Investigation of Whitening Mechanism on Cultural Relic Surfaces Treated with Paraloid B72

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Experimental Methods

- (1)

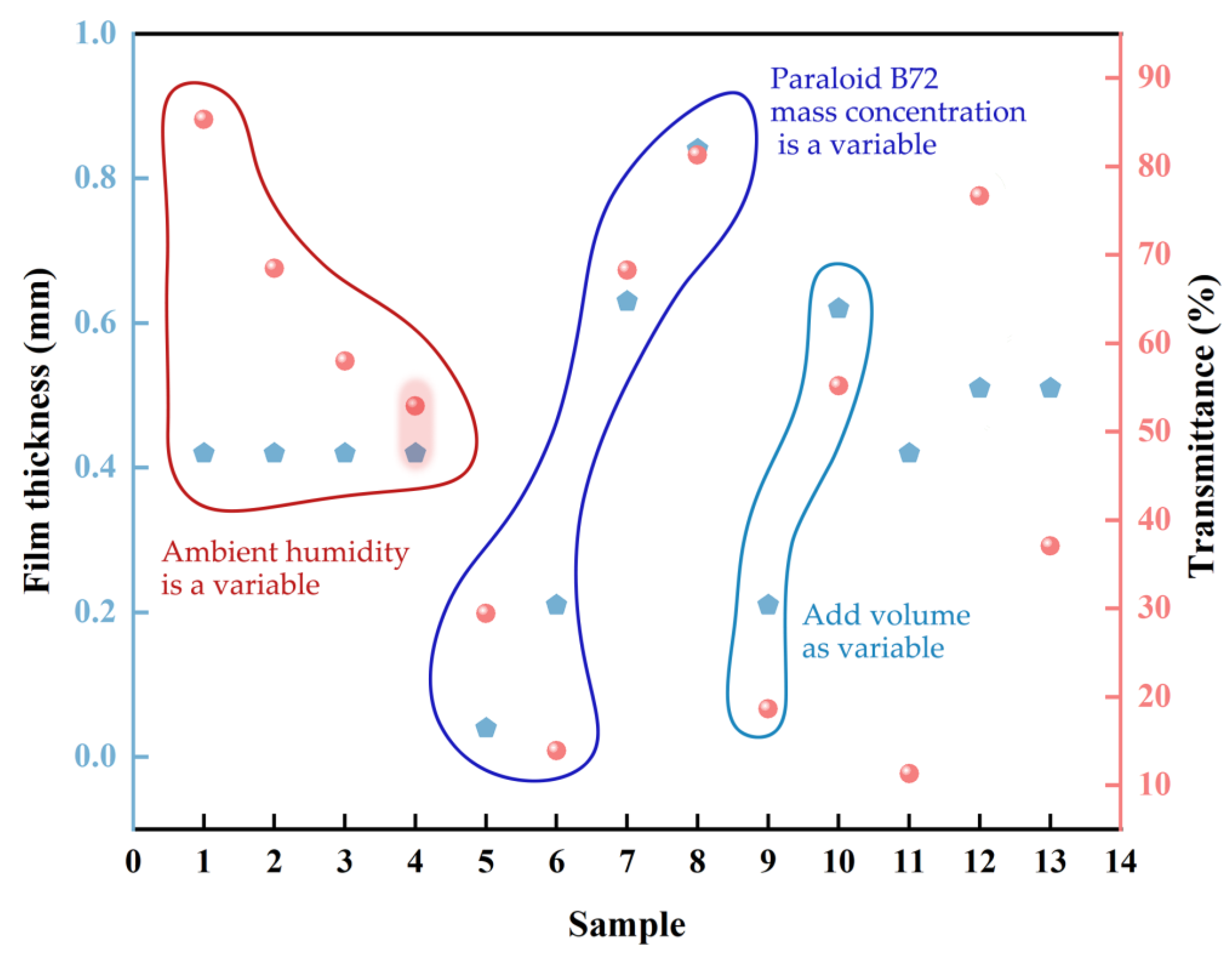

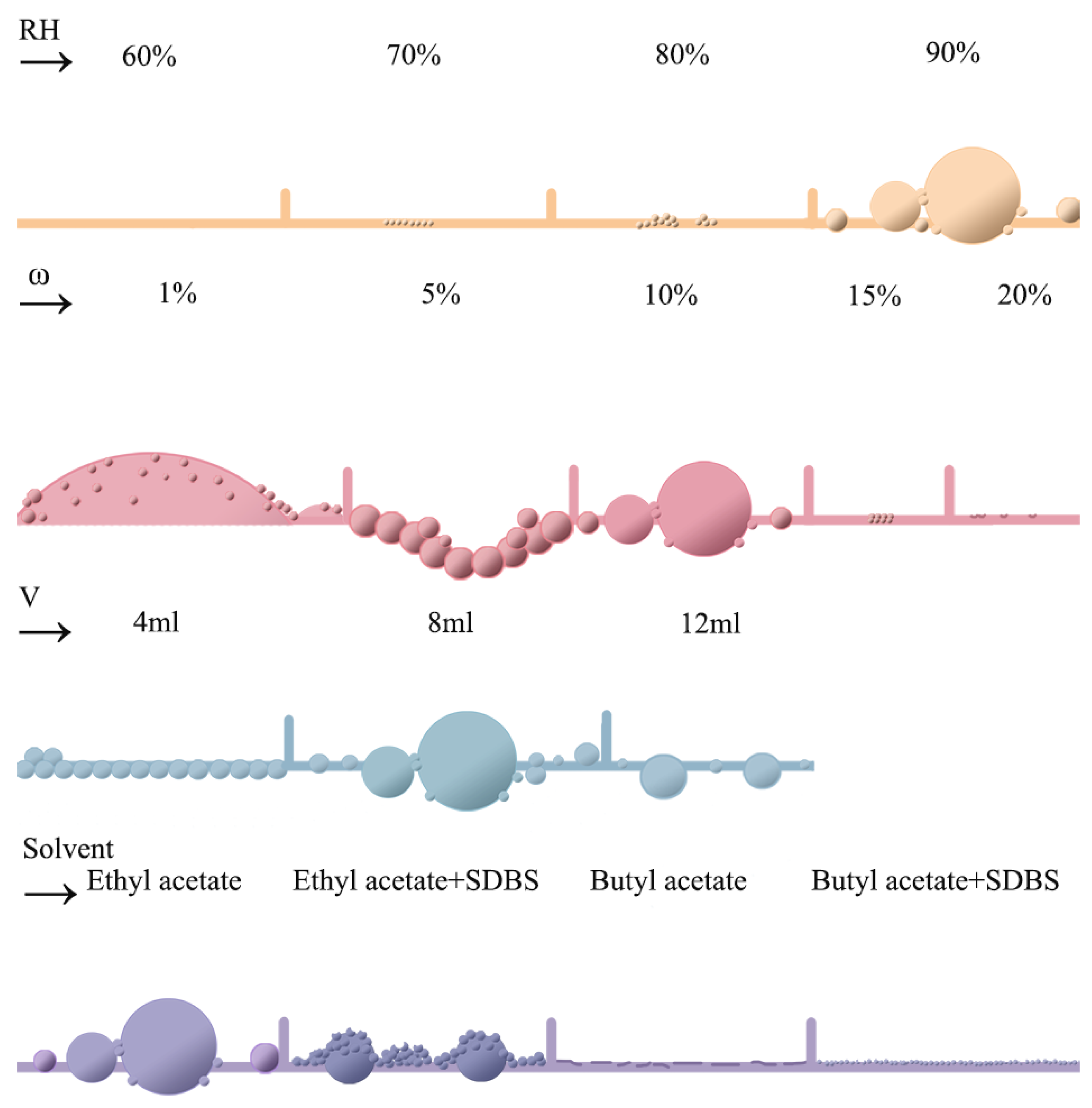

- Sample Preparation: Prior to the formal experiment, our research group conducted a series of preliminary experiments and reached the conclusion that the whitening of Paraloid B72 was related to the environmental humidity during the curing process. Based on this conclusion, we took the participating factors in the curing process as variables to study whether the participating factors would affect the degree of whitening. According to the pre-experiment results, the factors in the curing process of Paraloid B72 were designed as experimental variables to explore the whitening mechanism of Paraloid B72, as shown in Table 1. A certain amount of Paraloid B72 solution was placed in a silicone paper box with a bottom area of 7.6 × 2.5 cm2 and cured in a constant temperature and humidity chamber at different ambient humidities, with the temperature set at 25 °C. In order to increase the rationality of the experiment, three parallel samples were set for each group of samples, and the properties of the films were subsequently measured after curing. In order to guarantee the stipulated humidity conditions and to minimize the impact of the chamber’s air circulation system on the curing of Paraloid B72 films, an open acrylic box was positioned within the chamber, with the opening positioned away from the strongest airflow. The samples were then subjected to curing within the aforementioned acrylic box.

- (2)

- Transmittance Testing: The transmittance of the films was measured using a UV-VIS spectrophotometer. Samples were cut into 0.5 × 0.5 cm pieces and numbered, and then random sampling was conducted for testing the transmittance at 580 nm, with a scanning rate of 100 nm/min. The measurements were taken five times, and the average value was recorded.

- (3)

- Optical Microscopy Testing: The cured Paraloid B72 films were placed on the stage of an optical microscope with the side in contact with silicone paper facing downward. The samples were illuminated with transmitted light, and their morphology was observed at different magnifications.

- (4)

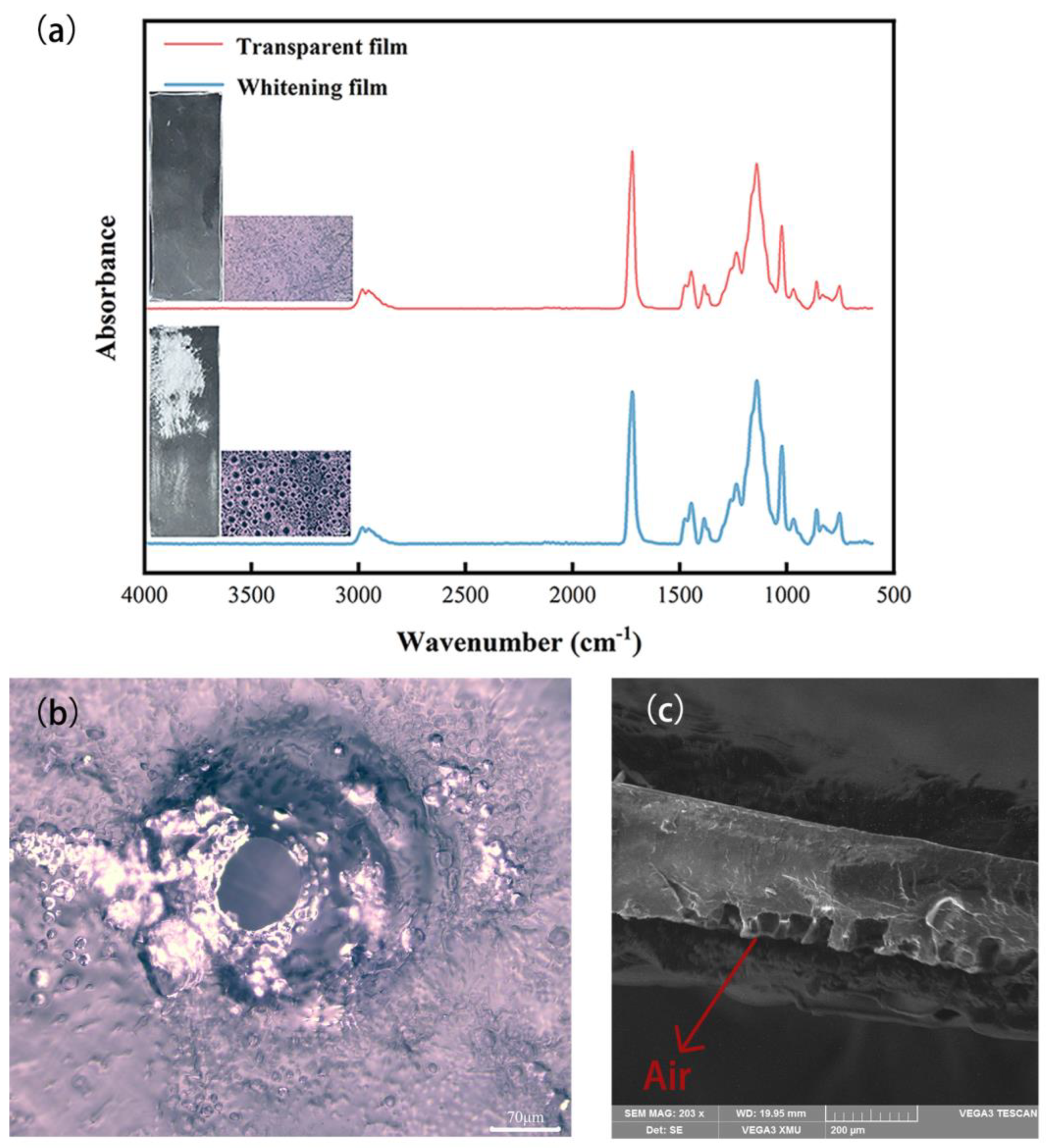

- Infrared Absorption Spectroscopy Testing: The infrared absorption spectra of the films were measured using a Fourier transform infrared spectrometer with an attenuated total reflectance (ATR) attachment. A small amount of film was placed on the ATR sample stage, and the spectra were recorded in the wavenumber range of 4000–600 cm−1 with a resolution of 4 cm−1. A total of 64 background and sample scans were conducted.

- (5)

- Scanning Electron Microscopy Testing: The microstructure of the cross-sections of the film samples, fractured in liquid nitrogen, was observed using a scanning electron microscope. The testing conditions were as follows: no gold coating, direct observation, scanning mode: secondary electrons (SEs), accelerating voltage: 10 kV, working distance: 19.95 mm, beam intensity: 10.00.

3. Results and Discussion

3.1. Physicochemical Characteristics of Whitening

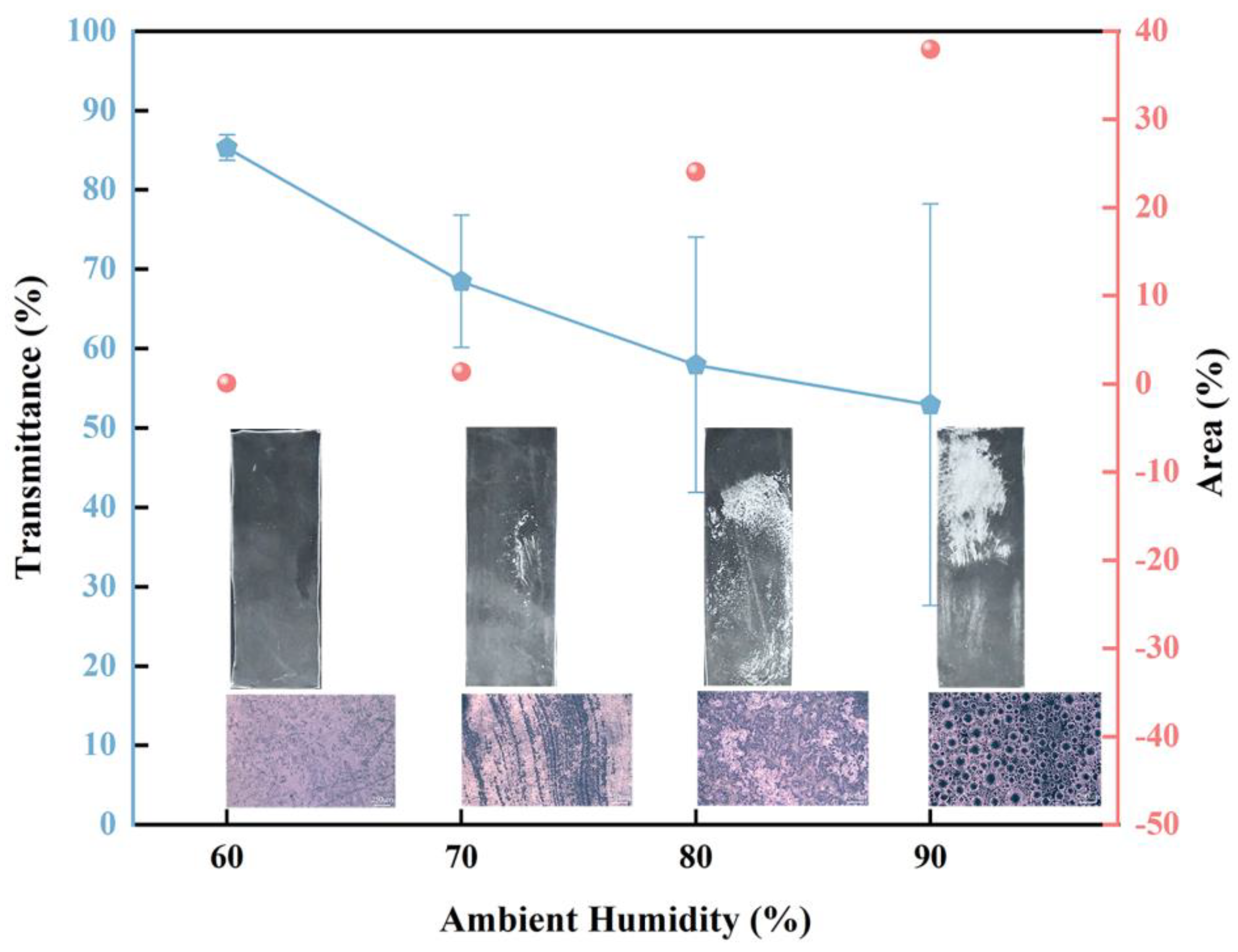

3.2. The Effects of Ambient Humidity on Whitening Phenomenon

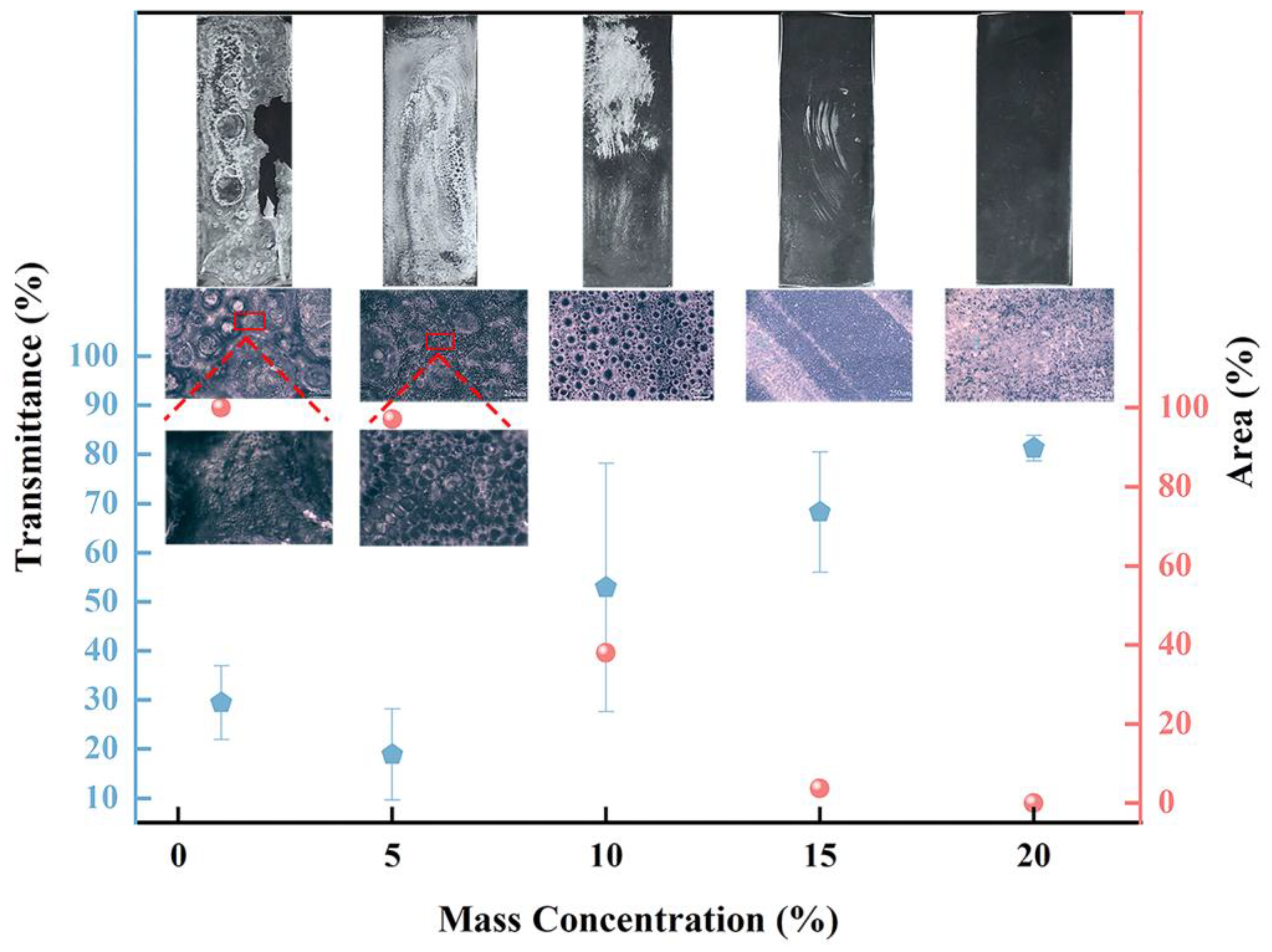

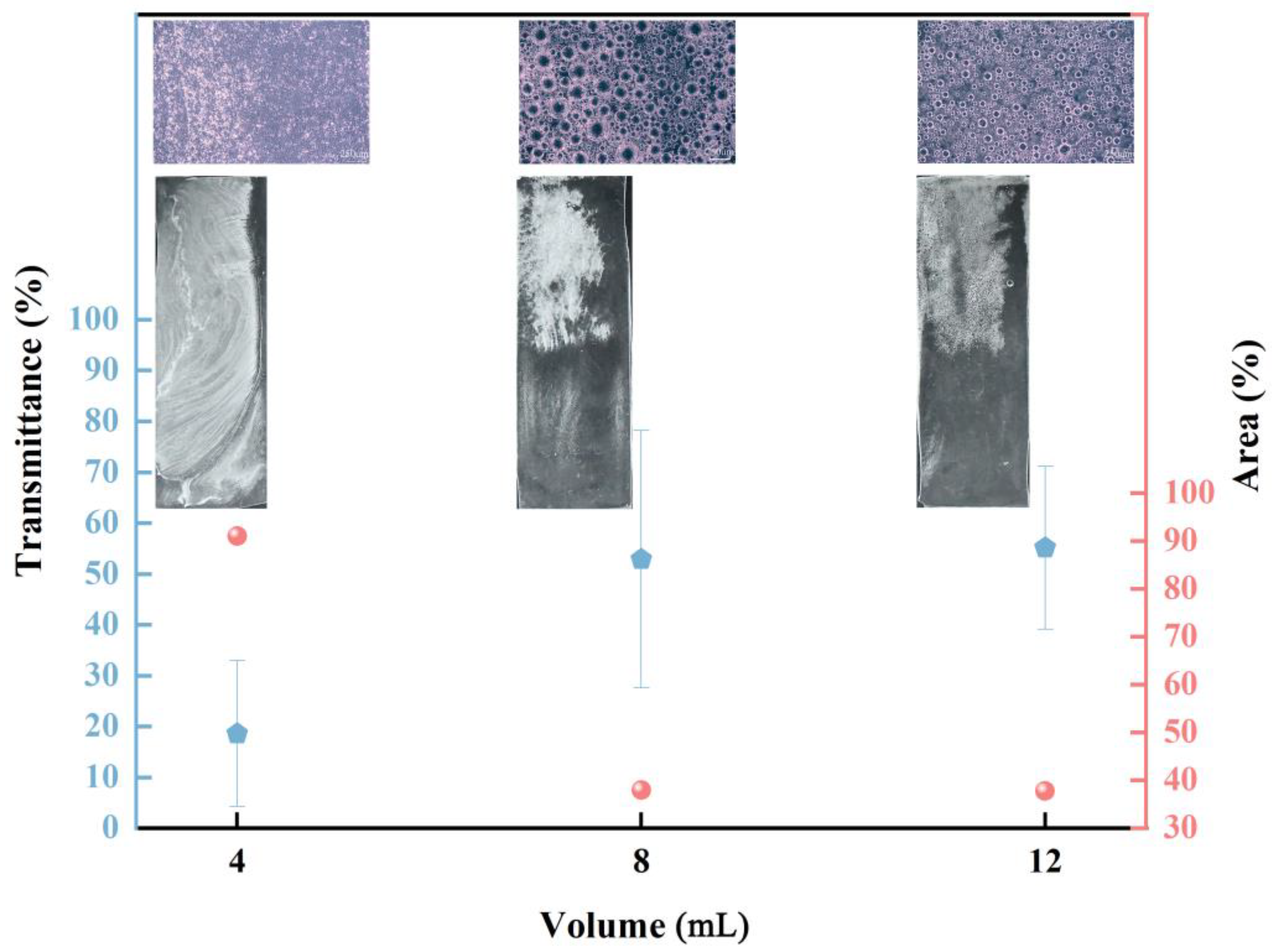

3.3. Effect of Paraloid B72 Mass Concentration and Solution Amount on Whitening Phenomenon

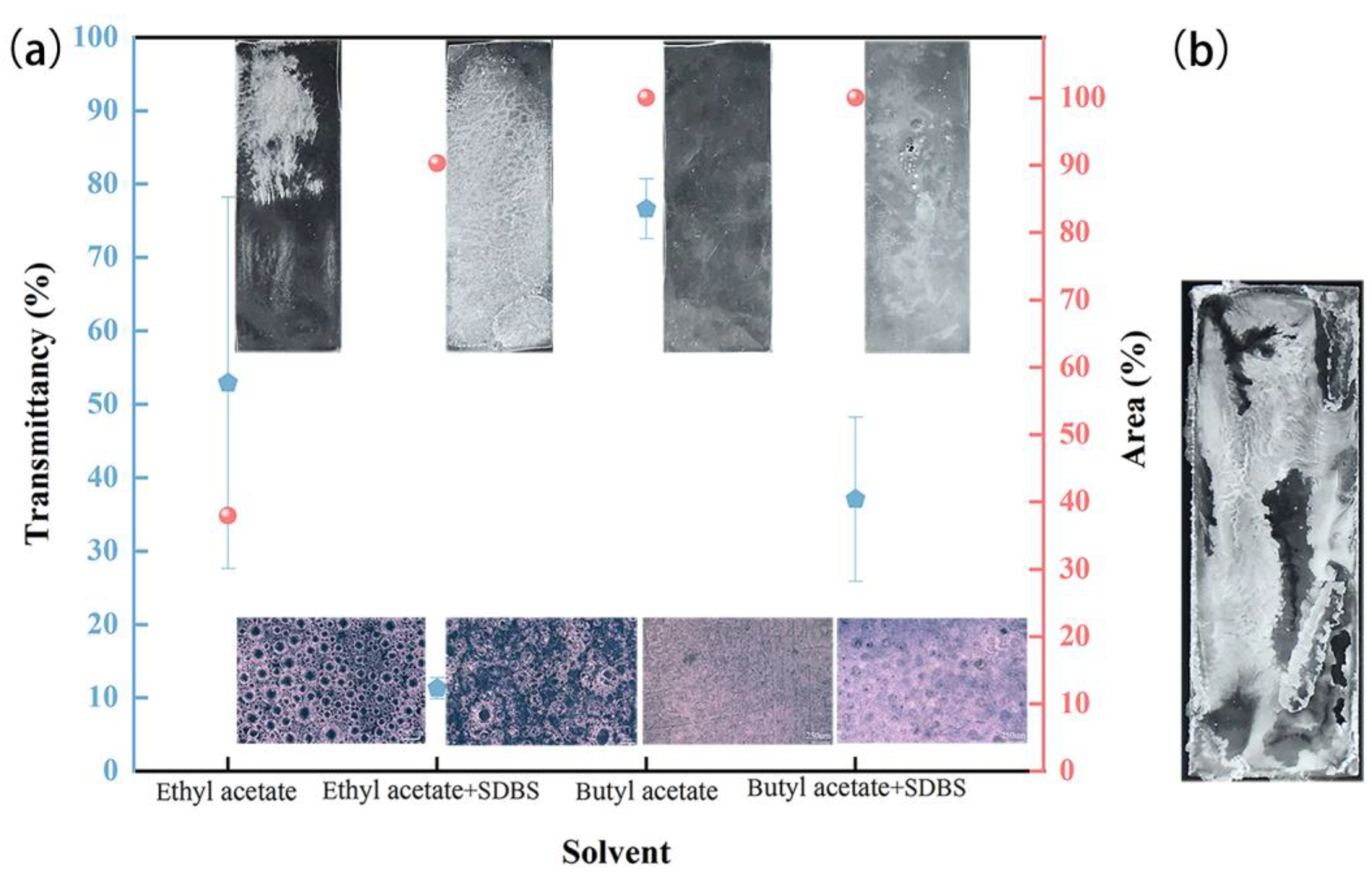

3.4. The Effect of Solvent on the Whitening Phenomenon

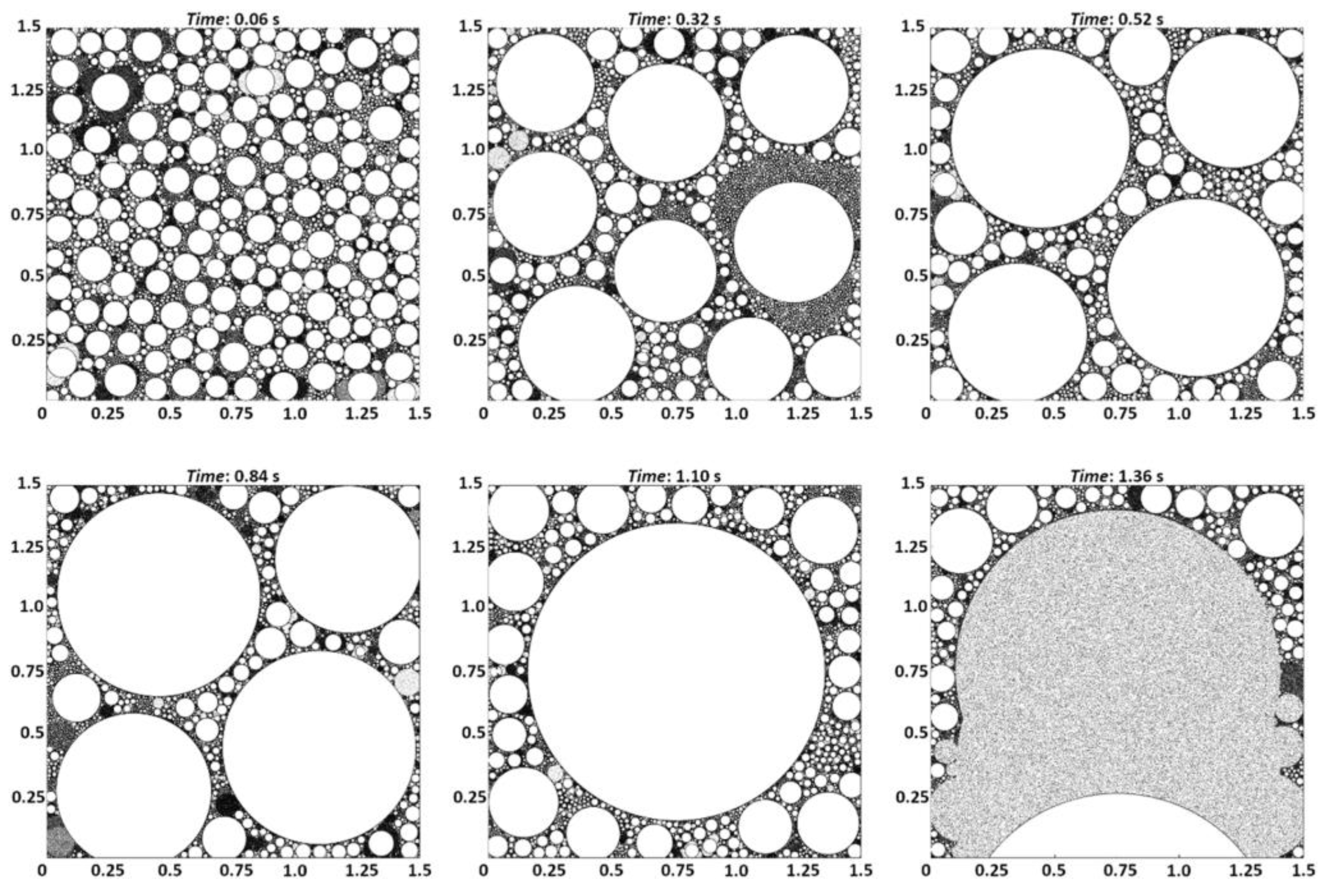

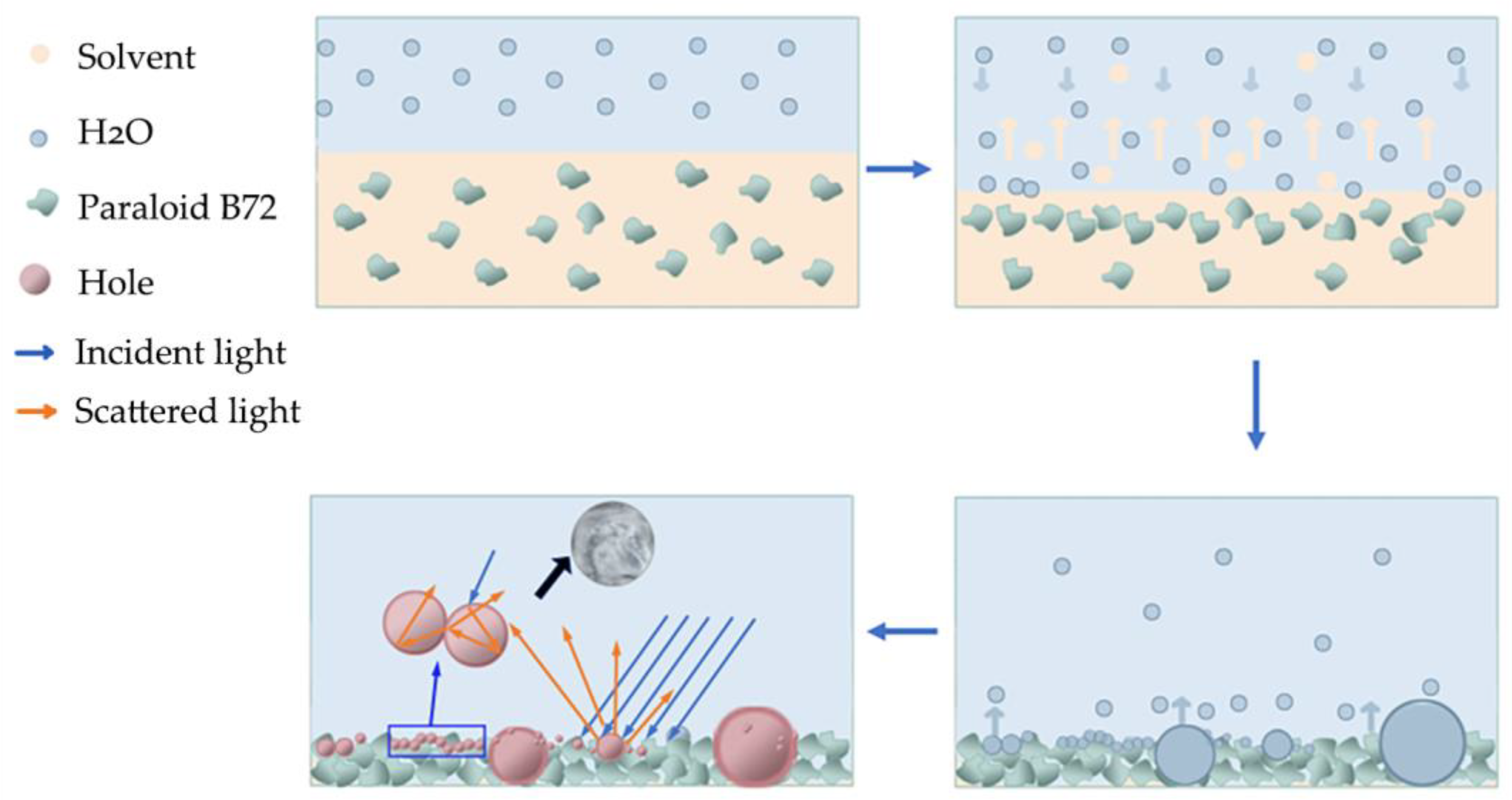

3.5. Mechanism of Whitening in Coating Films

4. Conclusions

- (1)

- Moisture content is a crucial factor in determining the extent of whitening. Variations in influencing factors lead to increased moisture content in the air, a decrease in the dew point temperature at the gas–liquid interface, moisture condensation on the film surface, and pore formation upon evaporation. This surface roughness causes optical heterogeneity, resulting in whitening.

- (2)

- During the Paraloid B72 curing process, factors such as ambient humidity, Paraloid B72 mass concentration, solution addition volume, and solvent type are interrelated. There is no fixed threshold for ambient humidity. Under normal humidity conditions, managing other influencing factors can still produce a whitening effect on the film.

- (3)

- In routine cultural heritage conservation, controlling factors such as ambient humidity (it is recommended to use under 50% ambient humidity) and solvent type can minimize the moisture involved in condensation or prevent the microenvironment from reaching the dew point temperature, thereby preventing whitening. According to the conclusion that the whitening is due to the change in physical structure on the surface of Paraloid B72, a further study could investigate whether the Paraloid B72 film can revert to the transparent state after the physical structure is changed again by placing the white film in an environment with a temperature higher than the glass transition temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Centenaro, S.; Franceschin, G.; Cattaruzza, E.; Traviglia, A. Consolidation and Coating Treatments for Glass in the Cultural Heritage Field: A Review. J. Cult. Herit. 2023, 64, 132–143. [Google Scholar] [CrossRef]

- Chiantore, O.; Lazzari, M. Characterization of Acrylic Resins. Int. J. Polym. Anal. Charact. 1996, 2, 395–408. [Google Scholar] [CrossRef]

- Chiantore, O.; Lazzari, M. Photo-Oxidative Stability of Paraloid Acrylic Protective Polymers. Polymer 2001, 42, 17–27. [Google Scholar] [CrossRef]

- Podany, J.; Garland, K.M.; Freeman, W.R.; Rogers, J. Paraloid B-72 as a Structural Adhesive and as a Barrier within Structural Adhesive Bonds: Evaluations of Strength and Reversibility. J. Am. Inst. Conserv. 2001, 40, 15–33. [Google Scholar] [CrossRef]

- Elghareb, W.K. Analysis and Restoration of Greco-Roman Pottery in Egypt. Int. J. Conserv. Sci. 2023, 14, 1327–1342. [Google Scholar] [CrossRef]

- Zhou, X.; He, W.; Ou, J.; Hu, Y.; Wang, F.; Fang, X.; Li, W.; Amirfazli, A. Translucent Superhydrophobic Coating for Murals Protection. Colloids Surf. A Physicochem. Eng. Asp. 2024, 689, 133750. [Google Scholar] [CrossRef]

- Han, Z.; Huang, X.; Chen, J.; Chen, J. 2-Mercaptobenzimidazole Compounded with the Conventional Sealer B72 for the Protection of Rusted Bronze. J. Cult. Herit. 2024, 67, 42–52. [Google Scholar] [CrossRef]

- Soytürk, E.E.; Kartal, S.N.; Terzi, E.; Önses, M.S.; Şarkdemir, K.; Çelik, N. Evaluation of Wood Treated with Paraloid B72® and Boric Acid: Thermal Behavior, Water Absorption and Mold Resistance. Eur. J. Wood Wood Prod. 2023, 81, 923–934. [Google Scholar] [CrossRef]

- Ionescu, C.Ş.; Lunguleasa, A.; Avram, A.; Spîrchez, C. Evaluation of the Efficiency of the Consolidation Treatment with Paraloid B72, Performed on Artworks with Degraded Wood Support. EDP Sci. 2021, 343, 02001. [Google Scholar] [CrossRef]

- Han, K.; Teri, G.; Cheng, C.; Tian, Y.; Huang, D.; Ge, M.; Fu, P.; Luo, Y.; Li, Y. Evaluation of Commonly Used Reinforcement Materials for Color Paintings on Ancient Wooden Architecture in China. Herit. Sci. 2024, 12, 122. [Google Scholar] [CrossRef]

- Molina, M.T.; Cano, E.; Leal, J.; Fort, R.; Álvarez de Buergo, M.; Ramírez-Barat, B. Protective Coatings for Metals in Scientific—Technical Heritage: The Collection of the Spanish National Museum of Science and Technology (MUNCYT). Heritage 2023, 6, 2473–2488. [Google Scholar] [CrossRef]

- Stafford, O.; Hinderliter, B.; Croll, S. Electrochemical Impedance Spectroscopy Response of Water Uptake in Organic Coatings by Finite Element Methods. Electrochim. Acta 2006, 52, 1339–1348. [Google Scholar] [CrossRef]

- Gong, X.; Han, X.; Chen, K. Anti-Aging Performance Evaluation of Acrylate Emulsion Used for Cultural Relics Conservation. Spectrosc. Spectr. Anal. 2023, 43, 2181–2187. [Google Scholar] [CrossRef]

- Mohamed, E.H. Effectiveness Assessment of Paraloid B-72 Enhanced with Nano Materials to Improve of Completion Mortars Properties for Conservation of Seti I Temple in El-Qurna, Thebes West Bank, Egypt. Multiscale Multidiscip. Model. Exp. Des. 2023, 6, 371–387. [Google Scholar] [CrossRef]

- He, W.; Ou, J.; Wang, F.; Lei, S.; Fang, X.; Li, W.; Amirfazli, A. Transparent and Superhydrophobic Coating via One-Step Spraying for Cultural Relic Protection against Water and Moisture. Colloids Surf. A Physicochem. Eng. Asp. 2023, 662, 130949. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Y.; Liu, C. Film Transparency and Opacity Measurements. Food Anal. Methods 2022, 15, 2840–2846. [Google Scholar] [CrossRef]

- Yousefi, F.; Mousavi, S.B.; Heris, S.Z.; Naghash-Hamed, S. UV-Shielding Properties of a Cost-Effective Hybrid PMMA-Based Thin Film Coatings Using TiO2 and ZnO Nanoparticles: A Comprehensive Evaluation. Sci. Rep. 2023, 13, 7116. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, Z.; Wang, K.; Fu, Q. Effects of Plasticizing on Mechanical and Viscous Characteristics of Poly (Vinyl Alcohol): A Comparative Study between Glycerol and Diethanolamine. Macromol. Mater. Eng. 2023, 308, 2300090. [Google Scholar] [CrossRef]

- Abdelbar, M.A. Technical Investigation and Conservation of Thin-walled Core Cast Leaded Bronze Statuettes of Osiris. Shedet 2024, 12, 325–343. [Google Scholar] [CrossRef]

- Avram, A.; Ionescu, C.S.; Lunguleasa, A. A Consolidation of Degraded Lime Wooden Support from Heritage Objects Using Two Types of Consolidant. BioResources 2023, 18, 4580. [Google Scholar] [CrossRef]

- El-Sayed, S.S.M. Restoration and Conservation of an Archaeological Marble Gravestone from the Greek Era-Al-Fustat-Egypt. J. Herit. Des. 2024, 4, 338–351. [Google Scholar]

- Abu-Baker, A. Analytical Investigation and Electrochemical Conservation Treatment for Archaeological Copper Alloy Artifacts from Jordan. Conserv. Património 2023, 42, 38–55. [Google Scholar] [CrossRef]

- Zhang, B.; Fan, B.; Huang, Z.; Higa, K.; Battaglia, V.S.; Prasher, R.S. A Review of Dispersion Film Drying Research. J. Electrochem. Energy Convers. Storage 2023, 20, 030801. [Google Scholar] [CrossRef]

- Holl, Y.; Keddie, J.; McDonald, P.; Winnik, W. Drying Modes of Polymer Colloids. Film. Form. Coat. 2001, 790, 2–26. [Google Scholar] [CrossRef]

- Weng, K.; Ye, L.; Zhu, L.; Xu, J.; Zhou, J.; Feng, X.; Lu, G.; Tan, S.; Liu, F.; Sun, Y. Optimized Active Layer Morphology toward Efficient and Polymer Batch Insensitive Organic Solar Cells. Nat. Commun. 2020, 11, 2855. [Google Scholar] [CrossRef]

- Guerrier, B.; Bouchard, C.; Allain, C.; Bénard, C. Drying Kinetics of Polymer Films. AIChE J. 1998, 44, 791–798. [Google Scholar] [CrossRef]

- Merklein, L.; Eser, J.C.; Börnhorst, T.; Könnecke, N.; Scharfer, P.; Schabel, W. Different Dominating Mass Transport Mechanisms for Drying and Sorption of Toluene-PMMA Films–Visualized with Raman Spectroscopy. Polymer 2021, 222, 123640. [Google Scholar] [CrossRef]

- Börnhorst, T.; Scharfer, P.; Schabel, W. Drying Kinetics from Micrometer-to Nanometer-Scale Polymer Films: A Study on Solvent Diffusion, Polymer Relaxation, and Substrate Interaction Effects. Langmuir 2021, 37, 6022–6031. [Google Scholar] [CrossRef]

- Ronsin, O.J.; Jang, D.; Egelhaaf, H.-J.; Brabec, C.J.; Harting, J. A Phase-Field Model for the Evaporation of Thin Film Mixtures. Phys. Chem. Chem. Phys. 2020, 22, 6638–6652. [Google Scholar] [CrossRef]

- Vinçotte, A.; Beauvoit, E.; Boyard, N.; Guilminot, E. Effect of Solvent on PARALOID® B72 and B44 Acrylic Resins Used as Adhesives in Conservation. Herit. Sci. 2019, 7, 42. [Google Scholar] [CrossRef]

- Yu, J.; Shen, Z.; Lu, W.; Zhu, Y.; Liu, Y.-X.; Neher, D.; Koch, N.; Lu, G. Composition Waves in Solution-Processed Organic Films and Its Propagations from Kinetically Frozen Surface Mesophases. Adv. Funct. Mater. 2023, 33, 2302089. [Google Scholar] [CrossRef]

- He, X.; Wang, S.; Zhang, B. A Semi-Theoretical Model for Water Condensation: Dew Used in Conservation of Earthen Heritage Sites. Water 2020, 13, 52. [Google Scholar] [CrossRef]

- Mirafiori, M.; Tancon, M.; Bortolin, S.; Del Col, D. Modeling of Growth and Dynamics of Droplets during Dropwise Condensation of Steam. Int. J. Heat Mass Transf. 2024, 222, 125109. [Google Scholar] [CrossRef]

- Farahani, M.F.; Bagheri, R.; Marouf, B.T. Investigation on the Onset and Progress of Stress Whitening in Polypropylene Using Digital Image Processing. Polym. Bull. 2024, 81, 7139–7156. [Google Scholar] [CrossRef]

- Zhang, S.; Bhagia, S.; Li, M.; Meng, X.; Ragauskas, A.J. Wood-Reinforced Composites by Stereolithography with the Stress Whitening Behavior. Mater. Des. 2021, 206, 109773. [Google Scholar] [CrossRef]

- Lyu, D.; Tang, Y.; Qian, L.; Chen, R.; Lu, Y.; Men, Y. Large Strain Cavitation Induced Stress Whitening in Propylene-Butene-1 Copolymer during Stretching. Polymer 2019, 167, 146–153. [Google Scholar] [CrossRef]

| Sample | Humidity (%) | Paraloid B72 Concentration (%) | Solution Amount (mL) | Solvent | Additive |

|---|---|---|---|---|---|

| 1 | 60 | 10 | 8 | Ethyl acetate | / |

| 2 | 70 | 10 | 8 | Ethyl acetate | / |

| 3 | 80 | 10 | 8 | Ethyl acetate | / |

| 4 | 90 | 10 | 8 | Ethyl acetate | / |

| 5 | 90 | 1 | 8 | Ethyl acetate | / |

| 6 | 90 | 5 | 8 | Ethyl acetate | / |

| 7 | 90 | 15 | 8 | Ethyl acetate | / |

| 8 | 90 | 20 | 8 | Ethyl acetate | / |

| 9 | 90 | 10 | 4 | Ethyl acetate | / |

| 10 | 90 | 10 | 12 | Ethyl acetate | / |

| 11 | 90 | 10 | 8 | Ethyl acetate | SDBS |

| 12 | 90 | 10 | 8 | Butyl acetate | / |

| 13 | 90 | 10 | 8 | Butyl acetate | SDBS |

| 14 | 60 | 1 | 8 | Acetone | / |

| Solvent | Relative Evaporation Rate | Miscibility with Wate (15 °C) |

|---|---|---|

| Butyl acetate | 100 | 7.83% |

| Ethyl acetate | 615 | 0.50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Li, X.; Zhang, S.; Niu, Q.; Li, Z.; Xue, C. Investigation of Whitening Mechanism on Cultural Relic Surfaces Treated with Paraloid B72. Coatings 2024, 14, 1240. https://doi.org/10.3390/coatings14101240

Zhao X, Li X, Zhang S, Niu Q, Li Z, Xue C. Investigation of Whitening Mechanism on Cultural Relic Surfaces Treated with Paraloid B72. Coatings. 2024; 14(10):1240. https://doi.org/10.3390/coatings14101240

Chicago/Turabian StyleZhao, Xing, Xia Li, Siyu Zhang, Qing Niu, Zongmin Li, and Cheng Xue. 2024. "Investigation of Whitening Mechanism on Cultural Relic Surfaces Treated with Paraloid B72" Coatings 14, no. 10: 1240. https://doi.org/10.3390/coatings14101240

APA StyleZhao, X., Li, X., Zhang, S., Niu, Q., Li, Z., & Xue, C. (2024). Investigation of Whitening Mechanism on Cultural Relic Surfaces Treated with Paraloid B72. Coatings, 14(10), 1240. https://doi.org/10.3390/coatings14101240