Abstract

Coating technology, as a part of surface engineering, has shown remarkable potential in future industrial applications. With the continuous development and improvement of coating technology, coatings have gradually become an indispensable part of industrial manufacturing, possessing various excellent properties and characteristics, such as superhydrophobicity and self-cleaning, enhanced biological antibacterial properties, and improved corrosion resistance. Intelligent coatings are not only rigid barriers between substrates and the environment but also coatings designed to respond to the environment and improve coating life or achieve certain special functions through this response. Biomimetics is a discipline that studies the structure, function, and behavior of living organisms and applies them to engineering design. Combining bionics with intelligent coating materials can not only improve the performance and functionality of intelligent coatings but also create more intelligent coating materials. This paper includes advanced superhydrophobic intelligent coatings, anticorrosion intelligent coatings, biological antibacterial intelligent coatings, and other intelligent coatings with specific functions. We also provide a detailed overview of the preparation methods and technologies of various representative intelligent coatings, as well as their properties and applications, which will offer some valuable references for the development direction of future intelligent coatings.

1. Introduction

Intelligent coatings are coatings that can make controllable responses to the environment. Generally speaking, this response requires triggering from the external environment, which includes factors such as moisture, pH, mechanical damage, temperature, redox activity, phase transition, lattice changes, etc. The biggest difference between ordinary coatings and functional coatings is that intelligent coatings not only serve as rigid barriers between substrates and the environment but are also designed to respond to the environment and improve the lifespan of coatings or achieve certain special functions through this response [1]. Firstly, the application fields of intelligent coatings are very extensive [2]. They can be applied in multiple fields such as aerospace, automotive, electronics, medical, and construction. For example, in the aerospace field, intelligent coatings can be used to manufacture intelligent aircraft surfaces [3], improving aircraft performance and safety by adjusting the structure and composition of the coating. In the automotive field, intelligent coatings can be used to manufacture intelligent car surfaces, improving the airtightness and comfort of the car by adjusting the superhydrophobic intelligent coating. In the field of electronics, intelligent coatings can be used to manufacture the surface of intelligent electronic products, improving the performance and aesthetics of electronic products by adjusting the conductivity and transparency of the coating [4]. In the medical field, intelligent coatings can be used to manufacture the surface of intelligent medical devices [5], improving the efficiency and safety of medical devices by adjusting the composition and characteristics of the coating. In the field of architecture [6], intelligent coatings can be used to manufacture intelligent building surfaces, improving building energy efficiency and environmental protection by adjusting the reflectivity and transparency of the coatings. Secondly, the market demand for intelligent coatings is very high. With the increasing emphasis on quality of life and environmental protection, the application scope and market prospects of intelligent coatings are becoming increasingly broad.

Surface hydrophobicity technology is a broad and profound fundamental technology with high practical value, which has a wide range of applications in people’s daily lives [7]. Coatings can provide new additional functions for solid materials by designing different structures and chemical and physical characteristics, especially for the rapidly growing demand for hydrophobic coatings in modern industry, giving the vitality of functionalized hydrophobic coatings. Superhydrophobic coatings are a new surface technology developed on this basis. Superhydrophobic coating is a new type of coating with special surface properties, which refers to a solid coating film with a water contact angle greater than 150° [8]. This special surface property makes it almost impossible for water droplets to adhere when in contact and they can easily roll on its surface. It has important characteristics such as waterproofing, antifog, antisnow, antipollution, antiadhesion, antioxidation, anticorrosion, and self-cleaning, as well as preventing current conduction [9], and has extremely broad application prospects in many fields such as scientific research, production, and daily life.

Due to the irreversibility of traditional metal anticorrosion coatings, once they age and are damaged, their protective effect on the metal substrate will significantly decrease, leading to equipment corrosion failure. Therefore, it is necessary to search for a self-healing coating to enhance the corrosion resistance of the coating and enhance the safety and stability of the metal system [10]. After being damaged by external forces in the environment, intelligent anticorrosion coatings can change the performance of materials and restore or even improve the anticorrosion performance and service life of coatings with minimal human intervention. This has become a hot research topic in the field of metal corrosion protection both domestically and internationally. According to whether intelligent coatings are implanted with external repair agents, they can be divided into external self-healing coatings and intrinsic self-healing coatings. External self-healing coating is a type of coating that encapsulates active repair materials in a certain carrier. When the external environment changes, the active repair material is released to complete the repair of the damaged area. Active repair materials can be mainly divided into two categories: self-healing materials loaded with polymer (healing agents), and self-healing materials loaded with corrosion inhibitors. Compared with external self-healing coatings, intrinsic self-healing coatings use unique chemical bonds or characteristic functional groups between material molecules for repair. According to the type of chemical bond, they can be divided into chemical and physical types of repair. Under external environmental stimulation, damaged parts of the coating can be repaired without the need for external repair agents [11].

Intelligent bactericidal coatings have the characteristics of transparency, colorlessness, and odorlessness and can be applied to various surfaces such as glass, metal, ceramics, wood, concrete, paper, and clothing [12]. The intelligent polymer of the bactericidal coating can quickly react to external contact or contaminated liquids. When hands or dirt come into contact with the surface of the coating, the polymer can sense the temperature of the human body or the moisture in the dirt and automatically release a large amount of disinfectants to kill harmful microorganisms, thereby controlling the spread of diseases. As long as they are simply sprayed on the surface of the object, they can achieve bactericidal function. This intelligent bactericidal coating is superior to traditional bactericidal coatings in that it can continuously and effectively kill bacteria for at least 30 days.

With the development of technology, researchers have now developed many intelligent coatings with specific functions. Intelligent coatings can be divided into two categories based on triggering factors: external triggering and internal triggering. External triggering includes touch-sensitive, photochromic, thermochromic, self-healing, and shape memory materials, while internal triggering includes antifouling, antireflection, radar wave absorption, self-stratification, and conductivity. According to their usage functions, intelligent coatings are also divided into thermochromic coatings, flame-retardant warning intelligent coatings, marine environment intelligent antifouling coatings, intelligent thermal control coatings, etc. [13,14].

2. Research Progress in Intelligent Coatings

2.1. Intelligent Superhydrophobic Coating

Superhydrophobic coating is a new type of coating technology that can make the surface of objects extremely difficult to be wetted by water and even form spherical water droplets on the surface, thereby achieving self-cleaning, pollution prevention, and other functions. The principle of superhydrophobic coatings is mainly based on the design and preparation of surface micro–nanostructures. Surface micro–nanostructure refers to the specific micro- and nano-level structures on the surface of the material, which endow the material with different functional characteristics. Forming micro–nanostructures on the surface of an object can make the surface rough, thereby increasing the surface area and contact angle of water droplets on the surface and achieving superhydrophobic effects. These structures typically have regular textures and a certain periodicity, achieving specific functions through different sizes and arrangement combinations [15].

2.1.1. Research Progress

Cho E.-C. synthesized transparent and superhydrophobic siloxane-based nanocomposites. The synthesized superhydrophobic nanoparticles had a high dispersibility and uniform particle size distribution in alcohol solvents and can be easily integrated into the solution. Nanoparticles of high dispersion and uniform particle size can improve the surface roughness of superhydrophobic materials, thereby enhancing the hydrophobic properties. The superhydrophobicity of the composite material was further improved through chemical modification with fluorosilane. The cast mixed surface exhibited transparent properties, superhydrophobicity, and non-sticking on various substrates. In addition, after 90 days of weather resistance testing, the superhydrophobic coating can maintain its extreme water repellency, while water contact angle (WCA) did not significantly decay. This simple and low-cost method provides a valid strategy and bright industrial applications for manufacturing superhydrophobic surfaces [16,17,18,19,20].

Feng G.N. prepared an epoxy fabric coating with high-quality antifouling properties and hydrophobicity using epoxy resin (EP), octadecylamine, and polytetrafluoroethylene (PTFE) particles through a feasible dip-coating method. The surface morphology and wettability of hydrophobic fabrics were characterized using a scanning electron microscope and a contact angle tester. The effects of additive amount and impregnation time on the hydrophobicity of fabric coatings were analyzed. After determining the optimal process conditions, oil–water separation efficiency and the stability of hydrophobic fabrics were investigated [21,22,23,24].

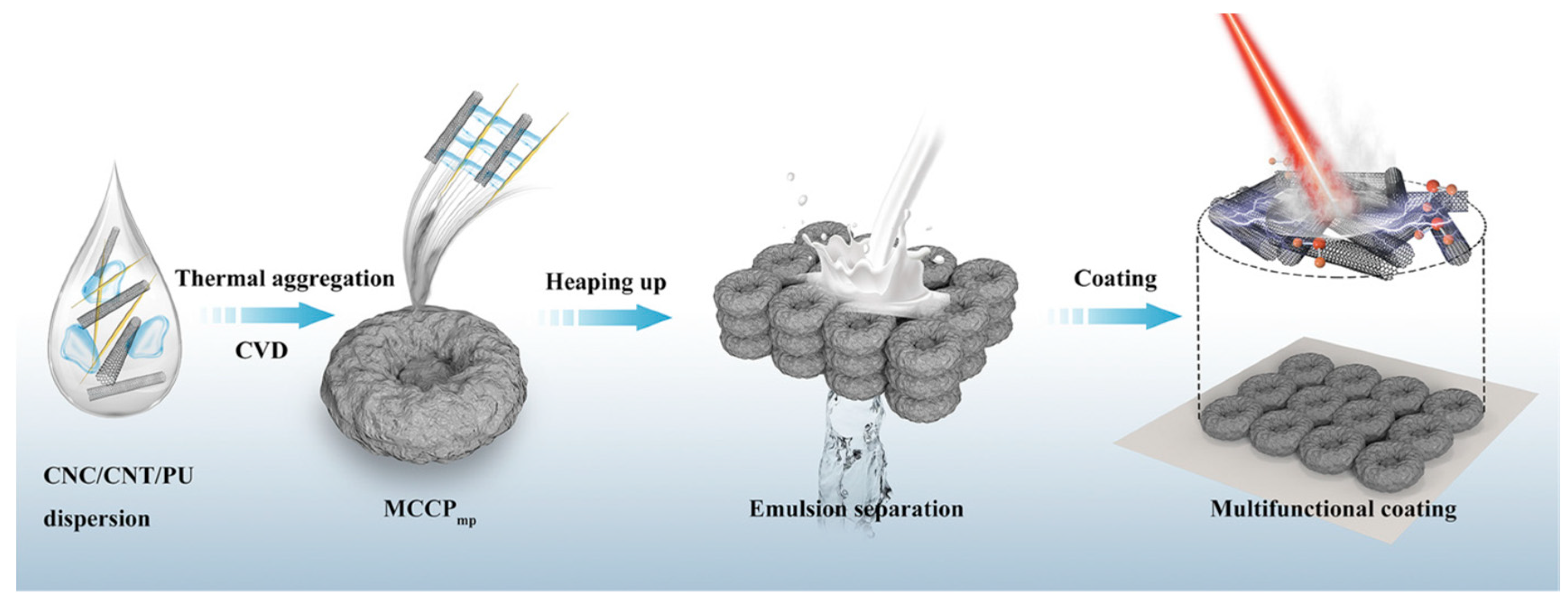

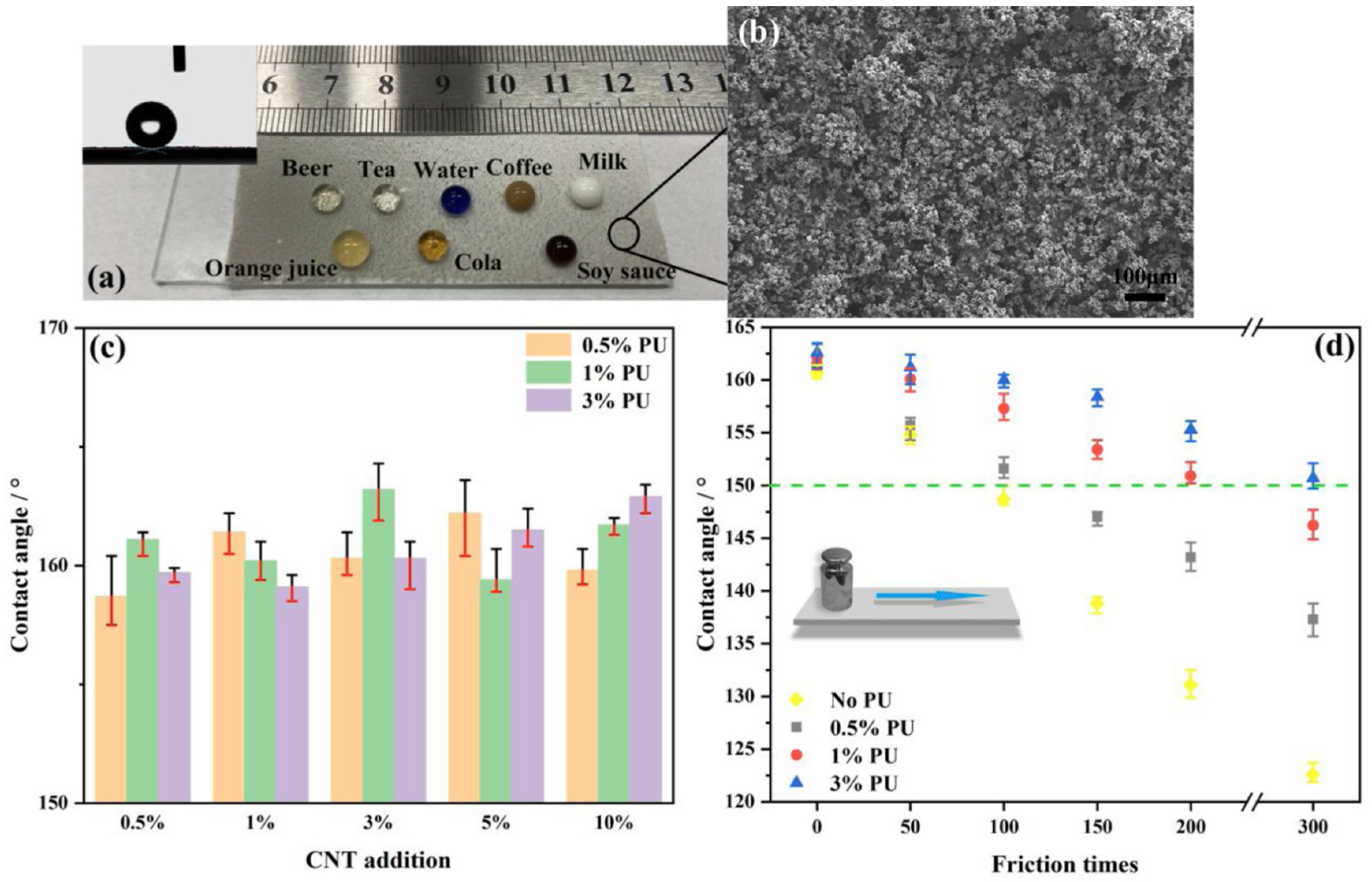

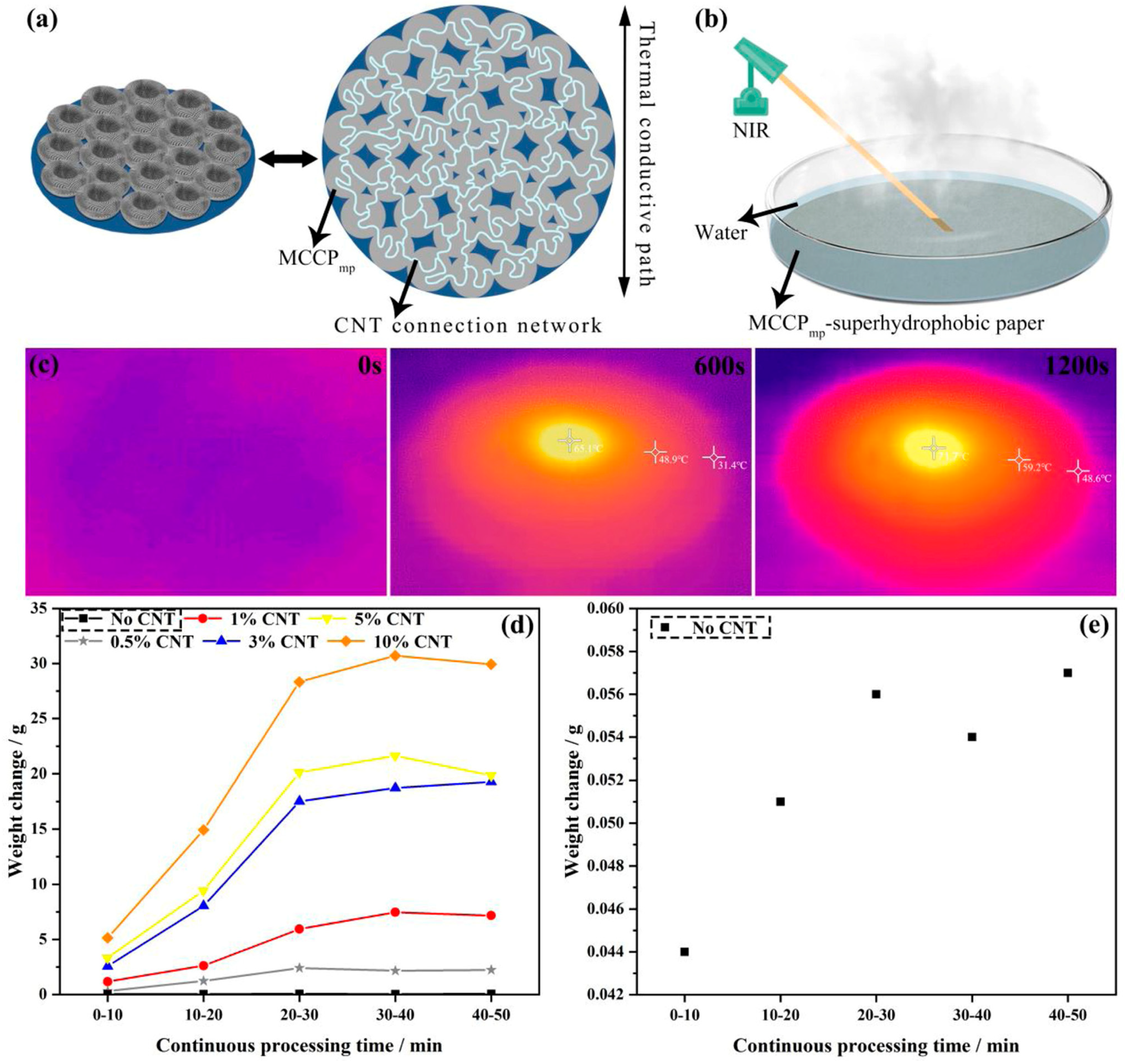

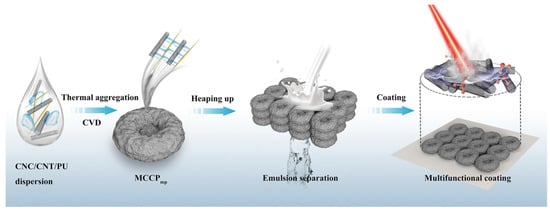

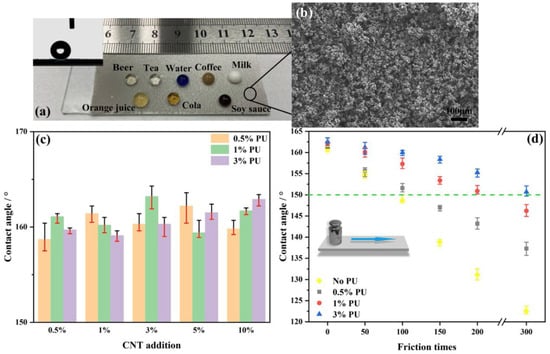

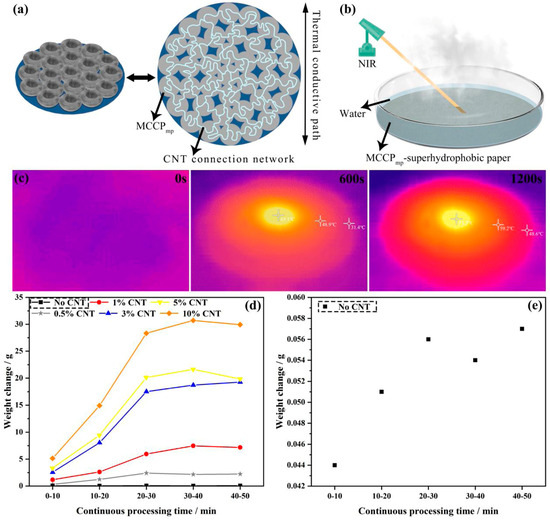

The uniform structure of carbon nanotubes (CNTs) and cellulose nanocrystals (CNCs) was achieved by Zhu Z. using spray drying to obtain rough annular particles with a hierarchical two-dimensional structure. The characteristics and structure of CNC are crucial for superhydrophobic modification and particle assembly (Figure 1). Polyurethane (PU) can be used to strengthen the hardness of particles during the thermal aggregation process. The studied CNC/CNT/PU particles exhibited an excellent separation property for water in oil lotion (Figure 2 and Figure 3) [25,26,27,28].

Figure 1.

Schematic presentation of the preparation process of the multifunctional and robust nanocellulose-based superhydrophobic coating for rapid and intelligent water removal [25]. Copyright 2020. Reproduced with permission from Elsevier.

Figure 2.

(a) Droplets of common liquids maintain a spherical shape on MCCPmp-superhydrophobic paper, which shows its great superhydrophobic properties. (b) The SEM image of surface of MCCPmp-superhydrophobic paper indicates dense packing of MCCPmp on paper. (c) CA of different MCCPmp-superhydrophobic papers. (d) Abrasion resistance test result of MCCPmp-superhydrophobic paper [25]. Copyright 2020. Reproduced with permission from Elsevier.

Figure 3.

(a) Schematic diagram of thermal conductive network. (b) Schematic diagram of fast and intelligent water removal. (c) Thermal images of MCCPmp-superhydrophobic paper under NIR. (d) Water-removing efficiency of MCCPmp-superhydrophobic paper under NIR and its enlarged picture for “No CNT” (e) [25]. Copyright 2020. Reproduced with permission from Elsevier.

Lili manufactured an intelligent superhydrophobic coating that can respond to stretching and bending by dispersing multiwalled carbon nanotubes in a thermoplastic elastomer solution for spraying. This intelligent coating is particularly suitable for flexible sensors [3,29,30,31].

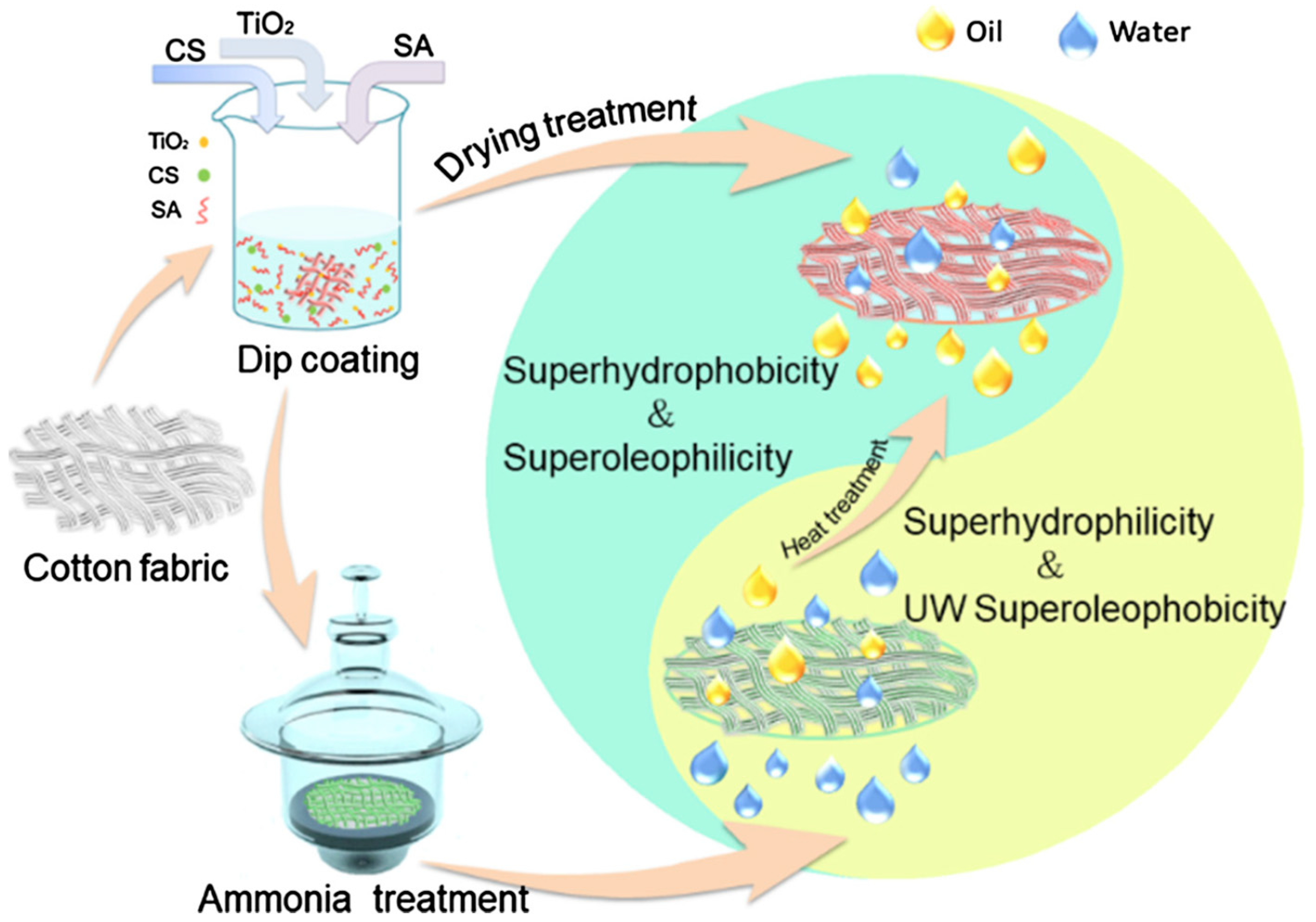

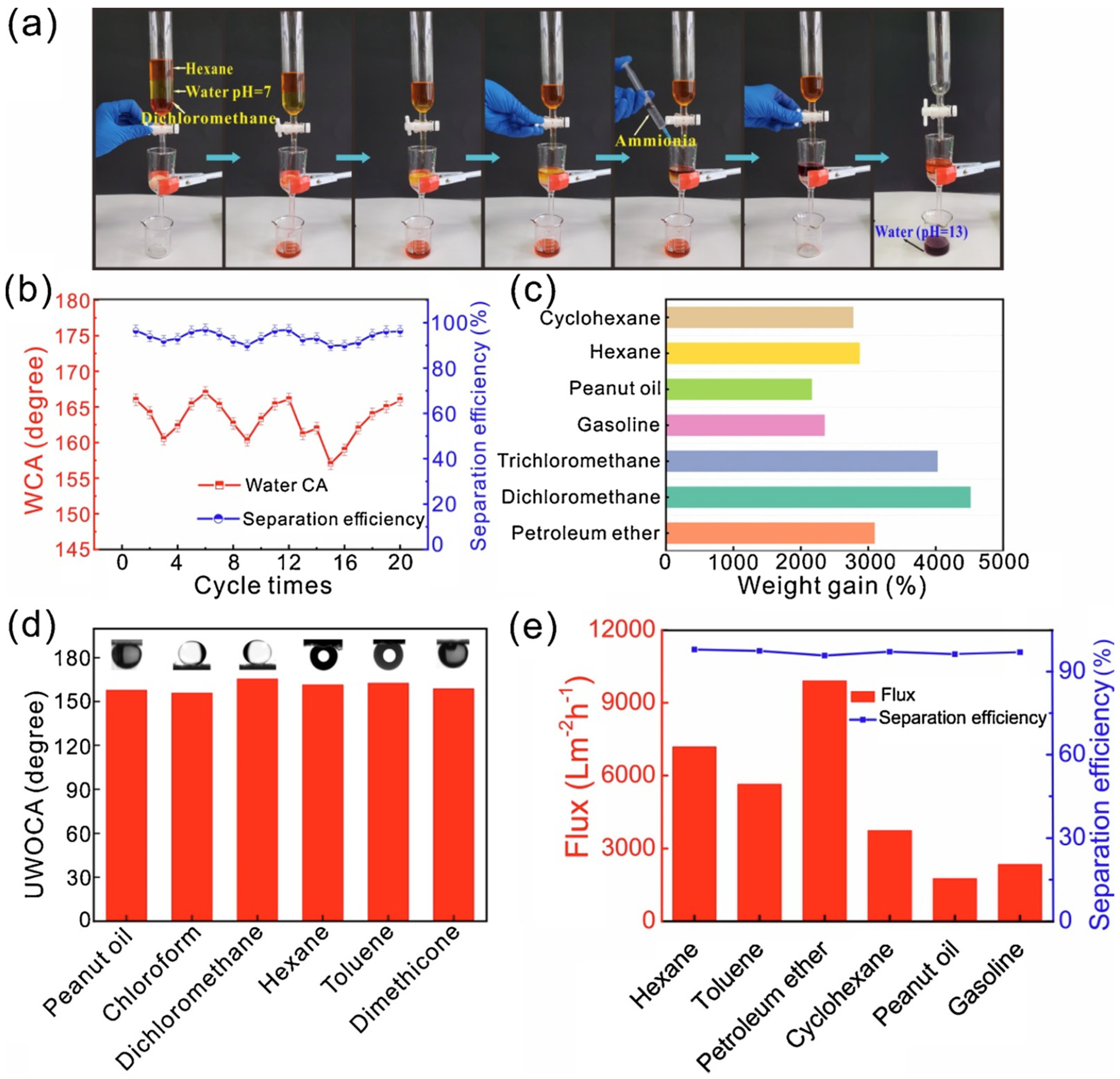

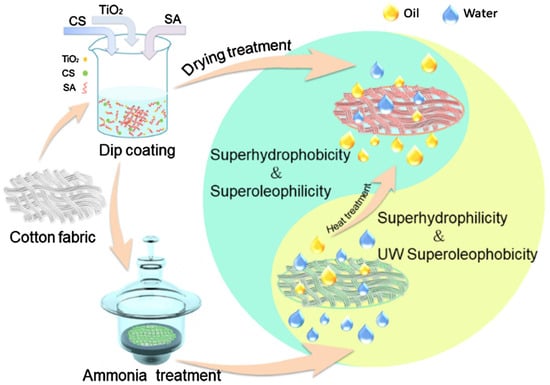

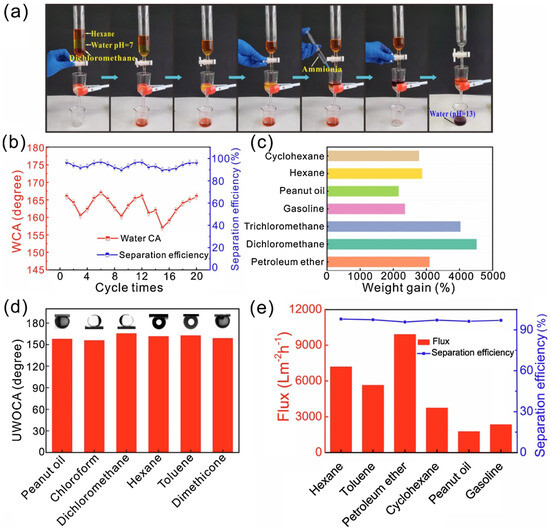

Intelligent response materials with tunable wettability surfaces that change with the environment are of great significance in oil–water separation. Jinping Ren prepared a unique pH-responsive bio-based oil–water separation material. Environmentally friendly chitosan (CS), stearic acid (SA), and low-cost titanium dioxide (TiO2) were used to form superhydrophobic TiO2@SA/CS coating. Under ammonia treatment, the coating material can transform from superhydrophobic to superhydrophilic, and the superhydrophobicity was restored through heating treatment (Figure 4). The stimulus response surface of this material was used to separate oil/water/oil mixtures and effectively separate various surfactant-stabilized oil in water lotions and water-in-oil emulsions before and after the wettability conversion (Figure 5). These results will provide new prospects for the exploration of intelligent responsive water–oil separation materials [32,33,34,35].

Figure 4.

Schematic illustration of the fabrication process of the pH-responsive coated materials using cotton fabric as an example and the transformation of wettability between superhydrophobicity and underwater (UW) superoleophobicity by ammonia and heating treatment [32]. Copyright 2020. Reproduced with permission from Elsevier.

Figure 5.

Schematic diagram of successive separation of oil/water/oil three-phase systems (a). Water contact angle and separation efficiency of modified superhydrophobic cotton fabric in multiple oil/water separation experiments (b). Absorption capacity of modified sponge for various oils and organic liquids (c). UWOCA of modified cotton treated with ammonia for different organic liquids (d). The flux and separation efficiency of modified cotton fabric after ammonia treatment in a variety of oil/water mixture separation experiments (e) [32]. Copyright 2020. Reproduced with permission from Elsevier.

Liu J. developed an efficient and simple photopolymerization induction method to prepare superhydrophobic surfaces containing graphene oxide and silica nanoparticles. Superhydrophobic surface materials had the characteristic of maintaining an air gap between solid substrates and corrosive liquids. In addition, this method is fast and inexpensive; consequently, it may lead to the expansion of future metal substrate applications [36,37,38,39,40].

Preparing efficient, hydrophobic, and soft environmentally friendly flame-retardant coatings for cotton fabrics is an urgent task, but it still faces challenges. Here, based on tannic acid (TA), biological phytic acid (PA), and vinyl trimethoxysilane (VTS), Rao W. constructed a fireproof and environmentally friendly hydrophobic coating on cotton fabric by a one-pot sol–gel method. This system used VTS as the silicon source, TA as the carbonizing agent, and PA as the acid source to construct a silicon/nitrogen/phosphorus high-efficiency composite flame-retardant system. In addition, TA can be reacted with VTS and PA, greatly reducing hydrophilic groups in the sol–gel process, and the hydrophobic vinyl functional groups can further change the hydrophilic surface into a hydrophobic surface on cotton fabric with a large water contact angle (117.2 degrees). Furthermore, the physical performances of the obtained cotton fabric hardly changed. This work provided a new perspective for the preparation of hydrophobic coatings with satisfactory environmental friendliness, flame retardancy, and flexibility [41,42,43,44].

2.1.2. The Advantages and Challenges of Intelligent Superhydrophobic Coatings

Both advantages and challenges exist in the further development of superhydrophobic coatings. Firstly, they have self-cleaning ability, which can prevent dust and stains from adhering, thus maintaining surface cleanliness. With anti-icing, antifog, antibacterial, and antifouling properties, superhydrophobic coatings have broad application prospects in multiple fields, such as aerospace, transportation, electronics and electrical, and daily life. These coatings usually have good durability, can resist long-term erosion and wear, reduce the need for frequent cleaning, and also help to save water resources and reduce energy consumption. Secondly, the production cost of superhydrophobic coatings is high, and the manufacturing process is complex, resulting in high prices. In addition, the fine and rough structures on these surfaces are easily damaged during processing and use, especially under impact or friction. Moreover, the fine structures on these surfaces are prone to accumulate dust and oily substances, leading to performance degradation.

2.2. Anticorrosion Intelligent Coating

Metal corrosion can lead to direct loss of metal materials, with approximately 100 million tons of metal scrapped due to metal corrosion worldwide each year, accounting for 20% to 40% of annual production. Metal corrosion may lead to the leakage of toxic substances, thereby polluting the environment and endangering human health. Traditional metal materials, especially steel, with various advantages such as abundant reserves, relatively low prices, mature technology, and acceptable performance, have been widely used in the shipbuilding industry, military manufacturing, municipal facilities, and other fields. However, a prominent issue attributed to high chemical and electrochemical activity leads to higher corrosion sensitivity, which greatly limits their application in corrosive environments. Therefore, scientists have invested themselves in long-term efforts to design and develop more environmentally friendly coatings as a benign alternative with equal or higher corrosion resistance [45].

2.2.1. Research Progress

Zhong X. reported a simple process of zinc coating using atmospheric plasma spraying (APS) technology. The zinc coating prepared at the optimal spraying current of 120A exhibited excellent structural characteristics, with high adhesion strength and low porosity. There was no significant corrosion damage on the surface in a NaCl solution immersion test. Owing to low self-corrosion potential and the isolation effect of zinc coatings, they can protect steel from corrosion damage and exhibit excellent anticorrosion performance [46,47].

Re G. studied the anticorrosion property of three kinds of protective coatings, which are derived from ethyl silicate (TEOS), polysilazane (PHPS), and calcium phosphate (CaP) minerals. These coatings have been applied to diverse materials that are part of carbonaceous and siliceous rock formations. TEOS coatings and CaP mineral were applied by immersing the sample in a specialized solution bath, while polysilazane was applied to the surface through spray and brush-coating techniques. The original and coated samples were analyzed using SEM/EDX and FTIR. Corrosive agents were used to test corrosion resistance of the coating samples in harsh acidic environments. The main results indicated that samples treated with inorganic PHPS provided a relatively high level of protection against acidic corrosion compared to other protective coatings [48,49].

Natural inspiration has led to the widespread development of biomimetic non-shrub surfaces, and intelligent self-healing technology is moving towards metal corrosion protection. Dan Jiang designed a new anticorrosion system consisting of lubricant, layered double hydroxide (LDH) film, and plasma electrolytic oxidation (PEO). The PEO coating grown in situ on magnesium alloys can provide a moderate corrosion barrier, while the LDH coating sandwiched in the middle combined the ternary effects of sealing PEO defects, anchoring lubricants, and loading corrosion inhibitors. The outermost smooth surface exhibited persistent repellency to water and self-healing ability against surface damage. The sturdy and self-healing film barrier combined with active corrosion inhibitors gave the system excellent anticorrosion performance. The dynamic self-repairing processes related to corrosion inhibition and barrier regeneration were verified at the microscale by scanning vibration electrode techniques and scanning Kelvin probes, respectively. This study is expected to provide reference for the exploration of versatile anticorrosion systems for magnesium alloys [50,51,52].

In order to improve the contact corrosion between steel rivets and magnesium alloy automotive parts during cold connection, a polytetrafluoroethylene (PTFE) and microarc oxidation (MAO) composite coating (PTFE-MAO) was prepared on 10B21 steel in an electrolyte composed of phosphate and aluminate. Because of the electrostatic adsorption of cations and anions, the discharge channel was drilled into by the anionic surfactant taking PTFE, playing a role in blocking the pores. The results indicated that the PTFE had a significant impact on the corrosion performance, surface microstructure morphology, and phase composition of MAO coatings. It significantly improved the hydrophobicity, wear resistance, and corrosion resistance of the coating. This method offered a reference for processing multifunctional anticorrosion coating materials on steel substrates [53,54,55].

Due to poor barrier properties, ordinary coatings fail to have satisfactory anticorrosion performance over a long period of time. Guo H. prepared LDH-MoO42-nano filler (KGO@LM) that was modified by GO and KH-570 in order to enhance the performance of corrosion resistance of epoxy resin (EP) coatings for a long time. The filler not only had favorable compatibility and dispersion in EP but also had characteristics of self-repair, barrier, and chloride ion trapping. The comparison experiment proved that the filler added with KGO@LM greatly improved the anticorrosion effect of EP coating. The significant sustained-release effect was demonstrated through sodium chloride immersion experiments [56,57,58,59,60].

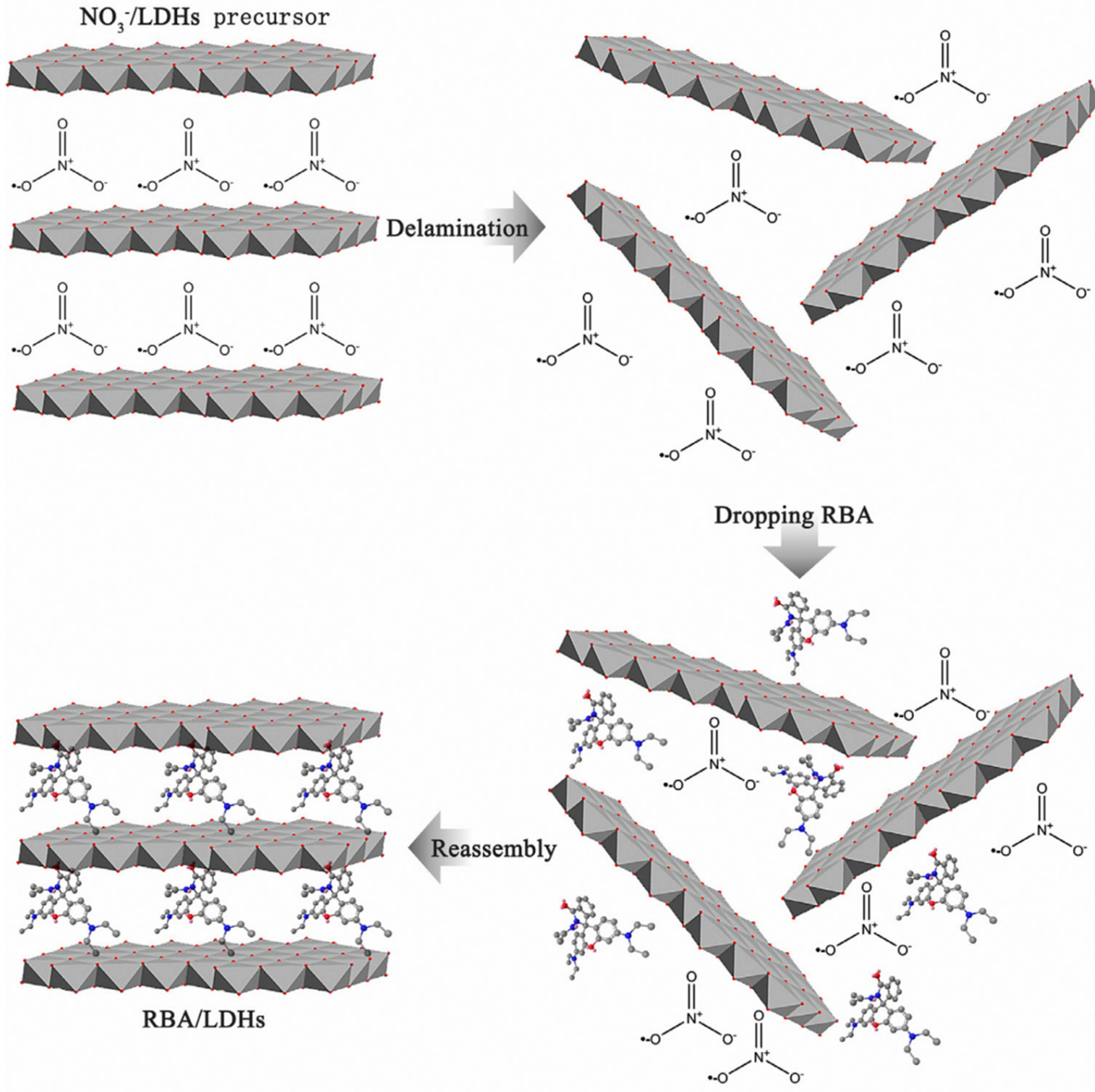

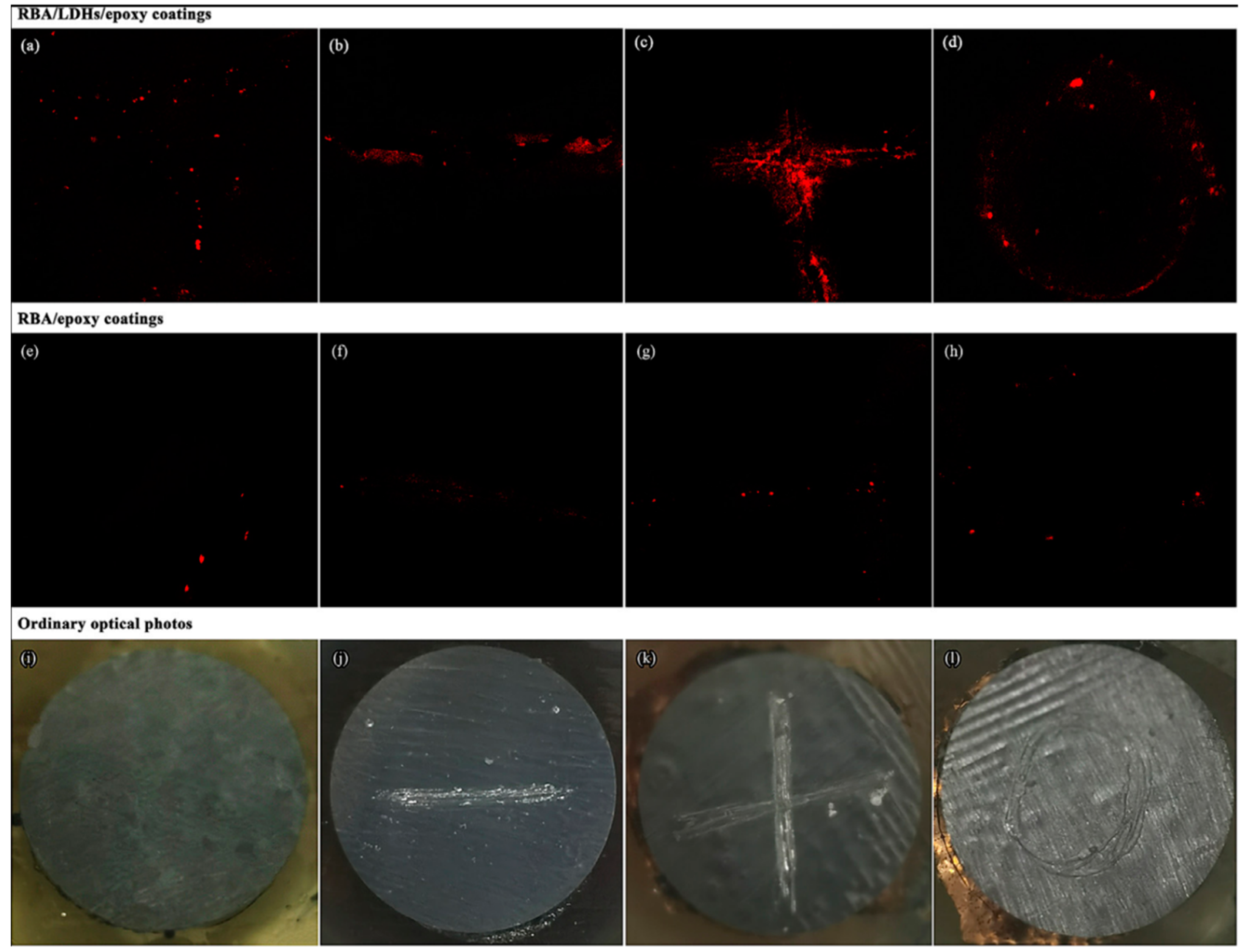

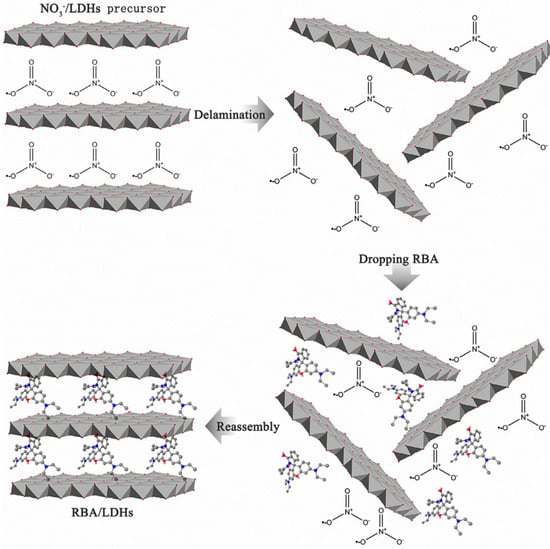

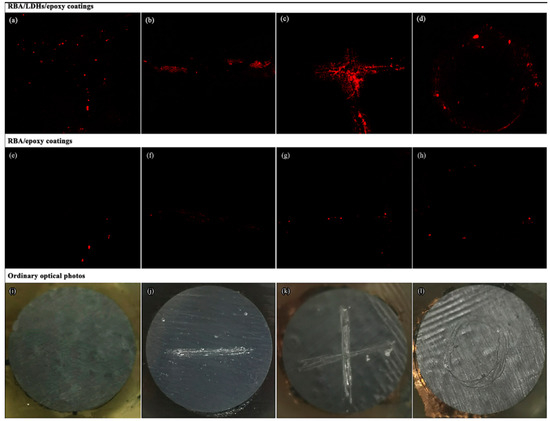

The early defects and corrosion below the anticorrosion coating of metal engineering structures are concealed. The corrosion has seriously developed once the corrosion is visible to the naked eye. Therefore, Lv J prepared iron-ion and proton-responsive fluorescent switch probes, Rhodamine B acyl hydrazone (RBA), to detect early corrosion of metals at the defects and under coatings. Layered double hydroxides (LDHs) can protect RBA from the effects of fluorescence quenching and from exposure to corrosive environments prematurely. In the presence of corrosive Cl−, the RBA carried by LDHs was exchanged with Cl− in the corrosive environment and, as a result, the RBA was released and Cl− was embedded and carried between the LDH layers (Figure 6). In epoxy coatings, RBA/LDHs demonstrated the occurrence of corrosion in the form of fluorescence and accurately located coating defects and corrosion sites. Meanwhile, the dispersed distribution and flaky morphology of RBA/LDHs enhanced the shield capability of the coating (Figure 7) [59,61].

Figure 6.

The preparation process of supramolecular RBA/LDHs [61]. Copyright 2021. Reproduced with permission from Elsevier.

Figure 7.

Corrosion detection performance and ordinary optical photos of RBA/LDHs/epoxy coatings and RBA/epoxy coatings: (a,e,i) coating sample with accelerated corrosion by polarization; (b,f,j) defective coatings with “-”-shaped scratch; (c,g,k) defective coatings with X-shaped scratch; (d,h,l) defective coatings with O-shaped scratch [61]. Copyright 2021. Reproduced with permission from Elsevier.

From the fluorescence photos, it can be seen that the RBA/LDHs in the coating effectively indicated the occurrence of corrosion under the coating and correctly located the corrosion site.

The layered double hydroxide (LDH) container layer was obtained on magnesium alloy by in situ hydrothermal growth, and then the outer layer of bioactive glass was covered by sol–gel spin LDH/bioactive glass (Bg) coating. The stimulation-triggered release experiment was used to study the ion exchange capacity of the LDH container layer. The electrochemical corrosion test showed that the layer delayed the onset of corrosion, reducing the corrosion current. In addition, mineralization evolution and corrosion degradation in vitro indicated that when LDH containers were coupled with bioactive glass and encapsulated with fluoride, clear self-healing effects and synergistic mineralization can be achieved. Specifically, self-healing was achieved by the formation of stable magnesium fluoride or fluorapatite in the erosion pit through the local redeposition of dissolved Ca2+ and the degradation product Mg2+ with displaced F ions. This two-stage strategy was intelligent and gradually delayed rapid degradation while promoting remineralization, which provided a universal approach for designing intelligent anticorrosion coatings or targeted drug delivery systems [62,63].

Kumar G.S. introduced a shape memory alloy (SMA) material with favorable anticorrosion properties that worked in the form of corrosion inhibitors. Only when corrosion occurred on the metal surface would the intelligent coating react, which extended the service life of the protective coating and effectively prevented corrosion [64].

Water-based anticorrosion coatings present poor water tolerance, which can easily lead to coating degradation and metal corrosion. A layer-by-layer construction method was used to prepare epoxy resin/polytetrafluoroethylene/dimethyl siloxane (EP/PTFE/PDMS) hydrophobic anticorrosion coatings in order to improve the anticorrosion performance of water-based coatings. The spatial structure and microstructure of hydrophobic coatings were determined by FTIR, XRD, and SEM. The corrosion resistance and hydrophobicity of the composite coating were assessed through hydrophobicity testing, mixed layer hydrophobicity and corrosion resistance testing, electrochemical polarization curves, AC impedance spectroscopy, and Tafel polarization curves. The results indicated that the corrosion process was still in the initial stage, mainly due to the good barrier and sealing performance of EP/PTFE/PDMS coating, as well as its high anticorrosion efficiency. This coating had a long service life and high anticorrosion efficiency, which was of great significance for metal anticorrosion in harsh marine environments [65,66].

In order to acquire a high-anticorrosion coating, avoid the disadvantages of epoxy resin (EP) such as losing mechanical properties, and improve physical shielding of ultraviolet (UV) radiation, Sun Y reported an intelligent composite coating method. Higher valance state Ce ion intercalated montmorillonite (M-Ce) offered reactive places for 2-fluoroaniline polymerization (PFA) and nanohybrids (PFAM-Ce) were used as valid additives to upgrade the corrosion and UV resistance of EP coatings. Compared with traditional epoxy-based composite materials, the corrosion resistance of functionalized MMT-based EP composite materials under ultraviolet radiation was significantly improved. The results indicated that PFAM-Ce was uniformly dispersed on the fracture surface of the mold coating, which can provide anodic protection, cathodic suppression, and physical shielding for the steel substrate. This new approach improved the UV resistance of epoxy coatings, revealing the importance of functionalized polyaniline in UV resistance and corrosion prevention [67,68].

The pH-responsive nanocontainer based on zeolite imidazolium salt frame-8 (ZIF-8) provides a new way to endow sol–gel anticorrosion coating with self-healing ability. However, ZIF-8-based nanocontainers make them poorly compatible with inorganic sol–gel coating substrate, so they are ineffective in anticorrosion. Huang Y introduced a new pH-responsive inhibitor release system (BTA-ZIF-8@SiO2) that was self-repairing sol–gel anticorrosion coating based on ZIF-8. A simple one-step self-assembly process was used to prepare a 1H benzotriazole (BTA)-encapsulated ZIF-8 core, and then a layer of silica was coated on it by a standard sol–gel method. The silica shell was able to provide better compatibility between the nanocontainer and the sol–gel matrix, thus enhancing the overall anticorrosion performance. The results revealed that BTA-ZIF-8@SiO2 can effectively improve the anticorrosion performance of the coating and show excellent self-repairing performance. This may be due to the enhanced passive protection, improved compatibility of the nanocontainer with the sol–gel matrix, and the synergistic effect of the inhibitor film formed on the metal surface [69].

Silva P.F.B. reported a strategy of using reduced graphene oxide (rGO) coating to protect sintered copper metal powder from corrosion by addressing the recurring galvanic corrosion problem of graphene. A layer of silane molecules, (3-aminopropyl) triethoxysilane (APTES), was deposited between the graphene oxide (GO) and pure Cu particles as a primer to enhance adhesion and an insulating intermediate layer to prevent the direct contact between Cu and conductive rGO, reducing galvanic corrosion. Due to the core–shell coating, rGO was uniformly distributed in Cu matrix after sintering, avoiding the aggregation of rGO, that occurs in traditional GO-Cu composite materials. The constant current polarization test by Tafel analysis showed that the dual coating of silane and GO improved the anticorrosion performance of the bulk sample [70].

Polyurethane coatings are good choices for protecting various structures owing to their unique properties. In order to enhance their barrier behavior against corrosive substances, different nanoparticles have been inserted into polymer coatings. Darabinajand B. modified ZSM-5 zeolite nanoparticles with graphene oxide. Fourier transform infrared spectroscopy and field emission scanning electron microscopy were used to characterize GO-modified and unmodified ZSM-5 zeolites. The effect of a GO-modified ZSM-5 molecular sieve on the anticorrosion performance of polyurethane (PU) coatings was evaluated through pull-off testing, Tafel polarization, and electrochemical impedance spectroscopy. GO-modified ZSM-5 zeolite had a significant impact on the anticorrosion performance of nanozeolite in polyurethane coatings. Among all kinds of PU coatings, the PU/ZSM-5-GO coating on low-carbon steel exhibited the best protective performance against active corrosion species [71].

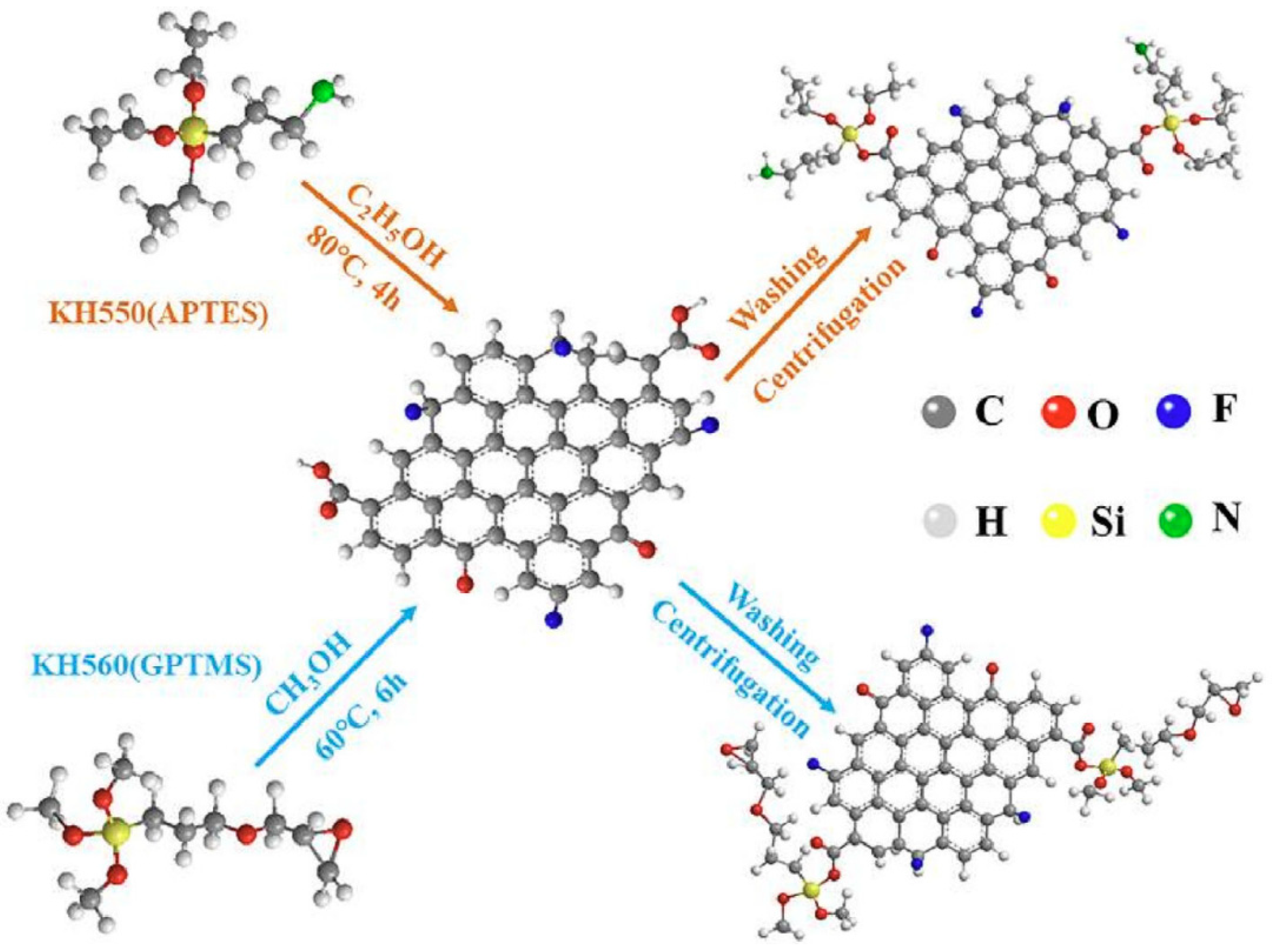

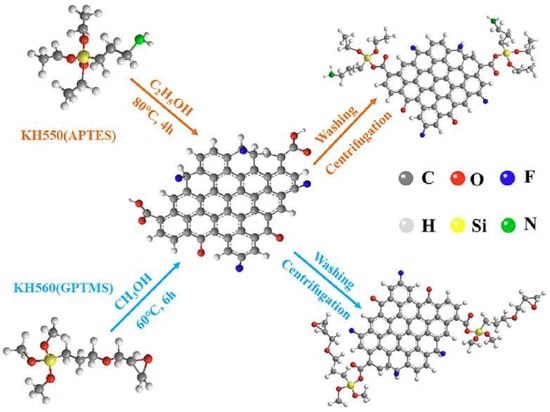

Fluorinated graphene (FG), as a derivative of graphene, possesses excellent insulation properties, but its dispersibility in organic coatings remains a difficulty in anticorrosion applications. Lin X proposed a simple method to effectively strengthen the dispersibility of FG and enhanced its interfacial compatible ability with epoxy resin. FG was modified with epoxy-terminated 3-glycidyloxypropyltrimethoxysilane (GPTMS) and amino-containing 3-aminopropyltriethoxysilane (APTES) (Figure 8). The results indicated that silane coupling agent significantly improved the dispersion ability of FG in epoxy coatings and enhanced the interfacial interaction between epoxy resin and FG, thus improving the barrier performance of epoxy coatings and stopping the penetration of corrosive media [72,73,74].

Figure 8.

Schematic representation of the reactions between FG and the silane coupling agents, APTES and GPTMS [72]. Copyright 2023. Reproduced with permission from Wiley.

Cao K. prepared a double hydroxide with F embedding (LDH-F) of a superhydrophobic MgAl layer by further modifying the anion of stearate (St). Then, the composite material was dispersed in epoxy resin to fabricate an anticorrosion coating for the corrosion protection of magnesium alloys. Firstly, the superhydrophobic membrane hindered the penetration of water molecules into the magnesium matrix. Secondly, the excellent anion exchange capability of LDH was able to be used to store chloride ions. Finally, the layered structure of LDH itself served as a physical barrier. The results indicated that the superhydrophobic layered coating (LDH-F-St-EP) exhibited good anticorrosion performance [75,76].

Wang J.J. successfully assembled a novel triple stimulus-responsive (acid/base/corrosion potential) intelligent nanocontainer (TSR-SNs) by installing a special structure of bistable pseudorotaxanes as supramolecular nanovalves on the pores of mesoporous silica nanoparticles to regulate the release of encapsulated corrosion inhibitor benzotriazole (BTA). Under any stimulation of alkali, corrosion potential, or acid, BTA molecules were rapidly released due to the open state of supramolecular nanovalves. TSR-SNs were added into SiO2-ZrO2 sol–gel coating as intelligent nanocontainers, and a self-repairing anticorrosion coating (SF-SHAC) with stimulus feedback and corrosion compensation was prepared [77].

Huang Y. prepared a new self-repairing shape memory polymer (SMP) film by incorporating dual functional microspheres containing corrosion inhibitor 8-hydroxyquinoline (8HQ) and polycaprolactone to protect the 2024-T3 aluminum alloy from corrosion [78].

Wang M.D. prepared hollow mesoporous silica nanoparticles (HMSNs) using a hard template method, which have been used as nanocontainers for the preservative benzotriazole. In the mixed zirconia silica sol–gel coating, an equal amount of acid- and alkaline-responsive nanocontainers were evenly distributed, thus forming an intelligent anticorrosion coating. Compared with the undoped coating, the sol–gel coating that was doped with pH-responsive nanocontainer showed obvious long-term anticorrosion performance [79].

Wang J. developed an intelligent coating based on mesoporous silica nanoparticles (MSN) containing 1,10-phenanthroline-5-amine (Phen-NH2) and hexadecyltrimethylammonium bromide (CTAB), which combined sensitive self-report and high-performance self-healing capabilities. In the obtained nanocontainers of MSN-PC, Phen-NH2 served as both a corrosion inhibitor and a color developer, while CTAB served as both a template and a corrosion inhibitor. The synthesis of MSN-PC adopted a one-step method, with high encapsulation degree. Phen-NH2 and CTAB both exhibited accelerated release behavior of MSN-PC induced by pH changes. Intelligent coatings achieved sensitive corrosion visualization and significantly delayed corrosion degradation, with enormous potential for long-term corrosion protection [80,81].

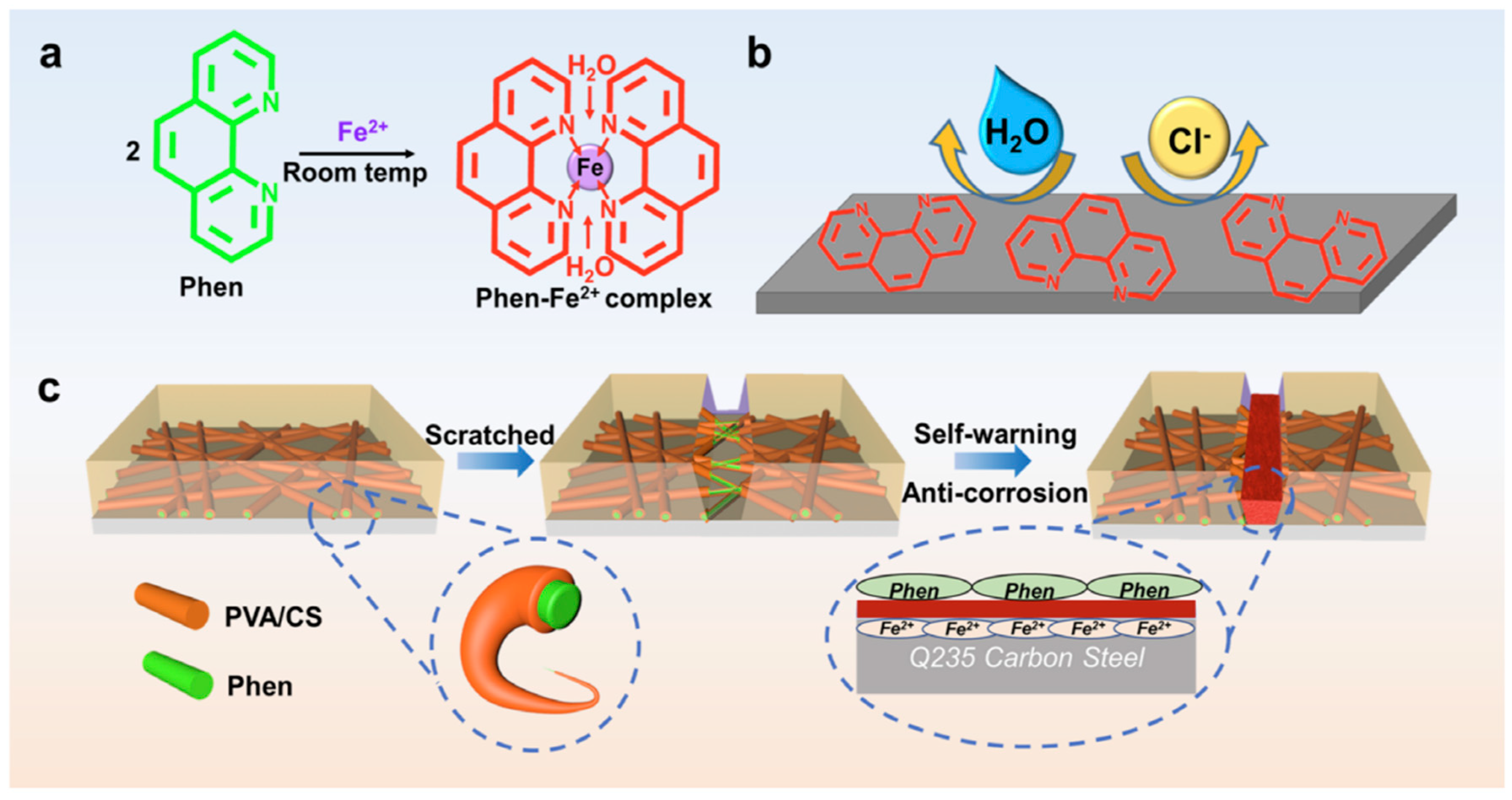

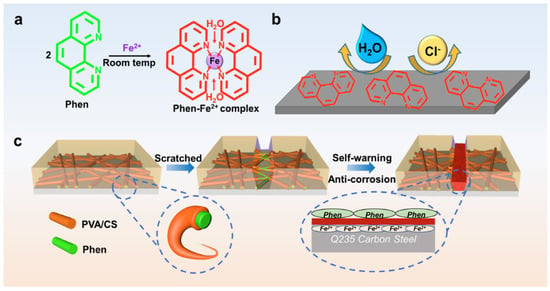

Cao L. reported an intelligent protective coating with warning and healing functions, which was achieved by inserting bifunctional nanofibers comprising 1, 10-phenanthroline (Phen) into the organic coatings. The nanofibers, consisting of a core (Phen) and a shell (poly-vinyl alcohol chitosan blend solution), were fabricated by coaxial electrospinning. The nanofiber-embedded coating (PVA/CS@Phen) exhibited self-repairing and high contrast damage area indication functions. This intelligent coating displayed high healing properties under artificial injuries and had the characteristic of self-warning, and the healing rate reached about 98.4% without external interference (Figure 9) [81,82].

Figure 9.

Schematic of the self-warning and self-healing synergetic process of the composite coatings loaded with PVA/CS. (a) The structure of Phen, (b) Phen is an excellent and stable π electron acceptor, and its adsorption on the surface of carbon steel follows the Langmuir adsorption isotherm. (c) Within seconds of contact with Fe ions, the color changes from yellow to red to achieve the purpose of naked-eye observation [82]. Copyright 2022. Reproduced with permission from ACS.

2.2.2. The Advantages of Intelligent Anticorrosion Coatings

- Long-term protection of metal surfaces from corrosion: Anticorrosion coatings can provide long-term protection to metal surfaces, preventing them from being affected by chemical reactions such as corrosion and oxidation, extending the service life of facilities.

- Reducing maintenance costs: Due to the protective effect of anticorrosion coatings, the maintenance costs of metal facilities can be greatly reduced, while reducing environmental pollution and emissions.

- Favorable adhesion ability: The anticorrosion coating is tightly attached to the surface of the metal layer and not easily detached.

- Beautiful and durable: The anticorrosion coatings not only look beautiful but also have a certain degree of durability, which can withstand long-term use and physical impact.

- Environmentally friendly: Most anticorrosion coatings are non-toxic, odorless, and do not release harmful substances, with minimal impact on the environment.

2.2.3. Challenges of Intelligent Anticorrosion Coatings

- External factors such as impact and weather changes may cause coating damage, which requires regular inspection, repair, or replacement.

- Compared to other materials, the cost of anticorrosion coatings is higher, and painting requires professional skills and equipment.

- The construction of anticorrosion coatings is difficult and requires professional technology and equipment. Improper surface treatment can affect the anticorrosion effect.

- Some anticorrosion coatings have a shorter protection time and require frequent repainting or replacement.

- Affecting the thermal conductivity of metal surfaces: The thickness of anticorrosion coatings may affect the thermal conductivity characteristics of metals, which can have a negative impact on certain processes and equipment.

- It may have a certain impact on the environment during preparation and use.

2.3. Intelligent Antibacterial Coating

The demand for antibacterial materials has been increasing worldwide. During the epidemic, the popularity of antibacterial coatings has reached a new height. Intelligent antibacterial coatings can effectively kill viruses and bacteria, reducing the possibility of disease transmission [83]. At present, the materials of intelligent antibacterial coatings mainly include copper, silver, titanium dioxide, and silicon nitride, among which titanium dioxide is one of the most widely used antibacterial substances. Titanium dioxide utilizes ultraviolet radiation to decompose organic substances in the air, producing oxides and free radicals, thereby achieving the effects of sterilization, deodorization, and air purification [84]. In order to improve the effectiveness of antibacterial coatings, scientists have collected and analyzed a large amount of data to effectively identify the antibacterial components that have the best bactericidal effect, thereby improving the bactericidal effect of intelligent antibacterial coatings [85]. In addition, the preparation of intelligent antibacterial coatings is also an important part of research and development. At present, commonly used coating preparation techniques include physical vapor deposition, chemical vapor deposition, sputtering technology, chemical solution method, etc. Different preparation techniques have a significant impact on the performance and antibacterial effect of coatings [86].

2.3.1. Research Progress

Cai H. constructed S-2-responsive nanocontainers via assembling zeolite imidazole ester framework-8 on silica nanoparticles. When S-2 was higher than 0.04 mM, the spontaneous leakage of the added biocide was almost suppressed and began to be released. This nanocontainer can respond to the microbial impact (MI) caused by sulfate-reducing bacteria (SRB) and the S-2 fluctuations caused by MI. The protective performance of intelligent nanocontainer coatings in an SRB environment was evaluated. It was indicated that the intelligent coating exhibited the least bacterial deposition and the highest impedance [87,88].

Yeh Y. proposed a method of fabricating valid antibacterial coatings via introducing tetrapolar ZnO (T-ZnO) nanomaterials onto fluoroethylene ether polymers (FEVE). T-ZnO nanomaterials were synthesized using a flame transfer method and characterized. The T-ZnO nanocomposite coating showed the optimal surface hydrophobicity. The T-ZnO on the proposed fluoroethylene-polymer-based coating presented higher antibacterial efficacy against Gram-positive Staphylococcus aureus and Gram-negative Escherichia coli compared to the coating based on standard polymers. Therefore, this study provided a safe, simple, and effective method for preparing antibacterial coatings [89,90].

Park C. developed a novel wearable device with diverse sensing capabilities by spraying carbon nanotubes (CNTs), nanoparticles, and reduced graphene oxide (rGO) onto fabrics. This electronic wearable device had antibacterial properties, proving its suitability for human–machine interfaces, medical monitoring, future military uniforms, intelligent soft robots, and intelligent sportswear. Due to the accumulation of static charges, both CNTs and rGO contributed to the characteristics of double-layer capacitance, while copper enhanced pseudocapacitance and charge transfer through redox reactions with electrolytes. This fabric had the characteristics of being flexible, stretchable, and resistant to external mechanical stress. Due to the supersonic impact in the coating process, the deposited material adhered well to the fabric surface to maintain durable mechanical performance. rGO/CNT/Cu-coated fabrics generated heat energy through Joule heating when applying voltage. This fabric can also sense changes in the surrounding temperature and external strain. The antibacterial performances of the fabric may prevent the spread of diseases [91,92].

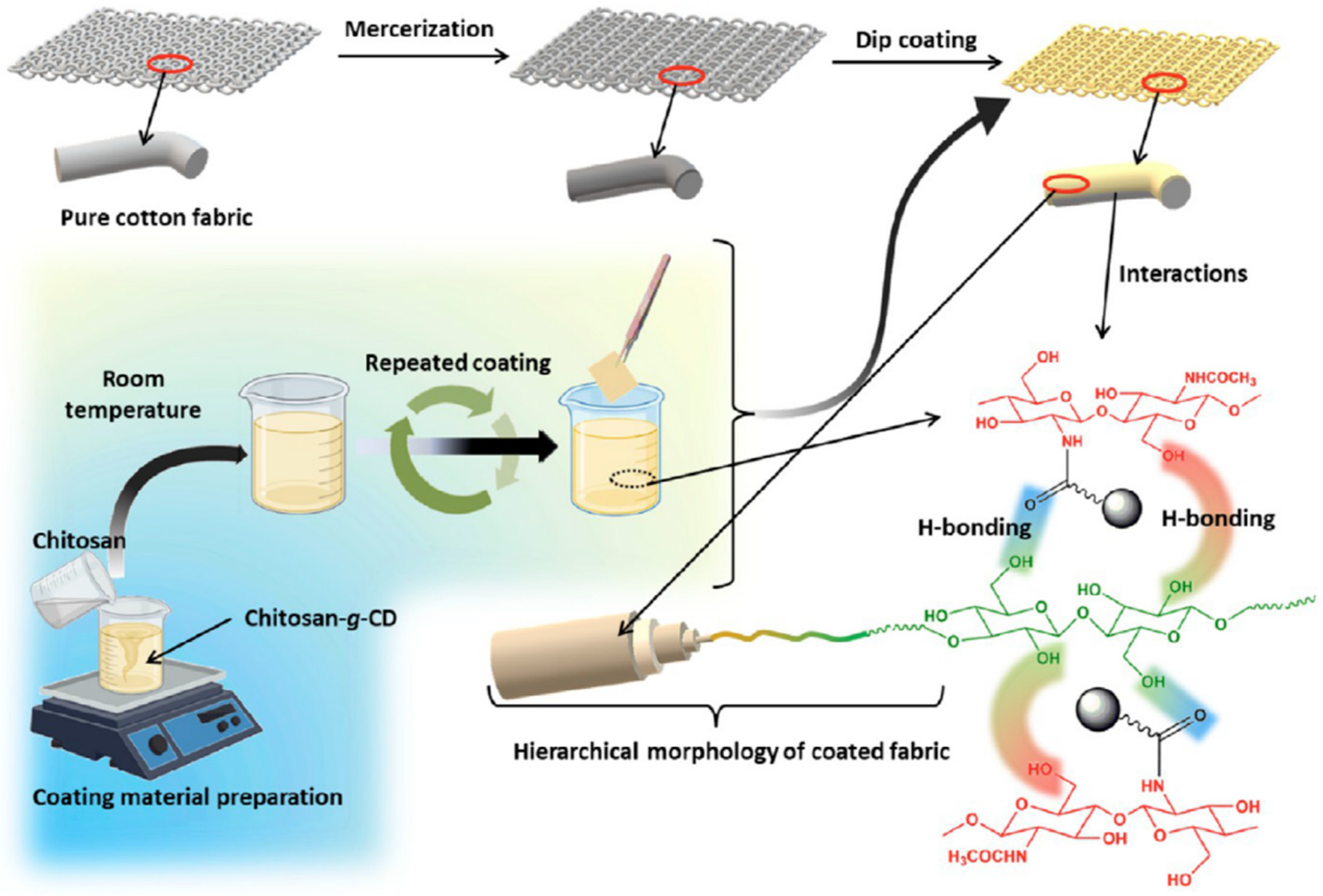

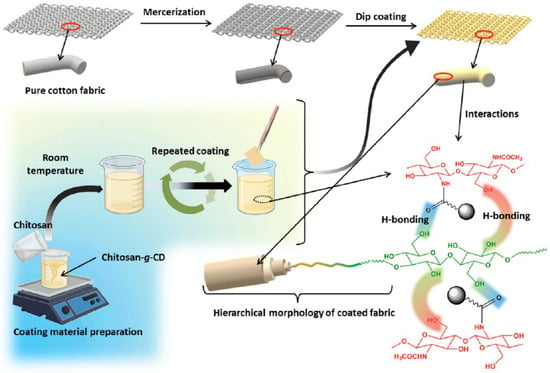

Das P. provided evidence for the first time of a directly pollution-free technique to prepare biopolymer composites for functional textiles with antibacterial and antioxidant properties. A simple physical composite strategy was used to prepare carbon-dot-reinforced biopolymer composite materials, which were then fixed on the fabric (Figure 10). Time-related antibacterial experiments showed that nanocomposites can significantly inhibit bacterial growth within just a few hours. This study may open up possibilities for the commercialization of low-cost intelligent textile substrates for preventing microbial contamination in the healthcare field [93].

Figure 10.

Coating process of textile and plausible interactions [93]. Copyright 2022. Reproduced with permission from ACS.

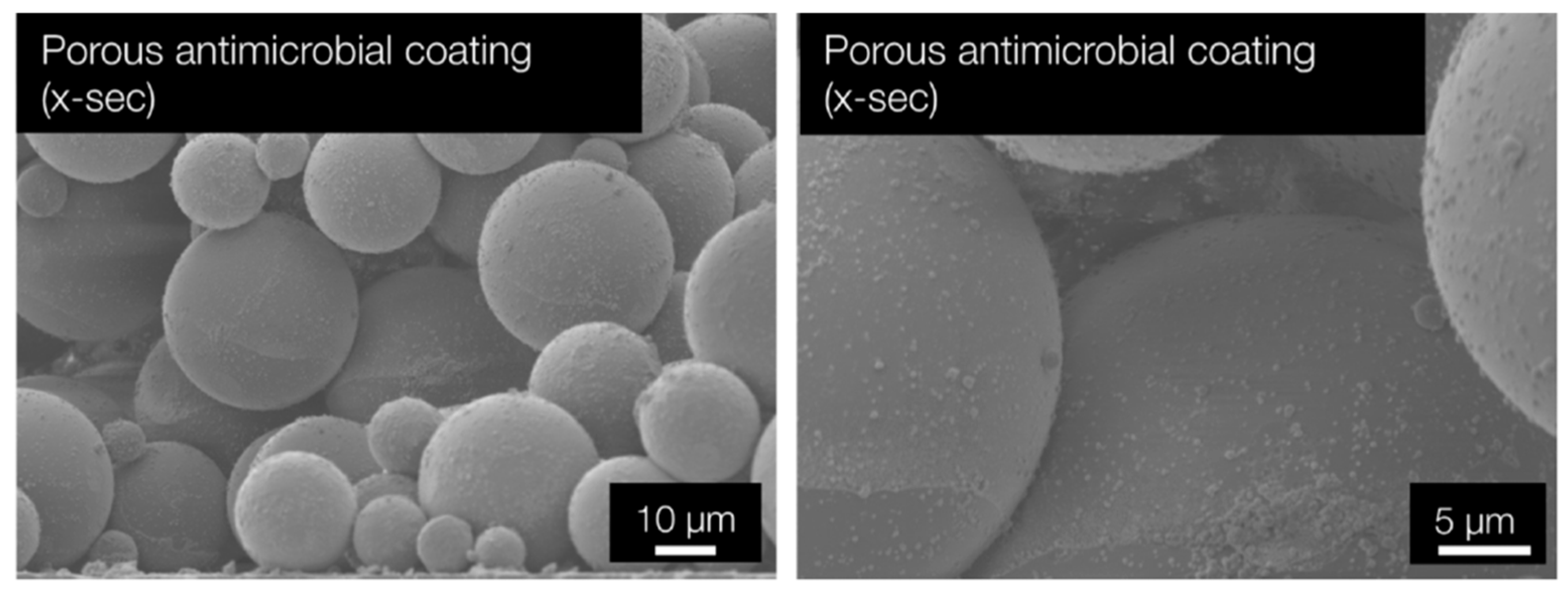

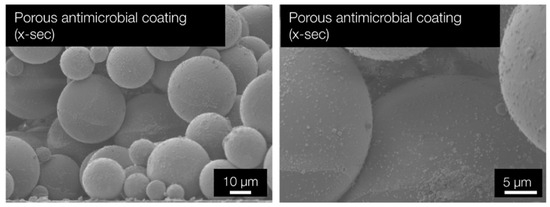

Behzadinasab S. designed a porous coating that can kill microorganisms faster than flat coatings of the same material. The coating consisted of two hierarchical structures: an antibacterial film within a porous structure containing active ingredients and a porous scaffold. The biological coating using methyl methacrylate (PMMA) as a scaffold and non-electrodeposited copper as the active ingredient was suitable for preventing the spread of infectious agents on commonly used objects (Figure 11) [94].

Figure 11.

SEM images of the porous antimicrobial coating (scaffold = PMMA). The antimicrobial layer (PDA/Cu) was successfully prepared inside the pores of the porous PMMA scaffold [94]. Copyright 2023. Reproduced with permission from ACS.

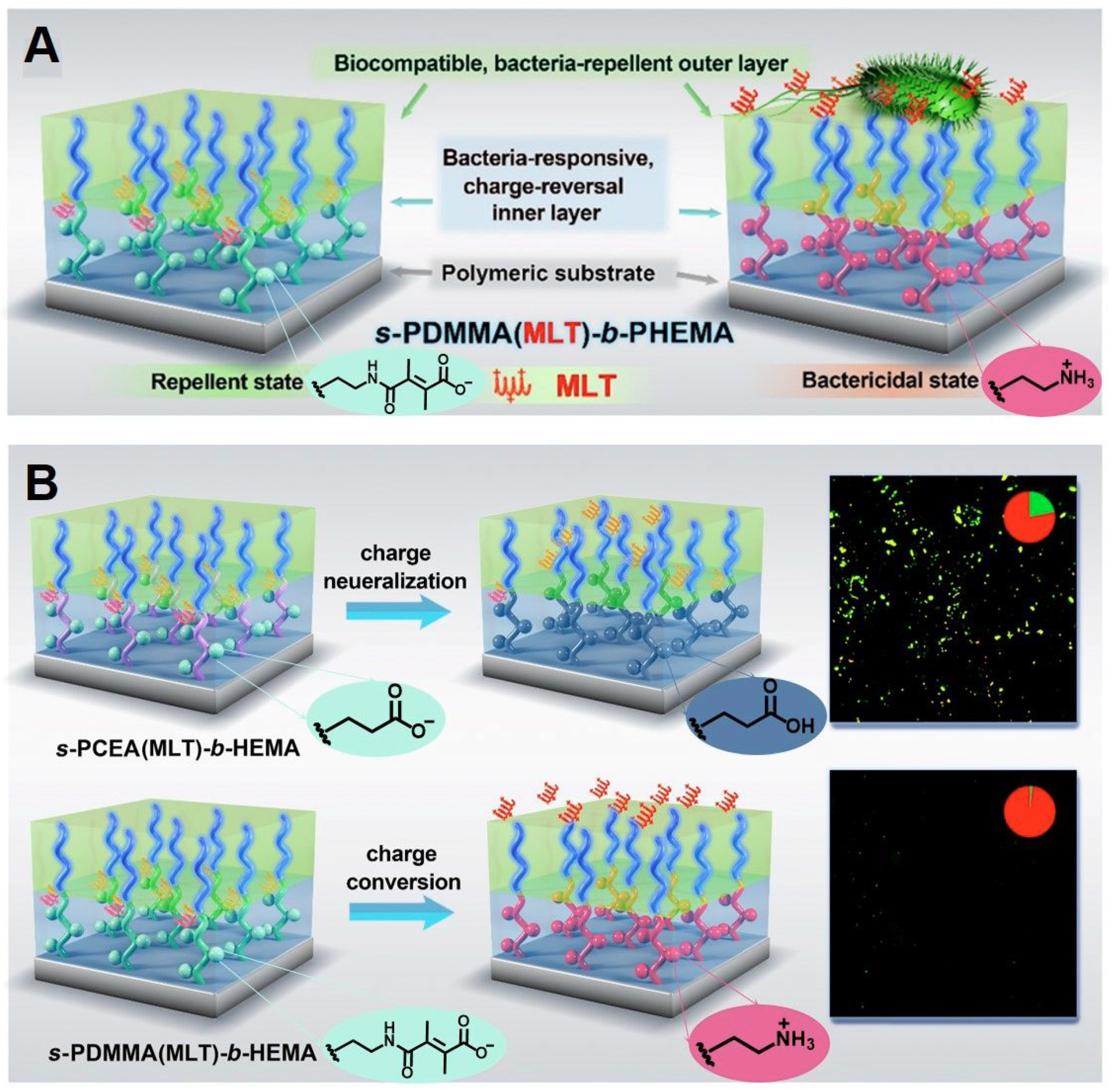

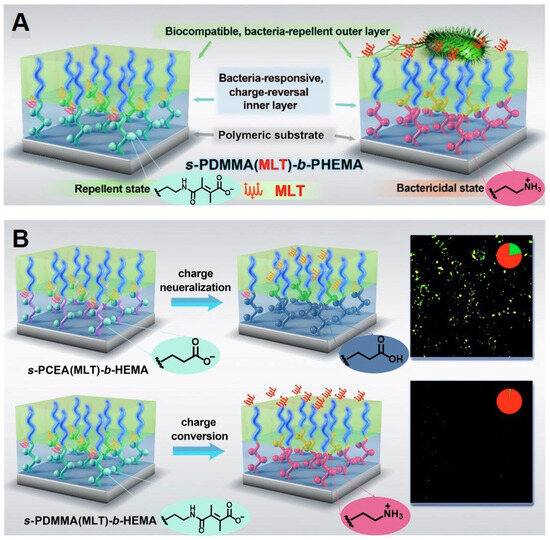

Liu T. proposed a graded polymer brush system and easily constructed it on a polymer substrate through photoactive grafting polymerization. The polymer brush system exhibited a unique hierarchical structure, consisting of an outer layer of poly (hydroxyethyl methacrylate) (PHEMA) and an inner layer of anions loaded with cationic antimicrobial peptides through electrostatic attraction. The surface of the system inhibited the initial adhering of bacteria through the outer layer of PHEMA hydration under neutral pH conditions. When bacteria adhered and proliferated on the surface, bacterially induced acidification triggered the breaking of unstable amide bonds in the inner layer, exposing amines of positive charge and violently releasing melittin (MLT), allowing the surfaces to kill the adhered bacteria in a timely manner (Figure 12). The graded surface adopted various antibacterial mechanisms to fight bacterial infections and exhibited high sensitivity and responsiveness to pathogens [95].

Figure 12.

Schematic diagram of antibacterial mechanism of the hierarchical platform. (A) The hierarchical platform provides a biocompatible and non-adhesive surface under normal physiological conditions. In the early stage of surface colonization by bacteria, the bacterially induced acidification triggers MLT release, turning the surface from non-adhesive to bactericidal when needed to attack the adhering bacteria. (B) Compared to the prevailing release model based on charge neutralization, the negative-to-positive charge-conversion mechanism renders the surface highly responsive to bacterial acidification and eliminates infections at early stages of the bacterial colonization of biomaterials [95]. Copyright 2020. Reproduced with permission from ACS.

2.3.2. The Advantages of Intelligent Antibacterial Coatings

- Transparent, colorless, and odorless: Intelligent antibacterial coatings can be applied to various surfaces, such as glass, metal, ceramics, wood, concrete, paper, and clothing, without changing the appearance or odor of these items.

- Continuous sterilization function: Compared with traditional sterilization coatings, intelligent antibacterial coatings can effectively sterilize for at least 30 days, reducing the need for frequent disinfection.

- Preventing microbial growth: Antibacterial coatings can prevent the growth of bacteria, fungi, algae, and other microorganisms, making the surface an unfavorable environment for microbial survival.

- Reducing the use of cleaning agents and disinfectants: The use of antibacterial coatings can reduce the demand for irritating cleaning agents and disinfectants, thereby reducing their impact on the environment, especially in public places such as medical facilities.

- Cost-effectiveness: Antibacterial coatings help to reduce maintenance costs as they prevent issues such as dyeing, discoloration, and leakage, reducing the additional economic burden and labor required for item replacement.

- Extending product life: Microbial protection combined with maintenance of antibacterial coatings can extend the service life of items and prevent discoloration, odor, and other damage caused by microbial activity.

- Enhancing infrastructure value: The application of antibacterial coatings helps to protect surfaces and improve overall infrastructure standards, providing people with a safer and cleaner environment.

2.4. Other Intelligent Coatings with Specific Functions

With the deepening of research, the classification of intelligent coating materials has become increasingly significant, covering a wider range of fields, closely related and cross-integrated with physics, chemistry, materials science, life sciences, surface engineering, and other fields, and corresponding branches have emerged. Intelligent coatings have an impact on every aspect of people’s daily lives, such as self-healing coatings on cars, thermal management coatings on building glass, easy to clean antifingerprint and antiglare coatings on transparent touch screens, anti/deicing coatings on aircraft windshields, and so on. They have brought many conveniences to people’s lives and played a driving role in the transformation of social production methods [96,97,98].

2.4.1. Research Progress

In order to improve the efficiency and reliability of aviation engine compressors, wear-resistant sealing coatings need to have good wear resistance due to reduced hardness. However, low hardness often combines with low bonding strength, causing the coating to peel off and fail during use. To overcome the contradiction between high bonding strength and low hardness, Tong Y.-Q. prepared a new wear-resistant sealing coating with a spherical closed cell structure. New coatings had both higher bonding strength and lower hardness. In the test, the coating showed fine wear resistance without any coating peeling, which is expected to improve the reliability and efficiency of the next generation of aviation engines [99].

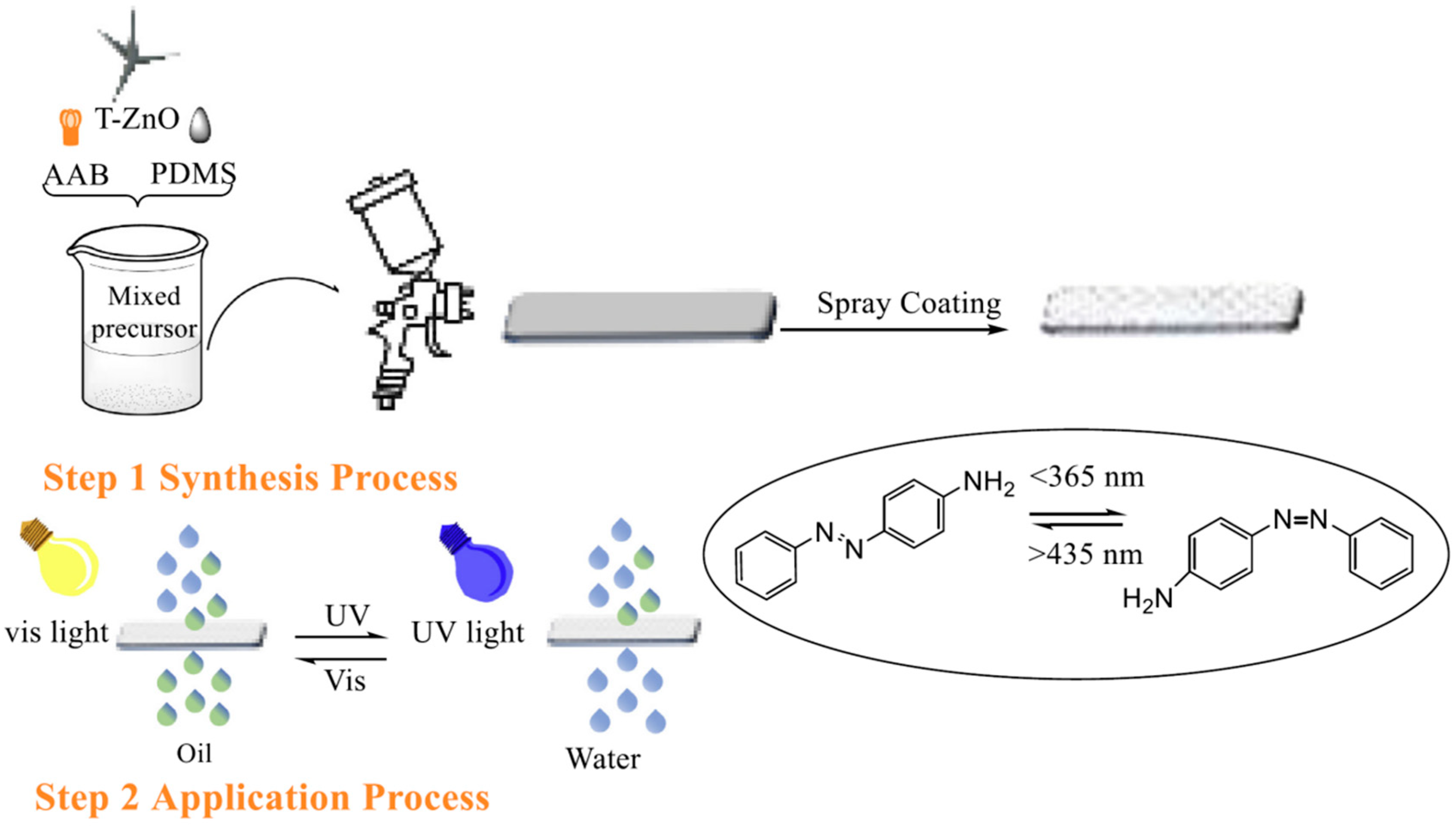

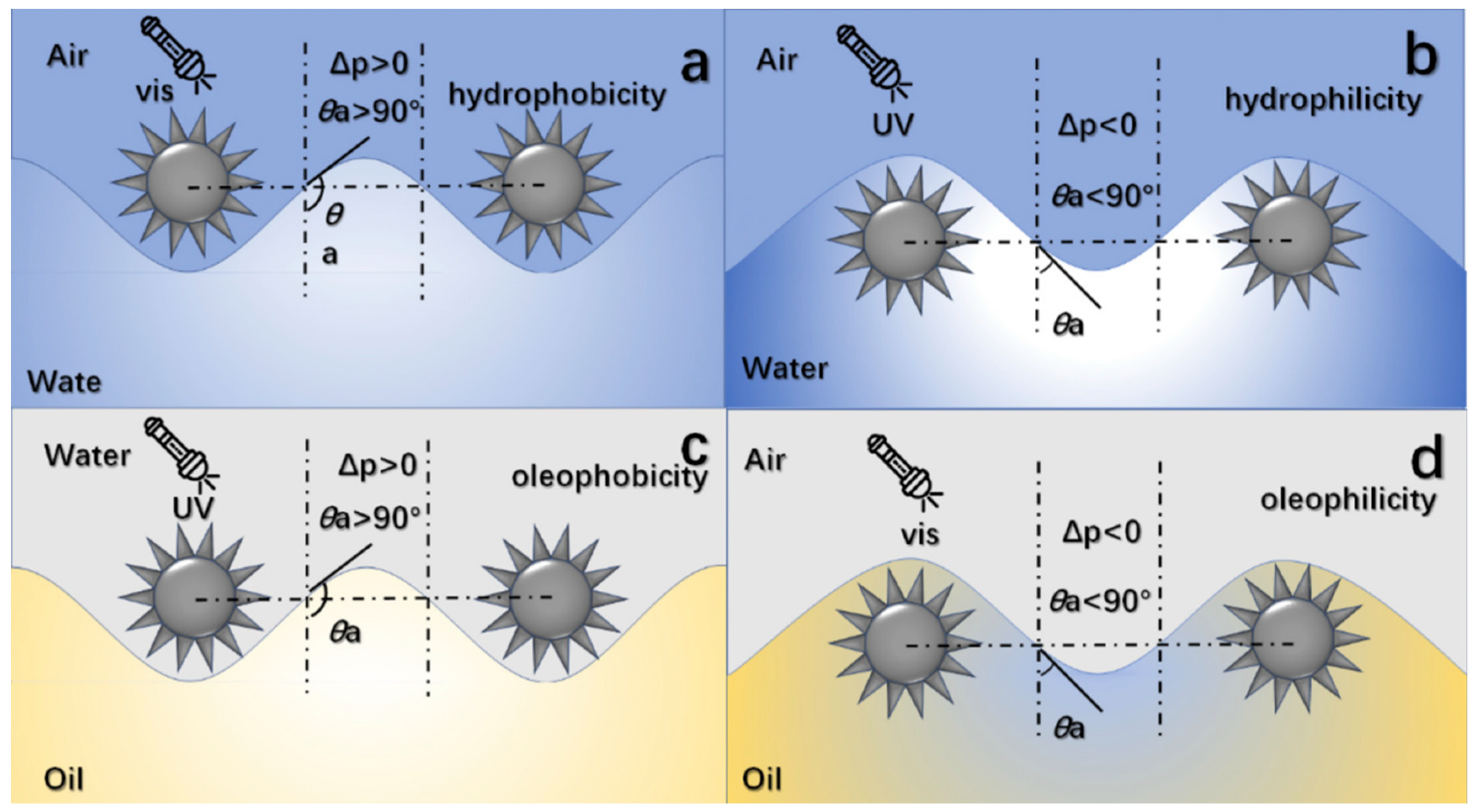

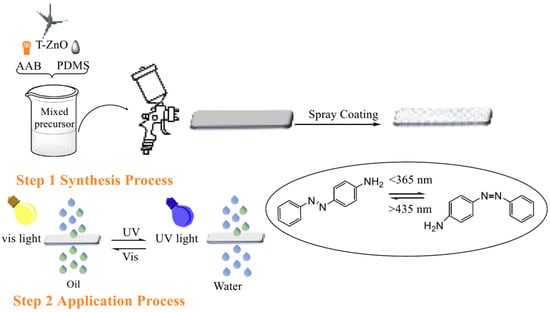

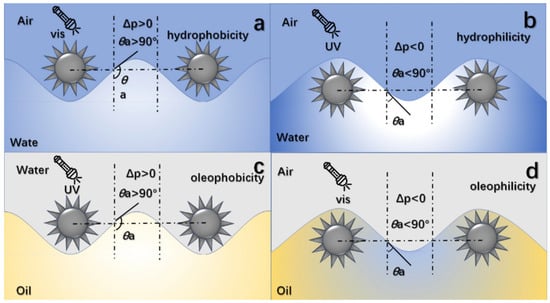

It is difficult to separate the required component (oil or water) in practical application, therefore, separating water/oil is a global challenge. In order to overcome this dilemma, Jin-Jin and Zhou prepared a V-type copolymer material inspired by mussels for pH-controlled oil/water separation. A ternary copolymer of poly (dimethylsiloxane) block poly (2-hydroxyethyl methacrylate) block poly (dimethylamino) ethyl methacrylate (PDMS-b-PHEMA-b-PDMAEMA) was synthesized through copper mediated by reversible deactivation radical polymerization (RDRP). The PHEMA block containing hydroxyl groups made covalent reactions happen between the polymer and the functionalized substrate of polydopamine (PDA). The hybrid polymer brush of pH-responsive PDMAEMA and hydrophobic/hydrophilic PDMS endowed the matrix with good stability and pH responsive water/oil wettability. In addition, functionalized sponges achieved oil capture and release reversibly in aqueous media [100,101,102,103]. Yang C. reported a spraying method for manufacturing flexible surfaces with reversible switching between hydrophilic and hydrophobic states under UV/vis illumination (Figure 13). The modified nylon (polyamide, PA) mesh was made of a novel four-legged ZnO (T-ZnO), polydimethylsiloxane (PDMS) hydrophobic coating and partially modified with 4-aminoazobenzene (AAB), which exhibited a porcupine-like surface structure, reversible light-responsive wettability, and multiple mechanical damage resistance. The main advantage of reversible light-responsive wettability composite materials is that they can utilize AAB photoisomerization, and the surface wettability of this intelligent material dynamically transitions between hydrophobicity and hydrophilicity under ultraviolet and visible light irradiation. Therefore, intelligent materials can reversibly transition between “oil removal” and “water removal” states through alternating lighting modes (Figure 14). Importantly, due to the porcupine-like surface of modified PA, this photoresponsive material exhibited outstanding resistance to multiple mechanical deformations and damage, capable of withstanding repeated mechanical deformations and various practical applications [104,105,106,107,108].

Figure 13.

Schematic illustration of the preparation of PA-PDMS-AAB/T-ZnO via spray coating and its application [104]. Copyright 2021. Reproduced with permission from Elsevier.

Figure 14.

Schematic diagram of oil and water wetting states. (a) Water cannot permeate through the as-obtained material and it shows hydrophobicity due to Δp > 0; (b) water can permeate through membrane after UV irradiation because Δp < 0; (c) oil cannot pass through the material under water as Δp > 0; and (d) oil will spontaneously pass through the membrane in air as Δp < 0 [104]. Copyright 2021. Reproduced with permission from Elsevier.

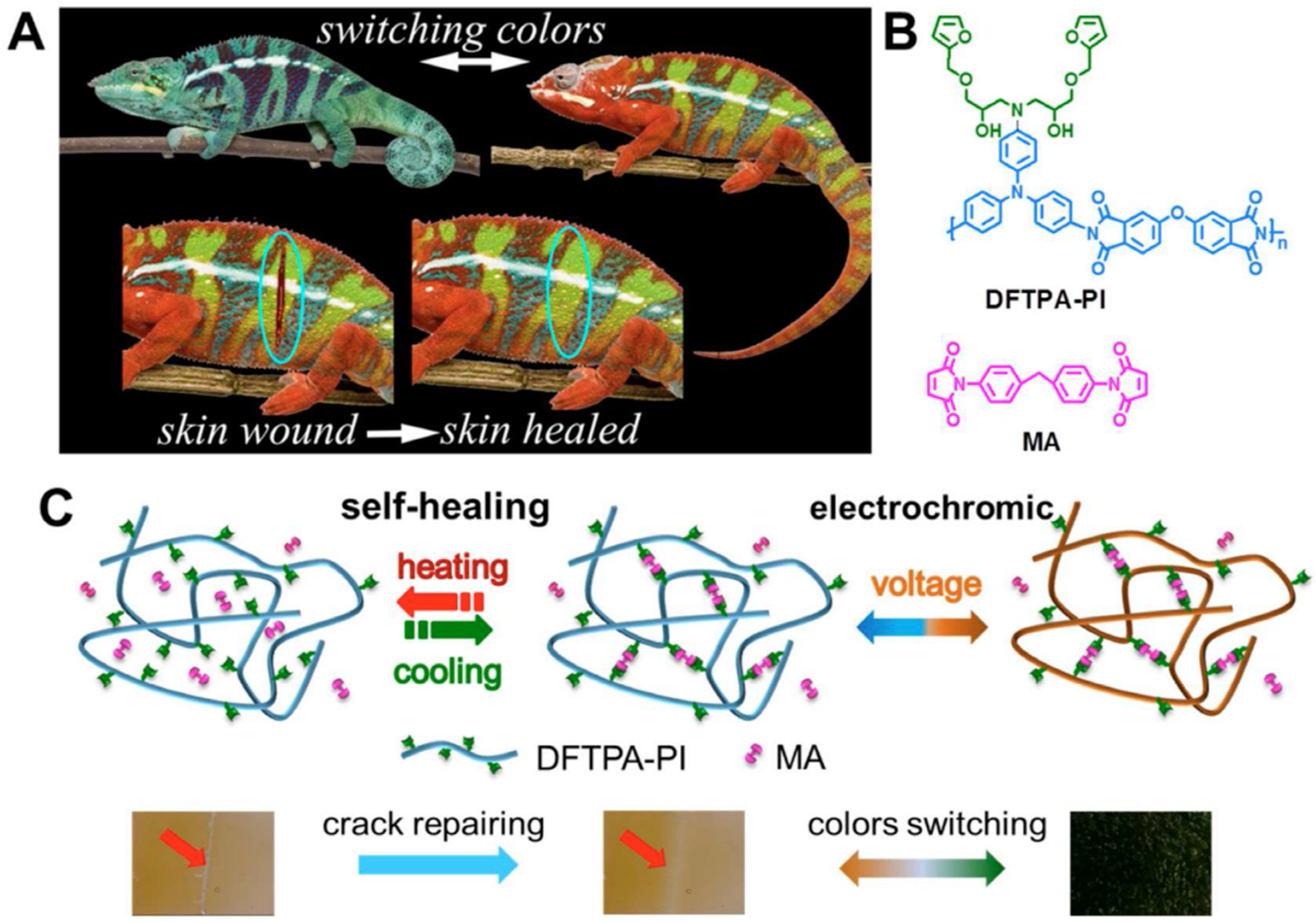

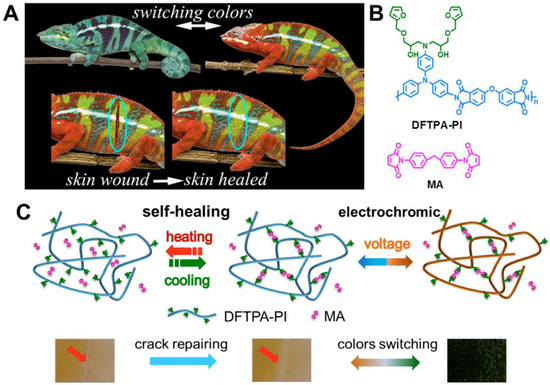

Recently, intelligent adhesion of geckos has been focused on more and more by researchers, however, they have all concentrated on a mere adhesion to solids or liquids, and obtaining a surface of switchable adhesion to both solids and water is still an obstacle. In view of this, Zhang H. reported a novel shape memory coating that can repeatedly display unfolded/curved shapes with excellent shape memory performance. The research results indicated that in addition to changes in contact area, appropriate surface energy was also critical for special adhesion. In addition, based on the performance of intelligent adhesives, the coating was used to demonstrate in situ capture/release of solids and liquids. This study proposed a thin coating with adjustable adhesion to liquid and solid, providing new ideas for designing new adhesive coatings and expanding the application range of adhesive materials [109,110,111,112]. Zheng R. prepared a copolymer coating with biomimetic properties, which integrated self-healing Diels–Alder groups and electrochromic triphenylamine simultaneously. This stretchable and flexible copolymer coating, like natural chameleon skin, exhibited significant color changes and excellent self-healing performances. These significant features make it a prospective intelligent material for solving the problem of cracks in traditional biomimetic chameleon skin (Figure 15) [113].

Figure 15.

(A) Color variations and self-healing function of chameleon skin (chameleon images from Guangzhou Yingmeiqing Information Technology Co., Ltd., Guangzhou, China). (B) Structure of monomer DFTPA-PI and MA. (C) Schematic diagram of self-healing and electrochromic function of copolymer DFTPA-PI-MA [113]. Copyright 2018. Reproduced with permission from ACS.

He W. invented a new type of coating used in intelligent camouflage, whose color can blend with the background. The composition and mix ratio of raw materials were determined through orthogonal design experiments. The chemical and physical properties of the coating, such as discoloration temperature and drying time, were tested. The results indicated that the coating had favorable coating effect, excellent chemical and mechanical properties, and can meet the requirements of seasonal camouflage [114,115].

Zhang J. adopted a feasible and cost-effective method: an annealing assisted solution strategy to fabricate VO2 coatings with high porosity, high purity, and uniform particle size, using self-made ammonium citrate vanadate (IV) and hexadecyltrimethylammonium bromide (CTAB) as precursors and dispersants. It is worth noting that the quantity of CTAB was crucial for controlling porosity and particle size, which in turn affected the overall property of the obtained VO2 coating. The results indicated that samples with high porosity and small particle size exhibited high visible region transmittance and enhanced solar modulation efficiency. This work may provide guidance for the modulation of transmittance from VO2 nanoparticle coatings to intelligent window coatings [116,117].

Lithium sulfur batteries are considered one of the most prospective energy storage units. However, its cycling property is severely hindered by the difficulty of handling polysulfide shuttle and the slow kinetics of polysulfide conversion. Yu Hanzhi prepared multifunctional MoSe2 nanotubes and coated them on a Celgard membrane. The nanotubes showed good performance in catalyzing sulfur conversion and capturing polysulfides. The hierarchical structure and polarity of MoSe2 nanotubes provided sufficient catalytic sites and exhibited strong chemical adsorption for the conversion of polysulfides [118].

Stents are medical devices used when blood or bodily fluids (such as in the gastrointestinal tract and blood vessels) do not flow smoothly due to benign or malignant diseases. When using electrospun coated scaffolds, the advantage lies in the ability to add various functions, such as with biodegradable polymers or coating drugs. However, due to the unique physical properties and shrinkage issues of electrospun fibers, electrospun coated scaffolds have not yet been used. Lee J.C. used biodegradable polymer PCL and medical grade silicone as scaffold coating materials to prepare electrospun PCL/silicone multilayer coatings. The prepared multilayer coating was able to compensate for the weaker physical performances of electrospun fibers by a silicone resin film. Furthermore, it was confirmed through cytotoxicity evaluation that there was no problem with using this type of multilayer film for medical purposes. When using electrospun multilayer film-coated scaffolds, performances similar to those of existing scaffolds through silicone coating added by electrospun fibers are expected [119].

Wang X. prepared a novel high-entropy ceramic using a two-step method in order to obtain a thermal environment barrier coating. The research results on lattice distortion and structural entropy indicated that the configuration entropy caused by mass disorder only contributed to the constancy of microstructure and thermal performance. The reason for the decrease in thermal properties could have been caused by lattice distortion. The prepared high-entropy ceramics exhibited relatively low thermal expansion coefficient, thermal conductivity, and thermal diffusivity [120].

Inspired by the lipid bilayer, Feng Li reported a carefully designed soybean-protein-based material with various functions. This material exhibited excellent toughness and high tensile strength, as well as excellent self-healing ability and fast healing time. The response performance of soybean-protein-based materials was studied, which showed long-term stability and good sensitivity. This soy-protein-based material with multiple intelligent functions may be applied in wearable electronics, bioengineering, and intelligent coatings [121].

Intelligent aviation engines require high-temperature sensors and, to achieve this, an electrical insulation layer needs to be installed on the base metal of the blade. However, the characteristics of sensors can be affected as the electrical insulation of ceramic materials deteriorates at high temperatures. Weng H. modified the ceramic material’s thermal barrier coating (TBC) formula by adding a certain quantity of Al2O3 to enhance its insulation performance at high temperatures. The surface of TBC was micromachined, including the preparation of thermistors and platinum point thermocouples on the TBC surface, and the high-temperature electrical insulation performance of modified TBC was studied. The results indicated that the addition of Al2O3 can improve electrical insulation by several orders of magnitude, meeting the requirements for constructing a secure thin film sensor on the TBC-topped surface of the turbine blade metal coating. In order to ensure the working ability of the TBC layer, several validation experiments were conducted, including high-temperature retention testing, thermal shock testing, and robustness testing [122].

With the speeding up of the urbanization process, comfortable, lightweight, and energy-saving materials have been increasingly widely used. An ideal real-time monitoring strategy combined with outstanding flame retardancy and fire-sensing capabilities and inserted in the communication network internet remains a huge challenge. For this purpose, Zhang S. developed a durable and sensitive fire alarm intelligent coating approach based on metal insulator transition Ti3O5 through layer-by-layer (LBL) assembly. They elucidated the transition of Ti3O5 from a charge ordered p-phase (electrically insulating state) to valence delocalization of α-phase (conductive state) through density functional theory calculations. Therefore, the thermally activated electronic jumps between local states contribute to early fire alarms, with an excellent response repeatability and sensitive response time [123].

The coatings developed by Dhyani A. team were mainly made of polyvinyl chloride (PVC) or polydimethylsiloxane (PDMS) plastic and silicone oil or vegetable oil, with low cost. Low interface toughness can cause cracks between ice and panels. Tests showed that the average ice and snow coverage of coated panels throughout the winter was about 28%, while the average ice and snow coverage of uncoated panels was about 59%. After spraying this coating on solar panels, the ice and snow on their panels were more likely to fall off, and it can be effectively maintained for up to a year. It is worth noting that, in addition to the solar energy industry, the coating can be deployed on other devices, including windscreens, laser radomes of autonomous vehicles, and cold weather optical sensors [124].

The Tian S. team has researched and excavated the key antifreeze modules of natural antifreeze proteins, constructed a simulated antifreeze protein polymer (PDSB), and added it to a self-healing material matrix to prepare a self-healing anti-icing coating with excellent anti-icing and easy deicing performance. This anti-icing coating reduced the heterogeneous nucleation temperature of surface ice. The results showed that compared with steel plates, the ice nucleation temperature of this coating decreased, and the ice diffusion rate decreased by two orders of magnitude. In addition, the ice adhesion strength of the coating was reduced, and the deicing performance of the coating was improved. The ice adhesion strength was only 1/23 of that of the blank steel plate. This coating achieved excellent low-temperature self-healing performance through strong hydrogen bonds, weak hydrogen bonds, disulfide bonds, and electrostatic interactions in the molecular structure of the material. Surface damage defects can achieve self-healing at −20 °C. After healing, the mechanical properties, anti-icing performance (nucleation temperature, freezing delay time), and deicing performance (ice adhesion strength) were all well restored, effectively suppressing defect-induced ice nucleation transmission and ice adhesion. Compared with the currently reported anti-icing coatings internationally, this coating can not only self-heal at low temperatures but also simultaneously inhibit ice nucleation, transfer, and adhesion. It has environmental adaptability and large-scale coating potential, providing new ideas for the development of anti-icing coatings applied in outdoor environments that are prone to damage [125].

Professor Li Wenge’s team has prepared a robust UV/moisture dual curing PDMS microcapsule silica functional material for self-healing and antifouling purposes. A micro–nanoscale structure was constructed on the surface of a polydimethylsiloxane (MAPDMS) matrix containing methacryloyloxy and methoxyisilane groups, and a polydimethylsiloxane microcapsule SiO2 (MPMS) functional material containing methacryloyloxy and methoxyisilane groups was prepared. Experiments have shown that the introduction of UV/wet dual curing mode and a micro–nano hierarchical structure endows MPMS functional materials with excellent mechanical properties, antifouling performance, and self-healing performance. The prepared MPMS is expected to be widely used in marine pollution prevention, pipeline network, anti-icing, microfluidics, wearable devices, medical equipment, electrochemical biosensors, and other fields [126].

Inspired by the superadhesion of marine mussels, the Wang L. research group of has constructed a composite hydrogel dressing with excellent adhesive, self-healing, antibacterial, antioxidant, and other functions by organically combining quaternary ammonium chitosan (QSC), dopamine (DA), quercetin (QT), and other ingredients. The significance of this study is constructing a dual network interpenetrating structure and combining the characteristics of quercetin and polydopamine. Hydrogel materials were endowed with self-adhesion, self-repair, antibacterial, coagulation, and antioxidant properties, and their low price and easy mass production have important implications for the development of new medical dressings [127].

Associate professor Wu Jin’s team prepared an intrinsically highly stretchable temperature sensor using polyacrylamide/carrageenan double network hydrogel. The team found that the solvent had an important influence on the temperature-sensitive properties of ionic hydrogels by further exploring the influence of solvent environment on the temperature-sensitive properties of hydrogels. Using the solvent replacement strategy, the water-retaining and antifreeze EG/Gly solvent was introduced to convert the traditional hydrogel with water as the solvent into an organic hydrogel with a a water–alcohol binary solvent system, and then a tensile temperature sensor with good thermal stability, self-healing, and ultrasensitivity was prepared [128].

2.4.2. Challenges and Development Directions for Future Functional Intelligent Coatings

- Challenges

- (1)

- Improving the adhesion of the coating further

Coating adhesion refers to the degree of attachment between the coating and the substrate. If the adhesion between the coating and the substrate is not strong enough, the coating is prone to detachment and peeling, resulting in color changes, cracks, bubbles, and other issues. Not only will it affect the appearance of the coating but it will also reduce its service life and performance. Therefore, the adhesion of coatings is crucial for the quality and stability of coatings. In the coating process, the adhesion of the coating still needs to be further improved.

- (2)

- Difference in thermal expansion coefficient between coating and base

The difference in thermal expansion coefficient between the coating and the substrate layer can result in significant thermal and residual stresses in the coating, which may lead to cracking during high- and low-temperature alternation, leading to a rapid decrease in coating adhesion and easy coating detachment.

- (3)

- Weather resistance of coatings

The weather resistance of a coating refers to its ability to maintain the required performance for a certain period of time under the influence of the external environment. Generally, the weather resistance of a coating is evaluated based on its surface appearance and other performance changes. The weather resistance of coatings, especially long-term weather resistance, is not only related to the performance of the coating itself but also to external environmental factors such as light, water, oxygen, ozone, temperature, humidity, etc. The weather resistance of coatings is an important guarantee of their quality, and its importance is self-evident for coating manufacturers and users. There are many factors that affect the weather resistance of coatings, and different coatings need to have different material layers and be subjected to different testing methods according to different environments in order to achieve the best results. Therefore, it is necessary to pay more attention to the weather resistance and adaptability of coatings in different environments during the coating development process.

- 2.

- Methods for improving coating performance

Improving the performance of coatings can make them more durable, easy to apply, aesthetically pleasing, etc. The following are reference methods for improving coating performance.

- (1)

- Using high-quality raw materials

The performance of coatings is largely related to the quality of raw materials. Choosing high-purity resins, pigments, and additives can greatly improve the quality of coatings and ensure their performance stability. For example, using advanced color layers such as aluminum silicate to improve the whiteness and covering power of coatings and using polymer layers to improve the durability and waterproofing of coatings.

- (2)

- Increase the types and amounts of additives in the formula

Adding some special additives to the coating formula can improve the performance of the coating. For example, adding thickeners can increase the viscosity of the coating, making it easier to apply; adding antioxidants can improve the durability of coatings and prevent them from deteriorating during long-term use. At the same time, it is also very important to control the dosage of additives reasonably. Improper use of too much or too little can affect the performance of the coating.

- (3)

- Adopting advanced intelligent coating technology

- (1)

- Nanocoating technology

Nanocoating technology is a refined coating technology that can produce nanoscale coatings through precise coating processes. This technology can improve the surface hardness, wear resistance, and corrosion resistance of materials and can also produce coatings with excellent properties such as transparency, antireflection, and antiultraviolet.

- (2)

- Ultrathin coating technology

Ultrathin coating technology is a high-precision and high-efficiency coating technology that can produce extremely thin coatings, typically ranging in thickness from a few nanometers to tens of nanometers. This coating can improve the surface hardness and corrosion resistance of materials, as well as enhance their electrical conductivity and high-temperature resistance.

- (3)

- Sputtering coating technology

Sputtering coating technology is an efficient coating technology that can produce high-quality, high-hardness, and high-strength coatings. Sputtering coating technology can improve the specific mechanical properties, wear resistance, corrosion resistance, and high-temperature resistance of materials.

3. Discussion and Conclusions

Superhydrophobic coating is a type of coating with a special surface structure that can have hydrophobic properties similar to the lotus leaf effect on its surface. It can prevent the surface of objects from adsorbing moisture or pollutants and has advantages such as self-cleaning and antipollution. The following are the development trends of superhydrophobic coatings:

- Surface nanostructure optimization: With the development of technology, researchers continuously optimize the surface nanostructure of superhydrophobic coatings. By controlling the nanoscale structural characteristics, the superhydrophobic performance can be further improved. For example, using structures such as nanopillars, nanopores, and nanoprotrusions to increase surface area and reduce contact angle, thereby achieving higher hydrophobic effects.

- Sustainable development and environmental friendliness: In the paint industry, green environmental protection has become an important development direction. Superhydrophobic coatings are no exception, and the future trend will involve paying more attention to the sustainability and environmental friendliness of materials. Researchers are working hard to develop more environmentally friendly superhydrophobic coatings, avoiding the use of chemicals that are harmful to the environment, and searching for renewable and biodegradable materials.

- Multifunctional applications: In addition to having hydrophobic properties, future superhydrophobic coatings are likely to have other functions. For example, characteristics such as UV resistance, high-temperature resistance, oxidation resistance, fire resistance, etc. This multifunctional superhydrophobic coating will help to meet the needs of different fields and expand its application range.

- Further application expansion: Currently, superhydrophobic coatings are applied in multiple fields, such as architecture, automotive, aerospace, etc. In the future, with further technological improvements and cost reductions, superhydrophobic coatings are expected to be applied in a wider range of fields, such as household appliances, textiles, medical devices, etc.

- Implementation of self-healing function: Currently, one of the main drawbacks of superhydrophobic coatings is their susceptibility to wear or damage. One of the future development trends is to achieve the self-healing function of superhydrophobic coatings, allowing them to automatically repair after damage and extend their service life.

Intelligent anticorrosion coatings can be divided into two categories: external self-healing coatings and intrinsic self-healing coatings, which can meet the requirements of reliability and long service life of anticorrosion coatings. However, currently, intelligent anticorrosion coatings are still in the theoretical research and preliminary development stage, with relatively few industrial applications. Further in-depth research is needed from the following aspects to develop intelligent self-healing coatings that can be fully applied in practice:

Simplifying the preparation process of coatings, reducing costs, selecting appropriate self-healing structures and repairing agents based on actual situations, and preferably applying them in practical production.

In order to enable intelligent anticorrosion coatings to adapt to different harsh environments, it is necessary to conduct more systematic exploration of coatings that also considers other functions such as self-cleaning, antibacterial, and self-warning. In order to be applied in the seawater system of nuclear power plants, it is necessary to verify the cathodic stripping resistance, impact resistance, wear resistance, seawater penetration resistance, and self-healing ability of intelligent anticorrosion coatings in seawater.

Intelligent antibacterial coatings are one of the future development directions. With the continuous progress of the Internet of Things and artificial intelligence, intelligent antibacterial coatings can integrate sensors and control systems to achieve real-time monitoring and automatic sterilization of bacteria and viruses. For example, air disinfection in public places can be achieved by setting temperature sensors and automatic spray systems. Such intelligent antibacterial coatings will have broad application prospects in fields such as epidemic prevention, healthcare, and food safety. The growing demand for antibacterial coatings in the fields of hygiene and health has driven the development of their technology and applications. Nanotechnology, sustainability, multifunctionality, and intelligence are the main trends in antibacterial coatings. In the future, we can look forward to the widespread application of antibacterial coatings in various fields, creating a healthier and safer living environment for people.

4. Future Directions

The technological content of intelligent coatings is very high. The research and development of intelligent coatings require a high level of knowledge and skills in multiple disciplines such as materials science, chemistry, physics, etc. With the continuous progress of technology and the improvement of innovation capabilities, the technological content and value of intelligent coatings will also continue to increase, and the development prospects of intelligent coatings will become increasingly broad.

By utilizing the principles of bionics, new materials, structures, systems, and equipment are designed and manufactured, forming a rapidly rising and developing field of bionic engineering research in recent years. The combination of biomimetic technology and nanoengineering surface materials exhibits unique surface properties, bringing disruptive changes to many fields. The combination of bionics and intelligent surface materials will help solve existing drawbacks. However, the research on biomimetic intelligent surface materials requires a large amount of experimentation and testing, which requires a lot of time and resources. Researchers can also try to use natural raw materials to improve the degradability of coatings and try to use non-toxic or low-toxicity additives to reduce the harm of coatings to the environment. Intelligent coating materials are becoming a new force in the coating industry, and their broad application prospects will create an unprecedented market space for the coating industry.

Author Contributions

L.H. and X.C. designed the study and wrote the main manuscript text. B.Z. provided the analytical methods used in the paper and participated in the design of the study and data interpretation, S.Z. prepared figures, Y.L. and C.S. organized references. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundamental Research Funds of Heilongjiang Province Colleges (No. 2022-KYYWF-0606).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Brodin, F.W.; Gregersen, Ø.W.; Syverud, K. Cellulose nanofibrils: Challenges and possibilities as a paper additive or coating material–A review. Nord. Pulp Pap. Res. J. 2014, 29, 156–166. [Google Scholar] [CrossRef]

- Nakayama, H.; Kaetsu, I.; Uchida, K.; Sakata, S.; Tougou, K.; Hara, T.; Matsubara, Y. Radiation curing of intelligent coating for controlled release and permeation. Radiat. Phys. Chem. 2002, 63, 521–523. [Google Scholar] [CrossRef]

- Li, L.; Bai, Y.; Li, L.; Wang, S.; Zhang, T. A superhydrophobic intelligent coating for flexible and wearable sensing electronics. Adv. Mater. 2017, 29, 1702517. [Google Scholar] [CrossRef] [PubMed]

- Kancharla, H.; Mandal, G.; Singh, S.; Mondal, K. Effect of prior copper-coating on the microstructural development and corrosion behavior of hot-dip galvanized Mn containing high strength steel sheet. Surf. Coat. Technol. 2022, 437, 128347. [Google Scholar] [CrossRef]

- Wang, Q.; Jaramillo, A.M.; Pavon, J.J.; Webster, T.J. Red selenium nanoparticles and gray selenium nanorods as antibacterial coatings for PEEK medical devices. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 104, 1352–1358. [Google Scholar] [CrossRef] [PubMed]

- Inspektor, A.; Salvador, P.A. Architecture of PVD coatings for metalcutting applications: A review. Surf. Coat. Technol. 2014, 257, 138–153. [Google Scholar] [CrossRef]

- Omar, A.H.; Muda, K.; Majid, Z.A.; Affam, A.C.; Ezechi, E.H. Effect of magnetic activated carbon on the surface hydrophobicity for initial biogranulation via response surface methodology. Water Environ. Res. 2020, 92, 73–83. [Google Scholar] [CrossRef]

- Lakshmi, R.; Bharathidasan, T.; Bera, P.; Basu, B.J. Fabrication of superhydrophobic and oleophobic sol-gel nanocomposite coating. Surf. Coat. Technol. 2012, 206, 3888–3894. [Google Scholar] [CrossRef]

- Erbil, H.Y. Practical applications of superhydrophobic materials and coatings: Problems and perspectives. Langmuir 2020, 36, 2493–2509. [Google Scholar] [CrossRef]

- El-Shamy, O.A.; Deyab, M.A. Eco-friendly biosynthesis of silver nanoparticles and their improvement of anti-corrosion performance in epoxy coatings. J. Mol. Liq. 2023, 376, 121488. [Google Scholar] [CrossRef]

- Kulyk, B.; Freitas, M.A.; Santos, N.F.; Mohseni, F.; Carvalho, A.F.; Yasakau, K.; Fernandes, A.J.S.; Bernardes, A.; Figueiredo, B.; Silva, R.; et al. A critical review on the production and application of graphene and graphene-based materials in anti-corrosion coatings. Crit. Rev. Solid State Mater. Sci. 2022, 47, 309–355. [Google Scholar] [CrossRef]

- Banerjee, I.; Pangule, R.C.; Kane, R.S. Antifouling coatings: Recent developments in the design of surfaces that prevent fouling by proteins, bacteria, and marine organisms. Adv. Mater. 2011, 23, 690–718. [Google Scholar] [CrossRef] [PubMed]