Research on the Performance of Steel Strand-Reinforced Reactive Powder Concrete with Mixed Steel Fibers and Basalt Fibers under the Salt Dry–Wet Erosion

Abstract

:1. Introduction

2. Materials and Experimental Methods

2.1. Raw Materials

2.2. The Manufacturing Methods

2.3. The Measuring Methods

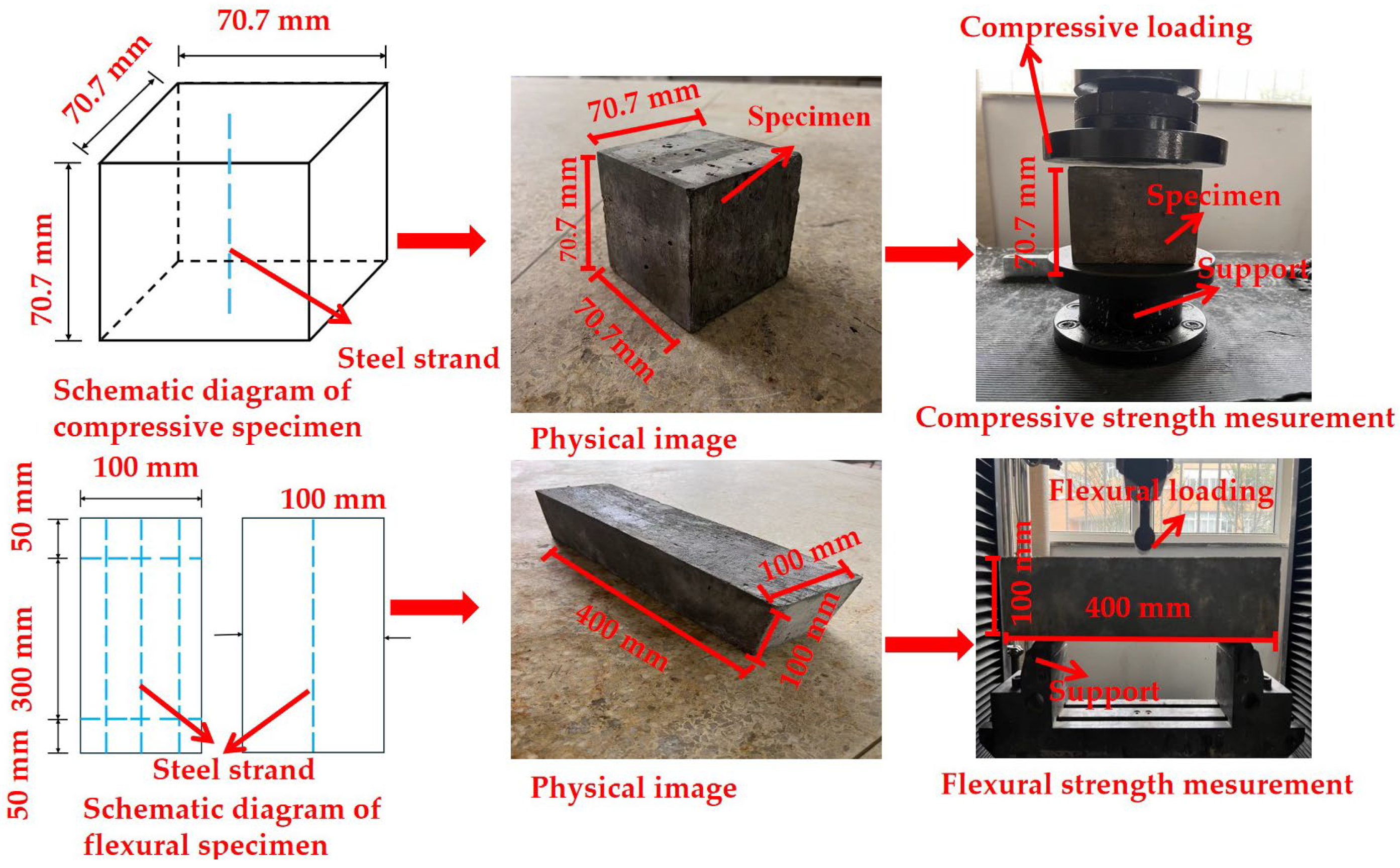

2.3.1. The Measurement of Mechanical Strength

2.3.2. Flexural Toughness

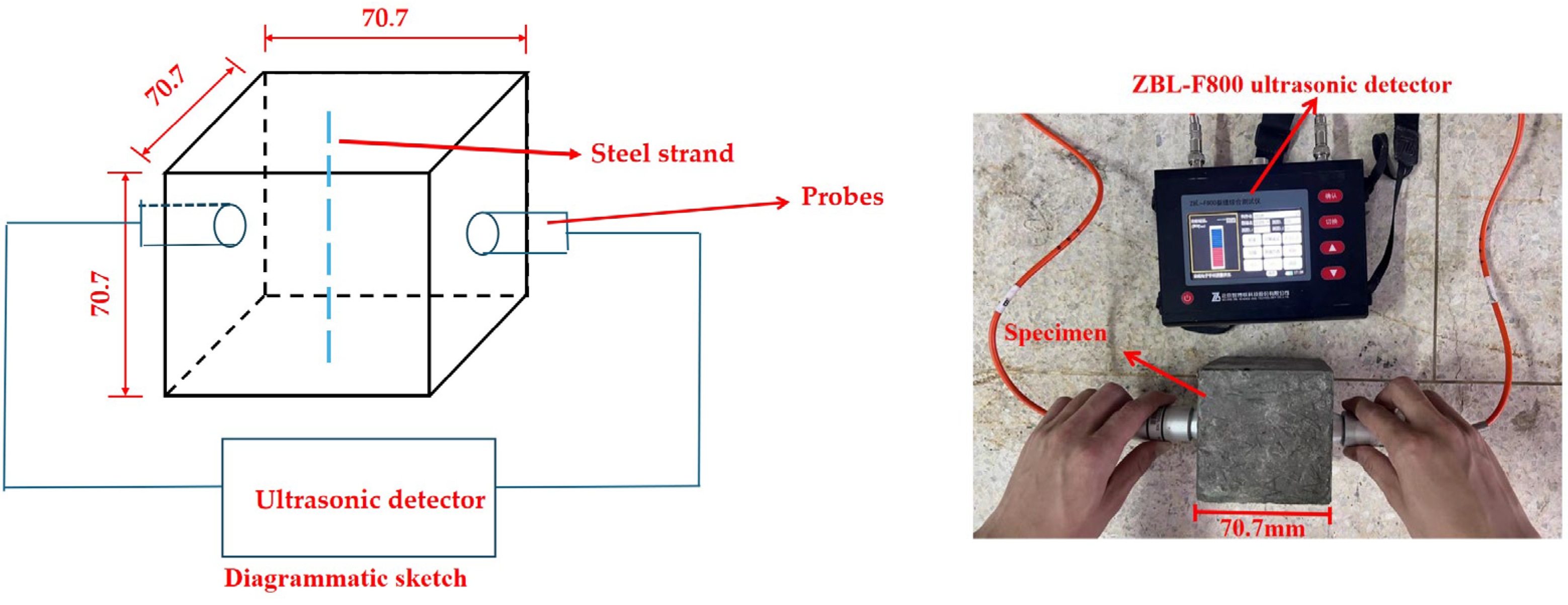

2.3.3. The Ultrasonic Velocity Test

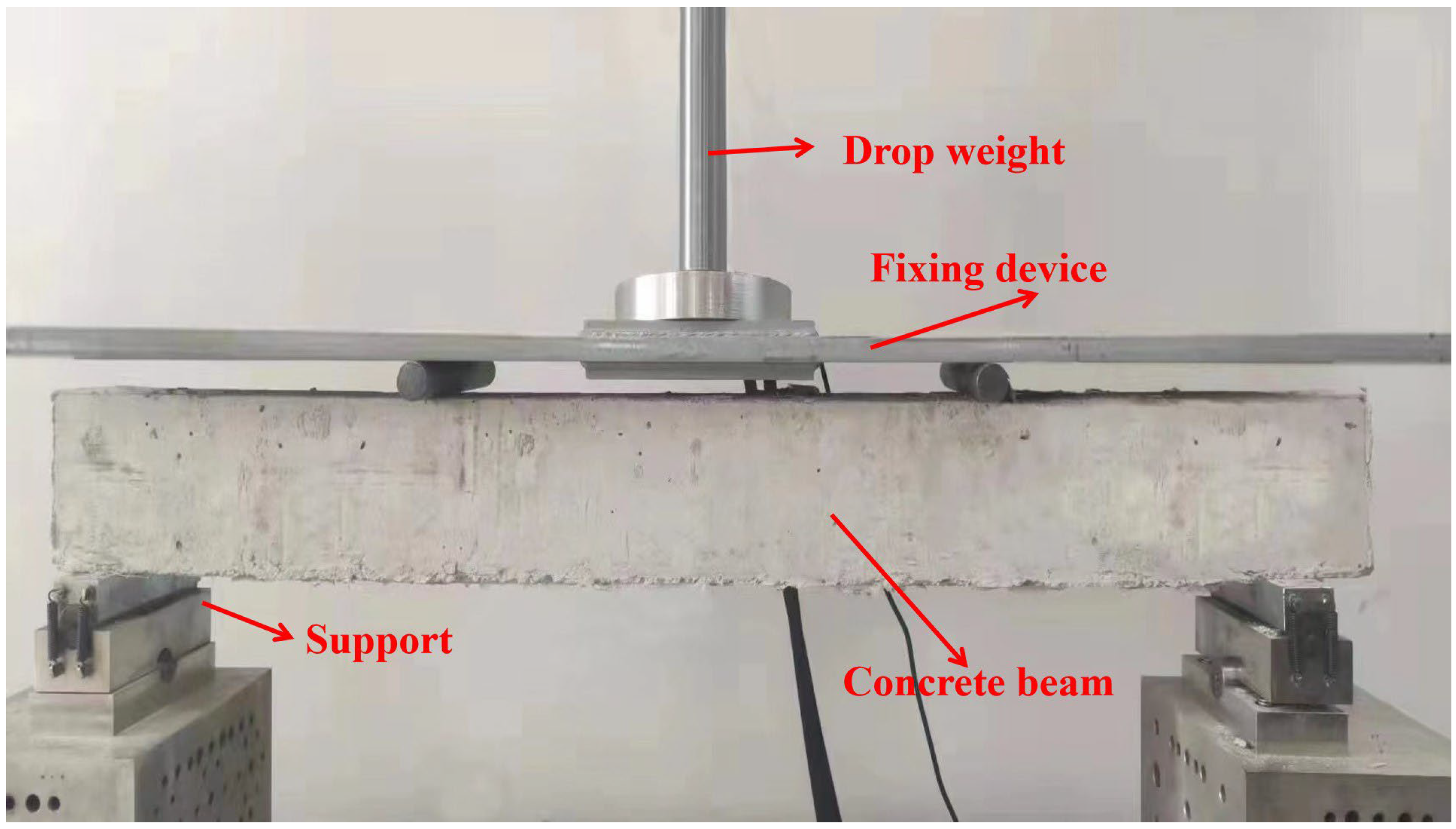

2.3.4. The Impact Toughness

2.3.5. The Dry–Wet Alternations

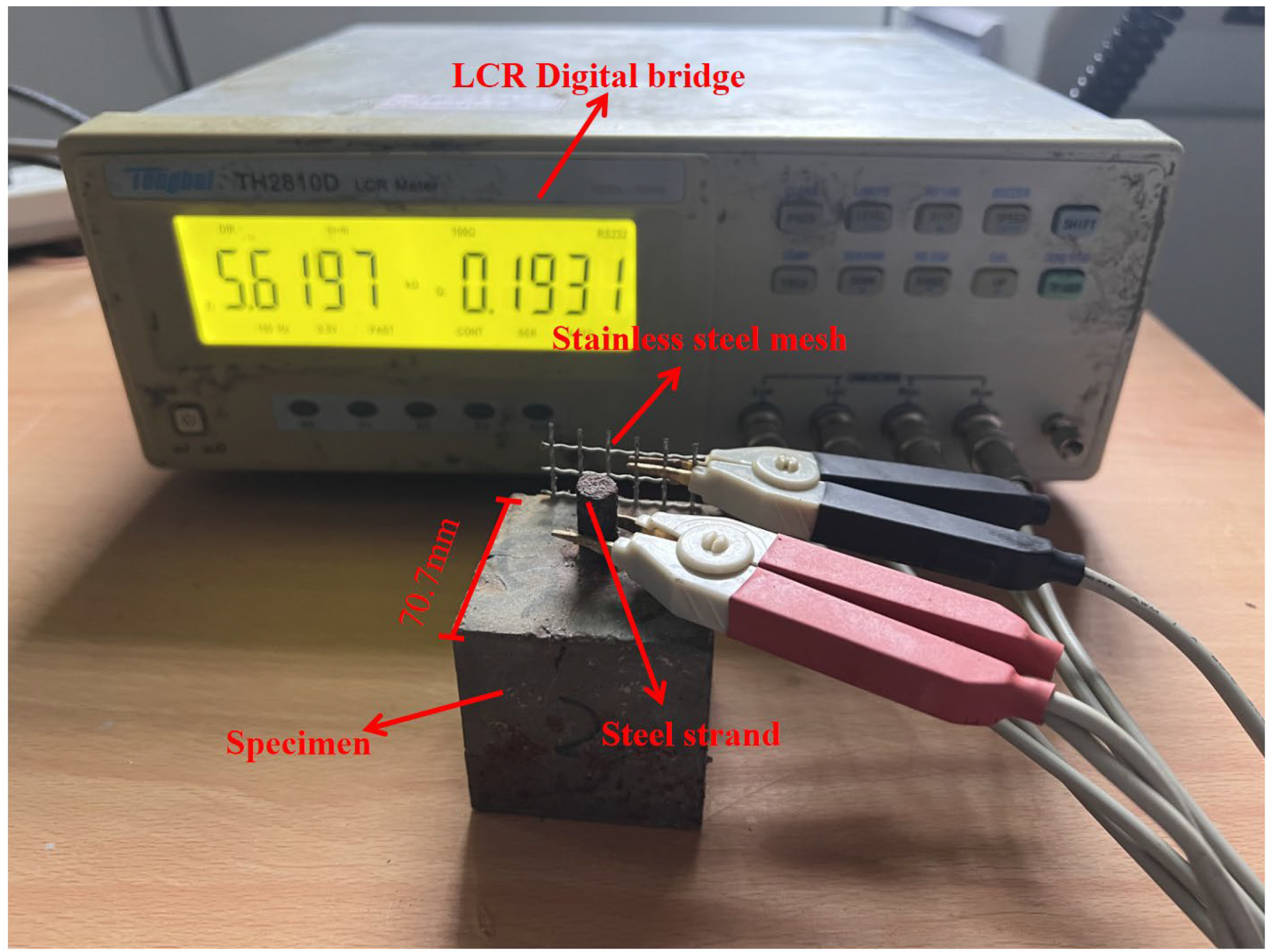

2.3.6. The Electrical Resistance

3. Results and Discussion

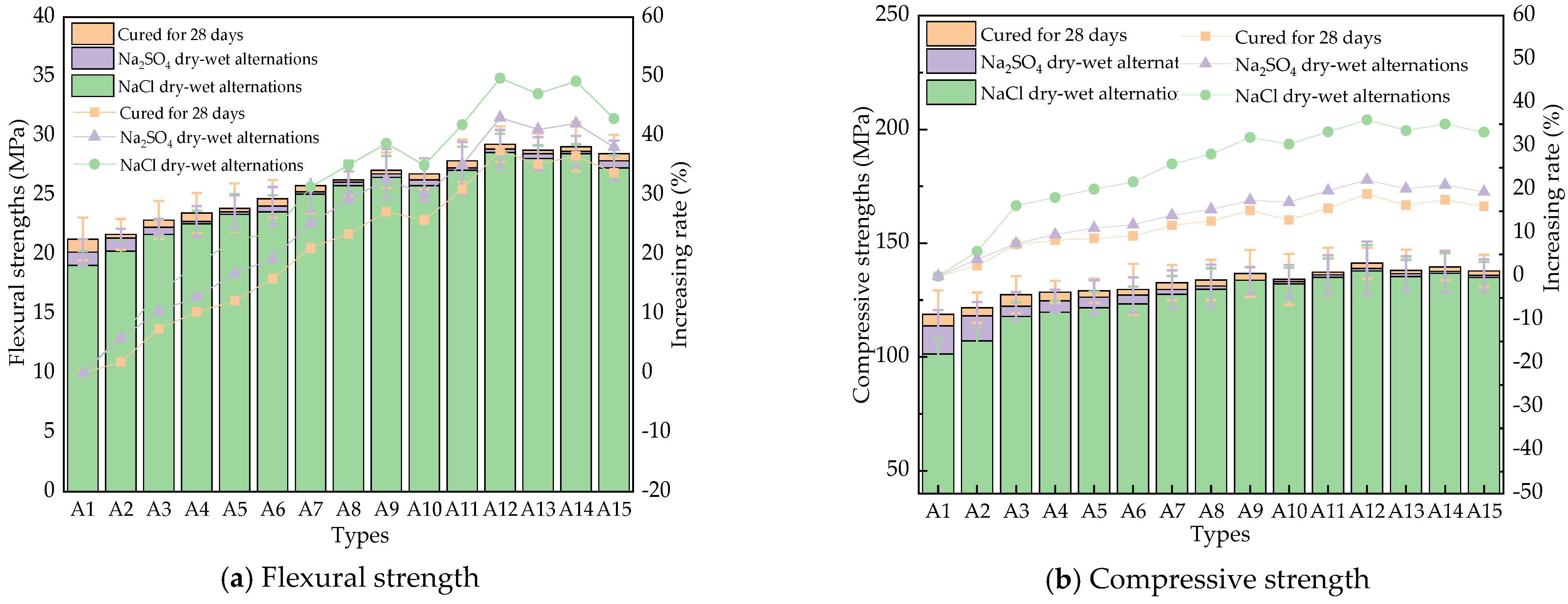

3.1. The Mechanical Strengths

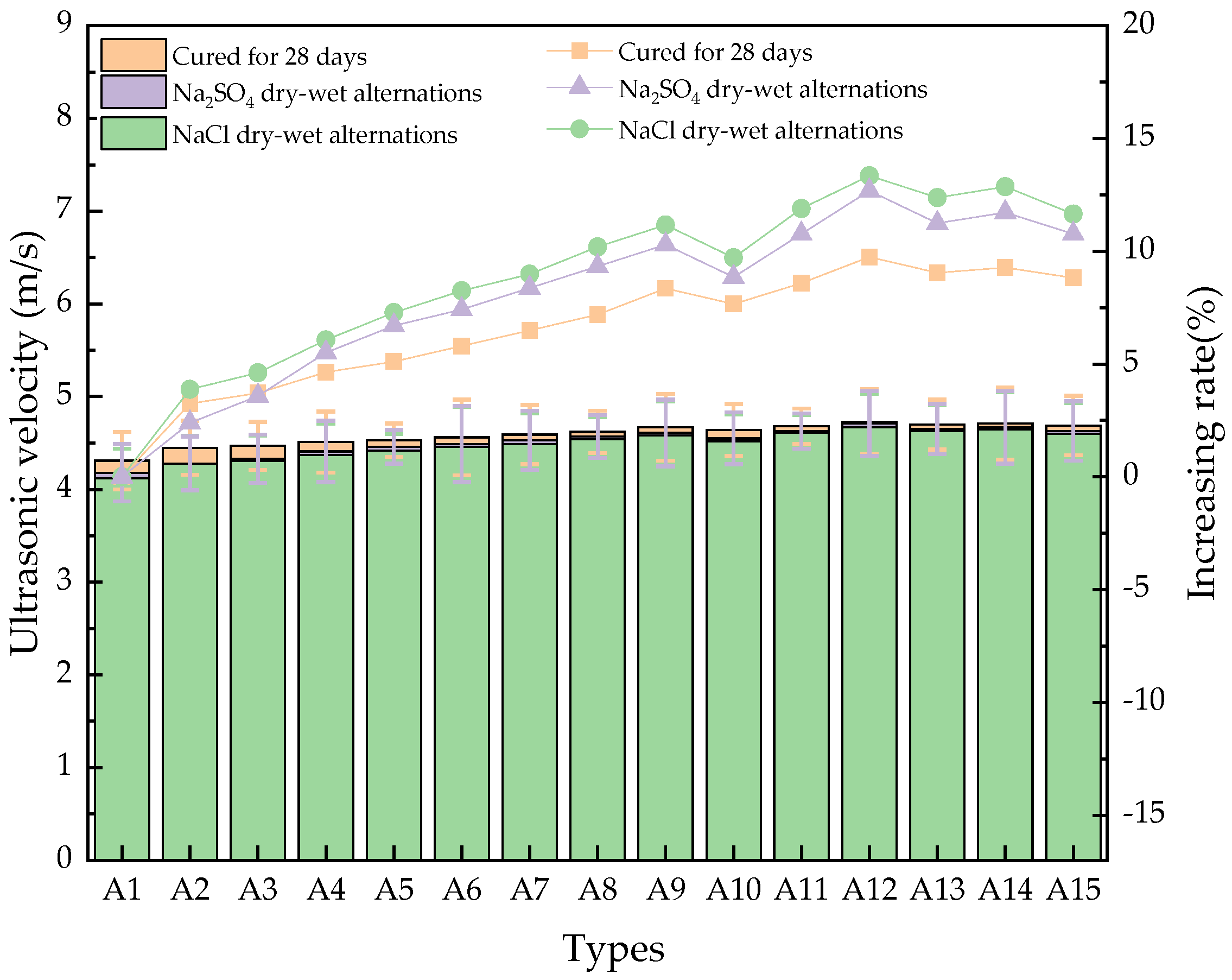

3.2. The Ultrasonic Velocity

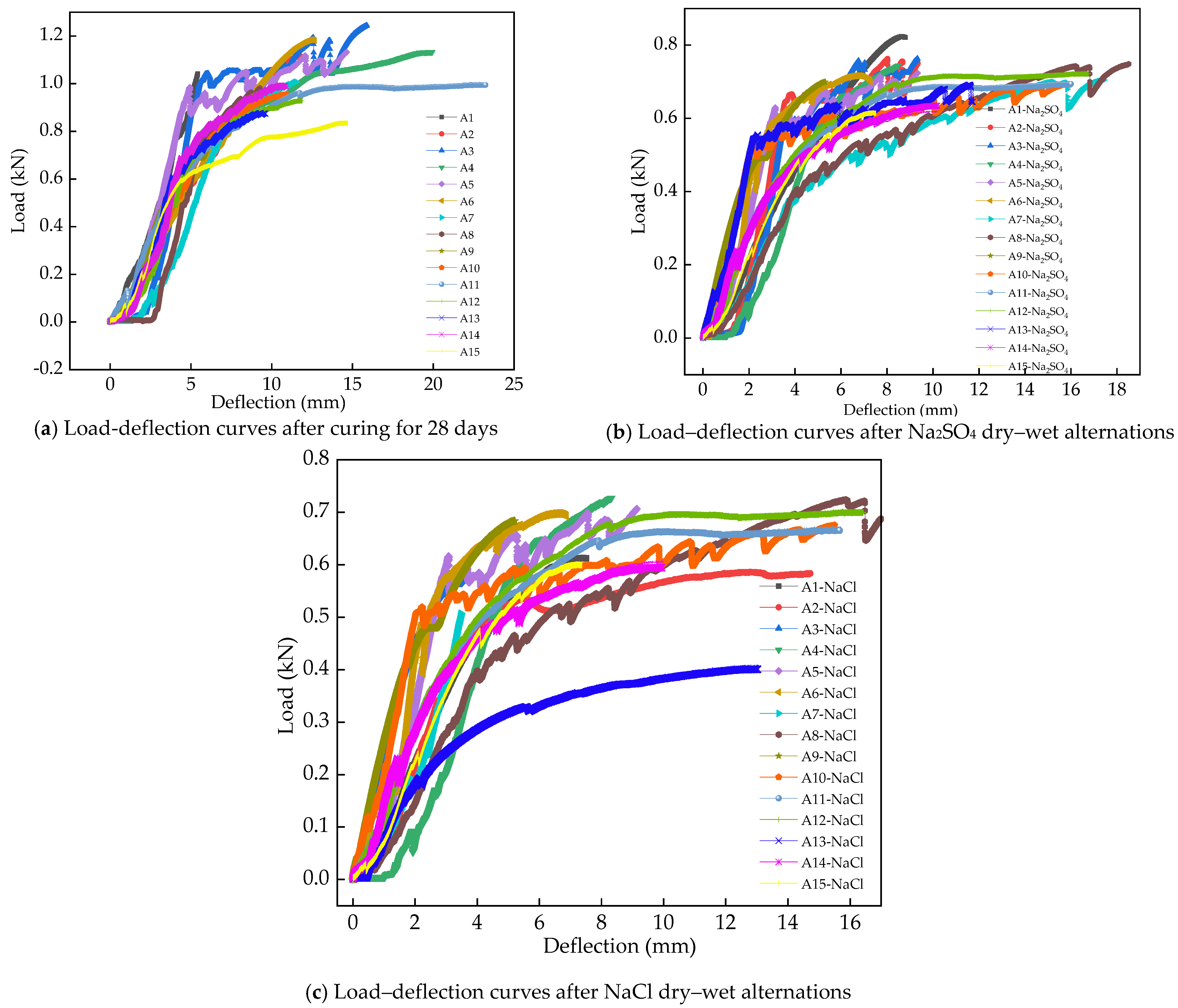

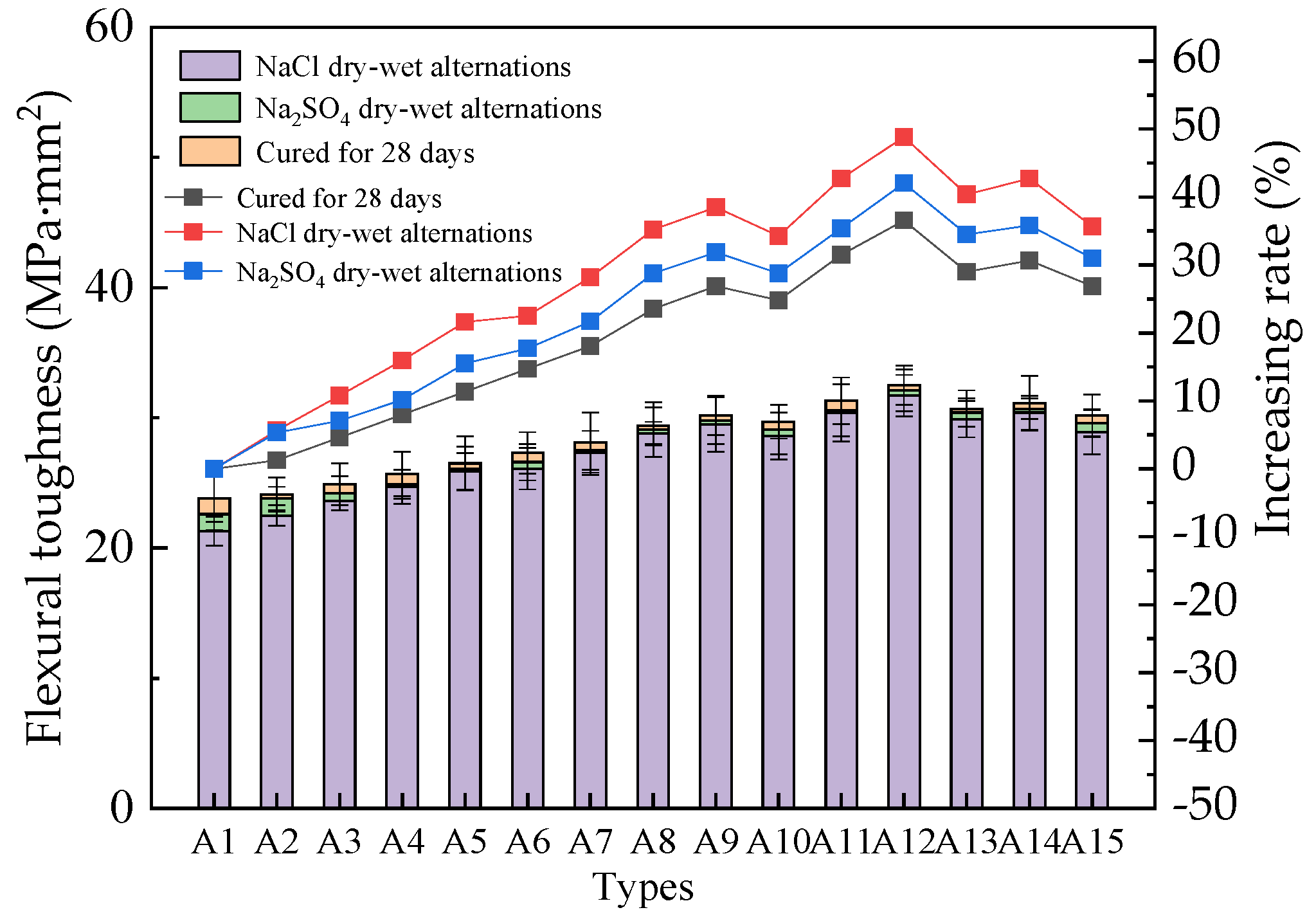

3.3. The Flexural Toughness

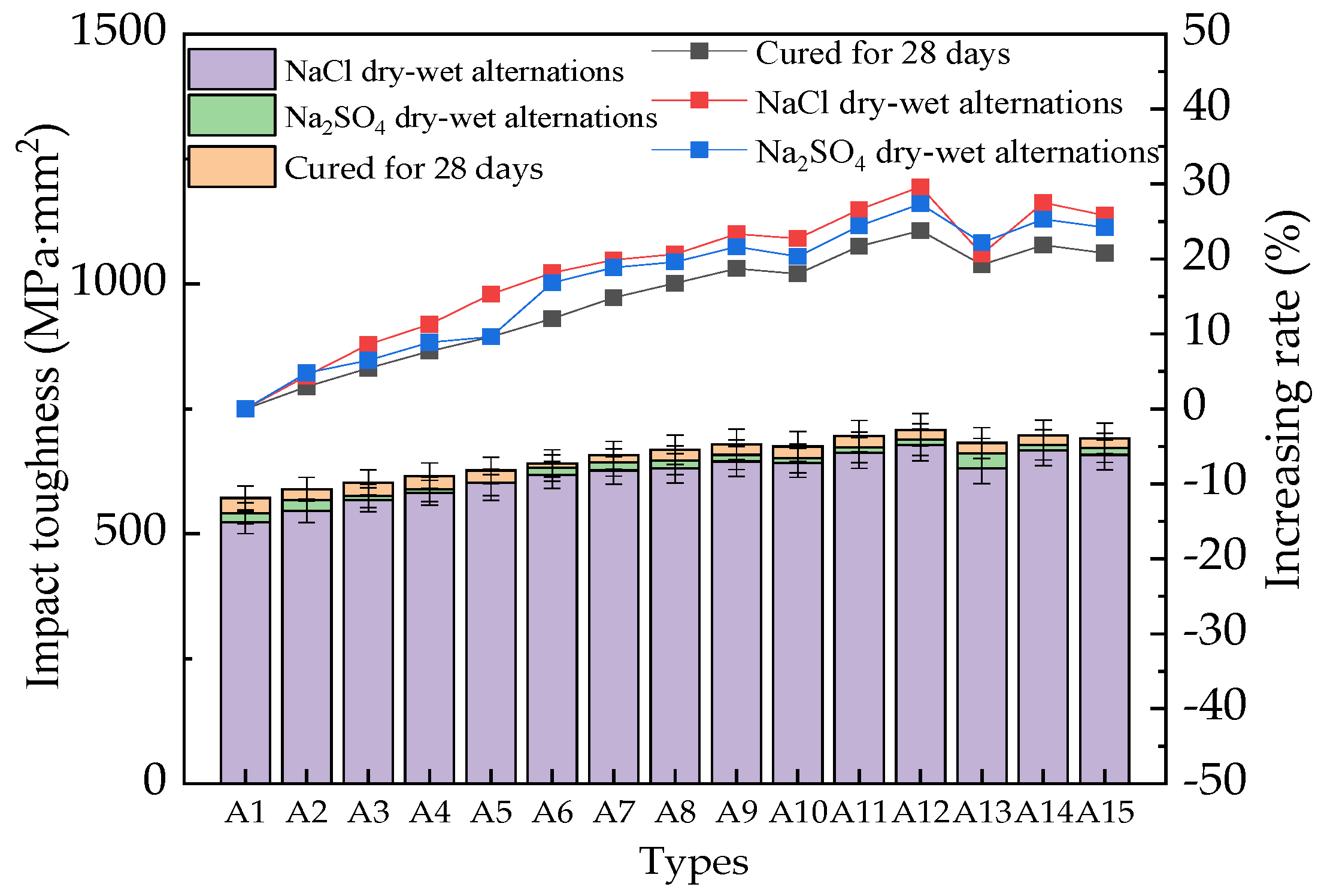

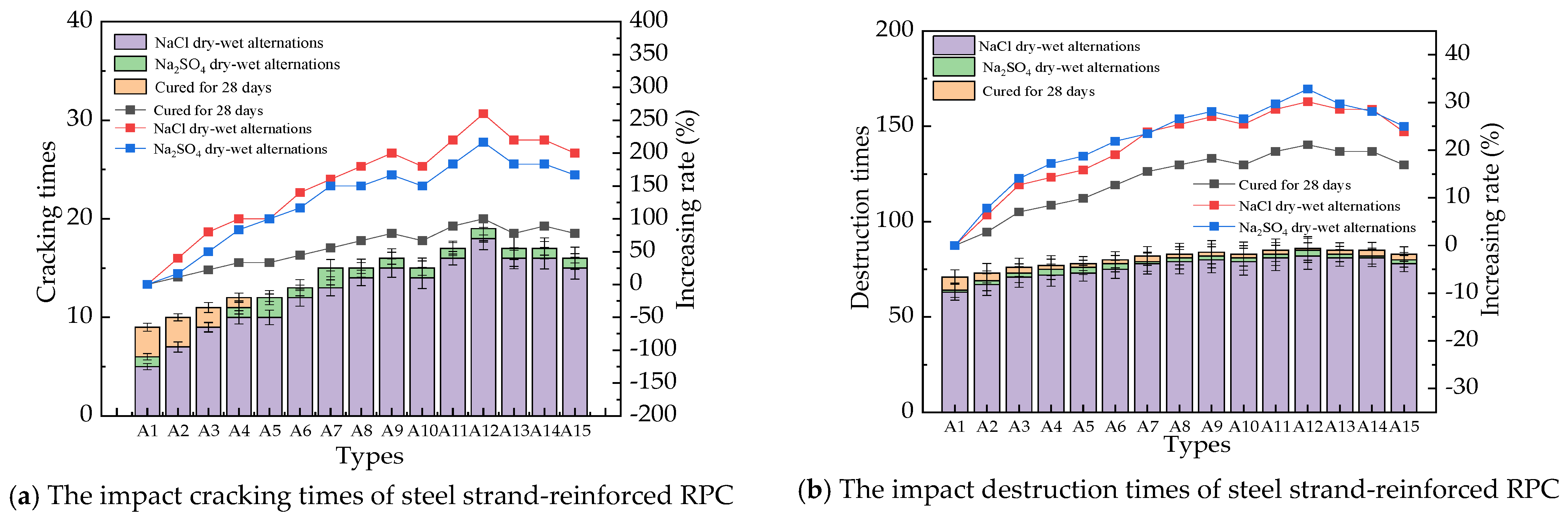

3.4. The Impact Toughness

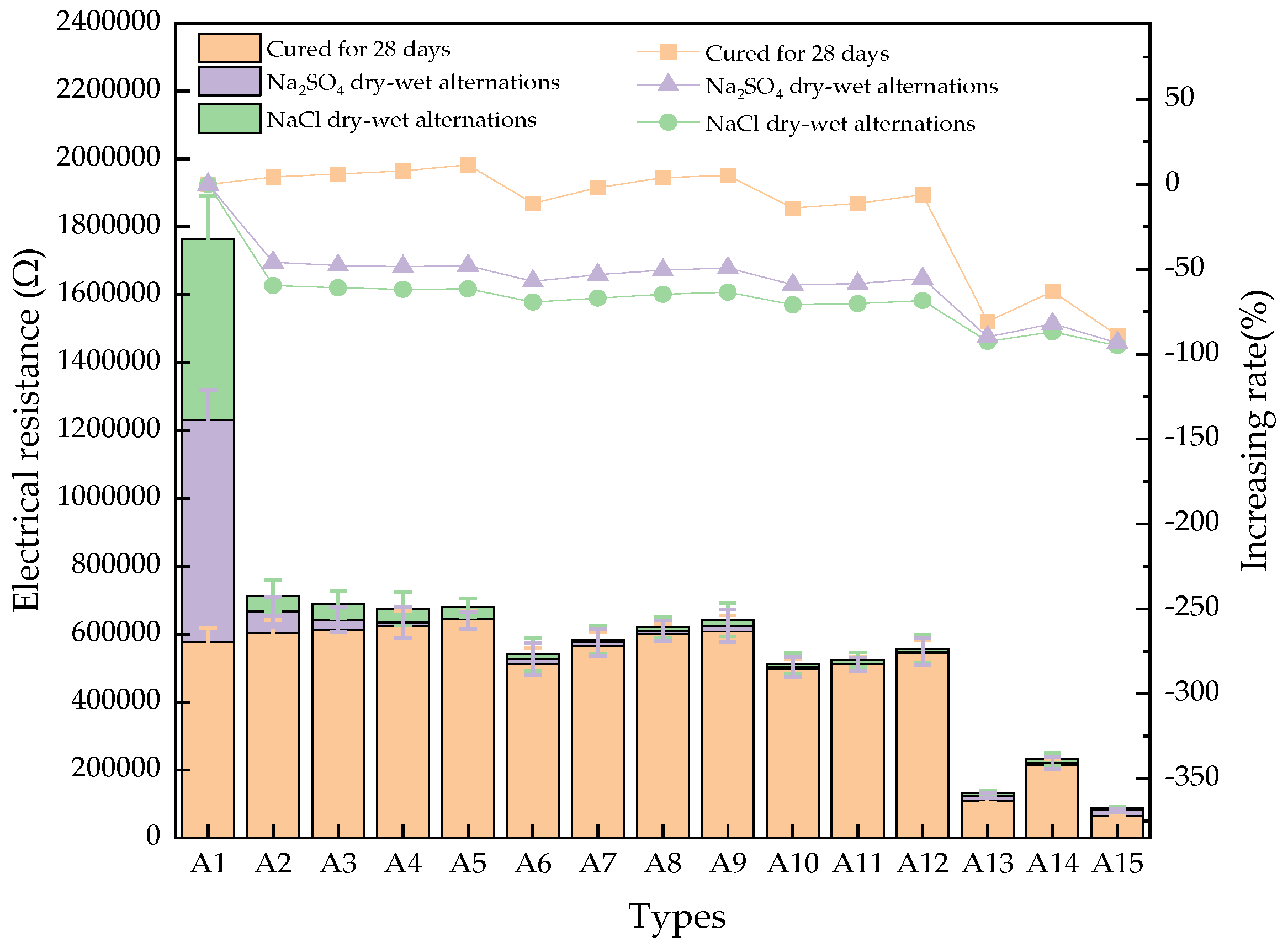

3.5. The Electrical Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Kaimakchi, A.; Rambo-Roddenberry, M. Flexural Behavior of Concrete Bridge Girders Prestressed with Stainless Steel Strands. ACI Struct. J. 2021, 118, 137–152. [Google Scholar] [CrossRef]

- Hyun, S.; Lee, S.J.; Yoo, D.Y. Bond Behavior of Pretensioned Strand Embedded in Ultra-High-Performance Fiber-Reinforced Concrete. Int. J. Concr. Struct. Mater. 2018, 12, 34–40. [Google Scholar] [CrossRef]

- Yu, J.B.; Xu, Z.Q.; Xia, Y.F.; Guo, Z.X. Seismic behavior of reactive powder concrete (RPC) interior beam-to-column joints under reversed cyclic loading. Case Stud. Constr. Mater. 2023, 18, e01792. [Google Scholar] [CrossRef]

- Zhao, H. Design of Concrete Building Structure in Marine Corrosion Zones. J. Coast. Res. 2020, 110, 266–270. [Google Scholar] [CrossRef]

- Cao, Z.H.; Wang, K.W.; Peng, X.; Wang, H.; Huang, R.M. Influence of NaCl Solution External Erosion on Corrosion Resistance of RPC Reinforced with Straw Fiber. Coatings 2023, 13, 1308. [Google Scholar] [CrossRef]

- Al-Kaimakchi, A.; Rambo-Roddenberry, M. Structural behavior of concrete girders prestressed and reinforced with stainless steel materials. Structures 2022, 35, 1191–1203. [Google Scholar] [CrossRef]

- Deng, N.C.; Xu, J.; Zhu, G.C.; Han, Z.Q. Study on the Mechanical Properties of Corroded Steel Strands at Deflection Angles. Buildings 2023, 13, 795. [Google Scholar] [CrossRef]

- Peng, W.; Fan, W. Experimental Study on Corrosion Development Model and Fatigue Performance of Strand Steel for Coastal Structures. J. Mar. Sci. Eng. 2023, 11, 665. [Google Scholar] [CrossRef]

- Zhang, S.P.; Zhao, B.H. Influence of polypropylene fibre on the mechanical performance and durability of concrete materials. Eur. J. Environ. Civ. Eng. 2012, 16, 1269–1277. [Google Scholar] [CrossRef]

- Kumutha, R.; Vijai, K. Effect of Steel Fibers on the Properties of Concrete. J. Reinf. Plast. Compos. 2010, 29, 531–538. [Google Scholar] [CrossRef]

- Ju, Y.Z.; Zhu, M.T.; Zhang, X.L.; Wang, D.H. Influence of steel fiber and polyvinyl alcohol fiber on properties of high performance concrete. Struct. Concr. 2022, 23, 1687–1703. [Google Scholar] [CrossRef]

- Gao, D.Y.; Tai, Y.Y.; Yang, L.; Zhang, Z.Q.; Liu, G.J.; You, P.B. Corrosion of Steel Fibers in Chloride-Contaminated Simulated Concrete Pore Solutions. J. Mater. Civ. Eng. 2023, 35, 04022429. [Google Scholar] [CrossRef]

- O’Brien, C.; McBride, A.; Zaghi, A.E.; Burke, K.A.; Hill, A. Mechanical Behavior of Stainless Steel Fiber-Reinforced Composites Exposed to Accelerated Corrosion. Materials 2017, 10, 772. [Google Scholar] [CrossRef]

- Farhan, N.A.; Sheikh, M.N.; Hadi, M.N.S. Experimental Investigation on the Effect of Corrosion on the Bond Between Reinforcing Steel Bars and Fibre Reinforced Geopolymer Concrete. Structures 2018, 14, 251–261. [Google Scholar] [CrossRef]

- Ding, B.M.; Zhang, L.; Liu, J.Q. The difference in weather resistance and corrosion process for different types of basalt fiber. J. Non-Cryst. Solids. 2022, 590, 121678. [Google Scholar] [CrossRef]

- Liang, N.H.; Mao, J.W.; Yan, R.; Liu, X.R.; Zhou, X.H. Corrosion resistance of multiscale polypropylene fiber-reinforced concrete under sulfate attack. Case Stud. Constr. Mater. 2022, 16, e01065. [Google Scholar] [CrossRef]

- Wei, A.F.; Tan, M.Y.; Koay, Y.C.; Hu, X.C.; Al-Ameri, R. Effect of carbon fiber waste on steel corrosion of reinforced concrete structures exposed to the marine environment. J. Cleaner Prod. 2021, 136, 128356. [Google Scholar] [CrossRef]

- Ficker, T. Quasi-static compressive strength of cement-based materials. Cem. Concr. Res. 2011, 41, 129–132. [Google Scholar] [CrossRef]

- Wang, Z.L.; Shi, Z.M.; Wang, J.G. On the strength and toughness properties of SFRC under static-dynamic compression. Compos. Part B 2011, 42, 1285–1290. [Google Scholar] [CrossRef]

- Yao, A.; Xu, J.Y.; Xia, W. An Experimental Study on Mechanical Properties for the Static and Dynamic Compression of Concrete Eroded by Sulfate Solution. Materials 2021, 14, 5387. [Google Scholar] [CrossRef]

- Dias, S.; Tadeu, A.; Almeida, J.; António, J.; de Brito, J. Steel-concrete bond behaviour of concrete mixes with wood waste: Pull-out and bending tests of full-scale beams and columns. Constr. Build. Mater. 2023, 383, 131343. [Google Scholar] [CrossRef]

- Xing, X.K.; Lin, L.R.; Qin, H.Y. Dynamic tensile behavior of steel strands at different strain rates. Structures 2021, 33, 378–389. [Google Scholar] [CrossRef]

- Yu, X.R.; Yao, G.W.; Gu, L.F.; Fan, W.Q. Numerical and Experimental Study on the Steel Strands under the Coupling Effect of a Salt Spray Environment and Cyclic Loads. Materials 2020, 13, 736. [Google Scholar] [CrossRef] [PubMed]

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2002.

- Han, Y.J.; Oh, S.K.; Kim, B. Effect of Load Transfer Section to Toughness for Steel Fiber-Reinforced Concrete. Appl. Sci. 2017, 7, 549. [Google Scholar] [CrossRef]

- Liu, W.; Xu, S.L.; Feng, P. Fatigue damage propagation models for ductile fracture of ultrahigh toughness cementitious composites. Int. J. Damage Mech. 2017, 26, 919–932. [Google Scholar] [CrossRef]

- GB/T 50081-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2009.

- Liu, W.; Luo, L.; Xu, S.; Zhao, H. Effect of fiber volume fraction on crack propagation rate of ultra-high toughness cementitious composites. Eng. Fract. Mech. 2014, 124, 52–63. [Google Scholar] [CrossRef]

- Chen, J.X.; Zhou, L.; Zhu, Z.M.; Ma, L.J.; Wang, M.; Deng, Z. Crack propagation analysis and mechanical properties of basalt fiber reinforced cement composites with changing fiber surface characteristics. Constr. Build. Mater. 2023, 392, 131738. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of fiber orientation and anisotropy on tensile strength and elastic modulus of short fiber reinforced polymer composites. Compos. Part B 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Ye, Y.X.; Liu, J.L.; Zhang, Z.Y.; Wang, Z.B.; Peng, Q.W. Experimental Study of High-Strength Steel Fiber Lightweight Aggregate Concrete on Mechanical Properties and Toughness Index. Adv. Mater. Sci. Eng. 2020, 2020, 5915034. [Google Scholar] [CrossRef]

- Jeon, C.H.; Lee, J.B.; Lon, S.; Shim, C.S. Equivalent material model of corroded prestressing steel strand. J. Mater. Res. Technol. 2019, 8, 2450–2460. [Google Scholar] [CrossRef]

- Dvorkin, L.; Bordiuzhenko, O.; Tekle, B.H.; Ribakov, Y. A Method for the Design of Concrete with Combined Steel and Basalt Fiber. Appl. Sci. 2021, 11, 8850. [Google Scholar] [CrossRef]

- Shao, J.X.; Kang, Y.L.; You, L.J.; Chen, M.J. Effect of dry-wet alternations on the mechanical strength of deep tight sandstone. J. Pet. Sci. Eng. 2021, 204, 108750. [Google Scholar] [CrossRef]

- Yang, H.S.; Chen, Y.L.; Feng, H.; Yang, P.; Zhang, J.; Shu, B.P. Optimized corrosion resistance in pure copper via surface mechanical attrition treatment and subsequent annealing. Mater. Today Commun. 2023, 35, 105645. [Google Scholar] [CrossRef]

- Peng, J.X.; Xiao, J.Y.; Yang, Y.M.; Dong, Y.; Zhang, J.R. Long-term experimental study and prediction of the mechanical performance on corroded prestressing steel strands subjected to marine salt spray environment. Constr. Build. Mater. 2024, 425, 136069. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Y.; Dasari, A.; Tan, K.H.; Weng, Y.W. Effect of spatial distribution of polymer fibers on preventing spalling of UHPC at high temperatures. Cem. Concr. Res. 2021, 140, 106281. [Google Scholar] [CrossRef]

- Fayzulla, B.J.; Eroglu, M.; Erklig, A. Investigation of the effect of steel fiber (200 mesh size) hybridization on properties of steel/glass fiber and steel/basalt fiber reinforced epoxy composite laminates. Polym. Compos. 2022, 43, 6647–6659. [Google Scholar] [CrossRef]

- Acebes, M.; Molero, M.; Segura, I.; Moragues, A.; Hernández, M.G. Study of the influence of microstructural parameters on the ultrasonic velocity in steel-fiber-reinforced cementitious materials. Constr. Build. Mater. 2011, 25, 3066–3072. [Google Scholar] [CrossRef]

- Liu, G.; Mu, S.; Cai, J.; Xie, D.; Zhou, Y.; Zhou, X. Influence of Crack on Concrete Damage in Salt-Freezing Environment. Adv. Mater. Sci. Eng. 2021, 2021, 5543286. [Google Scholar] [CrossRef]

- Li, H.; Yang, Y.M.; Wang, X.Z.; Tang, H. Effects of the position and chloride-induced corrosion of strand on bonding behavior between the steel strand and concrete. Structures 2023, 58, 105500. [Google Scholar] [CrossRef]

- Li, S.P.; Sun, Y.; Qian, Y.; Chen, W.J.; Hu, J.H. Flexural behaviour of post-tensioned precast beams manufactured with basalt-fibre-reinforced recycled concrete-conventional concrete. J. Build. Eng. 2023, 89, 109154. [Google Scholar] [CrossRef]

- Wang, H.T.; Tang, C.; Chen, M.S.; Shi, J.Z.; Cao, X.Y. Experimental study on the flexural performance of prestressed RC beams with post-tensioned CFRP strands. Eng. Struct. 2024, 309, 118118. [Google Scholar] [CrossRef]

- Wang, L.C.; Yin, S.P.; Wang, F. Interfacial bonding performance of textile reinforced ECC and seawater sea-sand concrete under a dry-wet environment. Constr. Build. Mater. 2023, 368, 130384. [Google Scholar] [CrossRef]

- Yang, W.R.; Huang, Y.W.; Tang, Z.Y.; Xiong, X.L.; Li, C.W.; Zhong, X.W.; Liu, L.I.; Zhou, H.; Zhang, X. Impermeability performance and corrosion resistance mechanism of basalt fiber recycled concrete under the coastal tidal environment. Constr. Build. Mater. 2024, 411, 134510. [Google Scholar] [CrossRef]

- Chairi, M.; El Bahaoui, J.; Hanafi, I.; Favaloro, F.; Borsellino, C.; Galantini, F.; Di Bella, G. The effect of span length on the flexural properties of glass and basalt fiber reinforced sandwich structures with balsa wood core for sustainable shipbuilding. Compos. Struct. 2024, 340, 118187. [Google Scholar] [CrossRef]

- Li, J.H.; Yang, L.Y.; Xie, H.Z.; Wei, P.; Li, D.Z.; Xu, Y.C.; Zhang, F. Research on impact toughness and crack propagation of basalt fiber reinforced concrete under SHPB splitting test. J. Build. Eng. 2023, 77, 107445. [Google Scholar] [CrossRef]

- Zhang, C.; Han, S.C.; Hua, Y. Flexural performance of reinforced self-consolidating concrete beams containing hybrid fibers. Constr. Build. Mater. 2018, 174, 11–23. [Google Scholar] [CrossRef]

- Liu, H.C.; Yu, Y.F.; Liu, Y.P.; Zhang, M.J.; Li, L.; Ma, L.; Sun, Y.; Wang, W.X. A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids. Polymers 2022, 14, 2376. [Google Scholar] [CrossRef]

| Types | SiO2 | Al2O3 | FexOy | MgO | CaO | SO3 | K2O | Na2O | Ti2O | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|---|

| OPC | 20.9 | 5.5 | 3.9 | 1.7 | 62.2 | 2.7 | / | / | / | 3.1 |

| GGBS | 34.1 | 14.7 | 0.2 | 9.7 | 35.9 | 0.2 | 3.5 | / | / | / |

| QS | 99.6 | / | 0.02 | / | / | / | / | / | / | / |

| FA | 55.00 | 20.00 | 6.00 | 10.20 | 4.50 | 0.11 | 1.26 | 2.13 | 0.06 | 0.74 |

| Types | Steel Fiber Volume | Basalt Fiber Volume |

|---|---|---|

| A1 | 0 | 0 |

| A2 | 0 | 0.5 |

| A3 | 0 | 1 |

| A4 | 0 | 1.5 |

| A5 | 0 | 2 |

| A6 | 0.5 | 0 |

| A7 | 0.5 | 0.5 |

| A8 | 0.5 | 1 |

| A9 | 0.5 | 1.5 |

| A10 | 1 | 0 |

| A11 | 1 | 0.5 |

| A12 | 1 | 1 |

| A13 | 1.5 | 0 |

| A14 | 1.5 | 0.5 |

| A15 | 2 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Xu, Z.; Cao, Z.; Xu, N.; Li, C.; Tian, X.; Wang, H. Research on the Performance of Steel Strand-Reinforced Reactive Powder Concrete with Mixed Steel Fibers and Basalt Fibers under the Salt Dry–Wet Erosion. Coatings 2024, 14, 833. https://doi.org/10.3390/coatings14070833

Wang D, Xu Z, Cao Z, Xu N, Li C, Tian X, Wang H. Research on the Performance of Steel Strand-Reinforced Reactive Powder Concrete with Mixed Steel Fibers and Basalt Fibers under the Salt Dry–Wet Erosion. Coatings. 2024; 14(7):833. https://doi.org/10.3390/coatings14070833

Chicago/Turabian StyleWang, Di, Zhiqiang Xu, Zihao Cao, Na Xu, Chuanqi Li, Xu Tian, and Hui Wang. 2024. "Research on the Performance of Steel Strand-Reinforced Reactive Powder Concrete with Mixed Steel Fibers and Basalt Fibers under the Salt Dry–Wet Erosion" Coatings 14, no. 7: 833. https://doi.org/10.3390/coatings14070833