Microstructure Evolution in Magnetron-Sputtered WC/SiC Multilayers with Varied WC Layer Thicknesses

Abstract

:1. Introduction

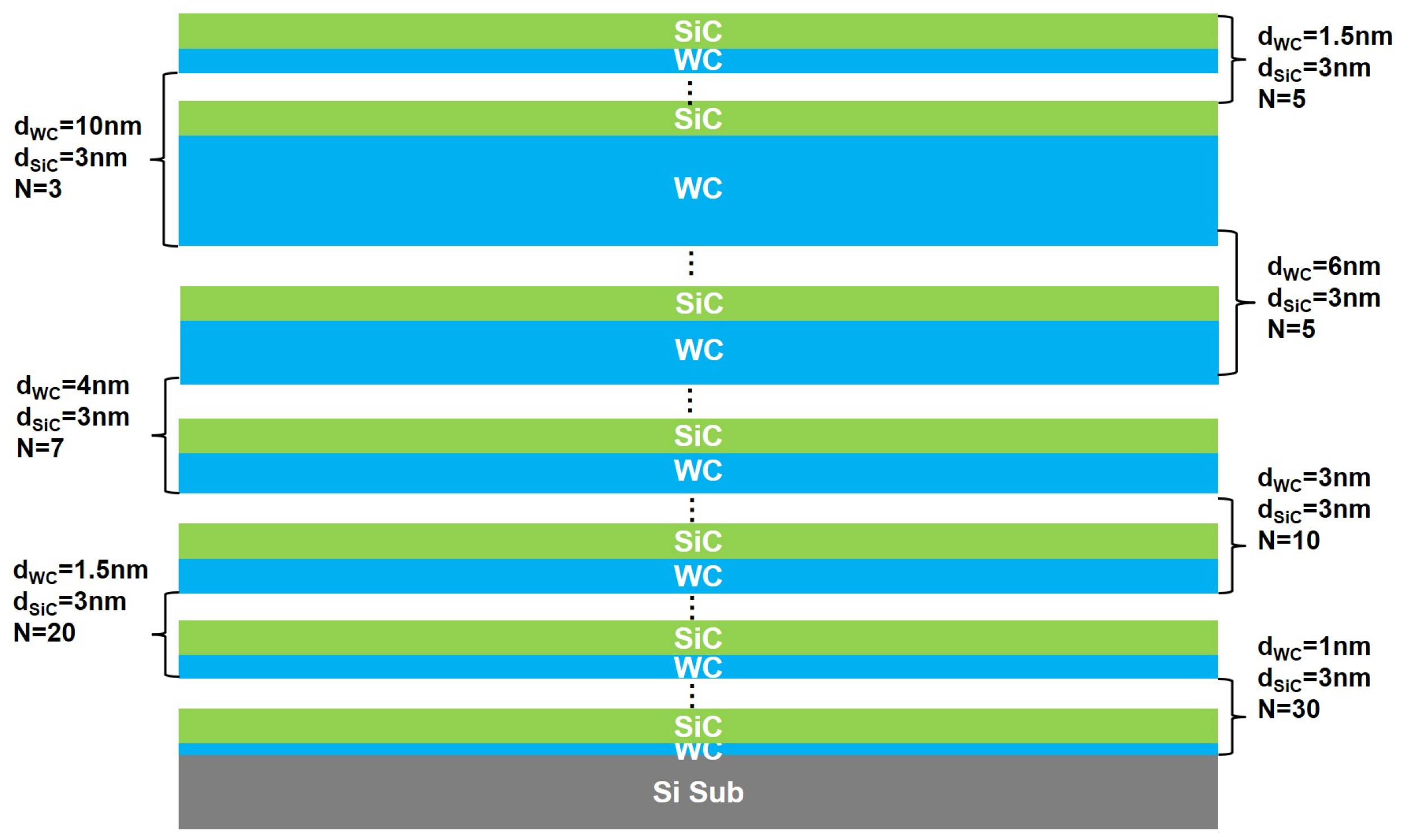

2. Materials and Methods

3. Results and Discussion

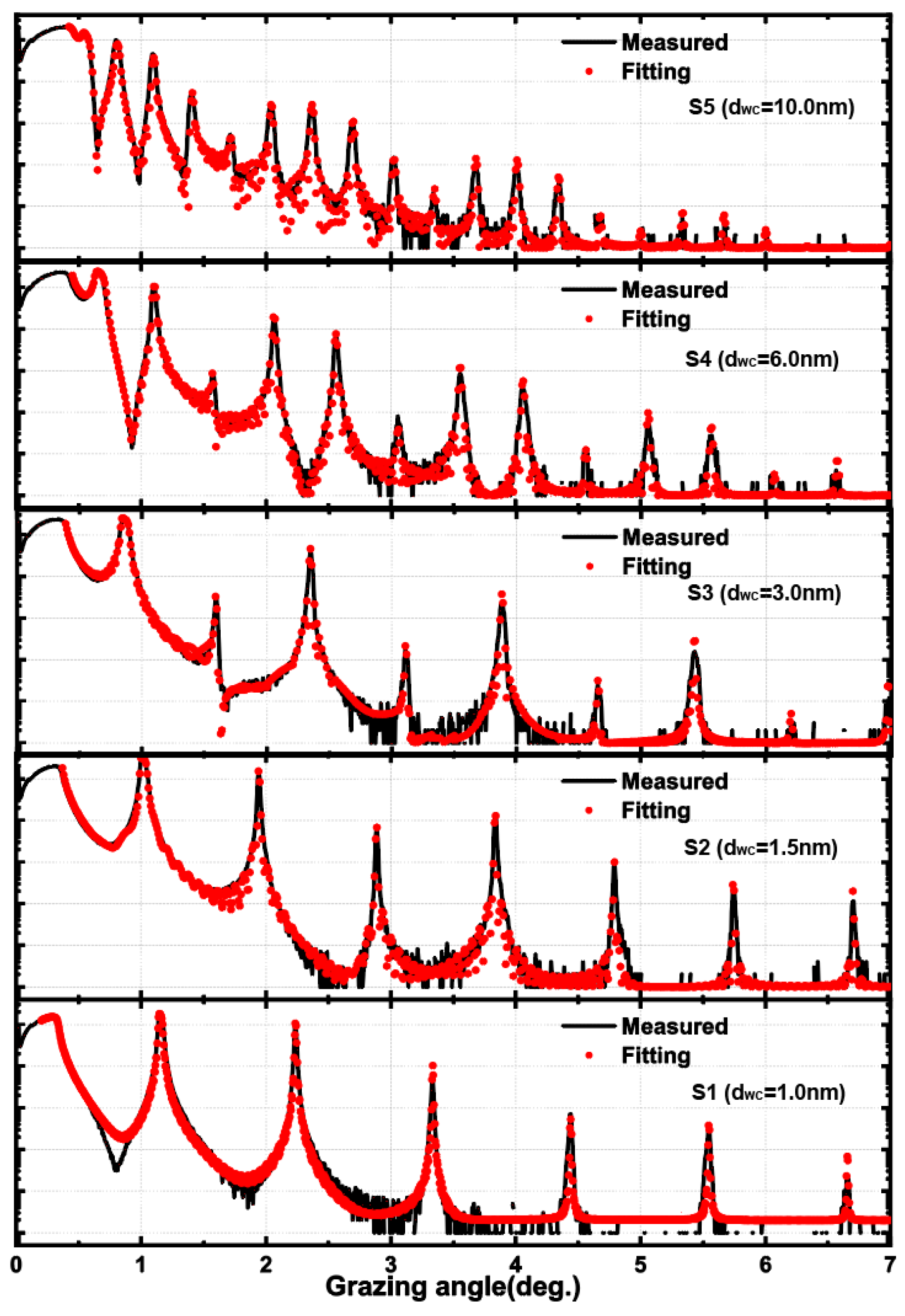

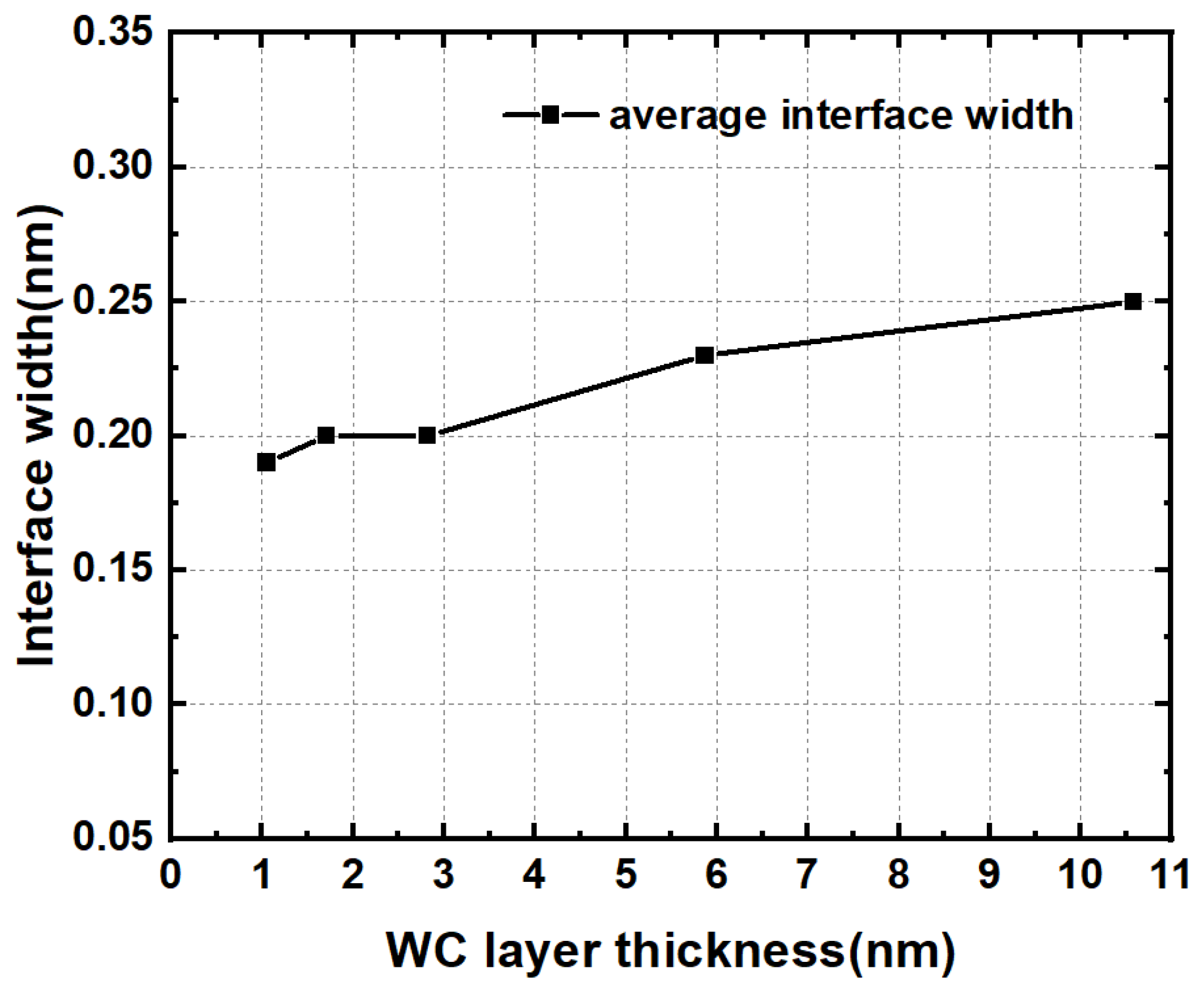

3.1. GIXR Measurement Analysis

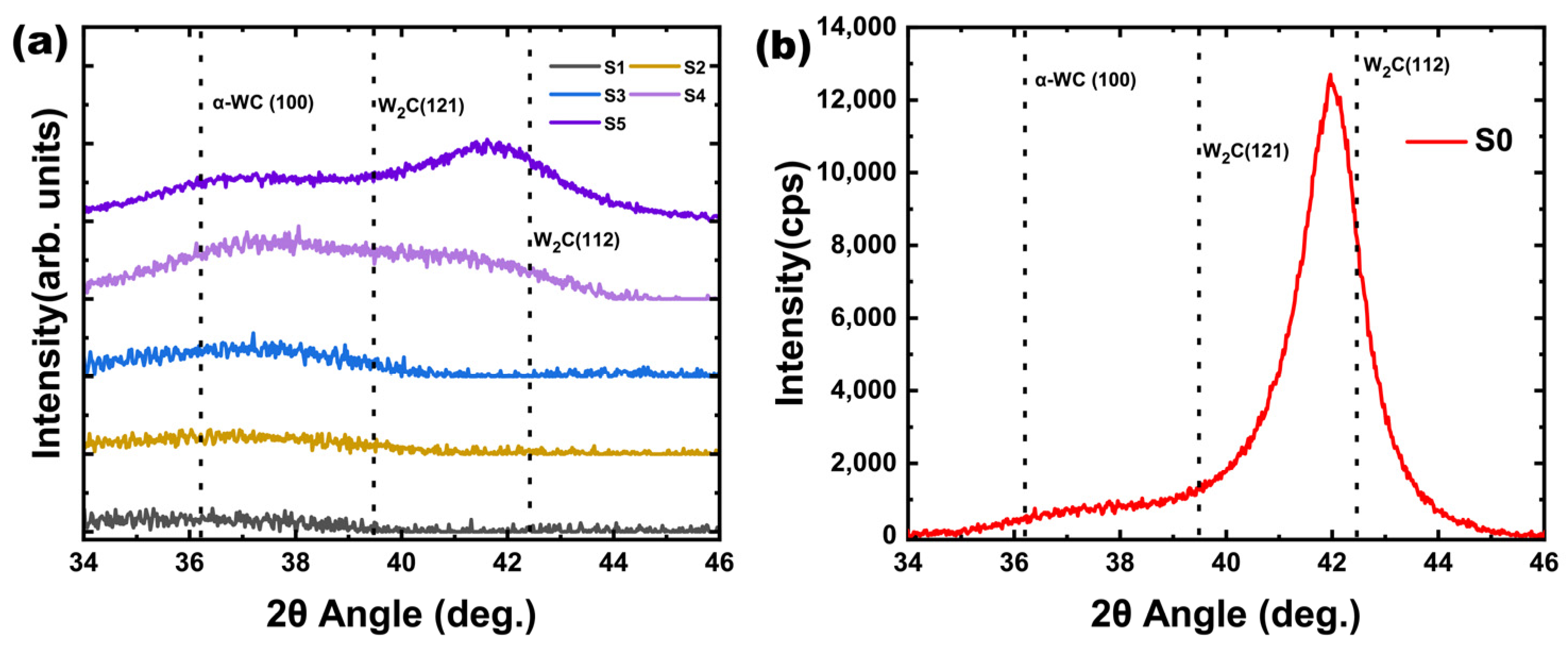

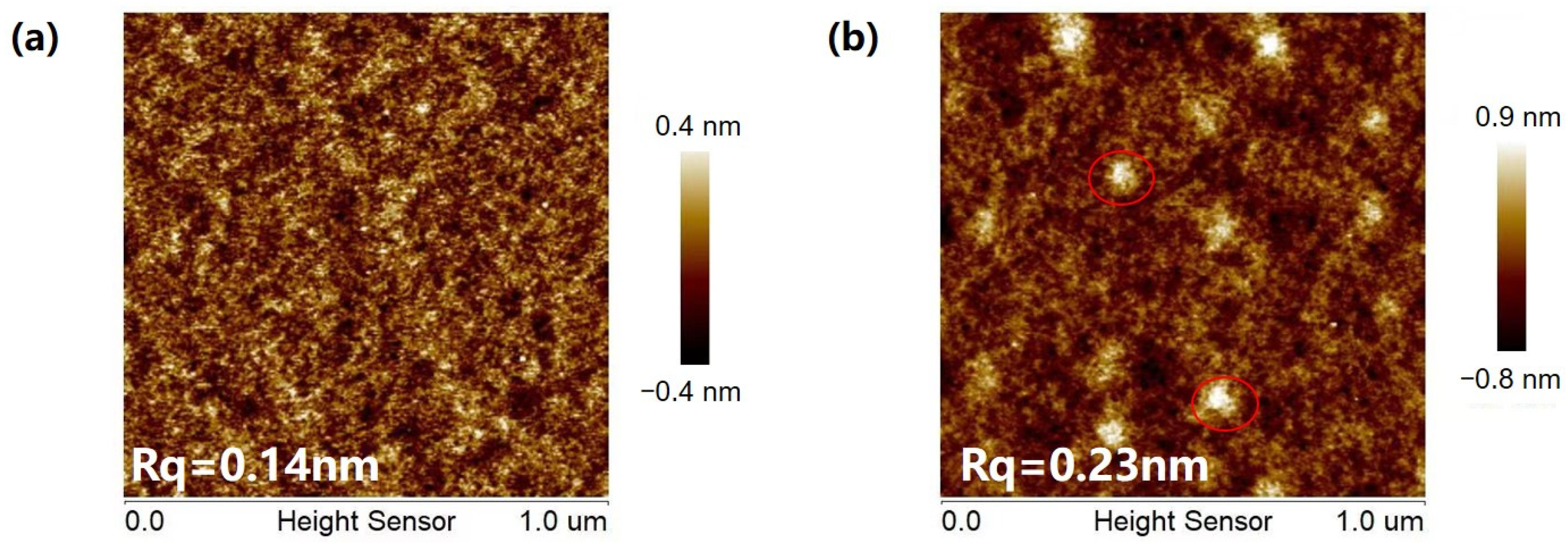

3.2. XRD and AFM Measurement Analysis

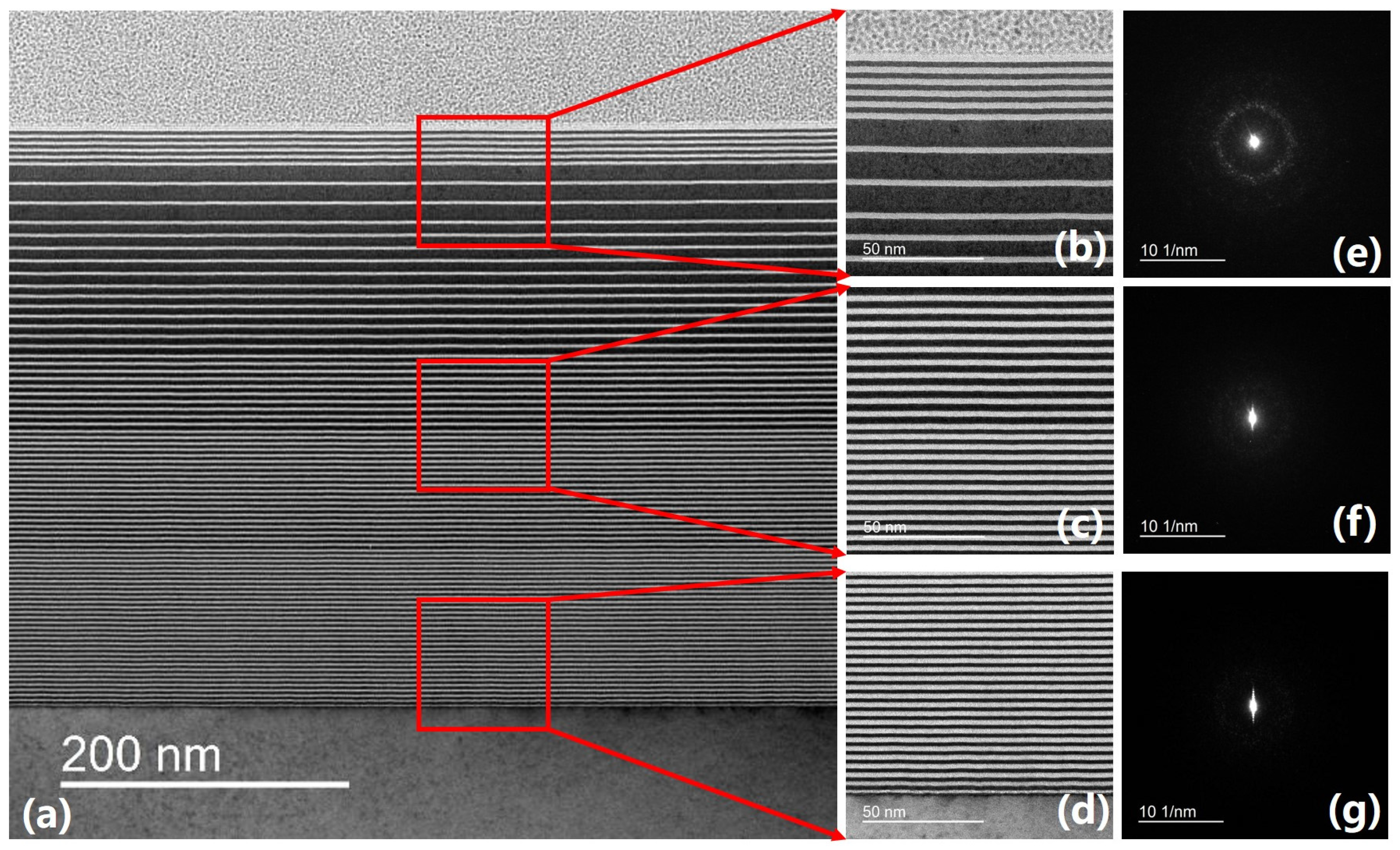

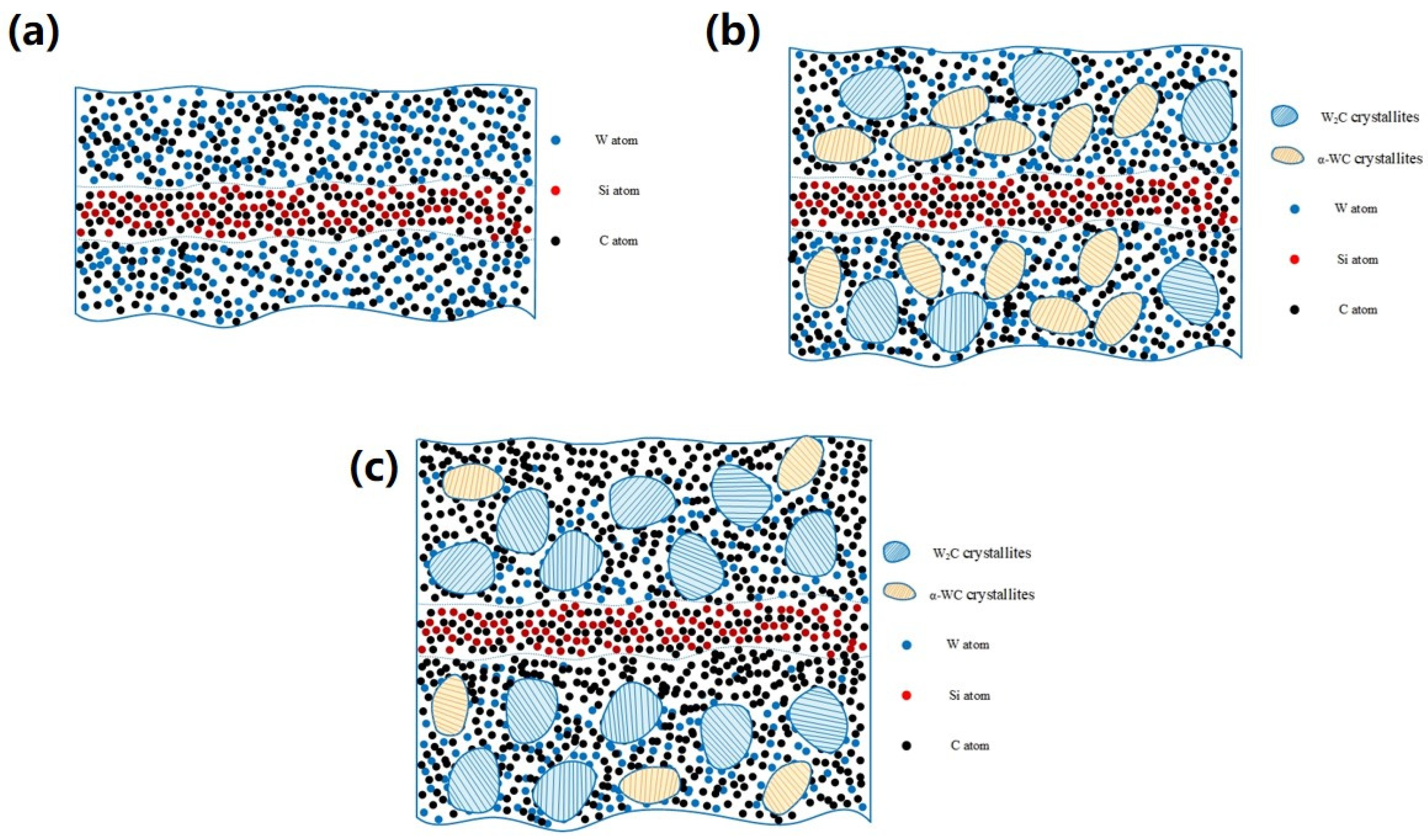

3.3. Transmission Electron Microscope Analysis

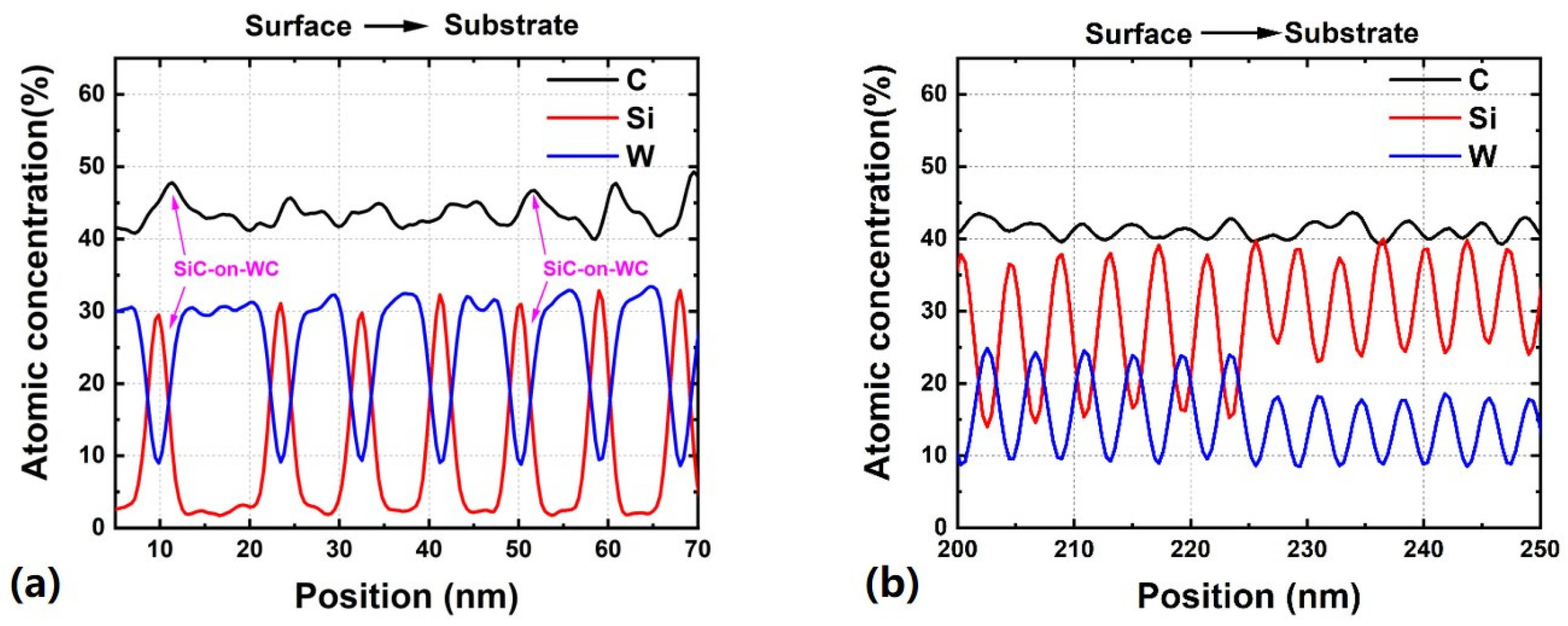

3.4. Energy-Dispersive X-ray Spectroscopy Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lider, V.V. Multilayer X-ray Interference Structures. Uspekhi Fiz. Nauk 2019, 189, 1137–1171. [Google Scholar] [CrossRef]

- Spiller, E. 14. Reflecting Optics: Multilayers. In Vacuum Ultraviolet Spectroscopy I; Lucatorto, T., Samson, J.A., Ederer, D.L., De Graef, M., Eds.; Academic Press: Cambridge, MA, USA, 1998; Volume 31, pp. 271–288. ISBN 1079-4042. [Google Scholar]

- Huang, Q.; Medvedev, V.; Van de Kruijs, R.; Yakshin, A.; Louis, E.; Bijkerk, F. Spectral Tailoring of Nanoscale EUV and Soft X-ray Multilayer Optics. Appl. Phys. Rev. 2017, 4, 011104. [Google Scholar] [CrossRef]

- Barrett, R.; Baker, R.; Cloetens, P.; Morawe, C.; Tucoulou, R.; Vivo, A. Reflective Optics for Hard X-ray Nanofocusing Applications at the ESRF. Synchrotron Radiat. News 2016, 29, 10–15. [Google Scholar] [CrossRef]

- Windt, D.L. Advancements in Hard X-ray Multilayers for X-ray Astronomy. In Optics for EUV, X-ray, and Gamma-ray Astronomy VII, Proceedings of the SPIE Optical Engineering + Applications 2005, San Diego, CA, USA, 9–13 August 2015; SPIE: Bellingham, WA, USA, 2015; Volume 9603, p. 96031C. [Google Scholar] [CrossRef]

- Leake, S.J.; Chahine, G.A.; Djazouli, H.; Zhou, T.; Richter, C.; Hilhorst, J.; Petit, L.; Richard, M.I.; Morawe, C.; Barrett, R.; et al. The Nanodiffraction Beamline ID01/ESRF: A Microscope for Imaging Strain and Structure. J. Synchrotron Radiat. 2019, 26, 571–584. [Google Scholar] [CrossRef]

- Pradhan, P.C.; Gangir, D.; Majhi, A.; Nayak, M.; Biswas, A.; Bhattacharyya, D.; Lodha, G.S. Fabrication and Performance of a High Resolution Ultra-Short Period W/B4C Multilayer Structure. J. Phys. D Appl. Phys. 2016, 49, 135305. [Google Scholar] [CrossRef]

- Majhi, A.; Nayak, M.; Pradhan, P.C.; Jena, S.; Gome, A.; Singh, M.N.; Srivastava, H.; Reddy, V.R.; Srivastava, A.K.; Sinha, A.K.; et al. Sub-Nanograin Metal Based High Efficiency Multilayer Reflective Optics for High Energies. RSC Adv. 2021, 11, 28097–28105. [Google Scholar] [CrossRef]

- Chon, K.S. Trilayer Model in Design of W/C Multilayer Mirrors with a Small Period Thickness. J. Mech. Sci. Technol. 2019, 33, 5837–5842. [Google Scholar] [CrossRef]

- Christensen, F.E.; Jensen, C.P.; Madsen, K.K.; Pivovaroff, M.J.; Chen, H.; Dariel, A.; Høghøj, P. Novel Multilayer Designs for Future Hard X-ray Missions. In Space Telescopes and Instrumentation II: Ultraviolet to Gamma Ray, Proceedings of the SPIE Astronomical Telescopes + Instrumentation 2006, Orlando, FL, USA, 24–31 May 2006; Society of Photo-Optical Instrumentation Engineers: Bellingham, WA, USA, 2006; Volume 6266, p. 626611. [Google Scholar] [CrossRef]

- Louis, E.; Yakshin, A.E.; Tsarfati, T.; Bijkerk, F. Nanometer Interface and Materials Control for Multilayer EUV-Optical Applications. Prog. Surf. Sci. 2011, 86, 255–294. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, J.; Zhu, Y.; Luo, H.; Li, Z.; Jiang, H.; Zhao, L. Asymmetric Interface and Growth Mechanism in Sputtered W/Si and WSi2/Si Multilayers. Appl. Surf. Sci. 2022, 604, 154531. [Google Scholar] [CrossRef]

- Harrison, F.A.; Boggs, S.E.; Bolotnikov, A.E.; Christensen, F.E.; Cook, W.R., III; Craig, W.W.; Hailey, C.J.; Jimenez-Garate, M.A.; Mao, P.H.; Schindler, S.M.; et al. Development of the High-Energy Focusing Telescope (HEFT) Balloon Experiment. In X-ray Optics, Instruments, and Missions III, Proceedings of the Astronomical Telescopes and Instrumentation 2000, Munich, Germany, 17–31 March 2000; Truemper, J.E., Aschenbach, B., Eds.; SPIE: Bellingham, WA, USA, 2000; Volume 4012, pp. 693–699. [Google Scholar]

- Jensen, C.P.; Madsen, K.K.; Christensen, F.E. Small D-Spacing WC/SiC Multilayers for Future Hard X-ray Telescope Designs. Exp. Astron. 2005, 20, 93–103. [Google Scholar] [CrossRef]

- Jensen, C.P.; Madsen, K.K.; Christensen, F.E. Investigation of New Material Combinations for Hard X-ray Telescope Designs. In Space Telescopes and Instrumentation II: Ultraviolet to Gamma R, Proceedings of the SPIE Astronomical Telescopes + Instrumentation 2006, Orlando, FL, USA, 24–31 May 2006; SPIE: Bellingham, WA, USA, 2006; Volume 6266, p. 626612. [Google Scholar] [CrossRef]

- Larruquert, J.I. Optical Properties of Thin Film Materials at Short Wavelengths; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780081020739. [Google Scholar]

- Fernández-Perea, M.; Pivovaroff, M.J.; Soufli, R.; Alameda, J.; Mirkarimi, P.; Descalle, M.A.; Baker, S.L.; McCarville, T.; Ziock, K.; Hornback, D.; et al. Ultra-Short-Period WC/SiC Multilayer Coatings for X-ray Applications. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2013, 710, 114–119. [Google Scholar] [CrossRef]

- Fernández-Perea, M.; Descalle, M.A.; Soufli, R.; Ziock, K.P.; Alameda, J.; Baker, S.L.; McCarville, T.J.; Honkimäki, V.; Ziegler, E.; Jakobsen, A.C.; et al. Physics of Reflective Optics for the Soft Gamma-Ray Photon Energy Range. Phys. Rev. Lett. 2013, 111, 1–5. [Google Scholar] [CrossRef]

- Pivovaroff, M.J.; Ziock, K.P.; Fernandez-Perea, M.; Harrison, M.J.; Soufli, R. Gamma-Ray Mirrors for Direct Measurement of Spent Nuclear Fuel. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2014, 743, 109–113. [Google Scholar] [CrossRef]

- Brejnholt, N.F.; Decker, T.A.; Hill, R.M.; Chen, H.; Williams, G.J.; Park, J.; Alameda, J.B.; Fernández-Perea, M.; Pivovaroff, M.J.; Soufli, R.; et al. Reflective Multilayer Optic as Hard X-ray Diagnostic on Laser-Plasma Experiment. Rev. Sci. Instrum. 2015, 86, 013110. [Google Scholar] [CrossRef]

- Bajt, S.; Prasciolu, M.; Fleckenstein, H.; Domaracký, M.; Chapman, H.N.; Morgan, A.J.; Yefanov, O.; Messerschmidt, M.; Du, Y.; Murray, K.T.; et al. X-ray Focusing with Efficient High-NA Multilayer Laue Lenses. Light Sci. Appl. 2018, 7, 17162. [Google Scholar] [CrossRef]

- Prasciolu, M.; Bajt, S. On the Properties of WC/SiC Multilayers. Appl. Sci. 2018, 8, 571. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Z.; Liu, Y.; Wang, Z. Crystallization and Composition of Ni-C/Ti Multilayer with Varied Ni-C Thickness. Coatings 2022, 12, 1144. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhang, Z.; Ma, S.; Qi, R.; Li, J.; Wang, Z.; Le Guen, K.; André, J.M.; Jonnard, P. The Transition from Amorphous to Crystalline in Al/Zr Multilayers. J. Appl. Phys. 2013, 113, 133508. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Z.; Qi, R.; Huang, Q.; Wang, Z. Microstructural Evolution of Ni/Ti Multilayers Doped with Nitrogen at Different d-Spacings for Neutron Supermirrors. Vacuum 2023, 210, 111881. [Google Scholar] [CrossRef]

- Oliver, J.B. Analysis of a Planetary-Rotation System for Evaporated Optical Coatings. Appl. Opt. 2016, 55, 8550. [Google Scholar] [CrossRef]

- Wei, Z.; Zhang, Z.; Jiang, L.; Yang, Y.; Chang, C.; Feng, Y.; Qi, R.; Huang, Q.; Yan, W.; Xie, C.; et al. Background Pressure Induced Structural and Chemical Change in NiV/B4C Multilayers Prepared by Magnetron Sputtering. Front. Phys. 2022, 10, 837819. [Google Scholar] [CrossRef]

- Henke, B.L.; Gullikson, E.M.; Davis, J.C. X-ray Interactions: Photoabsorption, Scattering, Transmission, and Reflection at E = 50–30,000 EV, Z = 1–92. At. Data Nucl. Data Tables 1993, 54, 181–342. [Google Scholar] [CrossRef]

- Wormington, M.; Panaccione, C.; Matney, K.M.; Bowen, D.K. Characterization of Structures from X-ray Scattering Data Using Genetic Algorithms. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 1999, 357, 2827–2848. [Google Scholar] [CrossRef]

- Smetanina, K.E.; Andreev, P.V.; Lantsev, E.A.; Nokhrin, A.V.; Murashov, A.A.; Isaeva, N.V.; Blagoveshchensky, Y.V.; Boldin, M.S.; Chuvil’deev, V.N. Nonuniform Distribution of Crystalline Phases and Grain Sizes in the Surface Layers of WC Ceramics Produced by Spark Plasma Sintering. Coatings 2023, 13, 1051. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Gong, L.; Tang, J.; Wang, X.; Guo, H.; Zhou, X. P-Doped W2C Nanoparticles for Hydrogen Evolution Reaction Powered by a Wind-Driven Triboelectric Nanogenerator. Nano Energy 2024, 121, 109242. [Google Scholar] [CrossRef]

- Mazur, M.; Poniedziałek, A.; Kaczmarek, D.; Wojcieszak, D.; Domaradzki, J.; Gibson, D. Investigation of Various Properties of HfO2-TiO2 Thin Film Composites Deposited by Multi-Magnetron Sputtering System. Appl. Surf. Sci. 2017, 421, 170–178. [Google Scholar] [CrossRef]

- Obstarczyk, A.; Kaczmarek, D.; Wojcieszak, D.; Mazur, M.; Domaradzki, J.; Kotwica, T.; Pastuszek, R.; Schmeisser, D.; Mazur, P.; Kot, M. Tailoring Optical and Electrical Properties of Thin-Film Coatings Based on Mixed Hf and Ti Oxides for Optoelectronic Application. Mater. Des. 2019, 175, 107822. [Google Scholar] [CrossRef]

| S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|

| WC thickness (dWC) | 1 nm | 1.5 nm | 3 nm | 6 nm | 10 nm |

| SiC thickness (dSiC) | 3 nm | 3 nm | 3 nm | 3 nm | 3 nm |

| Period | 4 nm | 4.5 nm | 6 nm | 9 nm | 13 nm |

| Number of bilayers (N) | 120 | 80 | 40 | 20 | 12 |

| Residence time for WC | 12.72 s | 19.08 s | 38.16 s | 76.32 s | 127.20 s |

| S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|

| WC thickness (dWC) | 1.05 nm | 1.71 nm | 2.82 nm | 5.87 nm | 10.58 nm |

| SiC thickness (dSiC) | 2.94 nm | 2.91 nm | 2.90 nm | 2.90 nm | 2.73 nm |

| Average interface width | 0.19 nm | 0.20 nm | 0.20 nm | 0.23 nm | 0.25 nm |

| Number of bilayers (N) | 120 | 80 | 40 | 20 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Zhang, Z.; Wang, Z.; Jiang, L.; Qi, R.; Huang, Q.; Zhang, Z.; Wang, Z. Microstructure Evolution in Magnetron-Sputtered WC/SiC Multilayers with Varied WC Layer Thicknesses. Coatings 2024, 14, 720. https://doi.org/10.3390/coatings14060720

Li T, Zhang Z, Wang Z, Jiang L, Qi R, Huang Q, Zhang Z, Wang Z. Microstructure Evolution in Magnetron-Sputtered WC/SiC Multilayers with Varied WC Layer Thicknesses. Coatings. 2024; 14(6):720. https://doi.org/10.3390/coatings14060720

Chicago/Turabian StyleLi, Tongzhou, Zhe Zhang, Zile Wang, Li Jiang, Runze Qi, Qiushi Huang, Zhong Zhang, and Zhanshan Wang. 2024. "Microstructure Evolution in Magnetron-Sputtered WC/SiC Multilayers with Varied WC Layer Thicknesses" Coatings 14, no. 6: 720. https://doi.org/10.3390/coatings14060720

APA StyleLi, T., Zhang, Z., Wang, Z., Jiang, L., Qi, R., Huang, Q., Zhang, Z., & Wang, Z. (2024). Microstructure Evolution in Magnetron-Sputtered WC/SiC Multilayers with Varied WC Layer Thicknesses. Coatings, 14(6), 720. https://doi.org/10.3390/coatings14060720