Microstructure and Wear Performance of TaC and Ta/TaC Coatings on 30CrNi2MoVA Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Coatings

2.3. Mechanical Tests and Surface Characterization

3. Results and Discussion

3.1. Morphologies and Structures of the Coatings

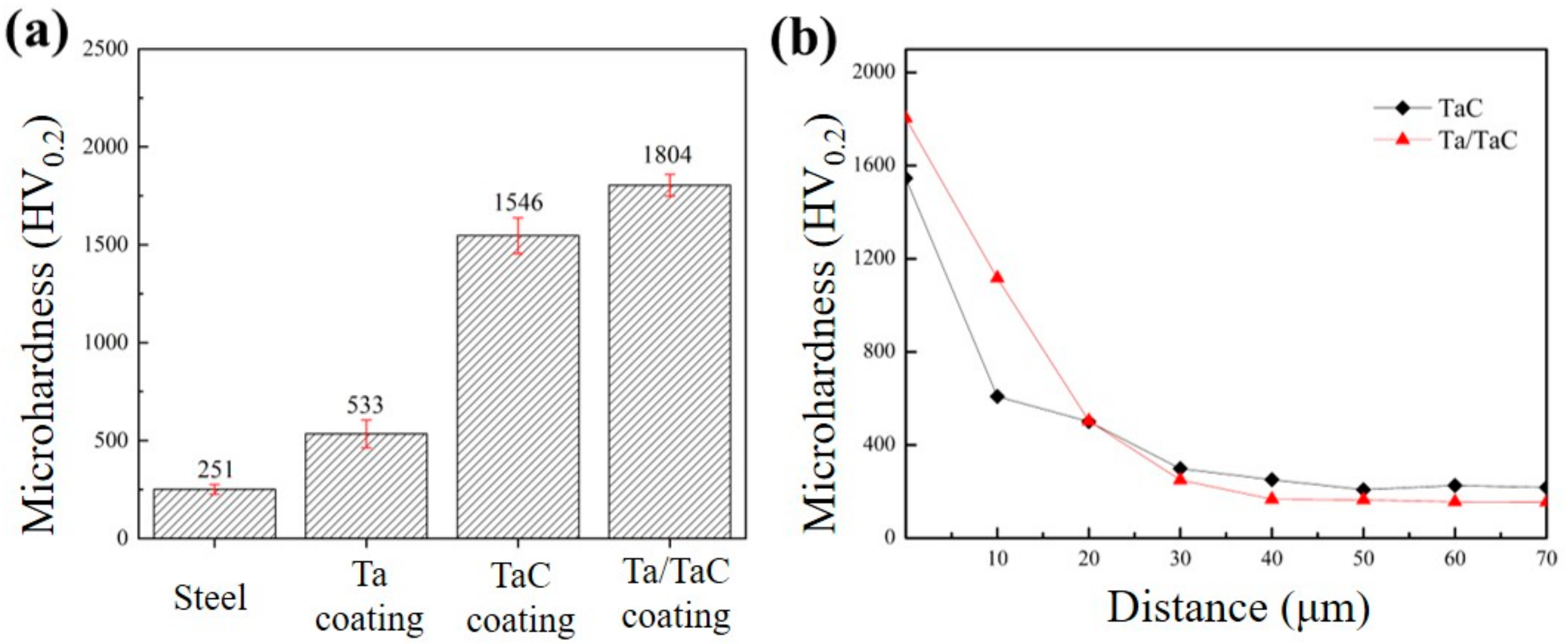

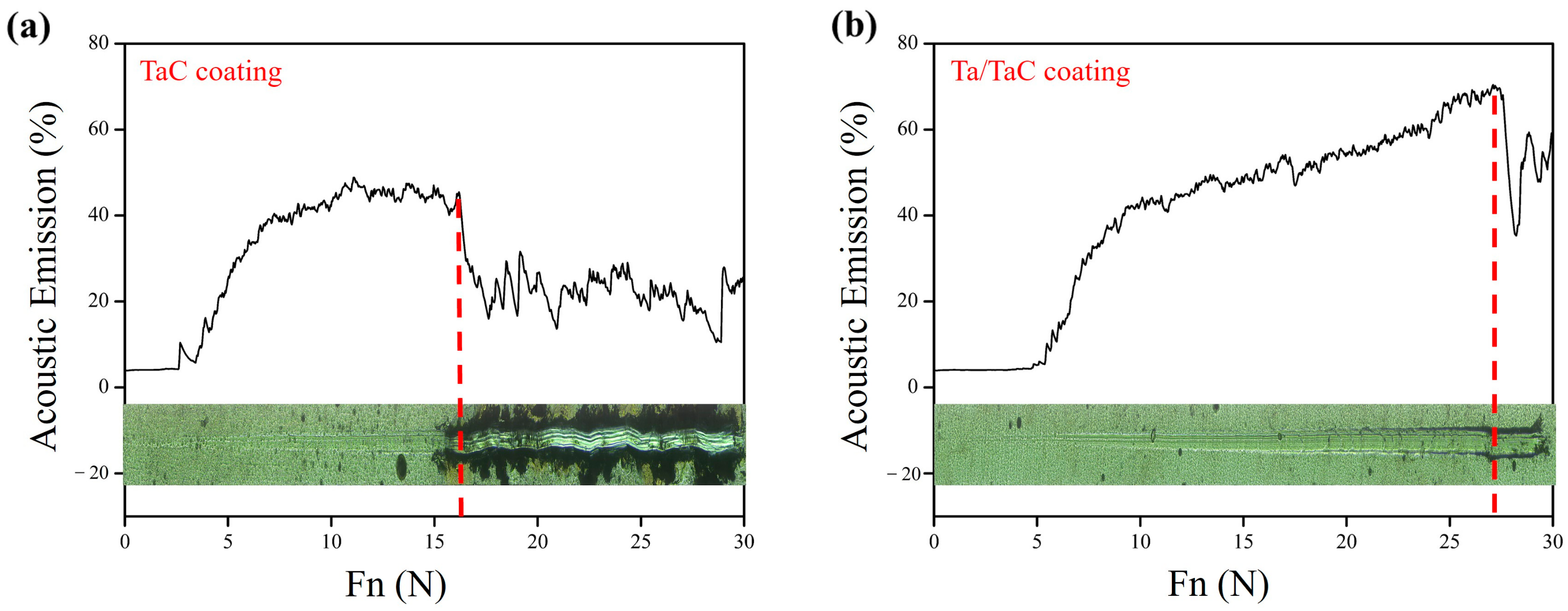

3.2. Hardness and Scratch Tests Analysis

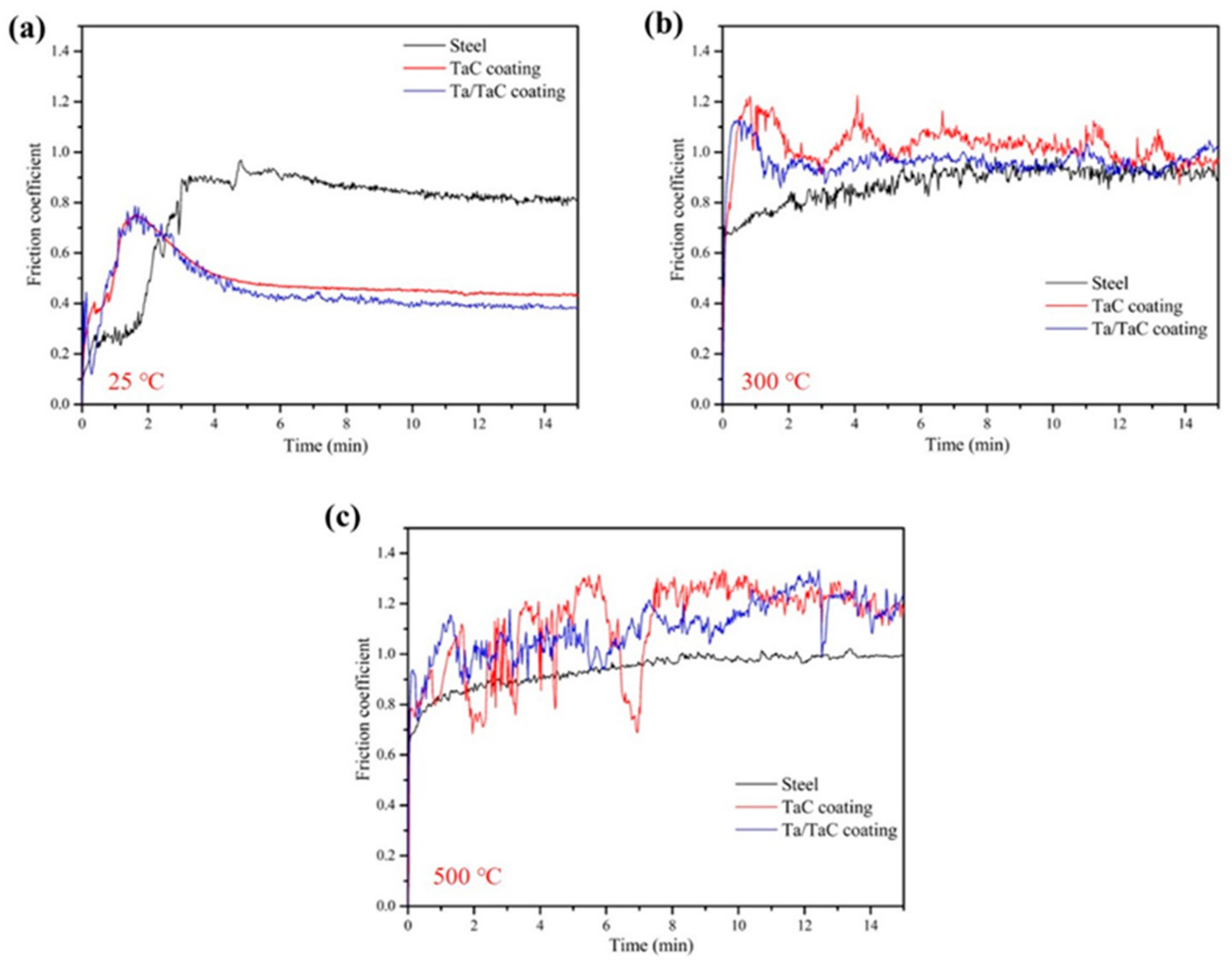

3.3. Tribology Performance

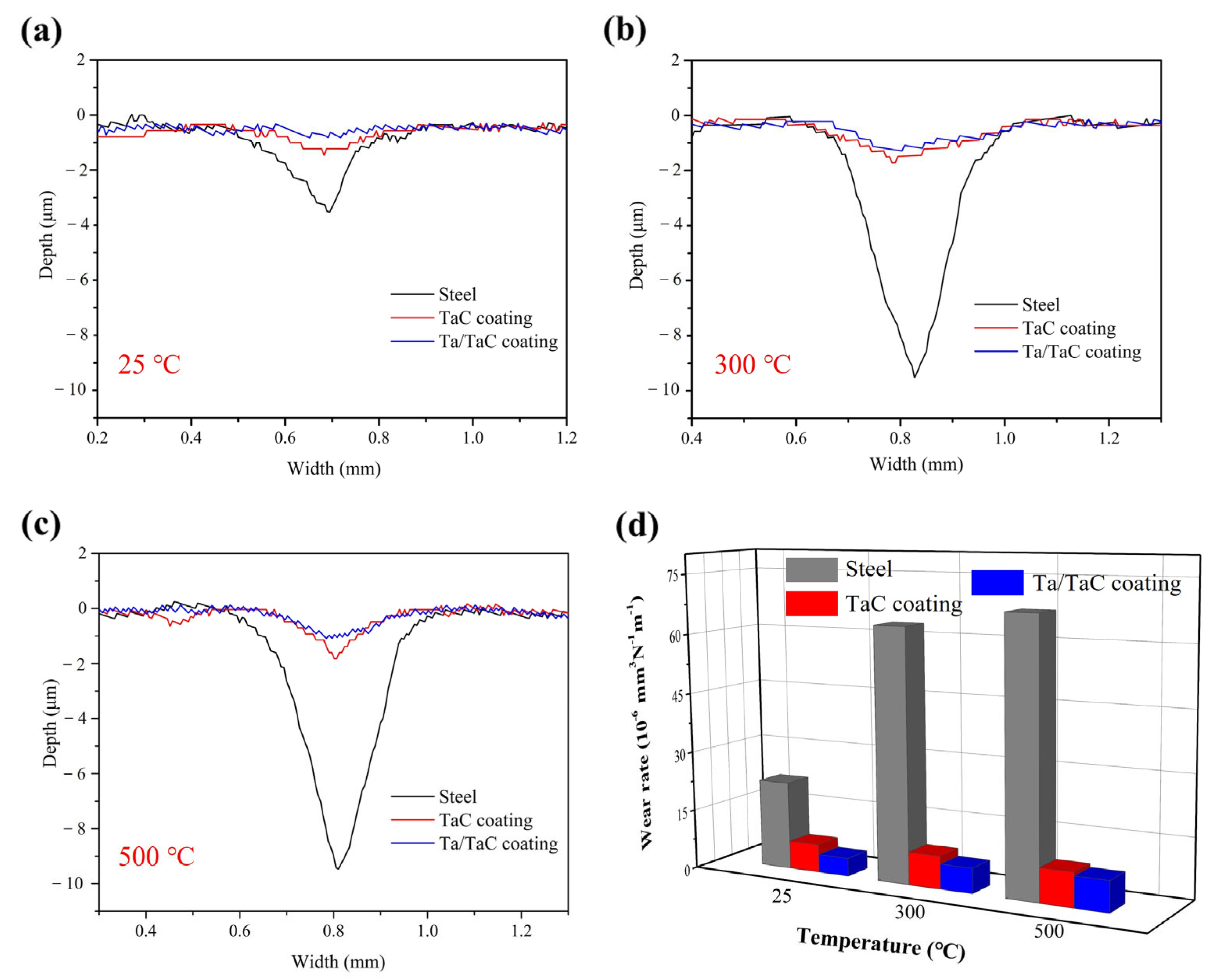

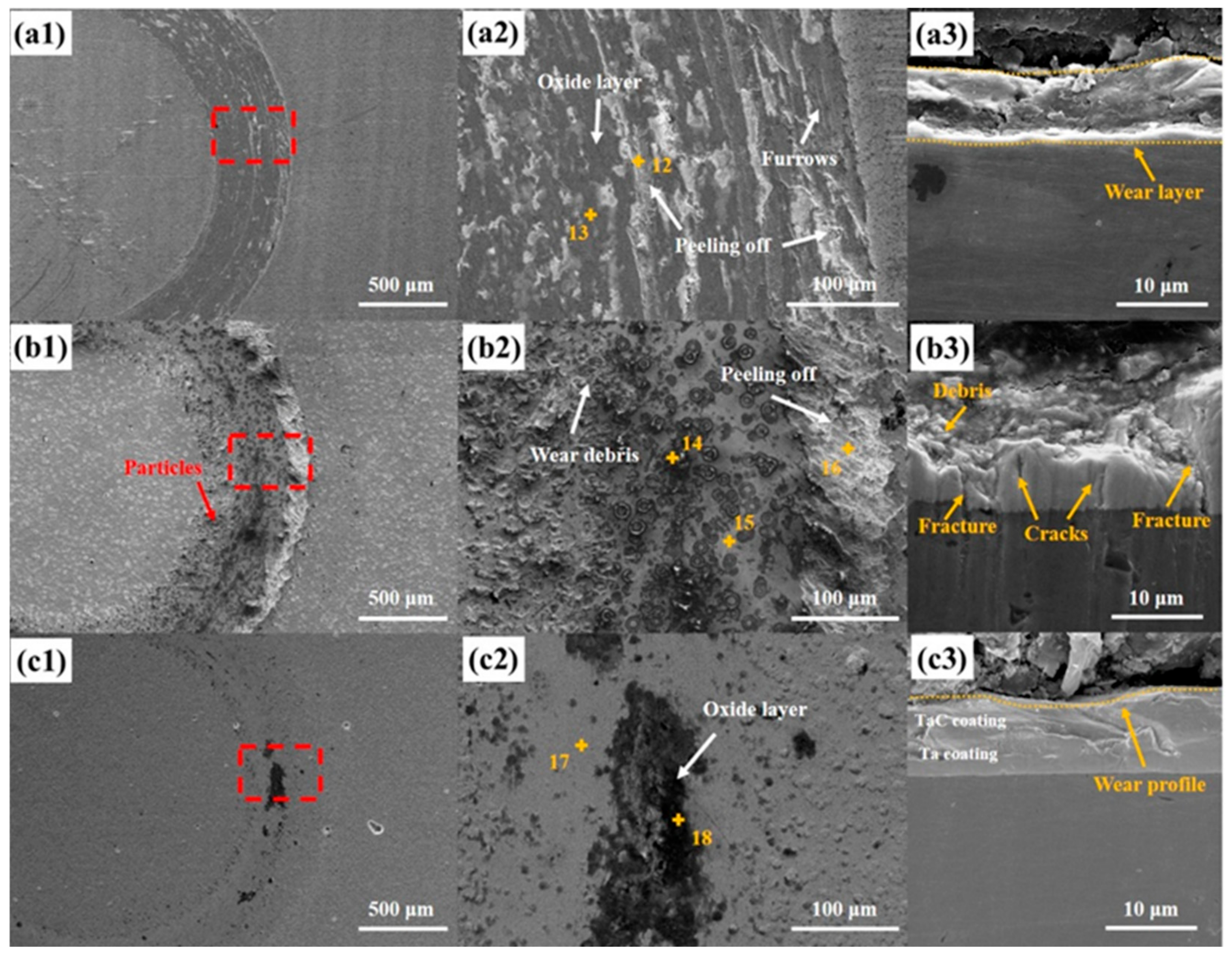

3.4. Wear Surface and Mechanism

4. Conclusions

- The prepared TaC and Ta/TaC coatings had thicknesses of approximately 10 μm and 17 μm, respectively. Both coatings exhibited dense internal structures with no microdefects at the interface with the substrate. The composite two-layer coating was almost seamless, forming a single entity with better surface smoothness. The XRD results indicate that the surface of the TaC coating was a pure TaC phase, while the composite coating showed a slight formation of the Ta2C phase due to the outward diffusion of Ta elements.

- Benefiting from the excellent mechanical properties of the TaC ceramic, the surface microhardnesses of the TaC and Ta/TaC-coated samples increased by approximately five times and six times, respectively, compared to the substrate. The cross-sectional hardnesses of both coatings exhibited a gradient distribution, affecting a depth of about 30 μm. The scratch test results demonstrate that the introduction of the Ta transition layer significantly enhanced the coating toughness, with the Ta/TaC coating exhibiting a scratch adhesion strength exceeding 30 N, more than double that of the TaC coating.

- The wear results show that both the TaC and Ta/TaC coatings significantly improved the wear resistance of the material, especially at high temperatures. The Ta/TaC coating displayed more stable friction coefficient curves, indicating a more stable wear performance, and a lower specific wear rate, approximately 11.4% of that of the substrate at 500 °C.

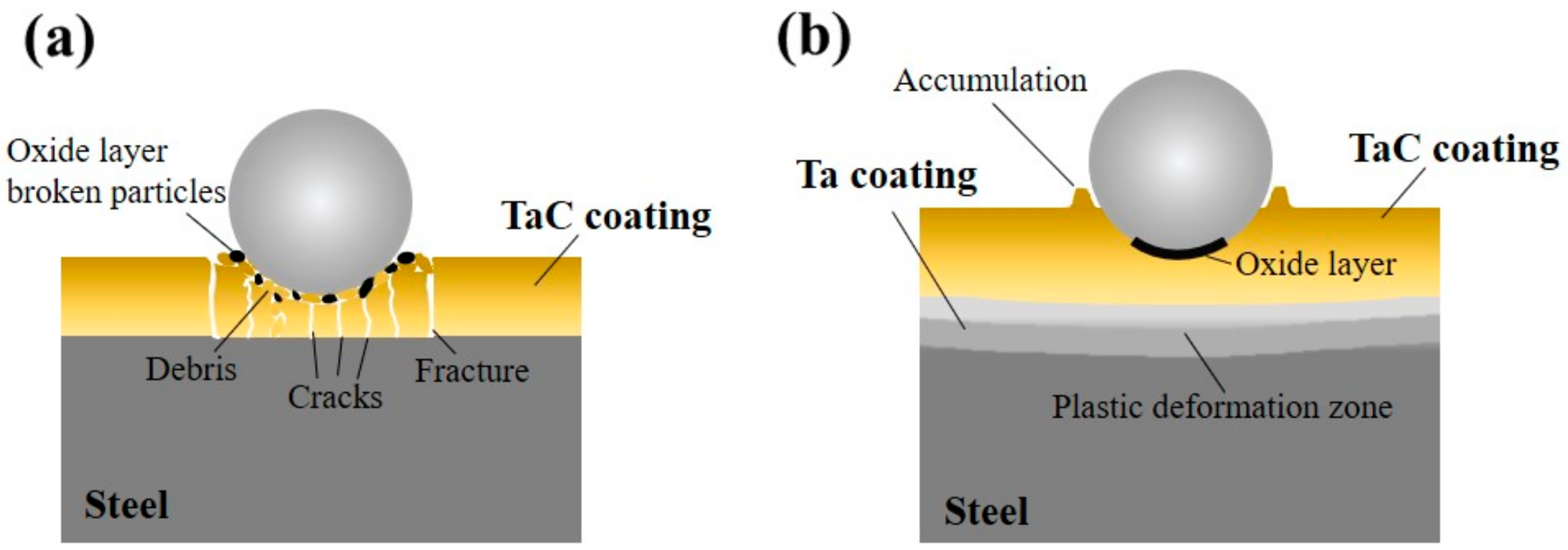

- As the wear temperature increased, the wear mechanism of the substrate transitioned from adhesive wear to abrasive and oxidation wear, forming an easily spallable wear layer on the surface. Both coatings exhibited only slight wear at room temperature, and showed slight oxidation wear at high temperatures. At 500 °C, although the single-layer TaC coating remained adhered to the substrate, thermal mismatch, as well as wear load-induced stress concentration, led to numerous internal cracks and edge fractures in the wear track. In contrast, the good compatibility between the Ta transition layer and TaC layer allowed for cooperative deformation with the substrate, creating a plastic deformation zone that reduced internal stresses and the stress concentration, maintaining an intact structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Zang, Y.; Mu, L.; Lian, Y.; Qin, Q. Erosion analysis of machine gun barrel and lifespan prediction under typical shooting conditions. Wear 2020, 444–445, 203177. [Google Scholar] [CrossRef]

- Wei, S.; Wang, G.; Zhao, X.; Zhang, X.; Rong, Y. Experimental study on vacuum carburizing process for low-carbon alloy steel. J. Mater. Eng. Perform. 2014, 23, 545–550. [Google Scholar] [CrossRef]

- Xu, F.; Yang, G.; Wang, L. Artillery structural dynamic responses optimization based on Stackelberg game method. J. Low Freq. Noise Vib. Act. Control 2022, 41, 140–159. [Google Scholar] [CrossRef]

- Niu, Y.; Xing, L.; Yang, F.; Li, H.; Chen, M.; Zhu, S.; Wang, F. Phase structure of sputtered Ta coating and its ablation behavior by laser pulse heating (LPH). J. Mater. Sci. Technol. 2021, 65, 7–17. [Google Scholar] [CrossRef]

- Shukla, P.; Awasthi, S.; Ramkumar, J.; Balani, K. Protective trivalent Cr-based electrochemical coatings for gun barrels. J. Alloys Compd. 2018, 768, 1039–1048. [Google Scholar] [CrossRef]

- Jani, H.; Kenichiro, M.; Kristoffer, M.; Miika, M.; Marko, V.; Jyrki, R.; Mikko, R.; Markku, L. Rhenium metal and rhenium nitride thin films grown by atomic layer deposition. Angew. Chem. 2018, 130, 14746–14750. [Google Scholar]

- Betiuk, M.; Domanowski, P. Obtaining the CrN coating inside the barrel using a cylindrical magnetron with a dynamic magnetic field. AIP Conf. Proc. 2018, 2017, 020002. [Google Scholar]

- Storm, R.; Withers, J.; Ramos, R.; Loutfy, R. Fabrication of Si3N4 Gun Barrel Liners for Very High Temperature Erosion Resistant Gun Barrels. Mater. Manuf. Process. 2012, 27, 875–877. [Google Scholar] [CrossRef]

- Alam, M.; Das, A. Advancement in cermet based coating on steel substrate: A review. Mater. Today Proc. 2022, 56, 805–810. [Google Scholar] [CrossRef]

- Chung, K.; Lee, R.; Readdy, A. Cannon Wear and Erosion Science and Technology Objective Program (STO) 155-mm Projectile Rotating Band/Obturation for Extended Range. Technical Report ARMET-TR-15001. 2015. Available online: https://apps.dtic.mil/sti/citations/ADA620119 (accessed on 1 June 2015).

- Wu, B.; Fang, L.; Chen, X.; Zou, Z.; Yu, X.; Chen, G. Fabricating aluminum bronze rotating band for large-caliber projectiles by high velocity arc spraying. J. Therm. Spray Technol. 2014, 23, 447–455. [Google Scholar] [CrossRef]

- Li, Q.; Hu, M.; Zhang, P.; Guo, C.; Niu, Q. Isothermal oxidation behavior and thermal shock resistance of three-kind Cr coatings on PCrNi3MoVA steel. Dig. J. Nanomater. Biostruct. 2020, 15, 721–732. [Google Scholar] [CrossRef]

- Wang, S.; Wang, C.; Li, W. Thermodynamic Coupling Simulation of CrN/Cr Composite Coating Barrel Bore. Coatings 2021, 11, 1358. [Google Scholar] [CrossRef]

- Barnett, B.; Trexler, M.; Champagne, V.; Pepi, M. Toxic metal reduction and life extension of gun barrel liners through cold sprayed refractory metals. Int. J. COMADEM 2016, 19, 51. [Google Scholar]

- Barnett, B.; Trexler, M.; Champagne, V. Cold Sprayed Refractory Metals for Chrome Reduction in Gun Barrel Liners. Int. J. Refract. Met. Hard Mater. 2015, 53, 139–143. [Google Scholar] [CrossRef]

- Niu, Y.; Chen, M.; Wang, J.; Yang, L.; Guo, C.; Zhu, S.; Wang, F. Preparation and thermal shock performance of thick α-Ta coatings by direct current magnetron sputtering (DCMS). Surf. Coat. Technol. 2017, 321, 19–25. [Google Scholar] [CrossRef]

- Miller, M.; Campo, F.; Troiano, E.; Smith, S.; Rosset, W. Explosive bonding of refractory metal liners. Mater. Manuf. Process. 2012, 27, 882–887. [Google Scholar] [CrossRef]

- Withers, J.; Storm, R.; Shapovalov, V.; Loutfy, R. An All Titanium Gun Barrel Containing a TiCN Liner. Mater. Manuf. Process. 2012, 27, 878–881. [Google Scholar] [CrossRef]

- Men, X.; Tao, F.; Gan, L.; Li, Y.; Liu, Z. Erosion and wear resistance of Cr3C2-NiCr composite ceramic coating for gun barrel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 678, 012075. [Google Scholar] [CrossRef]

- Rivard, J.; Blue, C.; Harper, D.; Stiglich, J.; Ramachandran, G.; Champagne, V. High-density infrared cladding of Ta on steel. Mater. Manuf. Process. 2006, 21, 612–617. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, J.; Wu, H.; Xu, Z.; Liu, X.; Lin, N.; Wei, D.; Zhang, P. A modern-day alchemy: Double glow plasma surface metallurgy technology. AIP Adv. 2022, 12, 030702. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, P.; Wei, D.; Ding, F.; Li, F.; Wei, X.; Ma, S. Preparation and characterization of Cr/CrC multilayer on γ-TiAl alloy by the double glow plasma surface alloying technology. Mater. Lett. 2018, 215, 292–295. [Google Scholar] [CrossRef]

- Qiu, Z.; Zhang, P.; Wei, D.; Wei, X.; Chen, X. A study on tribological behavior of double-glow plasma surface alloying W-Mo coating on gear steel. Surf. Coat. Technol. 2015, 278, 92–98. [Google Scholar] [CrossRef]

- Qi, Y.; Liang, W.; Miao, Q.; Lin, H.; Yi, J.; Gao, X.; Song, Y. Characterization of a CrN/Cr gradient coating deposited on carbon steel and synergistic erosion-corrosion behavior in liquid-solid flow impingement. Ceram. Int. 2023, 49, 33925–33933. [Google Scholar] [CrossRef]

- Chen, X.; Du, Y.; Chung, Y.W. Commentary on using H/E and H3/E2 as proxies for fracture toughness of hard coatings. Thin Solid Films 2019, 688, 137265. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Tavakoli, H. Hertzian Contact Stress. In Mechanical Design of Machine Elements by Graphical Methods; Materials Forming, Machining and Tribology; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Silvestroni, L.; Pienti, L.; Guicciardi, S.; Sciti, D. Strength and toughness: The challenging case of TaC-based composites. Compos. Part B Eng. 2015, 72, 10–20. [Google Scholar] [CrossRef]

- Smith, C.; Ross, M.; De Leon, N.; Weinberger, C.; Thompson, G. Ultra-high temperature deformation in TaC and HfC. J. Eur. Ceram. Soc. 2018, 38, 5319–5332. [Google Scholar] [CrossRef]

- Shi, X.; Liskiewicz, T.; Beake, B.; Chen, J.; Wang, C. Tribological performance of graphite-like carbon films with varied thickness. Tribol. Int. 2020, 149, 105586. [Google Scholar] [CrossRef]

- Roy, A.; Munagala, V.N.V.; Patel, P.; Sharifi, N.; Alidokht, S.; Makowiec, M.; Chromik, R.; Moreau, C.; Stoyanov, P. Friction and wear behavior of suspension plasma sprayed tantalum oxide coatings at elevated temperatures. Surf. Coat. Technol. 2023, 452, 129097. [Google Scholar] [CrossRef]

- Su, W.; Niu, S.; Huang, Y.; Wang, C.; Wen, Y.; Li, X.; Deng, C.; Deng, C.; Liu, M. Friction and wear properties of plasma-sprayed Cr2O3–BaCrO4 coating at elevated temperatures. Ceram. Int. 2022, 48, 8696–8705. [Google Scholar] [CrossRef]

- Cedillos-Barraza, O.; Grasso, S.; Al Nasiri, N.; Jayaseelan, D.; Reece, M.; Lee, W. Sintering behaviour, solid solution formation and characterisation of TaC, HfC and TaC-HfC fabricated by spark plasma sintering. J. Eur. Ceram. Soc. 2016, 36, 1539–1548. [Google Scholar] [CrossRef]

- Ouyang, J.; Sasaki, S. Unlubricated friction and wear behavior of low-pressure plasma-sprayed ZrO2 coating at elevated temperatures. Ceram. Int. 2001, 27, 251–260. [Google Scholar] [CrossRef]

- Tan, Z.; Wu, X.; Guo, J.; Zhu, W. Toughness mechanism and plastic insensitivity of submicron second phase Ta in a novel Ta-Hf6Ta2O17 composite ceramic. Ceram. Int. 2023, 49, 1932–1939. [Google Scholar] [CrossRef]

- Qi, Y.; Liang, W.; Miao, Q.; Yi, J.; Lin, H.; Liu, Y.; Ma, H. Role of the nitrogen ratio on mechanical properties and wear resistance of CrN/Fe functionally graded coating produced by double glow plasma alloying. Appl. Surf. Sci. 2022, 585, 152735. [Google Scholar] [CrossRef]

| Element | C | Cr | Ni | Mo | V | Mn | Si | Fe |

|---|---|---|---|---|---|---|---|---|

| Content | 0.32 | 0.90 | 2.27 | 0.25 | 0.19 | 0.46 | 0.25 | Bal. |

| Sample Cathode (V) | Sample Current (A) | Target Cathode (V) | Target Current (A) | Process Time (h) | |

|---|---|---|---|---|---|

| Ta coating | 510~520 | 2.20~2.30 | 800~820 | 0.90~1.00 | 2.0 |

| TaC coating | 510~520 | 2.20~2.30 | 900~920 | 1.20~1.30 | 4.0 |

| Analyzed Spot | Temperature (°C) | Sample | Element Contents (at %) | Ta-C Composition Ratio | ||||

|---|---|---|---|---|---|---|---|---|

| Fe | O | Al | Ta | C | ||||

| 1 | 25 | Steel | 59.01 | 29.20 | -- | -- | 10.99 | -- |

| 2 | Steel | 77.63 | 7.40 | -- | -- | 13.58 | -- | |

| 3 | TaC | 2.21 | -- | -- | 34.78 | 63.01 | 36%–64% | |

| 4 | TaC | 3.79 | 32.95 | -- | 37.21 | 26.05 | 59%–41% | |

| 5 | Ta/TaC | -- | -- | -- | 45.06 | 54.94 | 45%–55% | |

| 6 | Ta/TaC | -- | -- | -- | 47.45 | 52.55 | 47%–53% | |

| 7 | 300 | Steel | 37.49 | 55.54 | -- | -- | 6.97 | -- |

| 8 | Steel | 72.93 | 10.58 | -- | -- | 16.49 | -- | |

| 9 | TaC | 2.23 | 42.39 | 5.28 | 24.11 | 25.99 | 48%–52% | |

| 10 | TaC | 3.82 | 11.03 | -- | 37.43 | 47.72 | 44%–56% | |

| 11 | Ta/TaC | -- | 38.19 | -- | 30.82 | 30.99 | 50%–50% | |

| 12 | 500 | Steel | 33.96 | 57.76 | 2.73 | -- | 5.55 | -- |

| 13 | Steel | 32.37 | 58.76 | 1.91 | -- | 6.96 | -- | |

| 14 | TaC | 1.56 | 53.85 | 20.03 | 10.81 | 13.74 | 44%–56% | |

| 15 | TaC | 1.77 | 54.22 | 14.43 | 13.67 | 15.91 | 46%–54% | |

| 16 | TaC | 2.87 | 31.06 | 6.18 | 30.81 | 29.08 | 51%–49% | |

| 17 | Ta/TaC | -- | 11.24 | -- | 39.16 | 49.60 | 44%–56% | |

| 18 | Ta/TaC | 1.56 | 55.68 | 24.66 | 6.52 | 11.58 | 36%–64% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Lv, X.; Dang, B.; Lai, Z.; Chen, X.; Wei, D.; Li, S.; Zhang, P. Microstructure and Wear Performance of TaC and Ta/TaC Coatings on 30CrNi2MoVA Steel. Coatings 2024, 14, 1039. https://doi.org/10.3390/coatings14081039

Yang K, Lv X, Dang B, Lai Z, Chen X, Wei D, Li S, Zhang P. Microstructure and Wear Performance of TaC and Ta/TaC Coatings on 30CrNi2MoVA Steel. Coatings. 2024; 14(8):1039. https://doi.org/10.3390/coatings14081039

Chicago/Turabian StyleYang, Kai, Xuming Lv, Bo Dang, Zhuoyan Lai, Xiaohu Chen, Dongbo Wei, Shuqin Li, and Pingze Zhang. 2024. "Microstructure and Wear Performance of TaC and Ta/TaC Coatings on 30CrNi2MoVA Steel" Coatings 14, no. 8: 1039. https://doi.org/10.3390/coatings14081039

APA StyleYang, K., Lv, X., Dang, B., Lai, Z., Chen, X., Wei, D., Li, S., & Zhang, P. (2024). Microstructure and Wear Performance of TaC and Ta/TaC Coatings on 30CrNi2MoVA Steel. Coatings, 14(8), 1039. https://doi.org/10.3390/coatings14081039