Abstract

Currently, fast-melting SBS (Styrene-Butadiene-Styrene)-modified asphalt is widely used in pavements. However, in practical applications, complex environmental factors accelerate the deterioration of asphalt material properties, significantly affecting the service life of roads during their operational period. This study aims to examine the effects of complex environmental factors, including thermal oxidation, ultraviolet radiation, and various concentrations of salt solutions, on the high and low-temperature rheological properties of fast-melting SBS-modified asphalt (abbreviated as SBS-T-modified asphalt). Pressure aging–ultraviolet aging coupling and pressure aging–ultraviolet aging different concentration salt solution coupling were selected as the aging groups to simulate complex environmental conditions. Additionally, base asphalt and pressure-aged asphalt were used as control groups. The rheological properties of SBS-T-modified asphalt were evaluated using a dynamic shear rheometer (DSR) and bending beam rheometer (BBR). The results indicate that multiple-factor coupling aging reduces both the high-temperature and low-temperature performance of SBS-T-modified asphalt compared to single-factor aging, although the impact on rheological properties is not consistent across all conditions. After the combined effects of UV aging and pressure aging, the rutting resistance and high-temperature performance of SBS-T-modified asphalt are most severely impacted. However, when coupled with salt-solution aging, the rutting resistance of SBS-T-modified asphalt improves, with the complex modulus increasing by approximately 30%. This indicates that the presence of the salt solution enhances the high-temperature performance of the asphalt. An analysis of the low-temperature rheological properties of SBS-T-modified asphalt based on Burgers model shows that the low-temperature rheological performance of SBS-T-modified asphalt worsens under three-factor coupling aging compared to two-factor or single-factor aging, leading to poorer crack resistance. Notably, after adding salt solutions, the thermal sensitivity of SBS-T-modified asphalt increases significantly, with the ΔTc value decreasing approximately sixfold for every 2% increase in salt concentration.

1. Introduction

Over the long-term use of asphalt pavements, various types of distresses such as cracking, pumping, raveling, and delamination occur on road surfaces due to the influence of temperature, sunlight, water, and vehicle loads, ultimately affecting the service life of the asphalt pavement. Modifying asphalt is one of the key methods to enhance asphalt performance and improve the service quality of asphalt pavements, with SBS block copolymers being effective in improving both the low-temperature and high-temperature performance of asphalt, and their mechanical properties in complex environments directly affect the mechanical properties of asphalt concrete and road performance [1]. As a material with excellent high- and low-temperature properties, SBS-modified asphalt, prepared using dry-process modification techniques, has been widely used in pavement construction and maintenance, differing from traditional wet-process modification techniques. The dry process eliminates the processing steps in the modified asphalt plant by separating the use of the modifier and the base asphalt, with the SBS modifier being directly added to the mixing drum. This process consumes significantly less energy than the wet process used to produce the same amount of modified asphalt. Some researchers have explored the road performance of dry-process direct-addition SBS modifiers and analyzed various test results, showing that the technical requirements of direct-addition SBS-modified asphalt meet the standard specifications, with certain performance indicators even outperforming those of the wet-process method [2]. However, the study did not further take into account the impact of aging factors. Asphalt aging is a progress; an essential characteristic of asphalt pavements is their resistance to cracking induced by thermal shrinkage during temperature reductions or by the repeated action of traffic loads, typically exacerbated by ageing. Decreasing air and pavement temperatures lead to the development of tensile stresses within the asphalt mixture. Owing to bitumen’s intrinsic viscoelastic properties, it possesses the ability to relax and thereby reduce these tensile stresses over time. The tive process and its rate of development significantly impacts the service life of pavements. The essence of asphalt aging lies in the chemical structural changes of various compounds within the asphalt, which result in an increased solubility parameter difference between asphaltenes and maltenes. This leads to reduced compatibility between these components, ultimately manifesting as a decline in the performance of asphalt in road applications [3]. The addition of an SBS modifier significantly enhances the high- and low-temperature performance of asphalt and is, therefore, widely applied in engineering practice. However, after aging, the unsaturated double bonds in the SBS modifier can easily degrade, leading to a significant reduction in performance [4]. In addition, SBS-T-modified asphalt exhibits different performance characteristics depending on the temperature and loading duration. Under high temperatures and slow-moving loads, it behaves as a purely viscous material, making it prone to plastic deformation and rutting. At low temperatures and high loading rates, it behaves elastically but eventually becomes brittle, leading to low-temperature cracking [5]. The issues of high-temperature rutting and low-temperature cracking in asphalt pavements are primarily related to the rheological properties of asphalt. These characteristics must be evaluated and described using appropriate technical indicators [6,7]. Some researchers have studied the low-temperature performance of different types of asphalt using the Bending Beam Rheometer (BBR) test and fitted the BBR creep stiffness curves and master stiffness curves with the Burgers model equation. The results demonstrated that the Burgers model equation can effectively fit both the BBR creep stiffness curves and the master stiffness curves [8]. Therefore, this study also utilizes the Burgers model to conduct a more in-depth investigation into the low-temperature performance of modified asphalt. In conclusion, researchers from various countries have proposed different optimization indicators based on the rheological and mechanical properties of asphalt, resulting in varying evaluation outcomes and differing applicability. These indicators still have certain limitations and inapplicability in evaluating the high- and low-temperature performance of asphalt [9]. Most researchers use a dynamic shear rheometer (DSR) and bending beam rheometer (BBR) to study the rheological properties of modified asphalt. However, the research on the high- and low-temperature rheological performance of SBS-T-modified asphalt under different coupled aging conditions is still not thorough enough. Therefore, it is necessary to investigate the impact of coupled aging on the rheological properties of dry-process SBS-modified asphalt.

Laboratory aging simulation tests can more precisely control test conditions and accelerate the aging process, making them a common method for evaluating asphalt aging characteristics [10]. Researchers use the rolling thin-film oven test (RTFOT) to simulate short-term aging and the pressure aging vessel (PAV) test to simulate long-term aging in order to study the molecular weight changes of SBS-modified asphalt before and after aging [11]. However, due to the absence of ultraviolet radiation and the effects of water, these test conditions cannot fully replicate the actual pavement environment, which is relatively complex. For example, water acts as a medium that accelerates asphalt aging under the combined effects of time, heat, oxygen, and sunlight. Traxler [12] listed 15 factors contributing to asphalt aging and found that water accelerates asphalt aging under the combined effects of time and sunlight. Moreover, the water that comes into contact with asphalt pavement in the natural environment is not pure water. Salts are often used to melt snow and ice on pavements, and the resulting salt solutions can damage the asphalt pavement. The intrusion of moisture accelerates the deterioration of asphalt material performance, making it a significant factor affecting asphalt properties [13,14]. However, research in this area is relatively lacking, creating a situation where it has a substantial impact but remains underexplored. Roads and sidewalks in coastal areas are generally paved with asphalt materials, and the air, rain, and sea fog in these areas contain sea salt components, which can severely affect the performance and lifespan of asphalt pavements [15,16,17]. Behnam and others conducted experimental research on the impact of dynamic saltwater erosion on asphalt performance under freeze–thaw cycle conditions and found that salt is a significant factor contributing to asphalt deterioration [18]. Therefore, it is necessary to consider the effects of salt environments on asphalt aging. Wang believes that ultraviolet radiation is also a major cause of asphalt aging, leading to decreased fatigue resistance, increased creep stiffness, and reduced failure strain [19]. Therefore, the issue of photo-oxidative aging has garnered significant attention from many researchers. Studies have confirmed that light strongly accelerates the process of oxidative degradation [20]. Ultraviolet radiation is an essential factor in studying asphalt durability, and combining photo-oxidative aging with thermo-oxidative aging provides a better simulation of the aging phenomena occurring in asphalt during service [21]. Additionally, Bian introduced water molecules into the PAV test to study asphalt degradation [22]. The main forms of asphalt aging include oxidation, volatilization, natural hardening, and seepage hardening. The primary factors affecting aging are temperature, oxygen, light, dissolution, and damage fatigue over time, with aging often resulting from the combined effects of these factors [23]. Previous studies have mostly considered the impact of a single aging factor on asphalt without taking into account the coupled effects of multiple factors. This study, however, couples pressure aging, ultraviolet aging, and salt solution aging to explore the performance changes of dry-process SBS-modified asphalt under complex environmental conditions.

The primary objective of this study is to investigate the effects of pressure–ultraviolet-coupled aging and pressure–ultraviolet–salt solution three-factor coupled aging on the high- and low-temperature performance of dry-process SBS-modified asphalt. Based on short-term aging, this study employs a pressure aging vessel and an indoor accelerated ultraviolet aging test chamber to age dry-process SBS-modified asphalt. The performance changes of the dry-process SBS-modified asphalt under complex environmental conditions are revealed through dynamic shear rheometer (DSR) and bending beam rheometer (BBR) tests.

2. Materials and Methods

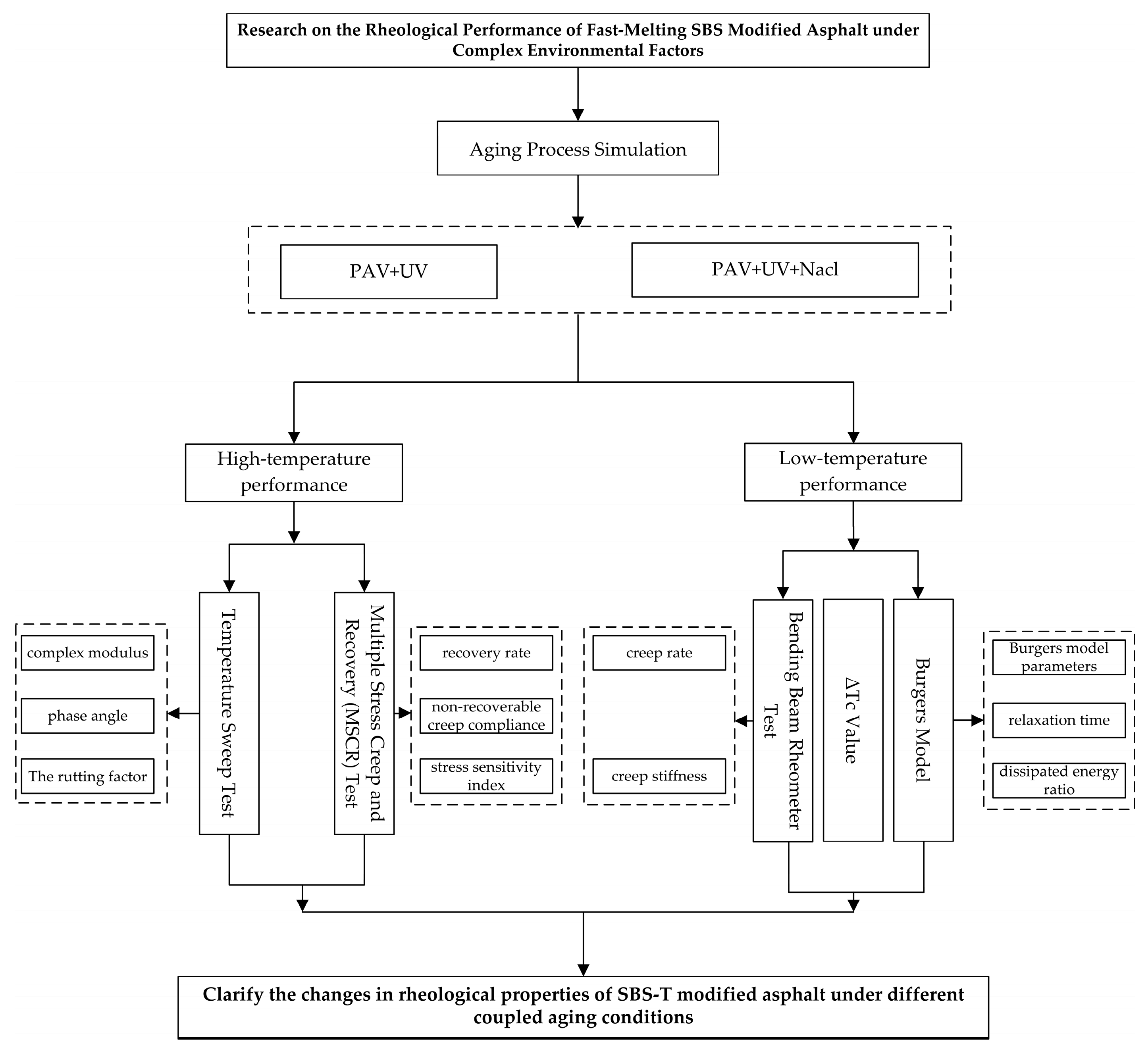

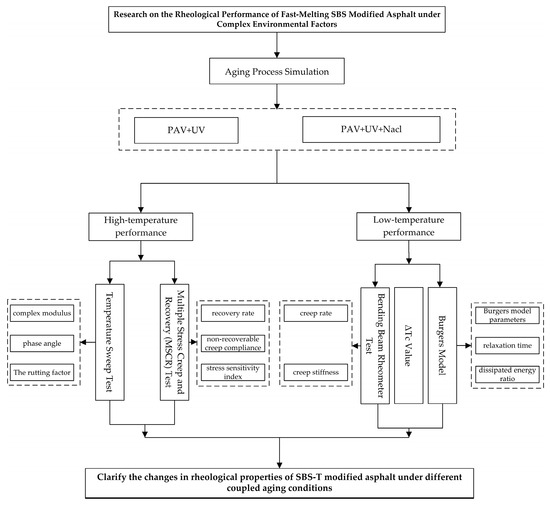

Figure 1 is a flowchart.

Figure 1.

Flowchart.

This is the specific test technology roadmap of this article.

2.1. Materials

The base asphalt used in this experiment was supplied by Beijing Guolu Hi-Tech Engineering Technology Research Institute Co., Ltd. (Beijing, China). The main indicators were tested according to the “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011 [24]), with specific test results shown in Table 1. The SBS-T polymer modifier (referred to as SBS-T in this paper) used to prepare polymer-modified asphalt was also provided by the Beijing Guolu Hi-Tech Engineering Technology Research Institute Co., Ltd., and its physical appearance is shown in Figure 2, with the technical indicators listed in Table 2.

Table 1.

Basic properties of base asphalt.

Figure 2.

Appearance of fast-melting SBS modifier.

Table 2.

Technical indexes of the SBS-T.

2.2. Preparation of Fast-Melting SBS-Modified Asphalt

Ordinary 70# road petroleum asphalt was modified by adding SBS-T rapid-dissolution type modifier. When the dosage exceeds 4%, the asphalt can meet the technical specifications for modified asphalt required in construction standards [25], and in practical applications, a 4% dosage is typically used. Therefore, this study employed a 4% SBS-T dosage. The base asphalt was heated to 180 °C and stirred, while the predetermined amount of SBS-T was added gradually at a rate of 800 r/min, ensuring that all SBS-T was added within 2 min. The SBS-T was introduced in small, multiple increments to ensure even mixing and avoid clumping. After fully incorporating the SBS-T, the temperature was maintained between 180–190 °C, and the shearing machine was set to a speed of 5000 r/min for 40 min to produce SBS-T-modified asphalt. We conducted penetration, softening point, and ductility tests on SBS-T-modified asphalt according to the specifications. This article tests the ductility of asphalt at 5 °C, with a tensile speed of 1 cm/min. The three major indicators of the three types of asphalt obtained are shown in Table 3.

Table 3.

Basic properties of SBS-T-modified asphalt.

2.3. Preparation of Salt Solutions

Sodium chloride (NaCl) was used as the compound to simulate the salt environment. Salt solutions with concentrations of 6%, 8%, and 10% were prepared using sodium chloride crystals. The technical specifications for the sodium chloride reagent conform to Chinese standards (GB/T 1266-2006 and GB/T 9853-2008). These different concentrations of salt solutions were used to simulate the effects of varying amounts of deicing salt on the performance of SBS-T-modified asphalt.

2.4. Experimental Methods

2.4.1. Aging Process Simulation

Before studying the coupled aging of asphalt, the short-term aging of the asphalt during mixing, transportation, and paving was first simulated using the rolling thin-film oven test (RTFOT). After short-term aging, the SBS-T-modified asphalt samples were placed in a pressure aging vessel (PAV) to simulate long-term aging. Subsequently, the long-term aged samples were subjected to ultraviolet aging in a UV aging test chamber, simulating the combined effects of thermo-oxidative and UV aging. As shown in Figure 3, the UV aging test chamber is equipped with a high-pressure mercury lamp, rated at 1 kW, with a UV wavelength of 350 nm. The sample was placed 50 cm away from the light source, and the UV radiation intensity, measured using a UV photometer, was 150 w/m2. The internal temperature of the UV aging chamber was set to 45 °C. Most scholars, both domestically and internationally, use an aging period of less than 15 days for UV aging [26,27,28]. Based on the relevant literature, this study selected a UV exposure time of 7 days. Additionally, to introduce the effects of a salt environment, a predetermined amount of prepared salt solution was sprayed onto the asphalt surface daily during UV aging.

Figure 3.

UV aging test chamber.

2.4.2. Dynamic Shear Rheometer Test

To evaluate the rheological properties of asphalt under specific temperatures and external force conditions, the American Superpave asphalt binder specification employs the dynamic shear rheometer (DSR) test. This study used the DSR to conduct temperature sweep tests and multiple stress creep recovery (MSCR) tests to investigate the effects of different temperatures and aging conditions on the high-temperature rheological performance of SBS-T-modified asphalt.

The temperature sweep was performed under a strain-controlled mode, with a strain setting of 8%, a frequency of 10 rad/s, and a temperature range from 52 °C to 82 °C, with a temperature gradient of 6 °C.

The MSCR test, developed to evaluate the elastic recovery capacity of asphalt binder, addresses the shortcomings of the original evaluation system. According to AASHTO MP19-10, the MSCR test was conducted on aged asphalt at 58 °C and 64 °C. The MSCR test provides data on the non-recoverable creep compliance (Jnr), the percent recovery (R), and the stress sensitivity index under different stress levels. The specific formulas for these calculations are provided in Equations (1)–(3):

where is the peak strain, is the residual strain, is the initial strain, and is the stress. The average values of R and Jnr over 10 cycles at stress levels of 0.1 kPa and 3.2 kPa were calculated.

2.4.3. Bending Beam Rheometer Test

The low-temperature performance of aged SBS-T-modified asphalt was measured using the bending beam rheometer (BBR) according to ASTM D6648 and AASHTO T313 standards. The beam specimen dimensions were 127 mm × 6.35 mm × 12.7 mm, and a load of 0.980 N was applied for 240 s. The creep stiffness (S) and creep rate (m) were measured at −6 °C, −12 °C, and −18 °C to evaluate the low-temperature performance of SBS-T. Typically, the 60 s stiffness modulus (S) and creep rate (m) are used for evaluation in practical applications. The ΔTc value was calculated using Equation (4) to analyze the low-temperature cracking resistance of the asphalt. Additionally, the low-temperature creep compliance curve was fitted using the Burgers model, and a low-temperature viscoelastic evaluation index for asphalt was established. Through mathematical derivation, such as Laplace transformation, the Burgers model creep equation can be obtained as shown in Equation (5). Dividing both sides of Equation (5) by stress yields the Burgers model creep compliance Equation (6), where creep compliance is the inverse of creep stiffness.

where is the critical temperature (s = 300 MPa) and is the critical temperature (m = 0.3).

where is the strain at time t; is the creep stress in MPa; t is the loading time in seconds; E1 and E2 are the instantaneous elastic modulus of the Maxwell model and the delayed elastic modulus of the Kelvin model, respectively, in MPa; and are the instantaneous damping coefficient of the Maxwell model and the delayed damping coefficient of the Kelvin model, respectively, in MPa∙s; is the creep compliance at time t in MPa−1; and is the creep stiffness at time t in MPa.

3. Results and Discussion

3.1. High-Temperature Characteristics

3.1.1. Temperature Sweep Test

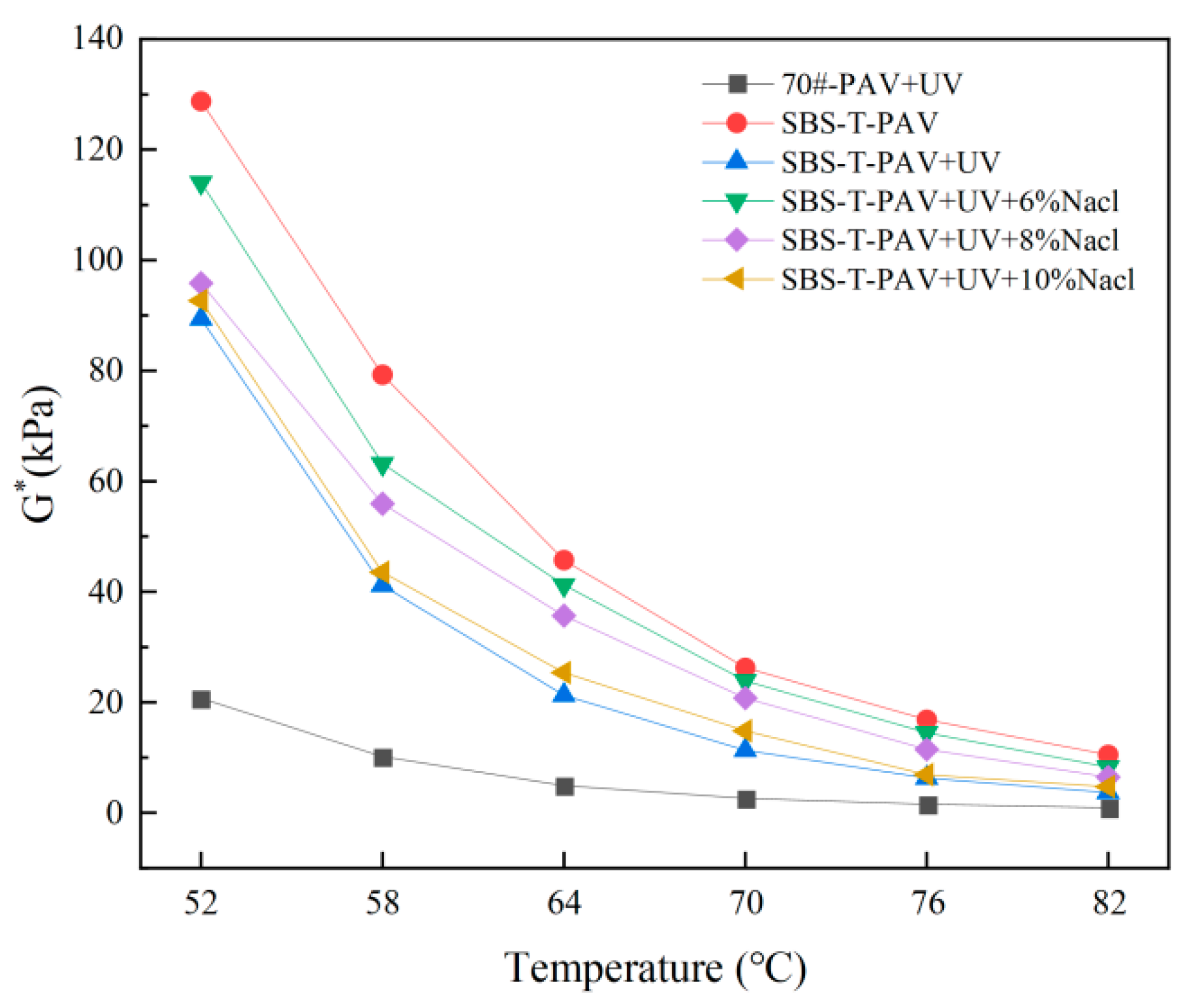

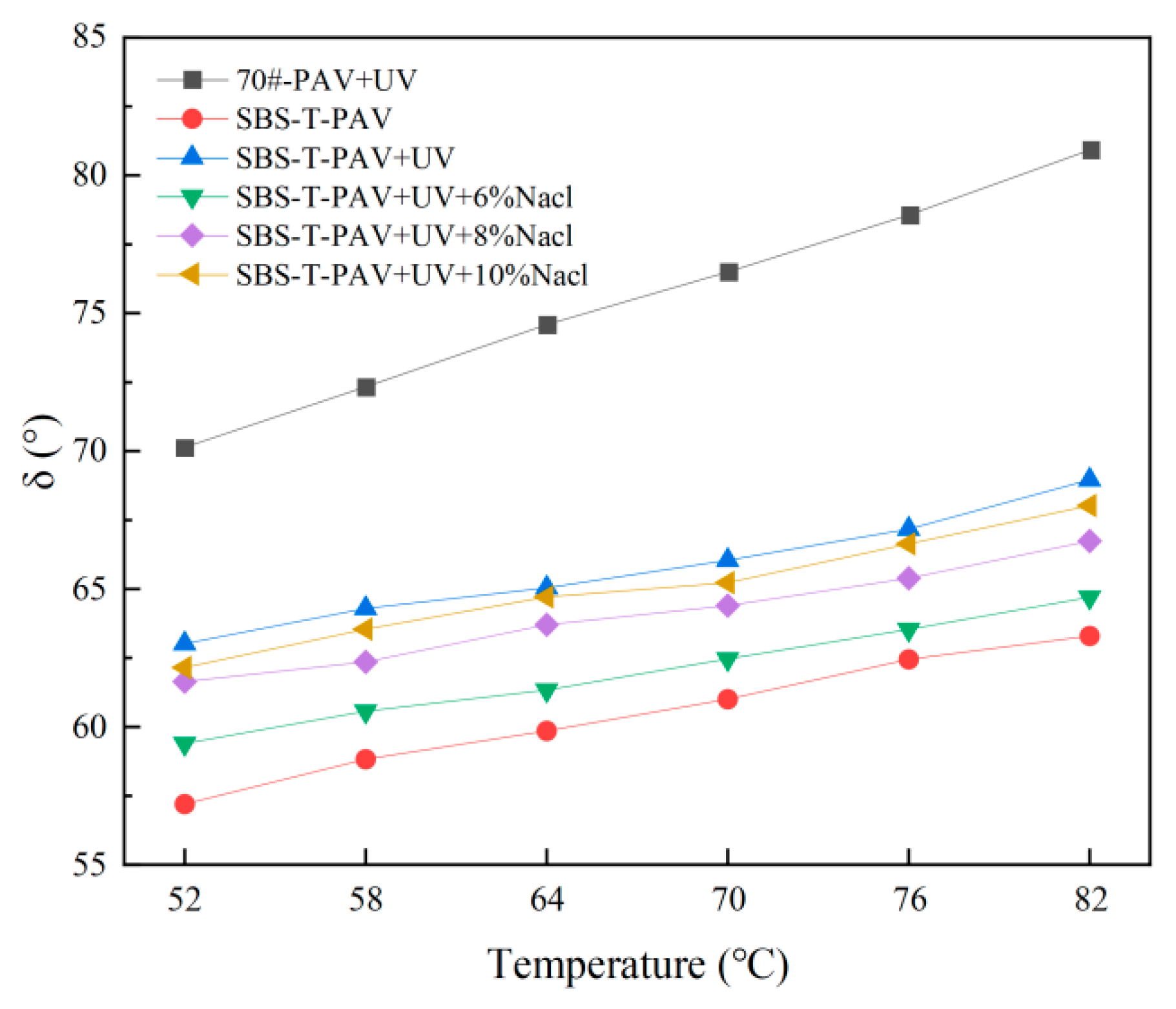

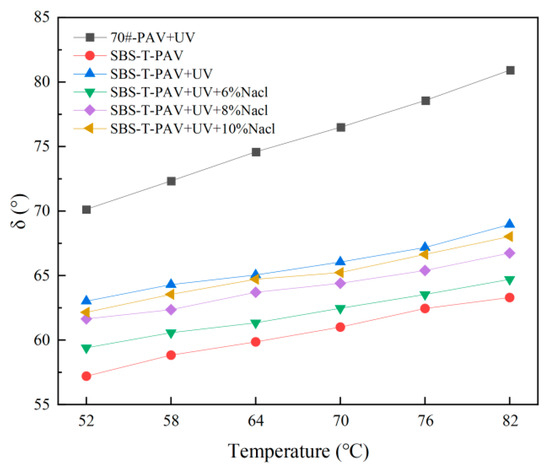

The complex shear modulus G*, also known as the complex modulus, is an indicator of the high-temperature rheological properties of asphalt. The higher the value, the stronger the asphalt’s resistance to deformation. The phase angle represents the lag in strain under external stress; a larger phase angle indicates an increase in viscous components, which can lead to greater irreversible deformation in the asphalt [29,30]. Temperature sweep tests were conducted on aged asphalt samples, and the variations in complex modulus G* and phase angle with temperature for different asphalt samples are shown in Figure 4 and Figure 5.

Figure 4.

Complex modulus of asphalt after various aging processes.

Figure 5.

Phase angle of asphalt after various aging processes.

As the temperature increases, the complex modulus of all asphalt samples gradually decreases, while the phase angle increases. This indicates that as the asphalt softens with heating, its rheological behavior transitions from elastic to viscous. Under the same temperature and aging conditions, the complex modulus of SBS-T-modified asphalt is consistently higher than that of 70# base asphalt, while the phase angle is consistently lower, indicating that the dry-process SBS modifier improves the asphalt’s resistance to deformation. The complex modulus of SBS-T-modified asphalt after pressure and UV-coupled aging is higher than that after single-factor (PAV) aging, with the opposite trend observed for the phase angle, indicating that these two factors combined accelerate asphalt aging. As the temperature increases, the asphalt exhibits typical two-point plastic flow, making it more prone to high-temperature rutting. After the addition of the salt solution factor, the complex modulus increases, and the phase angle decreases under the combined effects of pressure, UV, and salt solution, indicating that for salt-eroded asphalt samples, the viscous components decrease, while the elastic components increase, thereby enhancing the elastic.

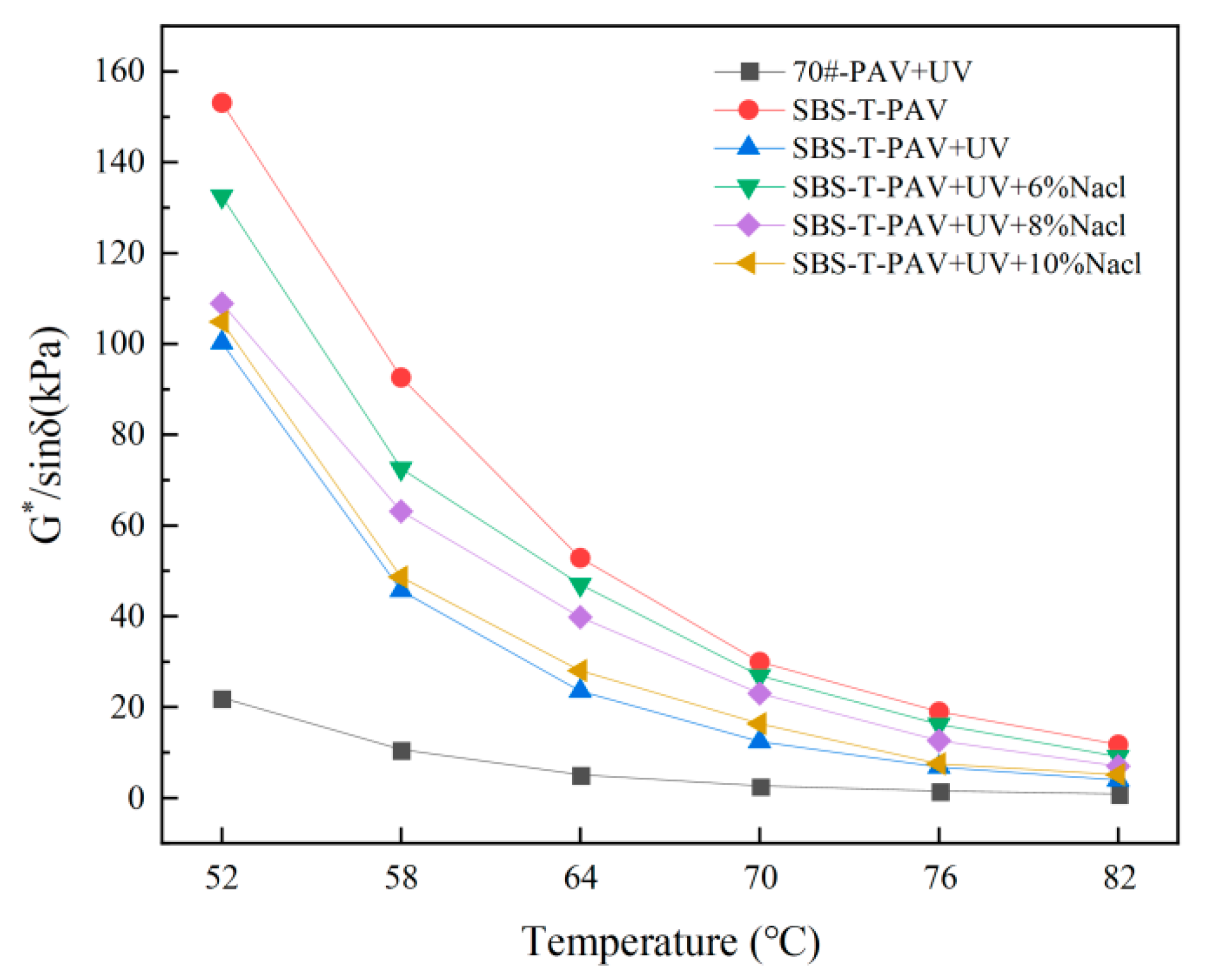

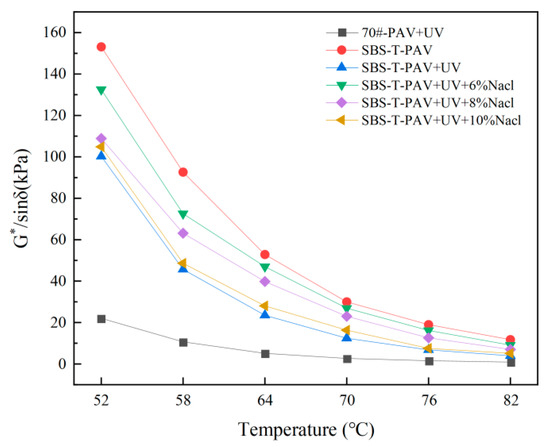

The rutting factor (G*/sinδ) is an indicator used to characterize the deformation resistance of asphalt at high temperatures. A higher rutting factor indicates less flow deformation and stronger deformation resistance. The test results for the rutting factor of different asphalt samples are shown in Figure 6. From Figure 6, it can be observed that as the temperature increases, the rutting factor of the asphalt tends to decrease. Higher temperatures cause the asphalt to soften, leading to increased viscosity and thus, reduced deformation resistance.

Figure 6.

The rutting factor of asphalt after various aging processes.

For SBS-T-modified asphalt samples, the rutting factor after combined pressure and UV aging is significantly lower than that after pressure aging alone, indicating that the combination of these two aging factors reduces the asphalt’s high-temperature deformation resistance. This reduction occurs because pressure aging causes a significant increase in the elastic components of the asphalt and a corresponding decrease in its viscous components. UV aging further exacerbates this by reducing the light fractions in the asphalt and increasing the heavy fractions, leading to asphalt hardening. Additionally, after UV aging, SBS molecules tend to interact with oxygen molecules to form hydroperoxides. These hydroperoxides, upon absorbing UV light, can induce further photo-oxidative reactions, leading to the photodegradation of asphalt components and polymers [31,32]. The combined effects of these two aging factors accelerate the aging of SBS-T-modified asphalt, reducing its high-temperature performance.

However, when the salt solution aging factor is added to this combination, the rutting factor of the modified asphalt after three-factor coupled aging becomes larger than that after pressure and UV aging alone. This suggests that the presence of the salt solution enhances the rutting resistance of the asphalt and improves its high-temperature performance.

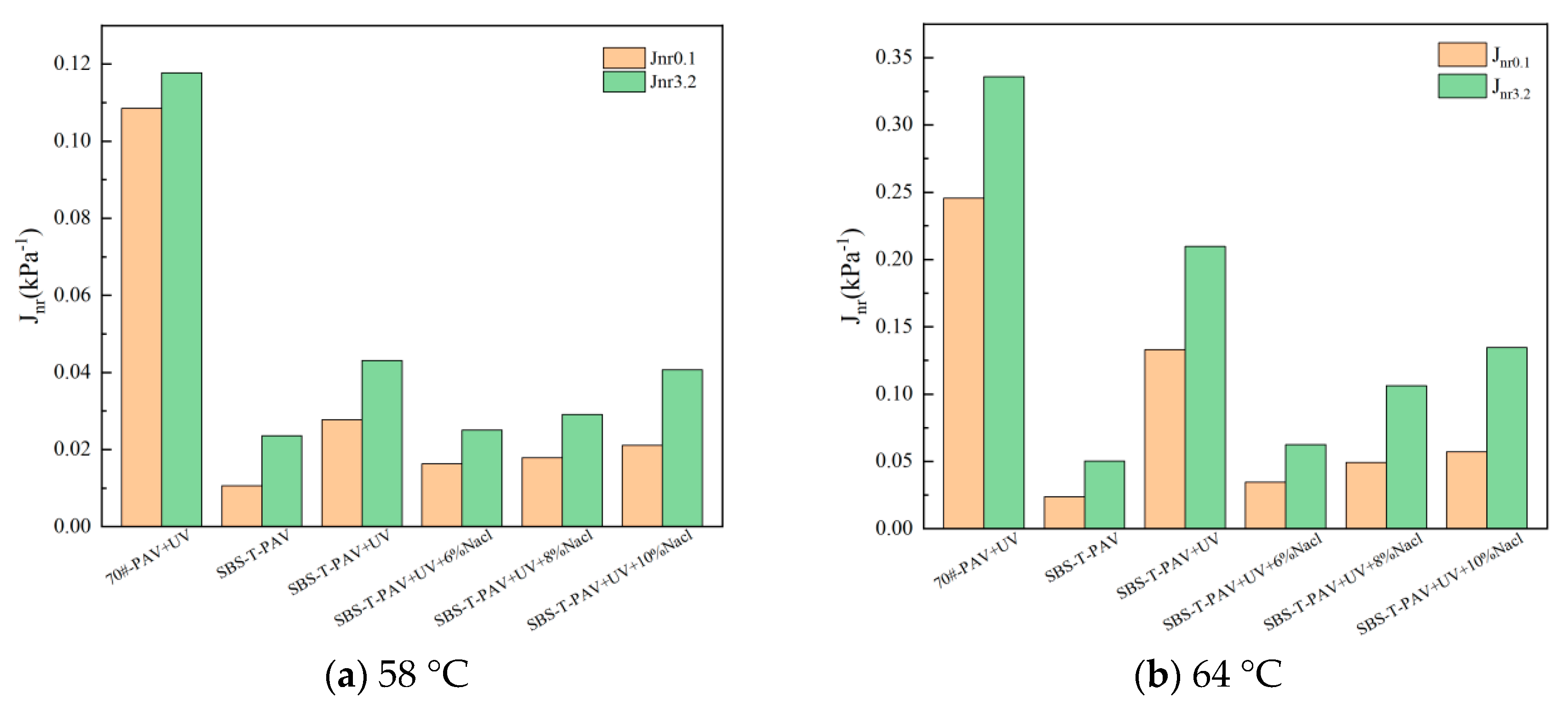

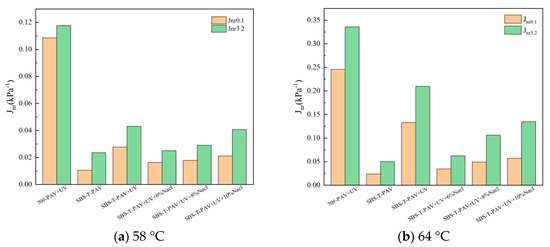

3.1.2. Multiple Stress Creep and Recovery (MSCR) Test

The MSCR parameters R and Jnr are critical indicators of the asphalt’s rutting resistance [33]. A lower Jnr and a higher R indicate stronger rutting resistance in the asphalt. The calculated Jnr and R values for different asphalt samples are shown in Figure 7 and Figure 8. From these figures, it is evident that as the temperature increases, the non-recoverable creep compliance (Jnr) of the six asphalt samples increases significantly, while the recovery rate (R) decreases. This indicates that higher temperatures lead to greater residual deformation and reduced rutting resistance in the asphalt. Under the same temperature and aging conditions, the R values of the SBS-T-modified asphalt are significantly higher than those of the 70# base asphalt, and the Jnr values are lower, indicating that the addition of the SBS-T modifier substantially increases the elastic component of the asphalt. As a result, the SBS-T-modified asphalt exhibits less permanent plastic deformation under external forces, allowing it to better withstand traffic loads.

Figure 7.

Jnr Values of asphalt after various aging processes.

Figure 8.

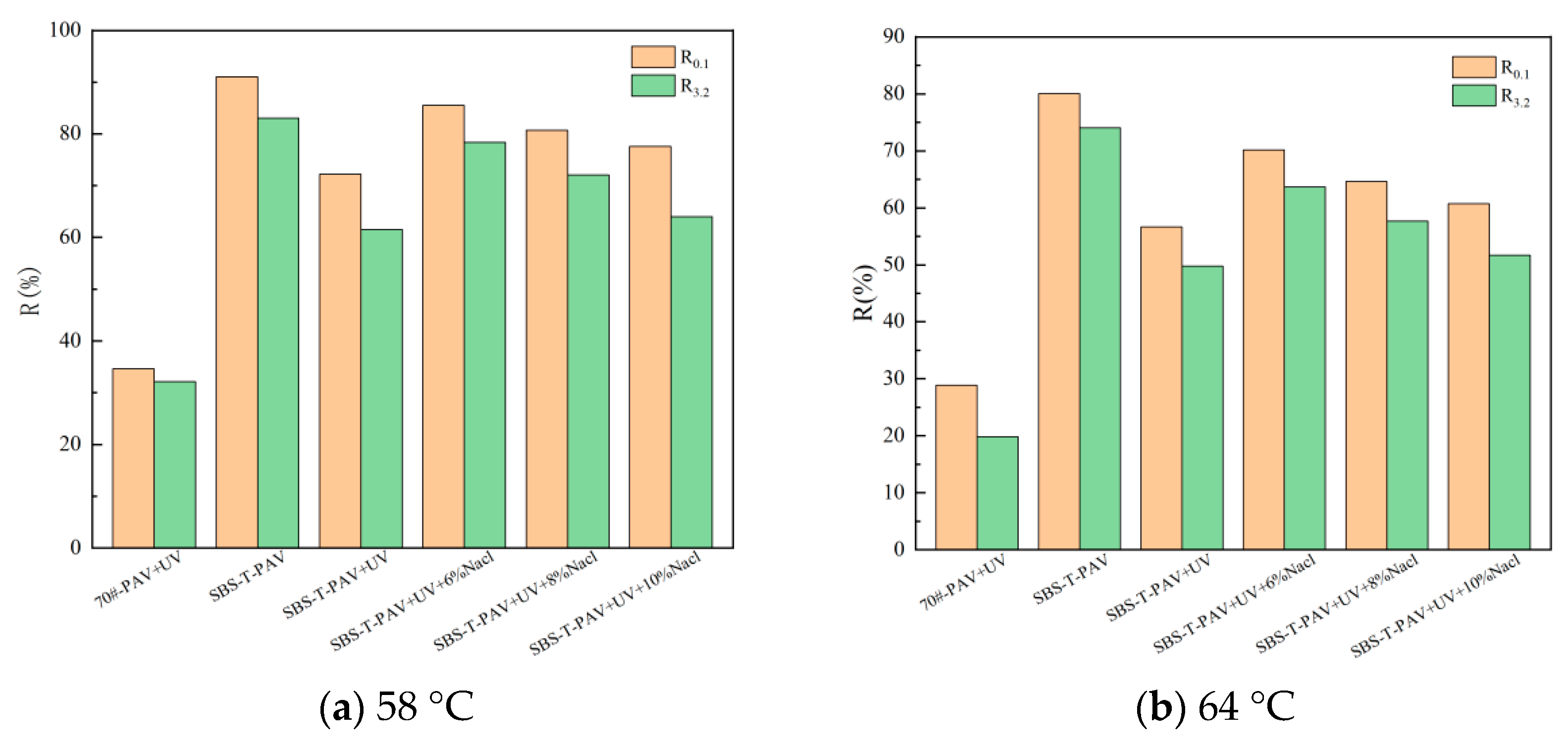

R values of asphalt after various aging processes.

Compared to pressure aging alone, the Jnr of SBS-T-modified asphalt increases significantly after combined pressure and UV aging, while the recovery rate (R) decreases. This suggests that the combined aging factors rapidly reduce the asphalt’s elastic recovery capacity, rendering the elastic recovery effect of aging ineffective. However, when salt solution aging is added to the mix, the R of the SBS-T-modified asphalt increases while Jnr decreases, indicating that salt solution aging improves the high-temperature performance of SBS-T-modified asphalt. Under the same aging factors, as the concentration of the salt solution increases, Jnr increases and R decreases, indicating that the asphalt’s elastic deformation capacity deteriorates, and rutting resistance declines. This suggests that while the salt solution can enhance the high-temperature performance of the SBS-T-modified asphalt, this improvement is limited to a certain concentration range; beyond that, performance may deteriorate.

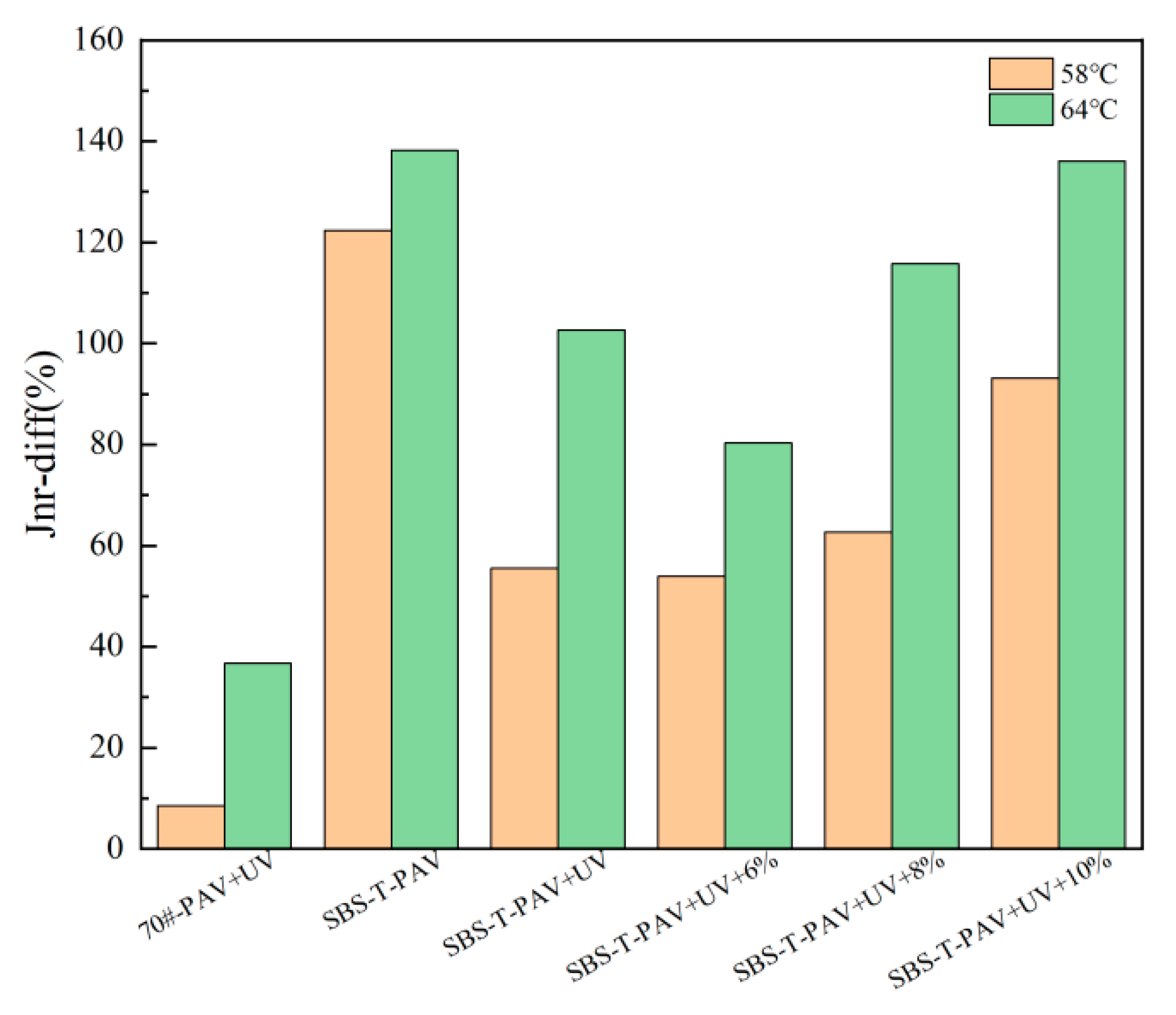

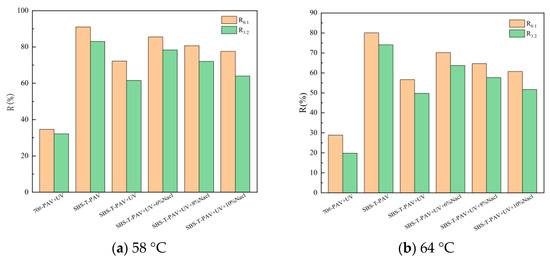

The stress sensitivity index reflects the sensitivity of the asphalt binder to changes in stress (from 0.1 kPa to 3.2 kPa) and can assess the non-linear mechanical response of the asphalt binder. Higher stress sensitivity indicates more pronounced non-linear characteristics as the stress level transitions from low to high [34]. The results calculated according to the formula are shown in Figure 9. It is observed that the value of SBS-T-modified asphalt after pressure aging is larger compared to 70# base asphalt, indicating that the modified asphalt is more sensitive to stress changes. Similarly, the value is higher for asphalt aged by pressure and UV combined, indicating that UV aging reduces the asphalt’s sensitivity. However, after combined aging with pressure, UV, and salt solution, the value increases compared to pressure and UV combined aging, indicating that salt makes the asphalt more sensitive to stress changes.

Figure 9.

Jnr-diff values of asphalt after various aging processes.

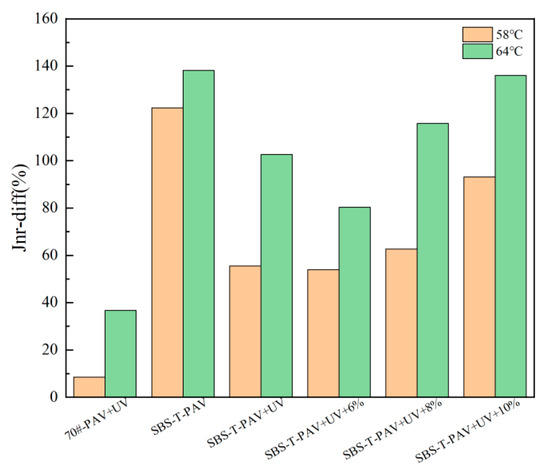

3.2. Low-Temperature Characteristics

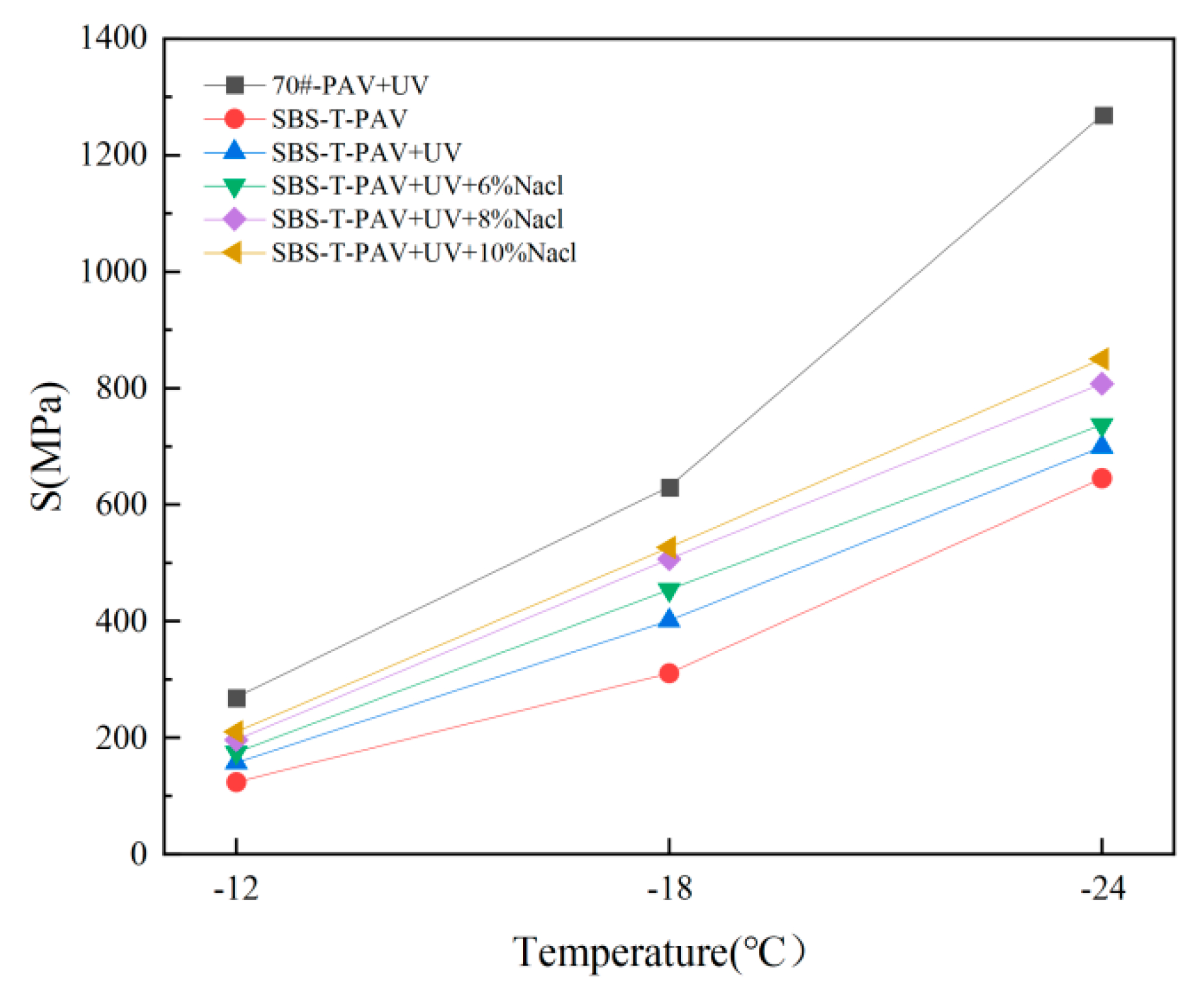

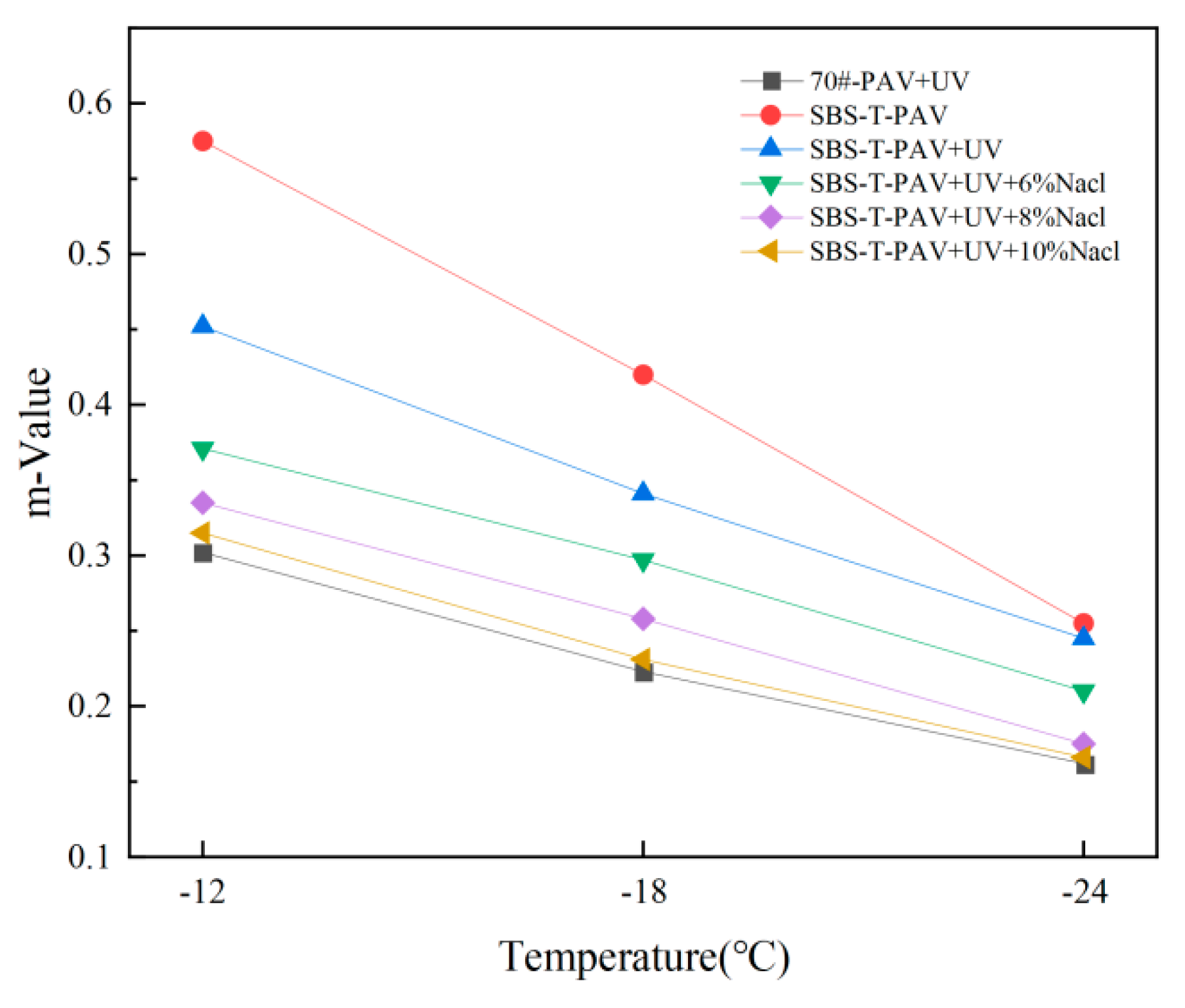

3.2.1. Creep Stiffness and Creep Rate

The creep rate (m) reflects the stress relaxation capacity of asphalt under low temperatures; the higher the creep rate, the stronger the stress relaxation capacity, and the better the low-temperature performance of the asphalt. The creep stiffness (S) reflects the deformation resistance of asphalt at low temperatures; the higher the creep stiffness, the greater the stress required to produce the same strain, indicating that the asphalt is harder and has poorer low-temperature crack resistance. Figure 10 and Figure 11 show the S and m values of asphalt under different temperatures and aging conditions.

Figure 10.

Creep stiffness of asphalt after various aging processes.

Figure 11.

Creep rate of asphalt after various aging processes.

The results indicate that after aging, the S values increase while the m values decrease for different asphalt samples, indicating that aging deteriorates the asphalt’s low-temperature flexibility and stress relaxation performance. Among them, under the same aging conditions, SBS-T-modified asphalt has lower S values and higher m values compared to base asphalt, indicating that the SBS-T modifier improves the asphalt’s temperature sensitivity, thereby enhancing its low-temperature performance. Comparing different aged SBS-T-modified asphalts, the lowest S values and highest m values were observed in asphalt samples aged solely by PAV. This is because the thermal-oxidative environment introduced causes the volatile components of the binder to evaporate, and UV aging further deteriorates the creep performance of asphalt, increasing stiffness at low temperatures and worsening low-temperature performance. After salt solution aging, the S values of SBS-T-modified asphalt increase, and the m values decrease, indicating that the salt solution factor accelerates the aging of SBS-modified asphalt. This may be due to moisture damaging the molecular structure of the modifier, as salt can penetrate cracks and adhere to the asphalt surface, reducing its bonding strength [35], leading to poorer low-temperature crack resistance. As the salt solution concentration increases, the S values increase, and the m values decrease, indicating that higher concentrations of salt accelerate aging in asphalt, generating more free radicals, and the presence of water accelerates the movement of these free radicals [36]. This suggests that higher salt concentrations lead to more severe aging in asphalt, further deteriorating stress relaxation and low-temperature performance.

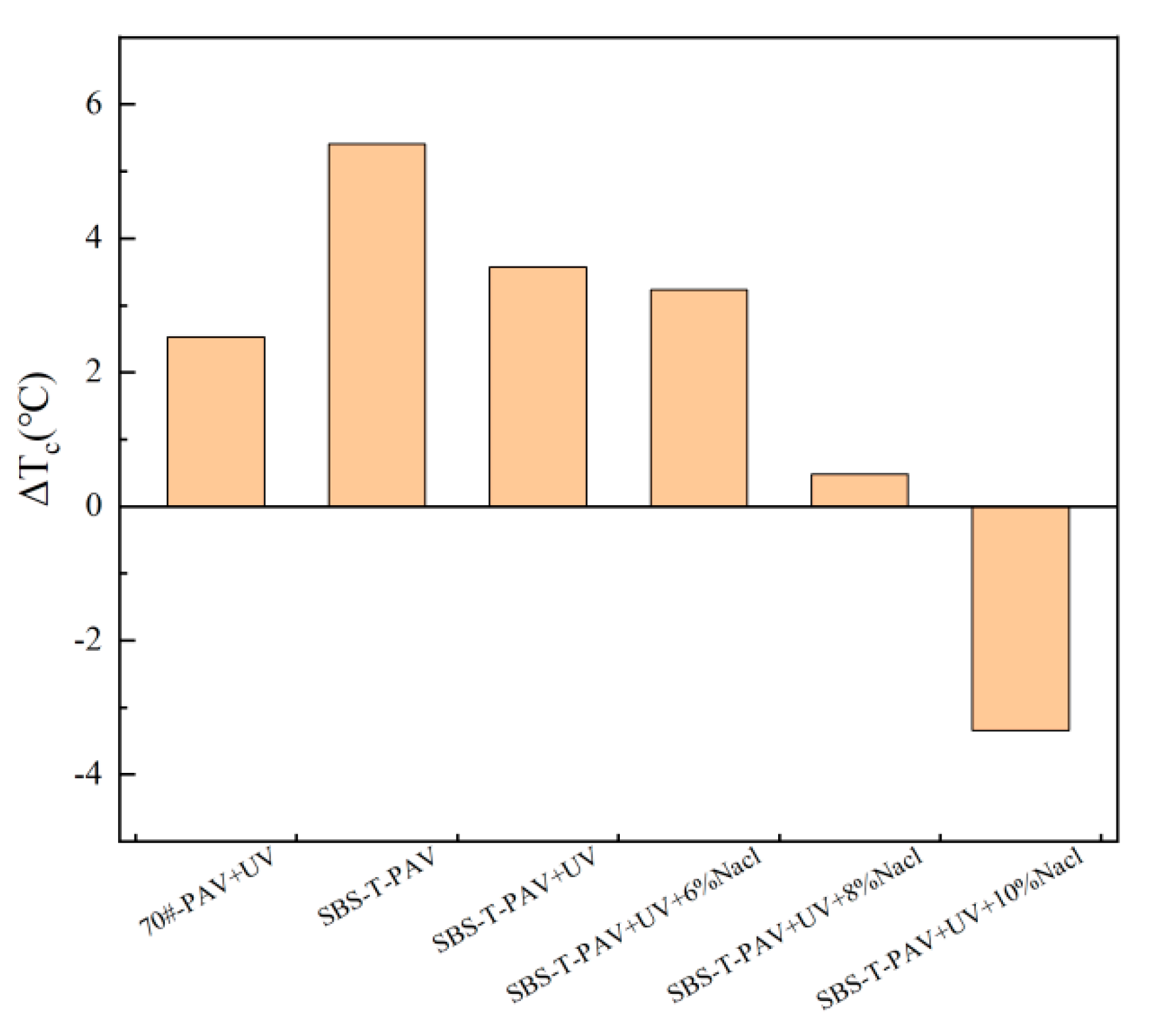

3.2.2. ΔTc Value

The ΔTc value is used to further analyze the performance of asphalt at low temperatures and can be used to evaluate the thermal sensitivity of asphalt. A lower ΔTc value indicates weaker recovery ability in the initial stages, as shown in Figure 12. It can be observed that ΔTc exhibits a certain regularity; under the same aging conditions, the addition of the SBS-T modifier increases the ΔTc value, indicating that this modifier reduces the thermal sensitivity of asphalt and enhances its low-temperature crack resistance. As the aging factors increase, the ΔTc values of the asphalt samples decrease. After combined UV and pressure aging, the ΔTc value decreases by 34% compared to pressure aging alone, indicating that the combined factors make the asphalt more susceptible to thermally induced stress. The introduction of different concentrations of salt solution further decreases the ΔTc value significantly; as the concentration of salt solution increases, the ΔTc values drop by about six times. This suggests that salt solution as an aging factor has a significant impact on the thermal sensitivity of asphalt, and when pressure, UV, and salt solution are combined, the asphalt’s low-temperature crack resistance significantly deteriorates. When the salt solution concentration reaches 10%, the ΔTc value becomes negative, indicating that aged SBS-T-modified asphalt is primarily controlled by m(t). Li et al. [37] suggests limiting ΔTc to −5 °C to prevent non-load-related cracking due to a poor relaxation performance of the asphalt binder. The ΔTc values of all asphalt samples are greater than −5 °C, regardless of the aging conditions, implying that the asphalt samples are not at risk of cracking. This is likely due to the significant improvement in stress relaxation provided by the addition of SBS-T.

Figure 12.

ΔTc values of asphalt after various aging processes.

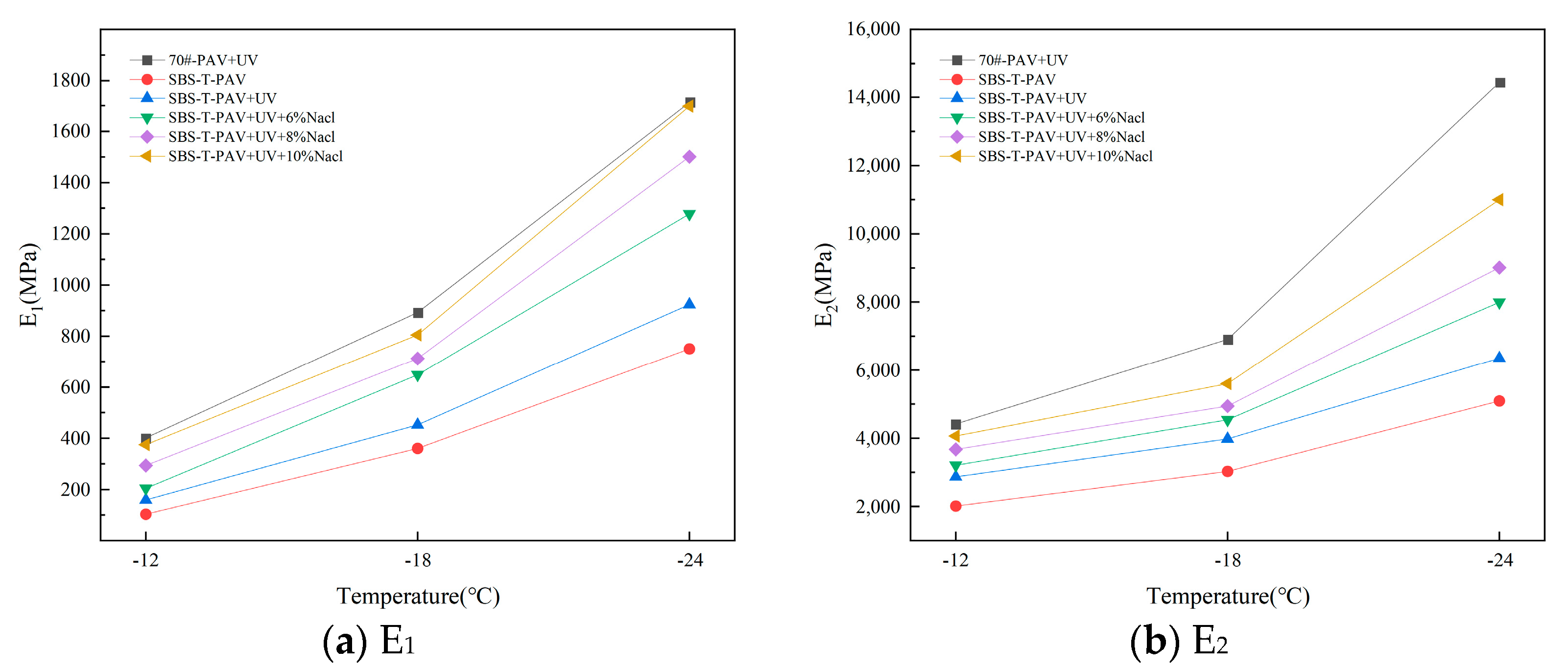

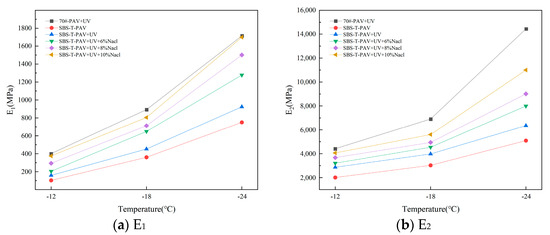

3.2.3. Low-Temperature Performance Evaluation Based on the Burgers Model

- Burgers Model Parameters

The test data for creep stiffness versus loading time were converted into creep compliance versus loading time data according to Equation (6) and inputted into Origin2021 software. Utilizing the non-linear curve fitting function in conjunction with the characteristics of the Burgers model, the fitting results are shown in Figure 13.

Figure 13.

Burgers model fitting parameters.

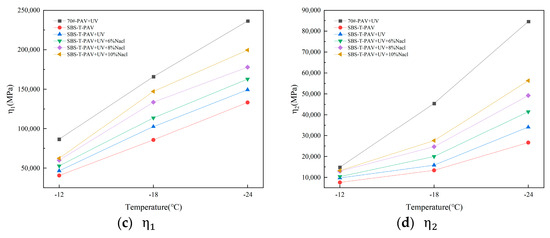

As shown in Figure 13, with decreasing temperature, all four parameters of the Burgers model—the instantaneous elastic modulus E1 of the Maxwell model, the delayed elastic modulus E2 of the Kelvin model, the instantaneous damping coefficient of the Maxwell model, and the delayed damping coefficient of the Kelvin model—increase, indicating that the stress relaxation capacity of the aged asphalt weakens at low temperatures. Furthermore, the increase in the four viscoelastic parameters for SBS-T-modified asphalt is less pronounced compared to base asphalt, indicating a better low-temperature performance after modification. From the perspective of the proportion of viscoelastic parameters, and are much larger than E1 and E2, with the former being one or two orders of magnitude higher than the latter. This indicates that, whether for base or modified asphalt, the parameters reflecting the viscous characteristics in the Burgers model, composed of the Maxwell and Kelvin models, are larger than those reflecting the elastic characteristics. Additionally, the more complex the aging factors and the higher the salt solution concentration, the larger the four parameters of the SBS-T asphalt.

- 2.

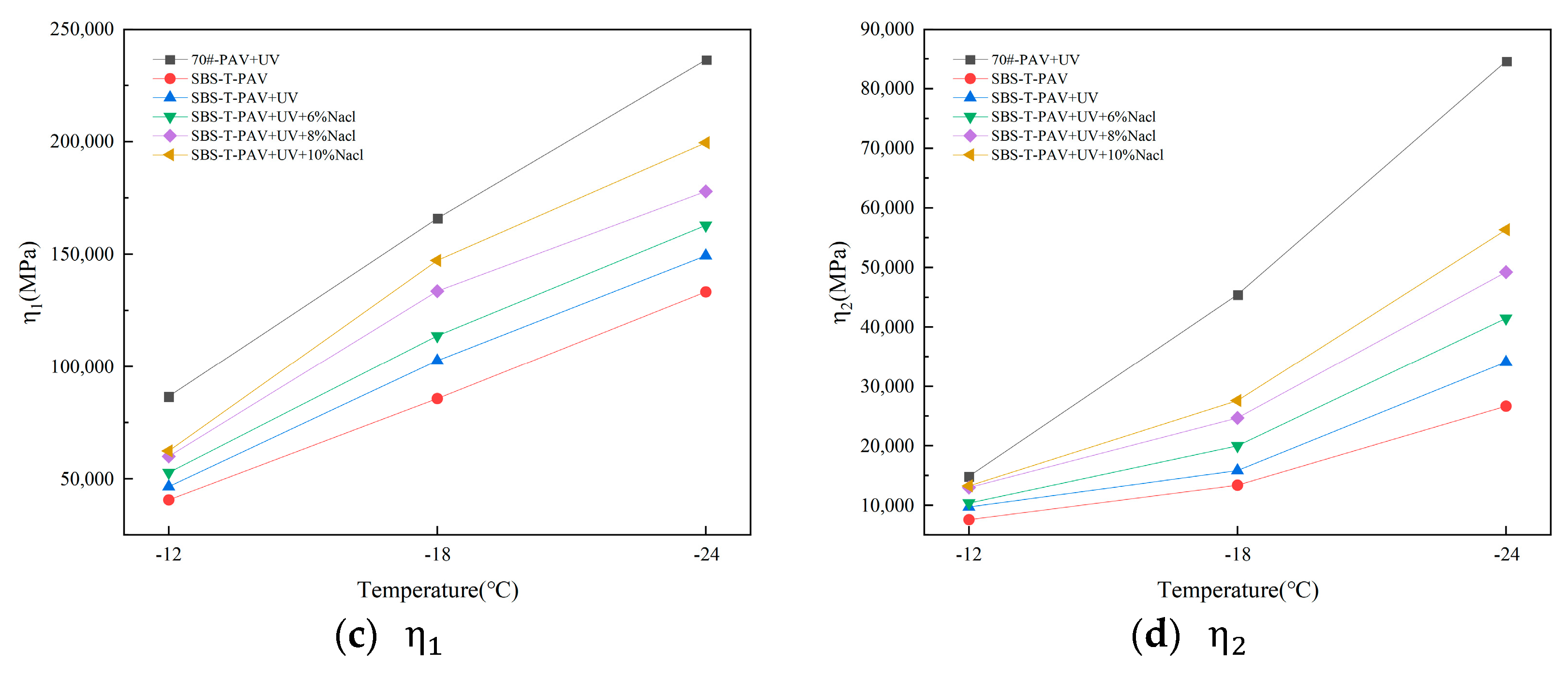

- Relaxation Time

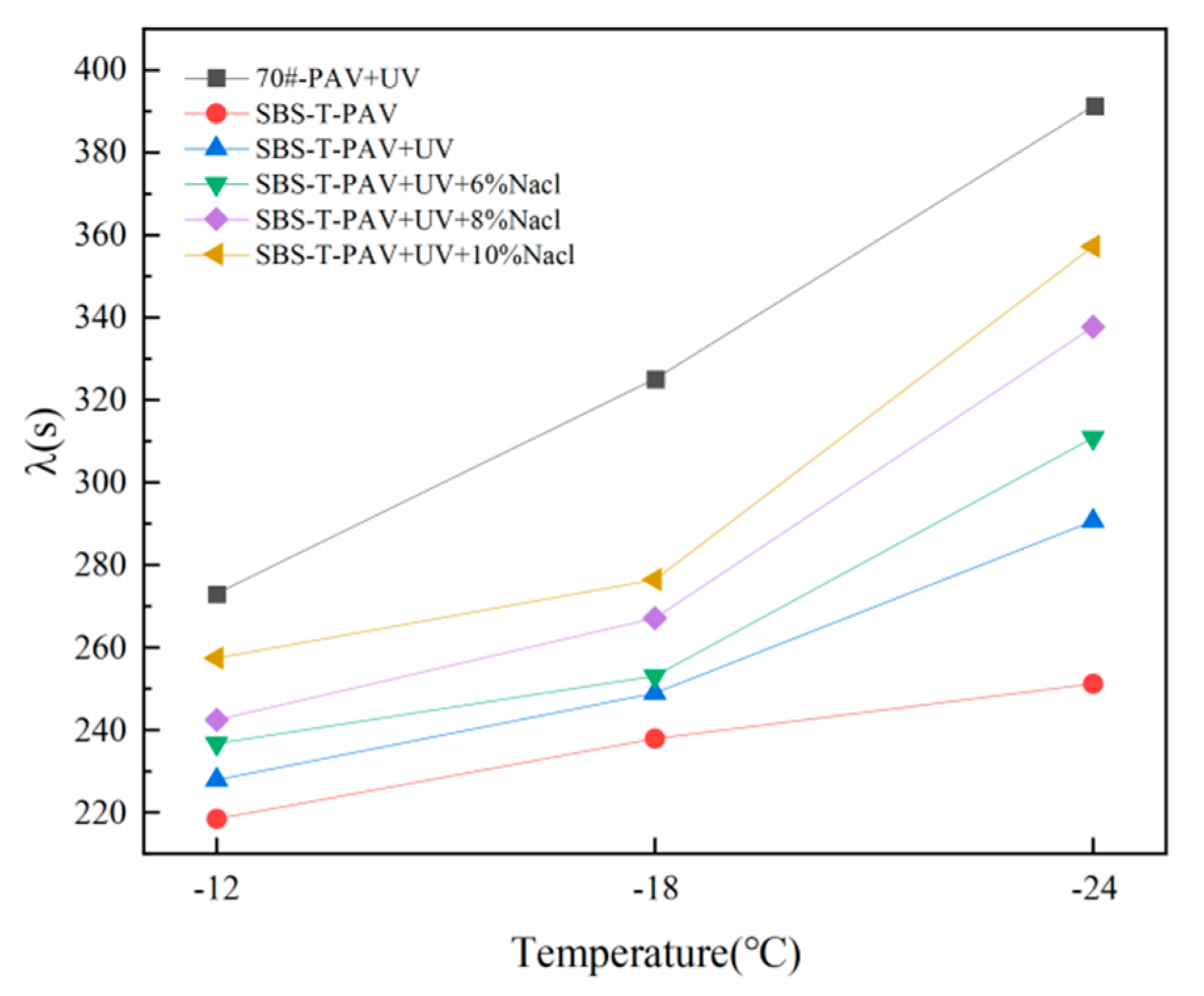

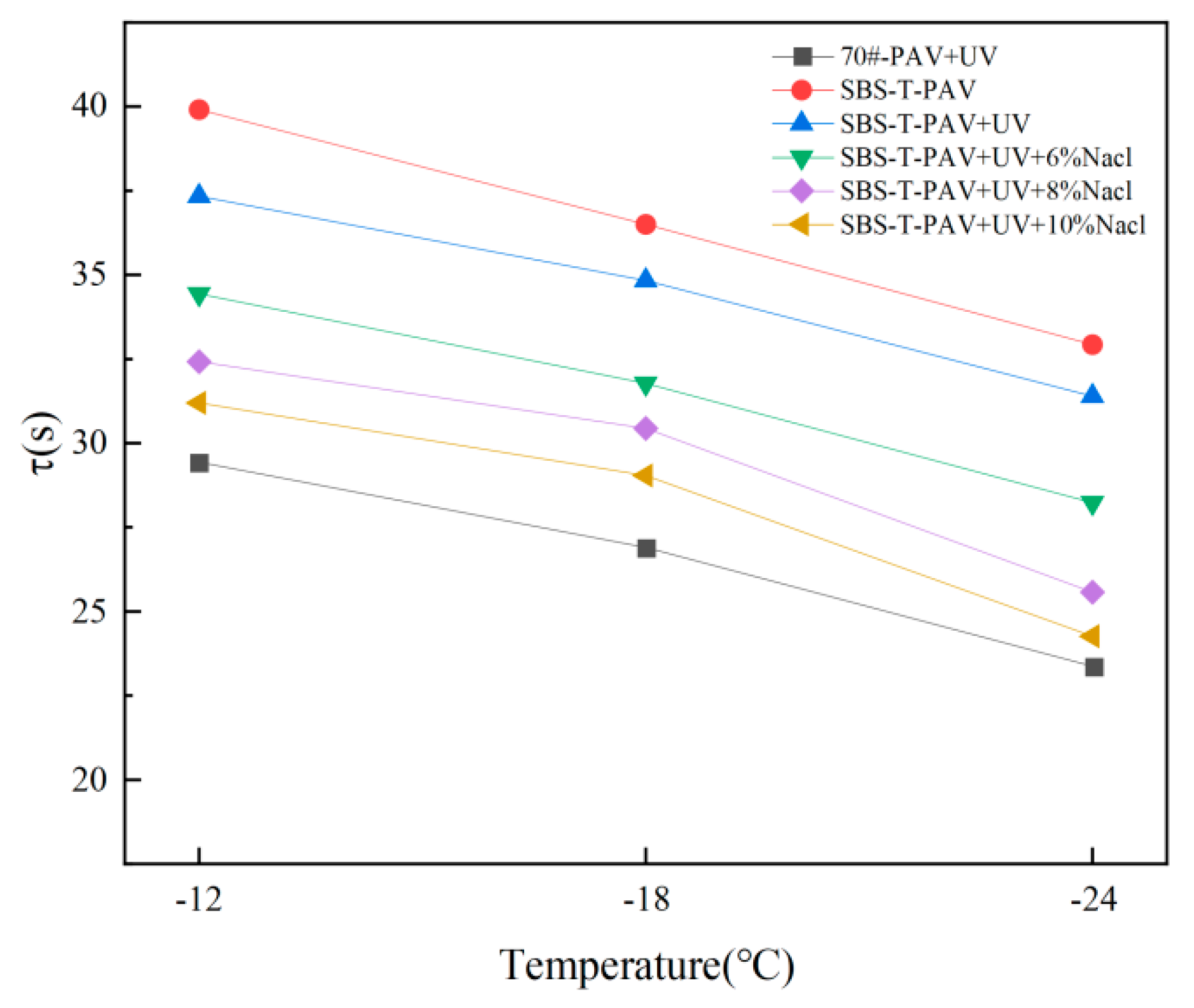

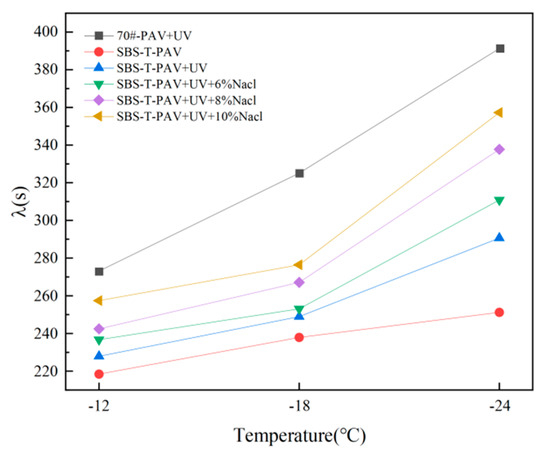

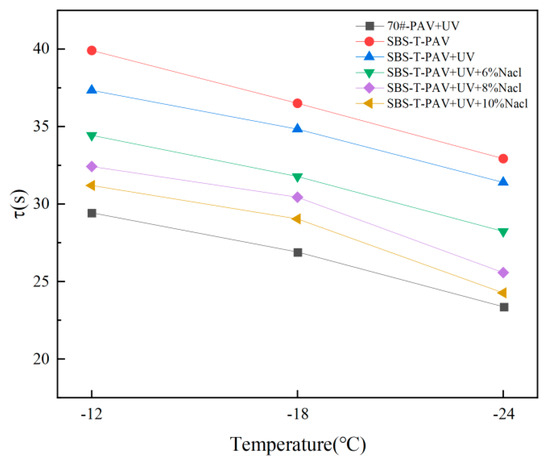

The relaxation time λ is an important measure reflecting the gradual dissipation of internal stress in asphalt over time. The shorter the relaxation time, the better the stress dissipation ability, and the less likely it is to accumulate internal stress, improving the asphalt’s low-temperature viscoelastic properties [38]. Based on the Burgers model fitting parameters, the relaxation time λ and retardation time τ of asphalt can be calculated using Equations (7) and (8).

where λ is the relaxation time in seconds and τ is the retardation time in seconds.

It can be seen from Figure 14 and Figure 15 that the relaxation time of the six asphalts gradually increase with a decrease in temperature, indicating that a reduction in temperature can increase the friction resistance of the movement of the asphalt molecular chain and reduce the ability of asphalt to quickly dissipate stress, so that the asphalt can be cracked and damaged at low temperatures. Compared with matrix asphalt, the relaxation time of modified asphalt after single-factor pressure aging is obviously shorter, because the modifier can significantly improve the viscoelasticity of the asphalt, reduce the energy consumption rate of asphalt, and make the asphalt not easy to crack at low temperatures. SBS-T-modified asphalt after pressure, ultraviolet, and salt solution coupling aging has a longer relaxation time than SBS-T-modified asphalt after pressure and ultraviolet coupling aging, and with the increase in the concentration of salt solution, the relaxation time becomes longer, indicating that the addition of salt damages the low-temperature cracking resistance of asphalt.

Figure 14.

Relaxation time of asphalt after various aging processes.

Figure 15.

Retardation time of asphalt after various aging processes.

- 3.

- Dissipated Energy Ratio

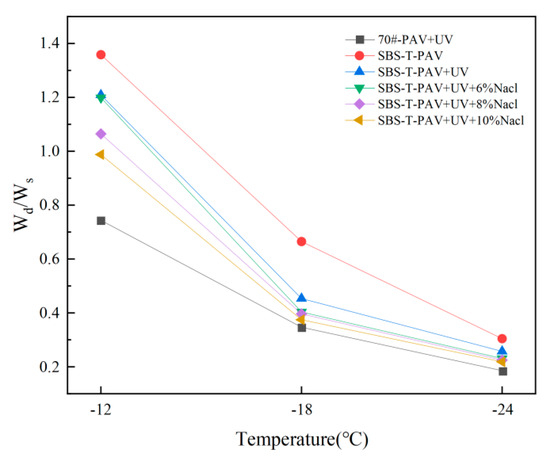

The dissipated energy in asphalt reflects the material’s ability to store and dissipate energy. By calculating the dissipated energy and stored energy, the dissipated energy ratio can be determined. The formulas for calculating stored energy and dissipated energy are as follows:

where t is the loading time in the BBR test, s; is the applied stress at the midpoint of the BBR test beam, MPa; P is the applied load in the test, mN; L is the span between the supports, mm; b is the width of the asphalt beam, mm; h is the height of the asphalt beam, mm.

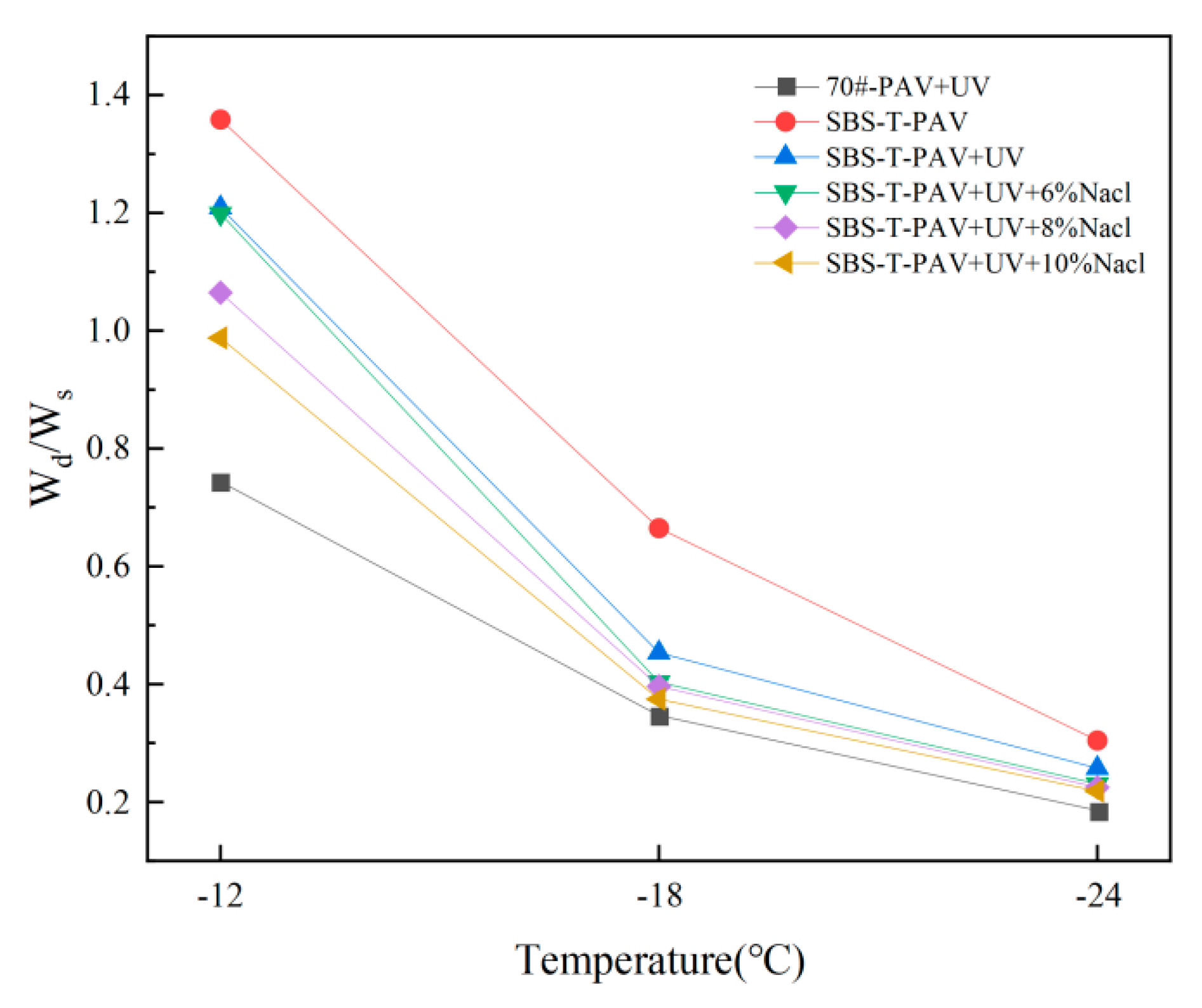

The dissipated energy ratio Wd/Ws reflects the stress relaxation ability of the asphalt material; the larger the ratio, the better the low-temperature performance of the asphalt. The dissipated energy ratio of aged asphalt is shown in Figure 16.

Figure 16.

Dissipated energy ratio of asphalt after various aging processes (60 s).

As seen in Figure 16, the dissipated energy ratio decreases as the temperature decreases, indicating that lower temperatures significantly reduce the dissipation of stored energy within the asphalt. Comparing the SBS-T-modified asphalt under different aging conditions, the asphalt aged by pressure alone shows the highest dissipated energy ratio and the best low-temperature crack resistance, followed by the asphalt aged by pressure and UV combined, and lastly, the asphalt aged by pressure, UV, and salt solution combined. This indicates that as UV and salt solution aging factors increase, the relaxation capacity of SBS-T-modified asphalt deteriorates. As the concentration of the salt solution increases, the dissipated energy ratio decreases, particularly at −18 °C and −24 °C. When the salt solution concentration reaches 10%, the dissipated energy ratio approaches that of the base asphalt, indicating that at lower temperatures, high concentrations of salt solution exacerbate the dissipation of stored energy in asphalt, leading to poorer low-temperature performance.

- 4.

- Low-Temperature Evaluation Indices

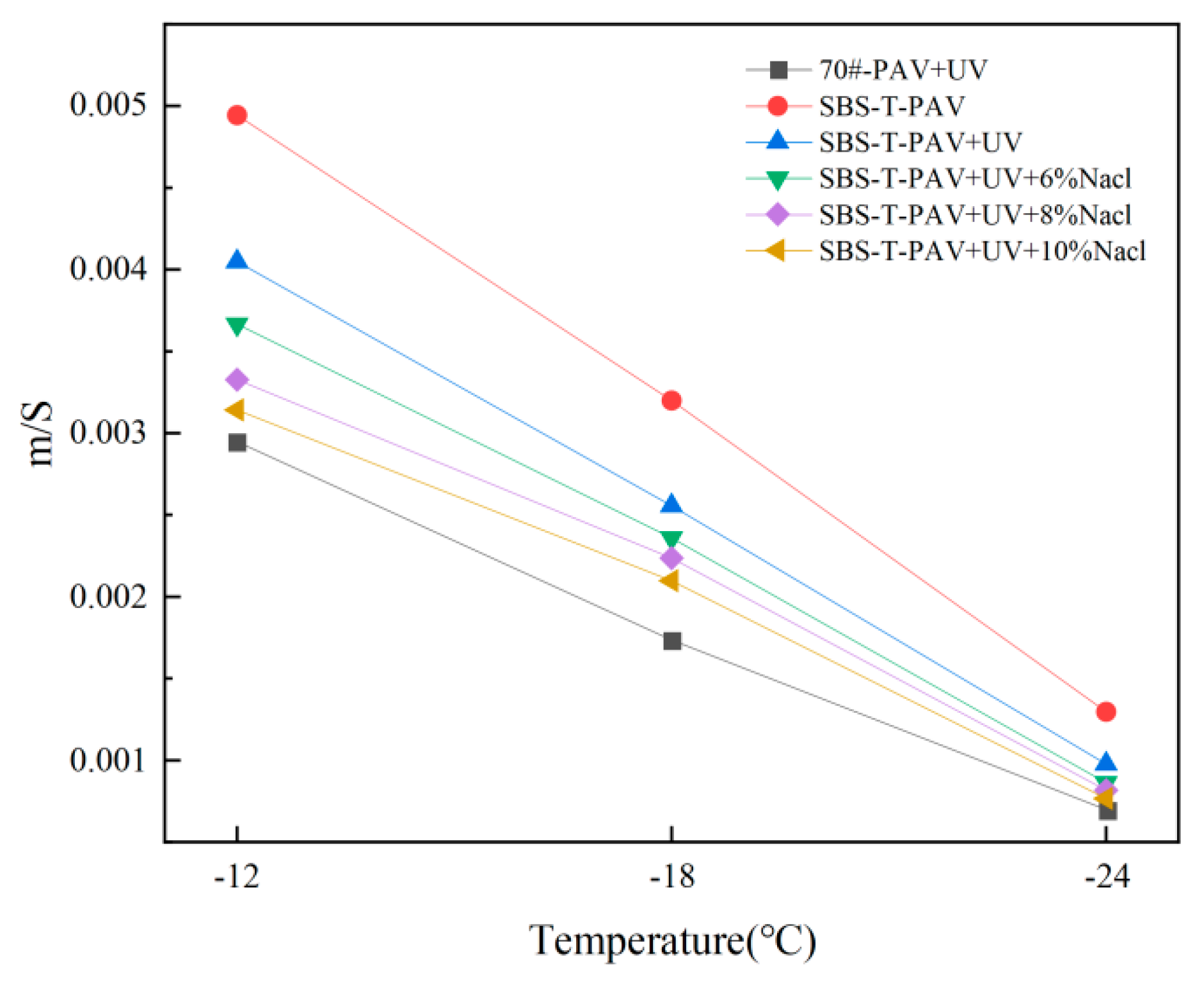

When analyzing the low-temperature performance of different asphalts, relying solely on the stiffness modulus (S) or the creep rate (m) can sometimes lead to inconsistent conclusions. To address this, Liu et al. [39] proposed a new index m(t)/S(t) to evaluate the low-temperature performance of asphalt. The creep stiffness modulus–time curve was subjected to regression analysis in a logarithmic coordinate system, yielding functional relationships for creep stiffness modulus–time and creep stiffness change rate–time, as shown in Equations (12) and (13). Through integration and applying the Burgers model creep equation, Equation (14) is derived.

where S(t) is the creep stiffness at time t, MPa; m(t) is the relaxation rate at time t.

As seen in Figure 17, the larger the m/S value, the better the low-temperature crack resistance of the asphalt. The graph shows that as the temperature decreases, the m/S values of all asphalts decline, with the decrease being more pronounced for the modified asphalt than for the base asphalt. After pressure and UV combined aging, the m/S values of SBS-T-modified asphalt are significantly lower than after pressure aging alone, indicating that UV aging negatively impacts the low-temperature crack resistance of SBS-T-modified asphalt. When the three factors are combined, the m/S values further decrease, and as the salt solution concentration increases, the m/S values drop, indicating that salt solution damages the low-temperature performance of modified asphalt. Additionally, the graph shows that the more complex the aging environment, the greater the damage to the low-temperature crack resistance of the asphalt.

Figure 17.

Low-temperature evaluation index m/S of asphalt after various aging processes (60 s).

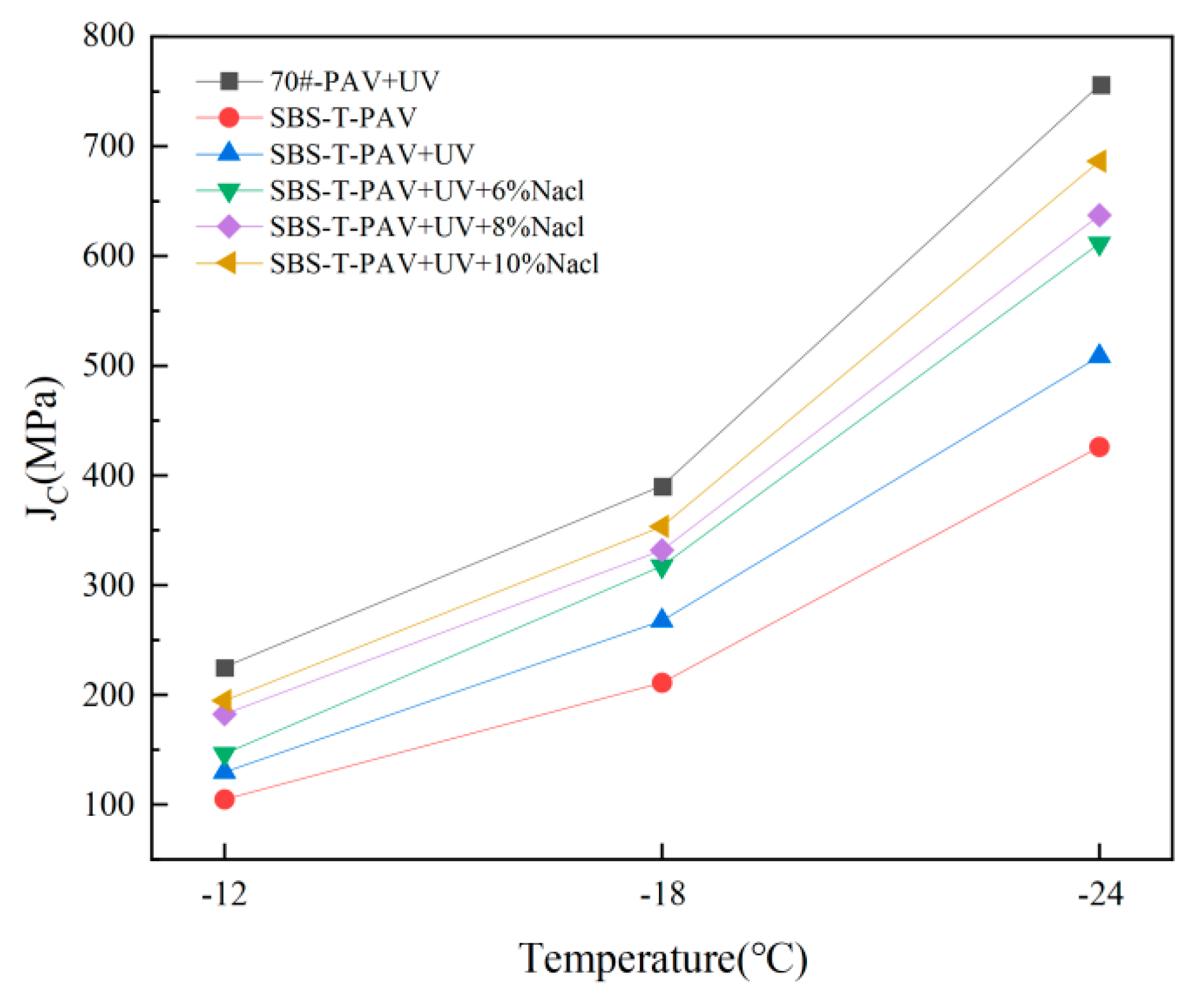

- 5.

- Comprehensive Low-Temperature Compliance Parameter

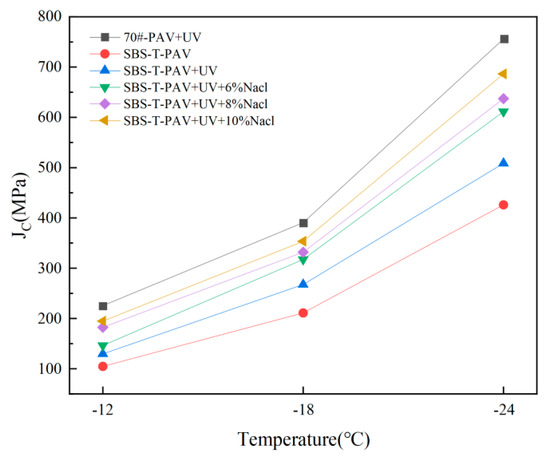

The comprehensive low-temperature compliance parameter uses the viscoelastic deformation ratio in the Burgers model to comprehensively grasp the viscoelastic characteristics of asphalt and more thoroughly evaluate its low-temperature performance [40]. The calculation method for the compliance parameter (JC) is given in Equation (15).

where .

The smaller the JC value, the better the low-temperature performance of the asphalt. Figure 18 shows that the comprehensive low-temperature compliance parameter increases as the temperature decreases. After pressure aging, the JC value for SBS-T-modified asphalt is lower than that of the 70# base asphalt, indicating that the viscous component proportion in the SBS-T-modified asphalt is relatively large, and its viscous properties can help relax tensile stress, reducing the likelihood of low-temperature cracking. SBS-T-modified asphalt shows the smallest JC value after pressure aging alone. When aging conditions become more complex, such as when pressure and UV are combined, or when pressure, UV, and salt solution are combined, the JC value increases, indicating that UV and salt solution reduce the low-temperature crack resistance of asphalt.

Figure 18.

Comprehensive low-temperature compliance parameter of asphalt after various aging processes (60 s).

Based on the viscoelastic parameters of asphalt calculated using the Burgers model, including the relaxation time, energy dissipation ratio, m/S value, and low-temperature comprehensive flexibility index, a combined analysis of these parameters and evaluation metrics reveal that the asphalt exhibits the best low-temperature crack resistance after pressure aging alone. This is followed by UV aging coupled with pressure aging, and then UV aging coupled with both pressure aging and a salt solution. These results indicate that the more complex the aging conditions, the greater the negative impact on the low-temperature crack resistance of SBS-T-modified asphalt. Additionally, as the concentration of the salt solution increases, the damage to the low-temperature performance of SBS-T-modified asphalt becomes more severe.

4. Conclusions

This study investigated the effects of thermo-oxidative, UV, and various concentrations of salt solution aging on the high-temperature and low-temperature rheological properties of base asphalt and SBS-T-modified asphalt using conventional methods and rheological tests. The main conclusions are as follows:

- The coupling effects of thermal oxidation, ultraviolet light, and salt solution better reflect the actual aging conditions of asphalt roads. As indicated by the results in Section 3, these coupled factors accelerate the aging of asphalt, affecting both high-temperature and low-temperature rheological performance. Few researchers in past studies have examined these factors in combination, highlighting that the influence of complex environmental factors on asphalt cannot be overlooked.

- Compared to unmodified asphalt, SBS-T-modified asphalt shows a significant improvement in both high-temperature rheological properties and low-temperature performance under the same aging conditions. The SBS-T modifier not only addresses the issue of easy segregation associated with traditional SBS modifiers, but also enhances the overall performance of the asphalt. The findings of this study provide a theoretical foundation for the practical application of SBS-T-modified asphalt in road construction.

- The dynamic shear rheometer (DSR) tests indicate that under multiple aging factors, the rutting factor (G*/sinδ) is the smallest, Jnr is the largest, and R is the smallest after PAV+UV aging. This combination of factors leads to the greatest reduction in the high-temperature performance of SBS-T-modified asphalt. However, after PAV+UV+salt solution aging, the performance of SBS-T-modified asphalt improves, but the positive impact on high-temperature performance diminishes as the salt solution concentration increases.

- The bending beam rheometer (BBR) tests reveal that under multiple aging factors, SBS-T-modified asphalt exhibits the smallest S value, the largest m value, and the highest ΔTc value after PAV+UV aging, indicating the least reduction in low-temperature performance. However, after aging under the combined influence of three factors including salt solution, the low-temperature performance of SBS-T-modified asphalt decreases significantly, with a sharp drop in the ΔTc value. The salt solution has the most significant negative impact on the low-temperature crack resistance of SBS-T-modified asphalt, leading to a notable decline in its low-temperature performance.

Author Contributions

Conceptualization, R.L. and Y.W.; methodology, Y.W.; software, W.Z.; validation, W.Z., Y.C. and J.Y.; formal analysis, R.L.; investigation, W.Z.; resources, Y.C.; data curation, Y.W.; writing—original draft preparation, R.L.; writing—review and editing, Y.C.; visualization, J.Y.; supervision, R.L.; project administration, Y.W.; funding acquisition, J.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Henan Provincial Department of Transportation (Grant No. 2021-2-13) and the Natural Science Foundation of Henan Province (Grant No. 242300420003).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Yijun Chen was employed by the company Henan Central Construction Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Chen, D. Research on Asphalt Aging and Self healing Performance in Complex Environments. Inn. Mong. Univ. Technol. 2018, 42, 446–457. [Google Scholar]

- Guo, S.; Wang, L.; Ma, K.; Lei, J.; Yi, J. Research on the Performance and Modification Mechanism of Direct throw SBS Modified Asphalt. North. Transp. 2024, 2, 22–26. [Google Scholar] [CrossRef]

- Pipintakos, G.; Sreeram, A.; Mirwald, J.; Bhasin, A. Engineering bitumen for future asphalt pavements: A review of chemistry, structure and rheology. Mater. Des. 2024, 244, 113157. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Wu, L.; Wang, H. Study on the compatibility of dry process modifier and matrix asphalt. Transp. Manag. World 2023, 33, 152–154. [Google Scholar]

- Little, D.N.; Allen, D.H.; Bhasin, A. Modeling and Design of Flexible Pavements and Materials; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Aflaki, S.; Hajikarimi, P. Implementing viscoelastic rheological methods to evaluate low temperature performance of modified asphalt binders. Constr. Build. Mater. 2012, 36, 110–118. [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.; Huang, H.; Shi, W.; Li, M. High and low temperature performance of warm mix flame-retardant asphalt based on rheological properties. J. Jiangsu Univ. Nat. Sci. Ed. 2023, 44, 483–489. [Google Scholar]

- Wang, K.; Hao, P. Low temperature performance and viscoelasticity analysis of asphalt in BBR test. J. Liaoning Univ. Eng. Technol. Nat. Sci. Ed. 2016, 35, 1138–1143. [Google Scholar]

- Buttlar, W.G.; Roque, R.; Roque, R. Experimental development and evaluation of the new SHRP measurement and analysis system for indirect tensile testing of asphalt mixtures at low temperatures. Transp. Res. Rec. 1994, 1454, 163–171. [Google Scholar]

- Zhang, Y.; Wei, H.; Dai, Y. Influence of Different Aging Environments on Rheological Behavior and Structural Properties of Rubber Asphalt. Materials 2020, 1810, 33–43. [Google Scholar] [CrossRef]

- Geng, J.; Zhang, Q.; Dai, J. Study on the degradation behavior of SBS in modified asphalt based on gel permeation chromatography. New Build. Mater. 2011, 38, 87–90. [Google Scholar]

- Traxler, R.N. Asphalt: Its Composition, Properties and Uses; Reinhold Publishing Corporation: New York, NY, USA, 1961. [Google Scholar]

- Xiao, P.; Shi, S.; Wu, M. Research on Water Aging Test of Rubber Asphalt. J. Sichuan Univ. (Eng. Sci. Ed.) 2014, 46, 183–186. [Google Scholar]

- Ran, L. Research on the Aging Mechanism of SBS Modified Asphalt under Heat, Light, and Water Coupling Conditions and Development of High Performance Regenerator. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2016. [Google Scholar]

- Zhang, Q.; Huang, Z. Investigation of the Microcharacteristics of Asphalt Mastics under Dry-Wet and Freeze-Thaw Cycles in a Coastal Salt Environment. Materials 2019, 12, 2627. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Sha, A.; Jiang, W.; Wang, Y. Effect and mechanism of salt erosion on performance of bitumen and asphalt mixtures. J. Chang. Univ. Nat. Sci. Ed. 2017, 37, 33–38+46. (In Chinese) [Google Scholar]

- Zhang, Q.; Wu, D.; Zhang, X.; Chang, K.; Wang, Y. Effect of organic deicing agents on asphalt rheology and analysis of the mechanism. Constr. Build. Mater. 2021, 284, 122649. [Google Scholar] [CrossRef]

- Behnam, A.; Saleh, S.T. Simultaneous effects of salted water and water flow on asphalt concrete pavement deterioration under freeze–thaw cycles. Int. J. Pavement Eng. 2014, 15, 383–391. [Google Scholar]

- Wang, J. Study on Ageing Mechanism and Rheologic Behavior of Asphalt under Simulate Ultraviolet Environment; Harbin Institute of Technology: Harbin, China, 2008. [Google Scholar]

- Xiao, P.; Wu, M.; Jiang, D. Experimental study on UV aging performance of rubber asphalt. J. Nanjing Univ. Aeronaut. Astronaut. 2013, 45, 152–156. [Google Scholar]

- Zhou, Z.; Jiang, T.; Jiang, W. Evaluation of water damage resistance of asphalt mixture in hot and humid area. J. Chang. Univ. Sci. Technol. Sci. 2013, 10, 8–14. (In Chinese) [Google Scholar]

- Bian, F.; Zhao, Y.; Huang, X.; Wang, Z. Experimental study of water aging on asphalt during service life of pavements. J. Southeast Univ. Engl. Ed. 2010, 26, 618–621. [Google Scholar]

- Glover, C.J.; Martin, A.E.; Chowdhury, A.; Han, R.; Prapaitrakul, N.; Jin, X.; Lawrence, J. Evaluation of Binder Aging and Its Influence in Aging of Hot Mix Asphalt Concrete: Literature Review and Experimental Design; Texas Transportation Institute: College Station, TX, USA, 2009. [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China National Standardization Administration Committee: Beijing, China, 2011.

- Wang, Y. Study on application of dry SBS modified asphalt in municipal road. Constr. Superv. Insp. Cost 2022, 15, 9–12+20. (In Chinese) [Google Scholar]

- Feng, Z.; Yu, J.; Zhang, H.; Kuang, D.; Xue, L. Effect of ultraviolet aging on rheology, chemistry and morphology of ultraviolet absorber modified bitumen. Mater. Struct. 2013, 46, 1123–1132. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, J.; Feng, K.; Xue, L.; Xie, D. Synthesis and characterization of triethoxyvinylsilane surface modified layered double hydroxides and application in improving UV aging resistance of bitumen. Appl. Clay Sci. 2016, 120, 1–8. [Google Scholar] [CrossRef]

- Feng, Z.; Wang, S.; Bian, H.; Guo, Q.; Li, X. FTIR and rheology analysis of aging on different ultraviolet absorber modified bitumens. Constr. Build. Mater. 2016, 115, 48–53. [Google Scholar] [CrossRef]

- Fan, S.; Zhu, H.; Zhong, W. Evaluation of rheological properties of bio-heavy oil regenerated asphalt based on DSR test. J. Build. Mater. 2022, 25, 320–326. [Google Scholar]

- Zhao, H.; Gao, W.; Cui, S.; Zhang, W.; Ma, S.; Miao, B.; Su, C.; Zhang, P.; Wang, X.; Wei, J. Study on the Dynamic Performance of PU and SBS-Modified Asphalt Mixtures with Dense Gradation. Coatings 2023, 13, 1143. [Google Scholar] [CrossRef]

- Kaya, D.; Topal, A.; Gupta, J.; McNally, T. Aging effects on the composition and thermal properties of styrene-butadiene-styrene (SBS) modified bitumen. Constr. Build. Mater. 2020, 235, 117450. [Google Scholar] [CrossRef]

- Han, M.Z.; Li, Z.Z.; Zhao, Z.P.; Zhou, H. Research progress on aging and antiaging of SBS modified asphalt. Sci. Technol. Rev. 2016, 34, 101–105. [Google Scholar]

- Liu, S.; Lin, Y.; Li, M. Evaluation and Grading of High Temperature Performance of Warm Mix Flame Retardant Asphalt Based on MSCR Test. Mater. Rep. 2023, 37, 146–151. [Google Scholar]

- Guo, Y.; Xu, L.; Wu, L. Evaluation of High Temperature Performance of Modified Asphalt Based on MSCR Test. J. Build. Mater. 2018, 21, 154–158. [Google Scholar]

- Romero-Sánchez, M.D.; Mercedes Pastor-Blas, M.; Martín-Martínez, J.M.; Walzak, M.J. Addition of ozone in the UV radiation treatment of a synthetic styrene-butadiene-styrene (SBS) rubber. Int. J. Adhes. Adhes. 2005, 25, 358–370. [Google Scholar] [CrossRef]

- Li, C.; Ma, F.; Fu, Z.; Dai, J.; Wen, Y.; Wang, Y. Rheological Behavior of Polyphosphoric Acid-Vulcanized Liquid Rubber Compound Modified Asphalt Binder. Iranian Journal of Science and Technology. Trans. Civ. Eng. 2022, 46, 3931–3945. [Google Scholar]

- Li, X.; Gibson, N.; Andriescu, A.; Arnold, T.S. Performance evaluation of REOB-modified asphalt binders and mixtures. Road Mater. Pavement Des. 2017, 18, 128–153. [Google Scholar] [CrossRef]

- Li, B.; Zhang, X.; Li, J.; Yang, K.; Tong, P. Low temperature performance evaluation of hard asphalt based on Burgers model. J. Build. Mater. 2021, 24, 1110–1116. (In Chinese) [Google Scholar]

- Liu, S.T.; Cao, W.D.; Shang, S.J.; Qi, H.; Fang, J. Analysis and application of relationships between low-temperature rheological performance parameters of asphalt binders. Constr. Build. Mater. 2010, 24, 471–478. [Google Scholar] [CrossRef]

- Li, X. Unified Evaluation Index for High-and-Low Temperature Properties of Asphalt Based on Rheological Theory; Harbin Institute of Technology: Harbin, China, 2013. (In Chinese) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).