A Review of the Preparation, Modification, and Applications of Polyetheretherketone Coating

Abstract

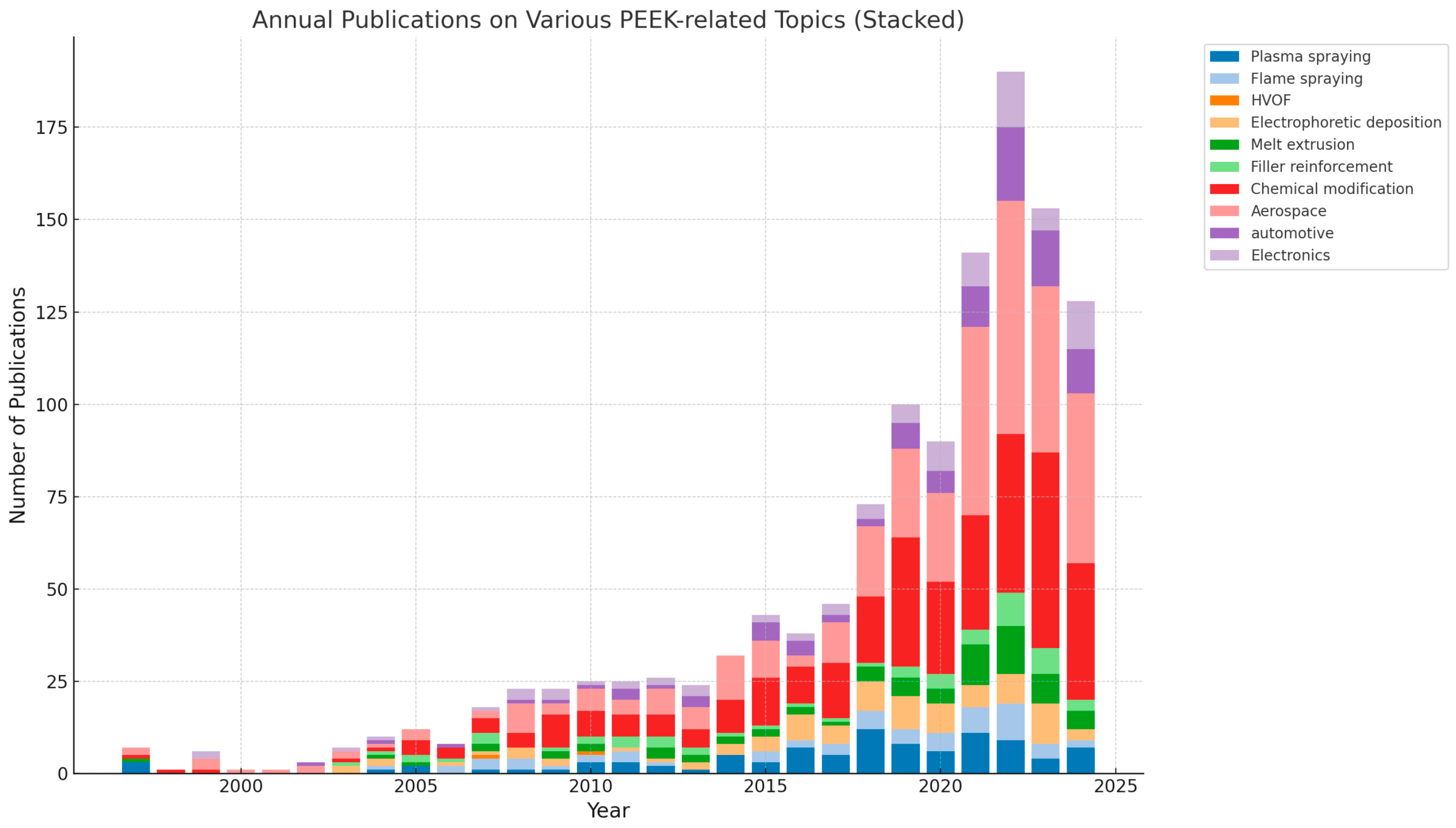

:1. Introduction

2. Preparation Methods for PEEK Coatings

2.1. Thermal Spraying

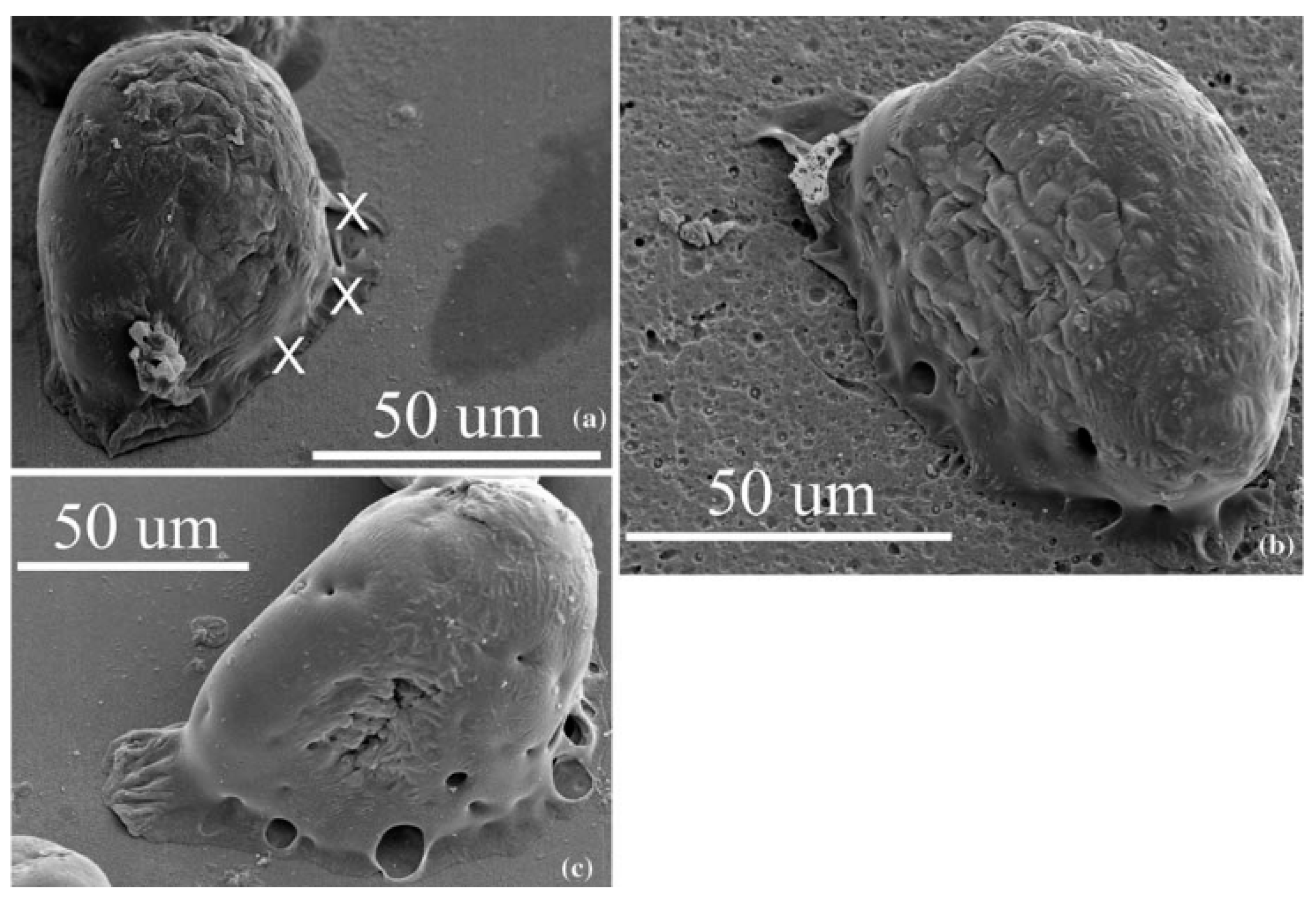

2.1.1. Plasma Spraying

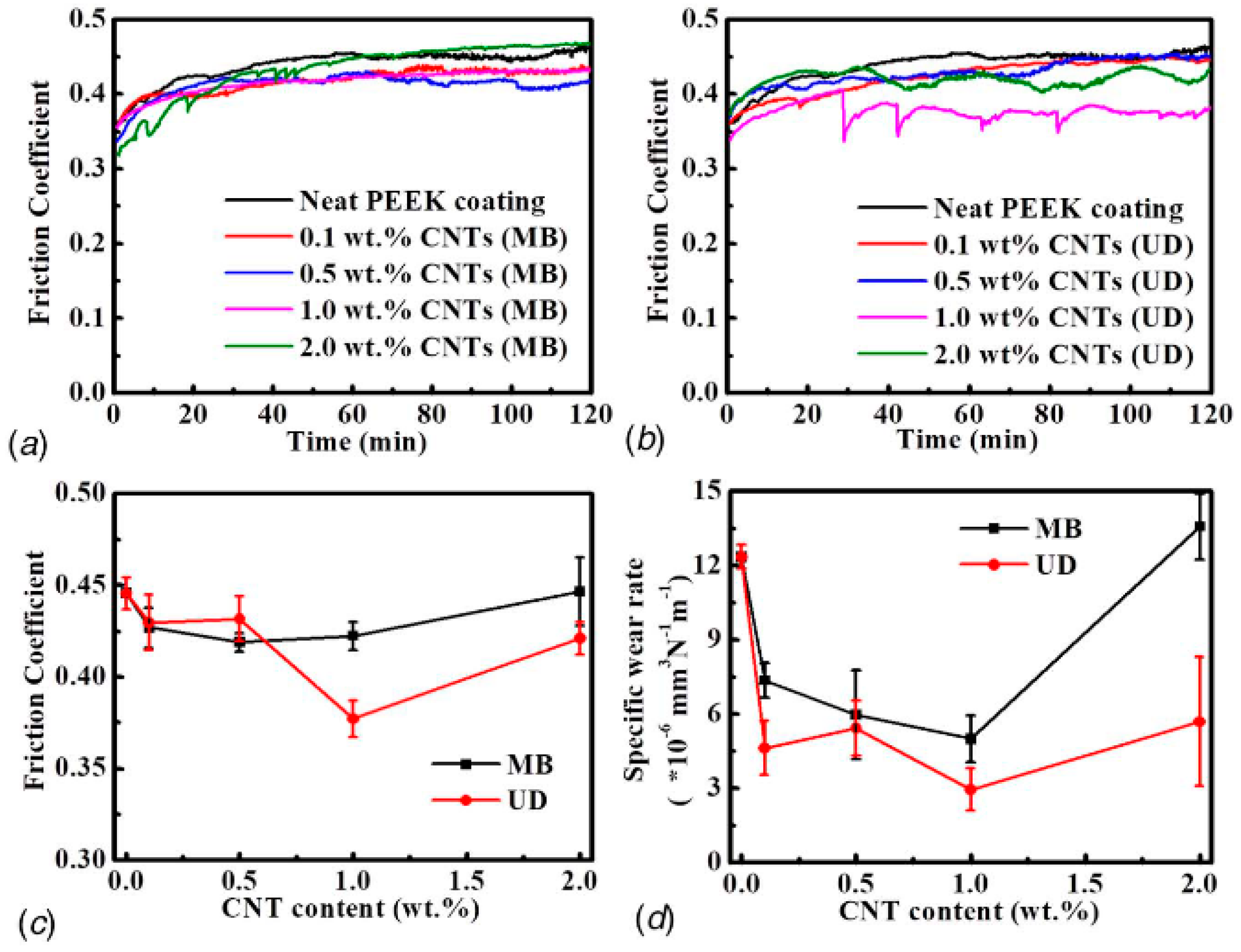

2.1.2. Flame Spraying

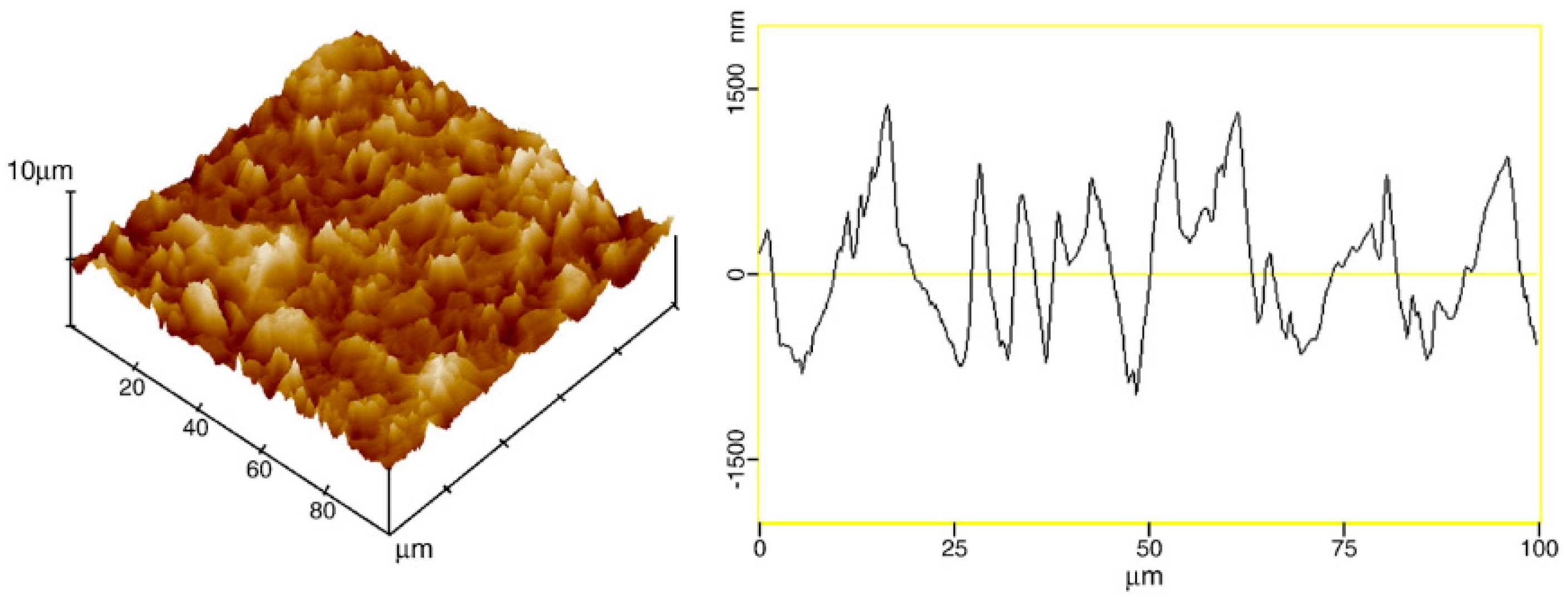

2.1.3. High-Pressure and High-Velocity Oxy–Fuel Spraying

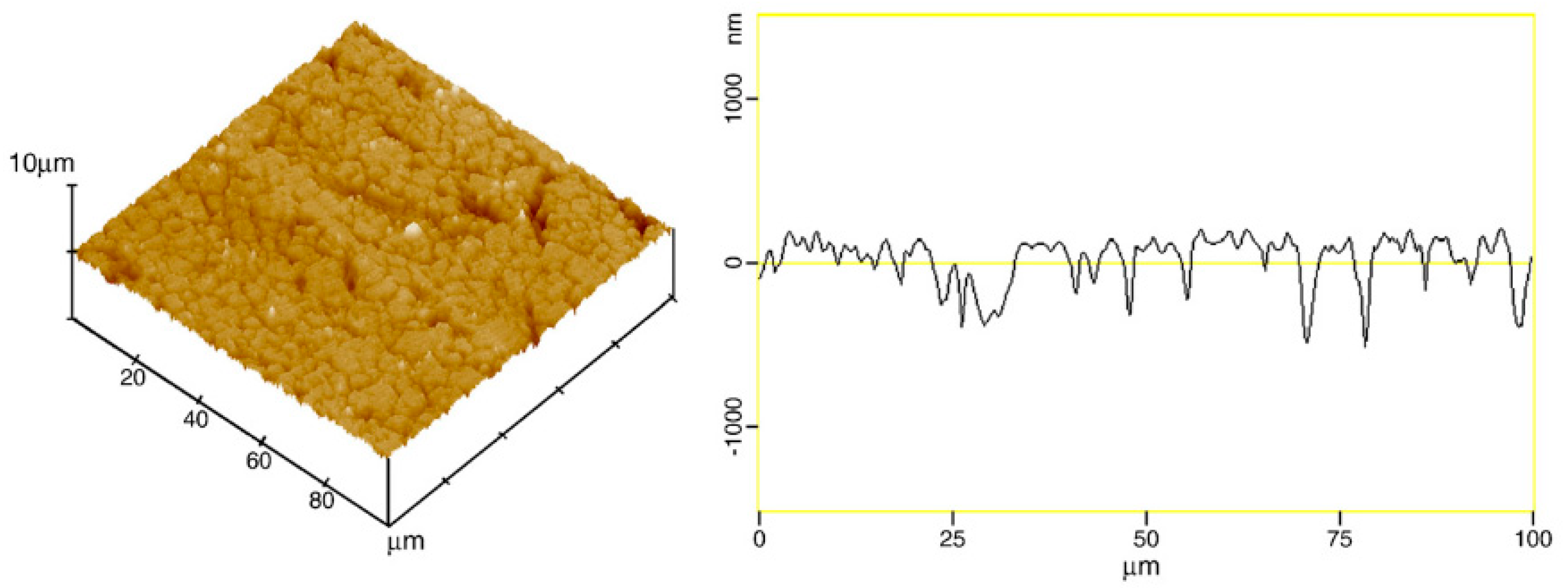

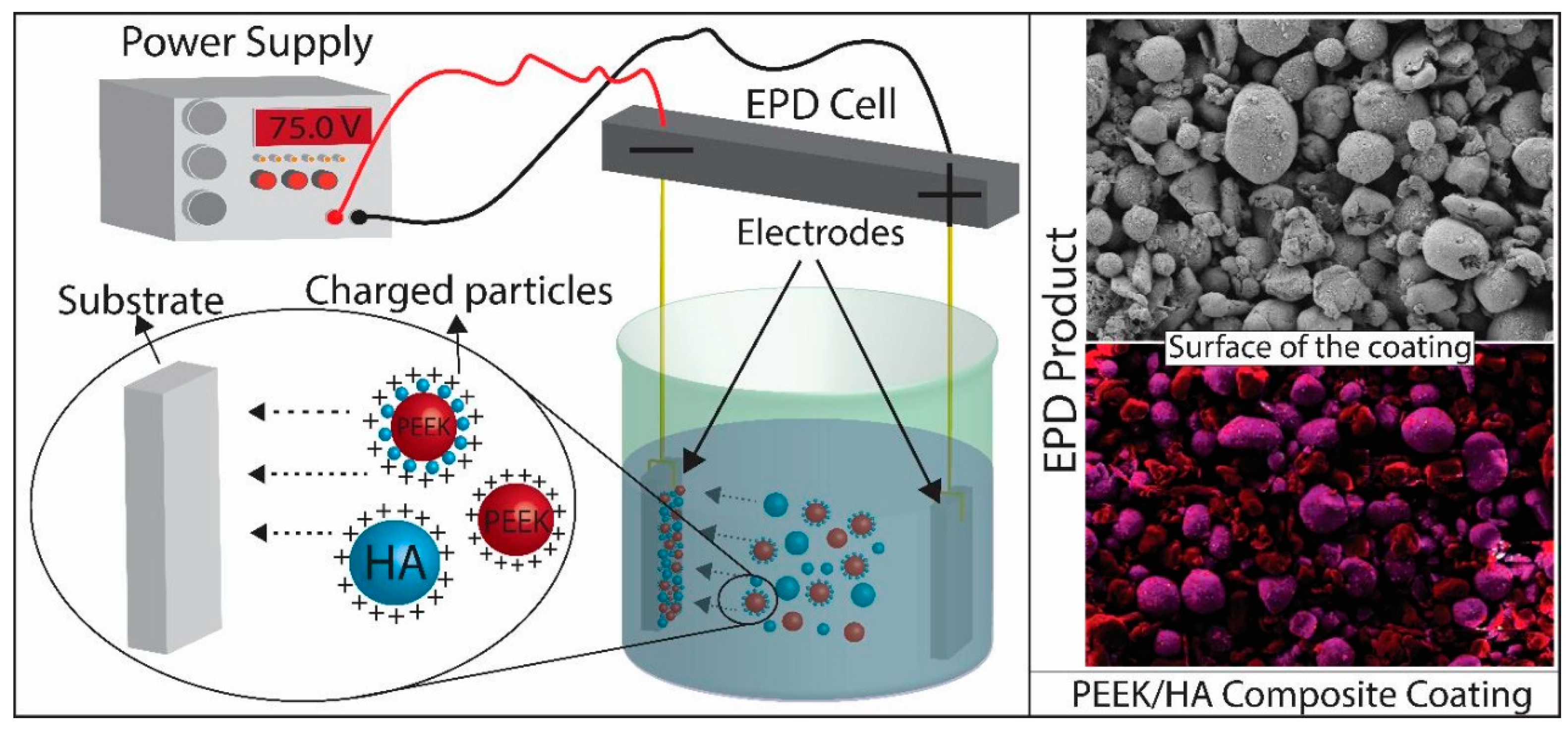

2.2. Electrophoretic Deposition

2.3. Melt Extrusion Coating

3. Modification Technology for PEEK Coatings

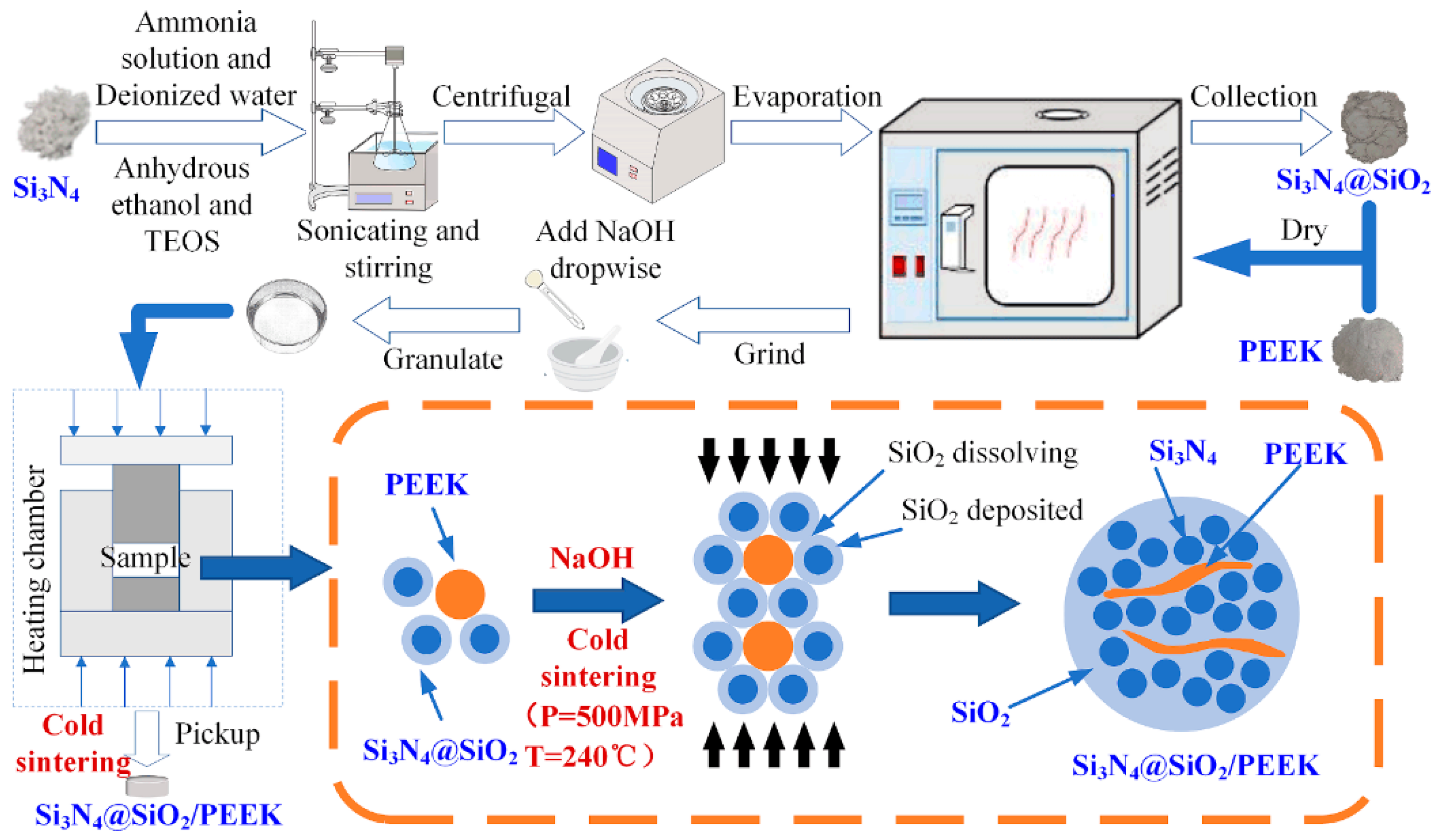

3.1. Filler Reinforcement

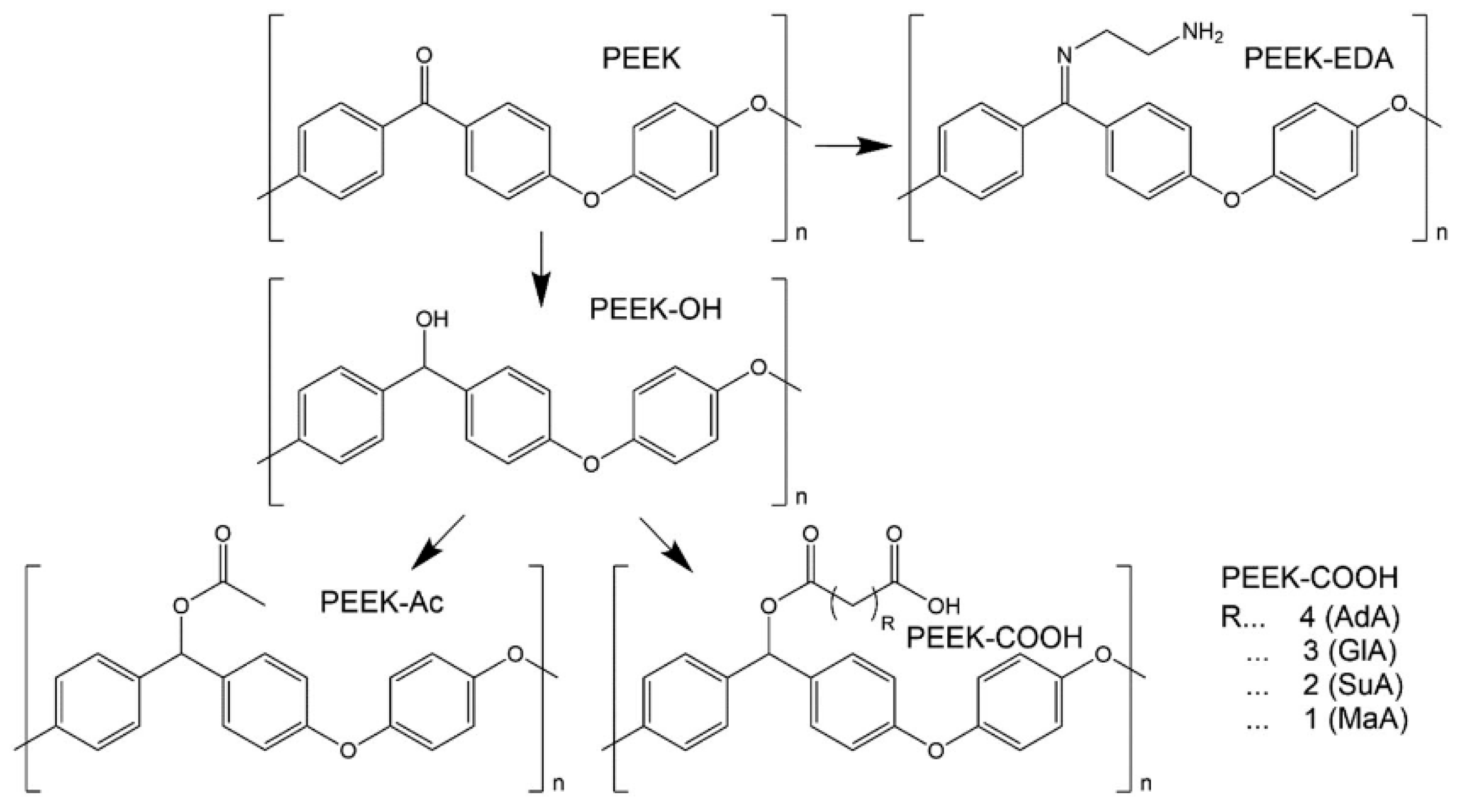

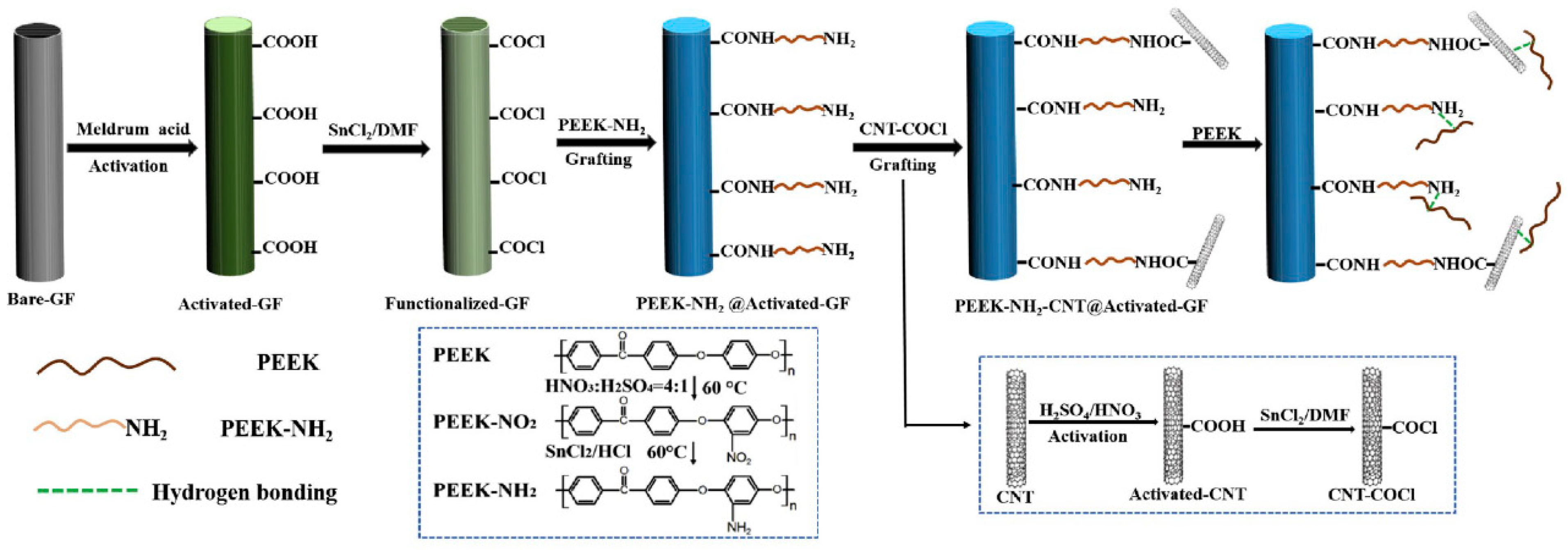

3.2. Chemical Modification

4. Application of PEEK Coatings

4.1. Aerospace

4.2. Auto Industry

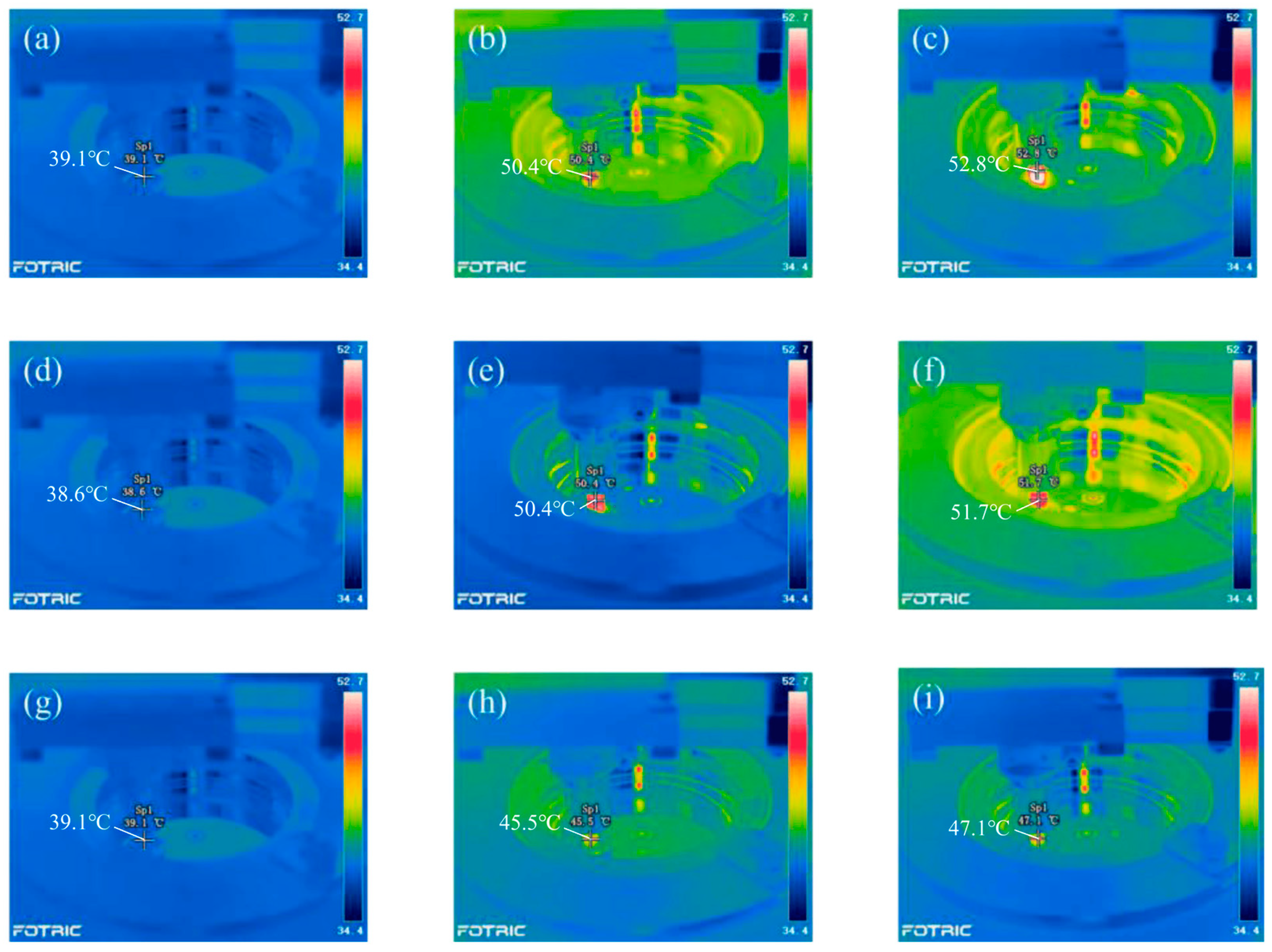

4.3. Electronics and Electrical

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pedroso, J.M.; Enger, M.; Bandeira, P.; Magalhães, F.D. Comparative Study of Friction and Wear Performance of PEK, PEEK and PEKK Binders in Tribological Coatings. Polymers 2022, 14, 4008. [Google Scholar] [CrossRef] [PubMed]

- Alam, F.; Varadarajan, K.M.; Koo, J.H.; Wardle, B.L.; Kumar, S. Additively Manufactured Polyetheretherketone (PEEK) with Carbon Nanostructure Reinforcement for Biomedical Structural Applications. Adv. Eng. Mater. 2020, 22, 2000483. [Google Scholar] [CrossRef]

- Wang, C.; Luan, J.; Xu, Z.; Zhao, W.; Zhang, M. Preparation and Properties of a Novel, High-Performance Polyether Ether Ketone Fabric. High Perform. Polym. 2018, 30, 794–802. [Google Scholar] [CrossRef]

- Jin, L.; Ball, J.; Bremner, T.; Sue, H.-J. Crystallization Behavior and Morphological Characterization of Poly(Ether Ether Ketone). Polymer 2014, 55, 5255–5265. [Google Scholar] [CrossRef]

- Goyal, R.K.; Tiwari, A.N.; Mulik, U.P.; Negi, Y.S. Thermal, Mechanical, and Dielectric Properties of High Performance PEEK/AIN Nanocomposites. J. Nanosci. Nanotechnol. 2009, 9, 6902–6909. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, L.; Hou, X.; Wu, J. Investigation on Dielectrical and Space Charge Characteristics of Peek Insulation Used in Aerospace High-Voltage System. IEEJ Trans. Electr. Electron. Eng. 2020, 15, 172–178. [Google Scholar] [CrossRef]

- Ve, T.A.; Hestad, O.L.; Hvidsten, S. The Effect of Water Content on Time Domain Dielectric Response in Polyetheretherketone. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 501–508. [Google Scholar] [CrossRef]

- Chan, K.W.; Liao, C.Z.; Wong, H.M.; Yeung, K.W.K.; Tjong, S.C. Preparation of Polyetheretherketone Composites with Nanohydroxyapatite Rods and Carbon Nanofibers Having High Strength, Good Biocompatibility and Excellent Thermal Stability. RSC Adv. 2016, 6, 19417–19429. [Google Scholar] [CrossRef]

- Zhu, Y.; Cao, Z.; Peng, Y.; Hu, L.; Guney, T.; Tang, B. Facile Surface Modification Method for Synergistically Enhancing the Biocompatibility and Bioactivity of Poly(Ether Ether Ketone) That Induced Osteodifferentiation. ACS Appl. Mater. Interfaces 2019, 11, 27503–27511. [Google Scholar] [CrossRef]

- Zhang, Y.X.; Chen, X.H.; Li, J.; Li, C.M.; Li, X.; Gao, T.; Li, H.; Jing, T.T.; Liu, W. Tribological Properties of PEEK-Based Composite Coating Prepared by Thermal Spraying. Phys. Scr. 2023, 98, 055923. [Google Scholar] [CrossRef]

- Dupuis, A.; Ho, T.H.; Fahs, A.; Lafabrier, A.; Louarn, G.; Bacharouche, J.; Airoudj, A.; Aragon, E.; Chailan, J.-F. Improving Adhesion of Powder Coating on PEEK Composite: Influence of Atmospheric Plasma Parameters. Appl. Surf. Sci. 2015, 357, 1196–1204. [Google Scholar] [CrossRef]

- Wu, J.; Munroe, P.R.; Withy, B.; Hyland, M.M. Study of the Splat-Substrate Interface for a PEEK Coating Plasma-Sprayed onto Aluminum Substrates. J. Therm. Spray Technol. 2010, 19, 42–48. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Y.; Chi, Y.; Mao, X.; Dong, Y.; Yang, Y.; He, J.; Lu, X. Wear and Corrosion Resistance of TiN/PEEK Composite Coatings Fabricated by Gas Twin-Tunnel Plasma Spraying. J. Therm. Spray. Technol. 2023, 32, 1273–1285. [Google Scholar] [CrossRef]

- Cui, Y.; Hu, Z.; Ma, Y.; Yang, Y.; Zhao, C.; Ran, Y.; Gao, P.; Wang, L.; Dong, Y.; Yan, D. Porous Nanostructured ZrO2 Coatings Prepared by Plasma Spraying. Surf. Coat. Technol. 2019, 363, 112–119. [Google Scholar] [CrossRef]

- Tailor, S.; Vashistha, N.; Modi, A.; Modi, S.C. One-Step Fabrication of Thermal Sprayed Polymer Coating on Metals. Mater. Res. Express 2020, 7, 016425. [Google Scholar] [CrossRef]

- Tharajak, J.; Palathai, T.; Sombatsompop, N. Morphological and Physical Properties and Friction/Wear Behavior of h-BN Filled PEEK Composite Coatings. Surf. Coat. Technol. 2015, 273, 20–29. [Google Scholar] [CrossRef]

- Li, Y.; Wei, L.; Man, Z.; Liu, S.; Wang, S.; Lei, M. Mechanical and Tribological Properties of Carbon Fiber-reinforced Polyetheretherketone Composite Coatings by Flame-spraying Method. Polym. Compos. 2022, 43, 8443–8457. [Google Scholar] [CrossRef]

- Li, Y.; Man, Z.; Lin, X.; Wei, L.; Wang, H.; Lei, M. Role of Well-Dispersed Carbon Nanotubes and Limited Matrix Degradation on Tribological Properties of Flame-Sprayed PEEK Nanocomposite Coatings. J. Tribol. 2022, 144, 012101. [Google Scholar] [CrossRef]

- Soveja, A.; Sallamand, P.; Liao, H.; Costil, S. Improvement of Flame Spraying PEEK Coating Characteristics Using Lasers. J. Mater. Process. Technol. 2011, 211, 12–23. [Google Scholar] [CrossRef]

- Yu, J.; Liu, X.; Yu, Y.; Li, H.; Liu, P.; Huang, K.; Sun, R. Research and Application of High-Velocity Oxygen Fuel Coatings. Coatings 2022, 12, 828. [Google Scholar] [CrossRef]

- Patel, K.; Doyle, C.S.; Yonekura, D.; James, B.J. Effect of Surface Roughness Parameters on Thermally Sprayed PEEK Coatings. Surf. Coat. Technol. 2010, 204, 3567–3572. [Google Scholar] [CrossRef]

- Abdulkareem, M.H.; Abdalsalam, A.H.; Bohan, A.J. Influence of Chitosan on the Antibacterial Activity of Composite Coating (PEEK /HAp) Fabricated by Electrophoretic Deposition. Prog. Org. Coat. 2019, 130, 251–259. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, P.; Li, S.; Wang, Q.; Zeng, D.; Yu, C.; Li, Q.; Liao, Y.; Lin, Z.; Li, W. Effects of TaN Nanoparticles on Microstructure, Mechanical Properties and Tribological Performance of PEEK Coating Prepared by Electrophoretic Deposition. Trans. Nonferrous Met. Soc. China 2022, 32, 3334–3348. [Google Scholar] [CrossRef]

- Kuśmierczyk, F.; Cieniek, Ł.; Kopia, A.; Zimowski, S.; Moskalewicz, T. Development and Characterization of Multilayered Cu/HA/ZnS + PEEK Coating System by Hybrid Technology. Met. Mater. Trans. A 2023, 54, 2803–2818. [Google Scholar] [CrossRef]

- Clavijo, S.; Membrives, F.; Boccaccini, A.R.; Santillán, M.J. Characterization of Polyetheretherketone Particle Suspensions for Electrophoretic Deposition. J. Appl. Polym. Sci. 2014, 131, 40953. [Google Scholar] [CrossRef]

- Baştan, F.E.; Atiq Ur Rehman, M.; Avcu, Y.Y.; Avcu, E.; Üstel, F.; Boccaccini, A.R. Electrophoretic Co-Deposition of PEEK-Hydroxyapatite Composite Coatings for Biomedical Applications. Colloids Surf. B Biointerfaces 2018, 169, 176–182. [Google Scholar] [CrossRef]

- Tseng, J.-W.; Liu, C.-Y.; Yen, Y.-K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.-B. Screw Extrusion-Based Additive Manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Yaragalla, S.; Zahid, M.; Panda, J.K.; Tsagarakis, N.; Cingolani, R.; Athanassiou, A. Comprehensive Enhancement in Thermomechanical Performance of Melt-Extruded PEEK Filaments by Graphene Incorporation. Polymers 2021, 13, 1425. [Google Scholar] [CrossRef]

- Tewatia, A.; Hendrix, J.; Dong, Z.; Taghon, M.; Tse, S.; Chiu, G.; Mayo, W.E.; Kear, B.; Nosker, T.; Lynch, J. Characterization of Melt-Blended Graphene—Poly(Ether Ether Ketone) Nanocomposite. Mater. Sci. Eng. B 2017, 216, 41–49. [Google Scholar] [CrossRef]

- Li, S.; Wen, F.; Sun, C.; Wang, Z.; Chen, R.; He, Q.; Mu, J. A Comparative Study on the Influences of Whisker and Conventional Carbon Nanotubes on the Electrical and Thermal Conductivity of Polyether Ether Ketone Composites. J. Appl. Polym. Sci. 2021, 138, 50720. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Wang, Y.; Wang, L.; Liu, G.; Chen, C.; Wei, L.; Li, H. Strength-Plasticity Synergetic CF/PEEK Composites Obtained by Adjusting Melt Flow Rate. Polymer 2024, 305, 127186. [Google Scholar] [CrossRef]

- Dahmen, M.; Vedder, C.; Speckens, M.; Stollenwerk, J.; Loosen, P. Influence of Surface Preheating and Pretreatment on the Adhesion of Laser-Melted PEEK to Aluminum Substrates. Surf. Coat. Technol. 2022, 448, 128922. [Google Scholar] [CrossRef]

- Curmi, A.; Rochman, A.; Buhagiar, J. Influence of Polyether Ether Ketone (PEEK) Viscosity on Interlayer Shear Strength in Screw Extrusion Additive Manufacturing. Addit. Manuf. 2024, 84, 104086. [Google Scholar] [CrossRef]

- Comelli, C.A.; Yi, N.; Davies, R.; Van Der Pol, H.; Ghita, O. Observation of Peek Melting Peaks within the Additive Manufacturing Material Extrusion Process in Relation to Isothermal and Non-Isothermal Processes. Macro Mater. Amp. Eng. 2024, 309, 2300386. [Google Scholar] [CrossRef]

- Keul, C.; Liebermann, A.; Schmidlin, P.; Roos, M.; Sener, B.; Stawarczyk, B. Influence of PEEK Surface Modification on Surface Properties and Bond Strength to Veneering Resin Composites. J. Adhes. Dent. 2014, 16, 383–392. [Google Scholar] [CrossRef]

- Doumeng, M.; Berthet, F.; Delbé, K.; Marsan, O.; Denape, J.; Chabert, F. Effect of Size, Concentration, and Nature of Fillers on Crystallinity, Thermal, and Mechanical Properties of Polyetheretherketone Composites. J. Appl. Polym. Sci. 2022, 139, 51574. [Google Scholar] [CrossRef]

- Saeed, H.M.; Jassim, R.K. Characterization and Assessment of PEEK/Silicon Dioxide Composite. Int. J. Dent. 2023, 2023, 3343071. [Google Scholar] [CrossRef]

- Li, M.; Yang, J.; Ma, S.; Liu, G.; Yang, H.; Yao, J. Effect of h-BN and Nano-SiO2 Fillers on the High-Temperature Tribological Properties of PEEK/PI-Based Composites. Lubricants 2023, 11, 416. [Google Scholar] [CrossRef]

- Gu, D.; Wang, G.; Chen, X.; Liu, Z.; Chen, S.; Xie, H. SiO2 Shell Thickness Affects the Tribological Properties of Si3N4@SiO2/PEEK Core–Shell Composite Prepared by Cold Sintering. Mater. Lett. 2023, 345, 134488. [Google Scholar] [CrossRef]

- Abd El-Fattah, A.; Youssef, H.; Gepreel, M.A.H.; Abbas, R.; Kandil, S. Surface Morphology and Mechanical Properties of Polyether Ether Ketone (PEEK) Nanocomposites Reinforced by Nano-Sized Silica (SiO2) for Prosthodontics and Restorative Dentistry. Polymers 2021, 13, 3006. [Google Scholar] [CrossRef]

- Chen, C.; Meng, L.; Hu, Y.; Su, Z.; Zhang, T.; Ouyang, Z.; Li, W.; Wan, J.; Wu, Q. Graphene Oxide-Reinforced Poly (Ether-Ether-Ketone)/Silica Composites with Improved Mechanical Performance and Surface Bioactivity. J. Mech. Behav. Biomed. Mater. 2021, 124, 104811. [Google Scholar] [CrossRef]

- Almasi, D.; Izman, S.; Assadian, M.; Ghanbari, M.; Abdul Kadir, M.R. Crystalline Ha Coating on Peek via Chemical Deposition. Appl. Surf. Sci. 2014, 314, 1034–1040. [Google Scholar] [CrossRef]

- Zimmerer, C.; Schwind, M.; Putzke, S.; Frenzel, R.; Drechsler, A.; Simon, F. Surface Functionalization of Poly(Ether Ether Ketone) by Wet-Chemical Modification with Carboxylic Acids and Diamine. J. Adhes. Sci. Technol. 2024, 38, 139–162. [Google Scholar] [CrossRef]

- Zhu, S.; Qian, Y.; Hassan, E.A.M.; Shi, R.; Yang, L.; Cao, H.; Zhou, J.; Ge, D.; Yu, M. Enhanced Interfacial Interactions by PEEK-Grafting and Coupling of Acylated CNT for GF/PEEK Composites. Compos. Commun. 2020, 18, 43–48. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, F.; Wang, X.; Zhang, J.; Sun, T. Roles of Chemistry Modification for Surface Wettability of Polyether-Ether-Ketone (PEEK) by Ultraviolet Laser Ablation. Mater. Res. Express 2023, 10, 065304. [Google Scholar] [CrossRef]

- Lyu, X.; Kanda, R.; Tsuda, S.; Hashimoto, Y.; Fujii, T.; Kashiwagi, K. Novel Carboxylation Method for Polyetheretherketone (PEEK) Surface Modification Using Friedel–Crafts Acylation. Int. J. Mol. Sci. 2023, 24, 15651. [Google Scholar] [CrossRef]

- Hassan, E.A.; Elagib, T.H.; Memon, H.; Yu, M.; Zhu, S. Surface Modification of Carbon Fibers by Grafting PEEK-NH2 for Improving Interfacial Adhesion with Polyetheretherketone. Materials 2019, 12, 778. [Google Scholar] [CrossRef]

- Bai, J.; Ding, R.; Wang, Y.; Chen, T.; Xu, Q.; Feng, B.; Duan, K.; Zhi, W.; Weng, J.; Wang, J. Surface Modification of Polyetheretherketone by Grafting Amino Groups to Improve Its Hydrophilicity and Cytocompatibility. Mater. Res. Express 2019, 6, 115413. [Google Scholar] [CrossRef]

- Gu, D.; Wang, Z.; Liu, K.; Xu, M.; Chen, S.; Li, Z.; Tang, Z.; Wang, S. Textured Surfaces Preparation and Tribological Properties of PTFE/PMMA and PEEK/PMMA Composites With Steel Spheres Embedded on Their Surfaces. Tribol. Trans. 2022, 65, 901–911. [Google Scholar] [CrossRef]

- Li, J.; Dong, H.; Tang, Z.; Li, P.; Wu, B.; Ma, Y.; Huang, L.; Zhang, L.; Li, C.; Xiong, J. Influence of Surface Pretreatment on the Bonding Mechanism and Mechanical Properties of AA5052/CFRP Friction Stir Spot Welded Joint. J. Manuf. Process. 2023, 105, 112–123. [Google Scholar] [CrossRef]

- Xu, Z.; Hui, J.; Lv, J.; Wei, D.; Yan, Z.; Zhang, H.; Wang, J. An Investigation of Methods to Enhance Adhesion of Conductive Layer and Dielectric Substrate for Additive Manufacturing of Electronics. Sci. Rep. 2024, 14, 10351. [Google Scholar] [CrossRef]

- Goyal, R.K.; Rokade, K.A.; Kapadia, A.S.; Selukar, B.S.; Garnaik, B. PEEK/SiO2 Composites with High Thermal Stability for Electronic Applications. Electron. Mater. Lett. 2013, 9, 95–100. [Google Scholar] [CrossRef]

- Quan, D.; Wang, G.; Zhao, G.; Alderliesten, R. On the Fracture Behaviour of Aerospace-Grade Polyether-Ether-Ketone Composite-to-Aluminium Adhesive Joints. Compos. Commun. 2022, 30, 101098. [Google Scholar] [CrossRef]

- Quan, D.; Ma, Y.; Yue, D.; Liu, J.; Xing, J.; Zhang, M.; Alderliesten, R.; Zhao, G. On the Application of Strong Thermoplastic–Thermoset Interactions for Developing Advanced Aerospace-Composite Joints. Thin-Walled Struct. 2023, 186, 110671. [Google Scholar] [CrossRef]

- Kalra, S.; Munjal, B.S.; Singh, V.R.; Mahajan, M.; Bhattacharya, B. Investigations on the Suitability of PEEK Material under Space Environment Conditions and Its Application in a Parabolic Space Antenna. Adv. Space Res. 2019, 63, 4039–4045. [Google Scholar] [CrossRef]

- Hastie, J.C.; Guz, I.A.; Kashtalyan, M. Response of Carbon/PEEK Automotive Driveshafts with/without an Inner Isotropic Layer at High Temperature Considering Temperature-Dependent Material Properties. Proc. Inst. Mech. Eng. Part. L J. Mater. Des. Appl. 2023, 237, 1406–1415. [Google Scholar] [CrossRef]

- Andrade, T.F.D.; Wiebeck, H.; Sinatora, A. Effect of Surface Finishing on Friction and Wear of Poly-Ether-Ether-Ketone (PEEK) under Oil Lubrication. Polímeros 2016, 26, 336–342. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.; Zhang, Y.; Luan, J.; Dang, H.; Jiang, D.; Yang, Y. Fabrication of High Thermal and Electrical Conductivity Composites via Electroplating Cu Network on 3D PEEK/CF Felt Skeletons. Compos. Commun. 2021, 28, 100909. [Google Scholar] [CrossRef]

- Niu, S.; Bai, X.; Cheng, Y.; Qin, H.; Zhang, Y.; Jiang, Z. Tuning High-Temperature Dielectric Properties of Poly Ether Ether Ketone by Using Self-Crosslinkable Polyetherimide and Nanoparticles. Polym. Test. 2023, 117, 107858. [Google Scholar] [CrossRef]

- Alimohammadi, M.; Ramazani, S.A. Surface Modification of Polyether Ether Ketone Implant with a Novel Nanocomposite Coating Containing Poly (Vinylidene Fluoride) toward Improving Piezoelectric and Bioactivity Performance. Colloids Surf. B Biointerfaces 2023, 222, 113098. [Google Scholar] [CrossRef]

| Sample | CF Size (Mesh) | CF Content (wt.%) | IC=O/IC=C | Tg (°C) | Tm (°C) | Xc (%) | dp (nm) |

|---|---|---|---|---|---|---|---|

| PEEK powder | 0 | 147.1 | 343.4 | 44.21 | 7 | ||

| Pure PEEK coating | - | - | 0.2 | 155.3 | 334.6 | 45.34 | 16 |

| CF/PEEK coating | 300 | 10 | 0.14 | 151.4 | 335.7 | 42.24 | 11 |

| CF/PEEK coating | 300 | 30 | 0.1 | 153.8 | 335.4 | 26.95 | 10 |

| CF/PEEK coating | 600 | 10 | 0.16 | 150.7 | 335.7 | 35.9 | 11 |

| CF/PEEK coating | 600 | 30 | 0.22 | 157.3 | 334.8 | 32.5 | 14 |

| Type | Data | |||||

|---|---|---|---|---|---|---|

| Researcher | Wu | Jiang | Soveja | Tharajak | Li | Patel |

| Current/A | 150 | 420 | - | - | - | - |

| Gas Flow Rates | N2:40 SLPM | Argon: 60–80 L/h, N2: 0.5 g/min | Acetylene:6 L/min, Oxygen: 16 L/min | Oxygen: 47.34 L/min (60 psi), Propane: 27.70 L/min (65 psi), Nitrogen: 160 psi | - | - |

| Spray Distance/mm | 80 | 100 | 140 | 120 | - | 280 |

| Powder Feed Rate | 10–20 g/min | Ti: 0.9 g/min, PEEK: 0.1 g/min | 35 L/min | 12 g/min | - | - |

| Preheating Temperature/°C | ~23 | - | - | 200 | 200 | - |

| Spray Gun Speed /mm s−1 | - | - | 150 | 80 | 300 | 300 |

| Method | Advantages | Applicable Scenarios | Limitations |

|---|---|---|---|

| Plasma spraying | Can reach extremely high temperatures, suitable for melting high-melting-point materials. | Where uniform thickness and high-density coating are required. | Complex equipment and high cost. |

| PEEK powder is deposited evenly, providing good bonding strength and wear resistance. | Suitable for precision parts in aerospace and electronic equipment. | Requires high technical level to operate. | |

| Flame spraying | Simple equipment and low cost. | Widely used in the automotive industry and general industrial equipment. | The coating bonding strength and density are lower than other methods. |

| Suitable for coating requirements of large-area substrates. | Suitable for wear-resistant and corrosion-resistant coatings with low requirements. | Not suitable for extreme environment applications. | |

| HVOF spraying | High particle velocity, resulting in dense, highly adhesive coatings. | Parts requiring high wear resistance and low friction in mechanical engineering. | High equipment costs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Ni, H.; Park, J.-J.; Lv, S. A Review of the Preparation, Modification, and Applications of Polyetheretherketone Coating. Coatings 2024, 14, 1451. https://doi.org/10.3390/coatings14111451

Chen Y, Ni H, Park J-J, Lv S. A Review of the Preparation, Modification, and Applications of Polyetheretherketone Coating. Coatings. 2024; 14(11):1451. https://doi.org/10.3390/coatings14111451

Chicago/Turabian StyleChen, Yufei, Hongjun Ni, Jae-Jun Park, and Shuaishuai Lv. 2024. "A Review of the Preparation, Modification, and Applications of Polyetheretherketone Coating" Coatings 14, no. 11: 1451. https://doi.org/10.3390/coatings14111451

APA StyleChen, Y., Ni, H., Park, J.-J., & Lv, S. (2024). A Review of the Preparation, Modification, and Applications of Polyetheretherketone Coating. Coatings, 14(11), 1451. https://doi.org/10.3390/coatings14111451