Strategic Selection of Refractory High-Entropy Alloy Coatings for Hot-Forging Dies by Applying Decision Science

Abstract

:1. Introduction and Background

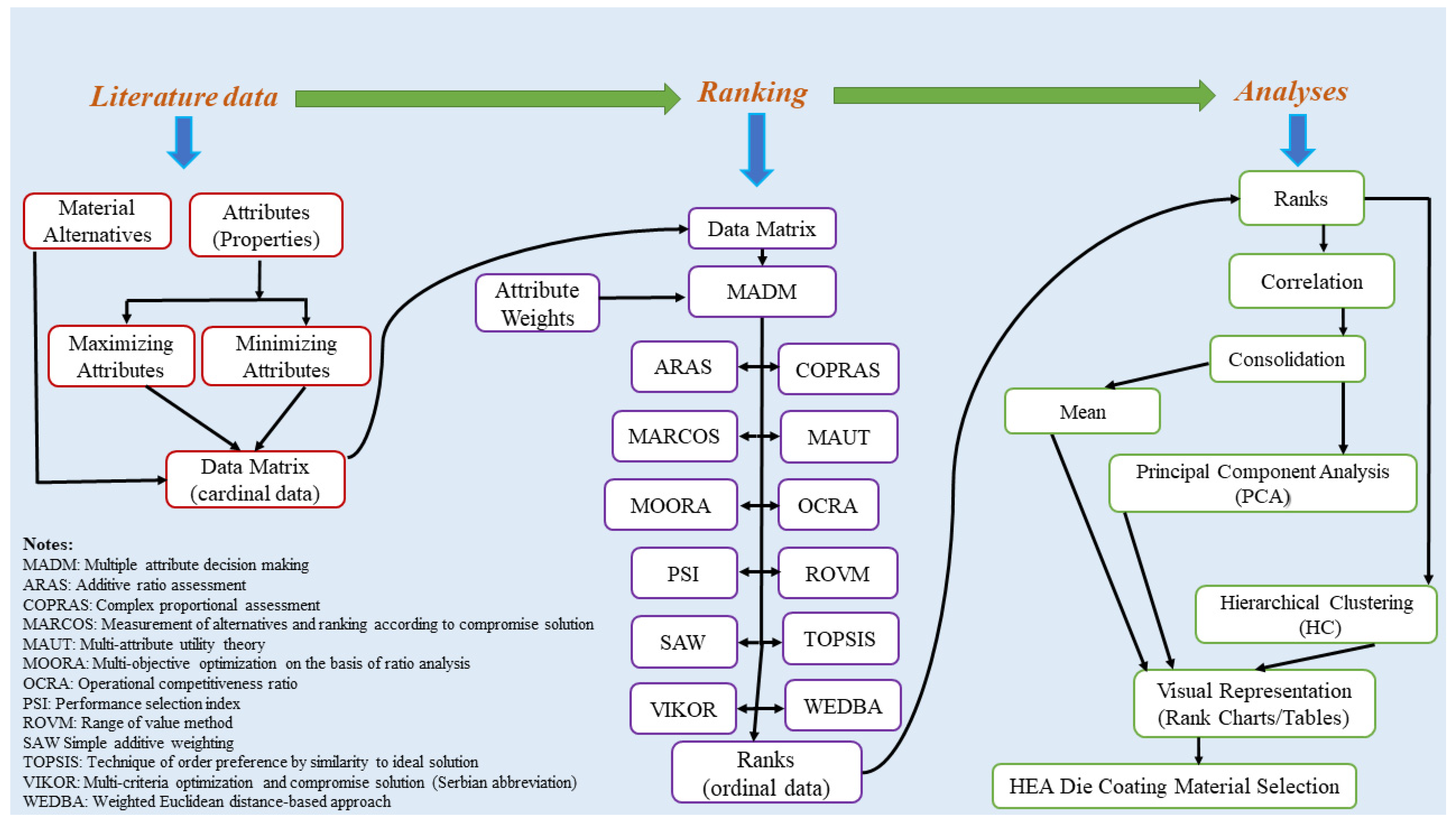

2. Methods

2.1. Literature Data

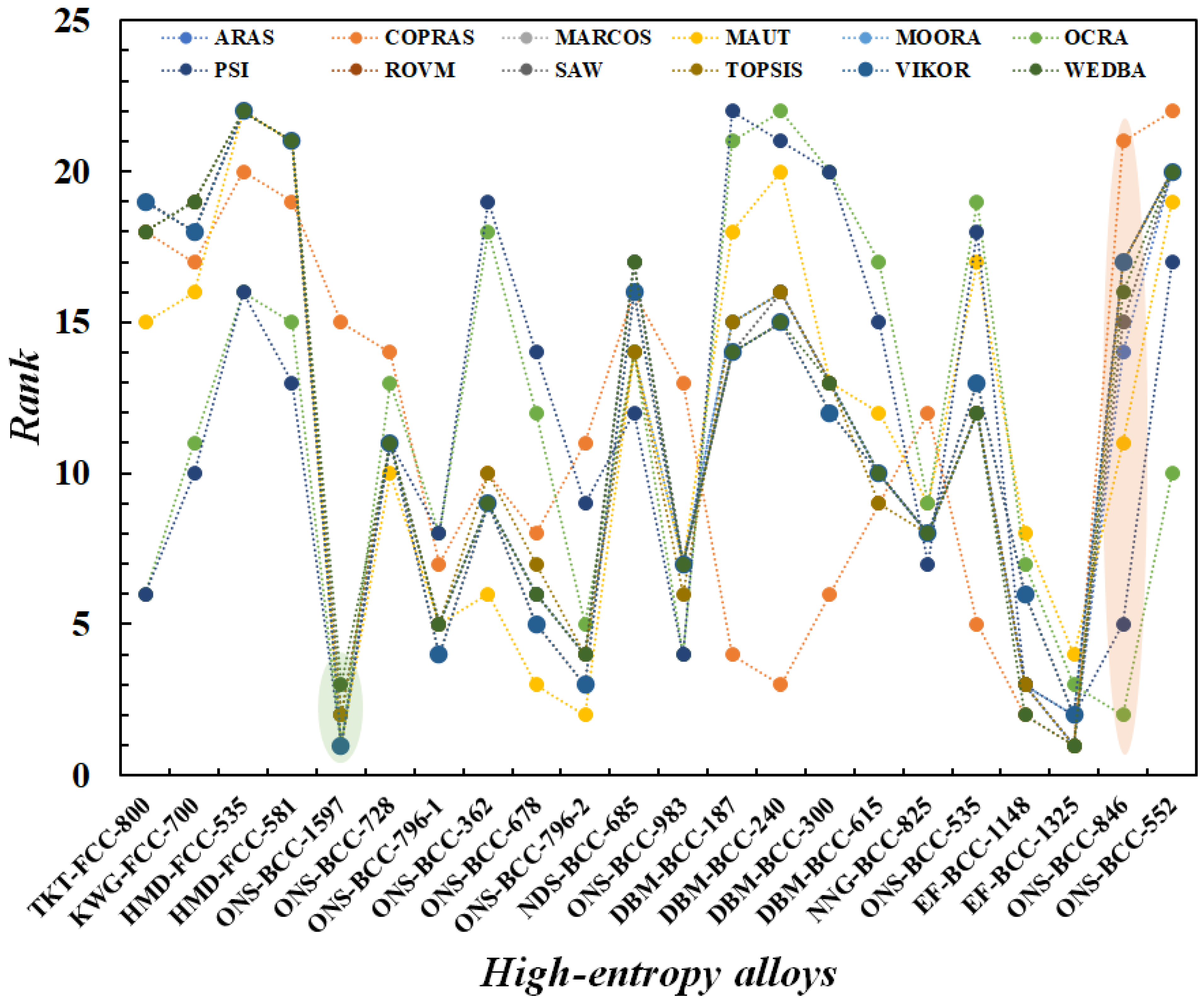

2.2. Ranking

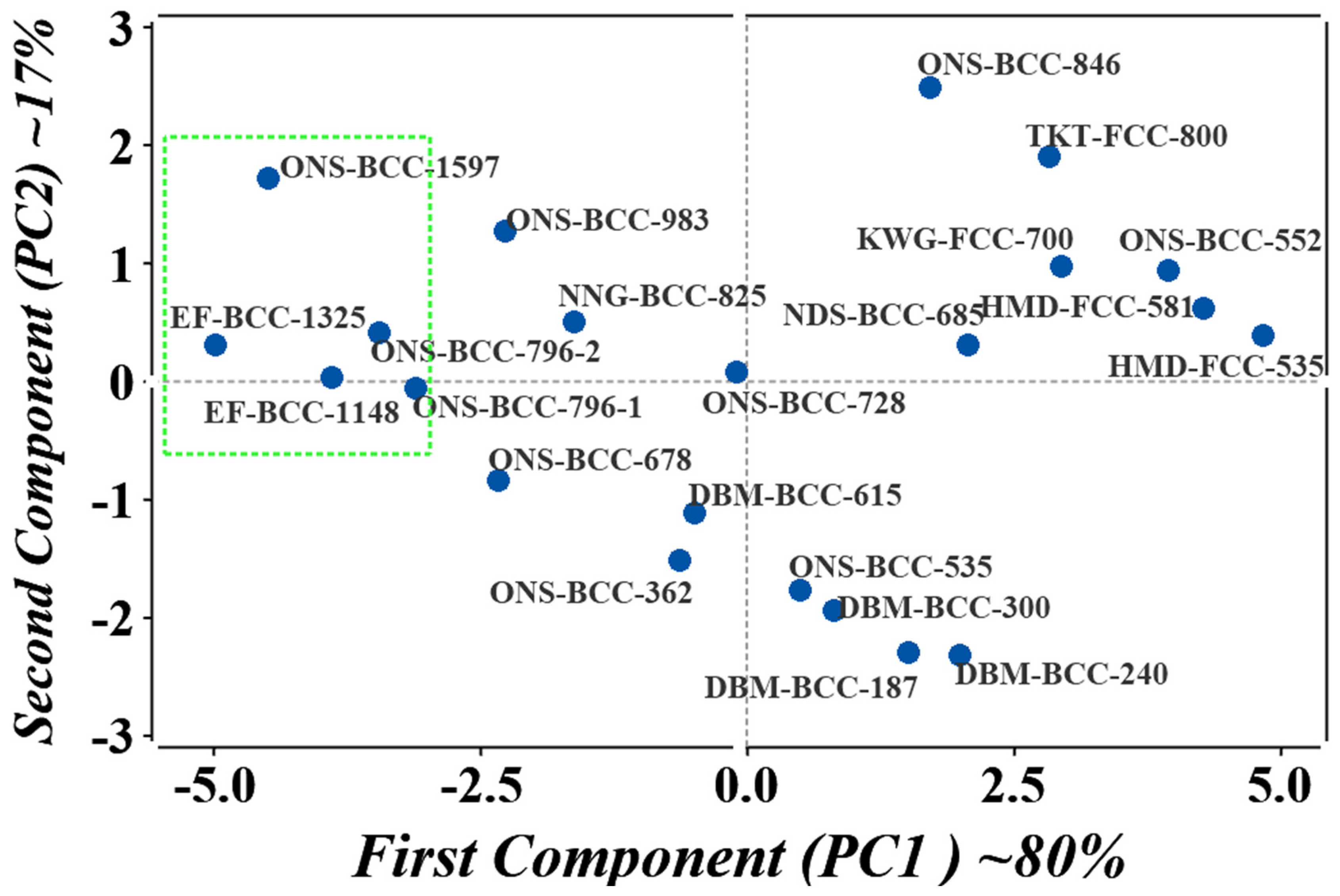

2.3. Analyses

3. Results and Discussion

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Distribution Statement

Disclaimer/Authors’ Note

References

- Ni, M.; Hu, Z.; Qin, X.; Xiong, X.; Ji, F. Microstructure and Mechanical Properties of Gradient Interfaces in Wire Arc Additive Remanufacturing of Hot Forging Die Steel. Materials 2023, 16, 2639. [Google Scholar] [CrossRef] [PubMed]

- Rajendran, N.; Yurgel, C.C.; Misiolek, W.Z.; de Sousa, R.A. Hot Forging Die Design Optimization Using FEM Analysis for Near-Net Forming of 18CrNiMo7-6 Steel Pinion Shaft. Metals 2023, 13, 815. [Google Scholar] [CrossRef]

- Metal Working: Bulk Forming. In ASM Handbook; ASM: Washington, DC, USA; Volume 14A.

- Finkl Steel Data Sheet, FINKL DC, -AISI H13. 2018. Available online: https://www.finkl.com/wp-content/uploads/2018/12/DC_EN_oct18-2.pdf (accessed on 20 November 2023).

- Babu, S.; Ribeiro, D.; Shivpuri, R. Material and Surface Engineering of Dies for Precision Forging; Forging Industry Association: Independence, OH, USA, 1999. [Google Scholar]

- Uddeholm Dievar—The New Generation Data Sheet. 2019. Available online: https://www.uddeholm.com/app/uploads/sites/43/2019/12/Tech-Uddeholm-Dievar-EN-1.pdf (accessed on 20 November 2023).

- Foster, J.; Cullen, C.; Fitzpatrick, S.; Payne, G.; Hall, L.; Marashi, J. Remanufacture of hot forging tools and dies using laser metal deposition with powder and a hard-facing alloy Stellite 21®. J. Remanufacturing 2019, 9, 189–203. [Google Scholar] [CrossRef]

- Matsumoto, R.; Osumi, Y.; Utsunomiya, H. Influence of thermal conductivity of die materials on hot forging characteristics. J. Jpn. Soc. Technol. Plast. 2013, 54, 363–367. [Google Scholar]

- Matsumoto, R.; Itamochi, T.; Mori, S. Effects of TiCN composite die with low thermal conductivity on hot forging performances. J. Mech. Eng. Autom. 2016, 6, 59–65. [Google Scholar] [CrossRef]

- Bochniak, W.; Korbel, A.; Szyndler, R.; Stalony, F.; Blaz, L.; Snarski, P. New forging method of bevel gears for structural steel. J. Mater. Process. Technol. 2006, 173, 75–83. [Google Scholar] [CrossRef]

- Xinbo, L.; Fubao, Z.; Jianhua, F.; Zhiliang, Z. Research on the flow stress characteristics of AISI 1006 and SISI 5140 in the temperature range of warm forging by means of thermo mechanical experiments. J. Mater. Process. Technol. 2002, 122, 38. [Google Scholar] [CrossRef]

- Smolik, J. Hard Protective Layers on Forging Dies—Development and Applications. Coatings 2021, 11, 376. [Google Scholar] [CrossRef]

- Cerwin, N. Die Improvement Die Preheating; Forging Die Life Improvement Workshop; Organized by Forging Industry Association (FIA): Cleveland, OH, USA, 2022. [Google Scholar]

- Cerwin, N. Selecting a Die for Maximum Performance; Forging Die Life Improvement Workshop; Organized by Forging Industry Association (FIA): Cleveland, OH, USA, 2022. [Google Scholar]

- Aravind, G.; Kumar, M. Enhancement of Die Life for Titanium alloy closed die forging. Int. Res. J. Eng. Technol. 2018, 5, 2135. [Google Scholar]

- Gargrave, N. Tool Coatings for Hot Work Steels; Forging Die Life Improvement Workshop-11-12 May 2022; Organized by Forging Industry Association (FIA): Cleveland, OH, USA, 2022. [Google Scholar]

- Widomski, P.; Gronostajski, Z. Comprehensive Review of Methods for Increasing the Durability of Hot Forging Tools. Procedia Manuf. 2020, 47, 349–355. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Sharma, A. HEA Coatings and Technology. Coatings 2021, 11, 372. [Google Scholar] [CrossRef]

- Canumalla, R.; Jayaraman, T.V. Ti-containing High Entropy Alloys for Aeroengine Turbine Applications. Mater. Res. 2023, 26, e20220213. [Google Scholar] [CrossRef]

- Arshad, M.; Amer, M.; Hayat, Q.; Janik, V.; Zhang, Z.; Moradi, M.; Bai, M. HEC for high temperature applications. Coatings 2022, 12, 691. [Google Scholar] [CrossRef]

- Meghwal, A.; Anupam, A.; Murthy, B.S.; Berndt, C.C.; Kottada, R.S.; Ang, A.S. Thermal spray HEA coatings: A review. J. Ther. Spray Tech. 2020, 29, 857–893. [Google Scholar] [CrossRef]

- Gao, Y.I.; Kou, G.P. Performance analysis of FeCoCr1.5NiAl HEA coating on H13 steel by laser cladding. J. Phys. Conf. Ser. 2022, 2256, 012022. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, Q.; Huang, Z.; Li, Y.; Liu, Y.; Li, Q.; He, Y.; Wang, H. Tribological Behavior of HEA coatings: A review. Coatings 2022, 12, 1428. [Google Scholar] [CrossRef]

- Wall, M.T.; Pantawane, M.V.; Joshi, S.; Gantz, F.; Ley, N.A.; Meyer, R.; Spires, A.; Young, M.L.; Dahotra, N. Laser-coated CoFeNiCeAlTi HEA onto a H13 steel die head. Surf. Coat. Technol. 2020, 387, 125473. [Google Scholar] [CrossRef]

- Patel, P.; Roy, A.; Sharifi, N.; Stoyanov, P.; Chromik, R.R.; Moreau, C. Tribological Performance of HECs: A Review. Materials 2022, 15, 3699. [Google Scholar] [CrossRef]

- Vyas, A.; Menghani, J.; Natu, H. Metallurgical and Mechanical Properties of Laser Cladded AlFeCuCrCoNi-WC10 HEA coating. IJE Trans. A 2020, 33, 1397–1402. [Google Scholar]

- Canumalla, R.; Jayaraman, T.V. Decision Science Driven Selection of High-Temperature Conventional Ti Alloys for Aeroengines. Aerospace 2023, 10, 211. [Google Scholar] [CrossRef]

- Guo, N.N.; Wang, L.; Luo, L.S.; Li, X.Z.; Su, Y.Q.; Guo, J.J.; Fu, H.Z. Microstructure and mechanical properties of refractory MoNbHfZrTi high entropy alloy. Mater. Des. 2015, 81, 87–94. [Google Scholar] [CrossRef]

- Tsao, T.K.; Yeh, A.C.; Kuo, C.M.; Kakehi, K.; Murakami, H.; Yeh, J.W.; Jian, S.R. The high temperature tensile and creep behaviors of high entropy superalloy. Sci. Rep. 2017, 7, 12658. [Google Scholar] [CrossRef] [PubMed]

- Gaber, K.W. The Design and Characterization of HEA for High-Temperature Applications; New Mexico Institute of Mining and Technology: Socorro, NM, USA, 2020. [Google Scholar]

- Daoud, H.M.; Manzoni, A.M.; Wanderka, N.; Glatzel, U. High-temperature tensile strength of Al10Co25Cr8Fe15Ni36Ti6 compositionally complex alloy (high entropy alloy). J. Mater. 2015, 67, 2271–2277. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C. Effect of aluminum on the microstructure and properties of two refractory high entropy alloys. Acta Mater. 2014, 68, 214–228. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.F. Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr. Mater. Sci. Eng. A 2011, 529, 311–320. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Salishchev, G.A.; Tikhonovsky, M.A. Structure and mechanical properties of a lightweight AlNbTiV high entropy alloy. Mater. Lett. 2015, 142, 153–155. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.; Miracle, D.B. Microstructure and properties of aluminum-contaning refractory high entropy alloys. J. Mater. 2014, 66, 2030–2042. [Google Scholar]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-density refractory multi-principal element alloys of CrNbTiVZr system: Microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Miracle, D.B.; Woodward, C. Mechanical properties of low-density refractory multi-principal element alloys of CrNbTiVZr system. Mater. Sci. Eng. A 2013, 565, 51–62. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Meisenkothen, F.; Miracle, D.B.; Woodward, C.F. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J. Mater. Sci. 2012, 47, 4062–4074. [Google Scholar] [CrossRef]

- Fazakas, E.; Zadorozhnyy, V.; Varga, L.K.; Inoue, A.; Louzguine-Luzgin, D.V.; Tian, F.; Vitos, L. Experimental and theoretical study of Ti20Zr20Hf20Nb20X20 (X 1/4 V or Cr) refractory high entropy alloys. Int. J. Refract. Met. Hard Mater. 2014, 47, 131–138. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making Methods and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Jahan, A.; Edwards, K.L.; Bahraminasab, M. Multi-Criteria Decision Analysis—For Supporting the Selection of Engineering Materials in Product Design, 2nd ed.; Butterworth-Heinemann: Oxford, UK; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Rao, R.V. Decision Making in the Manufacturing Environment, Using Graph Theory and Fuzzy Multiple Attribute Decision Making Methods; Springer: London, OH, USA, 2007. [Google Scholar]

- Zavadskas, E.K.; Turskis, Z. A new additive ratio assessment (ARAS) method in multicriterial decision making. Technol. Econ. Dev. Econ. (Balt. J. Sustain.) 2010, 16, 159–172. [Google Scholar] [CrossRef]

- Hezer, S.; Gelmez, E.; Ozceylan, E. Comparative analysis of TOPSIS, VIKOR and COPRAS methods for the COVID-19 Regional Safety Assessment. J. Infect. Public Health 2021, 14, 775–786. [Google Scholar] [CrossRef] [PubMed]

- Trung, D. Multi-criteria decision making under MARCOS method and weighting methods: Applied to milling, grinding, and turning processes. Manuf. Rev. 2022, 9, 1–13. [Google Scholar] [CrossRef]

- Alinezhad, A.; Khalili, J. New Methods and Applications in Multiple Attribute Decision Making MADM; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Chakraborty, S. Applications of the MOORA method for decision making in manufacturing environment. Int. J. Adv. Manuf. Technol. 2011, 4, 1155–1166. [Google Scholar] [CrossRef]

- Erdogan, S.; Aydin, S.; Balki, M.K.; Sayin, C. Operational evaluation of thermal barrier coated diesel engine fueled with biodiesel/diesel blend by using MCDM method base on engine performance, emission and combustion characteristics. Renew. Energy 2020, 151, 698–706. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, X. Application of the preference selection index method in multi-objective lightweight design of heavy commercial vehicle frames. Eng. Optim. 2023, 55, 1021–1039. [Google Scholar] [CrossRef]

- Madic, M.; Radovanovic, M.; Manic, M. Application of the ROV method of selection of cutting fluids. Decis. Sci. Lett. 2016, 5, 245–254. [Google Scholar] [CrossRef]

- Ibrahim, A.; Surya, R.A. The Implementation of Simple Additive Weighting (SAW) Method in Decision Support System for the Best School Selection in Jambi. J. Phys. Conf. Ser. 2019, 1338, 012054. [Google Scholar] [CrossRef]

- Chakraborty, S. TOPSIS and modified TOPSIS: A comparative analysis. Decis. Anal. J. 2022, 2, 100021. [Google Scholar] [CrossRef]

- Gul, M.; Celik, E.; Aydin, N.; Gumus, A.T.; Guneri, A.F. A state of the art literature review of VIKOR and its fuzzy extensions on applications. Appl. Soft Comput. 2016, 46, 60–89. [Google Scholar] [CrossRef]

- Rao, R.V.; Singh, D. Weighted Euclidean distance-based approach as a multiple attribute decision making method for plant or facility layout design selection. Int. J. Indust. Eng. Comp. 2021, 3, 365–382. [Google Scholar]

- Levine, D.M.; Ramsey, P.P.; Smidt, R.K. Applied Statistics for Engineers and Scientists; Prentice-Hall: Upper Saddle, NJ, USA, 2001. [Google Scholar]

- Cadima, J.; Jolliffle, I.T. Principal Component Analysis: A review and recent developments. Phil. Trans. R. Soc. A 2016, 374, 20150202. [Google Scholar]

- Rajan, K. Materials Informatics. Mater. Today 2005, 8, 38–45. [Google Scholar] [CrossRef]

- Arabie, P.; Hubert, L.J.; De Soete, G. Clustering and Classification; World Scientific: River Edge, NJ, USA, 1999. [Google Scholar]

- Wang, Y.; Li, P.; Na, N.; Zhang, B.; Wei, Y.; Zhang, L.; Wang, J.; Liu, S. Effect of Y2O3 on the microstructure and tribology of WMoTaNb refractory high entropy alloy coating prepared by laser cladding. Int. J. Refract. Met. Hard Mater. 2023, 115, 106273. [Google Scholar] [CrossRef]

- Nair, R.B.; Supekar, R.; Javid, S.M.; Wang, W.; Zou, Y.; McDonald, A.; Mostaghimi, J.; Stoyanov, P. High-Entropy Alloy Coatings Deposited by Thermal Spraying: A Review of Strengthening Mechanisms, Performance Assessments and Perspectives on Future Applications. Metals 2023, 13, 579. [Google Scholar] [CrossRef]

| # | Alloy Chemistry in at. % | Processing Step 1 | Processing Step 2 | Microstructure | Alloy Designation |

|---|---|---|---|---|---|

| 1 | Ni47.9-Al10.2-Co16.9-Cr7.4-Fe8.9-Mo0.9-Nb1.2-W0.4-C0.4-Ti5.8 | Vac. arc melting followed by DS to produce columnar microstructure | Solution treated (ST) at 1210 °C/10 h to homogenize; aging at 800 °C/20 h | γ + γ’ - L12 - Ni3(Ti,Al) (69% 290 nm avg. size) | TKT-FCC-800 |

| 2 | Al6.25-C1-Co15-Cr13-Fe4.5-Mo1.75-Nb0.6-Ni48-V5-Ti5 | Vac. arc melting (5 times) and suction casting | ST at 1175 °C/2 h-850 °C/8 h-650 °C/8 h-water quenched (WQ) | 60% vol. fraction of γ’ - L12; 450 nm-sized γ’ | KWG-FCC-700 |

| 3 | Al10-Co25-Cr8-Fe15-Ni36-Ti6 | Vac. induction melted and solidified directionally | Homogenized at 1220 °C/20 h/furnace cooled (FC)-900 °C/5 h/air cooled (AC) | L12 γ’ Ni3 (Ti,Al) (45% Vf/450 nm) in γ FCC solid sol. and B2/NiAl (needle-like, up to 50 μm long) (<5% Vf) precipitates | HMD-FCC-535 |

| 4 | Al10-Co25-Cr8-Fe15-Ni36-Ti6 | Vac. induction melted and solidified directionally | Homogenized at 1220 °C/20 h/FC-900 °C/50 h/AC | L12 γ’-Ni3(Ti,Al)(46% Vf/460 nm) in γ FCC solid sol. and B2/NiAl (needle-like, up to 50 μm long) (<5% Vf) ppts | HMD-FCC-581 |

| 5 | Al20.4-Mo10.5-Nb22.4-Ta10.1-Ti17.8-Zr18.8 | Vac. arc melting-remelted 5 times | AC, hot isostatic pressing (HIP) at 1400 °C/207 MPa/2 h, 1400 °C/24 in Ar | BCC1 + BCC2; 75 μm avg. grain size; nanolamellar structures of the two phases | ONS-BCC-1597 |

| 6 | Al21.9-Nb32-Ta9-Ti26.7-Zr10.3 | Vac. arc melting-remelted 5 times | AC, HIP at 1400 °C/207 MPa/2 h, 1400 °C/24 h in Ar | BCC; 2000 μm avg. grain size; nanophases | ONS-BCC-728 |

| 7 | Al7.9-Hf12.8-Nb23-Ta16.8-Ti18.9-Zr20.6 | Vac. arc melting-remelted 5 times | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h in Ar | BCC; 140 μm avg. grain size; nanophases | ONS-BCC-796-1 |

| 8 | Al5.7-Nb23.5-Ta17.6-Ti27.2-Zr26 | Vac. arc melting-remelted 5 times | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h in Ar | BCC1 + BCC2; 200 μm avg. grain size; nanolamellar structures of the two phases | ONS-BCC-362 |

| 9 | Al5.2-Nb23.4-Ta13.2-Ti27.7-V4.3-Zr26.2 | Vac. arc melting-remelted 5 times | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h in Ar | BCC; 180 μm avg. grain size; nanophases | ONS-BCC-678 |

| 10 | Al11.3-Nb22.3-Ta13.1-Ti27.9-V4.5-Zr20.9 | Vac. arc melting-remelted 5 times | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h in Ar | BCC1 + BCC2; 100 μm avg. grain size; nanolamellar structures of the two phases | ONS-BCC-796-2 |

| 11 | Al26.6-Nb23.8-Ti25.1-V24.5 | Vac. arc melting—remelting 5 times—and casting | Homogenized at 1200 °C/24 h | BCC SS (300 to 400 μm grain size) | NDS-BCC-685 |

| 12 | Nb20-Cr20-Mo10-Ta10-Ti20-Zr20 | Vac. arc melting and re-melted 5 times and casting | AC, HIP at 1450 °C/207 MPa/3 h | BCC1 (67% Vf) +BCC2 (16% Vf) + laves (FCC) (17% Vf) | ONS-BCC-983 |

| 13 | Nb28.3-Ti24.5-V23-Zr24.2 | Vac. arc melting and re-melted 5 times and casting | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h | BCC + submicron ppts | DBM-BCC-187 |

| 14 | Nb22.6-Ti19.4-V37.2-Zr20.8 | Vac. arc melting and re-melted 5 times and casting | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h | BCC1 + BCC2 + BCC3 | DBM-BCC-240 |

| 15 | Cr24.6-Nb26.7-Ti23.9-Zr24.8 | Vac. arc melting and re-melted 5 times and casting | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h | BCC + laves (ordered FCC) | DBM-BCC-300 |

| 16 | Cr20.2-Nb20-Ti19.9-V19.6-Zr20.3 | Vac. arc melting and re-melted 5 times and casting | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h | BCC + laves (ordered FCC) | DBM-BCC-615 |

| 17 | Hf20-Mo20-Nb20-Ti20-Zr20 | Vac. arc melting and re-melted 5 times and casting | AC, homogenized at 1100 °C/10 h/SC | BCC (dendritic)-no ordered phases | NNG-BCC-825 |

| 18 | Ta19.68-Nb18.93-Hf20.46-Zr21.23-Ti19.7 | Vac. arc melting and casting | AC, HIP at 1200 °C/207 MPa/2 h, 1200 °C/24 h (only homogenized) | BCC (dendritic and nonuniform); equiaxed grains about 100 μm bottom to 200 μm at the top | ONS-BCC-535 |

| 19 | Ti20-Zr20-Hf20-Nb20-V20 | Vac. induction melting and casting | As-cast | BCC + U (unknown intermetallic phase) | EF-BCC-1148 |

| 20 | Ti20-Zr20-Hf20-Nb20-Cr20 | Vac. induction melting and casting | As-cast | BCC + laves (L1 + L2) | EF-BCC-1325 |

| 21 | Mo20-Nb20-Ta20-V20-W20 | Vac. arc melting and casting | As-cast | BCC (dendritic) | ONS-BCC846 |

| 22 | Mo25-Nb25-Ta25-W25 | Vac. arc melting and casting | As-cast | BCC (dendritic) | ONS-BCC-552 |

| Alloy Designation | ΔSconfig/R (mol−1) | ρ (g/cm3) | κ (W/mK) | YS-AT (MPa) | YS-ET (MPa) |

|---|---|---|---|---|---|

| TKT-FCC-800 | 1.60 | 7.44 | 92.74 | 875 | 800 |

| KWG-FCC-700 | 1.66 | 7.60 | 90.48 | 1000 | 700 |

| HMD-FCC-535 | 1.60 | 7.38 | 92.46 | 568 | 535 |

| HMD-FCC-581 | 1.60 | 7.38 | 92.46 | 596 | 581 |

| ONS-BCC-1597 | 1.75 | 7.21 | 67.60 | 2000 | 1597 |

| ONS-BCC-728 | 1.50 | 6.74 | 59.53 | 1280 | 728 |

| ONS-BCC-796-1 | 1.74 | 8.86 | 43.44 | 1841 | 796 |

| ONS-BCC-362 | 1.51 | 7.91 | 45.45 | 1965 | 362 |

| ONS-BCC-678 | 1.60 | 7.49 | 43.54 | 1965 | 678 |

| ONS-BCC-796-2 | 1.67 | 7.27 | 48.45 | 2035 | 796 |

| NDS-BCC-685 | 1.39 | 5.46 | 65.51 | 1020 | 685 |

| ONS-BCC-983 | 1.76 | 8.19 | 58.90 | 1595 | 983 |

| DBM-BCC-187 | 1.38 | 6.50 | 35.08 | 1105 | 187 |

| DBM-BCC-240 | 1.35 | 6.44 | 34.23 | 918 | 240 |

| DBM-BCC-300 | 1.39 | 6.66 | 38.72 | 1260 | 300 |

| DBM-BCC-615 | 1.61 | 6.53 | 43.39 | 1298 | 615 |

| NNG-BCC-825 | 1.61 | 8.62 | 50.18 | 1575 | 825 |

| ONS-BCC-535 | 1.61 | 9.79 | 37.71 | 929 | 535 |

| EF-BCC-1148 | 1.61 | 8.00 | 29.76 | 1170 | 1148 |

| EF-BCC-1325 | 1.61 | 8.17 | 26.31 | 1375 | 1325 |

| ONS-BCC-846 | 1.61 | 12.36 | 102.87 | 1246 | 846 |

| ONS-BCC-552 | 1.39 | 13.75 | 109.49 | 1058 | 552 |

| ARAS | COPRAS | MARCOS | MAUT | MOORA | OCRA | PSI | ROVM | SAW | TOPSIS | VIKOR | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| COPRAS | 0.580 | ||||||||||

| MARCOS | 0.998 | 0.600 | |||||||||

| MAUT | 0.915 | 0.296 | 0.906 | ||||||||

| MOORA | 0.988 | 0.582 | 0.991 | 0.907 | |||||||

| OCRA | 0.484 | 0.276 | 0.457 | 0.608 | 0.440 | ||||||

| PSI | 0.529 | 0.144 | 0.505 | 0.589 | 0.502 | 0.932 | |||||

| ROVM | 0.983 | 0.587 | 0.988 | 0.916 | 0.989 | 0.417 | 0.453 | ||||

| SAW | 0.998 | 0.600 | 1.000 | 0.906 | 0.991 | 0.457 | 0.505 | 0.988 | |||

| TOPSIS | 0.988 | 0.592 | 0.989 | 0.894 | 0.995 | 0.453 | 0.521 | 0.983 | 0.989 | ||

| VIKOR | 0.983 | 0.587 | 0.988 | 0.916 | 0.989 | 0.417 | 0.453 | 1.000 | 0.988 | 0.983 | |

| WEDBA | 0.995 | 0.634 | 0.997 | 0.889 | 0.989 | 0.433 | 0.490 | 0.983 | 0.997 | 0.990 | 0.983 |

| PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 | PC8 | PC9 | PC10 | PC11 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Eigenvalue | 8.778 | 1.862 | 0.256 | 0.059 | 0.024 | 0.014 | 0.004 | 0.002 | 0.002 | 0.000 | 0.000 |

| Proportion | 0.798 | 0.169 | 0.023 | 0.005 | 0.002 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Cumulative | 0.798 | 0.967 | 0.991 | 0.996 | 0.998 | 0.999 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jayaraman, T.V.; Canumalla, R. Strategic Selection of Refractory High-Entropy Alloy Coatings for Hot-Forging Dies by Applying Decision Science. Coatings 2024, 14, 19. https://doi.org/10.3390/coatings14010019

Jayaraman TV, Canumalla R. Strategic Selection of Refractory High-Entropy Alloy Coatings for Hot-Forging Dies by Applying Decision Science. Coatings. 2024; 14(1):19. https://doi.org/10.3390/coatings14010019

Chicago/Turabian StyleJayaraman, Tanjore V., and Ramachandra Canumalla. 2024. "Strategic Selection of Refractory High-Entropy Alloy Coatings for Hot-Forging Dies by Applying Decision Science" Coatings 14, no. 1: 19. https://doi.org/10.3390/coatings14010019

APA StyleJayaraman, T. V., & Canumalla, R. (2024). Strategic Selection of Refractory High-Entropy Alloy Coatings for Hot-Forging Dies by Applying Decision Science. Coatings, 14(1), 19. https://doi.org/10.3390/coatings14010019