The Influence of Bias Voltage on the Structure and Properties of TiZrNbMo Coating Deposited by Magnetron Sputtering

Abstract

1. Introduction

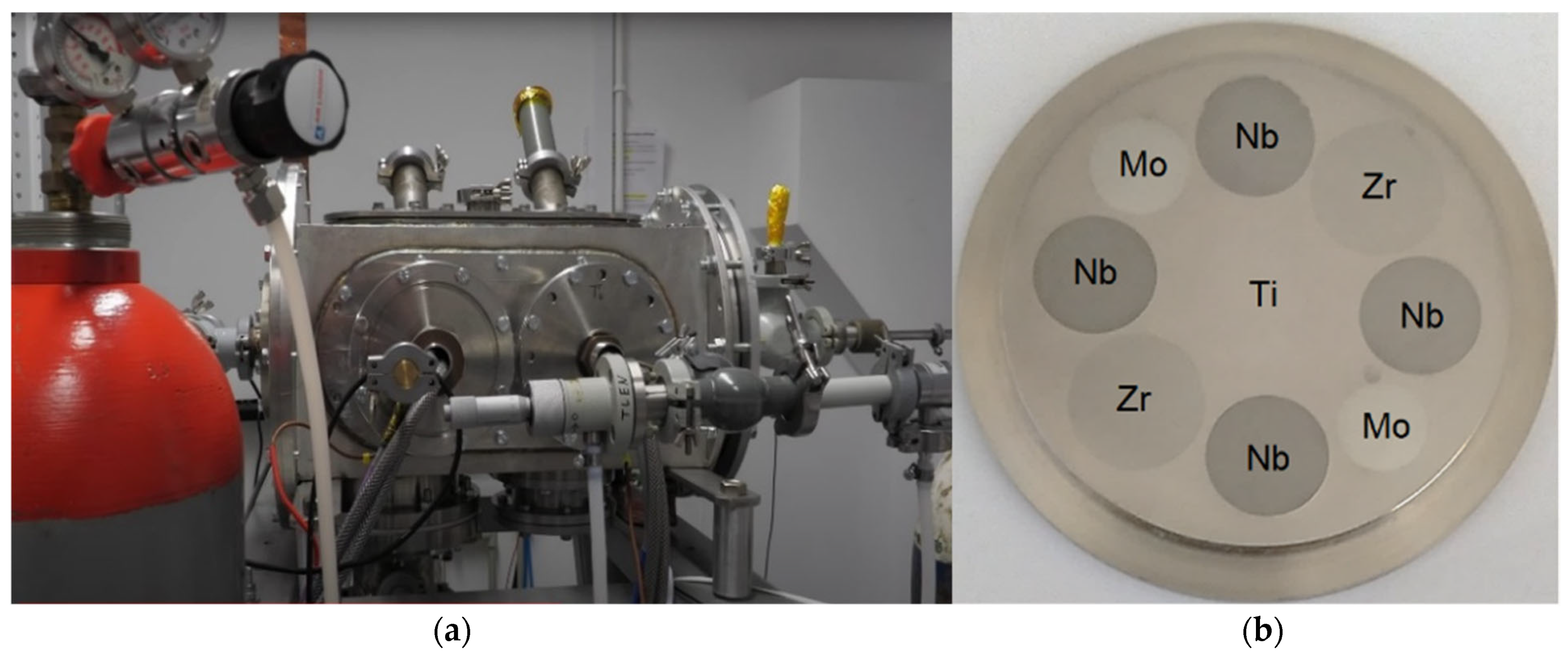

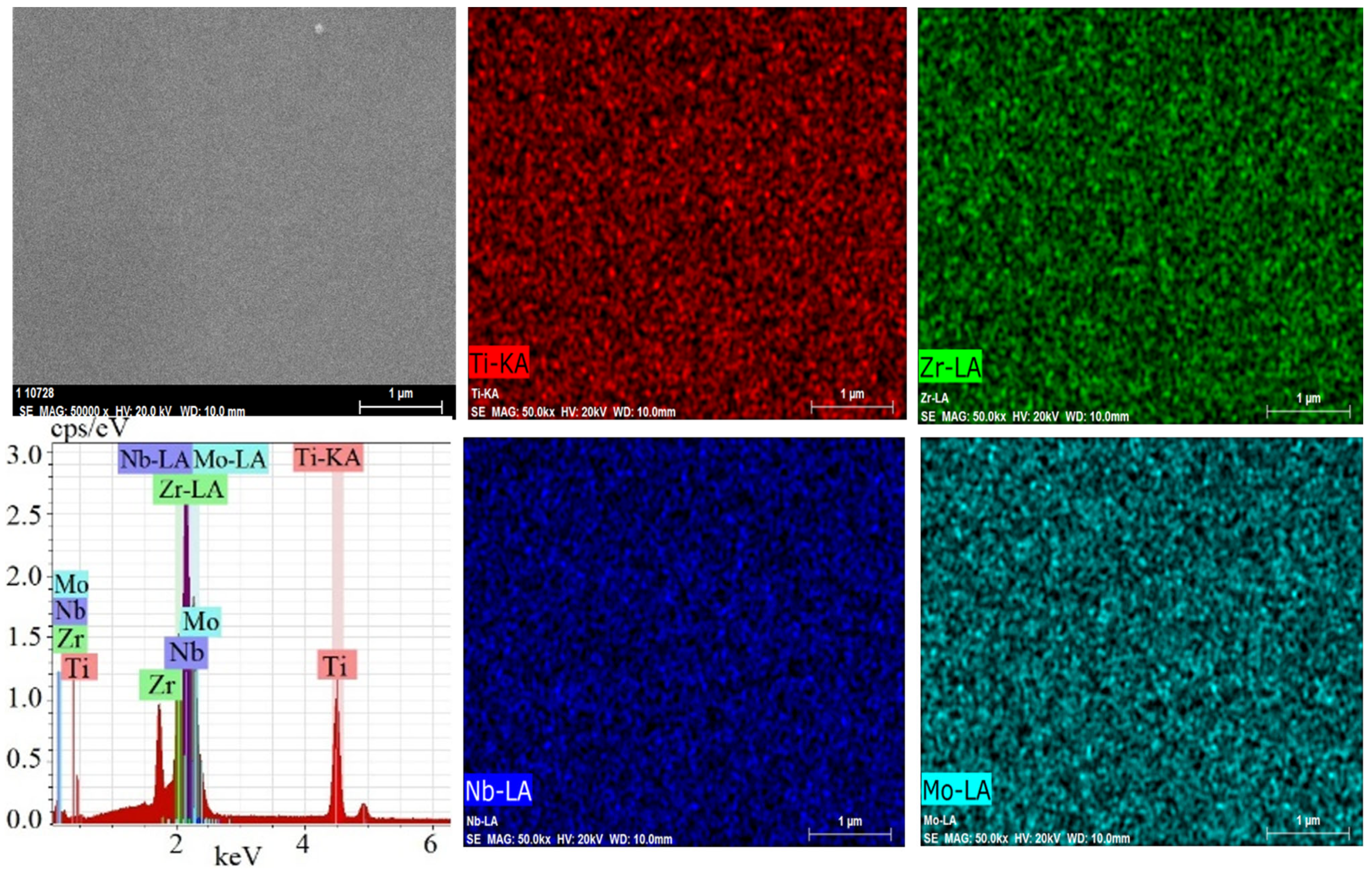

2. Materials and Methods

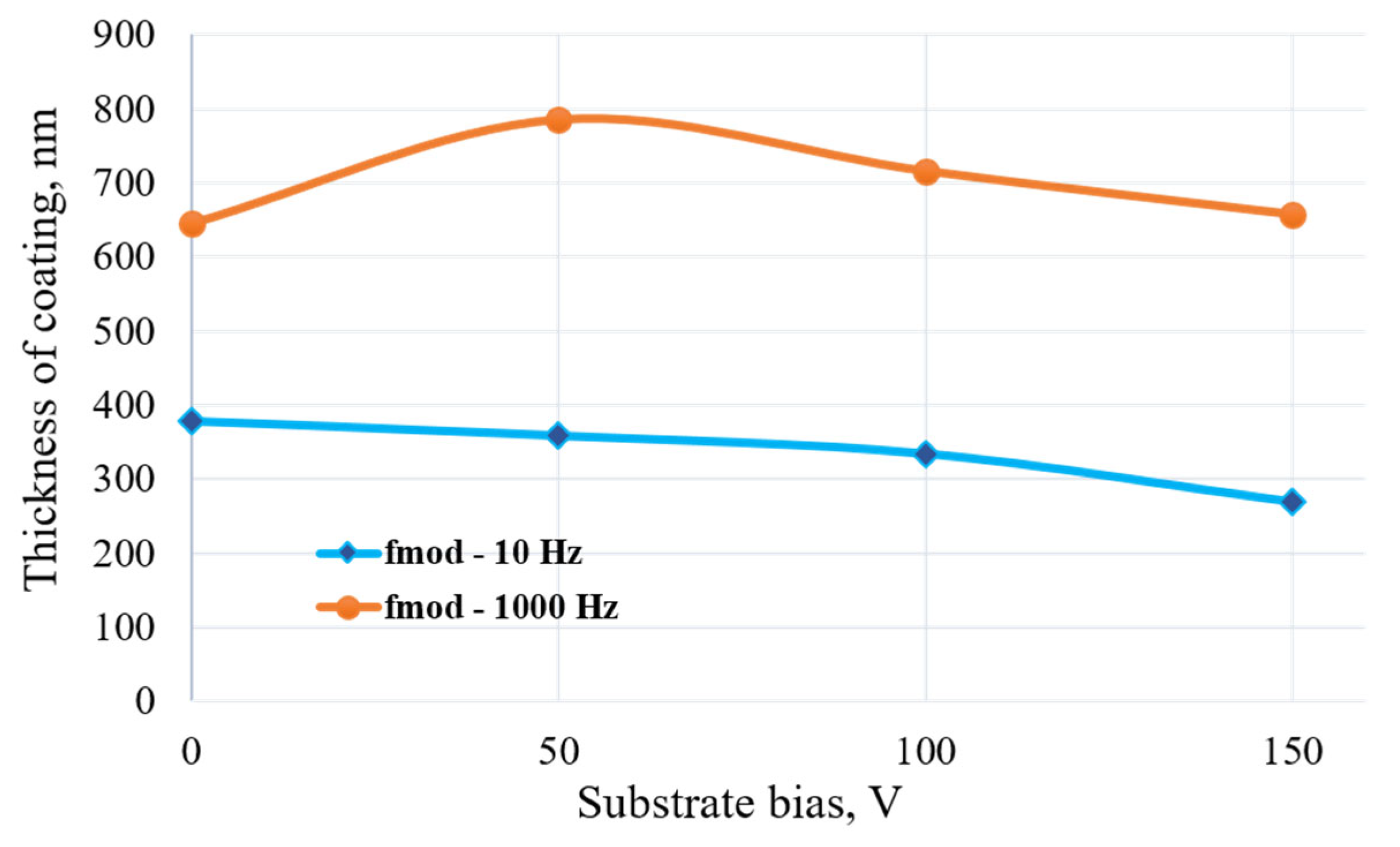

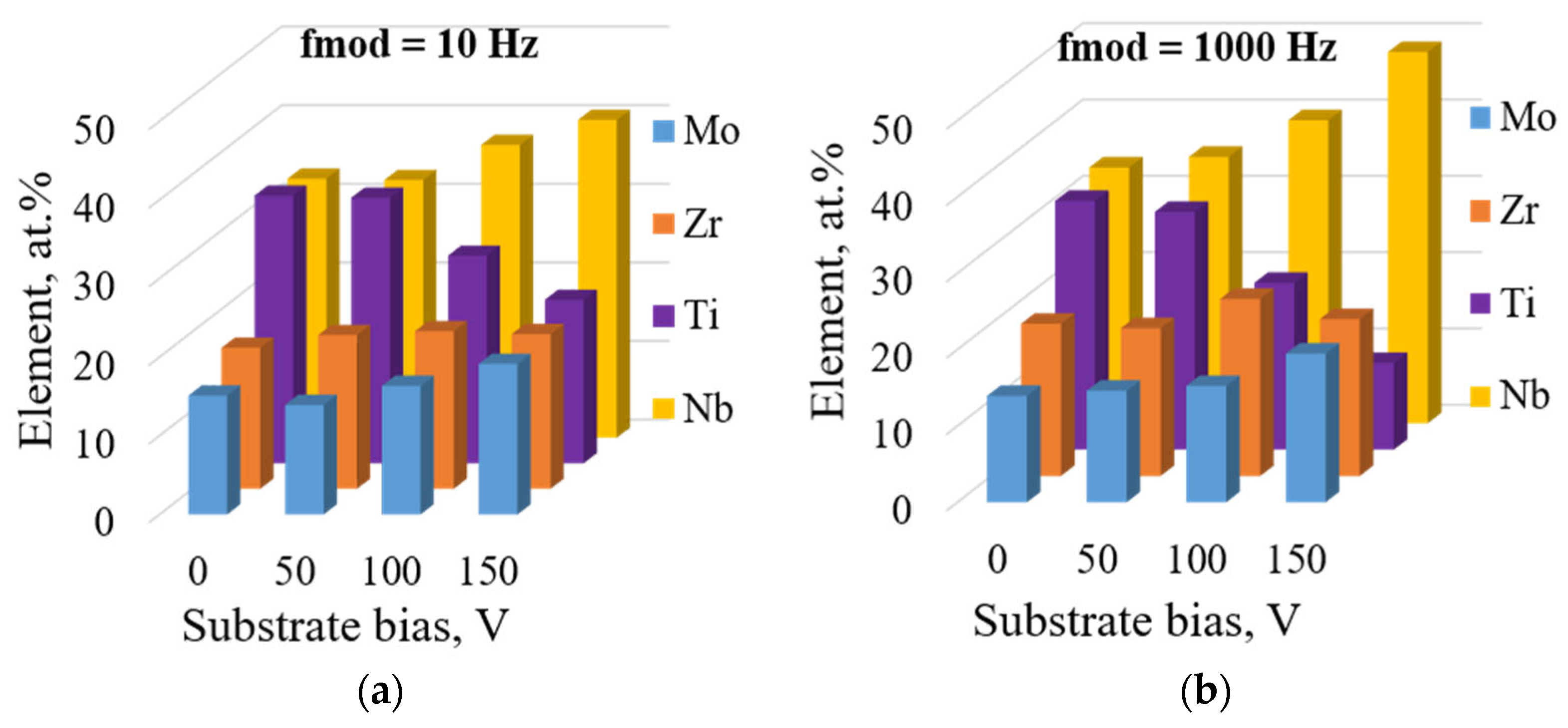

3. Results and Discussion

4. Conclusions

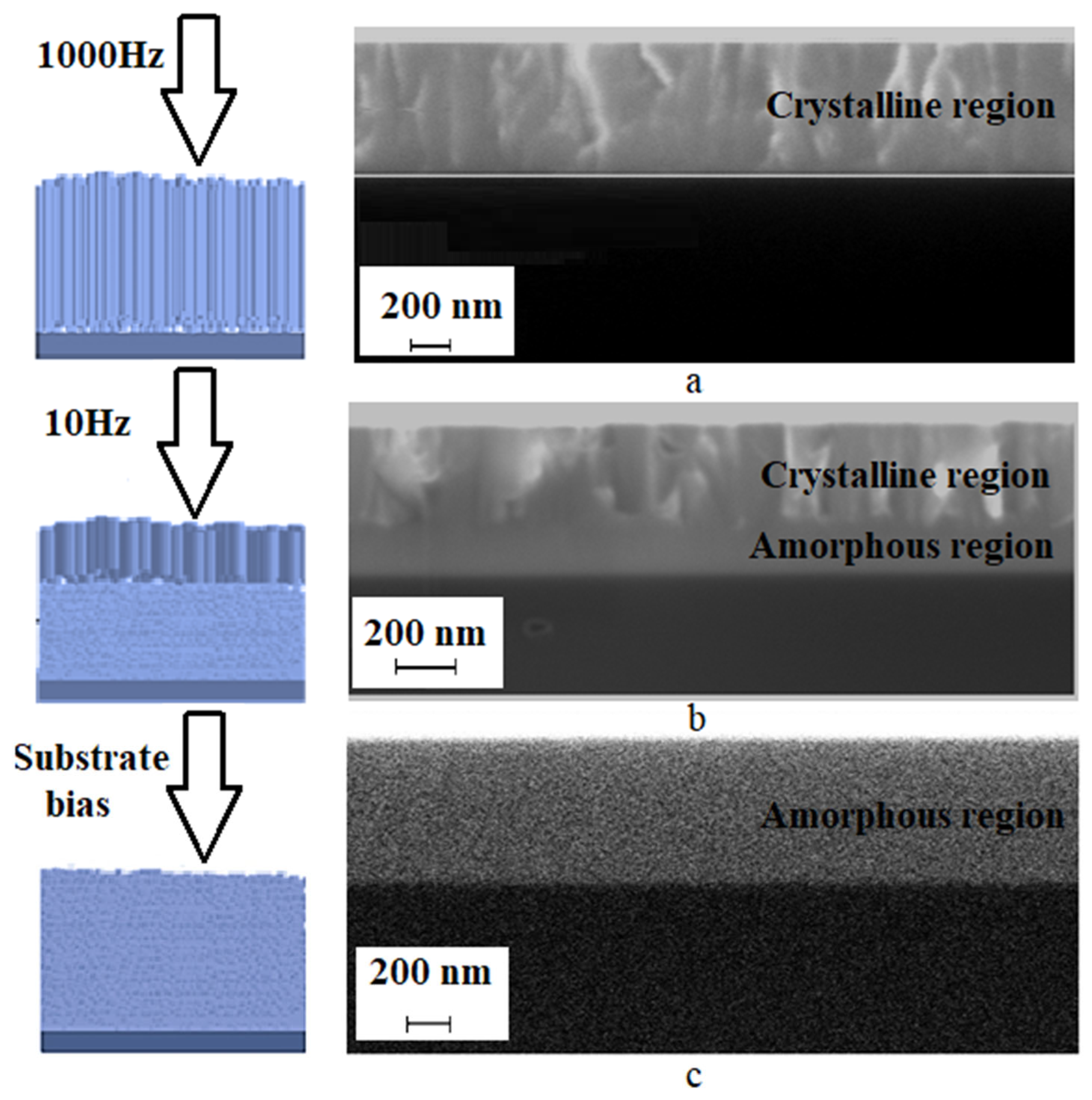

- Increasing the modulation frequency (from 10 Hz to 1000 Hz) promotes the formation of a columnar structure and increases the coating thickness.

- Increasing the negative voltage on the substrate decreases the deposition rate and significantly changes the chemical composition of the coating. The concentration of titanium decreases by a factor of three, while the concentrations of Mo and Nb increase by 42.8% and 48.5%, respectively.

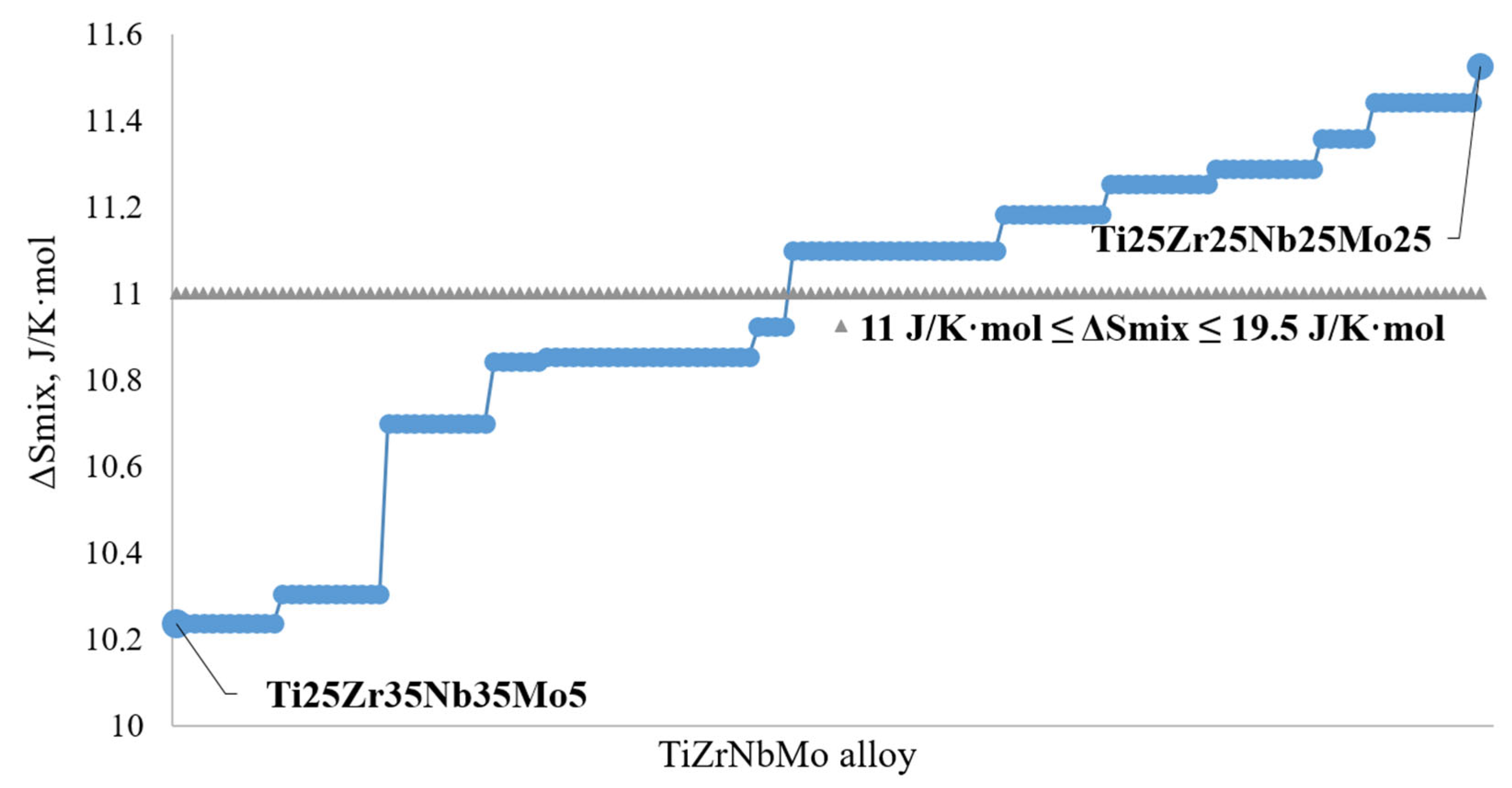

- Experimental data confirmed the theoretical assessments. The deposited TiZrNbMo coatings exhibited a homogeneous body-centered cubic (BCC) structure of solid solution without the presence of intermetallic compounds.

- The preferred crystallographic orientation for all coatings was (110). With an increase in the negative voltage on the substrate, the intensity and width of the diffraction peak decreases, as does the grain size. Coatings with the smallest grain size were obtained with a substrate bias of −100 V. At higher substrate biases (−150 V), an amorphous–nanocrystalline structure is formed.

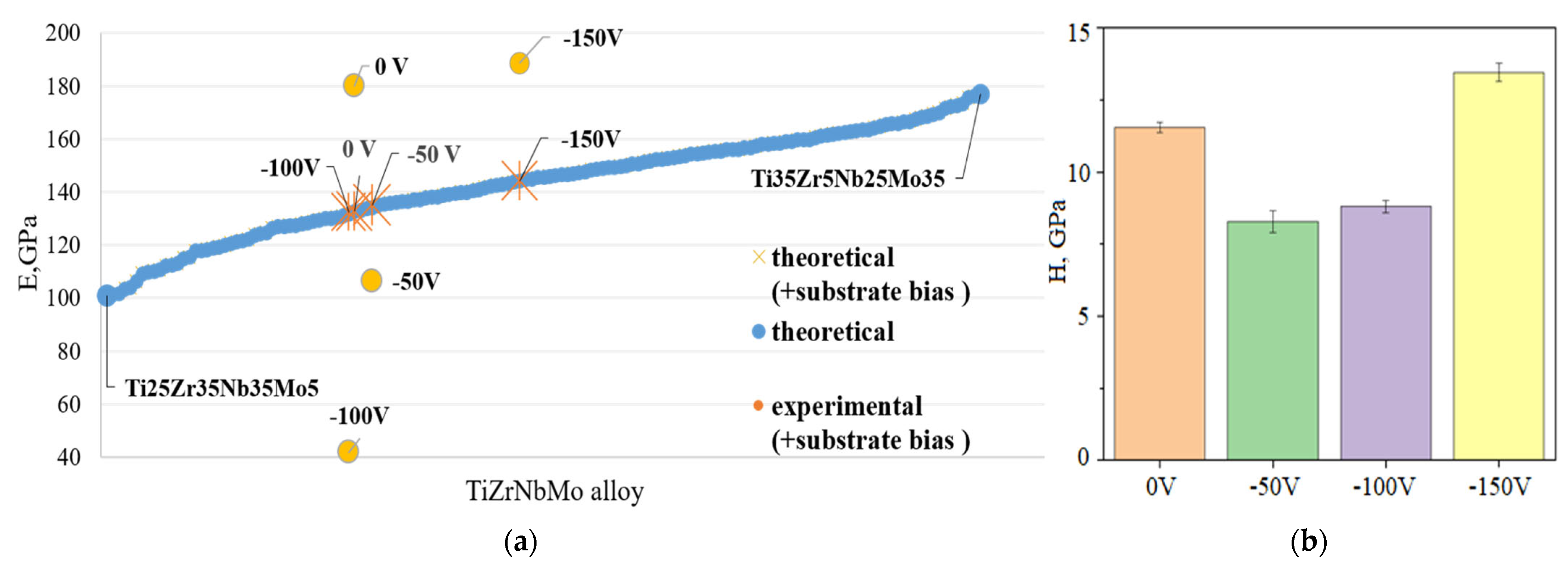

- With an increase in the substrate bias voltage, the hardness of the coating increases. The maximum values of hardness (13.45 GPa) and elastic modulus (188.6 GPa) are achieved at a substrate bias voltage of −150 V. Meanwhile, the minimum value of the elastic modulus (41.8 GPa) is attained at an intermediate substrate bias voltage of −100 V.

- The good correlation between the theoretical data and experimental results indicates the feasibility of using the magnetron sputtering method to obtain coatings with desired properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geanta, V.; Voiculescu, I.; Vizureanu, P.; Sandu, A.V. High Entropy Alloys for Medical Applications. Eng. Steels High Entropy-Alloys 2019, 10, 181–198. [Google Scholar] [CrossRef]

- Taran, V.S.; Garkusha, I.E.; Taran, A.V.; Muratov, R.M.; Vorontsov, P.M.; Gnidenko, Y.P.; Herasimov, H.M.; Starikov, V.V.; Baturin, A.A.; Romaniuk, S.P. Functional protective ZrN coatings on implants for trauma surgery. Probl. At. Sci. Technol. 2020, 130, 115–118. [Google Scholar] [CrossRef]

- Geantă, V.; Voiculescu, I.; Ştefănoiu, R.; Codescu, M.; Kelemen, H.; Pavel, G.; Vlădescu, A.; Sandu, V.A. Obtaining and characterisation of high entropy alloys used for medical applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 572, 012023. [Google Scholar] [CrossRef]

- Taran, V.; Garkusha, I.; Tymoshenko, O.; Taran, A.; Misiruk, I.; Skoblo, T.; Romaniuk, S.; Starikov, V.; Baturin, A.; Nikolaychuk, G. Development of niobium based coatings prepared by ion-plasma vacuum-arc deposition. Plasma Med. 2020, 10, 61–69. [Google Scholar] [CrossRef]

- Todai, M.; Nagase, T.; Hori, T.; Matsugaki, A.; Sekita, A.; Nakano, T. Novel TiNbTaZrMo high-entropy alloys for metallic biomaterials. Scr. Mater. 2017, 129, 65–68. [Google Scholar] [CrossRef]

- Popescu, G.; Ghiban, B.; Popescu, C.A.; Rosu, L.; Truscă, R.; Carcea, I.; Soare, V.; Dumitrescu, D.; Constantin, I.; Olaru, M.T. New TiZrNbTaFe high entropy alloy used for medical. IOP Conf. Ser. Mater. Sci. Eng. 2018, 400, 022049. [Google Scholar] [CrossRef]

- Wang, S.-P.; Xu, J. TiZrNbTaMo high-entropy alloy designed for orthopedic implants: As-cast microstructure and mechanical properties. Mater. Sci. Eng. C 2017, 73, 80–89. [Google Scholar] [CrossRef] [PubMed]

- Martins, D.Q.; Osório, W.R.; Souza, E.P.; Caram, R.; Garcia, A. Effects of Zr content on microstructure and corrosion resistance of Ti–30Nb–Zr casting alloys for biomedical applications. Electrochim. Acta 2008, 53, 2809–2817. [Google Scholar] [CrossRef]

- Dai, S.; Wang, Y.; Chen, F.; Yu, X.; Zhang, Y. Influence of Zr content on microstructure and mechanical properties of implant Ti–35Nb–4Sn–6Mo–xZr alloys. Trans. Nonferr. Met. Soc. China 2013, 23, 1299–1303. [Google Scholar] [CrossRef]

- Nnamchi, P.S. First principles studies on structural, elastic and electronic properties of new Ti-Mo-Nb-Zr alloys for biomedical applications. Mater. Des. 2016, 108, 60–67. [Google Scholar] [CrossRef]

- Jin, C.; Li, X.; Li, H.; Li, Q.; Wang, H. Tribological performance of a TiZrNbMo0.6 refractory high entropy alloy at elevated temperatures. J. Alloys Compd. 2022, 920, 165915. [Google Scholar] [CrossRef]

- Wong, K.; Hsu, H.; Wu, S.; Ho, W. Structure and properties of Ti-rich Ti–Zr–Nb–Mo medium-entropy alloys. J. Alloys Compd. 2021, 868, 159137. [Google Scholar] [CrossRef]

- Liu, H.; Wang, R.; Gao, Q.; Chen, P.; Hao, J.; Yang, H.; Liu, X. Evolution in microstructure and tribological behavior of laser cladded MoxNbTiZr high-entropy refractory alloy coatings with varying Mo content. Mater. Charact. 2023, 206, 113449. [Google Scholar] [CrossRef]

- Liu, L.; Liu, H.; Zhang, X.; Wang, Y.; Hao, X. Corrosion Behavior of TiMoNbX (X = Ta, Cr, Zr) Refractory High Entropy Alloy Coating Prepared by Laser Cladding Based on TC4 Titanium Alloy. Materials 2023, 16, 3860. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, X.; Zhang, Y.; Cai, W.; Wang, L.; Tang, L. Effect of substrate bias on the microstructure and mechanical and tribological properties of ZrNbTiMo refractory high entropy alloy film. Surf. Coat. Technol. 2023, 455, 129214. [Google Scholar] [CrossRef]

- Strzelecki, G.W.; Nowakowska-Langier, K.; Mulewska, K.; Zieliński, M.; Kosińska, A.; Okrasa, S.; Wilczopolska, M.; Chodun, R.; Wicher, B.; Mirowski, R.; et al. Multi-component low and high entropy metallic coatings synthesized by pulsed magnetron sputtering. Surf. Coat. Technol. 2022, 446, 128802. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Morinaga, M. The Molecular Orbital Approach to Titanium Alloy Design. Key Eng. Mater. 2018, 770, 217–223. [Google Scholar] [CrossRef]

- Changxi, L.; Chengliang, Y.; Jia, L.; Yujin, T.; Zhengjie, L.; Long, L.; Hai, L.; Weijie, L.; Liqiang, W. Medical high-entropy alloy: Outstanding mechanical properties and superb biological compatibility. Front. Bioeng. Biotechnol. 2020, 10, 952536. [Google Scholar]

- Guo, S.; Liu, C.T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Mohr, P.J.; Taylor, B.N.; Newell, D.B. CODATA recommended values of the fundamental physical constants: 2006. Rev. Mod. Phys. 2008, 80, 633. [Google Scholar] [CrossRef]

- Liu, X.; Cai, W.; Zhang, Y.; Wang, L.; Wang, J. Tuning microstructure and mechanical and wear resistance of ZrNbTiMo refractory high-entropy alloy films via sputtering power. Front. Mater. 2023, 10, 1145631. [Google Scholar] [CrossRef]

- Peng, H.-E.; Lee, C.-Y.; Chang, H.-Y.; Yeh, J.-W. Effect of Substrate Bias on the Microstructure and Properties of Non-Equimolar (AlCrSiTiZr)N Films with Different Cr/Zr Ratios Deposited Using Reactive Direct Current Magnetron Sputtering. Coatings 2023, 13, 1985. [Google Scholar] [CrossRef]

- Cao, F.; Munroe, P.; Zhou, Z.; Xie, Z. Influence of substrate bias on microstructural evolution and mechanical properties of TiAlSiN thin films deposited by pulsed-DC magnetron sputtering. Thin Solid Film. 2017, 639, 137. [Google Scholar] [CrossRef]

- Sahu, B.P.; Dutta, A.; Mitra, R. Influence of substrate bias voltage on structure and properties of DC magnetron sputtered Ni–Zr alloy thin films. J. Mater. Res. 2020, 35, 1543–1555. [Google Scholar] [CrossRef]

- He, Z.; Zhang, S.; Sun, D. Effect of bias on structure mechanical properties and corrosion resistance of TiNx films prepared by ion source assisted magnetron sputtering. Thin Solid Film. 2019, 676, 60. [Google Scholar] [CrossRef]

- Wang, J.-J.; Chang, S.-Y.; Ouyang, F.-Y. Effect of substrate bias on the microstructure and properties of (AlCrSiNbZr)Nx high entropy nitride thin film. Surf. Coat. Technol. 2020, 393, 125796. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Lo, W.-L.; Hsu, S.-Y.; Lin, Y.-C.; Tsai, S.-Y.; Lai, Y.-T.; Duh, J.-G. Improvement of high entropy alloy nitride coatings (AlCrNbSiTiMo)N on mechanical and high temperature tribological properties by tuning substrate bias. Surf. Coat. Technol. 2020, 401, 126247. [Google Scholar] [CrossRef]

- Chang, H.-W.; Huang, P.-K.; Yeh, J.-W.; Davison, A.; Tsau, C.-H.; Yang, C.-C. Influence of substrate bias, deposition temperature and post-deposition annealing on the structure and properties of multi-principal-component (AlCrMoSiTi)N coatings. Surf. Coat. Technol. 2008, 202, 3360–3366. [Google Scholar] [CrossRef]

- Lai, C.-H.; Lin, S.-J.; Yeh, J.-W.; Davison, A. Effect of substrate bias on the structure and properties of multi-element (AlCrTaTiZr)N coatings. J. Phys. D Appl. Phys. 2006, 39, 4628–4633. [Google Scholar] [CrossRef]

- Ding, J.C.; Wang, Q.M.; Liu, Z.R.; Jeong, S.; Zhang, T.F.; Kim, K.H. Influence of bias voltage on the microstructure, mechanical and corrosion properties of AlSiN films deposited by HiPIMS technique. J. Alloys Compd. 2019, 772, 112–121. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, S.; Brown, I.G. Nanoindentation and nanoscratching of hard carbon coatings for magnetic disks. Mat. Res. Soc. Symp. Proc. 1995, 383, 447–452. [Google Scholar] [CrossRef]

| Names of Samples | Modulation Frequency [Hz] | Power [W] | Negative Substrate Bias Voltage [V] | Sputtering Time [min] | Pressure [Pa] |

|---|---|---|---|---|---|

| No.1 | 1000 | 1000 | 0 | 20 | 0.5 |

| No.2 | −50 | ||||

| No.3 | −100 | ||||

| No.4 | −150 | ||||

| No.5 | 10 | 0 | |||

| No.6 | −50 | ||||

| No.7 | −100 | ||||

| No.8 | −150 |

| Enthalpy of Formation, kJ/mol | ||||||||

|---|---|---|---|---|---|---|---|---|

| No.1 | No.2 | No.3 | No.4 | No.5 | No.6 | No.7 | No.8 | |

| TiZr: | −0.313 | −0.314 | −0.33 | −0.267 | −0.3 | −0.305 | −0.329 | −0.333 |

| TiNb: | 2.961 | 2.935 | 2.538 | 1.371 | 2.961 | 2.961 | 2.824 | 2.48 |

| TiMo: | −3.944 | −4.26 | −4.95 | −4.573 | −4.04 | −3.871 | −4.701 | −5.242 |

| ZrNb: | 5.527 | 5.304 | 5.425 | 4.721 | 5.314 | 5.428 | 5.294 | 5.114 |

| ZrMo: | −8.261 | −8.597 | −8.029 | −8.947 | −8.72 | −8.414 | −8.629 | −8.944 |

| NbMo: | −6.194 | −6.233 | −5.711 | −6.043 | −6.23 | −6.194 | −6.268 | −6.629 |

| Composition | Ti | Zr | Nb | Mo | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 | No.7 | No.8 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bo | 2.79 | 3.086 | 3.099 | 3.063 | 2.99 | 3.00 | 3.02 | 3.09 | 2.99 | 2.99 | 3.01 | 3.02 |

| Md (eV) | 2.447 | 2.934 | 2.424 | 1.961 | 2.47 | 2.46 | 2.48 | 2.47 | 2.45 | 2.46 | 2.46 | 2.44 |

| Property | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 | No.7 | No.8 |

|---|---|---|---|---|---|---|---|---|

| ∆Smix (J/mol·K) | 11.048 | 11.062 | 10.993 | 10.326 | 11.023 | 11.003 | 11.112 | 11.071 |

| δ1 | 5.154 | 5.125 | 5.125 | 5.591 | 5.025 | 5.067 | 5.268 | 5.419 |

| ∆Hmix (kJ/mol) | −0.735 | −0.562 | −0.729 | −1.744 | −0.728 | −0.573 | −0.894 | −1.390 |

| Ttop | 2129.15 | 2105.31 | 2176.7 | 2309.9 | 2111.21 | 2103.5 | 2156.6 | 2209.3 |

| Δχ | 0.248 | 0.244 | 0.254 | 0.276 | 0.247 | 0.242 | 0.255 | 0.270 |

| Ω | 32.016 | 41.369 | 32.822 | 13.671 | 31.951 | 40.337 | 26.777 | 17.593 |

| VEC | 4.65 | 4.61 | 4.70 | 4.93 | 4.63 | 4.61 | 4.69 | 4.78 |

| Sample | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 | No.7 | No.8 |

|---|---|---|---|---|---|---|---|---|

| amix, Å | 3.15 | 3.16 | 3.18 | 3.25 | 3.15 | 3.15 | 3.17 | 3.18 |

| ρ, g/cm3 | 6.98 | 7.09 | 7.35 | 7.89 | 6.99 | 6.96 | 7.24 | 7.51 |

| E, Gpa | 132.59 | 134.98 | 132.51 | 144.29 | 135.68 | 133.07 | 136.41 | 142.47 |

| Substrate Bias | 0 V | −50 V | −100 V | −150 V |

|---|---|---|---|---|

| H/Er | 0.07 | 0.08 | 0.21 | 0.07 |

| H3/Er2 | 0.05 | 0.05 | 0.39 | 0.07 |

| We, % | 45.49 | 53.89 | 78.34 | 58.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romaniuk, S.; Nowakowska-Langier, K.; Strzelecki, G.W.; Mulewska, K.; Minikayev, R. The Influence of Bias Voltage on the Structure and Properties of TiZrNbMo Coating Deposited by Magnetron Sputtering. Coatings 2024, 14, 844. https://doi.org/10.3390/coatings14070844

Romaniuk S, Nowakowska-Langier K, Strzelecki GW, Mulewska K, Minikayev R. The Influence of Bias Voltage on the Structure and Properties of TiZrNbMo Coating Deposited by Magnetron Sputtering. Coatings. 2024; 14(7):844. https://doi.org/10.3390/coatings14070844

Chicago/Turabian StyleRomaniuk, Svitlana, Katarzyna Nowakowska-Langier, Grzegorz Witold Strzelecki, Katarzyna Mulewska, and Roman Minikayev. 2024. "The Influence of Bias Voltage on the Structure and Properties of TiZrNbMo Coating Deposited by Magnetron Sputtering" Coatings 14, no. 7: 844. https://doi.org/10.3390/coatings14070844

APA StyleRomaniuk, S., Nowakowska-Langier, K., Strzelecki, G. W., Mulewska, K., & Minikayev, R. (2024). The Influence of Bias Voltage on the Structure and Properties of TiZrNbMo Coating Deposited by Magnetron Sputtering. Coatings, 14(7), 844. https://doi.org/10.3390/coatings14070844