Hybrid Laser Additive Manufacturing of Metals: A Review

Abstract

:1. Introduction

2. Laser Additive Manufacturing Technology

2.1. Laser Powder Bed Fusion (LPBF)

2.2. Laser-Directed Energy Deposition (LDED)

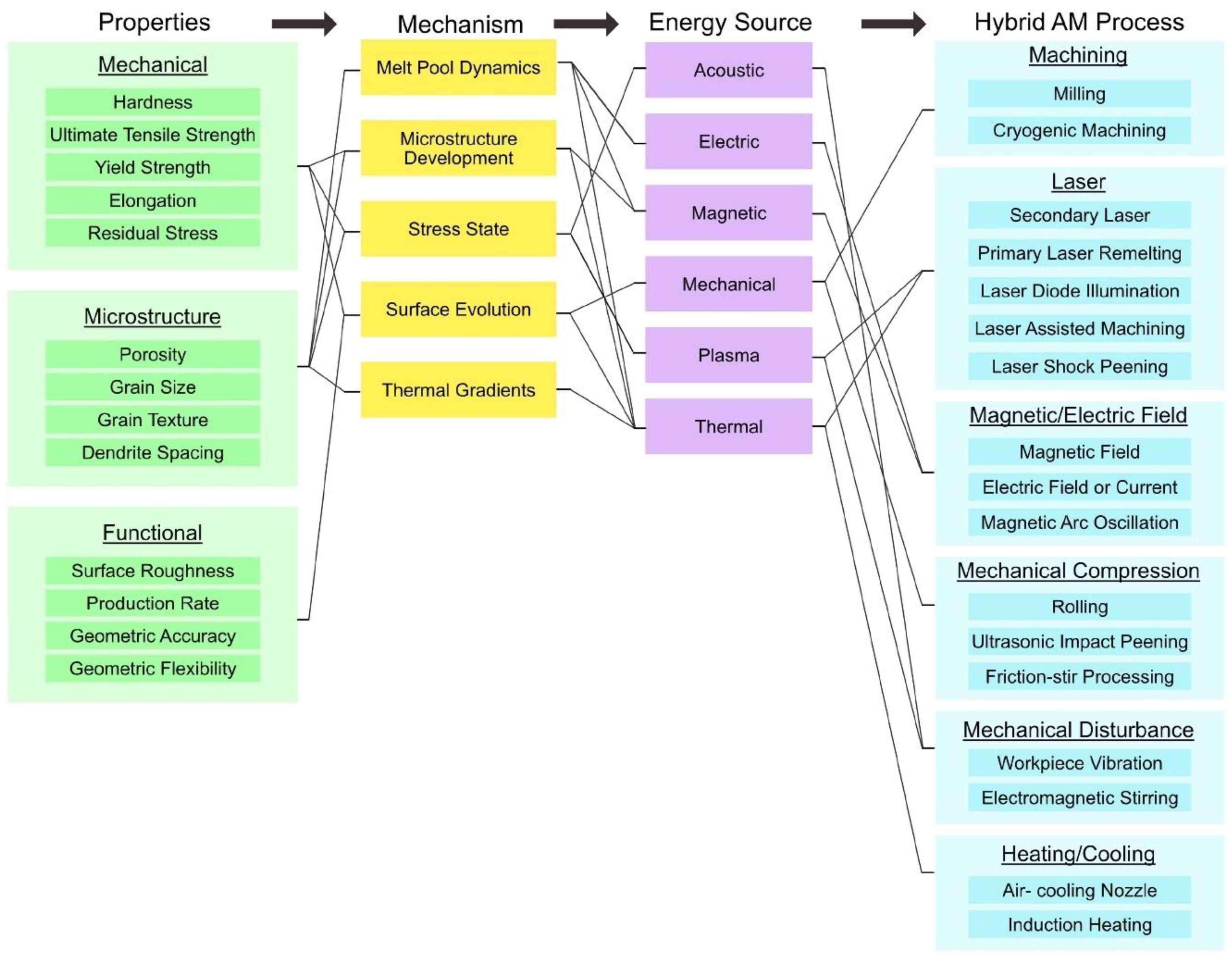

3. Hybrid Additive Manufacturing Technology

3.1. Multi-Process Hybrid Laser Additive Manufacturing Technology

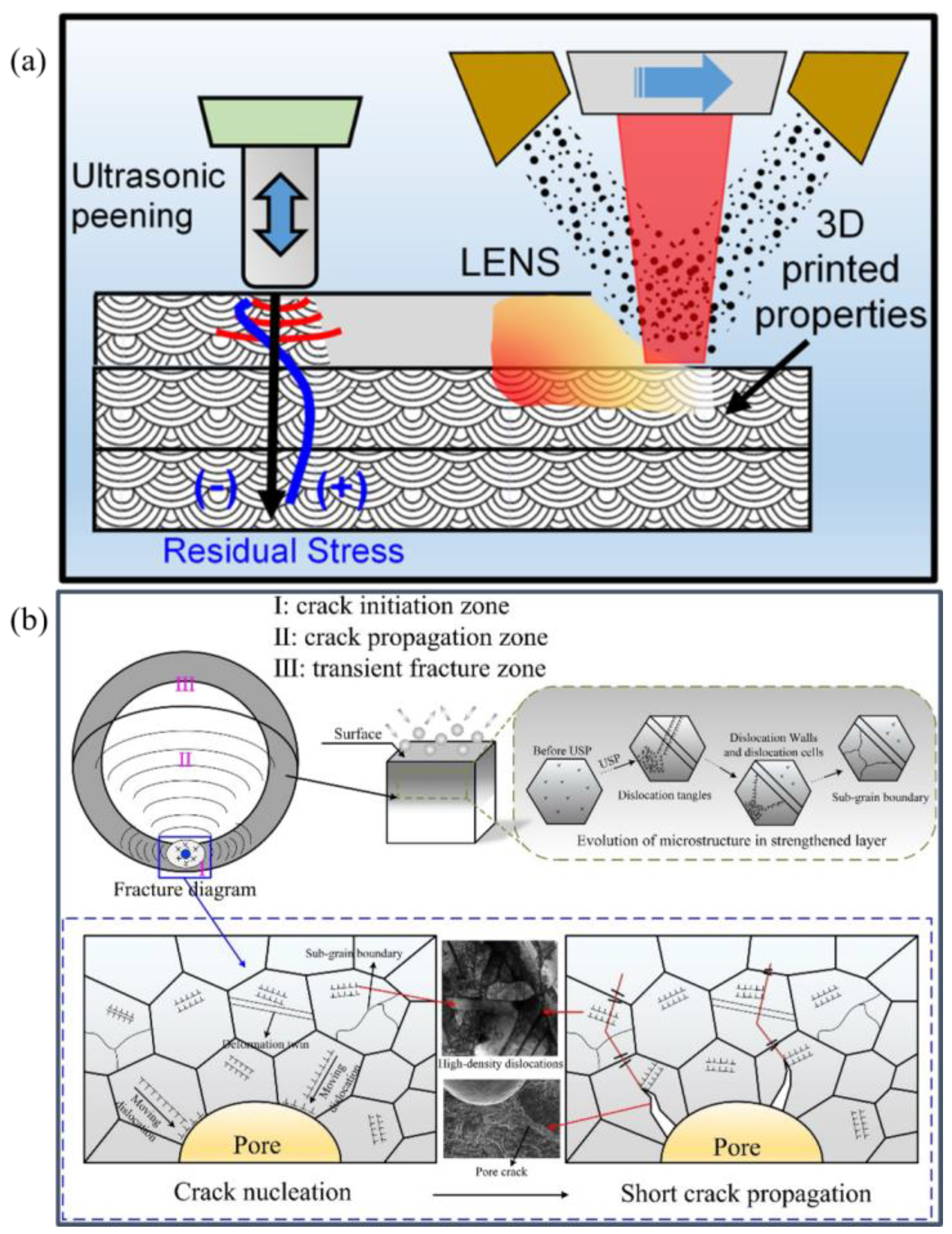

3.1.1. Shot Peening

3.1.2. Laser Remelting

3.1.3. Forging

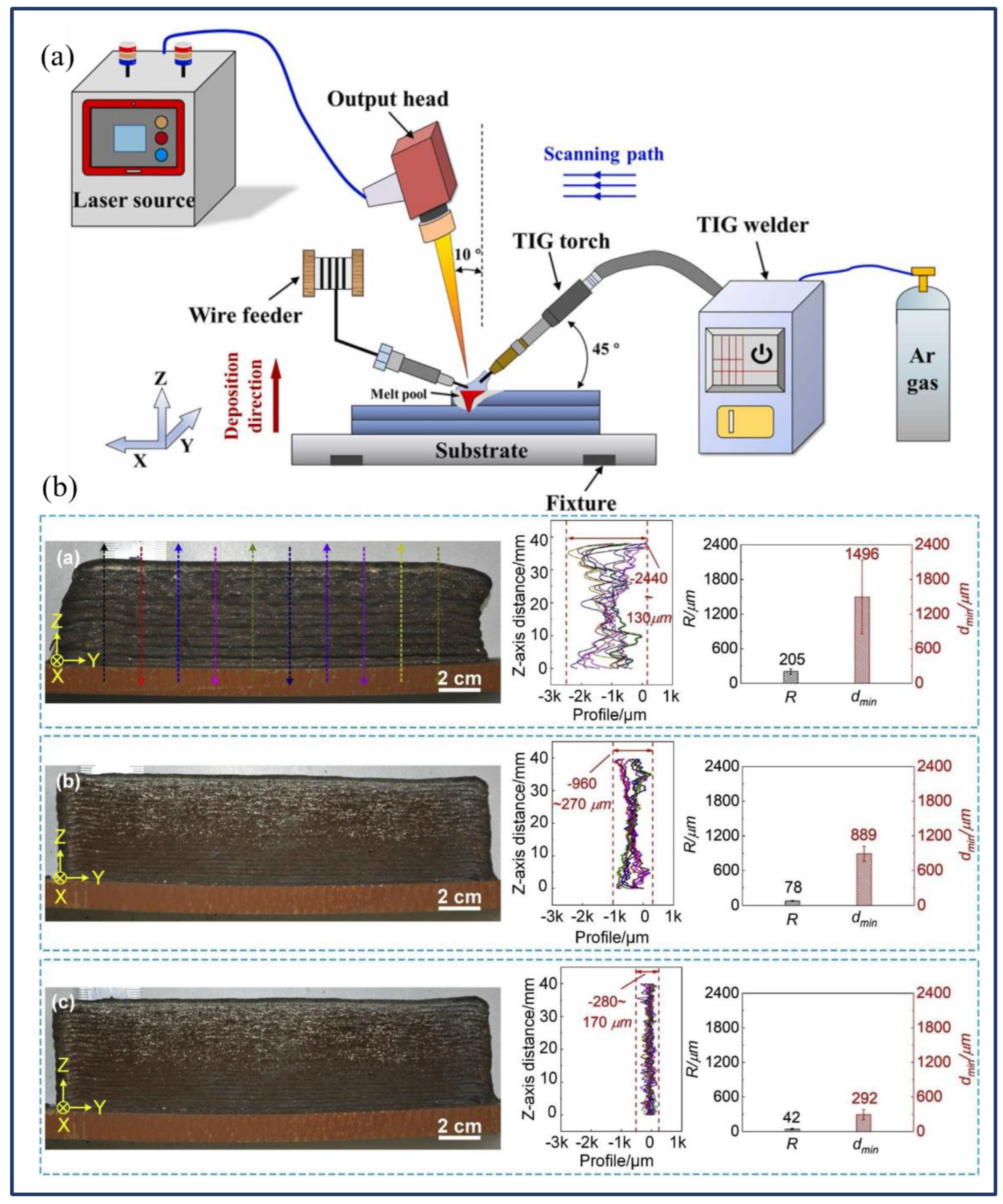

3.1.4. Arc Additive Manufacturing

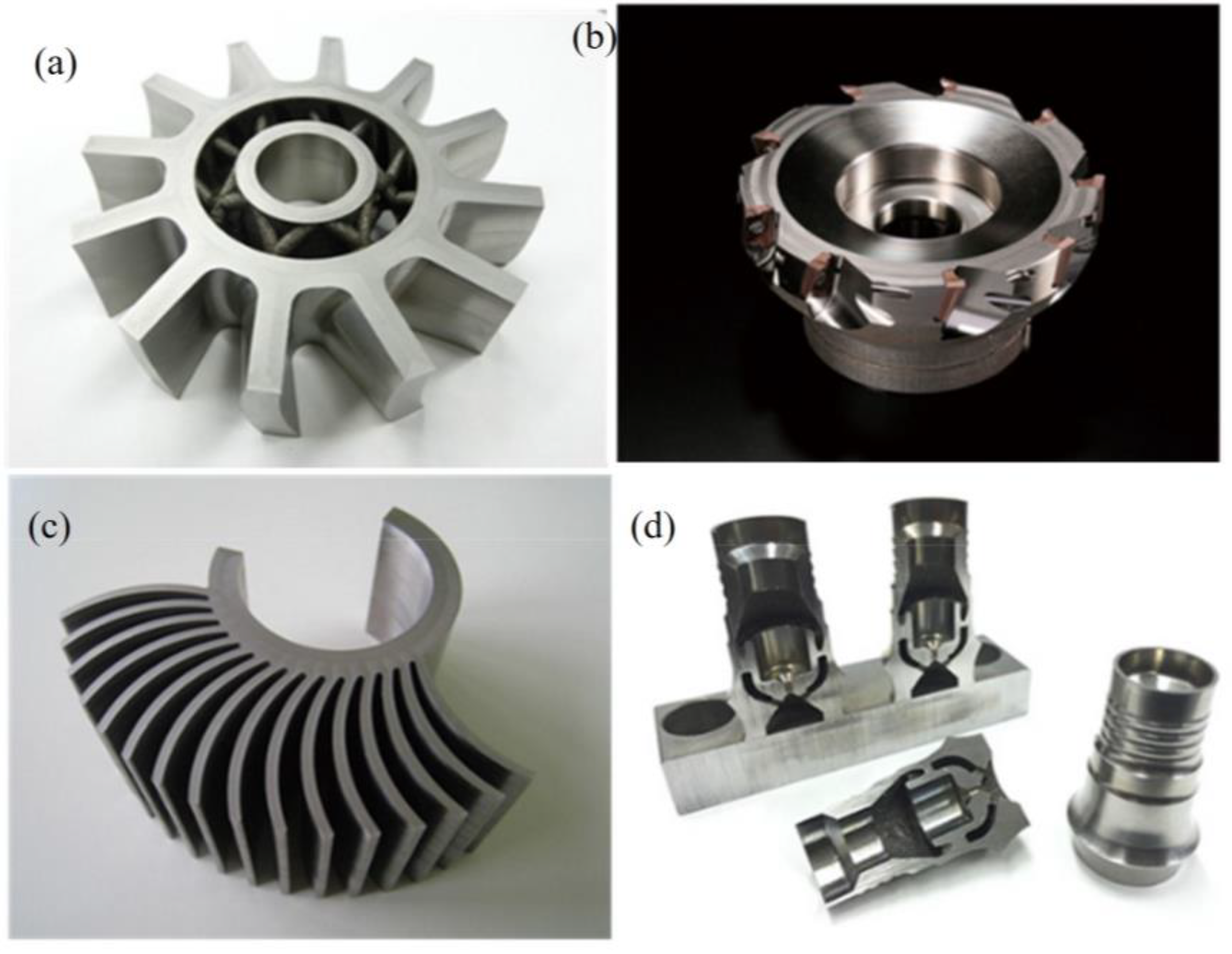

3.2. Additive–Subtractive Hybrid Manufacturing

3.3. Multi-Energy Field Hybrid Manufacturing Technology

3.3.1. Ultrasonic Vibration-Assisted Additive Manufacturing

| Materials (Substate/Cladding Layer) | Additive Manufacturing Processes | Optimal Process Parameters for Ultrasonic Vibration | Microstructure Evolution | Performance Improvements | Refs. |

|---|---|---|---|---|---|

| 45 steel/ Ni-WC ceramic hybrid coatings; | Laser cladding | 800 W | Refinement of dispersed dendrites | Improved surface hardness and wear resistance | [91] |

| Ti6Al4V/Ti + B4C | Laser cladding | 400 W | Dendrite gradually becomes granular | The friction performance is improved, the friction coefficient is 50% lower, and the wear resistance is 1.2 times that without ultrasonic vibration | [95] |

| 5CrNiMo steel/FeTi30 + FeCr70 | Laser cladding | 300 W | The ceramic particles are more evenly distributed, and the dendrite size is refined | Reduced surface roughness, increased coating dilution, improved hardness, and increased high-temperature oxidation resistance | [89] |

| 45 steel/Inconel 718 | Laser cladding | A = 25 μm | The average grain size is 0.522 times that of the non-vibration grain size. | Effectively reduced the porosity, decreased the friction coefficient to 0.628 times that without ultrasonic waves, and improved the microhardness and wear resistance | [85] |

| Low-carbon steel/In 718 | Laser-engineered net shaping | 25 kHz | The grain size is smaller, and the Laves phase changes from a long columnar to a granular shape | Excellent interfacial bonding ability, high microhardness, low porosity | [93] |

| WTaNbMo refractory high-entropy alloy coating/ IN718 | Laser cladding | 20.5 kHz; A = 9.6 μm | The average grain size of the coating decreased from 0.48 µm2 to 0.30 µm2; microstructure and element distribution are more uniform | Reduced residual stress in the coating, increased hardness, and improved high-temperature friction properties | [96] |

| Ti substrate/NiTi | DED | 25 kHz; 40 W | Homogenization of microstructure, reduction in secondary phases, and refinement of grains | Microhardness and Young’s modulus enhancement | [94] |

| Ti6Al4V/In 625 | DED | 20 kHz; 30 μm | Transition from coarse columnar crystals to fine equiaxed crystals (100 μm), microstructural homogeneity | Yield stress and tensile strength increased by 12% | [87] |

| Low-carbon steel/AISI 630 stainless steel | Laser-engineered net shaping | 41 kHz; 60 W | Reduction in porosity and microcracking | Increased tensile properties and hardness, increased powder utilization, and improved bonding of the deposited part to the substrate | [88] |

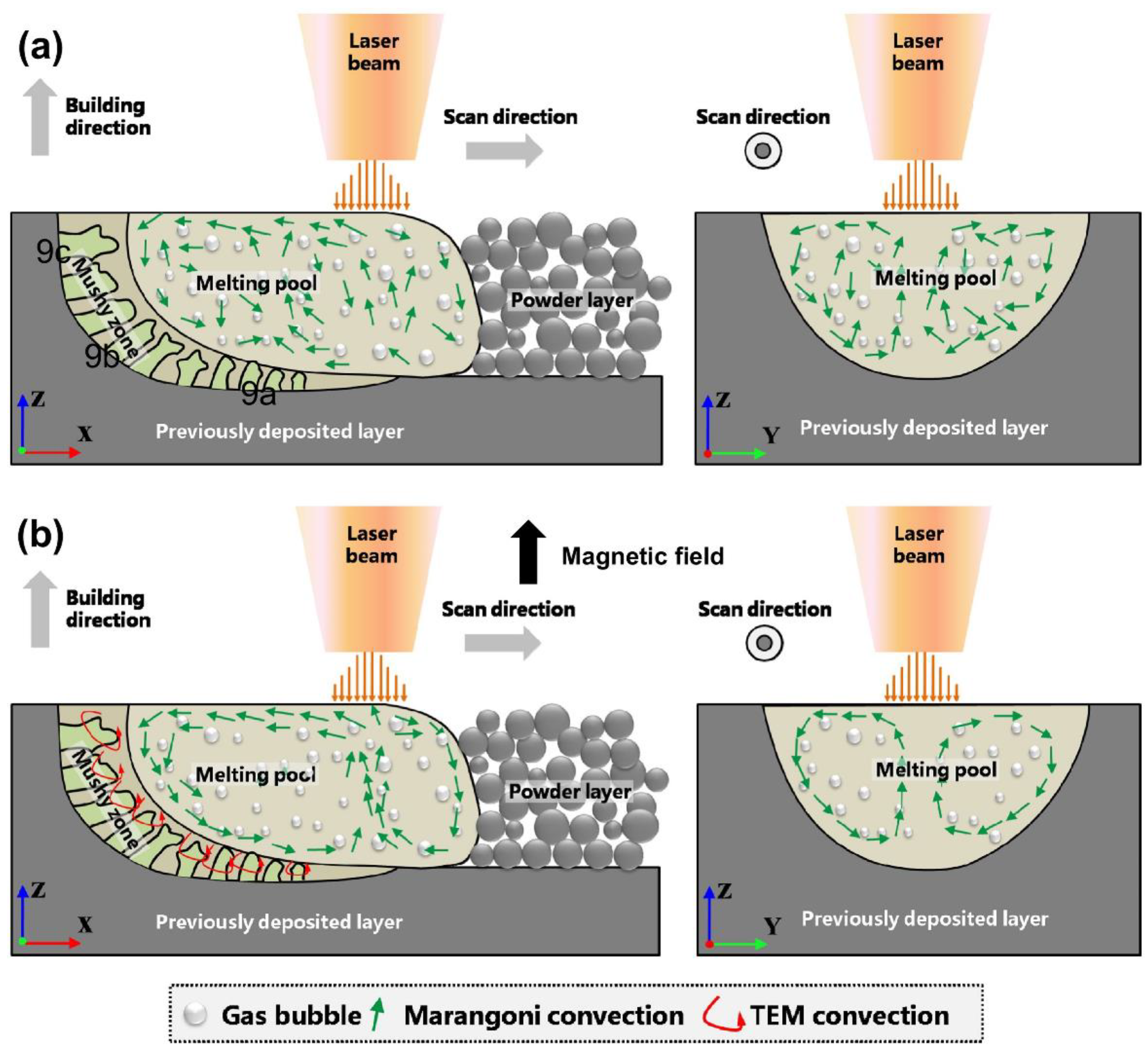

3.3.2. Electromagnetic-Assisted Laser Additive Manufacturing

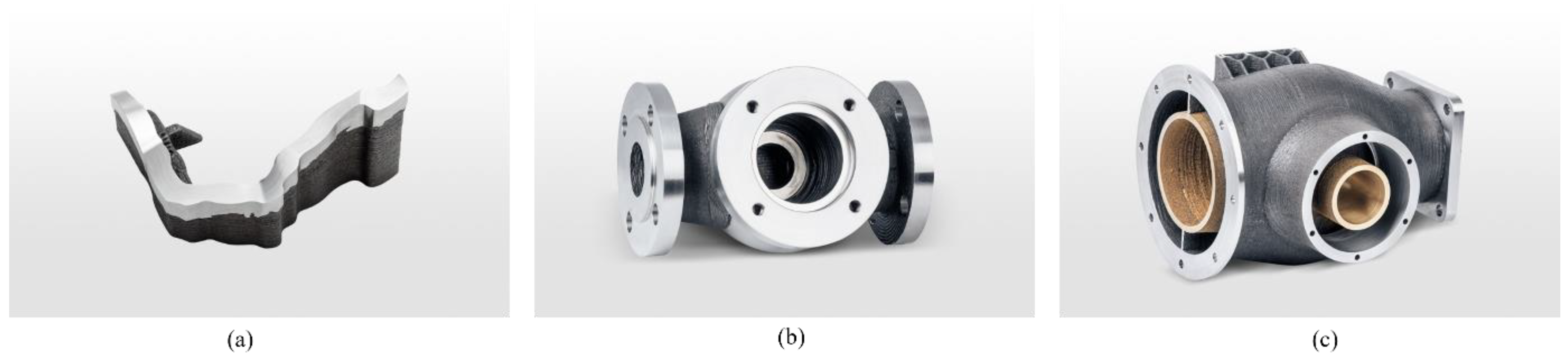

3.4. Multi-Material Hybrid Additive Manufacturing Technology

4. Challenges and Prospects for Hybrid Laser Additive Manufacturing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research Status of Laser Additive Manufacturing for Metal: A Review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive Manufacturing of Ti6Al4V Alloy: A Review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y.; Liou, F. Additive Manufacturing of Functionally Graded Metallic Materials Using Laser Metal Deposition. Addit. Manuf. 2020, 31, 100901. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Onuike, B.; Heer, B.; Bandyopadhyay, A. Additive manufacturing of Inconel 718—Copper alloy bimetallic structure using laser engineered net shaping (LENS™). Addit. Manuf. 2018, 21, 133–140. [Google Scholar] [CrossRef]

- Liu, J.; Liu, S.; Yang, X.; Li, A.; Shi, M.; Zhang, G.; Zhang, Z.; Han, S. Progress in Lightweight Application Research of Additive Manufacturing Technology. Mater. China 2020, 39, 163–168. [Google Scholar]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi-Scale Design to Versatile Functional Properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Gu, D.; Dai, D.; Xia, M.; Ma, C. Cross-Scale Physical Mechanisms for Structure and Performance Control of Metal Components Processed by Selective Laser Melting Additive Manufacturing. J. Nanjing Univ. Aeronaut. Astronaut. 2017, 49, 645–652. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the Build Orientation on the Mechanical Properties and Fracture Modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing Porosity in AlSi10Mg Parts Processed by Selective Laser Melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Tian, X.; Wu, L.; Gu, D.; Yuan, S.; Zhao, Y.; Li, X.; Ouyang, L.; Song, B.; Gao, T.; He, J.; et al. Roadmap for Additive Manufacturing: Toward Intellectualization and Industrialization. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100014. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A Critical Review of Powder-Based Additive Manufacturing of Ferrous Alloys: Process Parameters, Microstructure and Mechanical Properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective Laser Melting Additive Manufactured Inconel 718 Superalloy Parts: High-Temperature Oxidation Property and Its Mechanisms. Opt. Laser Technol. 2014, 62, 161–171. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D Printing of Aluminium Alloys: Additive Manufacturing of Aluminium Alloys Using Selective Laser Melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wang, Z.; Wang, L.; Liu, J.; Jiang, W. Densification Behavior of Gas and Water Atomized 316L Stainless Steel Powder during Selective Laser Melting. Appl. Surf. Sci. 2010, 256, 4350–4356. [Google Scholar] [CrossRef]

- Wang, Y.; Ji, X.; Liang, S.Y. Analytical Modeling of Temperature Distribution in Laser Powder Bed Fusion with Different Scan Strategies. Opt. Laser Technol. 2023, 157, 108708. [Google Scholar] [CrossRef]

- Wan, H.Y.; Zhou, Z.J.; Li, C.P.; Chen, G.F.; Zhang, G.P. Effect of Scanning Strategy on Mechanical Properties of Selective Laser Melted Inconel 718. Mater. Sci. Eng. A 2019, 753, 42–48. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Huang, C.; Song, M.; Yang, G.; Chen, J.; Huang, W. The Effect of Laser Scanning Path on Microstructures and Mechanical Properties of Laser Solid Formed Nickel-Base Superalloy Inconel 718. J. Alloys Compd. 2011, 509, 4505–4509. [Google Scholar] [CrossRef]

- Masoomi, M.; Thompson, S.M.; Shamsaei, N. Laser Powder Bed Fusion of Ti-6Al-4V Parts: Thermal Modeling and Mechanical Implications. Int. J. Mach. Tools Manuf. 2017, 118–119, 73–90. [Google Scholar] [CrossRef]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and Deformation Evaluations of Scanning Strategy Effect in Selective Laser Melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-Structured Aluminium Products with Controllable Texture by Selective Laser Melting of Pre-Alloyed AlSi10Mg Powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.; Dosbaeva, G.K.; Veldhuis, S.C. Thermal Post-Processing of AlSi10Mg Parts Produced by Selective Laser Melting Using Recycled Powder. Addit. Manuf. 2018, 21, 234–247. [Google Scholar] [CrossRef]

- Wolff, S.J.; Wu, H.; Parab, N.; Zhao, C.; Ehmann, K.F.; Sun, T.; Cao, J. In-Situ High-Speed X-Ray Imaging of Piezo-Driven Directed Energy Deposition Additive Manufacturing. Sci. Rep. 2019, 9, 962. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Rosen, D.; Stucker, B. Directed Energy Deposition Processes. In Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Gibson, I., Rosen, D., Stucker, B., Eds.; Springer: New York, NY, USA, 2015; pp. 245–268. ISBN 978-1-4939-2113-3. [Google Scholar]

- Shishkovsky, I.; Missemer, F.; Smurov, I. Metal Matrix Composites with Ternary Intermetallic Inclusions Fabricated by Laser Direct Energy Deposition. Compos. Struct. 2018, 183, 663–670. [Google Scholar] [CrossRef]

- Piscopo, G.; Iuliano, L. Current Research and Industrial Application of Laser Powder Directed Energy Deposition. Int. J. Adv. Manuf. Technol. 2022, 119, 6893–6917. [Google Scholar] [CrossRef]

- Kim, M.J.; Saldana, C. Thin Wall Deposition of IN625 Using Directed Energy Deposition. J. Manuf. Process. 2020, 56, 1366–1373. [Google Scholar] [CrossRef]

- Sealy, M.P.; Madireddy, G.; Williams, R.E.; Rao, P.; Toursangsaraki, M. Hybrid Processes in Additive Manufacturing. J. Manuf. Sci. Eng.-Trans. ASME 2018, 140, 060801. [Google Scholar] [CrossRef]

- Webster, S.; Lin, H.; Carter III, F.M.; Ehmann, K.; Cao, J. Physical Mechanisms in Hybrid Additive Manufacturing: A Process Design Framework. J. Mater. Process. Technol. 2021, 291, 117048. [Google Scholar] [CrossRef]

- Hackel, L.; Rankin, J.R.; Rubenchik, A.; King, W.E.; Matthews, M. Laser Peening: A Tool for Additive Manufacturing Post-Processing. Addit. Manuf. 2018, 24, 67–75. [Google Scholar] [CrossRef]

- Jebaraj, A.V.; Sugavaneswaran, M. Influence of Shot Peening on Residual Stress Distribution and Corrosion Resistance of Additive Manufactured Stainless Steel AISI 316L. Trans. Indian Inst. Met. 2019, 72, 1651–1653. [Google Scholar] [CrossRef]

- Slawik, S.; Bernarding, S.; Lasagni, F.; Navarro, C.; Perinan, A.; Boby, F.; Migot-Choux, S.; Dominguez, J.; Muecklich, F. Microstructural Analysis of Selective Laser Melted Ti6Al4V Modified by Laser Peening and Shot Peening for Enhanced Fatigue Characteristics. Mater. Charact. 2021, 173, 110935. [Google Scholar] [CrossRef]

- Lu, J.; Lu, H.; Xu, X.; Yao, J.; Cai, J.; Luo, K. High-Performance Integrated Additive Manufacturing with Laser Shock Peening –Induced Microstructural Evolution and Improvement in Mechanical Properties of Ti6Al4V Alloy Components. Int. J. Mach. Tools Manuf. 2020, 148, 103475. [Google Scholar] [CrossRef]

- Chi, J.; Cai, Z.; Zhang, H.; Zhang, H.; Guo, W.; Wan, Z.; Han, G.; Peng, P.; Zeng, Z. Combining Manufacturing of Titanium Alloy through Direct Energy Deposition and Laser Shock Peening Processes. Mater. Des. 2021, 203, 109626. [Google Scholar] [CrossRef]

- Lu, J.Z.; Duan, H.F.; Luo, K.Y.; Wu, L.J.; Deng, W.W.; Cai, J. Tensile Properties and Surface Nanocrystallization Analyses of H62 Brass Subjected to Room-Temperature and Warm Laser Shock Peening. J. Alloys Compd. 2017, 698, 633–642. [Google Scholar] [CrossRef]

- Lu, H.; Wu, L.; Wei, H.; Cai, J.; Luo, K.; Xu, X.; Lu, J. Microstructural Evolution and Tensile Property Enhancement of Remanufactured Ti6Al4V Using Hybrid Manufacturing of Laser Directed Energy Deposition with Laser Shock Peening. Addit. Manuf. 2022, 55, 102877. [Google Scholar] [CrossRef]

- Kalentics, N.; Boillat, E.; Peyre, P.; Ćirić-Kostić, S.; Bogojević, N.; Logé, R.E. Tailoring Residual Stress Profile of Selective Laser Melted Parts by Laser Shock Peening. Addit. Manuf. 2017, 16, 90–97. [Google Scholar] [CrossRef]

- AlMangour, B.; Yang, J.-M. Improving the Surface Quality and Mechanical Properties by Shot-Peening of 17-4 Stainless Steel Fabricated by Additive Manufacturing. Mater. Des. 2016, 110, 914–924. [Google Scholar] [CrossRef]

- Kalentics, N.; Boillat, E.; Peyre, P.; Gorny, C.; Kenel, C.; Leinenbach, C.; Jhabvala, J.; Logé, R.E. 3D Laser Shock Peening—A New Method for the 3D Control of Residual Stresses in Selective Laser Melting. Mater. Des. 2017, 130, 350–356. [Google Scholar] [CrossRef]

- Chen, S.; Gao, H.; Zhang, Y.; Wu, Q.; Gao, Z.; Zhou, X. Review on Residual Stresses in Metal Additive Manufacturing: Formation Mechanisms, Parameter Dependencies, Prediction and Control Approaches. J. Mater. Res. Technol.-JMRT 2022, 17, 2950–2974. [Google Scholar] [CrossRef]

- Tong, Z.; Liu, H.; Jiao, J.; Zhou, W.; Yang, Y.; Ren, X. Improving the Strength and Ductility of Laser Directed Energy Deposited CrMnFeCoNi High-Entropy Alloy by Laser Shock Peening. Addit. Manuf. 2020, 35, 101417. [Google Scholar] [CrossRef]

- Chen, H.; Guan, Y.; Zhu, L.; Li, Y.; Zhai, J.; Lin, J. Effects of Ultrasonic Shot Peening Process Parameters on Nanocrystalline and Mechanical Properties of Pure Copper Surface. Mater. Chem. Phys. 2021, 259, 124025. [Google Scholar] [CrossRef]

- Zhang, Q.; Duan, B.; Zhang, Z.; Wang, J.; Si, C. Effect of Ultrasonic Shot Peening on Microstructure Evolution and Corrosion Resistance of Selective Laser Melted Ti–6Al–4V Alloy. J. Mater. Res. Technol. 2021, 11, 1090–1099. [Google Scholar] [CrossRef]

- Wu, B.; Huang, J.; Yang, G.; Ren, Y.; Zhou, S.; An, D. Effects of Ultrasonic Shot Peening on Fatigue Behavior of TA15 Titanium Alloy Fabricated by Laser Melting Deposition. Surf. Coat. Technol. 2022, 446, 128769. [Google Scholar] [CrossRef]

- Walczak, M.; Szala, M. Effect of Shot Peening on the Surface Properties, Corrosion and Wear Performance of 17-4PH Steel Produced by DMLS Additive Manufacturing. Archiv. Civ. Mech. Eng. 2021, 21, 157. [Google Scholar] [CrossRef]

- Uzan, N.E.; Ramati, S.; Shneck, R.; Frage, N.; Yeheskel, O. On the Effect of Shot-Peening on Fatigue Resistance of AlSi10Mg Specimens Fabricated by Additive Manufacturing Using Selective Laser Melting (AM-SLM). Addit. Manuf. 2018, 21, 458–464. [Google Scholar] [CrossRef]

- dos Santos Paes, L.E.; Pereira, M.; Xavier, F.A.; Weingaertner, W.L.; D’Oliveira, A.S.C.M.; Costa, E.C.; Vilarinho, L.O.; Scotti, A. Understanding the Behavior of Laser Surface Remelting after Directed Energy Deposition Additive Manufacturing through Comparing the Use of Iron and Inconel Powders. J. Manuf. Process. 2021, 70, 494–507. [Google Scholar] [CrossRef]

- Yang, X.; Liu, J.; Cui, X.; Jin, G.; Liu, Z.; Chen, Y.; Feng, X. Effect of Remelting on Microstructure and Magnetic Properties of Fe-Co-Based Alloys Produced by Laser Additive Manufacturing. J. Phys. Chem. Solids 2019, 130, 210–216. [Google Scholar] [CrossRef]

- Soffel, F.; Lin, Y.; Keller, D.; Egorov, S.; Wegener, K. Laser Remelting Process Simulation and Optimization for Additive Manufacturing of Nickel-Based Super Alloys. Materials 2022, 15, 177. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Li, B.-Q.; Li, Z. Selective Laser Remelting of an Additive Layer Manufacturing Process on AlSi10Mg. Results Phys. 2019, 12, 982–988. [Google Scholar] [CrossRef]

- Zhou, J.; Han, X.; Li, H.; Liu, S.; Yi, J. Investigation of Layer-by-Layer Laser Remelting to Improve Surface Quality, Microstructure, and Mechanical Properties of Laser Powder Bed Fused AlSi10Mg Alloy. Mater. Des. 2021, 210, 110092. [Google Scholar] [CrossRef]

- Yasa, E.; Deckers, J.; Kruth, J. The Investigation of the Influence of Laser Re-melting on Density, Surface Quality and Microstructure of Selective Laser Melting Parts. Rapid Prototyp. J. 2011, 17, 312–327. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Jiang, F.; Yang, F.; Yang, Y.; Ma, B.; Liang, P. Effects of Laser Remelting on Morphology, Microstructure, Element Distribution and Crack Sensitivity of Al2O3-ZrO2 Laser Cladding Layer on TC4 Titanium Alloy. Surf. Technol. 2022, 51, 380–391. [Google Scholar] [CrossRef]

- Yu, Z.; Zheng, Y.; Chen, J.; Wu, C.; Xu, J.; Lu, H.; Yu, C. Effect of Laser Remelting Processing on Microstructure and Mechanical Properties of 17-4 PH Stainless Steel during Laser Direct Metal Deposition. J. Mater. Process. Technol. 2020, 284, 116738. [Google Scholar] [CrossRef]

- Xin, B.; Zhou, X.; Cheng, G.; Yao, J.; Gong, Y. Microstructure and Mechanical Properties of Thin-Wall Structure by Hybrid Laser Metal Deposition and Laser Remelting Process. Opt. Laser Technol. 2020, 127, 106087. [Google Scholar] [CrossRef]

- Vaithilingam, J.; Goodridge, R.D.; Hague, R.J.M.; Christie, S.D.R.; Edmondson, S. The Effect of Laser Remelting on the Surface Chemistry of Ti6al4V Components Fabricated by Selective Laser Melting. J. Mater. Process. Technol. 2016, 232, 1–8. [Google Scholar] [CrossRef]

- Han, T.; Liu, Y.; Liao, M.; Yang, D.; Qu, N.; Lai, Z.; Zhu, J. Refined Microstructure and Enhanced Mechanical Properties of AlCrFe2Ni2 Medium Entropy Alloy Produced via Laser Remelting. J. Mater. Sci. Technol. 2022, 99, 18–27. [Google Scholar] [CrossRef]

- Cai, Z.; Cui, X.; Liu, Z.; Li, Y.; Dong, M.; Jin, G. Microstructure and Wear Resistance of Laser Cladded Ni-Cr-Co-Ti-V High-Entropy Alloy Coating after Laser Remelting Processing. Opt. Laser Technol. 2018, 99, 276–281. [Google Scholar] [CrossRef]

- Meiners, F.; Ihne, J.; Jürgens, P.; Hemes, S.; Mathes, M.; Sizova, I.; Bambach, M.; Hama-Saleh, R.; Weisheit, A. New Hybrid Manufacturing Routes Combining Forging and Additive Manufacturing to Efficiently Produce High Performance Components from Ti-6Al-4V. Procedia Manuf. 2020, 47, 261–267. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Y.; Li, J.; Cui, D.; Wang, Z.; Wang, J. Microstructure and Mechanical Properties of Forging-Additive Hybrid Manufactured Ti–6Al–4V Alloys. Mater. Sci. Eng. A 2021, 811, 140984. [Google Scholar] [CrossRef]

- Ma, J.; Li, J.; Zhang, Y.; Li, Y.; Wang, Z.; He, F.; Wang, J. Formation Mechanism of Massive Phase in the Heat Affected Zone of Ti-6Al-4V Fabricated by Forging-Additive Hybrid Manufacturing. Opt. Laser Technol. 2023, 157, 108698. [Google Scholar] [CrossRef]

- Yang, Z. Study on Process Parameters and Residual Stress of 316L Stainless Steel Formed by Hybrid Additive Manufacturing by Laser Forging. Master’s Thesis, Guangdong University of Technology, Guangzhou, China, 2019. [Google Scholar]

- Wang, S.; Wang, Z.; Qian, T.; Bu, X.; Chen, B.; Chen, H.; You, F. Microstructure Control and Mechanical Behavior of Bonding Zone of TC4 Titanium Alloy Fabricated by Forging/SLMCombined Manufacturing. New Technol. New Process 2021, 9, 70–75. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Emdadi, A. Development of a Processing Route for Ti-6Al-4V Forgings Based on Preforms Made by Selective Laser Melting. J. Manuf. Process. 2019, 37, 150–158. [Google Scholar] [CrossRef]

- Wu, D.; Yu, C.; Wang, Q.; Niu, F.; Ma, G.; Wang, H.; Zhou, C.; Zhang, B. Synchronous-Hammer-Forging-Assisted Laser Directed Energy Deposition Additive Manufacturing of High-Performance 316L Samples. J. Mater. Process. Technol. 2022, 307, 117695. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, L.; Liu, X.; Li, J. Microstructure and Mechanical Properties of TC4 Alloy Formed by Additive Manufacturing Combined with Forging. Chin. J. Rare Met. 2021, 45, 897–904. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Wang, R.; Shi, J.; Niu, F.; Ma, G. Formation Mechanism of Al-Zn-Mg-Cu Alloy Fabricated by Laser-Arc Hybrid Additive Manufacturing: Microstructure Evaluation and Mechanical Properties. Addit. Manuf. 2022, 50, 102554. [Google Scholar] [CrossRef]

- Gong, M.; Meng, Y.; Zhang, S.; Zhang, Y.; Zeng, X.; Gao, M. Laser-Arc Hybrid Additive Manufacturing of Stainless Steel with Beam Oscillation. Addit. Manuf. 2020, 33, 101180. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, J.; Jia, Z.; Cheng, W.; Wang, J. Research on Laser Additive and Milling Subtractive Composite Remanufacturing Process of Compressor Blade. JMMP 2018, 2, 73. [Google Scholar] [CrossRef]

- Xiong, X.; QIn, X.; Hua, L.; Hu, Z.; Ji, F. Research Status and Development of Hybrid Additive Manufacturing Technology. China Mech. Eng. 2022, 33, 2087–2097. [Google Scholar] [CrossRef]

- Karunakaran, K.P.; Suryakumar, S.; Pushpa, V.; Akula, S. Low Cost Integration of Additive and Subtractive Processes for Hybrid Layered Manufacturing. Robot. Comput.-Integr. Manuf. 2010, 26, 490–499. [Google Scholar] [CrossRef]

- Bruzzo, F.; Catalano, G.; Demir, A.G.; Previtali, B. In-Process Laser Re-Melting of Thin Walled Parts to Improve Surface Quality after Laser Metal Deposition. Key Eng. Mater. 2019, 813, 191–196. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. A Novel Method for Additive/Subtractive Hybrid Manufacturing of Metallic Parts. Procedia Manuf. 2016, 5, 1018–1030. [Google Scholar] [CrossRef]

- LUMEX Avance-25|Hybrid Metal 3D Printer LUMEX Series. Available online: https://www.lumex-matsuura.com/english/lumex-avance-25 (accessed on 17 February 2023).

- Sefene, E.M.; Hailu, Y.M.; Tsegaw, A.A. Metal Hybrid Additive Manufacturing: State-of-the-Art. Prog. Addit. Manuf. 2022, 7, 737–749. [Google Scholar] [CrossRef]

- Yamazaki, T. Development of A Hybrid Multi-Tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. Procedia CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- LASERTEC 125 DED Hybrid. Available online: https://cn.dmgmori.com/products/machines/additive-manufacturing/powder-nozzle/lasertec-125-ded-hybrid (accessed on 14 February 2023).

- Zhang, C.; Dong, Y.; Ye, C. Recent Developments and Novel Applications of Laser Shock Peening: A Review. Adv. Eng. Mater. 2021, 23, 2001216. [Google Scholar] [CrossRef]

- Yuling, W.; Shanyong, L.; Xiangyu, Z.; Yongwu, L.; Rongchao, L. Experiments and Analyses of 3540Fe/CeO2 Coatings by Ultrasonic Vibration Assisted Laser Cladding. China Mech. Eng. 2018, 29, 2600. [Google Scholar] [CrossRef]

- Komarov, S.V.; Kuwabara, M.; Abramov, O.V. High Power Ultrasonics in Pyrometallurgy: Current Status and Recent Development. ISIJ Int. 2005, 45, 1765–1782. [Google Scholar] [CrossRef]

- Suslick, K.S. Applications of Ultrasound to Materials Chemistry. MRS Bull. 1995, 20, 29–34. [Google Scholar] [CrossRef]

- Chen, J.; Yao, Z.; Yao, J.; Liu, Y. State-of-Art Review on Ultrasonic Vibration Assisted Laser Cladding. Aeronaut. Manuf. Technol. 2021, 64, 36–46. [Google Scholar] [CrossRef]

- Nie, X.; Zhou, J.; Xu, J.; Huang, S.; Meng, X.; Huang, L.; Huo, K. Effect of Ultrasound Amplitude on Microstructure and Properties of Laser Cladding WC/IN718 Composite Coatings. Surf. Technol. 2020, 49, 206–214. [Google Scholar] [CrossRef]

- Zhu, L.; Yang, Z.; Xin, B.; Wang, S.; Meng, G.; Ning, J.; Xue, P. Microstructure and Mechanical Properties of Parts Formed by Ultrasonic Vibration-Assisted Laser Cladding of Inconel 718. Surf. Coat. Technol. 2021, 410, 126964. [Google Scholar] [CrossRef]

- Zhou, H.; Song, C.; Yang, Y.; Han, C.; Wang, M.; Xiao, Y.; Liu, Z. The Microstructure and Properties Evolution of SS316L Fabricated by Magnetic Field-Assisted Laser Powder Bed Fusion. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 845, 143216. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Zhang, D.; Bermingham, M.J.; Lui, E.W.; Brandt, M.; StJohn, D.H.; Qian, M. Grain Structure Control during Metal 3D Printing by High-Intensity Ultrasound. Nat. Commun. 2020, 11, 142. [Google Scholar] [CrossRef]

- Cong, W.; Ning, F. A Fundamental Investigation on Ultrasonic Vibration-Assisted Laser Engineered Net Shaping of Stainless Steel. Int. J. Mach. Tools Manuf. 2017, 121, 61–69. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, G.L.; Wang, X.H.; Liu, S.S.; Ying, W.L. Microstructure Evolution and Properties of In-Situ Ceramic Particles Reinforced Fe-Based Composite Coating Produced by Ultrasonic Vibration Assisted Laser Cladding Processing. Surf. Coat. Technol. 2020, 403, 126445. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Brandt, M.; StJohn, D.H.; Qian, M. Grain Refinement of Stainless Steel in Ultrasound-Assisted Additive Manufacturing. Addit. Manuf. 2021, 37, 101632. [Google Scholar] [CrossRef]

- Li, M.; Zhang, Q.; Han, B.; Song, L.; Cui, G.; Yang, J.; Li, J. Microstructure and Property of Ni/WC/La2O3 Coatings by Ultrasonic Vibration-Assisted Laser Cladding Treatment. Opt. Lasers Eng. 2020, 125, 105848. [Google Scholar] [CrossRef]

- Han, X.; Li, C.; Yang, Y.; Gao, X.; Gao, H. Experimental Research on the Influence of Ultrasonic Vibrations on the Laser Cladding Process of a Disc Laser. Surf. Coat. Technol. 2021, 406, 126750. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Y.; Ning, F.; Cong, W. Ultrasonic Vibration-Assisted Laser Engineered Net Shaping of Inconel 718 Parts: Effects of Ultrasonic Frequency on Microstructural and Mechanical Properties. J. Mater. Process. Technol. 2020, 276, 116395. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Y.; Wang, H.; Cong, W. Ultrasonic Vibration-Assisted Laser Directed Energy Deposition in-Situ Synthesis of NiTi Alloys: Effects on Microstructure and Mechanical Properties. J. Manuf. Process. 2020, 60, 328–339. [Google Scholar] [CrossRef]

- Mi, H.; Chen, T.; Deng, Z.; Li, S.; Liu, J.; Liu, D. Microstructure and Mechanical Properties of TiC/TiB Composite Ceramic Coatings In-Situ Synthesized by Ultrasonic Vibration-Assisted Laser Cladding. Coatings 2022, 12, 99. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, M.; Hou, J.; Chen, Y.; Zhang, C.; Cheng, J.; Li, R. Microstructure and High Temperature Properties of Laser Cladded WTaNbMo Refractory High Entropy Alloy Coating Assisted with Ultrasound Vibration. J. Alloys Compd. 2022, 920, 165888. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Marussi, S.; Atwood, R.C.; Towrie, M.; Withers, P.J.; Lee, P.D. In Situ X-Ray Imaging of Defect and Molten Pool Dynamics in Laser Additive Manufacturing. Nat. Commun. 2018, 9, 1355. [Google Scholar] [CrossRef]

- Du, D.; Haley, J.C.; Dong, A.; Fautrelle, Y.; Shu, D.; Zhu, G.; Li, X.; Sun, B.; Lavernia, E.J. Influence of Static Magnetic Field on Microstructure and Mechanical Behavior of Selective Laser Melted AlSi10Mg Alloy. Mater. Des. 2019, 181, 107923. [Google Scholar] [CrossRef]

- Lu, Y.; Sun, G.; Wang, Z.; Zhang, Y.; Su, B.; Feng, A.; Ni, Z. Effects of Electromagnetic Field on the Laser Direct Metal Deposition of Austenitic Stainless Steel. Opt. Laser Technol. 2019, 119, 105586. [Google Scholar] [CrossRef]

- Gao, J.; Han, M.; Kao, A.; Pericleous, K.; Alexandrov, D.V.; Galenko, P.K. Dendritic Growth Velocities in an Undercooled Melt of Pure Nickel under Static Magnetic Fields: A Test of Theory with Convection. Acta Mater. 2016, 103, 184–191. [Google Scholar] [CrossRef]

- Wei, C.; Li, L. Recent Progress and Scientific Challenges in Multi-Material Additive Manufacturing via Laser-Based Powder Bed Fusion. Virtual Phys. Prototyp. 2021, 16, 347–371. [Google Scholar] [CrossRef]

- Functionally Graded Ti6Al4V-Mo Alloy Manufactured with DED-CLAD® Process. Addit. Manuf. 2017, 17, 55–66. [CrossRef]

- Reichardt, A.; Shapiro, A.A.; Otis, R.; Dillon, R.P.; Borgonia, J.P.; McEnerney, B.W.; Hosemann, P.; Beese, A.M. Advances in Additive Manufacturing of Metal-Based Functionally Graded Materials. Int. Mater. Rev. 2021, 66, 1–29. [Google Scholar] [CrossRef]

- Zhang, X.; Chueh, Y.; Wei, C.; Sun, Z.; Yan, J.; Li, L. Additive Manufacturing of Three-Dimensional Metal -Glass Functionally Gradient Material Components by Laser Powder Bed Fusion with in Situ Powder Mixing. Addit. Manuf. 2020, 33, 101113. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H. Additive Manufacturing of Functionally Graded Metallic Materials: A Review of Experimental and Numerical Studies. J. Mater. Res. Technol. 2021, 13, 1628–1664. [Google Scholar] [CrossRef]

- Heer, B.; Bandyopadhyay, A. Compositionally Graded Magnetic-Nonmagnetic Bimetallic Structure Using Laser Engineered Net Shaping. Mater. Lett. 2018, 216, 16–19. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Min, L. Interfacial Characteristic and Mechanical Performance of Maraging Steel-Copper Functional Bimetal Produced by Selective Laser Melting Based Hybrid Manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Li, W.; Karnati, S.; Kriewall, C.; Liou, F.; Newkirk, J.; Brown Taminger, K.M.; Seufzer, W.J. Fabrication and Characterization of a Functionally Graded Material from Ti-6Al-4V to SS316 by Laser Metal Deposition. Addit. Manuf. 2017, 14, 95–104. [Google Scholar] [CrossRef]

- Woo, W.; Kim, D.-K.; Kingston, E.J.; Luzin, V.; Salvemini, F.; Hill, M.R. Effect of Interlayers and Scanning Strategies on Through-Thickness Residual Stress Distributions in Additive Manufactured Ferritic-Austenitic Steel Structure. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2019, 744, 618–629. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, L.; Zhang, S.; Sun, C.; Wang, W.; Yang, G.; Li, Q.; Wei, Y. The Influence of Combined Gradient Structure with Residual Stress on Crack-Growth Behavior in Medium Carbon Steel. Eng. Fract. Mech. 2019, 209, 369–381. [Google Scholar] [CrossRef]

- Meng, W.; Xiaohui, Y.; Zhang, W.; Junfei, F.; Lijie, G.; Qunshuang, M.; Bing, C. Additive Manufacturing of a Functionally Graded Material from Inconel625 to Ti6Al4V by Laser Synchronous Preheating. J. Mater. Process. Technol. 2020, 275, 116368. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Otis, R.A.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; Liu, Z.-K.; Beese, A.M. Additive Manufacturing of a Functionally Graded Material from Ti-6Al-4V to Invar: Experimental Characterization and Thermodynamic Calculations. Acta Mater. 2017, 127, 133–142. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Roberts, S.; Otis, R.; Kolodziejska, J.; Dillon, R.P.; Suh, J.; Shapiro, A.A.; Liu, Z.-K.; Borgonia, J.-P. Developing Gradient Metal Alloys through Radial Deposition Additive Manufacturing. Sci. Rep. 2014, 4, 5357. [Google Scholar] [CrossRef]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.-O.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.-K.; Beese, A.M. Functionally Graded Material of 304L Stainless Steel and Inconel 625 Fabricated by Directed Energy Deposition: Characterization and Thermodynamic Modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- First-Principles Calculations and CALPHAD Modeling of Thermodynamics|SpringerLink. Available online: http://link-springer-com-s.webvpn.stu.edu.cn:8118/article/10.1007/s11669-009-9570-6 (accessed on 9 February 2023).

- Bobbio, L.D.; Bocklund, B.; Otis, R.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; McEnerney, B.; Liu, Z.-K.; Beese, A.M. Characterization of a Functionally Graded Material of Ti-6Al-4V to 304L Stainless Steel with an Intermediate V Section. J. Alloys Compd. 2018, 742, 1031–1036. [Google Scholar] [CrossRef]

- Reichardt, A.; Dillon, R.P.; Borgonia, J.P.; Shapiro, A.A.; McEnerney, B.W.; Momose, T.; Hosemann, P. Development and Characterization of Ti-6Al-4V to 304L Stainless Steel Gradient Components Fabricated with Laser Deposition Additive Manufacturing. Mater. Des. 2016, 104, 404–413. [Google Scholar] [CrossRef]

- Moustafa, A.R.; Durga, A.; Lindwall, G.; Cordero, Z.C. Scheil Ternary Projection (STeP) Diagrams for Designing Additively Manufactured Functionally Graded Metals. Addit. Manuf. 2020, 32, 101008. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D Printing of High-Strength Aluminium Alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Wang, J.; Lin, P.; Liu, H. Microstructure and Mechanical Properties of Functionally Graded TiCp/Ti6Al4V Composite Fabricated by Laser Melting Deposition. Ceram. Int. 2017, 43, 16638–16651. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial Microstructure and Mechanical Properties of 316L /CuSn10 Multi-Material Bimetallic Structure Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, W.; Zhang, Y.; Zheng, Z.; Lai, Y. Hybrid Laser Additive Manufacturing of Metals: A Review. Coatings 2024, 14, 315. https://doi.org/10.3390/coatings14030315

Yue W, Zhang Y, Zheng Z, Lai Y. Hybrid Laser Additive Manufacturing of Metals: A Review. Coatings. 2024; 14(3):315. https://doi.org/10.3390/coatings14030315

Chicago/Turabian StyleYue, Wenwen, Yichuan Zhang, Zhengxin Zheng, and Youbin Lai. 2024. "Hybrid Laser Additive Manufacturing of Metals: A Review" Coatings 14, no. 3: 315. https://doi.org/10.3390/coatings14030315

APA StyleYue, W., Zhang, Y., Zheng, Z., & Lai, Y. (2024). Hybrid Laser Additive Manufacturing of Metals: A Review. Coatings, 14(3), 315. https://doi.org/10.3390/coatings14030315