Thick Columnar-Structured Thermal Barrier Coatings Using the Suspension Plasma Spray Process

Abstract

:1. Introduction

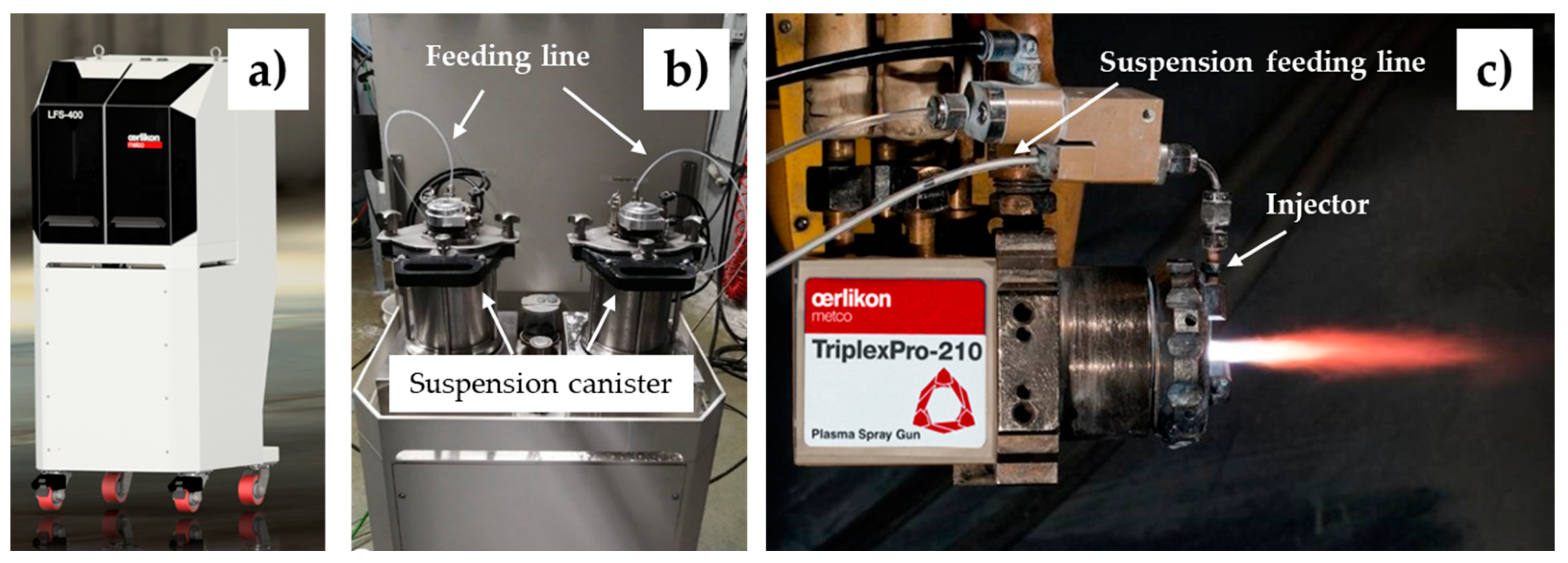

2. Experimental Procedures

3. Results and Discussion

3.1. Optimization of Suspension Injection and Deposition Efficiency

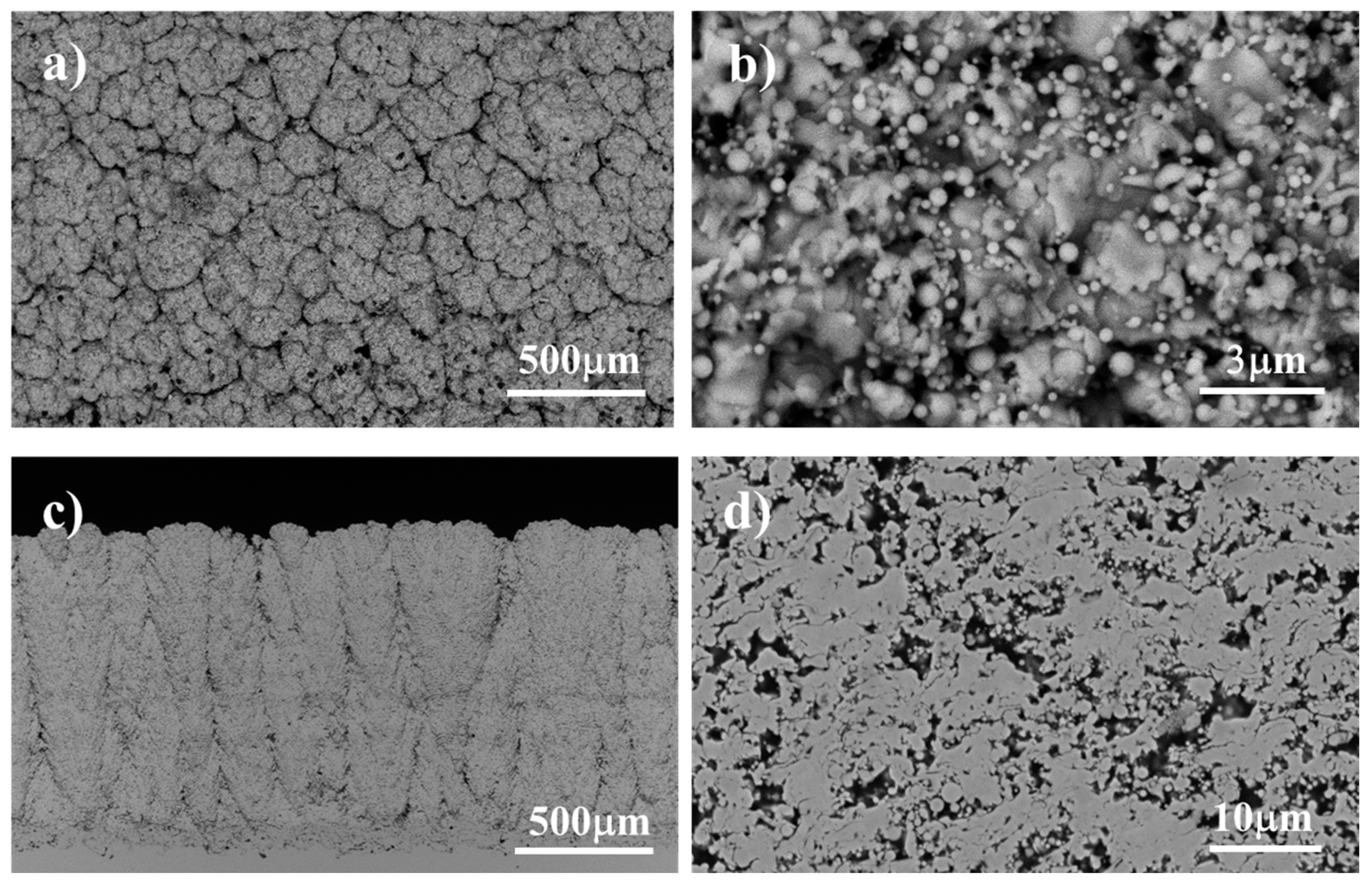

3.2. Morphologies of SPS Deposits

3.3. Coating Microstructure

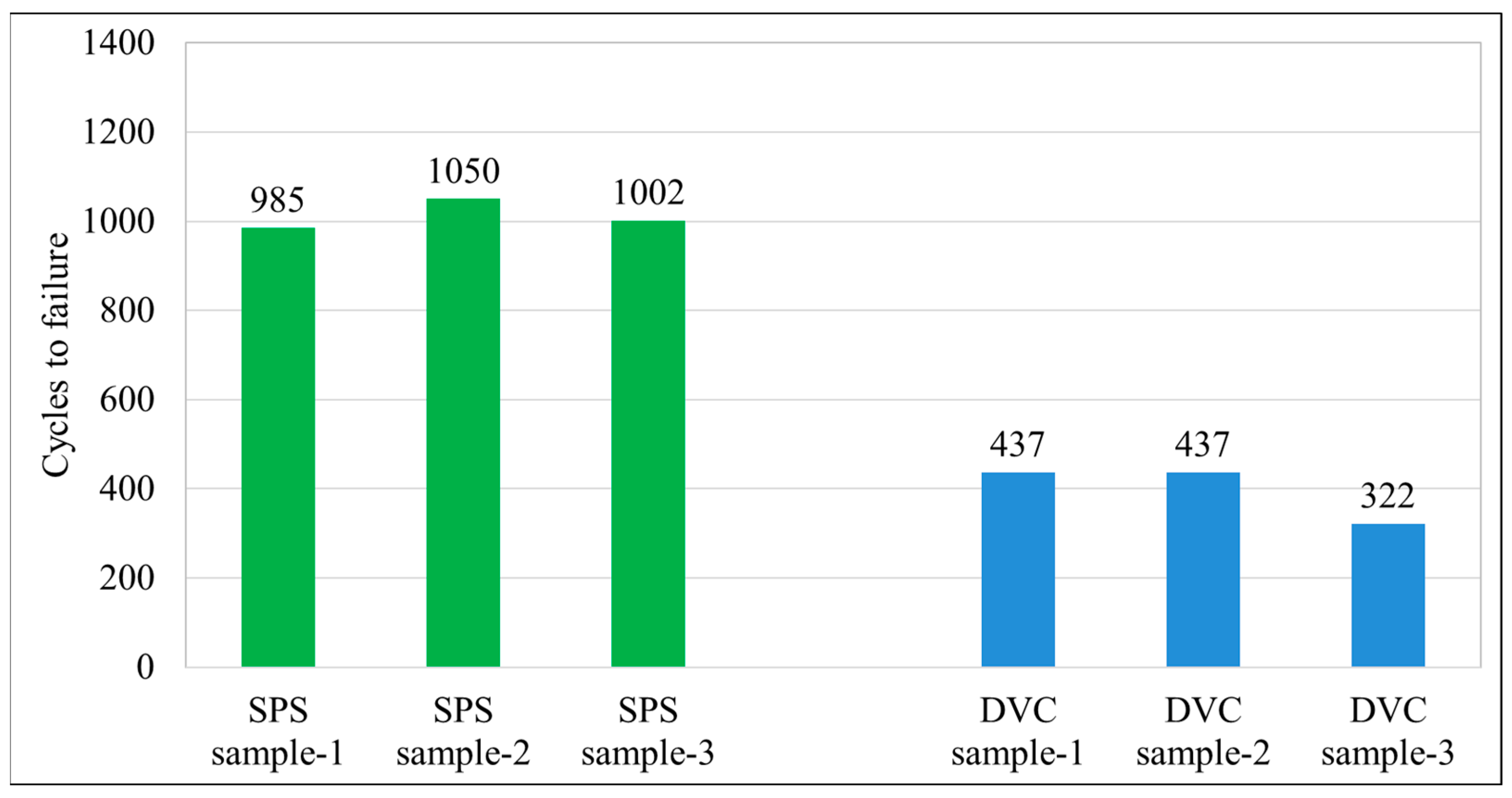

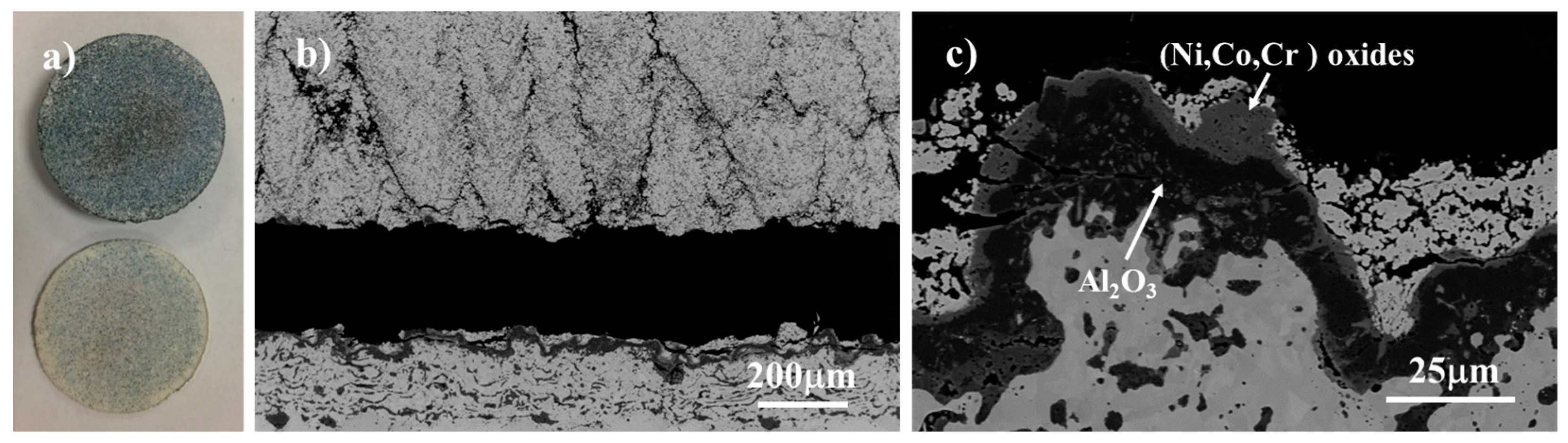

3.4. Furnace Cycle Behavior

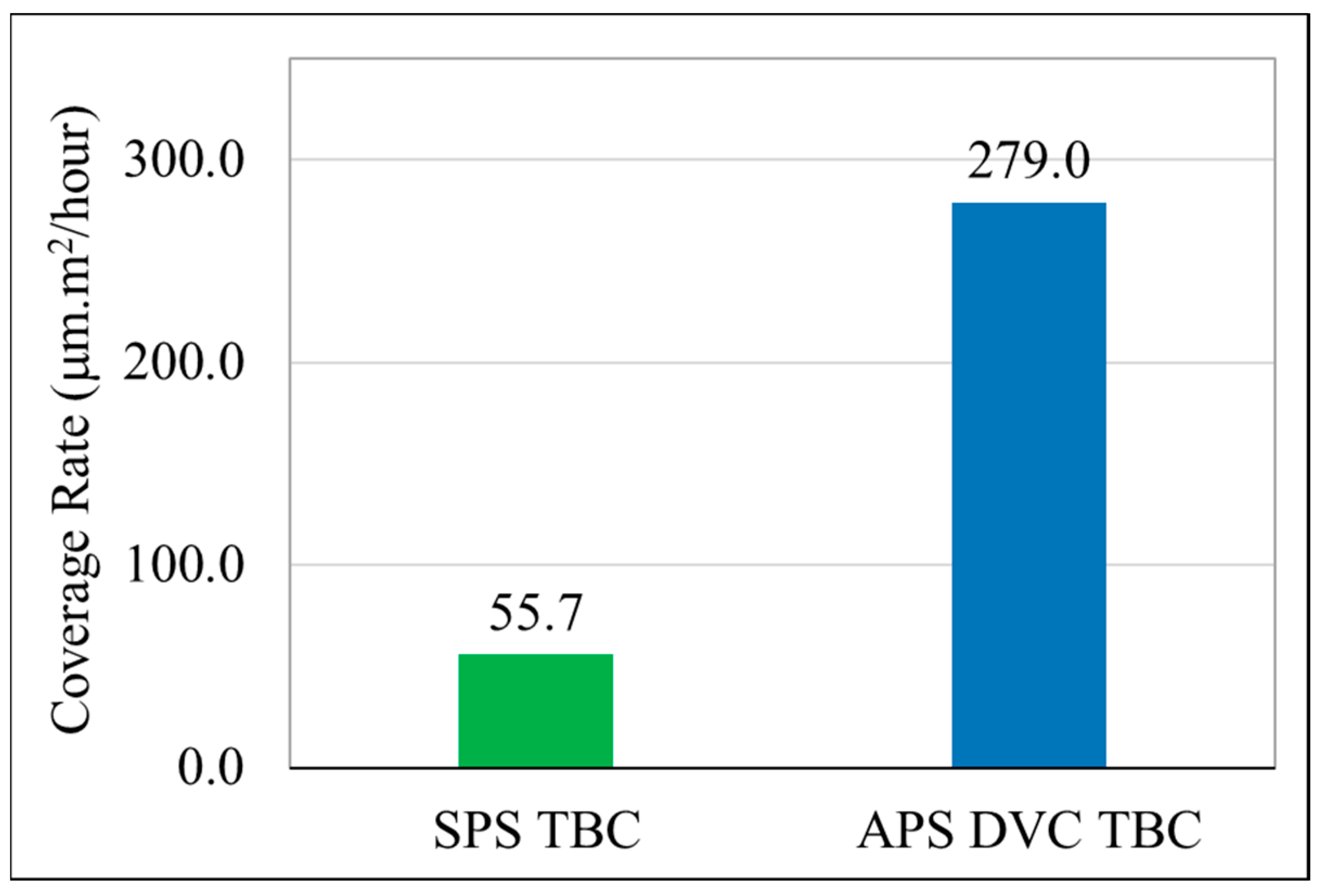

3.5. Coverage Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898. [Google Scholar] [CrossRef]

- Darolia, R. Thermal barrier coatings technology: Critical review, progress update, remaining challenges and prospects. Int. Mater. Rev. 2013, 58, 315–348. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Hardwicke, C.U.; Lau, Y.C. Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review. J. Therm. Spray Technol. 2013, 22, 564–576. [Google Scholar] [CrossRef]

- Miller, R.A. Thermal Barrier Coatings for Aircraft Engines: History and Directions. J. Therm. Spray Technol. 1997, 6, 35–42. [Google Scholar] [CrossRef]

- Bose, S.; DeMasi-Marcin, J. Thermal barrier coating experience in gas turbine engines at Pratt & Whitney. J. Therm. Spray Technol. 1997, 1997, 99–104. [Google Scholar]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Meier, S.M.; Gupta, D.K. The Evolution of Thermal Barrier Coatings in Gas Turbine Engine Applications. J. Eng. Gas Turbines Power 1994, 116, 250–257. [Google Scholar] [CrossRef]

- Vaßen, R.; Bakan, E.; Mack, D.E.; Guillon, O. A Perspective on Thermally Sprayed Thermal Barrier Coatings: Current Status and Trends. J. Therm. Spray Technol. 2022, 31, 685–698. [Google Scholar] [CrossRef]

- Smialek, J.L.; Miller, R.A. Revisiting the Birth of 7YSZ Thermal Barrier Coatings: Stephan Stecura. Coatings 2018, 8, 255. [Google Scholar] [CrossRef]

- Taylor, T.A. Thermal Barrier Coating for Substrates and Process for Producing It. U.S. Patent 5073433, 17 December 1991. [Google Scholar]

- Guo, H.; Kuroda, S.; Murakami, H. Segmented thermal barrier coatings produced by atmospheric plasma spraying hollow powders. Thin Solid Films 2006, 506–507, 136–139. [Google Scholar] [CrossRef]

- Chen, D.; Rocchio-Heller, R.; Dambra, C. Segmented Thermal Barrier Coatings for ID and OD Components Using the SinplexPro Plasma Torch. J. Therm. Spray Technol. 2019, 28, 1664–1673. [Google Scholar] [CrossRef]

- Chen, D.; Dambra, C.; Dorfman, M. Process and properties of dense and porous vertically-cracked yttria stabilized zirconia thermal barrier coatings. Surf. Coatings Technol. 2020, 404, 126467. [Google Scholar] [CrossRef]

- Chen, D.; Dambra, C.; Dorfman, M. Deposition, Microstructure and Thermal Cycling Performance of Strain-Tolerant Thermal Barrier Coatings. J. Therm. Spray Technol. 2023, 32, 1108–1114. [Google Scholar] [CrossRef]

- Karger, M.; Vaßen, R.; Stöver, D. Atmospheric plasma sprayed thermal barrier coatings with high segmentation crack densities: Spraying process, microstructure and thermal cycling behavior. Surf. Coat. Technol. 2011, 206, 16–23. [Google Scholar] [CrossRef]

- Beeck, A.; Bögli, A.; Fernihough, J. Process of Plugging Cooling Holes of a Gas Turbine Component. EP1076107A1, 14 February 2001. [Google Scholar]

- Fernihough, J.; Boegli, A.; Stankowski, A. Process of Masking Cooling Holes of a Gas Turbine Component. U.S. Patent 20050215686A1, 29 September 2005. [Google Scholar]

- Kassner, H.; Siegert, R.; Hathiramani, D.; Vassen, R.; Stoever, D. Application of Suspension Plasma Spraying (SPS) for Manufacture of Ceramic Coatings. J. Therm. Spray Technol. 2008, 17, 115–123. [Google Scholar] [CrossRef]

- Vaßen, R.; Kaßner, H.; Mauer, G.; Stöver, D. Suspension Plasma Spraying: Process Characteristics and Applications. J. Therm. Spray Technol. 2010, 19, 219–225. [Google Scholar] [CrossRef]

- Tang, Z.; Kim, H.; Yaroslavski, I.; Masindo, G.; Celler, Z.; Ellsworth, D. Novel Thermal Barrier Coatings produced by Axial Suspension Plasma Spray. In Proceedings of the International Thermal Spray Conference & Exposition, Hamburg, Germany, 27–29 September 2011; pp. 571–575. [Google Scholar]

- Cotler, E.M.; Chen, D.; Molz, R.J. Pressure-Based Liquid Feed System for Suspension Plasma Spray Coatings. J. Therm. Spray Technol. 2011, 20, 967–973. [Google Scholar] [CrossRef]

- VanEvery, K.; Krane, M.; Trice, R.; Wang, H.; Porter, W.; Besser, M.; Sordelet, D.; Ilavsky, J.; Almer, J. Column Formation in Suspension Plasma-Sprayed Coatings and Resultant Thermal Properties. J. Therm. Spray Technol. 2011, 20, 817–828. [Google Scholar] [CrossRef]

- Joeris, J.; Tiwari, A.; Brinckmann, S.; Kurze, F.; Guillon, O.; Vaßen, R. Evaluation of major factors influencing the TBC topcoat formation in axial suspension plasma spraying (SPS). Int. J. Appl. Ceram. Technol. 2023, 20, 884–895. [Google Scholar] [CrossRef]

- Bernard, B.; Quet, A.; Bianchi, L.; Schick, V.; Joulia, A.; Malié, A.; Rémy, B. Effect of Suspension Plasma-Sprayed YSZ Columnar Microstructure and Bond Coat Surface Preparation on Thermal Barrier Coating Properties. J. Therm. Spray Technol. 2017, 26, 1025–1037. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Thermal conductivity and thermal cyclic fatigue of multilayered Gd2Zr2O7/YSZ thermal barrier coatings processed by suspension plasma spray. Surf. Coat. Technol. 2015, 283, 329–336. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, M.; Vardelle, A.; Goutier, S. What Do We Know, What are the Current Limitations of Suspension Plasma Spraying? J. Therm. Spray Technol. 2015, 24, 1120–1129. [Google Scholar] [CrossRef]

- VanEvery, K.; Krane, M.J.M.; Trice, R.W. Parametric study of suspension plasma spray processing parameters on coating microstructures manufactured from nanoscale yttria-stabilized zirconia. Surf. Coat. Technol. 2012, 206, 2464–2473. [Google Scholar] [CrossRef]

- Delbos, C.; Fazilleau, J.; Rat, V.; Coudert, J.F.; Pateyron, B. Phenomena Involved in Suspension Plasma Spraying Part 2: Zirconia Particle Treatment and Coating Formation. Plasma Chem. Plasma Process. 2006, 26, 393–414. [Google Scholar] [CrossRef]

- Zhou, D.; Guillon, O.; Vaßen, R. Development of YSZ Thermal Barrier Coatings Using Axial Suspension Plasma Spraying. Coatings 2017, 7, 120. [Google Scholar] [CrossRef]

- Ganvir, A.; Joshi, S.; Markocsan, N.; Vassen, R. Tailoring columnar microstructure of axial suspension plasma sprayed TBCs for superior thermal shock performance. Mater. Des. 2018, 144, 192–208. [Google Scholar] [CrossRef]

- Bellippady, M.; Florent, M.; Björklund, S.; Li, X.H.; Robert, F.; Kjellman, B.; Joshi, S.; Markocsan, N. Characteristics and performance of suspension plasma sprayed thermal barrier coatings on additively manufactured superalloy substrates. Surf. Coat. Technol. 2023, 472, 129926. [Google Scholar] [CrossRef]

- Gupta, M.; Li, X.-H.; Peng, R.; Ottosson, A.; Gillberg, P.; Girgulis, J. Understanding the effect of bondcoat surface treatment on enhanced lifetime of suspension plasma sprayed thermal barrier coatings. Surf. Coatings Technol. 2024, 482, 130716. [Google Scholar] [CrossRef]

| Layer | Composition (%) | Thickness |

|---|---|---|

| Top Coat | 8 wt%Y2O3-stabilized ZrO2 | ~1000 μm |

| Amdry 386-4 Bond Coat | Co: 22, Cr: 17, Al:12, Hf: 0.5, Y:0.5, Si: 0.4, Ni: balance | ~150.0 μm |

| Hastelloy X Substrate | Cr:22.24, Fe: 18.09, Mo: 8.55, Co: 1.46, W: 0.62, Mn: 0.46, Si: 0.31, Cu: 0.11, Ti: 0.020, Ni: balance | ~5.0 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Dambra, C. Thick Columnar-Structured Thermal Barrier Coatings Using the Suspension Plasma Spray Process. Coatings 2024, 14, 996. https://doi.org/10.3390/coatings14080996

Chen D, Dambra C. Thick Columnar-Structured Thermal Barrier Coatings Using the Suspension Plasma Spray Process. Coatings. 2024; 14(8):996. https://doi.org/10.3390/coatings14080996

Chicago/Turabian StyleChen, Dianying, and Christopher Dambra. 2024. "Thick Columnar-Structured Thermal Barrier Coatings Using the Suspension Plasma Spray Process" Coatings 14, no. 8: 996. https://doi.org/10.3390/coatings14080996