Synergistic Effect of Elliptic Textures and H-DLC Coatings for Enhancing the Tribological Performance of CuAl10Fe5Ni5 Valve Plate Surfaces

Abstract

:1. Introduction

2. Experiment Details

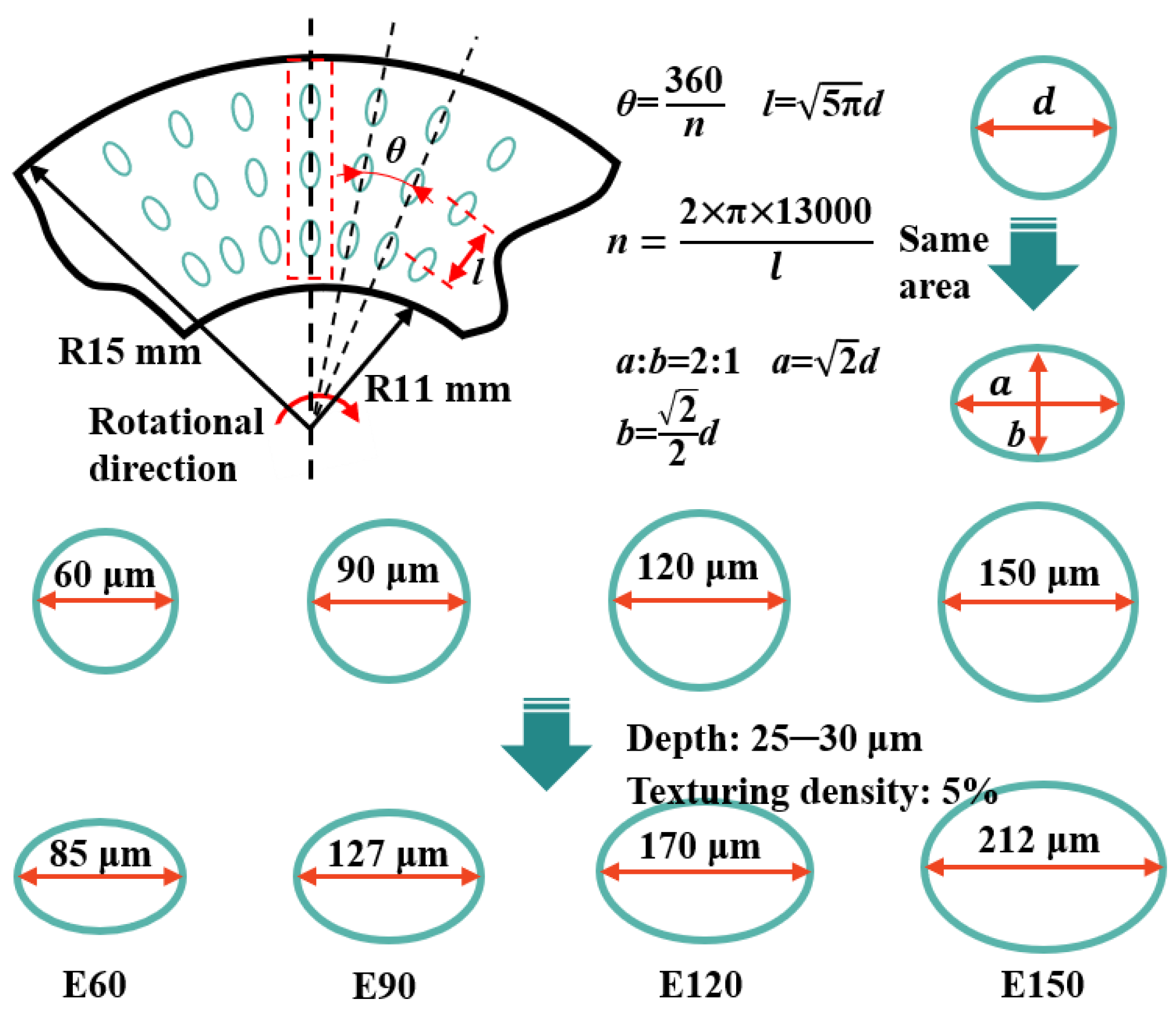

2.1. Laser Surface Texturing and Coating Deposition

2.2. Friction and Wear Tests

3. Results and Discussion

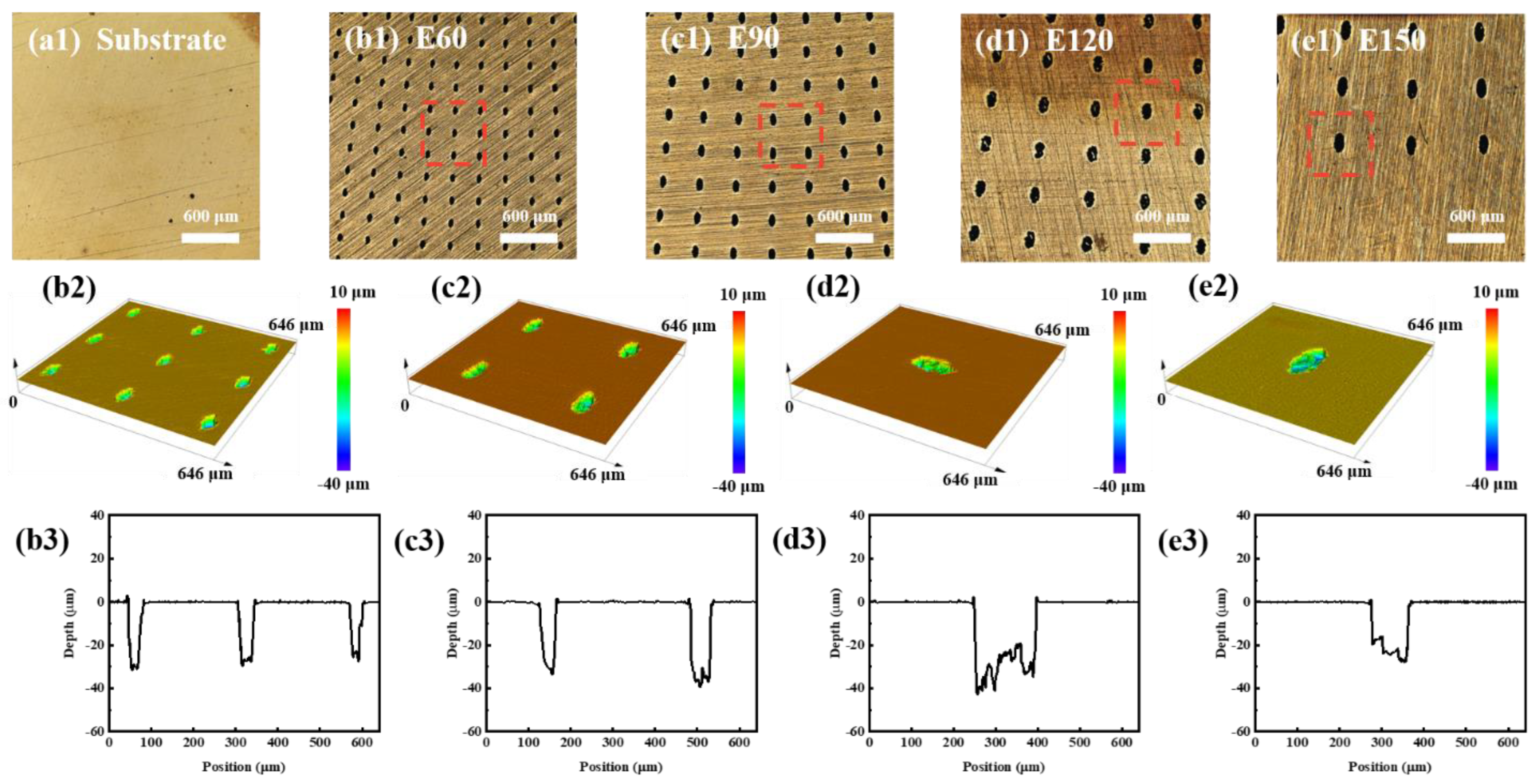

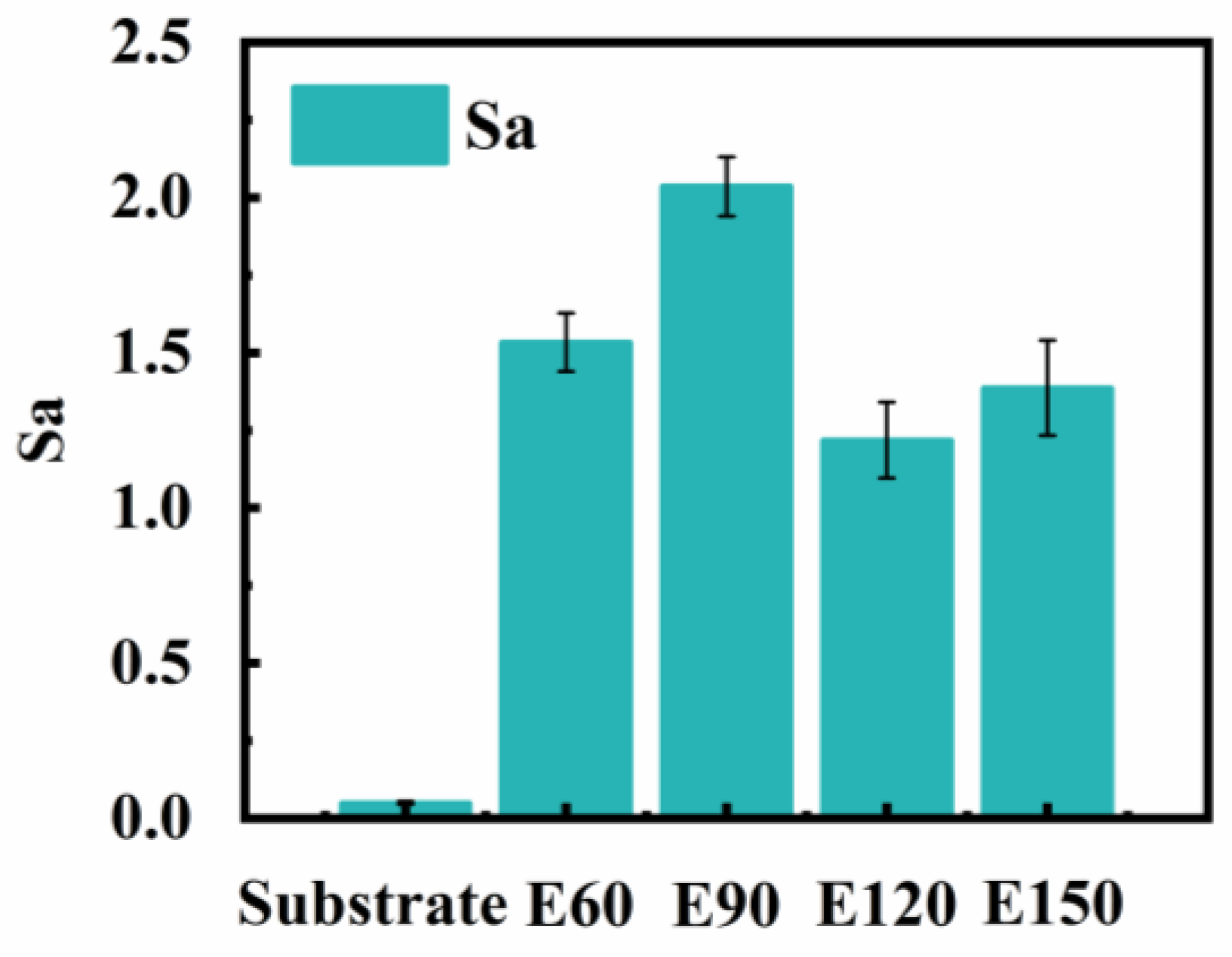

3.1. Characterization of Morphology and Structure

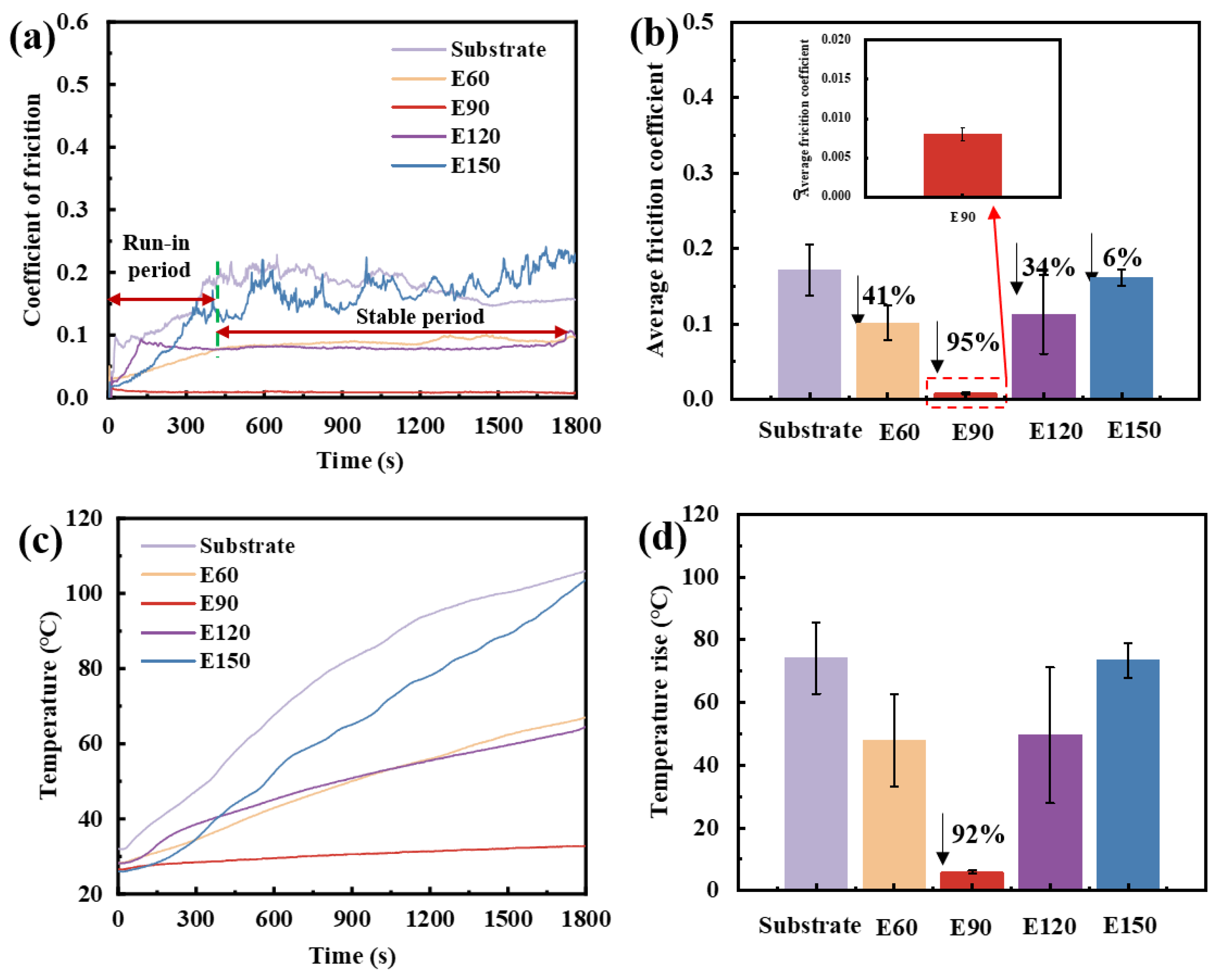

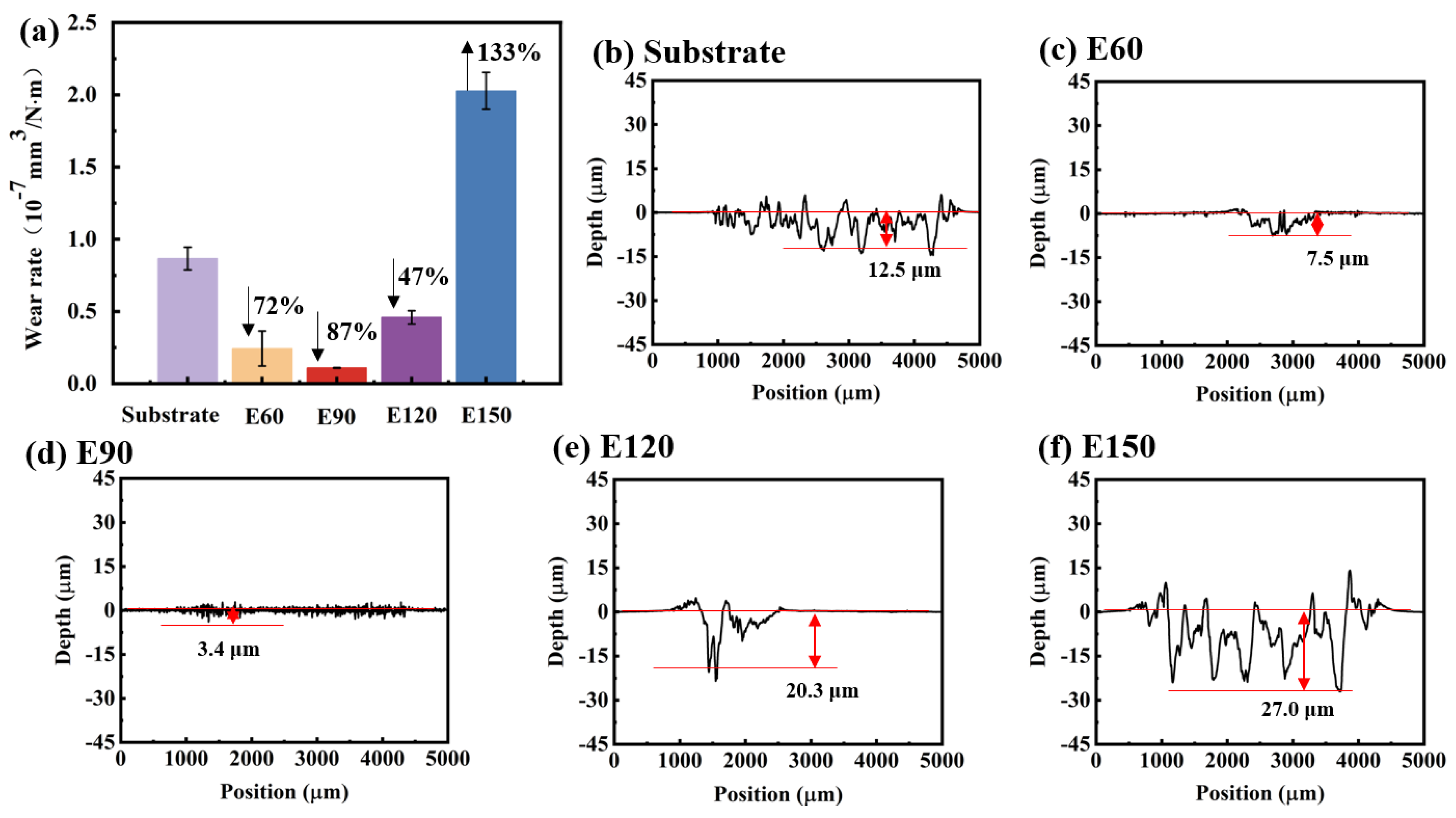

3.2. Tribological Properties of Textured CuAl10Fe5Ni5 Surfaces

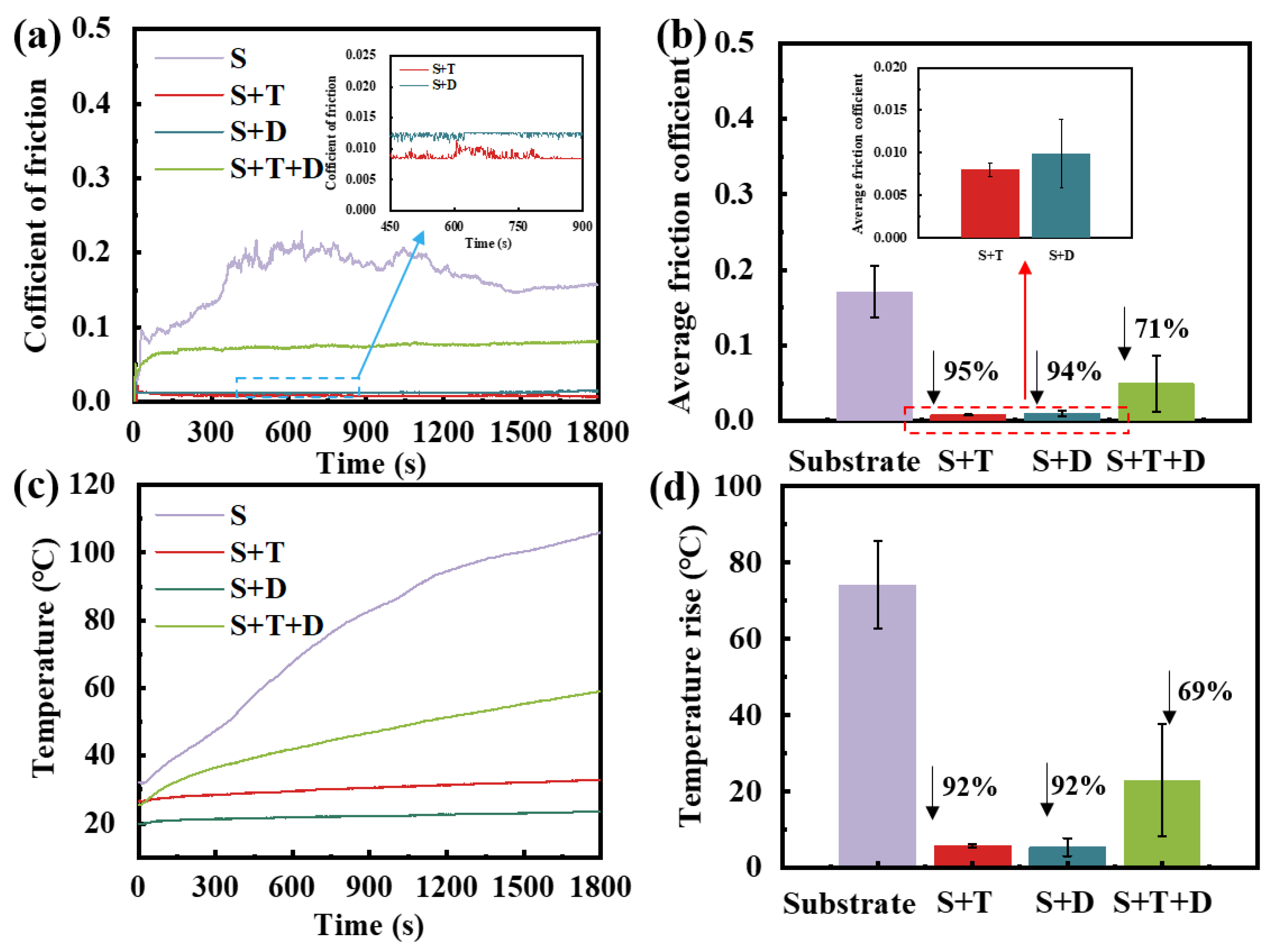

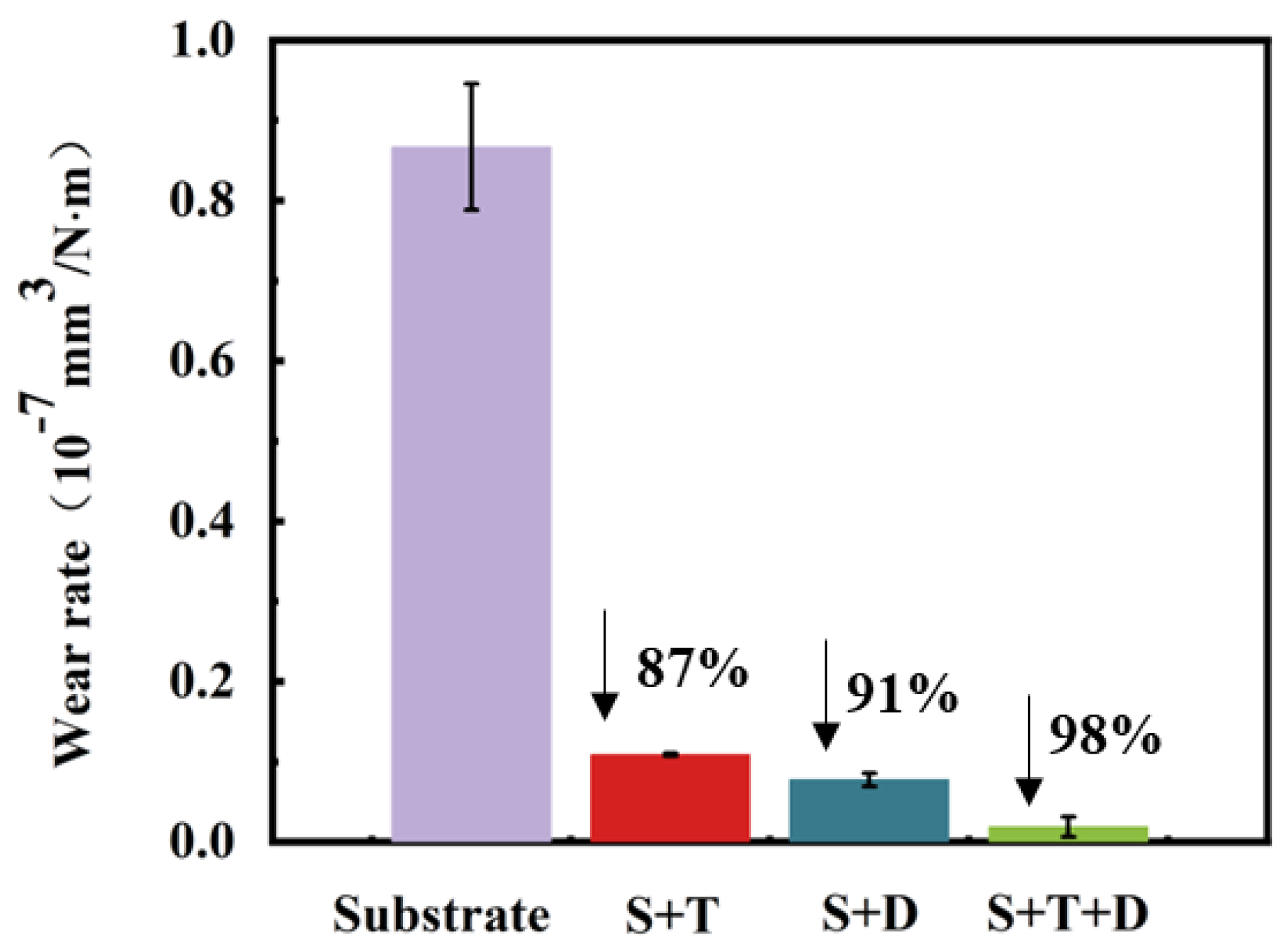

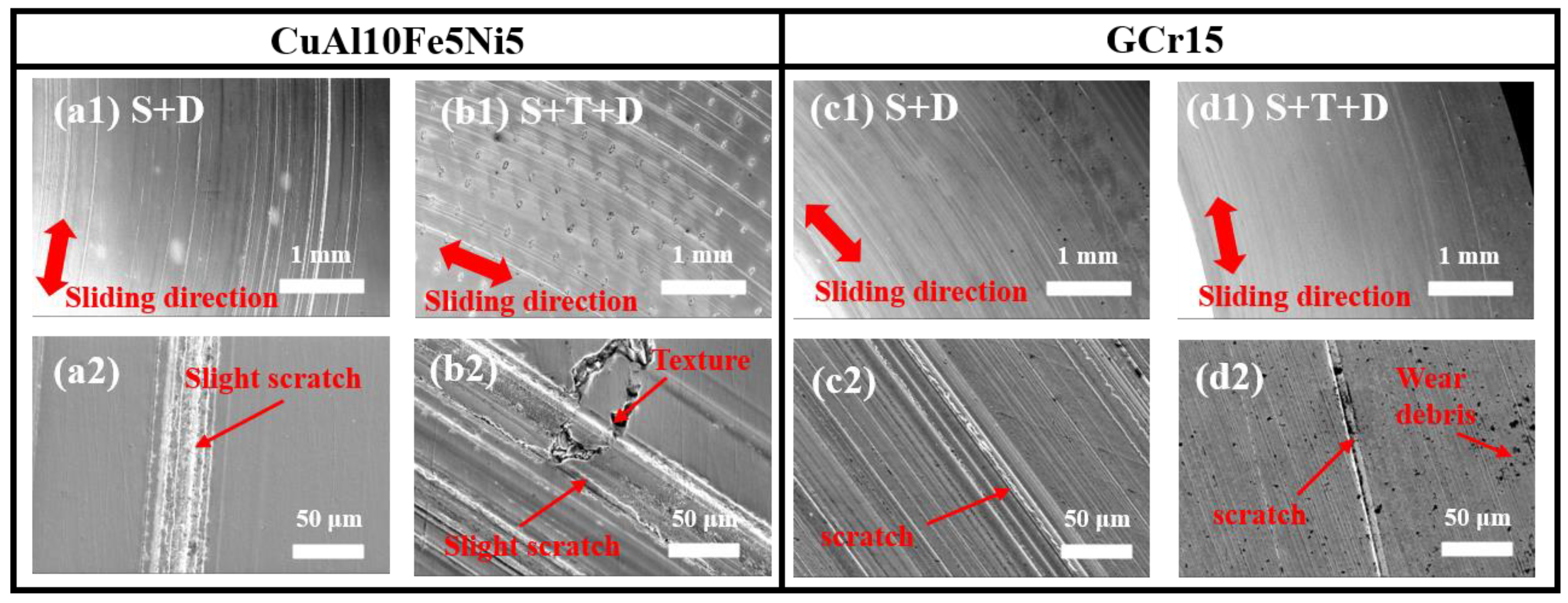

3.3. Tribological Properties of Textured H-DLC Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suo, X.; Jiang, Y.; Wang, W. Hydraulic axial plunger pump: Gaseous and vaporous cavitation characteristics and optimization method. Eng. Appl. Comp. Fluid. 2021, 15, 712–726. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, H.; Yuan, S.; Wang, J.; Lin, N.; Liu, Z.; Wu, Y. Research progress on service damage and protection of axial piston pump sliding shoe pair. Surf. Technol. 2023, 6, 126–139. [Google Scholar]

- Xu, L. Study on the Lubrication Characterisics of the Valve Plate Bearing in Hydraulic Axial Piston Pump; Beijing Institute of Technology: Beijing, China, 2016. [Google Scholar]

- Wang, H.; Lin, N.; Yuan, S.; Liu, Z.; Yu, Y.; Zeng, Q.; Wu, Y. Structural improvement, material selection and surface treatment for improved tribological performance of friction pairs in axial piston pumps: A review. Tribol. Int. 2024, 198, 109838. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Xu, B.; Chao, Q.; Liu, G. Multi-objective optimization of micronscale surface textures for the cylinder/valve plate interface in axial piston pumps. Tribol. Int. 2019, 138, 316–329. [Google Scholar] [CrossRef]

- Kalin, M.; Majdic, F.; Vižintin, J.; Pezdirnik, J.; Velkavrh, I. Analyses of the long-term performance and tribological behavior of an axial piston pump using diamondlike-carbon-coated piston shoes and biodegradable oil. J. Tribol-T ASME 2008, 130, 011013-1-8. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.; Wang, W.; Zhang, H.; Liu, Z.; Wu, Y. Correlation between surface textural parameter and tribological behaviour of four metal materials with laser surface texturing (LST). Appl. Surf. Sci. 2022, 583, 152410. [Google Scholar] [CrossRef]

- Wang, H.; Tian, L.; Zheng, J.; Yang, D.; Zhang, Z. The synergetic effects of laser texturing and super-hydrophobic coatings on improving wear properties of steel. Tribol. Int. 2022, 173, 107657. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Y.; Xu, B.; Chao, Q.; Zhu, Y.; Huang, X. Effect of surface texture on wear reduction of the tilting cylinder and the valve plate for a high-speed electro-hydrostatic actuator pump. Wear 2018, 414, 68–78. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Z.; Song, W. Process-surface morphology-tribological property relationships for H62 brass employing various manufacturing approaches. Tribol. Int. 2020, 148, 106320. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Z.; Wang, L.; Kong, L.; Gao, F.; Wang, Q. Study on tribological properties of boronized and textured composite surface and its application on camshaft connecting-rod type hydraulic motor. Wear 2021, 482, 203964. [Google Scholar] [CrossRef]

- Xu, Y.; Zheng, Q.; Abuflaha, R.; Olson, D.; Furlong, O.; You, T.; Tysoe, W.T. Influence of dimple shape on tribofilm formation and tribological properties of textured surfaces under full and starved lubrication. Tribol. Int. 2019, 136, 267–275. [Google Scholar] [CrossRef]

- Wang, H.; Li, Y.; Zhu, H. Influence of geometrical parameters and arrangement Mode of elliptic cylindrical Texture on lubrication and antifriction performance. J. Tribol. 2016, 36, 77–83. [Google Scholar] [CrossRef]

- Babu, P.V.; Ismail, S.; Ben, B.S. Experimental and numerical studies of positive texture effect on friction reduction of sliding contact under mixed lubrication. P. I. Mech. Eng. J—J. Eng. 2021, 235, 360–375. [Google Scholar] [CrossRef]

- Chen, P.; Xin, X.; Shao, T.; La, Y.; Li, J. Effect of triangular texture on the tribological performance of die steel with TiN coatings under lubricated sliding condition. Appl. Surf. Sci. 2016, 389, 361–368. [Google Scholar] [CrossRef]

- Xin, T.; Pei, H.; Shucai, Y. Coating and micro-texture techniques for cutting tools. J. Mater. Sci. 2022, 57, 17052–17104. [Google Scholar] [CrossRef]

- Evaristo, M.; Fernandes, F.; Cavaleiro, A. Influence of the alloying elements on the tribological performance of DLC coatings in different sliding conditions. Wear 2023, 526, 204880. [Google Scholar] [CrossRef]

- Zhuo, X.; Cao, J.; Huang, H.; Liu, L.; Suo, X.; Ye, P.; Abbas, Z. Cavitation erosion resistance and tribological performance of PAI/PI/EP soft coating on 20CrMo. Wear 2024, 536, 205176. [Google Scholar] [CrossRef]

- Zhao, J.; Fu, Y.; Wang, M.; Fu, J.; Chao, Q.; Wang, S.; Deng, M. Experimental research on tribological characteristics of TiAlN coated valve plate in electro-hydrostatic actuator pumps. Tribol. Int. 2021, 155, 106782. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Fu, A.; Cao, X.; Yin, C.; Liu, Z. Investigation of the tribological properties and corrosion resistance of multilayer Si-DLC films on the inner surfaces of N80 steel pipes. Coatings 2024, 14, 385. [Google Scholar] [CrossRef]

- Leonardo, I.; Farfan, C.; Julio, A.; Seungjoo, L.; Merve, U.; Ali, E. Tribological behavior of H-DLC and H-free DLC coatings on bearing materials under the influence of DC electric current discharges. Wear 2023, 522, 204709. [Google Scholar]

- Liu, Y.; Jiang, Y.; Sun, J.; Wang, L.; Liu, Y.; Chen, L.; Qian, L. Durable superlubricity of hydrogenated diamond-like carbon film against different friction pairs depending on their interfacial interaction. Appl. Surf. Sci. 2021, 560, 150023. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Liu, T.; Zhang, P. Effect of normal loads and mating pairs on the tribological properties of diamond-like carbon film. Wear 2021, 486, 204083. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Quazi, M.M.; Al Mahmud, K.A.H.; Habibullah, M. Effects of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition. Appl. Surf. Sci. 2015, 356, 1135–1149. [Google Scholar] [CrossRef]

- Vallinot, I.B.; de la Guerra Ochoa, E.; Otero, J.E.; Tanarro, E.C.; Martínez, I.F.; Varela, J.A.S. Individual and combined effects of introducing DLC coating and textured surfaces in lubricated contacts. Tribol. Int. 2020, 151, 106440. [Google Scholar] [CrossRef]

- Xing, Y.; Zhu, M.; Wu, Z.; Li, Z.; Bai, S.; Zhang, K.; Liu, L. High-temperature tribological properties of Si3N4/TiC ceramic with bionic surface textures and DLC coatings. Tribol. Int. 2023, 186, 108648. [Google Scholar] [CrossRef]

- Qi, H.; Hu, C.; Zhang, G.; Yu, J.; Zhang, Y.; He, H. Comparative study of tribological properties of carbon fibers and aramid particles reinforced polyimide composites under dry and sea water lubricated conditions. Wear 2019, 436, 203001. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, X.; Du, Z.; Zhu, Z.; Wu, Z.; Liu, L. Synergistic effect of surface textures and DLC coatings for enhancing friction and wear performances of Si3N4/TiC ceramic. Ceram. Int. 2022, 48, 514–524. [Google Scholar] [CrossRef]

- He, D.; He, C.; Li, W.; Shang, L.; Wang, L.; Zhang, G. Tribological behaviors of in-situ textured DLC films under dry and lubricated conditions. Appl. Surf. Sci. 2020, 525, 146581. [Google Scholar] [CrossRef]

- Xing, Y.; Luo, C.; Wan, Y.; Huang, P.; Wu, Z.; Zhang, K. Formation of bionic surface textures composed by micro-channels using nanosecond laser on Si3N4-based ceramics. Ceram. Int. 2021, 47, 12768–12779. [Google Scholar] [CrossRef]

- Jiao, W.; Xia, Y.; Ma, H.; Zhu, Z.; Xia, S. Effect of running-in on the low-pressure tribological performance of valve plate pair in axial piston pumps. Wear 2023, 532, 205113. [Google Scholar] [CrossRef]

- Lou, D.; Yang, D.; Dong, C.; Chen, C.; Jiang, H.; Li, Q.; Liu, D. Enhancement of pool boiling heat transfer by laser texture-deposition on copper surface. Appl. Surf. Sci. 2024, 661, 160015. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, X.; ZHAO, W. Texture heat transfer mechanism and structure optimization of the outer Surface of mechanical seal moving ring. Tribology 2020, 40, 538–550. [Google Scholar]

- Yu, M.; Peng, X.; Meng, X.; Jiang, J.; Ma, Y. Influence of cavitation on the heat transfer of high-Speed mechanical seal with textured side wall. Lubricants 2023, 11, 378. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Amanov, A.; Tsuboi, R.; Oe, H.; Sasaki, S. The influence of bulges produced by laser surface texturing on the sliding friction and wear behavior. Tribol. Int. 2013, 60, 216–223. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Trib. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Effect of WEDM surface texturing on Al2O3/TiCN composite ceramic tools in dry cutting of hardened steel. Ceram. Int. 2018, 44, 2510–2523. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, J.; Meng, Y.; Yue, H. Tribological performance of steel guideway with biomimetic hexagonal micro-textures. Surf. Eng. 2020, 36, 756–764. [Google Scholar] [CrossRef]

- Li, C.; Yang, X.; Wang, S.; Wang, Y.; Lu, C.; Cao, J. Study on friction and lubrication characteristics of surface with unidirectional convergence texture. Coatings 2019, 9, 780. [Google Scholar] [CrossRef]

| Elements | Cu | Al | Fe | Ni | Mn |

|---|---|---|---|---|---|

| Content/wt% | Balance | 8.0–11.0 | 3.4–5.5 | 3.4–6.5 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Zhu, M.; Hu, X.; Liu, K.; Fan, X.; Meng, X.; Peng, X.; Wang, J. Synergistic Effect of Elliptic Textures and H-DLC Coatings for Enhancing the Tribological Performance of CuAl10Fe5Ni5 Valve Plate Surfaces. Coatings 2024, 14, 1161. https://doi.org/10.3390/coatings14091161

Wang M, Zhu M, Hu X, Liu K, Fan X, Meng X, Peng X, Wang J. Synergistic Effect of Elliptic Textures and H-DLC Coatings for Enhancing the Tribological Performance of CuAl10Fe5Ni5 Valve Plate Surfaces. Coatings. 2024; 14(9):1161. https://doi.org/10.3390/coatings14091161

Chicago/Turabian StyleWang, Mengjiao, Mingbo Zhu, Xinzheng Hu, Kun Liu, Xuefeng Fan, Xiangkai Meng, Xudong Peng, and Jinqing Wang. 2024. "Synergistic Effect of Elliptic Textures and H-DLC Coatings for Enhancing the Tribological Performance of CuAl10Fe5Ni5 Valve Plate Surfaces" Coatings 14, no. 9: 1161. https://doi.org/10.3390/coatings14091161