Research on the Skidding Resistance and Attenuation Characteristics of Asphalt Pavement Based on Image Recognition-Analysis Strategy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Test Methods

2.2.1. Sand Patch Method

2.2.2. Skidding Resistance of Asphalt Pavement Based on Texture Structure

Image Acquisition and Processing of Asphalt Pavement

- (1)

- Standardized image acquisition

- (2)

- Image processing

- (3)

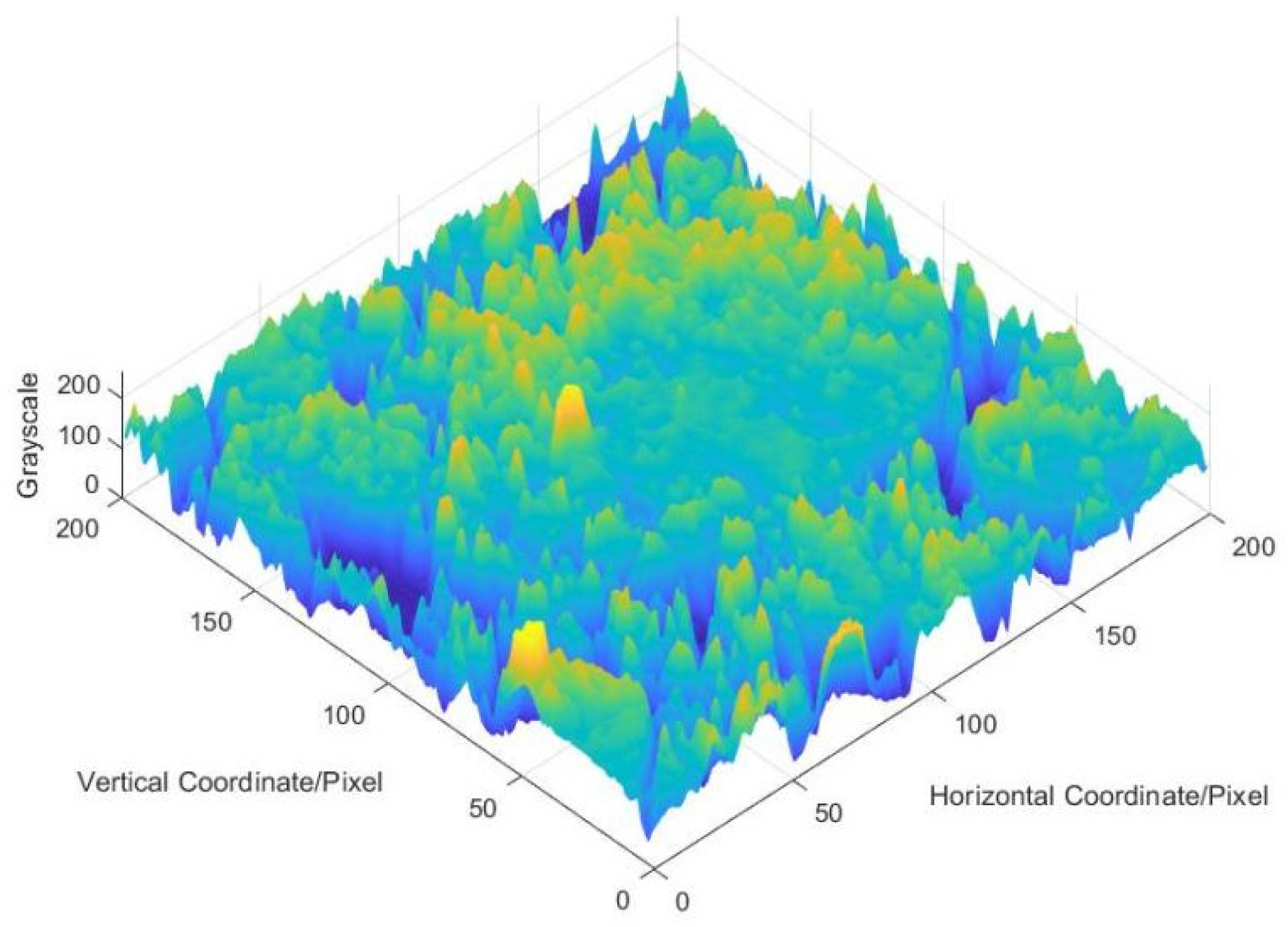

- Three-dimensional reconstruction of texture image

Texture Parameters Based on Gray-Level Co-Occurrence Matrix

- (1)

- Energy

- (2)

- Entropy

- (3)

- Inertial moment

- (4)

- Correlation

Texture Parameters Based on Multifractal Theory

2.2.3. Attenuation Test of Skidding Resistance for Asphalt Pavement

3. Results and Discussion

3.1. Evaluation of Texture Properties of Asphalt Pavement

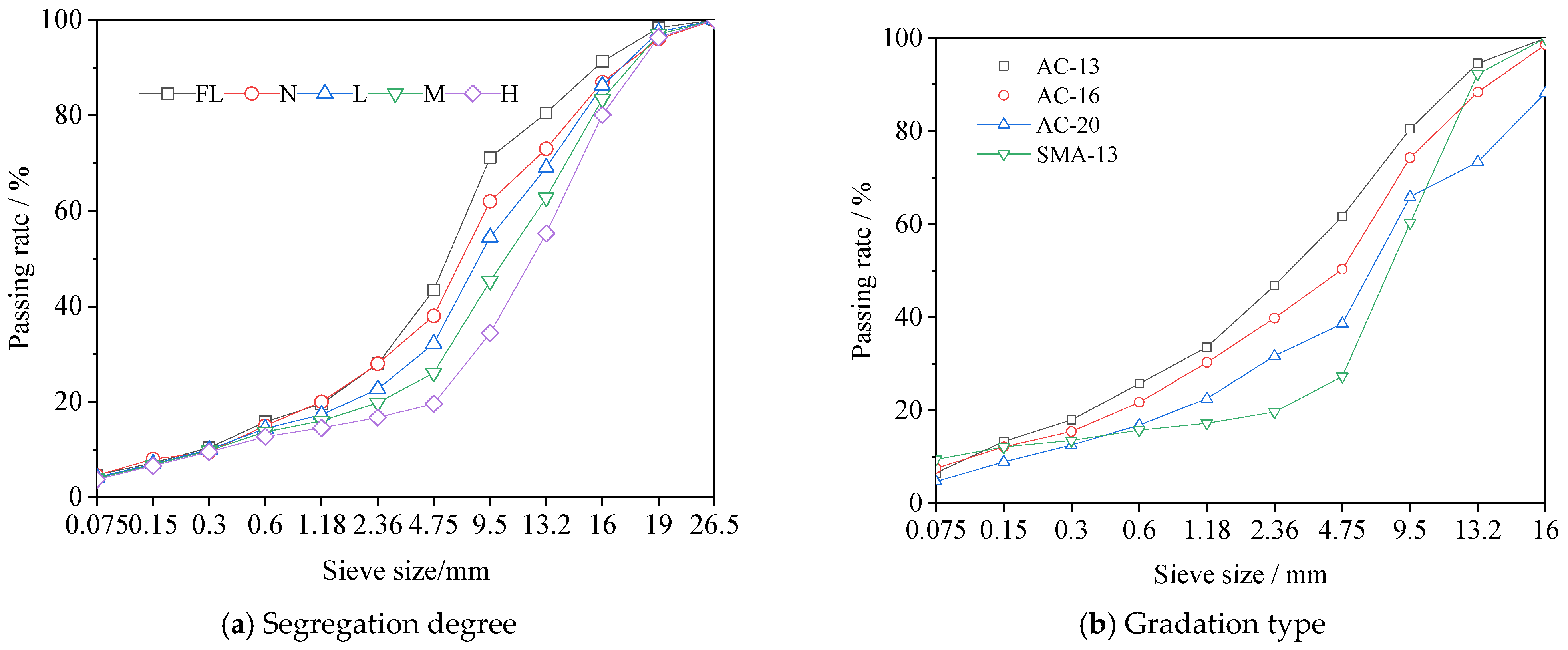

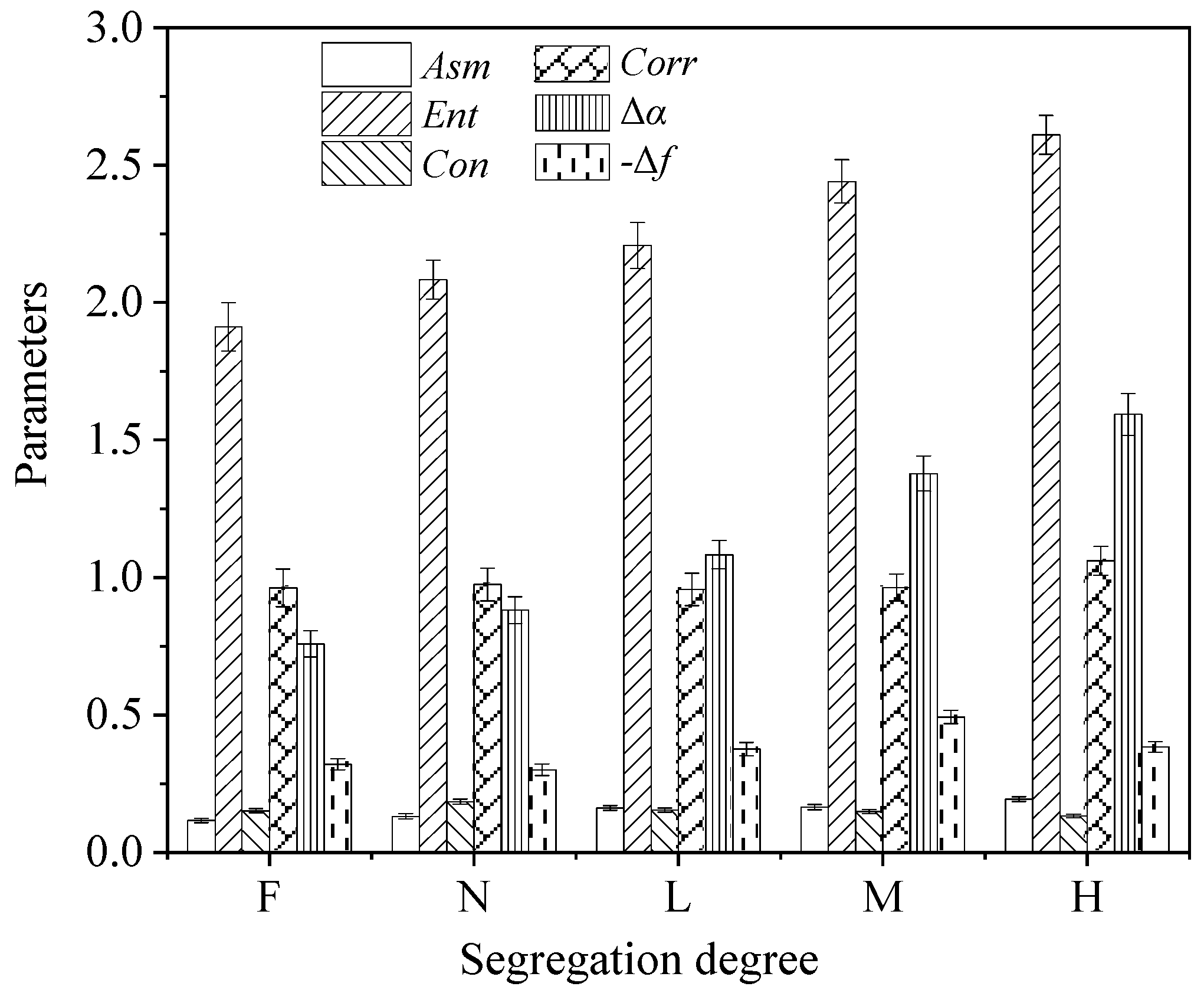

3.1.1. Texture Properties of Asphalt Pavement with Various Segregation Degrees

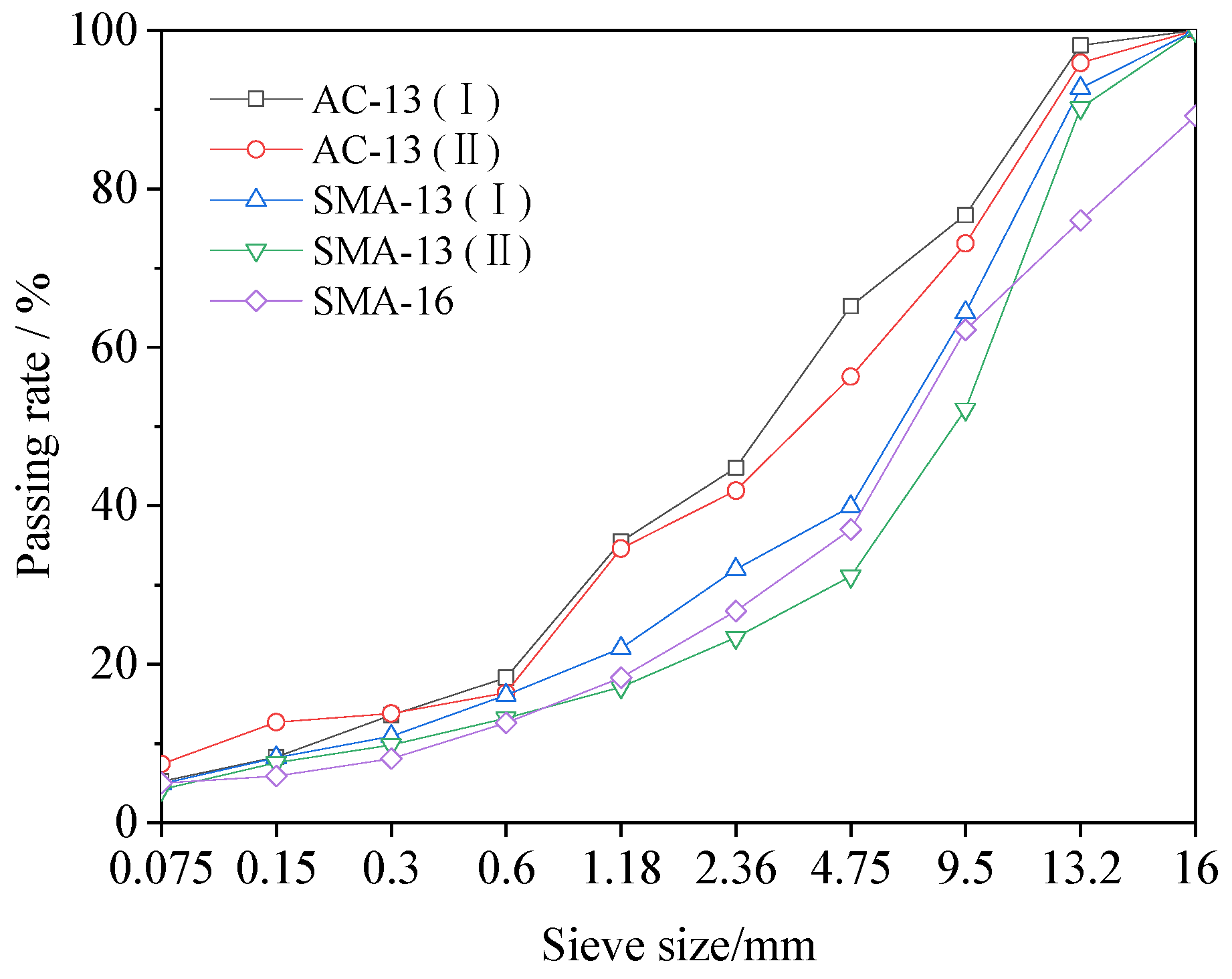

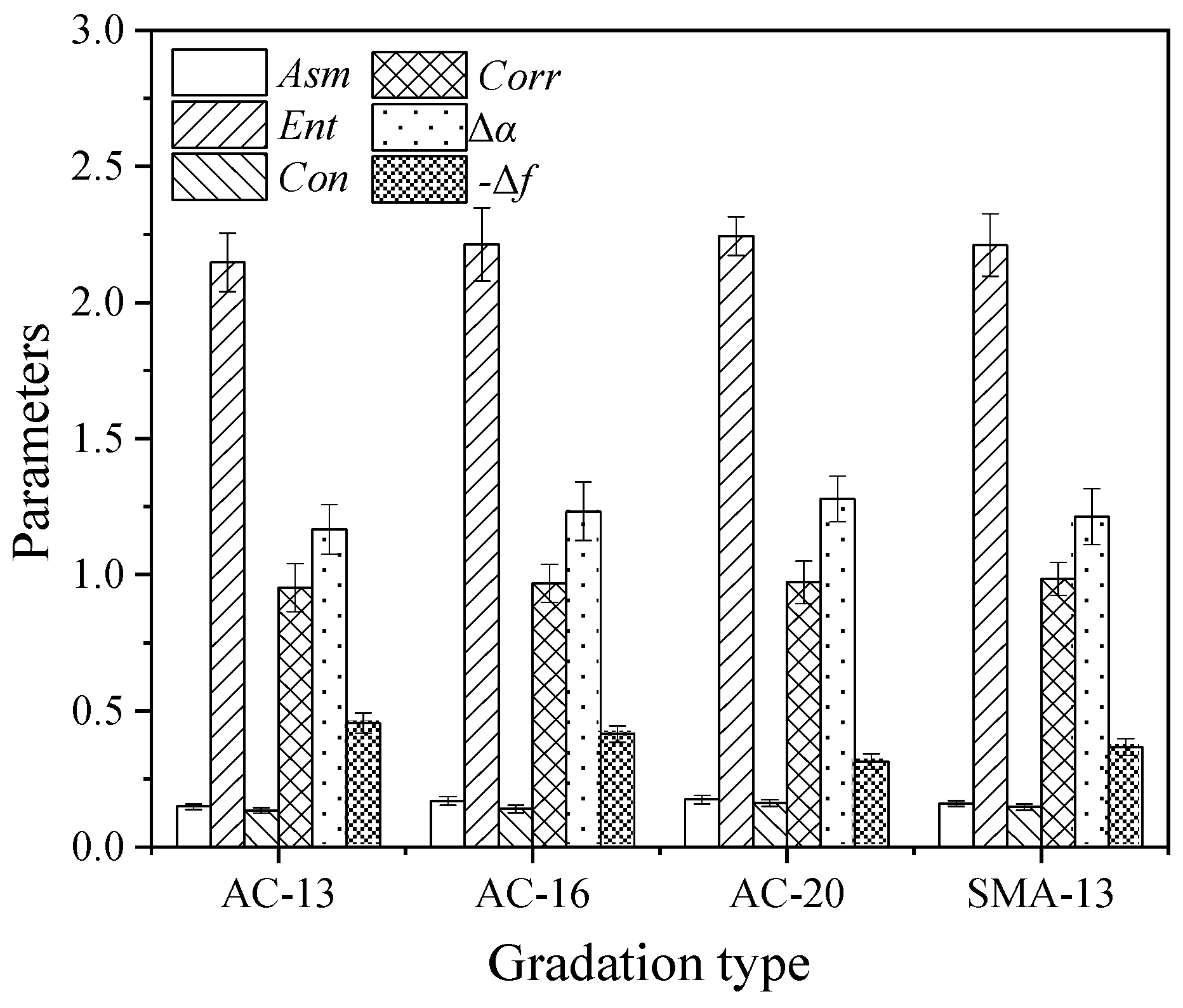

3.1.2. Texture Properties of Asphalt Pavement with Various Gradation Types

3.2. Evaluation of Skidding Resistance of Asphalt Pavement Based on Texture Properties

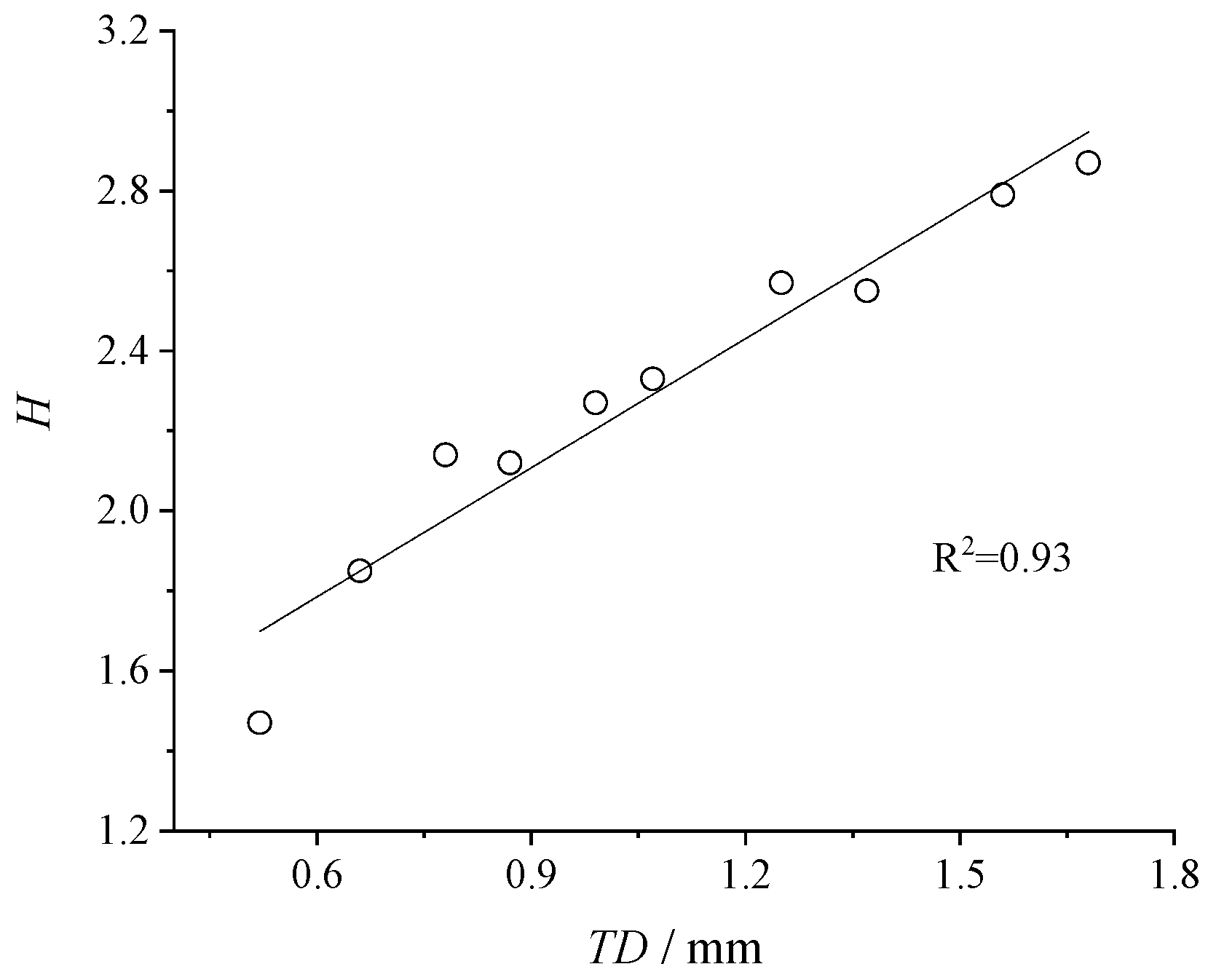

3.2.1. Correlation Analysis between Texture Parameters and Anti-Skidding Performance

3.2.2. Evaluation Index of Anti-Skidding Performance of Asphalt Pavement

3.3. Attenuation Characteristics of Anti-Skidding Performance of Asphalt Pavement

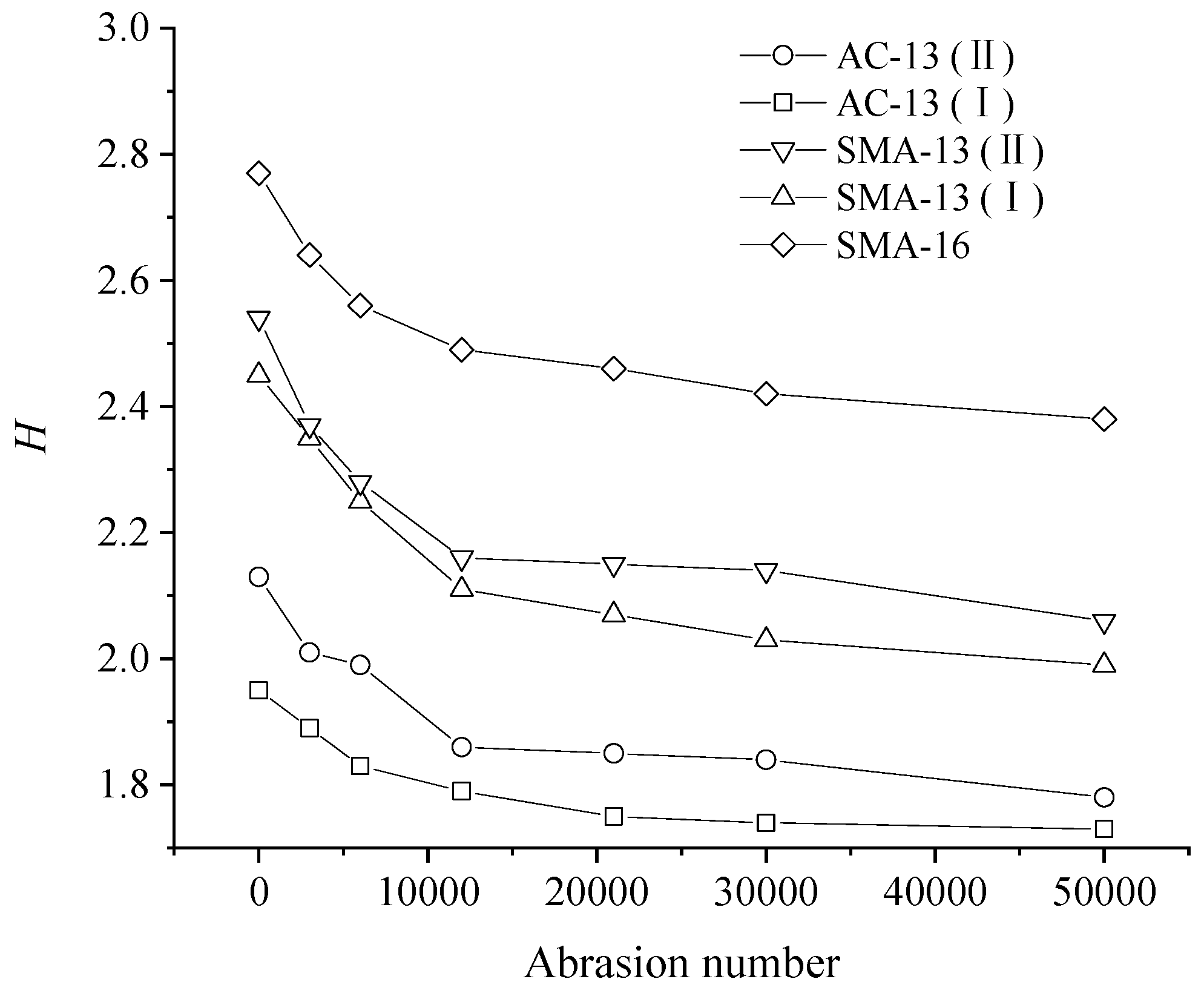

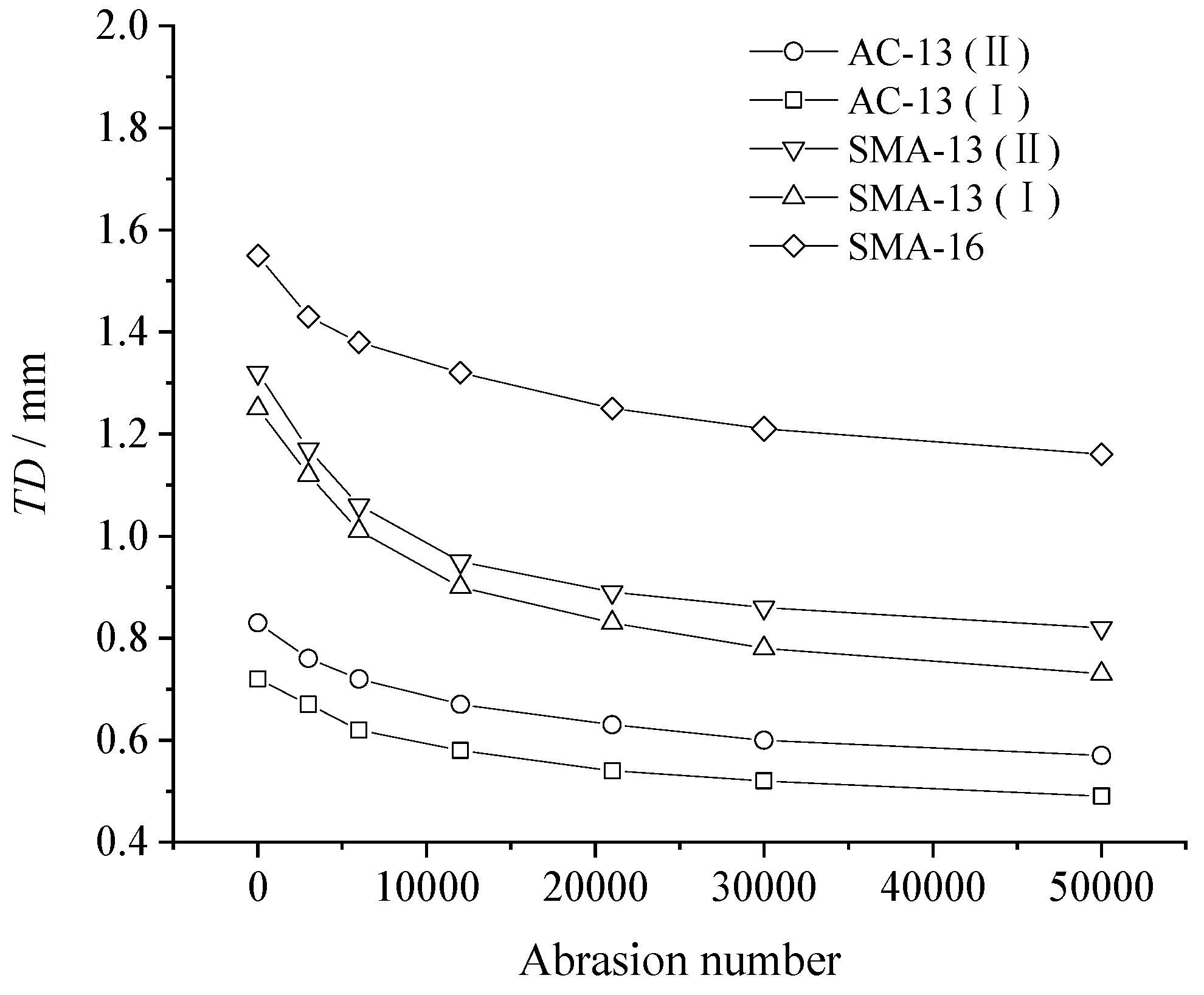

3.3.1. Attenuation Characteristics of Skidding Resistance for Asphalt Pavement

3.3.2. Attenuation Fitting Model of Skidding Resistance for Asphalt Mixture

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pranjić, I.; Deluka-Tibljaš, A. Pavement Texture–Friction relationship establishment via image analysis methods. Materials 2022, 15, 846. [Google Scholar] [CrossRef]

- Dell’Annunziata, G.N.; Adiletta, G.; Farroni, F.; Sakhnevych, A.; Timpone, F. Tire wear sensitivity analysis and modeling based on a statistical multidisciplinary approach for high-performance vehicles. Lubricants 2023, 11, 269. [Google Scholar] [CrossRef]

- Guo, R.; Liu, S.; He, Y.; Xu, L. Study on vehicle-road interaction for autonomous driving. Sustainability 2022, 14, 11693. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Hu, H.; Shi, X.; Chen, L. Developing a skid resistance prediction model for newly built pavement: Application to a case study of steel bridge deck pavement. Road Mater. Pavement Des. 2022, 23, 2334–2352. [Google Scholar] [CrossRef]

- Chen, B.; Xiong, C.; Li, W.; He, J.; Zhang, X. Assessing surface texture features of asphalt pavement based on three-dimensional laser scanning technology. Buildings 2021, 11, 623. [Google Scholar] [CrossRef]

- Chen, J.; Yuan, X.; Liu, Q.; Zhao, C.; Zhou, R.; Huang, J. Identifying texture and friction of asphalt pavement surface with optimized close-range photogrammetry method. J. Test. Eval. 2023, 51, 3081–3094. [Google Scholar] [CrossRef]

- Zelelew, H.; Khasawneh, M.; Abbas, A. Wavelet-based characterization of asphalt pavement surface macro-texture. Road Mater. Pavement Des. 2014, 15, 622–641. [Google Scholar] [CrossRef]

- Miller, T.; Swiertz, D.; Tashman, L.; Tabatabaee, N.; Bahia, U. Characterization of asphalt pavement surface texture. Transp. Res. Rec. 2012, 2295, 19–26. [Google Scholar] [CrossRef]

- Dan, H.; Gao, L.; Wang, H.; Tang, J. Discrete-element modeling of mean texture depth and wearing behavior of asphalt mixture. J. Mater. Civ. Eng. 2022, 34, 04022027. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, Z.; Han, Y.; Hao, X.; Pei, L. Pavement skidding resistance evaluation based on hyperopt-NGBoost fusion model using non-contact measurement of 3D macrotexture data. Arab. J. Sci. Eng. 2023, 48, 5507–5524. [Google Scholar] [CrossRef]

- Hoang, N.D.; Tran, V.; Tran, X.L. Image processing-based classification of pavement fatigue severity using extremely randomized trees, deep neural network, and convolutional neural network. Int. J. Pavement Eng. 2023, 24, 2201902. [Google Scholar] [CrossRef]

- Lu, J.; Pan, B.; Ren, W.; Liu, Q.; Liu, P.; Oeser, M. Regeneration of pavement surface textures using M-sigmoid-normalized generative adversarial networks. Comput. Aided Civ. Infrastruct. Eng. 2023, 38, 2225–2241. [Google Scholar] [CrossRef]

- He, J.; Shao, L.; Li, Y.; Wang, K.; Liu, W. Pavement damage identification and evaluation in UAV-captured images using gray level co-occurrence matrix and cloud model. J. King Saud Univ. Comput. Inf. Sci. 2023, 35, 101762. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, Z.; Han, Y.; Li, W.; Pei, L. Evaluate pavement skidding resistance performance based on bayesian-Light GBM using 3D surface macrotexture data. Materials 2022, 15, 5275. [Google Scholar] [CrossRef] [PubMed]

- Roy, N.; Kuna, K.K. Image texture analysis to evaluate the microtexture of coarse aggregates for pavement surface courses. Int. J. Pavement Eng. 2023, 24, 2099854. [Google Scholar] [CrossRef]

- Sun, P.; Zhang, K.; Sen, H.; Xiao, Y. Aggregate geometrical features and their influence on the surface properties of asphalt pavement. Materials 2022, 15, 3222. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, P.; Li, L.; Zhao, Y.; Zhao, Y.; Zhang, Z. A novel evaluation method of aggregate distribution homogeneity for asphalt pavement based on the characteristics of texture structure. Constr. Build. Mater. 2021, 306, 124927. [Google Scholar] [CrossRef]

- Liang, J.; Gu, X.; YChen, Z.; Ni, F.; Zhang, T. A novel pavement mean texture depth evaluation strategy based on three-dimensional pavement data filtered by a new filtering approach. Measurement 2020, 166, 108265. [Google Scholar] [CrossRef]

- Dan, H.; Lu, B.; Li, M. Evaluation of asphalt pavement texture using multiview stereo reconstruction based on deep learning. Constr. Build. Mater. 2024, 412, 134837. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Cheng, Y.; Xue, J. Evaluation of the decay characteristics of pavement skidding resistance using three-dimensional texture from accelerated abrasion test. J. Transp. Eng. Part B Pavements 2020, 146, 04020073. [Google Scholar] [CrossRef]

- Salehi, M.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Blume, A. Characterization of counter-surface substrates for a laboratory abrasion tester (LAT100) compared with asphalt and concrete to predict car tire performance. Lubricants 2022, 10, 8. [Google Scholar] [CrossRef]

- Yu, Y.; Tang, S.; Xu, G.; Fan, Y.; Wu, Y.; Wang, H.; Yang, J. Investigations on the long-term skidding resistance of epoxy asphalt mixture based on accelerated loading test. Constr. Build. Mater. 2023, 365, 130150. [Google Scholar] [CrossRef]

- Wu, X.; Zheng, N.; Lei, J. Influencing factors and mechanism for the attenuation of the skidding resistance for bauxite clinker-asphalt mixtures. Constr. Build. Mater. 2021, 283, 122670. [Google Scholar] [CrossRef]

- Wang, P.; Wei, H.; Liu, X.; Ren, R.; Wang, L. Identifying the long-term thermal storage stability of SBS-polymer-modified asphalt, including physical indexes, rheological properties, and micro-structures characteristics. Sustainability 2021, 13, 10582. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, Z.; Pei, L.; Han, Y.; Li, W. Evaluate asphalt pavement frictional characteristics based on IGWO-NGBoost using 3D macro-texture data. Expert Syst. Appl. 2024, 242, 122786. [Google Scholar] [CrossRef]

- Zhang, K.; Wei, G.; Xie, W.; Yang, B.; Li, W.; Luo, Y. A novel evaluation method of construction homogeneity for asphalt pavement based on the characteristic of component distribution. Materials 2022, 15, 7284. [Google Scholar] [CrossRef] [PubMed]

- JTG F40-2004; Technical Specification for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Zhang, K.; Wei, G.; Luo, Y.; Zhao, Y.; Zhao, Y.; Zhang, J. Evaluation of aggregate distribution homogeneity for asphalt pavement based on the fractal characteristic of three-dimensional texture. Int. J. Pavement Res. Technol. 2024, 17, 577–594. [Google Scholar] [CrossRef]

- Zhao, X.; Xue, L.; Xu, F. Asphalt pavement paving segregation detection method using more efficiency and quality texture features extract algorithm. Constr. Build. Mater. 2021, 277, 122302. [Google Scholar] [CrossRef]

- Sun, L.; Wang, Y. Three-dimensional reconstruction of macrotexture and microtexture morphology of pavement surface using six light sources-based photometric stereo with lowrank approximation. J. Comput. Civ. Eng. 2017, 31, 04016054. [Google Scholar] [CrossRef]

- Li, Y.; Qin, Y.; Wang, H.; Xu, S.; Li, S. Study of texture indicators applied to pavement wear analysis based on 3D image technology. Sensors 2022, 22, 4955. [Google Scholar] [CrossRef]

- Cong, L.; Shi, J.; Wang, T.; Yang, F.; Zhu, T. A method to evaluate the segregation of compacted asphalt pavement by processing the images of paved asphalt mixture. Constr. Build. Mater. 2019, 224, 622–629. [Google Scholar] [CrossRef]

- Ashvin, B.; Chhabra, C.; Meneveau, R.V.; Jensen, K.R. Direct determination of the f(α) singularity spectrum and its application to fully developed turbulence. Phys. Rev. A Gen. Phys. 1989, 40, 5284–5294. [Google Scholar]

- Luo, Y.; Zhao, X.; Zhang, K.; Shi, X.; Li, G. Research on skid-resistance durability of high viscosity modified asphalt mixture by accelerated abrasion test. Case Stud. Constr. Mater. 2024, 20, e02878. [Google Scholar]

- Zeng, S.; Zhang, C.; Zeng, K.; Liang, N.; Song, S. Real-time identification of asphalt mixture segregation during paving process using digital imaging technique and Four-side static moment. Constr. Build. Mater. 2023, 397, 132436. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Yang, J.; Shi, X.; Xu, X.; Luo, S.; Huang, W. Evaluation of anti-skid performance of asphalt mixture based on accelerated loading test. Appl. Sci. 2023, 13, 4796. [Google Scholar] [CrossRef]

- Shi, L.; Wang, D.; Jin, C.; Li, B.; Liang, H. Measurement of coarse aggregates movement characteristics within asphalt mixture using digital image processing methods. Measurement 2020, 163, 107948. [Google Scholar] [CrossRef]

- Zhu, S.; Ji, X.; Zhang, Z.; Shao, D.; Li, H.; Yun, C. Evolution characteristics of the surface texture of the wearing course on asphalt pavement based on accelerated pavement polishing. Constr. Build. Mater. 2022, 333, 127266. [Google Scholar] [CrossRef]

- Ran, M.; Xiao, S.; Zhou, X.; Xiao, W. Evaluation of segregation in asphalt pavement surface using concave multifractal distribution. J. Test. Eval. 2018, 46, 2100–2109. [Google Scholar] [CrossRef]

- Dong, S.; Han, S.; Zhang, Q.; Han, X.; Zhang, Z.; Yao, T. Three-dimensional evaluation method for asphalt pavement texture characteristics. Constr. Build. Mater. 2021, 287, 122966. [Google Scholar] [CrossRef]

- Zhu, S.; Ji, X.; Yuan, H.; Li, H.; Xu, X. Long-term skid resistance and prediction model of asphalt pavement by accelerated pavement testing. Constr. Build. Mater. 2023, 375, 131004. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Bu, Y.; You, Z.; Yang, X.; Oeser, M. Correlate aggregate angularity characteristics to the skid resistance of asphalt pavement based on image analysis technology. Constr. Build. Mater. 2020, 242, 118150. [Google Scholar] [CrossRef]

- Yi, Y.; Jiang, Y.; Tian, T.; Fan, J.; Bai, C.; Deng, C.; Xue, J.; Ji, X. Attenuation pattern of skid resistance of heat reflective coatings under the effect of simulated pavement abrasion. Int. J. Pavement Eng. 2023, 24, 10298436. [Google Scholar] [CrossRef]

- Li, S.; Xiong, R.; Dong, X.; Sheng, Y.; Guan, B.; Zong, Y.; Xie, C.; Zhai, J.; Li, C. Effect of chemical composition of calcined bauxite aggregates on mechanical and physical properties for high friction surface course. Constr. Build. Mater. 2021, 302, 124390. [Google Scholar] [CrossRef]

- Riekstins, A.; Haritonovs, V.; Balodis, A. Evaluation of adhesion between bitumen and aggregate with the digital image processing method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 660, 012047. [Google Scholar] [CrossRef]

| Test | Results | Requirements | |

|---|---|---|---|

| Penetration (25 °C,100 g, 5 s)/0.1 mm | 67 | 60–80 | |

| Softening point (R & B)/°C | 50 | ≥46 | |

| Ductility (15 °C, 5 cm/min)/cm | 158 | ≥100 | |

| Flash point/°C | 322 | ≥260 | |

| Solubility/% | 99.7 | ≥99.5 | |

| Relative density (25 °C) | 1.042 | — | |

| Residue after RTFOT | Mass change/% | 0.14 | — |

| Residual penetration ratio (25 °C)/% | 70.1 | ≥61 | |

| Residual ductility (10 °C)/cm | 102 | ≥6 | |

| Mixture Type | Asphalt Content (%) | Void Ratio (%) |

|---|---|---|

| AC-20-NL | 4.25 | 3.1 |

| AC-20-N | 3.98 | 4.0 |

| AC-20-L | 3.52 | 8.9 |

| AC-20-M | 3.13 | 11.4 |

| AC-20-H | 2.88 | 13.5 |

| AC-13 | 4.81 | 3.9 |

| AC-16 | 4.53 | 4.0 |

| AC-20 | 4.12 | 4.1 |

| SMA-13 | 6.19 | 3.6 |

| AC-13 (Ⅰ) | 4.86 | 3.9 |

| AC-13 (Ⅱ) | 4.75 | 4.3 |

| SMA-13 (Ⅰ) | 6.28 | 3.5 |

| SMA-13 (Ⅱ) | 6.02 | 4.0 |

| SMA-16 | 6.14 | 3.7 |

| Gradation Type | Index | a | b | c | R2 |

|---|---|---|---|---|---|

| AC-13 (I) | H | 0.47 | 1.472 × 10−4 | 0.37 | 0.922 |

| TD | 0.31 | 1.722 × 10−4 | 0.46 | 0.916 | |

| AC-13 (II) | H | 0.49 | 1.482 × 10−4 | 0.42 | 0.975 |

| TD | 0.32 | 1.612 × 10−4 | 0.52 | 0.964 | |

| SMA-13 (I) | H | 0.63 | 1.836 × 10−4 | 0.54 | 0.961 |

| TD | 0.47 | 1.587 × 10−4 | 0.66 | 0.964 | |

| SMA-13 (II) | H | 0.59 | 1.766 × 10−4 | 0.57 | 0.918 |

| TD | 0.43 | 1.673 × 10−4 | 0.63 | 0.934 | |

| SMA-16 | H | 0.51 | 1.722 × 10−4 | 0.64 | 0.956 |

| TD | 0.63 | 1.962 × 10−4 | 0.71 | 0.943 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Xi, D.; Zhao, Y.; Xie, W.; Zhang, W.; Gao, J. Research on the Skidding Resistance and Attenuation Characteristics of Asphalt Pavement Based on Image Recognition-Analysis Strategy. Coatings 2024, 14, 749. https://doi.org/10.3390/coatings14060749

Zhang K, Xi D, Zhao Y, Xie W, Zhang W, Gao J. Research on the Skidding Resistance and Attenuation Characteristics of Asphalt Pavement Based on Image Recognition-Analysis Strategy. Coatings. 2024; 14(6):749. https://doi.org/10.3390/coatings14060749

Chicago/Turabian StyleZhang, Ke, Dianliang Xi, Yu Zhao, Wei Xie, Wei Zhang, and Jiantao Gao. 2024. "Research on the Skidding Resistance and Attenuation Characteristics of Asphalt Pavement Based on Image Recognition-Analysis Strategy" Coatings 14, no. 6: 749. https://doi.org/10.3390/coatings14060749