Recent Development of Abrasive Machining Processes Enhanced with Non-Newtonian Fluids

Abstract

1. Introduction

2. Abrasive Machining Processes

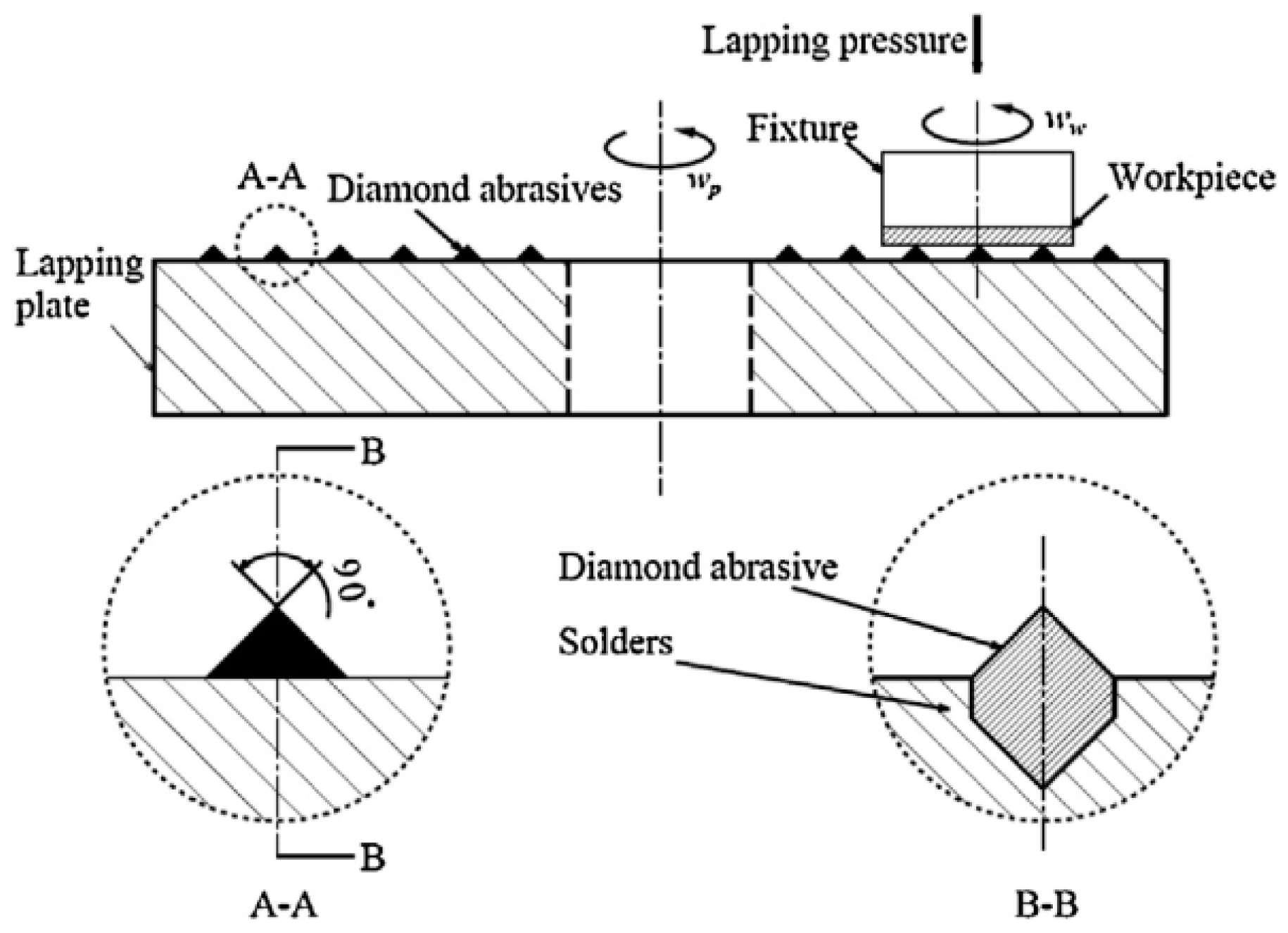

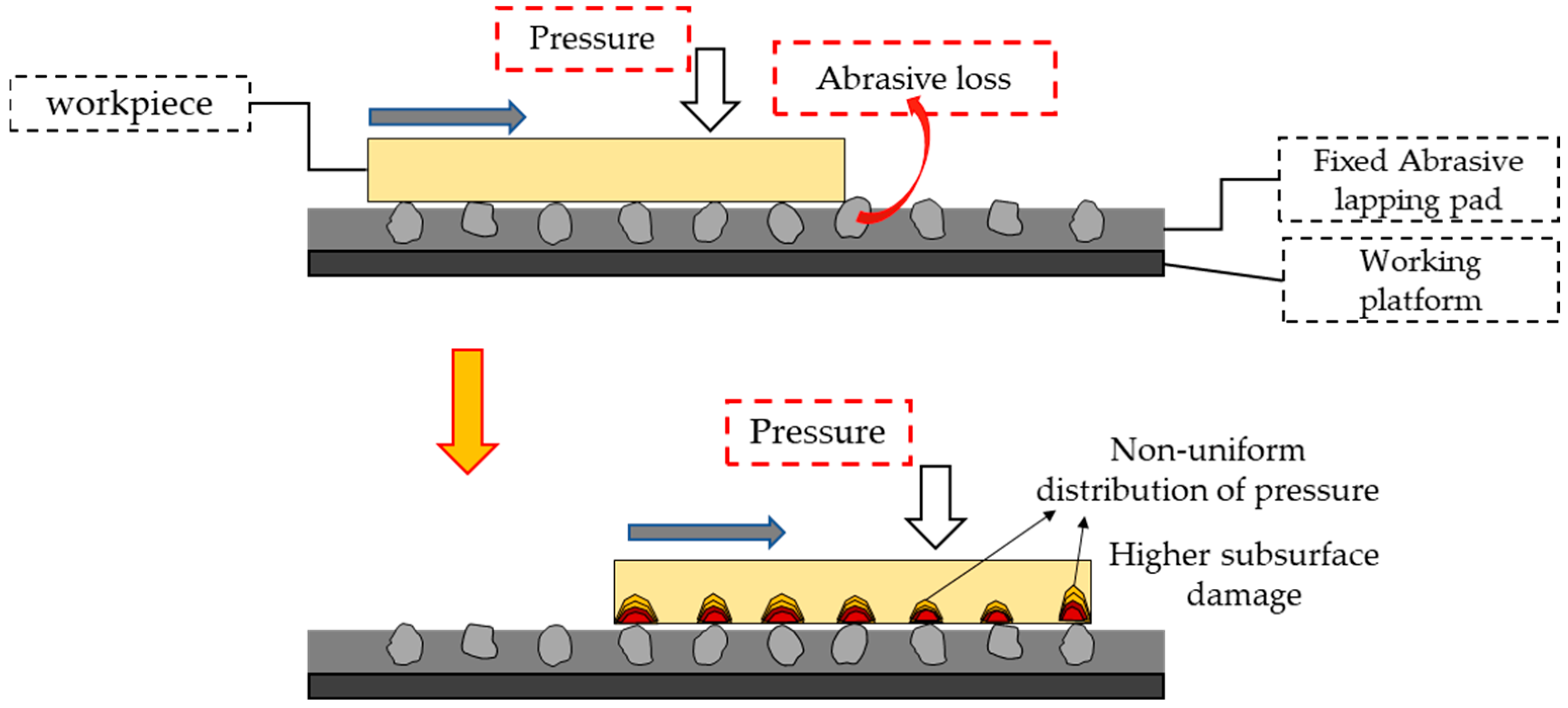

2.1. Abrasive Lapping

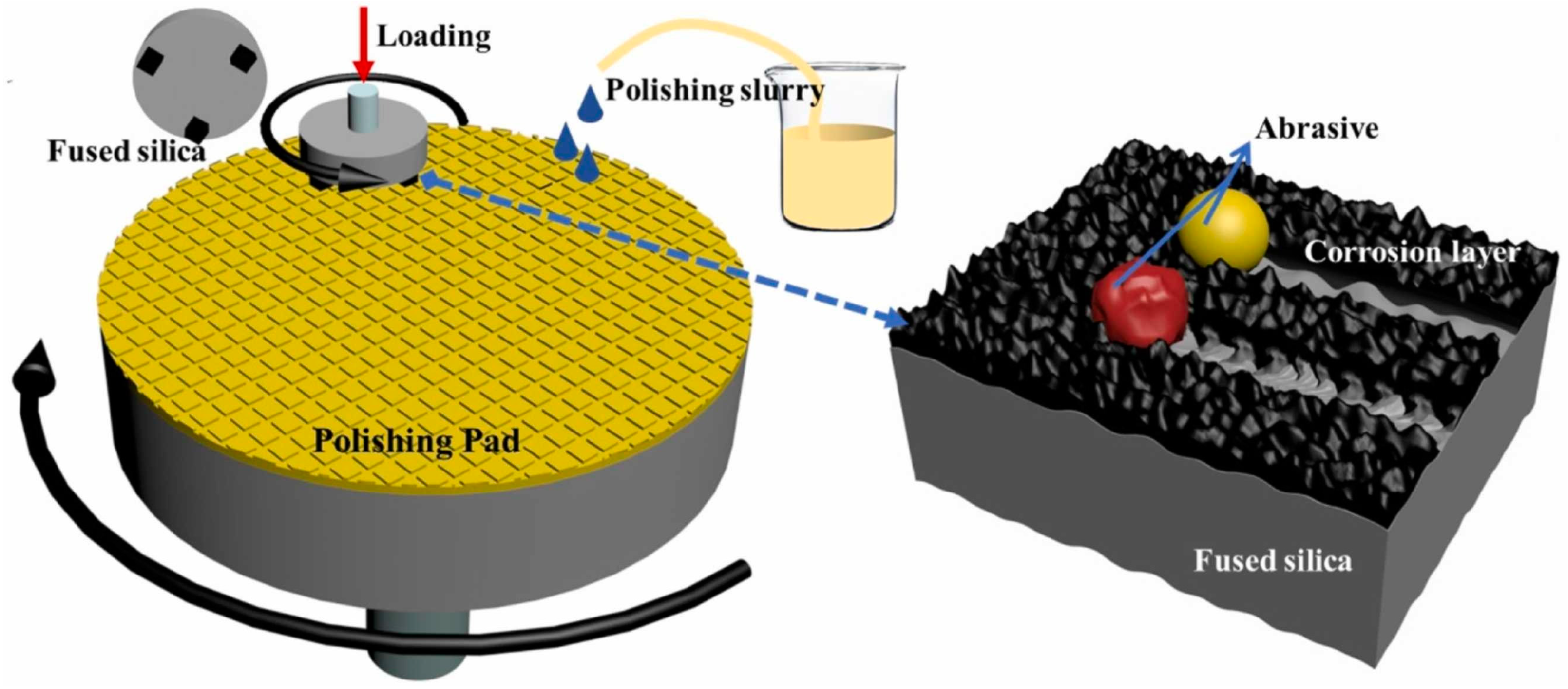

2.2. Abrasive Polishing

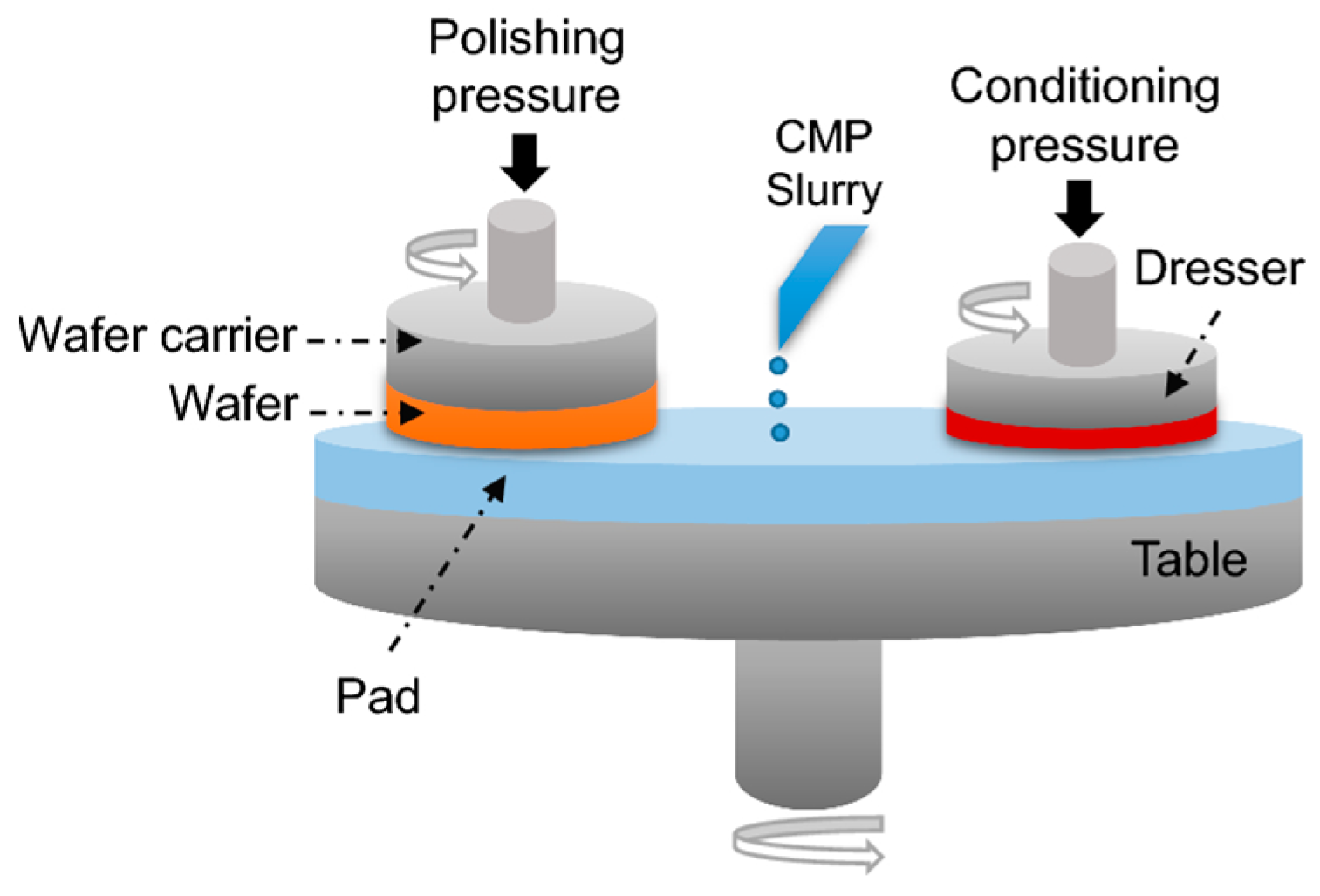

2.3. Chemical Mechanical Polishing

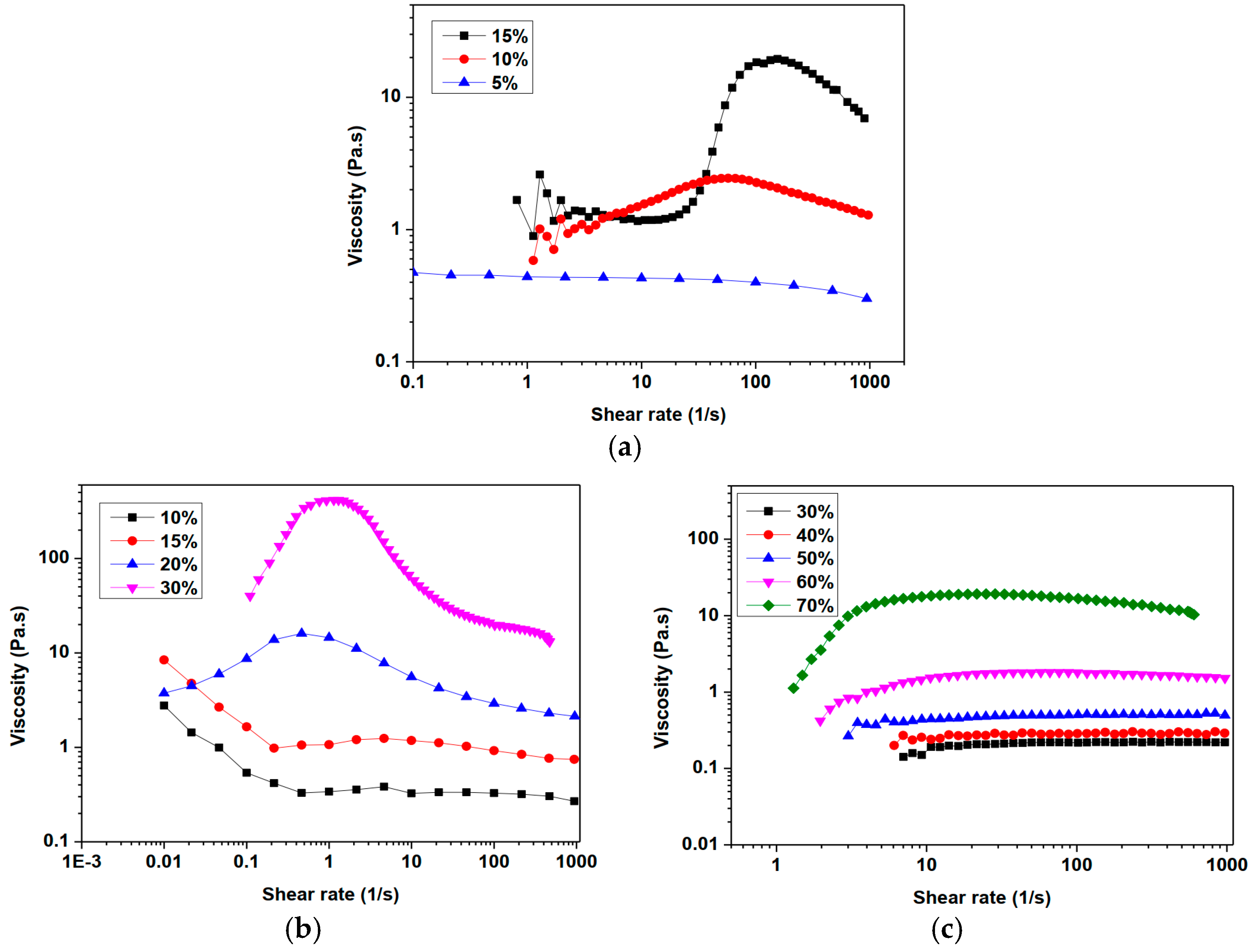

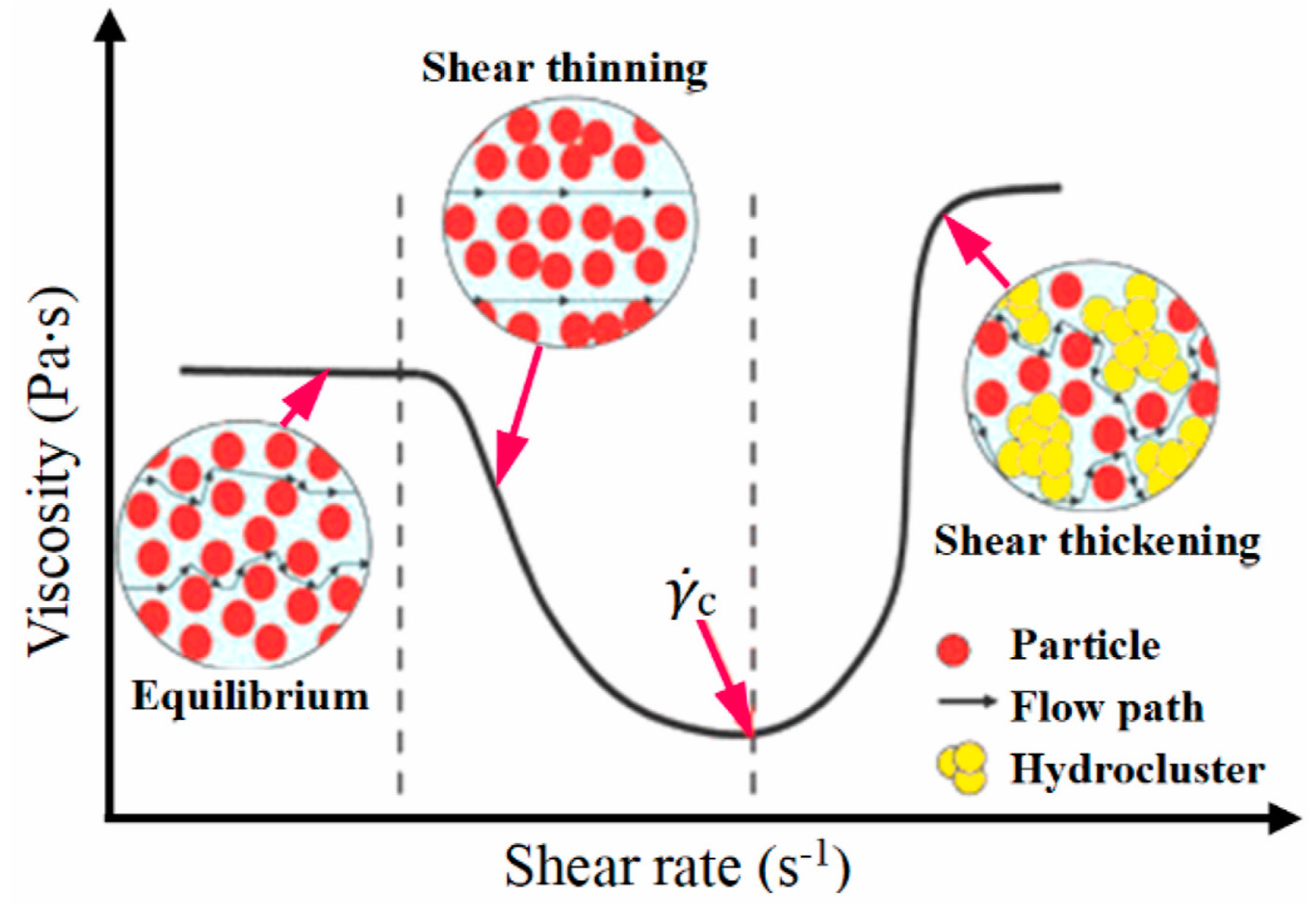

3. Characteristics of Non-Newtonian Fluids

4. Abrasive Machining Processes with Non-Newtonian Fluids

4.1. Shear-Thickening Principle

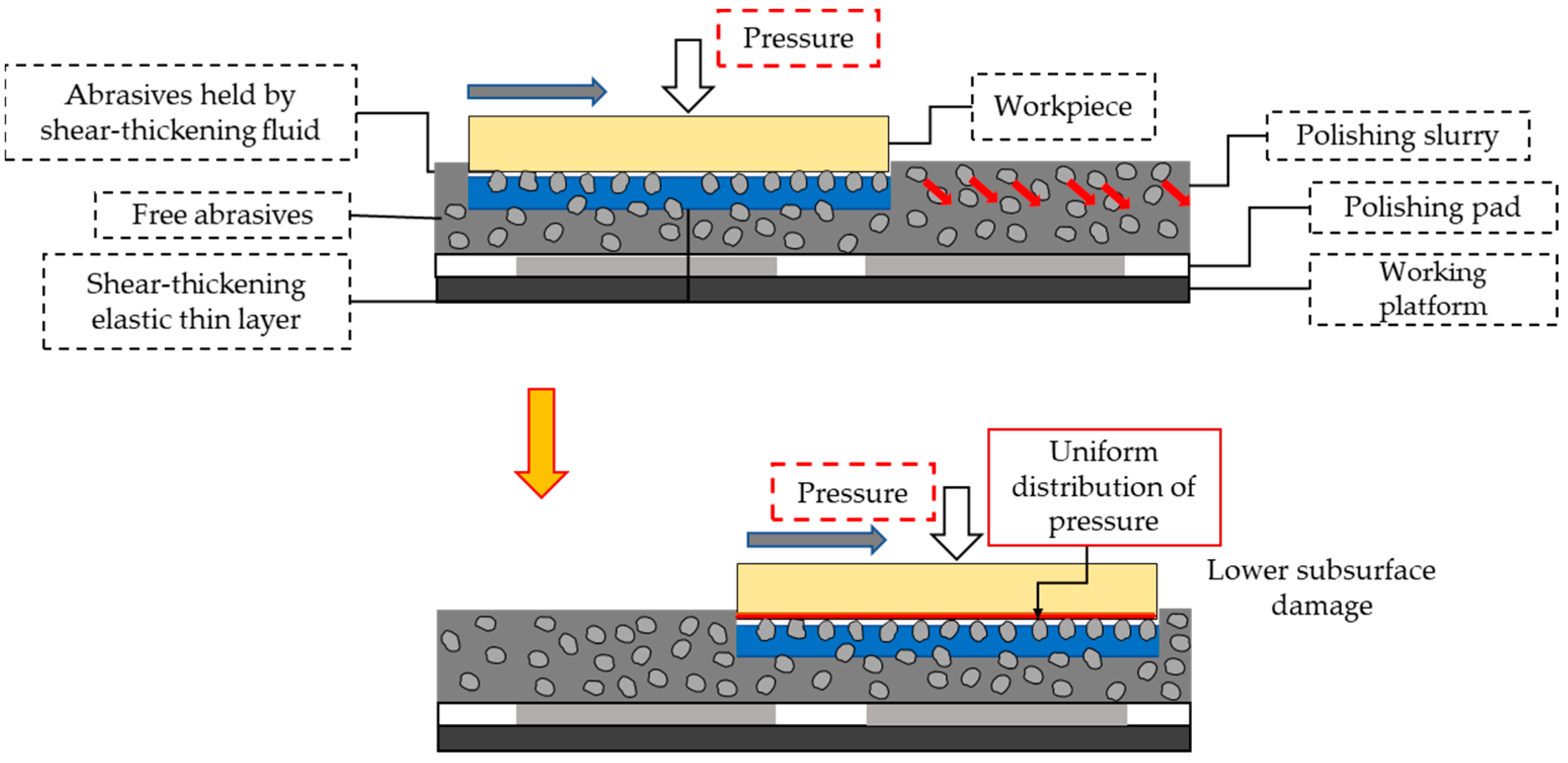

4.2. Comparison between Shear Thickening and Traditional Abrasive Machining Processes

4.3. Potential of Abrasive Machining with Non-Newtonian Fluids

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Piao, Y.; Li, C.; Hu, Y.; Cui, H.; Luo, X.; Geng, Y.; Zhang, F. Nanoindentation induced anisotropy of deformation and damage behaviors of MgF2 crystals. J. Mater. Res. Technol. 2024, 28, 4615–4625. [Google Scholar] [CrossRef]

- Lou, Z.; Yan, Y.; Wang, J.; Zhang, A.; Cui, H.; Li, C.; Geng, Y. Exploring the structural color of micro-nano composite gratings with FDTD simulation and experimental validation. Opt. Express 2023, 32, 2432–2451. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Yan, J.; Wang, S.; Zhang, S.; Chen, G.; Ren, C. A theoretical and deep learning hybrid model for predicting surface roughness of diamond-turned polycrystalline materials. Int. J. Extrem. Manuf. 2023, 5, 035102. [Google Scholar] [CrossRef]

- Yang, X.; Lai, Y.; Zhang, Z.; Zhang, T.; Yao, X.; Song, F.; Hou, Y.; Qi, H.; Tang, H. Microstructure evolution and mechanical properties of H13 steel produced by Selective Electron Beam Melting. Mater. Charact. 2023, 203, 113053. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Z.; Zhang, T.; Song, F.; Yao, X.; Xiao, B.; Lin, P.; Qi, H.; Liu, S.; Tang, H. Multi-build orientation effects on microstructural evolution and mechanical behavior of truly as-built selective laser melting Ti6Al4V alloys. J. Mater. Res. Technol. 2024, 30, 3967–3976. [Google Scholar] [CrossRef]

- Shen, Q.; Chen, F.; Tao, Q.; Ji, R.; Zhang, L.; Cai, D.; Saetang, V.; Qi, H. Numerical investigation of various laser-waterjet coupling methods on spot power density distribution. AIP Adv. 2024; in press. [Google Scholar]

- Yang, X.; Song, F.; Zhang, T.; Yao, X.; Wang, W.; Zhang, Z.; Hou, Y.; Qi, H.; Tang, H. Surface enhancement by micro-arc oxidation induced TiO2 ceramic coating on additive manufacturing Ti-6Al-4V. Chin. J. Mech. Eng. 2024; in press. [Google Scholar]

- Chen, H.; Wang, L.; Peng, F.; Xu, Q.; Xiong, Y.; Zhao, S.; Tokunaga, K.; Wu, Z.; Ma, Y.; Chen, P.; et al. Hydrogen retention and affecting factors in rolled tungsten: Thermal desorption spectra and molecular dynamics simulations. Int. J. Hydrogen Energy 2023, 48, 30522–30531. [Google Scholar] [CrossRef]

- Qi, H.; Wen, D.; Lu, C.; Li, G. Numerical and experimental study on ultrasonic vibration-assisted micro-channelling of glasses using an abrasive slurry jet. Int. J. Mech. Sci. 2016, 110, 94–107. [Google Scholar] [CrossRef]

- Qi, H.; Wen, D.; Yuan, Q.; Zhang, L.; Chen, Z. Numerical investigation on particle impact erosion in ultrasonic-assisted abrasive slurry jet micro-machining of glasses. Powder Technol. 2017, 314, 627–634. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Z.; Qi, Z.; Cai, D.; Cheng, Z.; Qi, H. CFD-based study of the abrasive flow characteristics within constrained flow passage in polishing of complex titanium alloy surfaces. Powder Technol. 2018, 333, 209–218. [Google Scholar] [CrossRef]

- Li, H.N.; Yang, Y.; Zhao, Y.J.; Zhang, Z.; Zhu, W.; Wang, W.; Qi, H. On the periodicity of fixed-abrasive planetary lapping based on a generic model. J. Manuf. Process. 2019, 44, 271–287. [Google Scholar] [CrossRef]

- Ji, R.; Shen, Q.; Zhang, L.; Zeng, X.; Qi, H. Novel photocatalysis-assisted mechanical polishing of laser cladding cobalt-based alloy using TiO2 nanoparticles. Powder Technol. 2024; in press. [Google Scholar] [CrossRef]

- Gu, Q.; Zhang, Z.; Zhou, H.; Yu, J.; Wang, D.; Feng, J.; Shi, C.; Yang, J.; Qi, J. A novel approach of jet polishing for interior surface of small-grooved components using three developed setups. Int. J. Extrem. Manuf. 2024, 6, 025101. [Google Scholar] [CrossRef]

- Li, C.; Hu, Y.; Wei, Z.; Wu, C.; Peng, Y.; Zhang, F.; Geng, Y. Damage evolution and removal behaviors of GaN crystals involved in double-grits grinding. Int. J. Extrem. Manuf. 2024, 6, 025103. [Google Scholar] [CrossRef]

- Qi, H.; Qin, S.; Cheng, Z.; Teng, Q.; Hong, T.; Xie, Y. Towards understanding performance enhancing mechanism of micro-holes on K9 glasses using ultrasonic vibration-assisted abrasive slurry jet. J. Manuf. Process. 2021, 64, 585–593. [Google Scholar] [CrossRef]

- Qi, H.; Qin, S.; Cheng, Z.; Zou, Y.; Cai, D.; Wen, D. DEM and experimental study on the ultrasonic vibration-assisted abrasive finishing of WC-8Co cemented carbide cutting edge. Powder Technol. 2021, 378, 716–723. [Google Scholar] [CrossRef]

- Qian, H.; Chen, M.; Qi, Z.; Teng, Q.; Qi, H.; Zhang, L.; Shan, X. Review on Research and Development of Abrasive Scratching of Hard Brittle Materials and Its Underlying Mechanisms. Crystals 2023, 13, 428. [Google Scholar] [CrossRef]

- Tan, Y.; Ni, Y.; Xu, W.; Xie, Y.; Li, L.; Tan, D. Key technologies and development trends of the soft abrasive flow finishing method. J. Zhejiang Univ. Sci. A 2023, 24, 1043–1064. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C.Y.; Li, L.; Wu, J.F.; Yin, Z.C.; Tan, D.P. Numerical investigation of mesoscale multiphase mass transport mechanism in fibrous porous media. Eng. Appl. Comput. Fluid Mech. 2024; in press. [Google Scholar]

- Zhu, W.-L.; Beaucamp, A. Generic three-dimensional model of freeform surface polishing with non-Newtonian fluids. Int. J. Mach. Tools Manuf. 2022, 172, 103837. [Google Scholar] [CrossRef]

- Zou, Z.; Guo, Z.; Zhang, K.; Xiao, Y.; Yue, T.; Liu, J. Electrochemical discharge machining of microchannels in glass using a non-Newtonian fluid electrolyte. J. Mater. Process. Technol. 2022, 305, 117594. [Google Scholar] [CrossRef]

- Li, L.; Xu, P.; Xu, W.X.; Lu, B.; Wang, C.Y.; Tan, D.P. Multi-field coupling vibration patterns of the multiphase sink vortex and distortion recognition method. Mech. Syst. Signal Process. 2024; in press. [Google Scholar]

- Malakshah, V.M.; Darabi, M.; Sattari, A.; Hanafizadeh, P. Numerical investigation of double emulsion formation in non-Newtonian fluids using double co-flow geometry. Chem. Eng. Res. Des. 2024, 203, 165–177. [Google Scholar] [CrossRef]

- Li, L.; Lu, B.; Xu, W.X.; Wang, C.Y.; Wu, J.F.; Tan, D.P. Dynamic behaviors of multiphase vortex-induced vibration for hydropower energy conversion. Energy, 2024; in press. [Google Scholar]

- Ming, Y.; Huang, X.; Zhou, D.; Li, X. A novel Non-Newtonian fluid polishing technique for zirconia ceramics based on the weak magnetorheological strengthening thickening effect. Ceram. Int. 2022, 48, 7192–7203. [Google Scholar] [CrossRef]

- Fan, Z.; Tian, Y.; Zhou, Q.; Shi, C. Enhanced magnetic abrasive finishing of Ti–6Al–4V using shear thickening fluids additives. Precis. Eng. 2020, 64, 300–306. [Google Scholar] [CrossRef]

- Salunkhe, A.A.; Overney, R.M.; Berg, J.C. The use of boundary lubricants for the reduction of shear thickening and jamming in abrasive particle slurries. Colloids Surf. A Physicochem. Eng. Asp. 2018, 537, 13–19. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhou, X.; Wang, J.; Guo, L.; Deng, Q.; Yuan, J.; Lyu, B. Electrolysis combined shear thickening polishing method. J. Manuf. Process. 2023, 107, 179–198. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Z.; Hong, B.; Hang, W.; Zhang, P.; Cao, X.; Xu, Q.; Chen, P.; Chen, H.; Yuan, J.; et al. Study on the affecting factors of material removal mechanism and damage behavior of shear rheological polishing of single crystal silicon carbide. J. Manuf. Process. 2024, 112, 225–237. [Google Scholar] [CrossRef]

- Wang, L.; Wu, M.; Chen, H.; Hang, W.; Wang, X.; Han, Y.; Chen, H.; Chen, P.; Beri, T.H.; Luo, L.; et al. Damage evolution and plastic deformation mechanism of passivation layer during shear rheological polishing of polycrystalline tungsten. J. Mater. Res. Technol. 2024, 28, 1584–1596. [Google Scholar] [CrossRef]

- Qian, C.; Tian, Y.; Ahmad, S.; Ma, Z.; Li, L.; Fan, Z. Theoretical and experimental investigation on magnetorheological shear thickening polishing force using multi-pole coupling magnetic field. J. Mater. Process. Technol. 2024, 328, 118414. [Google Scholar] [CrossRef]

- He, X.; Yang, L.; Zhang, K.; Li, R.; Peng, Y. Research on the shear thickening polishing CaF2 with textured hollow polishing tool. J. Manuf. Process. 2024, 119, 193–203. [Google Scholar] [CrossRef]

- Deng, J.; Lu, J.; Zeng, S.; Yan, Q.; Pan, J. Processing properties for the Si-face of the 4H-SiC substrates using the magnetically-controlled abrasive solidification orientation–solid-phase Fenton reaction for the fabrication of the lapping–polishing plate. Diam. Relat. Mater. 2021, 120, 108652. [Google Scholar] [CrossRef]

- Deng, J.; Xiong, Q.; Nie, X.; Yan, Q.; Cao, J.; Lu, J. Optimisation of free-abrasive assisted lapping process with vitrified bonded diamond plates for sapphire substrates. Precis. Eng. 2024, 86, 183–194. [Google Scholar] [CrossRef]

- Liu, H.; Li, Z.; Li, J.; Wu, H.; Zuo, D. Removal mechanism on 4H–SiC single crystal by picosecond laser ablation-assisted chemical mechanical polishing (CMP). Ceram. Int. 2024, 50, 13266–13275. [Google Scholar] [CrossRef]

- Wen, D.; Qi, H.; Ma, L.; Lu, C.; Li, G. Kinematics and trajectory analysis of the fixed abrasive lapping process in machining of interdigitated micro-channels on bipolar plates. Precis. Eng. 2016, 44, 192–202. [Google Scholar] [CrossRef]

- Dong, Z.; Cheng, H. Study on removal mechanism and removal characters for SiC and fused silica by fixed abrasive diamond pellets. Int. J. Mach. Tools Manuf. 2014, 85, 1–13. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, Z.; Meng, F.; Liu, L.; Liu, D.; Shi, C.; Cui, X.; Wang, J.; Wen, W. Atomic-scale surface of fused silica induced by chemical mechanical polishing with controlled size spherical ceria abrasives. J. Manuf. Process. 2023, 85, 783–792. [Google Scholar] [CrossRef]

- Su, J.X.; Zhang, Z.Q.; Yao, J.G.; Ma, L.J.; Feng, Q.G. Study on Chemical Mechanical Polishing Parameters of 6H-SiC Crystal Substrate Based on Diamond Abrasive. Adv. Mater. Res. 2013, 797, 261–265. [Google Scholar] [CrossRef]

- Guo, J.; Shi, X.; Song, C.; Niu, L.; Cui, H.; Guo, X.; Tong, Z.; Yu, N.; Jin, Z.; Kang, R. Theoretical and experimental investigation of chemical mechanical polishing of W-Ni-Fe alloy. Int. J. Extrem. Manuf. 2021, 3, 025103. [Google Scholar] [CrossRef]

- Hongyu, C.; Wang, L.; Peng, F.; Shen, M.; Hang, W.; Beri, T.H.; Zhang, H.; Zhao, J.; Han, Y.; Lyu, B. Efficient chemical mechanical polishing of W promoted by Fenton-like reaction between Cu2+ and H2O2. Trans. Nonferrous Met. Soc. China, 2024; in press. [Google Scholar]

- Xie, W.; Zhang, Z.; Wang, L.; Cui, X.; Yu, S.; Su, H.; Wang, S. Chemical mechanical polishing of silicon wafers using developed uniformly dispersed colloidal silica in slurry. J. Manuf. Process. 2023, 90, 196–203. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, Z.; Yu, S.; Chen, X.; Shi, C.; Zhou, H.; Meng, F.; Yu, J.; Wen, W. Unprecedented atomic surface of silicon induced by environmentally friendly chemical mechanical polishing. Nanoscale 2023, 15, 9304–9314. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Y.; Song, X.; Zhang, X.; Gong, Y.; Peng, C. Study on the influence of non-newtonian fluid characteristics on the hydraulic performance and internal flow field of multiphase pump. Chem. Eng. Res. Des. 2024, 202, 178–190. [Google Scholar] [CrossRef]

- Barman, P.; Kairi, R.; Das, A.; Islam, R. An Overview of Non-Newtonian Fluid. Int. J. Appl. Sci. Eng. 2016, 4, 97. [Google Scholar] [CrossRef]

- Yu, M. The Study on the Shear Thickening Behaviors of Nanosilica Fluids. Master’s Thesis, Shanghai Jiaotong University, Shanghai, China, 2020. [Google Scholar]

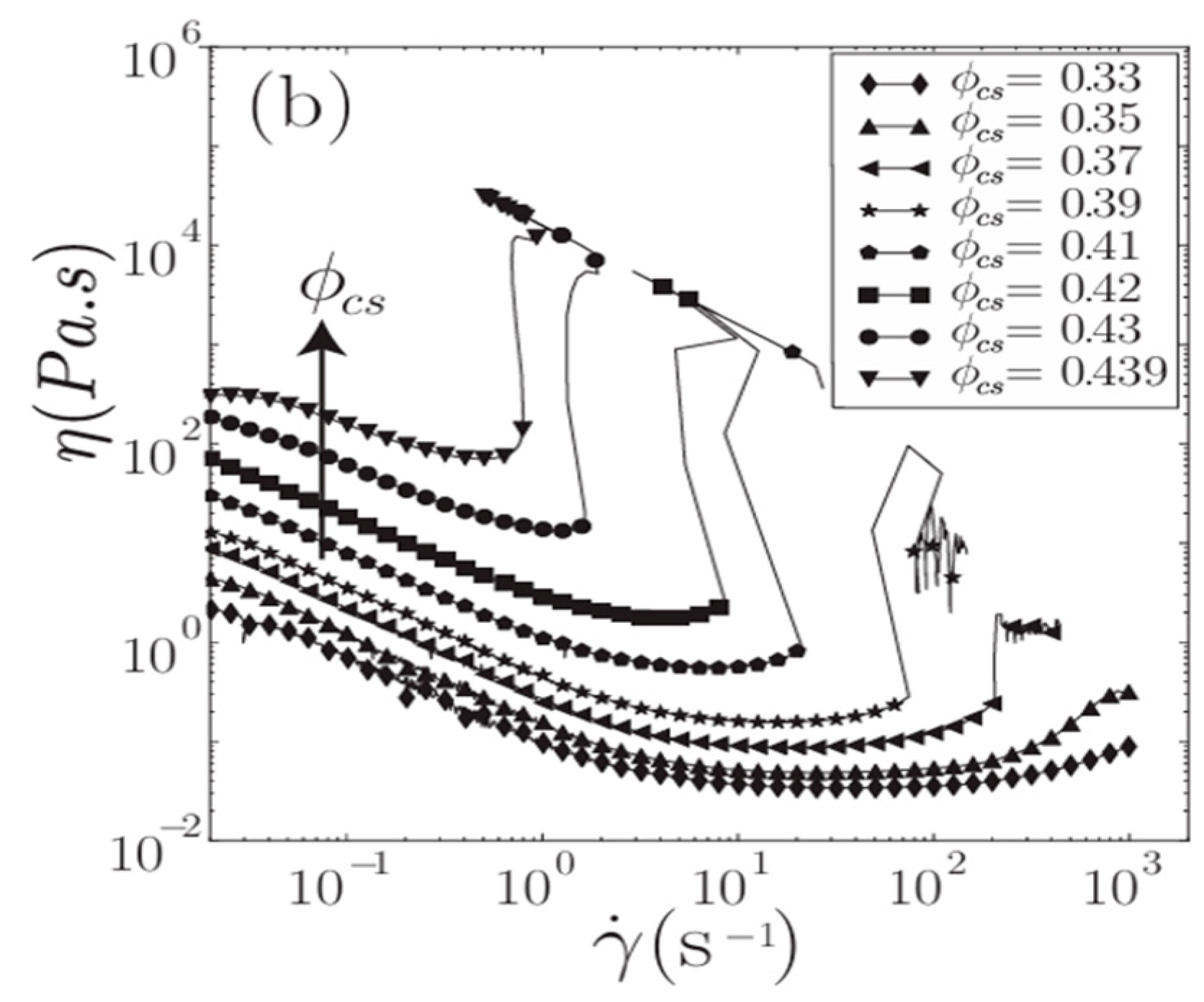

- Madraki, Y.; Hormozi, S.; Ovarlez, G.; Guazzelli, É.; Pouliquen, O. Enhancing shear thickening. Phys. Rev. Fluids 2017, 2, 033301. [Google Scholar] [CrossRef]

- Jiang, W.; Sun, Y.; Xu, Y.; Peng, C.; Gong, X.; Zhang, Z. Shear-thickening behavior of polymethylmethacrylate particles suspensions in glycerine–water mixtures. Rheol. Acta 2010, 49, 1157–1163. [Google Scholar] [CrossRef]

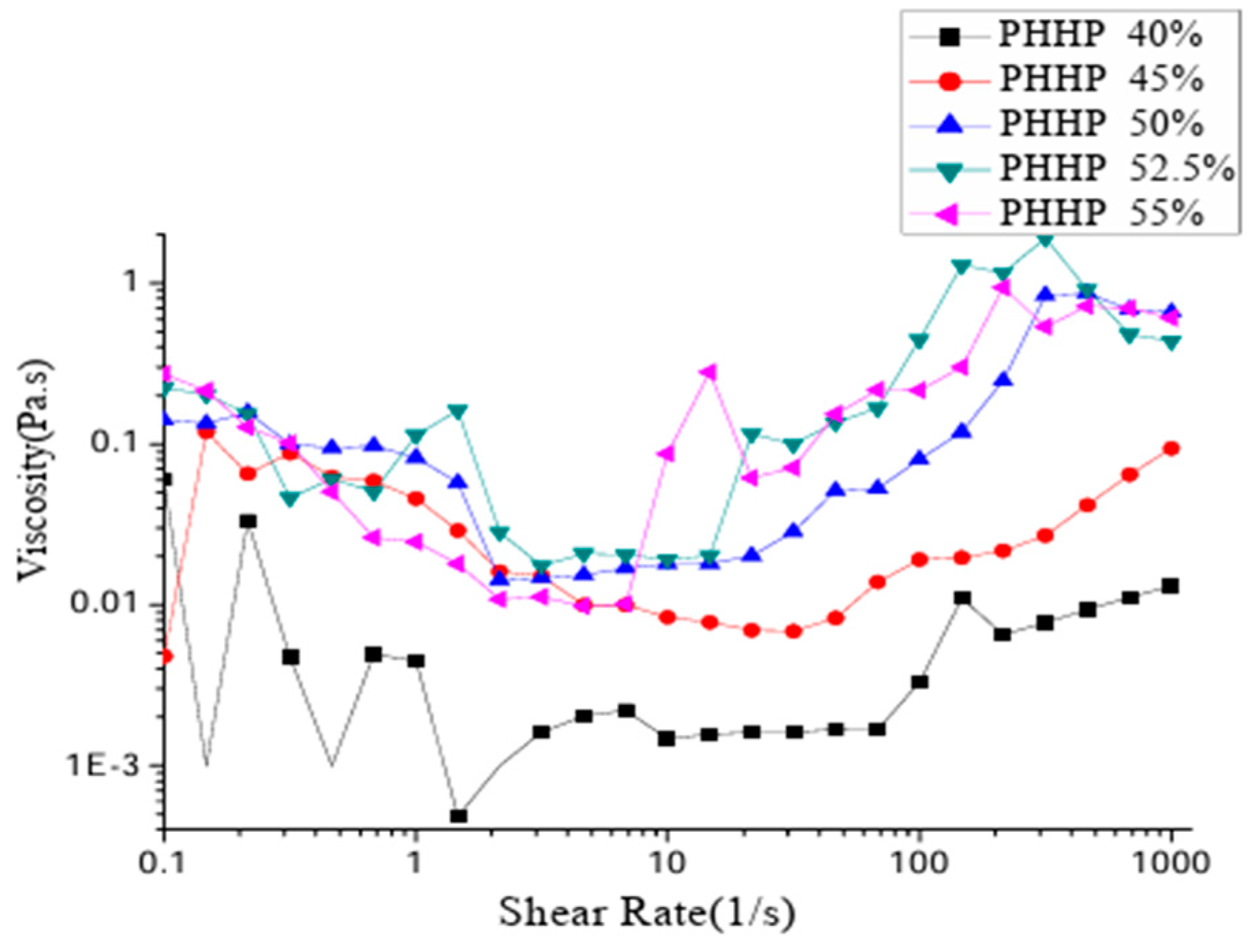

- Dong, C. Research on Material Removal Mechanism of Shear Thickening Polishing and Characteristics of Polishing Slurry. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2021. [Google Scholar]

- Mari, R.; Seto, R.; Morris, J.F.; Denn, M.M. Shear thickening, frictionless and frictional rheologies in non-Brownian suspensions. J. Rheol. 2014, 58, 1693–1724. [Google Scholar] [CrossRef]

- Chen, K.; Wang, Y.; Xuan, S.; Gong, X. A hybrid molecular dynamics study on the non-Newtonian rheological behaviors of shear thickening fluid. J. Colloid Interface Sci. 2017, 497, 378–384. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Karpuschewski, B.; Ohmori, H.; Riemer, O.; Wang, Y.; Dong, T. Adaptive shearing-gradient thickening polishing (AS-GTP) and subsurface damage inhibition. Int. J. Mach. Tools Manuf. 2021, 160, 103651. [Google Scholar] [CrossRef]

- Pinto, F.; Meo, M. Design and Manufacturing of a Novel Shear Thickening Fluid Composite (STFC) with Enhanced out-of-Plane Properties and Damage Suppression. Appl. Compos. Mater. 2017, 24, 643–660. [Google Scholar] [CrossRef]

- Wagner, N.J.; Brady, J.F. Shear thickening in colloidal dispersions. Phys. Today 2009, 62, 27–32. [Google Scholar] [CrossRef]

- Li, M.; Liu, M.; Riemer, O.; Karpuschewski, B.; Tang, C. Origin of material removal mechanism in shear thickening-chemical polishing. Int. J. Mach. Tools Manuf. 2021, 170, 103800. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, P.; Dong, F.; Pang, M.; Ma, L.; Zhao, H.; Su, J. Performance on lapping quartz glass by UV curing fixed abrasive pad with Gr2O3-diamond composite abrasives. Mater. Sci. Semicond. Process. 2024, 169, 107926. [Google Scholar] [CrossRef]

- Liu, N.; Wu, P.; Niu, F.; Hou, T.; Zhu, Y. Kinematics and trajectory analysis of swinging fixed abrasive plane lapping: Effect of swinging mode on the lapping uniformity. Precis. Eng. 2024, 86, 331–341. [Google Scholar] [CrossRef]

- Fan, C.; Zhao, J.; Zhang, L.; Wong, Y.S.; Hong, G.S.; Zhou, W. Modeling and analysis of the material removal profile for free abrasive polishing with sub-aperture pad. J. Mater. Process. Technol. 2014, 214, 285–294. [Google Scholar] [CrossRef]

- Gürgen, S.; Sert, A. Polishing operation of a steel bar in a shear thickening fluid medium. Compos. Part B Eng. 2019, 175, 107127. [Google Scholar] [CrossRef]

- Li, J.; Fan, Z.; Gao, J.; Yang, Z.; Tian, Y. Multi-pole magnetorheological shear thickening polishing on inner surface of aluminum alloy slender tubes. J. Mater. Res. Technol. 2023, 27, 8258–8270. [Google Scholar] [CrossRef]

| Fluids | η (Pa·s) |

|---|---|

| Air | 10−5 |

| Water | 10−3 |

| Alcohol | 1.2 × 10−3 |

| Mercury | 1.5 × 10−3 |

| Glycol | 20 × 10−3 |

| Olive oil | 0.1 |

| Glycerol | 1.5 |

| Honey | 10 |

| Corn syrup | 100 |

| Asphalt | 108 |

| Fused glass | 1012 |

| Non-Newtonian Fluids | Particle Size (μm) | Concentration | Critical Shear Rate (s−1) | Maximum Viscosity (Pa·s) |

|---|---|---|---|---|

| Corn starch suspension | 13 | 41% | 20 | 1000 |

| PMMA suspension | 14 | 45% | 5 | 29 |

| SiO2/PEG suspension | 14 | 40% | 2 | 1 |

| PHHP suspension | 14 | 40% | 1.5 | 0.01 |

| Non-Newtonian Fluids | Particle Size (μm) | Concentration | Critical Shear Rate (s−1) | Maximum Viscosity (Pa·s) |

|---|---|---|---|---|

| Corn starch suspension | 13 | 41% | 20 | 1000 |

| PMMA suspension | 14 | 55% | 5 | 29 |

| SiO2/PEG suspension | 0.03 | 30% | 1 | 400 |

| PHHP suspension | 14 | 52.5% | 8 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; He, X.; Wu, X.; Wu, J.; Hong, T. Recent Development of Abrasive Machining Processes Enhanced with Non-Newtonian Fluids. Coatings 2024, 14, 779. https://doi.org/10.3390/coatings14070779

Zhu L, He X, Wu X, Wu J, Hong T. Recent Development of Abrasive Machining Processes Enhanced with Non-Newtonian Fluids. Coatings. 2024; 14(7):779. https://doi.org/10.3390/coatings14070779

Chicago/Turabian StyleZhu, Linghong, Xiaofeng He, Xiaoming Wu, Jixuan Wu, and Tao Hong. 2024. "Recent Development of Abrasive Machining Processes Enhanced with Non-Newtonian Fluids" Coatings 14, no. 7: 779. https://doi.org/10.3390/coatings14070779

APA StyleZhu, L., He, X., Wu, X., Wu, J., & Hong, T. (2024). Recent Development of Abrasive Machining Processes Enhanced with Non-Newtonian Fluids. Coatings, 14(7), 779. https://doi.org/10.3390/coatings14070779