Properties of Laser-Clad Stainless Steel–Ni/WC Double-Layer Coatings

Abstract

:1. Introduction

2. Material and Methodology

2.1. Laser Cladding Materials

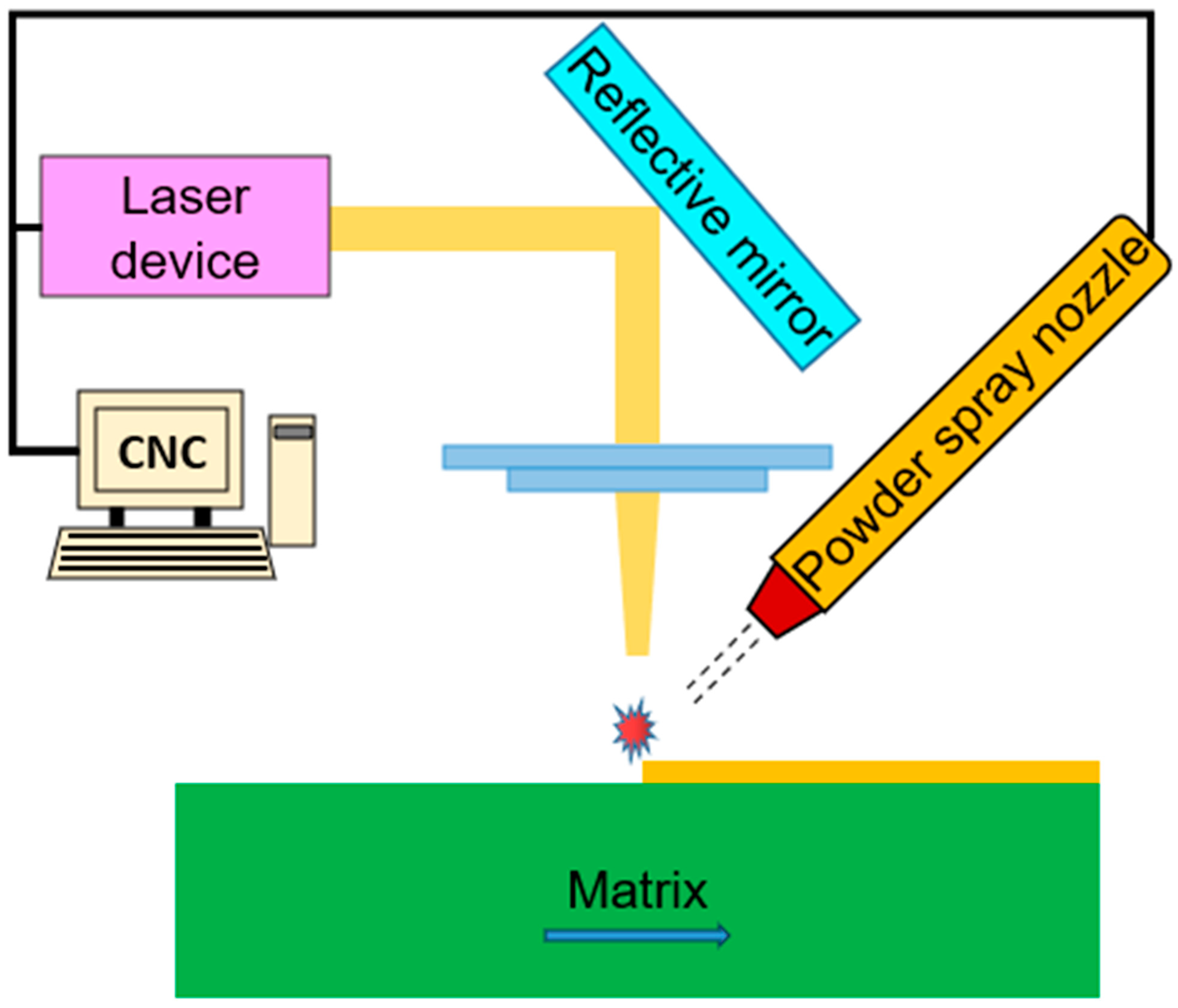

2.2. Laser-Cladding Equipment

2.3. Laser-Cladding of Double-Layer Coatings

2.4. Experimental Methodology

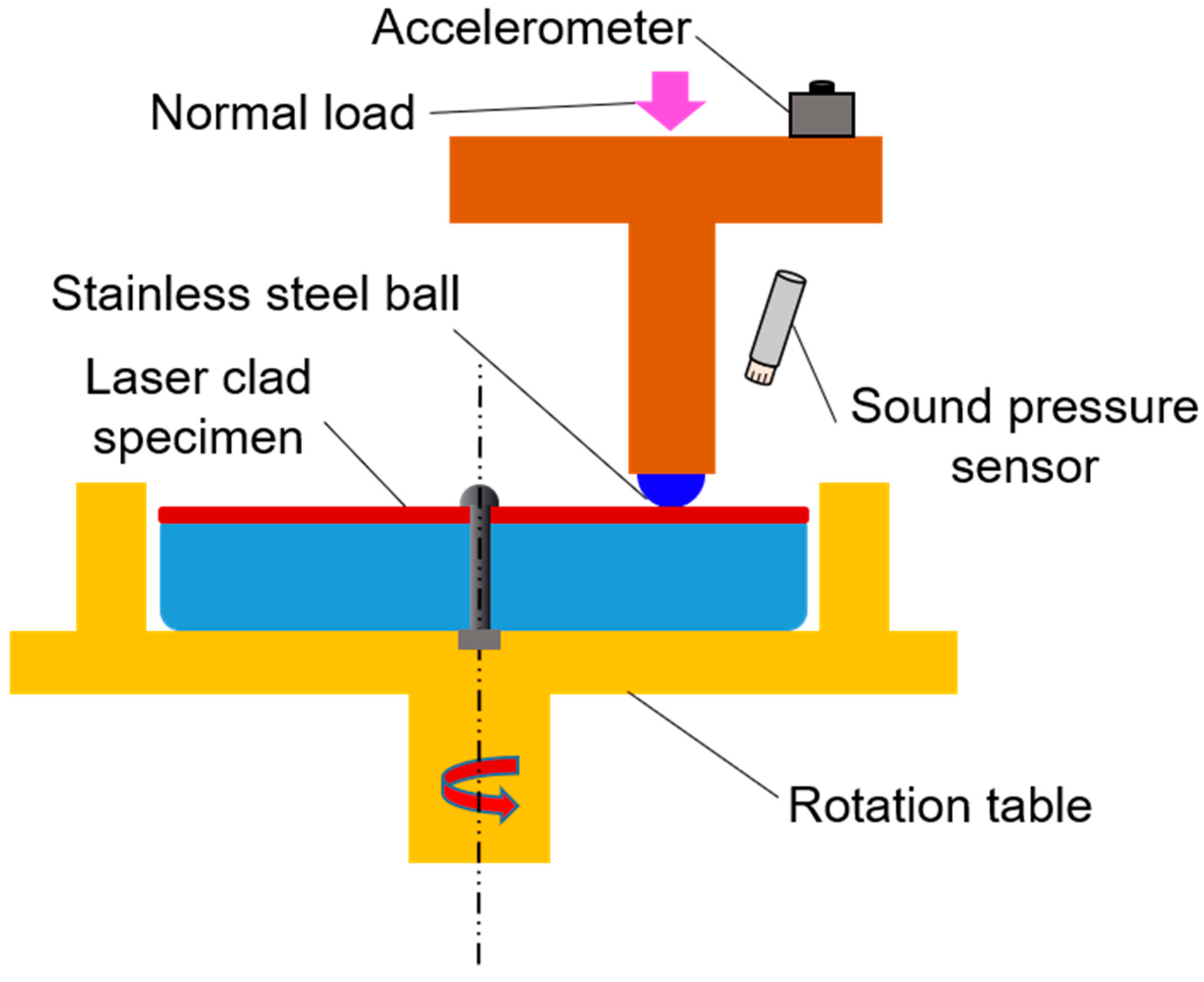

2.4.1. Friction and Wear Tests

2.4.2. Vibration and Noise Measurements

2.4.3. Residual Stress Measurements

2.4.4. Electrochemical Corrosion Tests

2.4.5. Micro-Structure Analysis

3. Results and Discussion

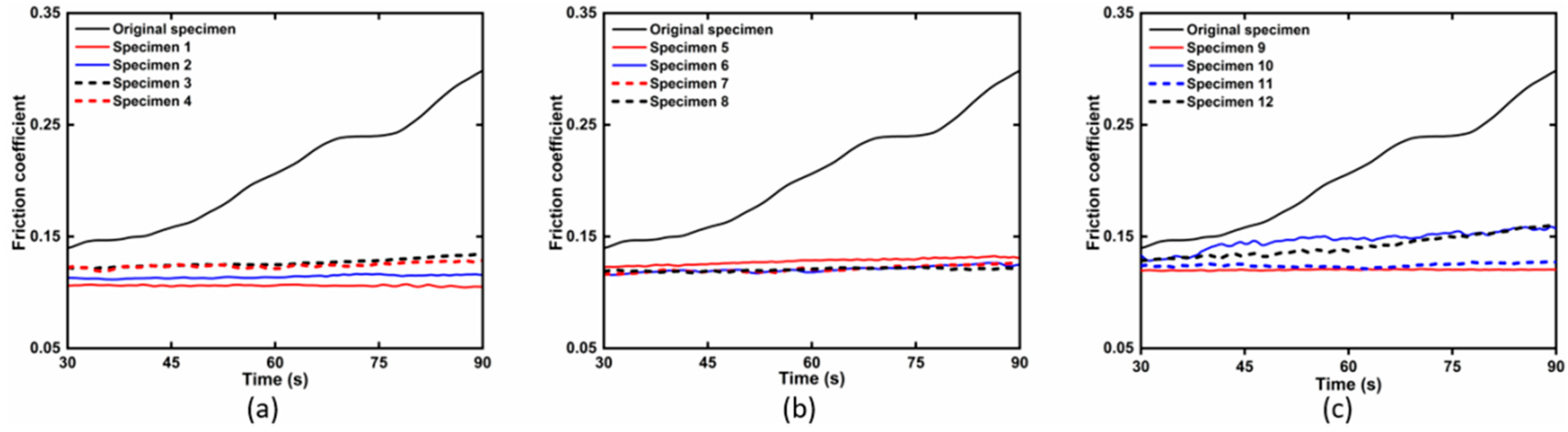

3.1. Friction

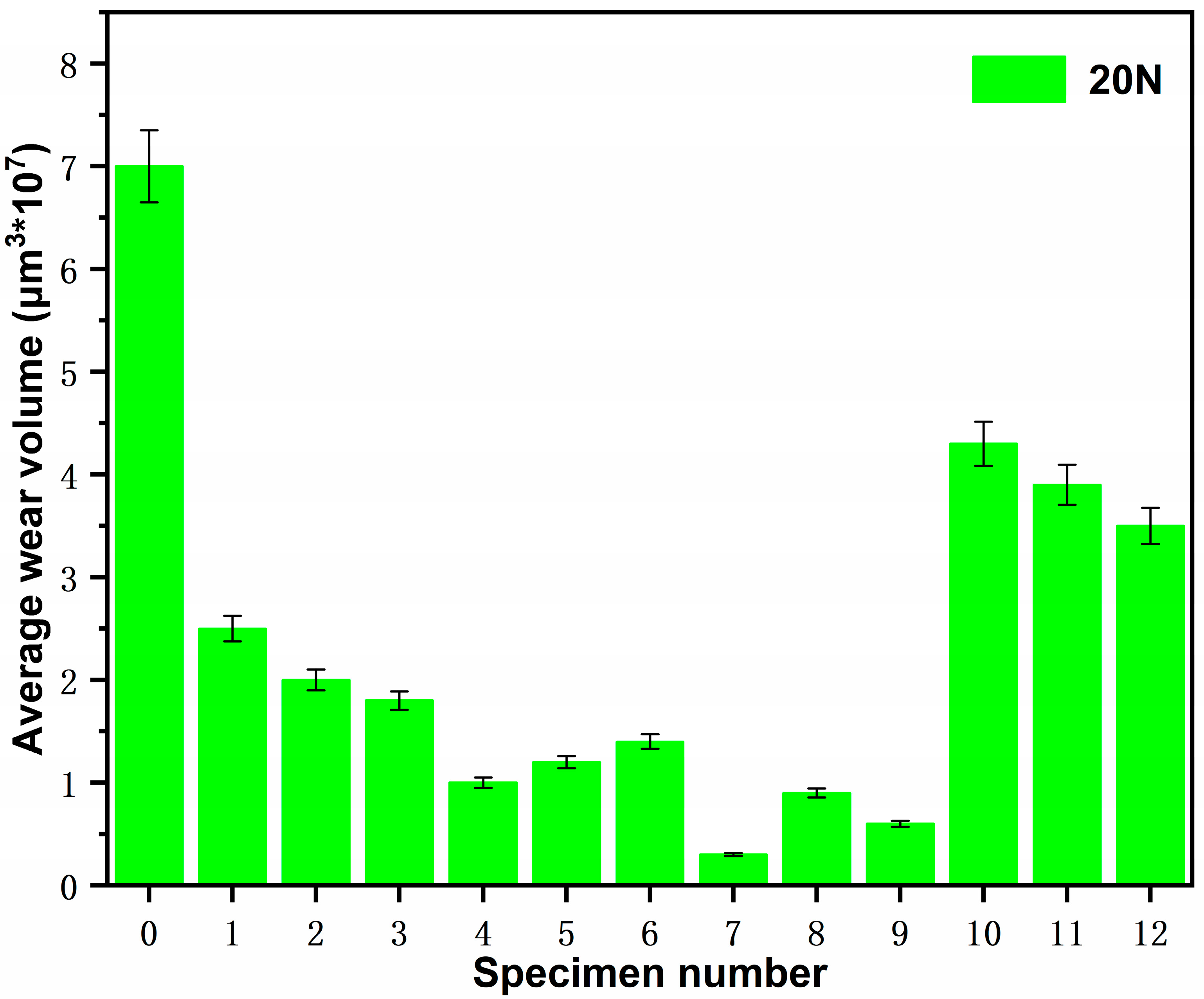

3.2. Wear

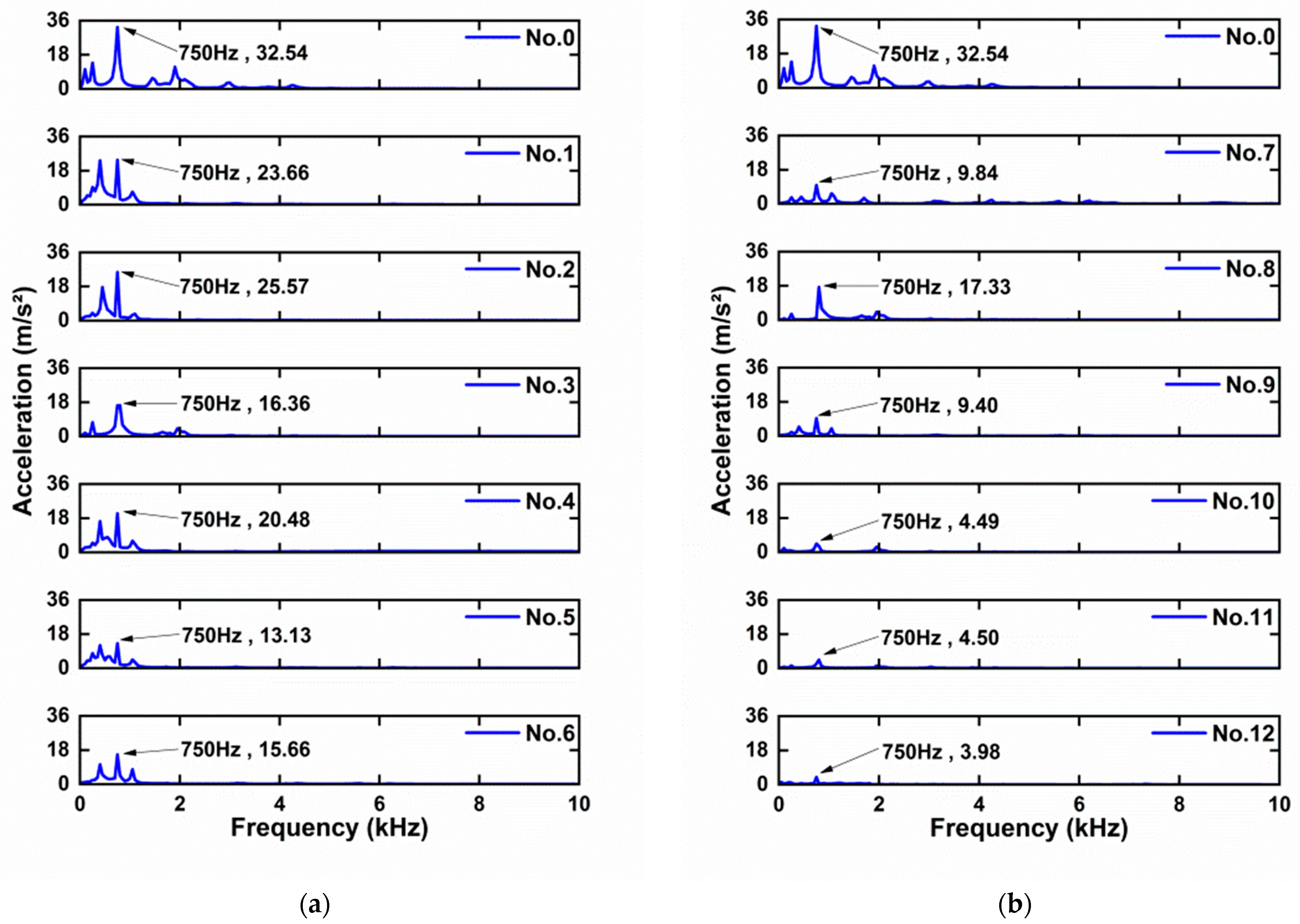

3.3. Vibrations

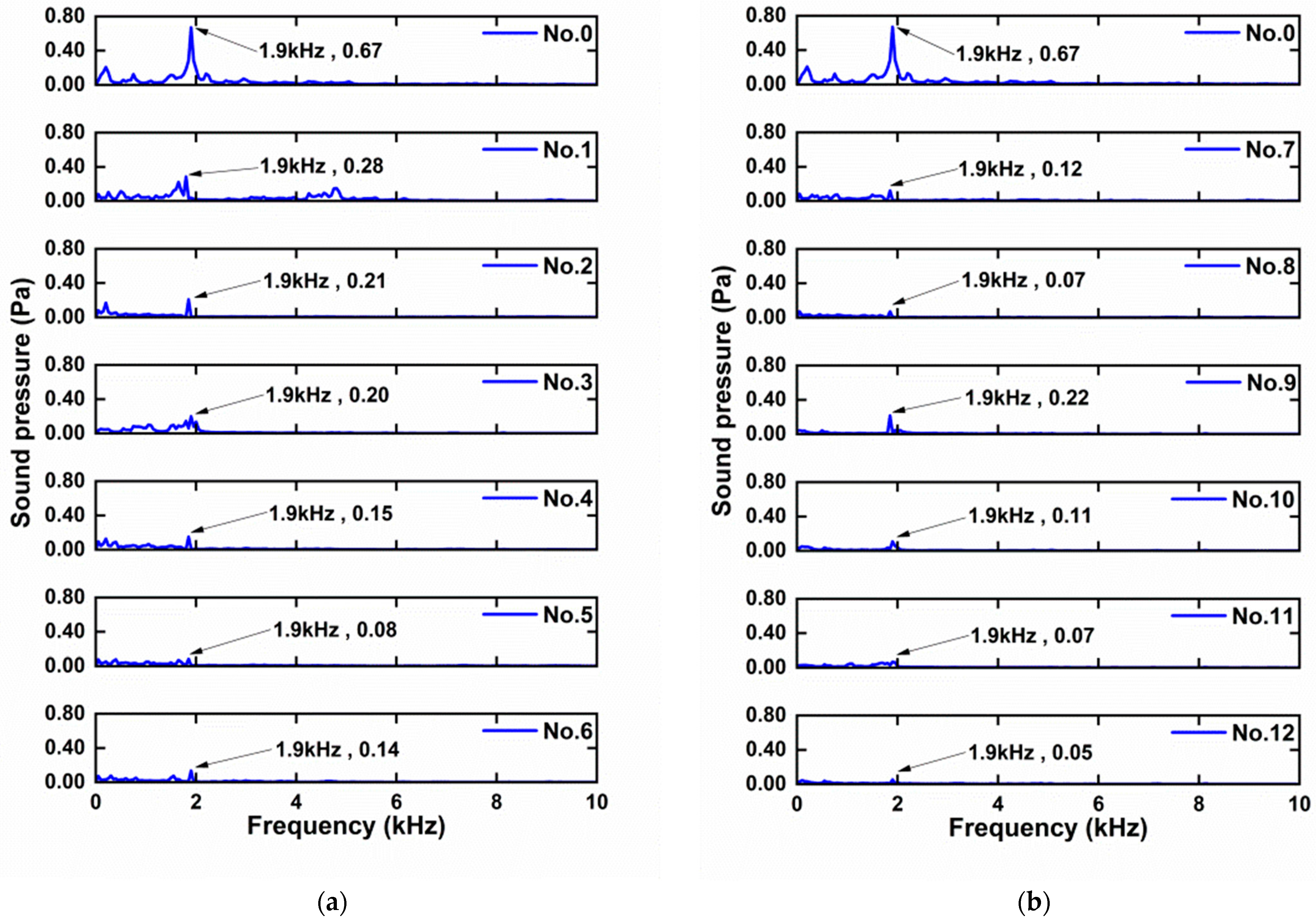

3.4. Noise

3.5. Residual Stress

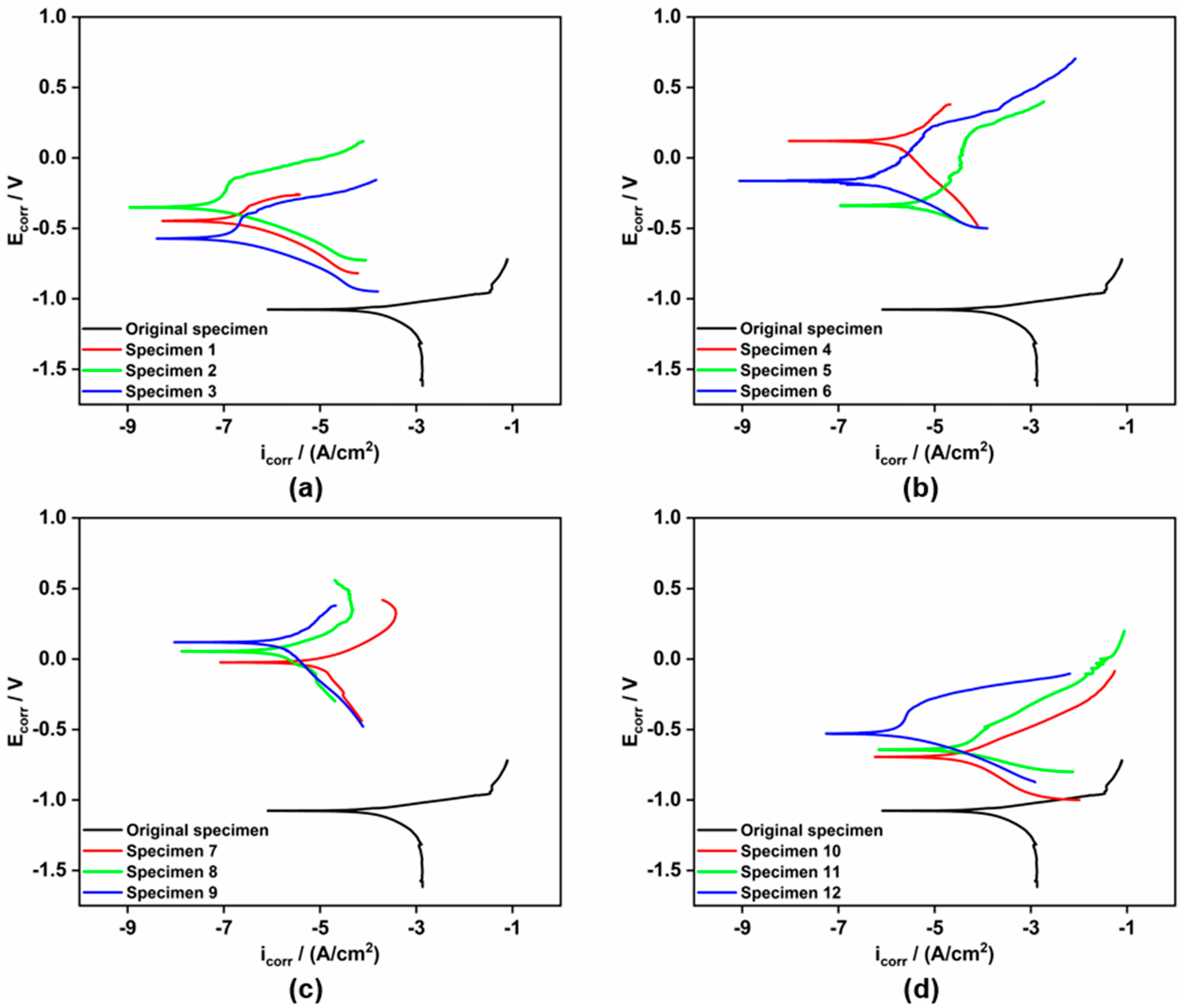

3.6. Electrochemical Property

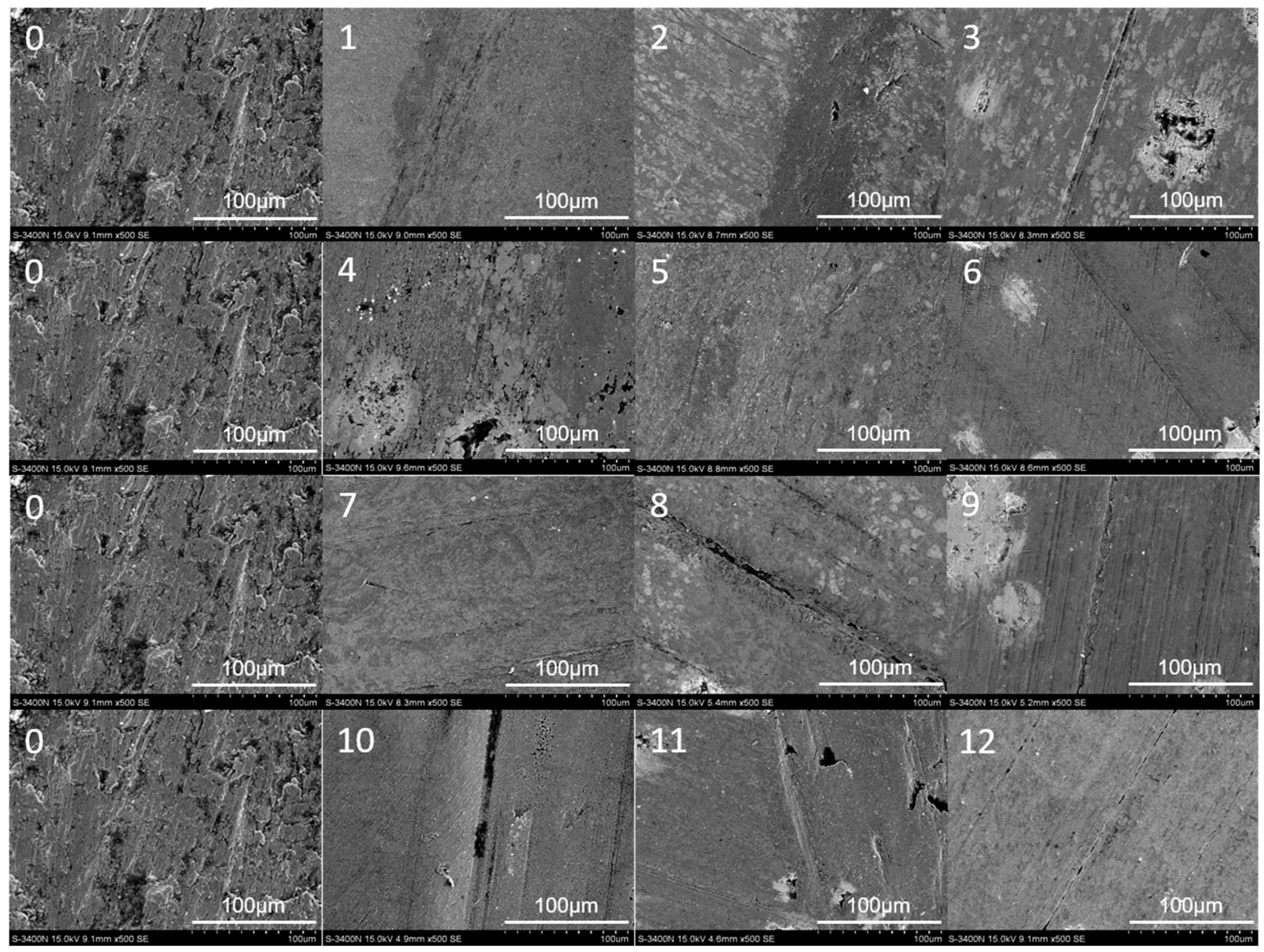

3.7. Microstructure Analysis

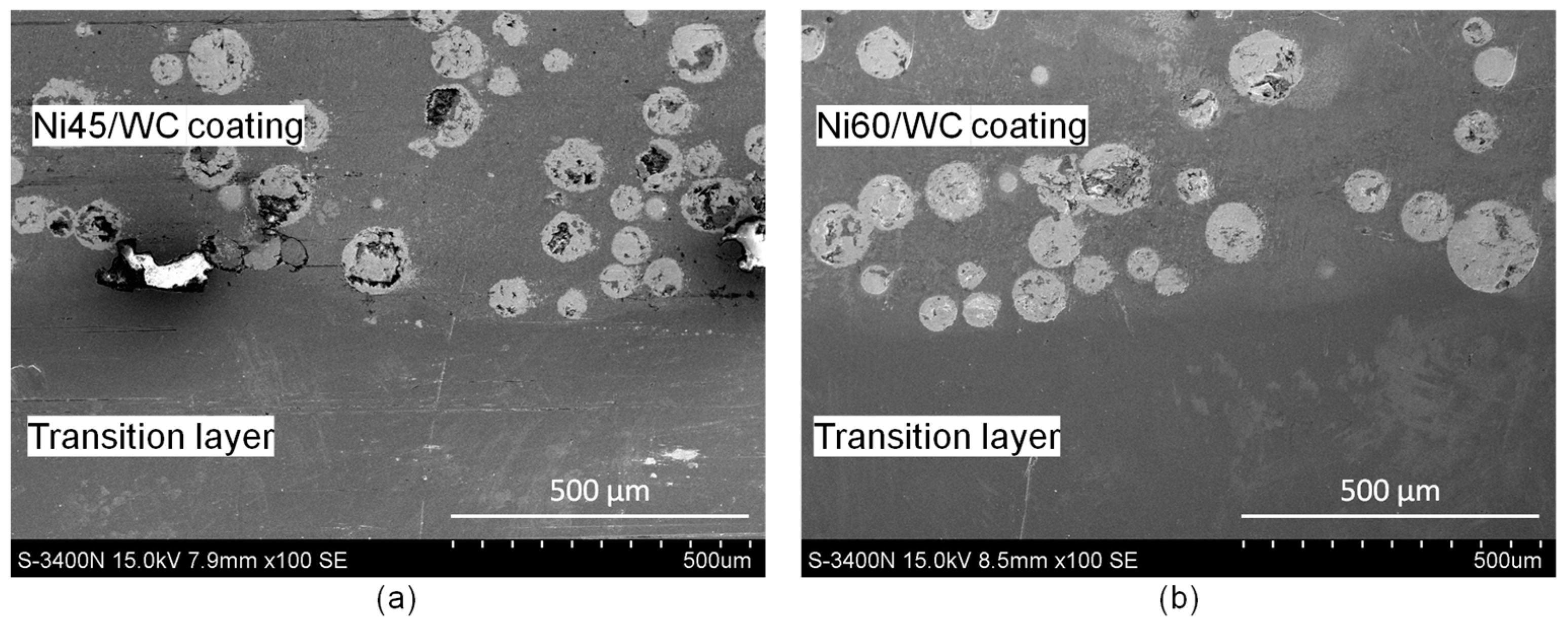

3.7.1. SEM Observation

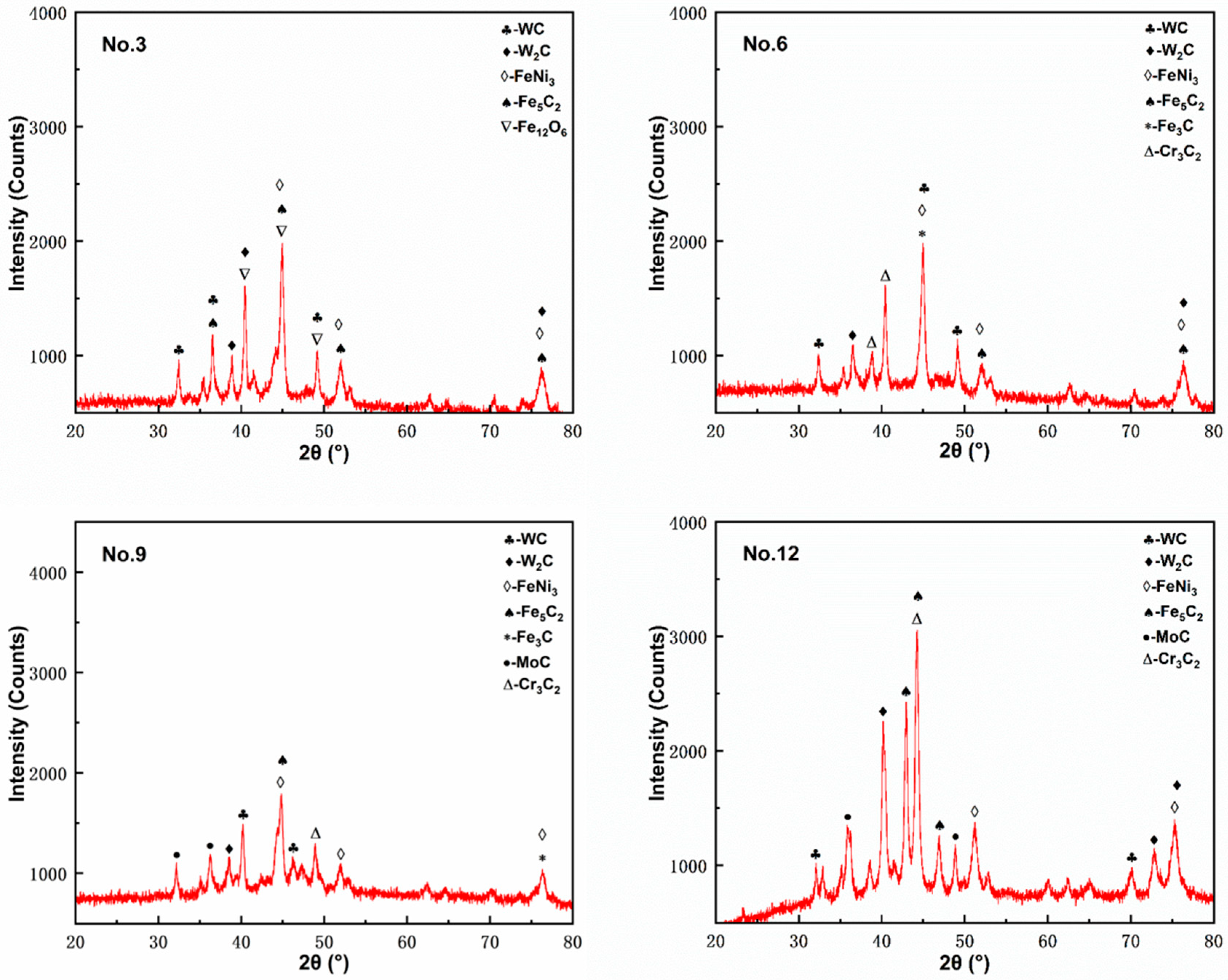

3.7.2. XRD Analysis

4. Conclusions

- (1)

- In ball-on-plate tribological testing, the COFs of all the laser-clad specimens are significantly lower and more stable than those of the specimens without laser-clad coating. Similarly, the wear rates of all the laser-clad specimens are significantly lower than those of the specimens without laser-clad coating.

- (2)

- Under the same tribological testing conditions, all the laser-clad specimens have excellent performance in vibration- and noise-damping compared with the unclad specimen. Specimens 10–12 with the Ni625/WC coatings have the best overall performance in both vibration and noise reduction, indicating that Ni625/WC is the best laser-cladding composite material for reducing vibration and noise effects. The Ni35/WC-clad specimens have the worst noise and vibration performance.

- (3)

- The corrosion potential of the laser-clad specimens is significantly increased compared with the unclad specimen, indicating that the corrosion resistance of the base material has been improved by the Ni/WC laser-cladding process. The laser-clad Ni/WC coatings are shown to contain multiple phases of WC, W2C, FeNi, Fe5C2, Cr3C2, and MoC, which are likely to play an important role in the enhancement of the anti-corrosion properties of the laser-clad specimens. However, these initial corrosion results need to be confirmed by long-term immersion tests, exposing the clad surfaces to (say) 3.5% NaCl solution for at least 30 days.

- (4)

- High levels of compressive residual stresses were found in all the specimens with laser-clad coatings, which compares with the low levels of tensile residual stress measured in the unclad specimen. It is thought that these high compressive residual stresses contribute to the improvement in the anti-wear/corrosion and vibration/noise properties of the laser-clad specimens.

- (5)

- In this study, the Ni625/WC coatings gave the best performance in frictional vibration and noise reduction, while the Ni60/WC coatings gave the best performance in anti-wear and corrosion resistance. Generally, the coatings produced with the higher laser power settings gave improved performance. However, this performance is highly dependent on the particular laser-clad materials chosen, and further optimization of the laser-processing parameters for different materials would be desirable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, H.; Liu, Z.; Li, J.; Liu, Q.; Zhang, J.; Wei, T. Optimization design of environmental-friendly Cu-Fe laser cladding coating for self-grown microchannel in a marine corrosive environment. J. Alloys Compd. 2023, 940, 168820. [Google Scholar] [CrossRef]

- Zou, Y.; Ma, B.; Cui, H.; Lu, F.; Xu, P. Microstructure, wear, and oxidation resistance of nanostructured carbide-strengthened cobalt-based composite coatings on Invar alloys by laser cladding. Surf. Coat. Technol. 2020, 381, 125188. [Google Scholar] [CrossRef]

- Khorram, A.; Davoodi Jamaloei, A.; Paidar, M.; Cao, X. Laser cladding of Inconel 718 with 75Cr3C2+25(80Ni20Cr) powder: Statistical modeling and optimization. Surf. Coat. Technol. 2019, 378, 124933. [Google Scholar] [CrossRef]

- Caneda, C.M.; Fogagnolo, J.B.; Kiminami, C.S.; Afonso, C.R.M. Ultrafine eutectic coatings from Fe-Nb-B powder using laser cladding. Mater. Charact. 2020, 160, 110080. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R.; Berkebile, S.P. Effect of ultrasonic nanocrystal surface modification on wear mechanisms of thermally-sprayed WC-Co coating. Wear 2021, 477, 203873. [Google Scholar] [CrossRef]

- Kumar, J.K.; Rao, T.B.; Krishna, K.R. The Microstructural properties and tribological performance of Al2O3 and TiN nanoparticles reinforced Ti-6Al-4V composite coating deposited on AISI304 steel by TIG cladding. J. Tribol. 2023, 1, 145. [Google Scholar] [CrossRef]

- Zhang, C.; Pei, S.; Ji, H.; Cui, Y.; Li, M. Fabrication of Ni60-SiC coating on carbon steel for improving friction, corrosion properties. Mater. Sci. Technol. 2017, 33, 446–453. [Google Scholar] [CrossRef]

- Tian, Z.-H.; Zhao, Y.-T.; Jiang, Y.-J.; Ren, H.-P. Microstructure and properties of Inconel 625 + WC composite coatings prepared by laser cladding. Rare Met. 2021, 40, 2281–2291. [Google Scholar] [CrossRef]

- Wang, X.H.; Liu, S.S.; Zhang, M.; Qu, K.L. Effect of rare earth oxide on the microstructure and wear properties of in situ-synthesized ceramics-reinforced Fe-based laser cladding coatings. Tribol. Trans. 2020, 63, 345–355. [Google Scholar] [CrossRef]

- Wang, G.; Wang, S.; Yin, Z.; Yang, X.; Wen, D.; Sun, Y. Synthesis of Ni-WC/Al-Ni functionally graded coating with advanced corrosion and wear resistance on AZ91D Mg alloy by laser cladding. Mater. Lett. 2023, 333, 133645. [Google Scholar] [CrossRef]

- Arias-González, F.; del Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J. Fiber laser cladding of nickel-based alloy on cast iron. Appl. Surf. Sci. 2016, 374, 197–205. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Q.; Chen, Z.; Wang, L.; Yao, J.; Kovalenko, V. Study on the element segregation and Laves phase formation in the carbon nanotubes reinforced IN718 superalloy by laser cladding. Powder Technol. 2019, 355, 163–171. [Google Scholar] [CrossRef]

- Zhang, M.; Luo, S.X.; Liu, S.S.; Wang, X.H. Effect of molybdenum on the wear properties of (Ti,Mo)C-TiB2-Mo2B particles reinforced Fe-based laser cladding composite coatings. J. Tribol. 2018, 140, 051603. [Google Scholar] [CrossRef]

- Liu, Y.P.; Liang, Y.L.; Fu, H.G. Improvement properties of laser cladding Ni45-Cr3C2 coatings by adding B4C and V. Mater. Sci. Technol. 2023, 39, 443–453. [Google Scholar]

- Jiang, D.; Cui, H.; Zhao, X.; Chen, H.; Ma, G.; Song, X. Beneficial effects of Co to CoCrNiMoCB coatings obtained by laser cladding. Mater. Lett. 2022, 323, 132558. [Google Scholar] [CrossRef]

- Yuan, S.H.; Li, H.L.; Han, C.F.; Li, W.Q.; Xu, X.F.; Chen, C.; Wei, R.; Wang, T.; Wu, S.J.; Li, F.S. FeCoNiCrAl0.6 high-entropy alloy coating on Q235 steel fabricated by laser cladding. Mater. Sci. Technol. 2023, 39, 705–713. [Google Scholar] [CrossRef]

- Wang, T.Y.; Zhao, M.X.; Li, Z.; Wang, X.N.; Wei, J.C. Effect of indium on the microstructure and corrosion resistance of the galvanising coating. Mater. Sci. Technol. 2023, 39, 767–776. [Google Scholar] [CrossRef]

- Riquelme, A.; Escalera-Rodriguez, M.D.; Rodrigo, P.; Rams, J. Role of laser cladding parameters in composite coating (Al-SiC) on aluminum alloy. J. Therm. Spray Technol. 2016, 25, 1177–1191. [Google Scholar] [CrossRef]

- Teixeira, M.F.; Pacheco, J.T.; da Silva, L.J.; Rabelo, A.; Pereira, M.; Niño, C.E. Laser cladding of Metco 1040® (Fe-V-Mn-C) on Hadfield steel: Effect of processing parameters on microstructure and wear resistance. Opt. Laser Technol. 2021, 142, 107219. [Google Scholar] [CrossRef]

- Mahade, S.; Awe, S.A.; Björklund, S.; Lukáč, F.; Mušálek, R.; Joshi, S. Sliding wear behavior of a sustainable Fe-based coating and its damage mechanisms. Wear 2022, 500–501, 204375. [Google Scholar] [CrossRef]

- Tonolini, P.; Montesano, L.; Pola, A.; Landriani, E.; Gelfi, M. The effect of laser-cladding on the wear behavior of gray cast iron brake disc. Procedia Struct. Integr. 2021, 33, 1152–1161. [Google Scholar] [CrossRef]

- Manoj, A.; Saurabh, A.; Narala, S.K.R.; Saravanan, P.; Natu, H.P.; Verma, P.C. Surface modification of grey cast iron by laser cladding for automotive brake disc application. Wear 2023, 532–533, 205099. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, R.; Zhao, C.; Wei, R.; Li, H.; Deng, R.; Bai, Q.; Liu, Y. Multi-layer laser cladding analysis and high-temperature oxidative wear behavior of cast iron with a low expansion coefficient. Surf. Coat. Technol. 2023, 474, 130079. [Google Scholar] [CrossRef]

- Li, Y.J.; Dong, S.Y.; Yan, S.X.; Li, E.Z.; Liu, X.T.; He, P.; Xu, B.S. Deep pit repairing of nodular cast iron by laser cladding NiCu/Fe-36Ni low-expansion composite alloy. Mater. Charact. 2019, 151, 273–279. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.; Tian, X.; Yang, H.; Hao, J. Microstructural evolution and corrosion properties of Ni-based alloy coatings fabricated by multi-layer laser cladding on cast iron. J. Alloys Compd. 2020, 822, 153708. [Google Scholar] [CrossRef]

- Wang, S.W.; Liao, Y.H.; Wang, T.D. Properties of vibration and noise reduction and friction/wear performance of laser clad Ni625/WC coatings. China Surf. Eng. 2021, 34, 94–103. [Google Scholar]

- Yuan, W.; Li, R.; Chen, Z.; Gu, J.; Tian, Y. A comparative study on microstructure and properties of traditional laser cladding and high-speed laser cladding of Ni45 alloy coatings. Surf. Coat. Technol. 2021, 405, 126582. [Google Scholar] [CrossRef]

- Chen, Y.; Cui, H.; Li, L.; Song, X.; Feng, Y.; Zhang, C.; Huang, W. Effect of WC incorporation on the microstructure and mechanical properties of Ni625/WC spark plasma sintered composites. Ceram. Int. 2024, 50, 16987–16997. [Google Scholar] [CrossRef]

- Morin, L.; Braham, C.; Tajdary, P.; Seddik, R.; Gonzalez, G. Reconstruction of heterogeneous surface residual-stresses in metallic materials from X-ray diffraction measurements. Mech. Mater. 2021, 158, 103882. [Google Scholar] [CrossRef]

- Zhu, D.P.; Yu, X.K.; Sai, Q.Y.; Wang, S.W.; Barton, D.; Fieldhouse, J.; Kosarieh, S. Noise and vibration performance of automotive disk brakes with laser-machined M-shaped grooves. Proc. Inst. Mech. Eng. Part D 2023, 237, 978–990. [Google Scholar]

- Wang, S.; Yan, S.; Lin, J.; Batako, A.D. Study on the effects of laser quenching power and scanning speed on the property of cast iron. J. Phys. Conf. Ser. 2022, 2198, 012050. [Google Scholar] [CrossRef]

- Wang, S.W.; Guo, W.; Zeng, K.; Zhang, X.G. Characterization of automotive brake discs with laser-machined surfaces. Automot. Innov. 2019, 2, 190–200. [Google Scholar] [CrossRef]

- Cui, G.; Han, W.; Zhang, W.; Li, J.; Kou, Z. Friction and wear performance of laser clad Mo modified Stellite 12 matrix coatings at elevated temperature. Tribol. Int. 2024, 196, 109738. [Google Scholar] [CrossRef]

| C | Cr | Si | Fe | Ni | B | Mo | Co | Mn | P | S | Nb | Al | Ti | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni35 | <0.3 | 8.0–15.0 | 2.8–3.8 | <8 | 70.4–79.4 | 1.5–2.5 | ||||||||

| Ni45 | 0.2–0.6 | 2.0–7.0 | 3.0–4.5 | <8 | 76.9–84.8 | 2.0–3.0 | ||||||||

| Ni60 | 0.5–1.1 | 14–20 | 3.5–5.5 | <15 | 65–80 | 3.0–4.5 | 0.503 | |||||||

| Ni625 | 0.1 | 23 | 0.5 | 5 | 54.92 | 10 | 1 | 0.5 | 0.015 | 0.015 | 4.15 | 0.4 | 0.4 |

| WC | Al | Ca | Fe | K | Mg | Mo | Na | S | Si |

|---|---|---|---|---|---|---|---|---|---|

| ≥99.8 | 0.002 | 0.002 | 0.02 | 0.0015 | 0.002 | 0.01 | 0.0015 | 0.002 | 0.003 |

| Laser Power (W) | Feed Speed (mm/min) | Rotating Speed of Powder Feeder (r/min) | Protective Gas Flow (L/min) | Powder Feed Gas Flow (L/min) |

|---|---|---|---|---|

| 1100 | 600 | 1.5 | 15.0 | 5.0 |

| No. | Laser Power (W) | Feed Speed (mm/min) | Rotating Speed of Powder Feeder (r/min) | Protective Gas Flow (L/min) | Powder Feed Gas Flow (L/min) | WC Content (%) | Ni Content (%) and Type | |

|---|---|---|---|---|---|---|---|---|

| 1 | 1100 | 580 | 4.9 | 15.4 | 5.8 | 40 | 60 | Ni35 |

| 2 | 1400 | 660 | 4.4 | 15.3 | 4.2 | 30 | 70 | |

| 3 | 2000 | 600 | 4.5 | 15.1 | 5.4 | 10 | 90 | |

| 4 | 1100 | 580 | 4.9 | 15.4 | 5.8 | 40 | 60 | Ni45 |

| 5 | 1400 | 660 | 4.4 | 15.3 | 4.2 | 30 | 70 | |

| 6 | 2000 | 600 | 4.5 | 15.1 | 5.4 | 10 | 90 | |

| 7 | 1100 | 580 | 4.9 | 15.4 | 5.8 | 40 | 60 | Ni60 |

| 8 | 1400 | 660 | 4.4 | 15.3 | 4.2 | 30 | 70 | |

| 9 | 2000 | 600 | 4.5 | 15.1 | 5.4 | 10 | 90 | |

| 10 | 1100 | 580 | 4.9 | 15.4 | 5.8 | 40 | 60 | Ni625 |

| 11 | 1400 | 660 | 4.4 | 15.3 | 4.2 | 30 | 70 | |

| 12 | 2000 | 600 | 4.5 | 15.1 | 5.4 | 10 | 90 | |

| Equipment | Model | Manufacturer |

|---|---|---|

| Electronic balance | ME104E | Beijing Grand Boyu Technology, Beijing, China |

| Magnetic stirrer | MS7-H550-Pro | Qingdao Juchuang Environmental Protection Group, Qingdao, China |

| Supersonic cleaner | KQ-250 DB | Kunshan Ultrasonic Instruments, Kunshan, China |

| Constant-temperature water tank | HC-l | Qingdao Mingbo Environmental Protection Technology, Qingdao, China |

| Gamry electrochemical workstation | Interface1010E | Gamry Instruments, Warminster, PA, USA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Liao, Y.; Sai, Q.; Wang, S.; Barton, D.; Bai, M. Properties of Laser-Clad Stainless Steel–Ni/WC Double-Layer Coatings. Coatings 2024, 14, 1054. https://doi.org/10.3390/coatings14081054

Zhang R, Liao Y, Sai Q, Wang S, Barton D, Bai M. Properties of Laser-Clad Stainless Steel–Ni/WC Double-Layer Coatings. Coatings. 2024; 14(8):1054. https://doi.org/10.3390/coatings14081054

Chicago/Turabian StyleZhang, Ruipeng, Yuhong Liao, Qingyi Sai, Shuwen Wang, David Barton, and Mingwen Bai. 2024. "Properties of Laser-Clad Stainless Steel–Ni/WC Double-Layer Coatings" Coatings 14, no. 8: 1054. https://doi.org/10.3390/coatings14081054