Abstract

Tomb No. 2 of Tushan in Xuzhou is the tomb of King Chu of the Eastern Han Dynasty, and it was an important archaeological discovery in China. The unique placement and crafting techniques of a lacquer coffin that was unearthed from the burial corridor are of significant importance in the study of tombs. In order to characterise the sample’s microstructure, elemental composition, and structural composition, as well as to study the crafting techniques of the coffin in the corridor, a range of analytical techniques were employed, including ultra-depth microscopy, scanning electron microscopy with SEM-EDS, Raman spectroscopy, FTIR, and XRD. The results indicate that the cross-sectional structure of the fragments comprises a pigment layer and a lacquer ash layer, with the latter being further divided into tile ash and bone ash layers. No lacquer film layer was observed. The primary colouring agent in the pigment layer was HgS, which contained a minor quantity of organic binder. The primary component of the tile ash layer was quartz, while the osseous ash layer comprised particles and collagen derived from mammalian bones. The lacquer crafting technique employed in the construction of the coffin was relatively simple and inconsistent with the assumption of it having a noble status. The findings of this research offer experimental data for the identification, preservation, and technical restoration of the corridor coffin in the future.

1. Introduction

Lacquerware, with its rich historical background and unique cultural value, represents one of the most significant examples of ancient Chinese craftsmanship. The earliest evidence of lacquerware can be traced back to the Neolithic period in China, approximately 8000 BCE [1], and artefacts of that period are being unearthed in archaeological sites along the Yangtze River basin. Over time, the techniques for lacquerware production gradually matured during the Shang and Zhou dynasties (circa 1600-256 BCE), and they reached their peak during the Warring States period and Han dynasty (circa 475 BCE-220 CE). The production of lacquerware in the Han dynasty reached unprecedented heights, marking the first significant peak in the history of lacquer craftsmanship [2]. Exquisite and diverse lacquerware items were widely used in daily life, religious rituals, and funerary practices. Over the centuries, the art of lacquerware continued to evolve and innovate, spreading through trade to the East and Southeast Asian countries, where it integrated with local cultures, thus becoming a key element of Asian artistry.

As time elapsed, the materials, structures, and techniques employed in the production of lacquerware underwent a substantial evolution. One of the principal methodologies for the study of excavated lacquerware artefacts was the initial analysis of the composition of the lacquer film. A number of researchers have employed a variety of modern analytical techniques in order to characterise lacquerware. For example, techniques such as FTIR, Py-GC-MS, and SEM-EDS have been employed to analyse Vietnamese and other lacquerware from Southeast Asia, identifying lacquers derived from three distinct tree species [3]. Furthermore, Raman spectroscopy and XRD have been utilised to identify the mineral pigments that were incorporated during lacquer production [4]. Instruments such as thermally assisted hydrolysis and methylation–gas chromatography/mass spectrometry (THM-GC/MS) and optical microscopy (OM) under visible (Vis) and ultraviolet (UV) light have been employed to identify the components of lacquer materials and their distribution within lacquer stratigraphy, thus facilitating the analysis of the original manufacturing techniques [5,6]. By employing modern analytical techniques in conjunction with historical research and document analysis, it is possible to elucidate the distinctive characteristics of lacquerware production, thereby enhancing and deepening our understanding of the technological evolution of ancient Chinese lacquer craftsmanship.

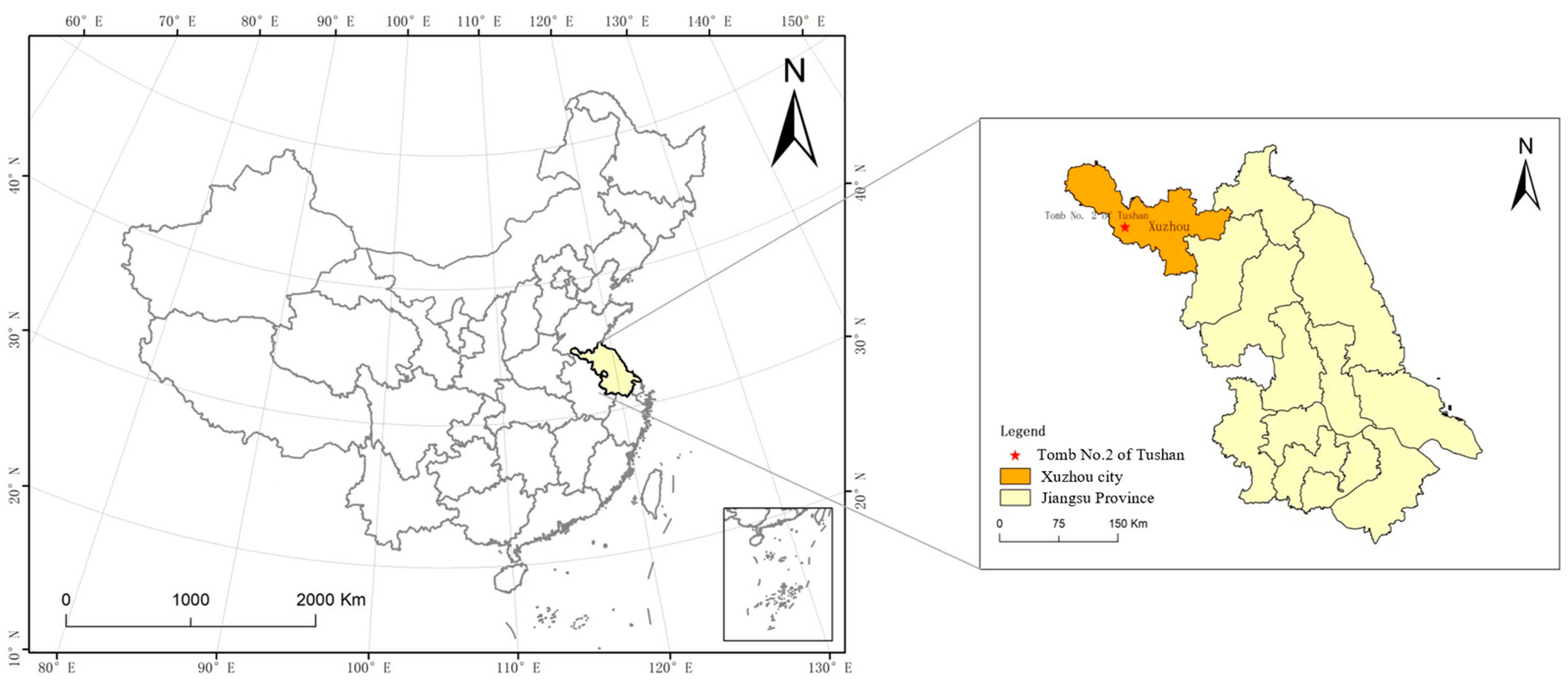

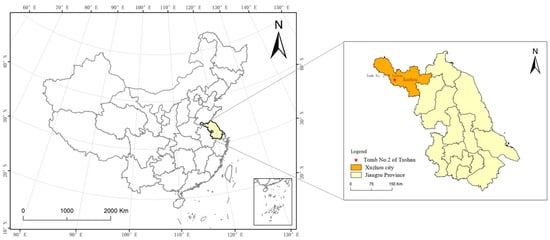

Xuzhou, situated in the northwestern region of Jiangsu Province, China, boasts a wealth of mineral resources and occupies a pivotal geographical location. Historically, it was one of the nine provinces in Han Dynasty, and it is regarded as the birthplace of Han culture. In 206 BC, the Chu State was established with its capital situated in the area that is now Xuzhou [7].

Tomb No. 2 of Tushan is situated at the northern foot of Yunlong Mountain in Xuzhou, and it represents the principal tomb of the Tushan Han tomb group (Figure 1). It is postulated that this may be the tomb of the first or second king of Chu, with an estimated age of approximately 2000 years. At present, it is the most well-preserved and information-rich, large-scale tomb of an Eastern Han dynasty feudal king that has been discovered in China, which has led to its designation as one of the “Top Ten Archaeological Discoveries in China for 2020”.

Figure 1.

Geographical location of Tomb No. 2 in Tushan, Xuzhou.

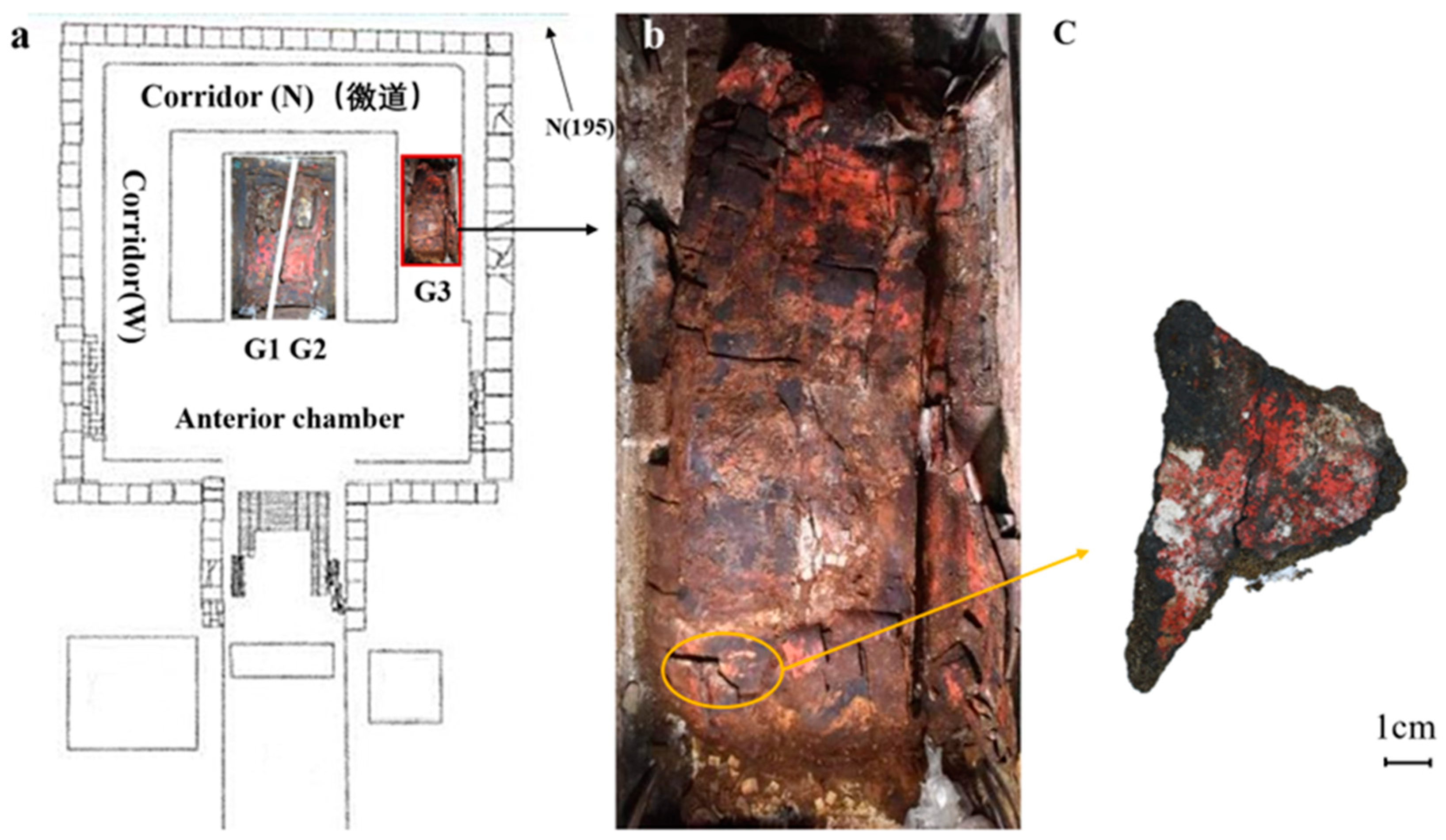

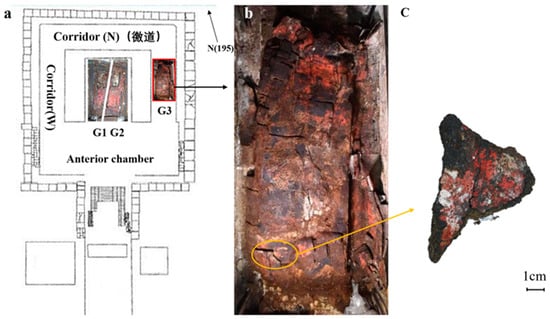

Three lacquered wooden coffins (G1, G2, and G3) were discovered at Tomb No. 2 of Tushan (Figure 2a). Two of the coffins (G1 and G2) were positioned in close proximity to one another within the rear chamber, suggesting that they were interred together; thus, they could have been a king and queen. In the eastern corridor of the tomb chamber, a single-layered coffin made by catalpa wood was discovered. It has been designated the “corridor coffin (徼道棺)” (G3) due to its unique placement. The corridor coffin was discovered in a state of severe deterioration, having collapsed into a flat shape. The wooden body was almost completely decayed, the lacquer layer was significantly broken, and the majority of the lacquer film was fragmented and deteriorated, exhibiting severe surface paint peeling and powdering (Figure 2b). This paper focuses on the lacquer film fragments of the corridor coffin from Tushan Tomb No. 2 (Figure 2c). The microstructure, elemental composition, and structural characteristics of the corridor coffin were analysed using ultra-depth microscopy, scanning electron microscopy–energy dispersive spectroscopy (SEM-EDS), Raman spectroscopy, Fourier-transform infrared spectroscopy (FTIR), and X-ray diffraction (XRD). This was performed to provide valuable insights into the conservation and restoration of lacquer-covered wooden coffins, as well as into the traditional Chinese funeral system.

Figure 2.

Position of the coffin and sample: (a) schematic diagram of the location of the coffin(G1,G2,G3 are the abbreviation for coffin number); (b) current excavation status of the coffin; and (c) the experimental sample.

2. Materials and Methods

2.1. Samples

The sample from the surface of the lacquer coffin was broken into pieces with irregular shapes, and it included all levels, from the pigment layer to the grey layer. The thickness was approximately 17 mm. It was taken from the southern end of the inner side of the lacquered coffin lid on the east side of Tomb No. 2 in Tushan (the elliptical position in Figure 2b).

2.2. Experimental Instruments and Methods

2.2.1. Ultra-Depth Microscope

A Zeiss Smartzoom5 (Oberkochen, Germany) ultra-depth microscope was employed for the observation of the surface and cross-section of the lacquer film samples. The specific testing conditions were as follows: magnification of 50× to 200×, with a built-in high-brightness LED transmission light and a ring light source. The surface, back, and cross-section of the sample was then observed.

2.2.2. Scanning Electron Microscope (SEM)

A Thermo Scientific Apreo S (Waltham, MA, USA) scanning electron microscope was employed for this purpose. The specific testing conditions included the use of a compound lens, an acceleration voltage of 8 kV, a low vacuum environment, a working distance of 15 mm, and carbon coating. The pigment layer and ground ash layer of the sample were observed separately.

2.2.3. X-ray Energy Dispersive Spectroscopy (EDS)

An X-MAX20 (Oxfordshire, UK) X-ray energy dispersive spectrometer was utilised for this purpose. The specific testing conditions were as follows: the SuperATW window had an active area of 20 mm2, a resolution of greater than 127 eV, and an analysis range encompassing elements from Be4 to U92. Elemental analysis at multiple sites on the pigment layer and ground ash layer of the sample was also performed.

2.2.4. X-ray Diffraction (XRD)

A D8 Advance (Bruker, Bremen, Germany) X-ray diffractometer was employed for this purpose. The specific testing conditions included the use of a copper target, a tube voltage of 40 kV, a tube current of 40 mA, a scanning speed of 0.2°/s, and a scanning range of 10° to 40°. The powder of the 5–8 mg ground ash layer sample was measured.

2.2.5. Fourier Transform Infrared Spectroscopy (FT-IR)

A LUMOS (Bruker, Bremen, Germany) Fourier transform infrared spectrometer was employed for this purpose. The specific testing conditions included a wavelength range of 4000 to 500 cm−1, 24 scans, and a resolution of 4 cm−1. Then, a 1~4 mg pigment layer, a tiled ash layer, and bone ash layer sample powders were prepared separately, which were then mixed and grinded with 200–400 mg of dry KBr for tablet preparation.

2.2.6. Micro-Raman Spectroscopy

An InVia micro-Raman spectrometer (Renishaw, Gloucestershire, UK) was employed for this purpose. The specific testing conditions included the use of a semiconductor laser with a wavelength of 780 nm, a grating of 1200 lines/mm, a scanning range of 100 to 1000 cm−1, an exposure time of 10 s, and a single scan. The objective lens was 50× and the spatial resolution was 1–2 μm. The pigment layer of the sample was then tested.

3. Results and Discussion

3.1. Structural Composition Analysis

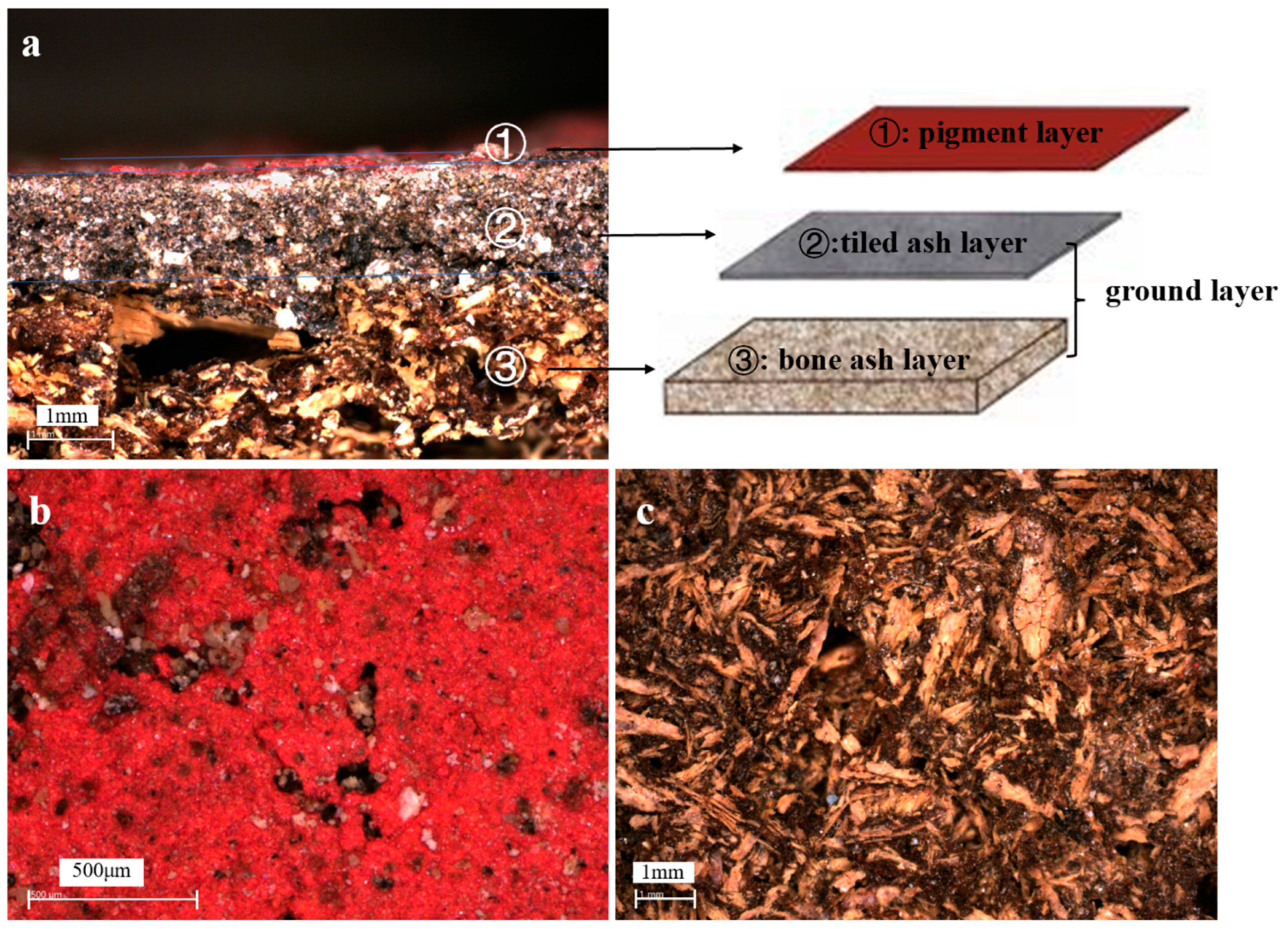

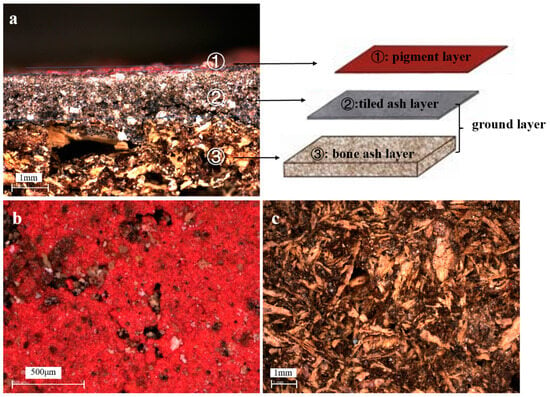

At 50× magnification, the lacquer film structure was composed of a pigment layer and a ground layer (Figure 3a), with the pigment layer being a single layer with an average thickness of 0.2 mm. The ground layer had a dual-layer structure, comprising a tile ash layer and a bone ash layer. The tile ash layer was predominantly composed of grey-black clay tile ash, with an average thickness of 1.73 mm. The bone ash layer was relatively thick, with an average thickness of 15 mm. At 200× magnification, the pigment layer surface displayed a vibrant colouration, with finely textured painted areas being interspersed with white particulate deposits. The pigment layer structure was observed as being loose, with evidence of debris detachment (Figure 3b). The wood substrate of the sample was severely decayed, and the cross-sectional micrograph indicated that the lacquer ash layer had become detached from the substrate, leaving only wood traces. The bone ash layer featured a substantial presence of light yellow flaky bone particles within the ash (Figure 3c). It is noteworthy that no transitional lacquer film layer was present between the pigment layer and the lacquer ash layer, which differed from previously unearthed lacquer films.

Figure 3.

Microscopic observation of the sample’s structure: (a) microscopic observation of a cross-section of the sample; (b) microscopic observation of the sample’s front; and (c) microscopic observation of the sample’s bottom.

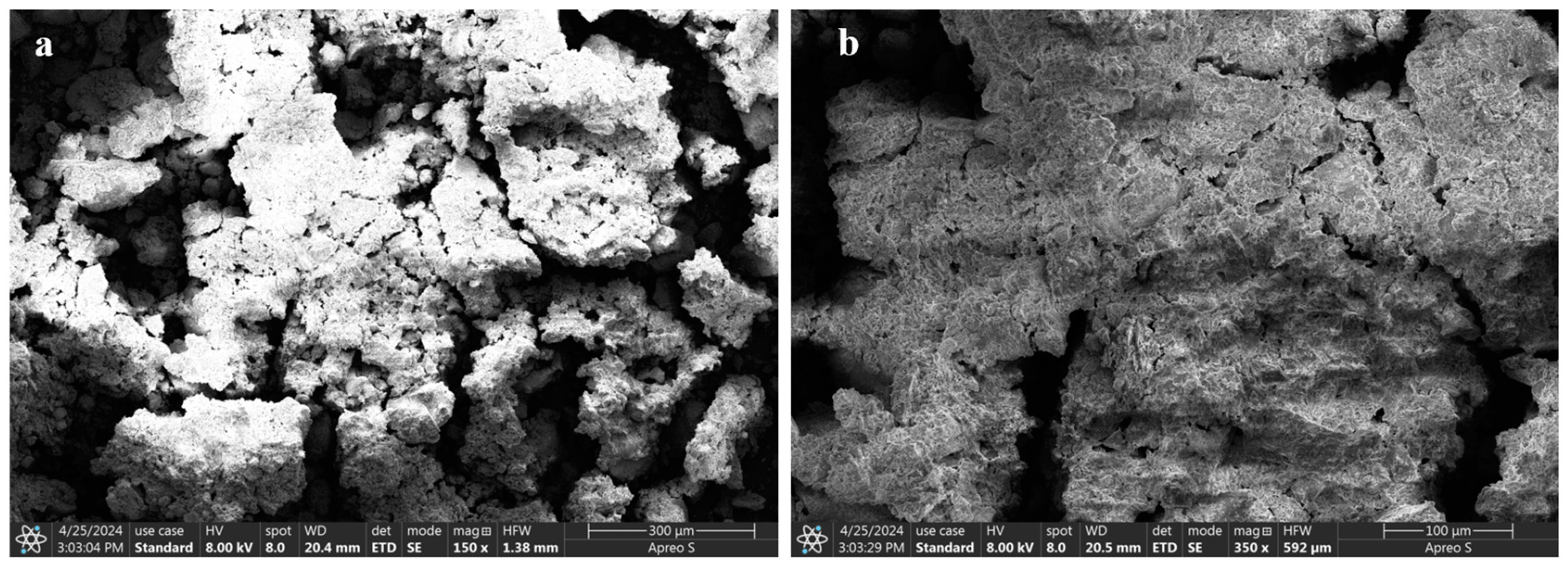

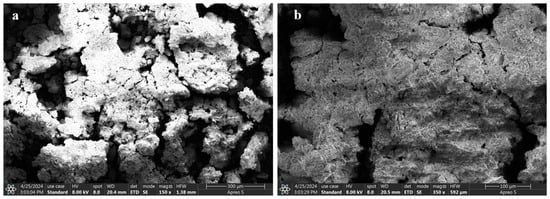

3.2. Pigment Layer Analysis

The results, as illustrated in Figure 4, indicate that the pigment layer has a loose surface structure with numerous fine cracks, within which some particulate matter was embedded, suggesting poor preservation. The EDS analysis (Table 1) revealed that the pigment layer contained significant amounts of mercury and sulphur, with concentrations of 34.6% and 7.1%, respectively. This led to the conclusion that the red pigment is cinnabar (HgS). The elevated levels of carbon and oxygen were presumably attributable to the residual organic binders employed in the manufacturing of the pigment layer [8].

Figure 4.

Microscopic observation of the pigment layer: (a) magnification factor 150×; (b) magnification factor 800×.

Table 1.

Elemental analysis results of the pigment layer (wt%).

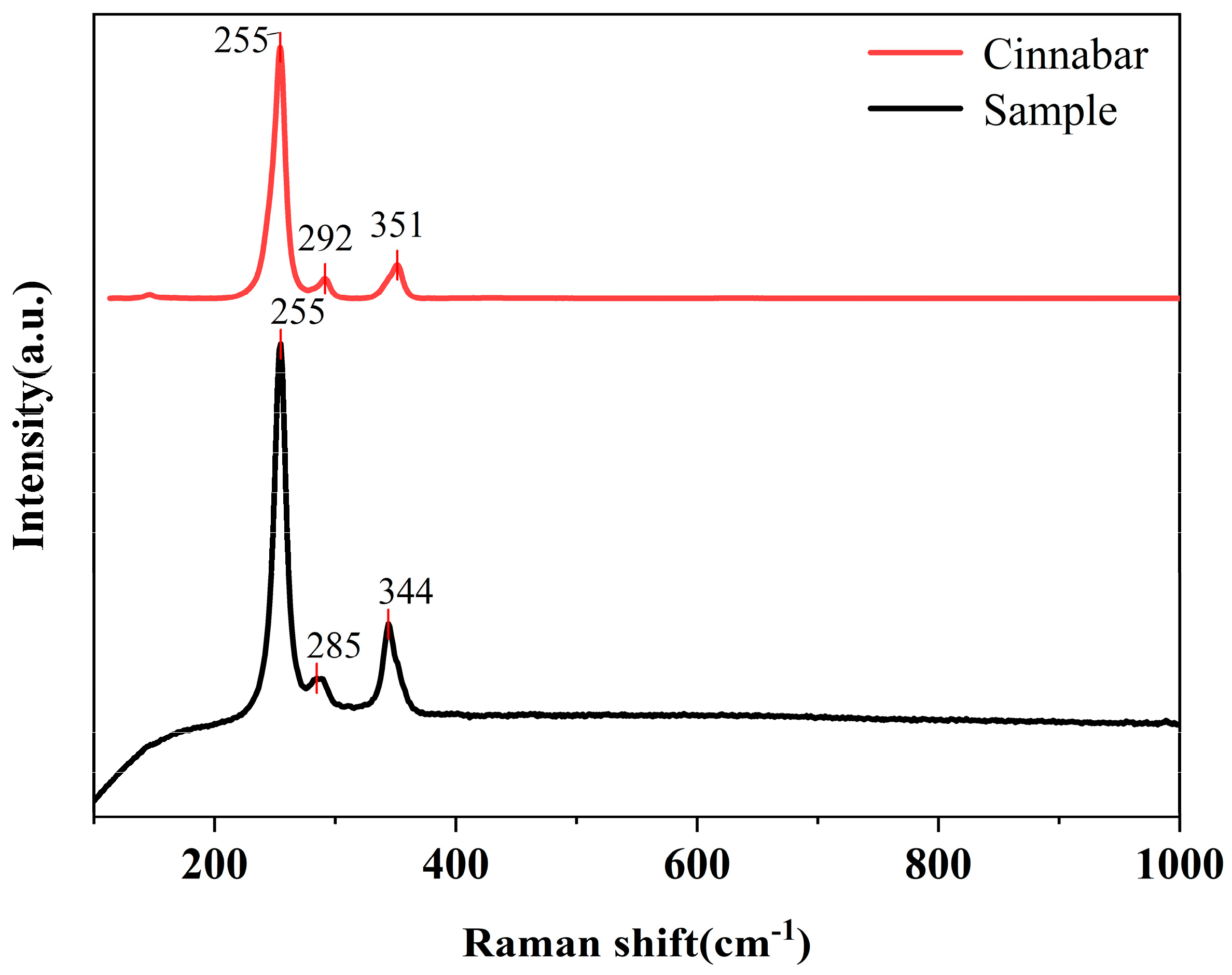

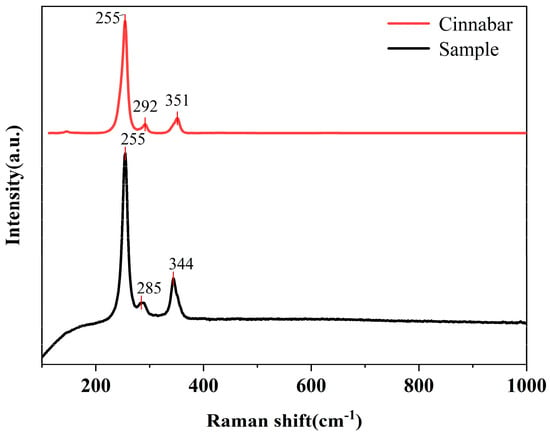

As illustrated in Figure 5, the three distinctive peaks at 255 cm−1, 285 cm−1, and 344 cm−1 exhibited a high degree of similarity to the Raman scattering peaks of the cinnabar (HgS) standard sample (255 cm−1, 291 cm−1, and 351 cm−1) [9]. This corroborates the hypothesis that the red pigmentation observed in the layer is cinnabar (HgS). This conclusion is also consistent with the results obtained from the EDS analysis.

Figure 5.

The Raman spectrum of the pigment layer.

3.3. Analysis of the Lacquer Ash Layer

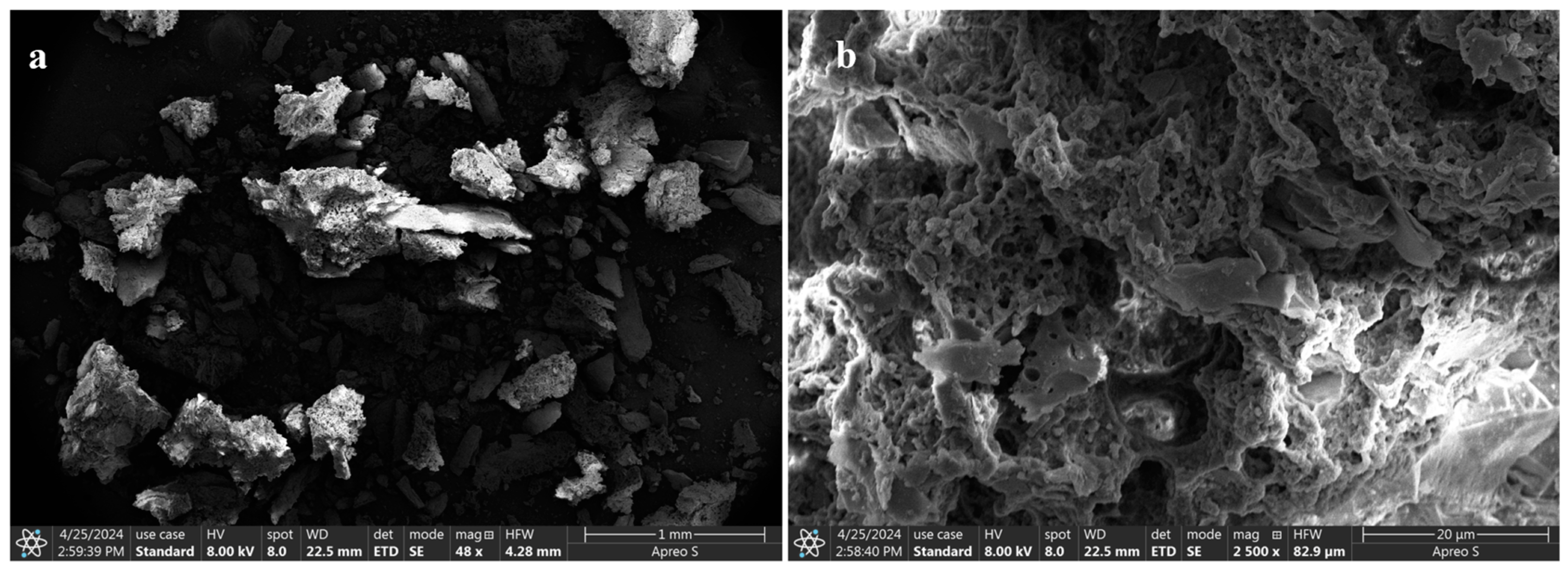

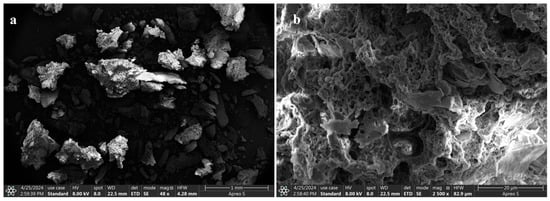

The SEM images (Figure 6a) demonstrate that the lacquer ash layer is characterised, with evidence of significant ageing, by an internal structure that is loose and porous. The layer contains a multitude of irregular prismatic and blocky particles, some of which are flat (Figure 6b), indicating the possibility of bone particles or bone matrix incorporation during the lacquer ash preparation [10]. The EDS analysis results (Table 2) demonstrate that the sample contains a substantial quantity of calcium and a moderate amount of phosphorus, with concentrations of 14.4% and 4.6%, respectively. In light of the preceding research findings indicating the prevalence of bone powder (hydroxyapatite) in the lacquer ash from Han dynasty lacquerware [11,12,13], it can be inferred that the irregular prismatic particles distributed within the ground layer are hydroxyapatite (Ca10(PO4)6(OH)2).

Figure 6.

Microscopic observation of the lacquer ash layer: (a) magnification factor 48×; (b) magnification factor 2500×.

Table 2.

Elemental analysis results of the lacquer ash layer (wt%).

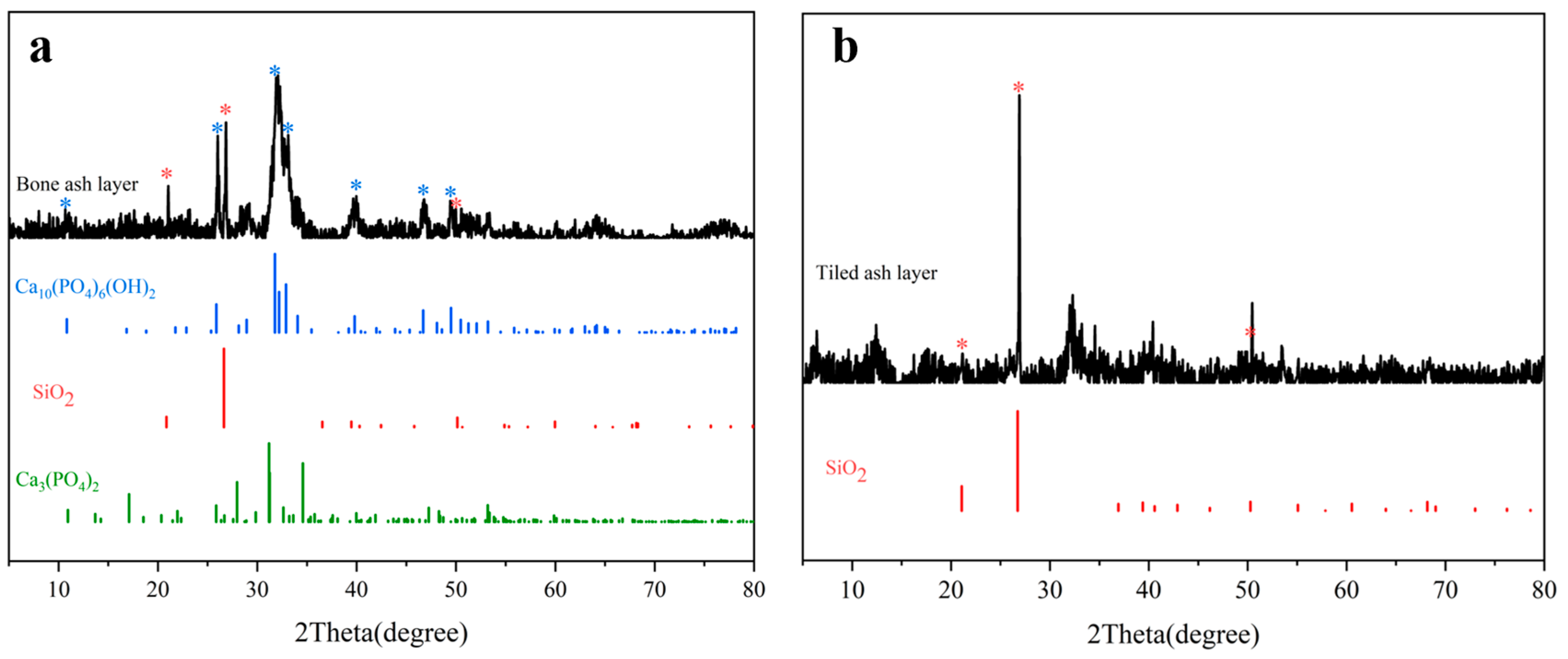

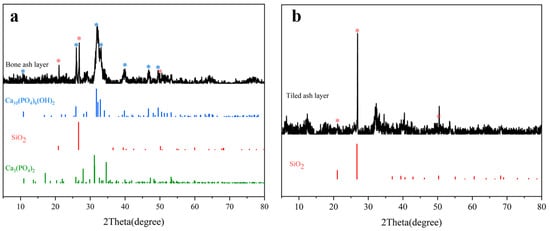

To further investigate the composition of the lacquer ash and confirm the addition of bone powder, XRD was employed to test the sample’s ground ash layer. The test results demonstrate that the bone ash layer displayed distinct diffraction peaks of quartz (SiO2) and hydroxyapatite (Ca10(PO4)6(OH)2) (Figure 7a) [14,15], which are consistent with the EDS analysis results. The hydroxyapatite (Ca10(PO4)6(OH)2) content was relatively high, representing 76.6% of the total composition, while the SiO2 content was 23.4%. The primary constituent of the tile ash layer was SiO2 (quartz) (Figure 7b).

Figure 7.

The XRD patterns: (a) bone ash layer(‘*’ Corresponding to the characteristic peak of SiO2; ‘*’ Corresponding to the characteristic peak of Ca10(PO4)6(OH)2); (b) tiled ash layer(‘*’ Corresponding to the characteristic peak of SiO2).

As documented in the extant literature, bone material was incorporated into the lacquer ash liquid during the production of lacquerware in the Han dynasty. This was performed to reinforce the substrate and to facilitate shaping, with the bone serving as a skeletal filler [16]. The main component of the bone was hydroxyapatite, which is mainly extracted from animal bones and minerals and is usually obtained by burning bones. However, according to Figure 7a, the XRD test results of the bone ash layer did not show the characteristic peak of the calcium phosphate. Therefore, it was speculated that hydroxyapatite was directly used in the production process of the bone ash layer without firing treatment, or the temperature during firing of the bone was low, which resulted in incomplete thermal degradation of the hydroxyapatite, meaning that the components of the hydroxyapatite were mainly retained. Historical records indicate that, due to the high viscosity of the coating, ancient artisans added clay minerals that contained quartz as a filler in the coating to facilitate application and to embed or bond the pigment layer with the bone ash layer [17]. The test results corroborate the assertion that the primary constituents of the bone ash layer were bone powder and quartz while the main component of the tile ash layer was quartz.

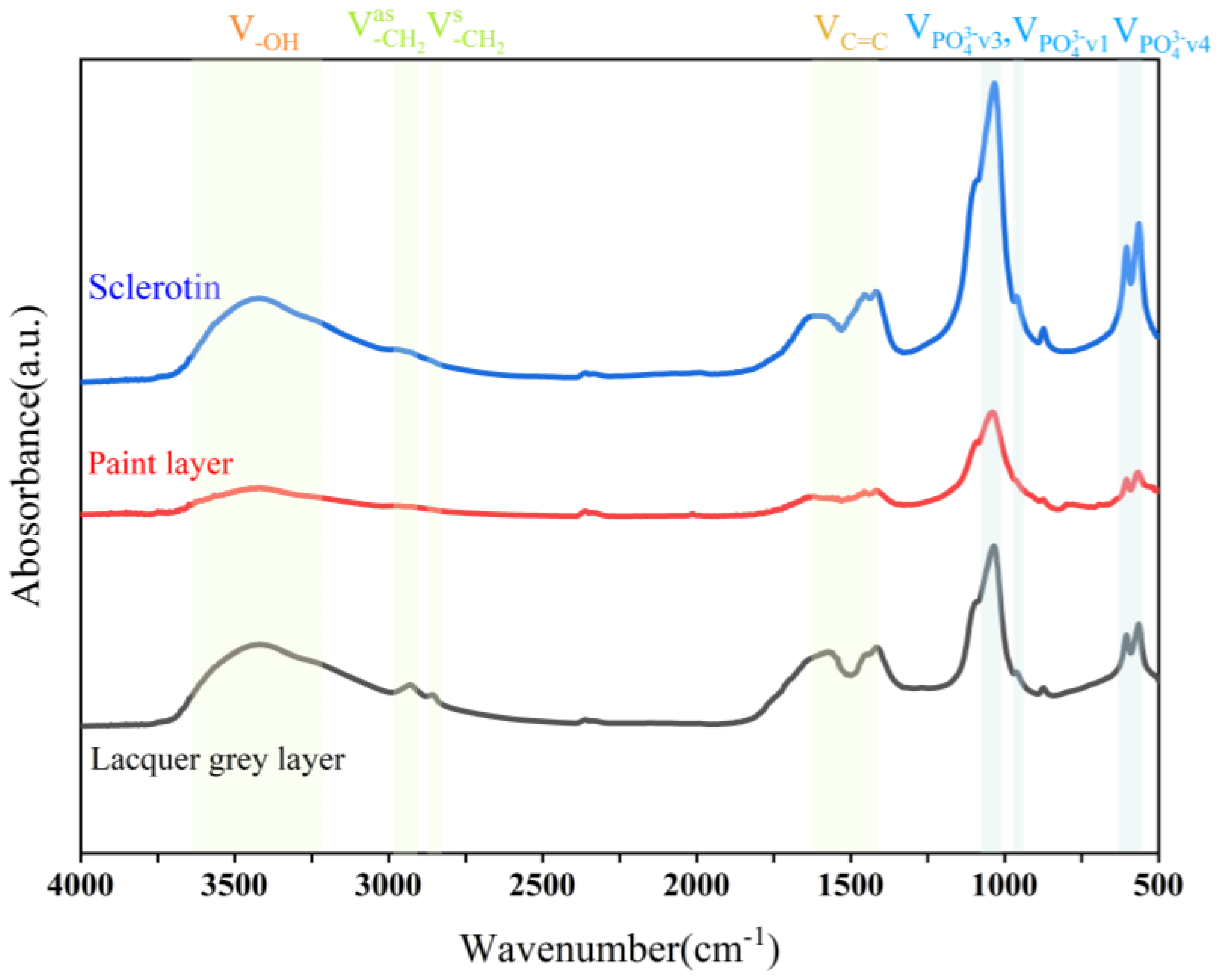

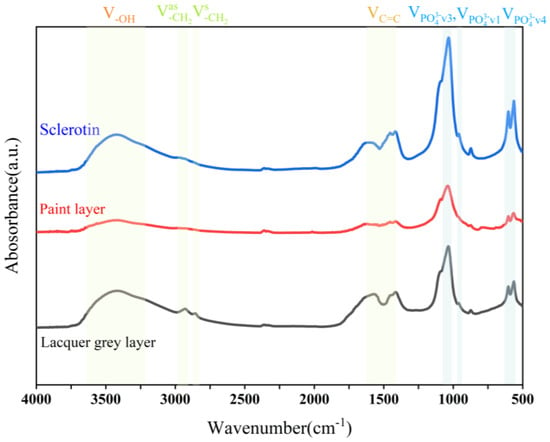

The infrared spectroscopy results of the lacquer’s ash layer, as illustrated in Figure 8, demonstrate the presence of a broad and intense absorption peak at approximately 3420 cm−1. This peak can be attributed to the hydroxyl group (-OH) absorption peak on the benzene ring, which falls within the range of 3200 cm−1 to 3600 cm−1 [18]. The absorption peaks at 2929 cm−1 and 2855 cm−1 were attributed to the asymmetric and symmetric stretching vibrations of the methylene groups, respectively [19]. The absorption peak at 1575 cm−1 was attributed to the C-C stretching vibration absorption band of the benzene ring (1450 cm−1 to 1650 cm−1), or it could be the absorption of water molecules [20]. In light of the characteristic functional groups corresponding to these peaks and the findings of previous infrared spectrum studies of lacquer coatings, it can be inferred that the lacquer ash layer in the sample was mixed with raw lacquer or drying oil during its preparation [21]. In contrast, the infrared spectrum of the pigment layer displayed less pronounced peaks that corresponded to the aforementioned lacquer substances. The hydroxyl characteristic peak of the lacquer benzene ring was of lower intensity, and the absorption intensity of the benzene ring at 1712 cm−1 was weaker than that at 1622 cm−1, indicating the absence of tung oil in the pigment layer [22]. This is the primary reason for the severe peeling and powdering of the pigment layer, which resulted in poor preservation. The presence of other organic substances in smaller amounts cannot be ruled out, but their specific identities remain unclear. They may include lacquer or other drying oils. Compared with fresh lacquer film, the C-H mode intensity was less than the O-H modes of the sample paint layer and the lacquer’s grey layer, indicating that the degradation of the paint was very strong and that the mineral part was the majority [23,24].

Figure 8.

The infrared spectrum of the sample.

Additionally, the infrared absorption spectrum of the lacquer ash layer exhibited distinctive peaks that were characteristic of bone material, specifically hydroxyapatite. To further identify the type of bone present in the lacquer ash, a small quantity of bone particles was isolated and subjected to infrared spectroscopy analysis. The results demonstrated that the characteristic peaks of the hydroxyapatite in the isolated bone material at 1033 cm−1, 961 cm−1, 602 cm−1, and 563 cm−1 were sharper and exhibited higher absorption intensities when compared to the infrared spectrum of the lacquer ash layer. In particular, the peaks at 602 cm−1 and 563 cm−1 were ascribed to the PO43− v4 vibrational absorption, 961 cm−1 to the PO43− v1 vibrational absorption, and 1033 cm−1 to the PO43− v3 vibrational absorption [25,26]. A review of the literature revealed that these distinctive peaks are consistent with the infrared absorption spectrum characteristics of mammalian hard tissues [27]. Nevertheless, the precise identification of the mammalian species from which the bone material originated will necessitate more detailed detection and analysis in future studies.

Based on a comprehensive analysis of the aforementioned detection results, the lacquer film of the corridor coffin can be categorised into two main layers: the pigment layer and the lacquer ash layer. The ground layer comprises a dual-layer structure of tile ash and bone ash. The lacquering process for this coffin entailed a minimum of three pivotal stages. The initial stage of the lacquering process involved the application of a substantial layer of coarse lacquer ash, predominantly comprising raw lacquer blended with bone keratin. Subsequently, a tile ash layer was applied and was mixed with fine quartz particles as the primary filler. The bone ash layer beneath served to augment the thickness and strength of the lacquer film, while the tile ash layer above provided a smooth surface for the application of pigments. No intermediate lacquer film layer was present between the tile ash layer and the pigment layer. Instead, a red pigment layer, primarily composed of cinnabar, was directly applied to the tile ash layer for decorative purposes.

Historical records indicate that the aforementioned lacquerware technique had already emerged and been utilised during the Warring States period. This is evidenced by items such as the armour, lacquer zither, and lacquered coffin from the tomb of Marquis Yi of Zeng, which features multiple layers of grey undercoating and 1–2 layers of red lacquer on the surface [28,29]. However, in contrast to other aristocratic lacquer funerary objects that have been unearthed since the Han Dynasty [30,31,32], the lacquer and pigment layers of this particular coffin were applied in a single layer, without the complex stratification seen in the sample of this study. The pigment layer was relatively thin, exhibiting no indications of sophisticated techniques such as carved or piled lacquer. However, the grey undercoating layer was thicker than those observed in previously unearthed lacquer films. It is noteworthy that the coffin lacks the protective lacquer film commonly found on such items, which is surprising given the aristocratic status of the coffin’s owner. Historically, the burial objects found in noble tombs were not only symbols of the deceased’s status, but also showcased the highest level of craftsmanship of the time. The choice of this simpler manufacturing technique, therefore, presents a stark contrast to the noble status of the coffin’s owner.

4. Conclusions

This study focused on the lacquer film fragments from the corridor coffin unearthed in Tomb No. 2 of Tushan. A comprehensive analysis was conducted utilising a range of techniques, including ultra-depth-of-field microscopy, scanning electron microscopy with energy-dispersive spectroscopy (SEM-EDS), Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), and Raman spectroscopy. The results indicate the following.

(1) The lacquer film structure comprises a pigment layer and a lacquer ash undercoating layer, which is further divided into a tile ash layer and a bone ash layer, thus forming a dual-layer structure. A transitional lacquer film layer was absent between the pigment layer and the lacquer ash layer, with the bone ash layer being notably thick.

(2) The surface structure of the lacquer film sample was observed as being loose, porous, and containing numerous small cracks. The primary chromogenic substance present in the pigment layer was cinnabar (HgS). The principal constituent of the tile grey layer was quartz, whereas the bone ash layer was predominantly composed of hydroxyapatite and quartz. The degradation of lacquer was severe, and the main residual parts were inorganic minerals.

(3) The lacquered coffin was crafted using a single-layer lacquering technique. The ground layer consisted of a thick coating of ash, where the lacquer served as a binding material. This layer included a mixture of clay-like substances (quartz) and mammalian bone and keratin. On top of this, a layer of tile ash material, primarily composed of quartz, was applied. This was followed by a pigment layer made from red cinnabar. No tung oil was detected, suggesting that other organic coatings might have been added (though in minimal amounts). Notably, the lacquer film, typically used as a protective layer for the coffin, was absent. Considering the noble status of the coffin’s owner, the craftsmanship appeared relatively simple.

This study presents a comprehensive analysis of the composition and manufacturing techniques employed in the production of the lacquer film from the corridor coffin unearthed in Tomb No. 2 of Tushan. The findings provide valuable insights into the craftsmanship of the excavated artefacts and serve as a reference point for future conservation and restoration efforts. Subsequent research will concentrate on the identification of the organic substances present in the pigment layer and the sources of the bone residues observed in the bone ash layer.

Author Contributions

Z.L.: investigation, data curation, writing—original draft, and writing—review and editing. X.L.: writing—review and supervision. J.Y.: visualization. Y.S.: writing—original draft and investigation. J.G.: visualization and investigation. X.Z.: resources, supervision, and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (52203126); the Key Research and Development Plan of Shaanxi Province (2022SF321); the Projects of the Social Science Foundation of Shaanxi Province (2021G001); the Shaanxi Province Youth Science and Technology Rising Star Project (2024ZC-KJXX-033); and the National Key Cultural Relics Protection Special Fund Subsidy Project (22-5-13-3200-314).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used and/or analysed during the current study are available from the first author on reasonable request.

Acknowledgments

The authors would like to thank Feng Yuan, from the Xuzhou Museum, and Xiaowei Zhao, from the Xuzhou Museum Cultural Protection Technology Center, for their support of this research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chang, J.; Schilling, M.R. Reconstructing lacquer technology through Chinese classical texts. Stud. Conserv. 2016, 61, 38–44. [Google Scholar] [CrossRef]

- Fang, L. Ceramics of the Qin and Han Dynasties the History of Chinese Ceramics; Springer Nature Singapore: Singapore, 2023; pp. 127–177. [Google Scholar]

- Szczepanowska, H.; Ploeger, R. The Chemical analysis of southeast asian lacquers collected from forests and workshops in Vietnam, Cambodia, and Myanmar. J. Cult. Herit. 2019, 40, 215–225. [Google Scholar] [CrossRef]

- Colomban, P.; Mancini, D. Lacquerware pigment identification with fixed and mobile raman microspectrometers: A potential technique to differentiate original fake artworks. Arts 2013, 2, 111–123. [Google Scholar] [CrossRef]

- Pintus, V.; Baragona, J.; Wieland, K.; Miklin-Kniefacz, S.; Haisch, C.; Schreiner, M. Comprehensive multi-analytical investigations on the Vietnamese lacquered wall-panel “The Return of the Hunters” by Jean Dunand. Sci. Rep. 2019, 9, 18837. [Google Scholar] [CrossRef]

- Huang, Y.; Fu, Y.C.; Shen, D.; Lindahl, K.; Wei, S. Characterization and identification of an archaeological “lacquer” pipe. Herit. Sci. 2024, 12, 142. [Google Scholar] [CrossRef]

- Liu, Y. Archaeological Manifestations of Rank and Status, the Wooden Chamber Tombs in the Mid-Yangzi Region (206 BC-AD 25). Ph.D. Thesis, University of Oxford, Oxfordshire, UK, 2015. [Google Scholar]

- Zheng, L.; Wang, L.; Zhao, X.; Xi, K.Z.; Wu, X.Z.; Fan, X.P. Characterization of the Materials and Techniques of Red Lacquer Painting of a Horizontal Plaque Inscribed by General Feng Yü-hsiang. Coatings 2023, 13, 583. [Google Scholar] [CrossRef]

- Scovil, J. A mineral excursion to China: 2004. Rocks Miner. 2005, 80, 12–22. [Google Scholar] [CrossRef]

- Hao, X.Y.; Wang, X.; Zhao, Y.; Tong, T.; Gong, Y.X. Identification of minerals and mineral pigments in lacquer by the comprehensive comparative analysis of spectroscopy information. Spectrosc. Lett. 2021, 54, 446–457. [Google Scholar] [CrossRef]

- Li, T.; Xie, Y.F.; Yang, Y.M.; Yang, Y.M.; Wang, C.S.; Fang, X.Y.; Shi, J.L.; He, Q.J. Pigment identification and decoration analysis of a 5th century Chinese lacquer painting screen: A micro-Raman and FTIR study. J. Raman. Spectrosc. 2009, 40, 1911–1918. [Google Scholar] [CrossRef]

- Wang, R.; Nie, F.; Chen, J.M.; Li, Y.F. Studies on the Ground Layer of Lacquerwares from Between the Mid-Warring States Period and the Mid-Western Han Dynasty Unearthed in the Changsha Region. Archaeometry 2017, 59, 105–120. [Google Scholar] [CrossRef]

- Jin, P.J.; Liu, C.H.; Zhu, J.X. Preliminary study on the lacquers Unearthed from T23 of No. 1 in terracotta warrior and horse figure pit. New Comments Conserv. Cult. Relics 2012, 3, 144–150. [Google Scholar]

- Zhao, H.X.; Li, Q.H.; Liu, S.; Hu, Y.Q.; Gan, F.X. Nondestructive analysis of jade artifacts from the Cemetery of the Ying State in Henan Province, China using confocal Raman microspectroscopy and portable X-ray fluorescence spectroscopy. J. Raman. Spectrosc. 2014, 45, 173–178. [Google Scholar] [CrossRef]

- Paterlini, V.; Bettinelli, M.; Rizzi, R.; El Khouri, K.A.; Rossi, M.; Della Ventura, G.; Capitelli, F. Characterization and luminescence of Eu3+-and Gd3+-doped hydroxyapatite Ca10(PO4)6(OH)2. Crystals 2020, 10, 806. [Google Scholar] [CrossRef]

- Sung, M.; Jung, J.; Lu, R.; Miyakoshi, T. Study of historical Chinese lacquer culture and technology–Analysis of Chinese Qin-Han dynasty lacquerware. J. Cult. Herit. 2016, 21, 889–893. [Google Scholar] [CrossRef]

- Jin, P.J.; Hu, Y.L.; Ke, Z.B. Characterization of lacquer films from the middle and late Chinese warring states period 476–221BC. Microsc. Res. Tech. 2017, 80, 1344–1350. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.R.; Xu, Y.L.; Lin, J.H. UV-induced polymerization of urushiol. II: Effects of hydrogenation degree of urushiol on surface morphology. Prog. Org. Coat 2010, 67, 365–369. [Google Scholar] [CrossRef]

- Liu, X.Y.; Lv, M.Q.; Liu, M.; Wu, Z.H.; Lv, J.H. Characterization and identification of lacquer films from the Qin and Han Dynasties. BioResources 2019, 14, 9509–9517. [Google Scholar] [CrossRef]

- Yang, J.H.; Zhu, J.F.; Liu, W.H.; Deng, J.P.; Ding, Y.Y. Prepolymerization of lacquer sap under pure oxygen atmosphere and its effects on the properties of lacquer film. Int. J. Polym. Sci. 2015, 2015, 517202. [Google Scholar] [CrossRef]

- Fu, Y.C.; Chen, Z.F.; Zhou, S.L.; Wei, S.Y. Comparative study of the materials and lacquering techniques of the lacquer objects from Warring States Period China. J. Archaeol. Sci. 2020, 114, 105060. [Google Scholar] [CrossRef]

- Li, X.Y.; Wu, X.J.; Zhao, Y.; Wen, Q.Y.; Xie, Z.B.; Yuan, Y.H.; Tong, T.; Shen, X.Y.; Tong, H. Composition/structure and lacquering craft analysis of Wenzhou Song dynasty lacquerware. Anal. Methods 2016, 8, 6529–6536. [Google Scholar] [CrossRef]

- Ion, R.-M.; Iancu, L.; Grigorescu, R.M.; Slamnoiu-Teodorescu, S.; Dulama, I.; Bucurica, L.A. Degradation Products Assessment of the Wooden Painted Surfaces from a XVIIth Heritage Monastery. Appl. Sci. 2023, 13, 2124. [Google Scholar] [CrossRef]

- Pagnin, L.; Calvin, R.; Wiesinger, R.; Weber, J.; Schreiner, M. Photodegradation kinetics of alkyd paints: The influence of varying amounts of inorganic pigments on the stability of the synthetic binder. Front. Mater. 2020, 7, 600887. [Google Scholar] [CrossRef]

- Ildefonse, P.; Morin, G. Chemical and structural changes in Cervus elaphus tooth enamels during fossilization (Lazaret cave): A combined IR and XRD Rietveld analysis. Appl. Geochem. 1995, 10, 145–159. [Google Scholar]

- Miller, L.M.; Vairavamurthy, V.; Chance, M.R.; Mendelsohn, R.; Paschalis, E.P.; Betts, F.; Boskey, A.L. In situ analysis of mineral content and crystallinity in bone using infrared micro-spectroscopy of the ν4 PO43− vibration. BBA-Gen Subj. 2001, 1527, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Turner-Walker, G.; Xu, B.Y. Identification of animal hard tissues using Fourier transform infrared spectroscopy, Natural History collections. In Proceedings of the Preprints ICOM-CC 17th Triennial Conference, Melbourne, Australia, 15 September 2014. [Google Scholar]

- Wu, M.; Zhang, Y.F.; Zhang, B.J.; Li, L. Study of colored lacquerwares from Zenghou Yi Tomb in early Warring States. New J. Chem. 2021, 45, 9434–9442. [Google Scholar] [CrossRef]

- Chen, D. The Design Aesthetics of Lacquerware in the Han Dynasty. International Conference on Education, Language, Art and Intercultural Communication (ICELAIC-14); Atlantis Press: Amsterdam, The Netherlands, 2014; pp. 526–530. [Google Scholar]

- Wei, S.Y.; Pintus, V.; Pitthard, V.; Schreiner, M.; Song, G.D. Analytical characterization of lacquer objects excavated from a Chu tomb in China. J. Archaeol. Sci. 2011, 38, 2667–2674. [Google Scholar] [CrossRef]

- Yang, J. The underground luxury of a Western Han Marquis: Major discoveries from the tomb of the Marquis of Haihun in Nanchang. Asian Archaeol. 2019, 2, 65–102. [Google Scholar] [CrossRef]

- Ma, X.; Shi, Y.; Khanjian, H.; Schilling, M.; Li, M.; Fang, H.; Cui, D.; Kakoulli, l. Characterization of early imperial lacquerware from the luozhuang Han tomb, China. Archaeometry 2017, 59, 121–132. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).