, 0.45 and 0.5 90 days: 10% (15%) zeolite use reduced maximum permeability by 12% (22%), 26% (36%), 12% (36%) and 10% (21%) for w/b ratios of 0.35, 0.4, 0.45 and 0.5 | [17] |

| Concrete | 15%, 30% by mass of cement | water absorption | water absorption increased for zeolite mixes; age and replacement percentage had little impact. | [11] |

| Concrete | 5%, 10%, 15%, 20% by mass of cement | water absorption | initial and final absorption for w/b = 0.45 decreased linearly with zeolite content at 28 and 90 days; initial and final absorption for w/b = 0.38 was lowered for all zeolite mixes, with similar values at 90 days. | [28] |

| Concrete | 10%, 15% by mass of cement | water absorption | water absorption decreased with increasing zeolite content. | [34] |

| Concrete | 10%, 20%, 30% by mass of cement | water absorption | water absorption decreased for 30% zeolite use compared to control and was similar for other mixes. | [48] |

| Concrete | 10%, 15% by mass of cement | water absorption | water absorption after immersion increased by up to 12.5% and 25% for 10% and 15% zeolite use, respectively, after 365 days of curing; water absorption after immersion and boiling was higher than the control by 11.7% and 23.5% for 10% and 15% zeolite use, respectively. | [51] |

| Concrete | 10% by mass of cement | water absorption | water absorption increased by 23% compared to reference mix. | [7] |

| Concrete | 10%, 20% by mass of cement | water absorption | ~20% reduction in water absorption when using zeolite. | [49] |

| Concrete | 2.5%, 5%, 7.5%, 10% by mass of cement | water absorption | water absorption decreased with increasing zeolite percentage; 2.5% and 5% zeolite use resulted in values close to the control; 7.5% and 10% zeolite use resulted in values less than half of the control. | [30] |

| Concrete | 5%, 10%, 15%, 20% by mass of cement | water absorption | zeolite lowered water absorption with a similar percentage for all specimens (20%). | [2] |

| Concrete | 10%, 20%, 30% by mass of cement | sorptivity | sorptivity decreased compared to control for 10% and 20% zeolite use. | [48] |

| Concrete | 15% by mass of cement | sorptivity | capillary absorption decreased at various ages up to 365 days; values were 1.33–1.63 times lower than control. | [43] |

| Concrete | 10%, 15% by mass of cement | sorptivity | sorptivity decreased with increasing zeolite content (by 25% and 42%) | [51] |

| Concrete | 10%, 15% by mass of cement | sorptivity | capillary absorption (measured at 28, 90 and 270 days) was improved by zeolite use; reduction percentages were between 20% and 53%. | [17] |

| Material | Replacement Percentage | Measurement | Findings | Ref. |

|---|---|---|---|---|

| Concrete | 10%, 15% by mass of cement | accelerated carbonation | 10% zeolite use increased carbonation depth by 105%–253% for w/b between 0.35 and 0.5; 15% zeolite use increased carbonation depth by 163%–495% for w/b between 0.35 and 0.5. | [17] |

| Concrete | 10%, 15% by mass of cement | accelerated and natural carbonation | carbonation depth (accelerated test) increased 4 times and 9 times for 10% and 15% zeolite use, respectively; mass gain (accelerated test) was 3 times larger for 15% zeolite mix compared to reference; carbonation depth (natural) increased only for 15% zeolite use (7 mm). | [56] |

| Material | Replacement Percentage | Measurement | Findings | Ref. |

|---|---|---|---|---|

| Concrete | 10%, 20%, 30% by mass of cement | AC Impedance Spectrometry | the 28 days resistivity increased with increasing zeolite content (up to ~3.5 times compared to reference); The 365 days resistivity increased 3 times (10% and 20% zeolite) and 4 times (30% zeolite). | [48] |

| Concrete | 10%, 20% by mass of cement | AC Impedance Spectrometry | resistivity increased by 3.5 to 6 times with increase in zeolite content. | [49] |

| Concrete | 5%, 10%, 15%, 20% by mass of cement | AC Impedance Spectrometry | resistivity during aging increased more with increasing zeolite percentage; at 90 days, resistivity of 20% zeolite mix is 3 times higher than control. | [2] |

| Concrete | 15% by mass of cement | electrical resistivity of water-saturated concrete | resistance increased by zeolite use and age; 365 days value was 3.5 times larger for zeolite mix compared to reference. | [43] |

| Concrete | 10%, 15% by mass of cement | electrical resistivity of water-saturated concrete | the 365 days resistivity was 2 times and 3 times larger for 10% and 15% zeolite use, respectively, compared to control. | [51] |

| Concrete | 10%, 15% by mass of cement | electrical resistivity of water-saturated concrete | the 28 days resistance increased for 10% (15%) zeolite use compared to control, for w/b of 0.35, 0.4, 0.45 and 0.5, with 82%–159% (96%–200%); at 90 days and 270 days, resistance increased more, with up to 200%–300%. | [17] |

| Material | Replacement Percentage | Measurement | Findings | Ref. |

|---|---|---|---|---|

| Mortar | 10% by mass of cement | Early age shrinkage | shrinkage decreased by 5% compared to control when a blend of limestone powder and zeolite powder was used. | [15] |

| Mortar | 15%, 30% by mass of cement | Drying shrinkage | shrinkage was increased by natural zeolite by up to 48.69%; calcination of zeolite did not improve the shrinkage behavior. | [13] |

| Concrete | 10% by mass of cement | Drying shrinkage | drying shrinkage was ~3 times lower when using zeolite compared to reference. | [7] |

| Concrete | 15%, 30% by mass of cement | Drying shrinkage | drying shrinkage, measured at 90 days, was 84% and 64% of the control value for 15% and 30% zeolite specimens, respectively. | [11] |

| High performance concrete | 5%, 10%, 15% by mass of cement | Autogenous shrinkage | early age autogenous shrinkage was reduced with increasing zeolite percentage; long-term autogenous shrinkage decreased for lower zeolite percentage (5%); both short-term and long-term autogenous shrinkage decreased with increasing zeolite particle size. | [27] |

| Ultra-high performance concrete | 25%, 50%, 75%, 100% by mass of silica fume | Autogenous shrinkage | autogenous shrinkage of ultra-high performance concrete was significantly reduced with increasing zeolite content. | [5] |

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | SO3 | LOI | Reference(s) |

|---|---|---|---|---|---|---|---|---|---|

| 1.68 | 67.79 | 13.66 | 1.44 | 1.2 | 2.04 | 1.42 | 0.52 | 10.23 | [11,16,31,34,36,38,48,52] |

| 1.33 | 66.70 | 11.48 | 0.9 | 0.22 | 1.8 | 3.42 | 3.43 | 14.10 | [3] |

| 1.22 | 71.50 | 11.30 | 2.05 | 0.17 | 1.24 | 4.55 | - | - | [5] |

| 3.3 | 72.5 | 12.5 | 1.7 | 0.6 | 0.2 | 3.6 | - | 5.6 | [9] |

| 1.77 | 64.44 | 8.3 | 1.66 | 0.07 | 2.3 | 2.24 | 0.04 | 18.95 | [10] |

| 2.18 | 70.11 | 11.45 | 1.89 | 1.62 | 0.77 | 2.36 | 0.03 | 9.52 | [13] |

| 7.97 | 68.7 | 13.59 | 2.43 | 1.12 | 3.03 | 2.69 | - | - | [14] |

| 3.48 | 75.04 | 12.85 | 2.38 | 0.8 | 0.5 | 4.86 | - | - | [14] |

| 5.91 | 68.8 | 14.06 | 2.56 | 0.97 | 3.84 | 2.83 | - | - | [14] |

| 2.58 | 76.55 | 12.76 | 1.47 | 0.95 | 0.77 | 4.86 | - | - | [14] |

| 2.74 | 76.93 | 14.68 | 1.39 | 0.79 | 1.23 | 2.07 | - | - | [14] |

| 2.71 | 62.87 | 13.46 | 1.35 | 2.38 | - | - | - | - | [18] |

| 3.04 | 71.29 | 11.43 | 2.16 | 1.11 | 1.72 | 0.95 | 0.05 | 7.69 | [21] |

| 3.1 | 66.5 | 11.8 | 1.3 | 0.8 | 2.03 | 2.1 | 0.52 | 9.85 | [22] |

| 1.99 | 64.27 | 12.7 | 0.68 | 0.46 | 2.30 | 2.90 | 0.34 | 14.18 | [26] |

| 4.11 | 60.25 | 18.45 | 1.9 | 1.12 | 1.66 | 1.18 | - | 11.33 | [27] |

| 1.51 | 68.4 | 12.5 | 1.32 | 1.4 | 2.2 | 1.3 | 0.45 | - | [28] |

| 2.10 | 71.35 | 13.10 | 0.9 | 1.07 | 0.8 | 2.45 | - | - | [30] |

| 3.67 | 66.98 | 19.88 | 1.21 | 0.49 | - | 0.06 | 0.71 | 4.71 | [31] |

| 5.50 | 59.81 | 14.32 | 1.04 | 0.83 | 5.76 | 1.36 | - | 7.47 | [33] |

| 2.24 | 69.2 | 15.28 | 3.01 | 1.4 | 2.2 | 2.1 | 0.45 | - | [34] |

| 3.56 | 69.28 | 10.43 | 0.49 | 0.5 | 0.73 | 1.27 | 0.005 | 12.97 | [36] |

| 4.34 | 68.28 | 12.30 | 0.08 | 1.05 | 0.26 | 0.94 | - | - | [12] |

| 3.28 | 74.69 | 14.99 | 1.53 | 0.653 | 0.834 | 3.6 | - | 5.32 | [42] |

| 3.6 | 63.32 | 11.7 | 0.32 | 1.2 | - | - | 0.088 | 8.49 | [49] |

| 3.97 | 68.85 | 11.71 | 1.29 | 1.06 | 0.29 | 2.19 | 0.18 | 10 | [57] |

| 9.20 | 50.89 | 9.00 | 1.18 | 7.68 | 1.03 | 2.43 | 0.04 | 18.17 | [64] |

| 9.73 | 60.9 | 11.0 | 7.91 | - | - | 8.89 | - | - | [64,65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alexa-Stratulat, S.-M.; Olteanu, I.; Toma, A.-M.; Pastia, C.; Banu, O.-M.; Corbu, O.-C.; Toma, I.-O. The Use of Natural Zeolites in Cement-Based Construction Materials—A State of the Art Review. Coatings 2024, 14, 18. https://doi.org/10.3390/coatings14010018

Alexa-Stratulat S-M, Olteanu I, Toma A-M, Pastia C, Banu O-M, Corbu O-C, Toma I-O. The Use of Natural Zeolites in Cement-Based Construction Materials—A State of the Art Review. Coatings. 2024; 14(1):18. https://doi.org/10.3390/coatings14010018

Chicago/Turabian StyleAlexa-Stratulat, Sergiu-Mihai, Ioana Olteanu, Ana-Maria Toma, Cristian Pastia, Oana-Mihaela Banu, Ofelia-Cornelia Corbu, and Ionut-Ovidiu Toma. 2024. "The Use of Natural Zeolites in Cement-Based Construction Materials—A State of the Art Review" Coatings 14, no. 1: 18. https://doi.org/10.3390/coatings14010018