Stiffness Degradation of Expansive Soil Stabilized with Construction and Demolition Waste Under Wetting–Drying Cycles

Abstract

1. Introduction

2. Materials and Methods

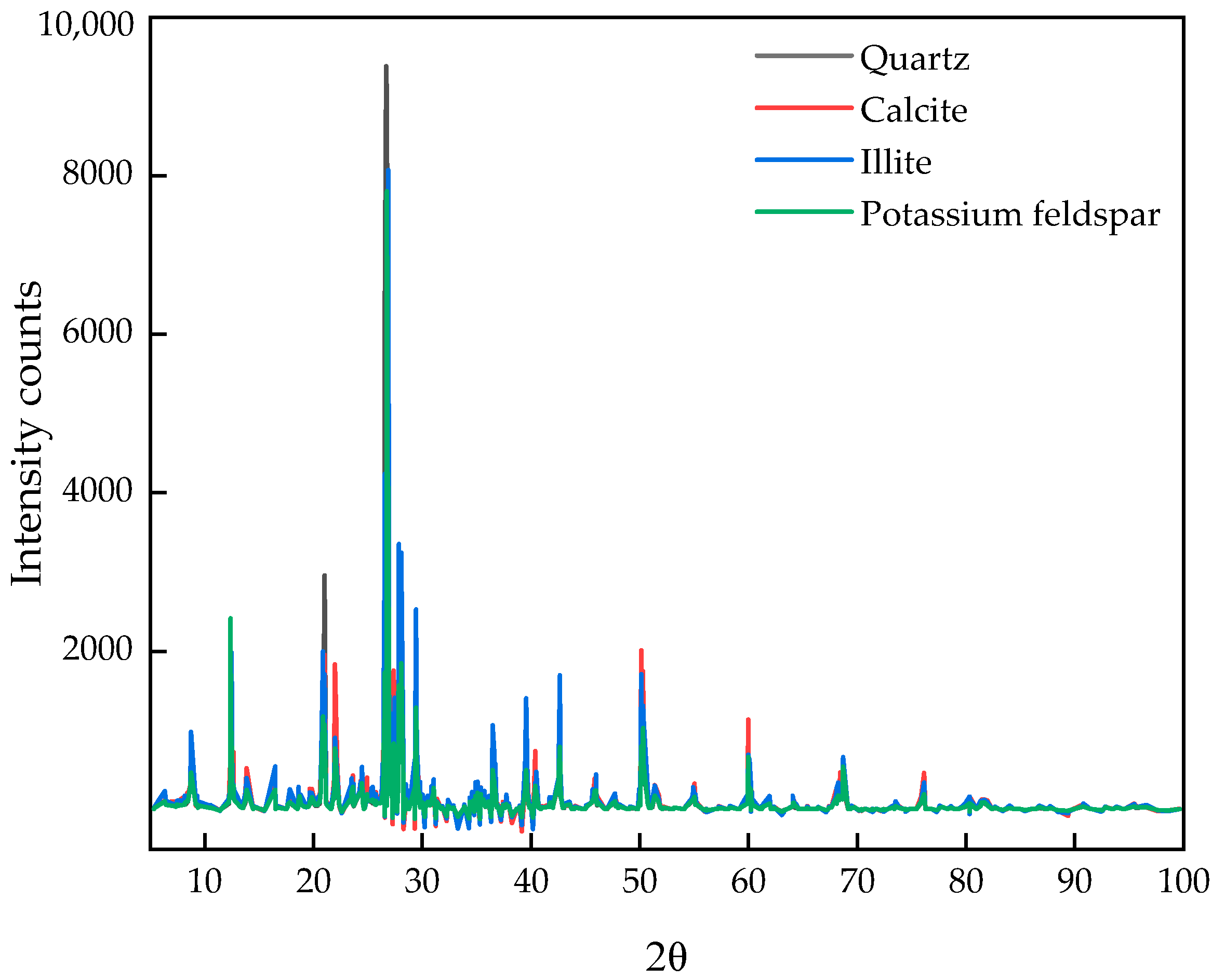

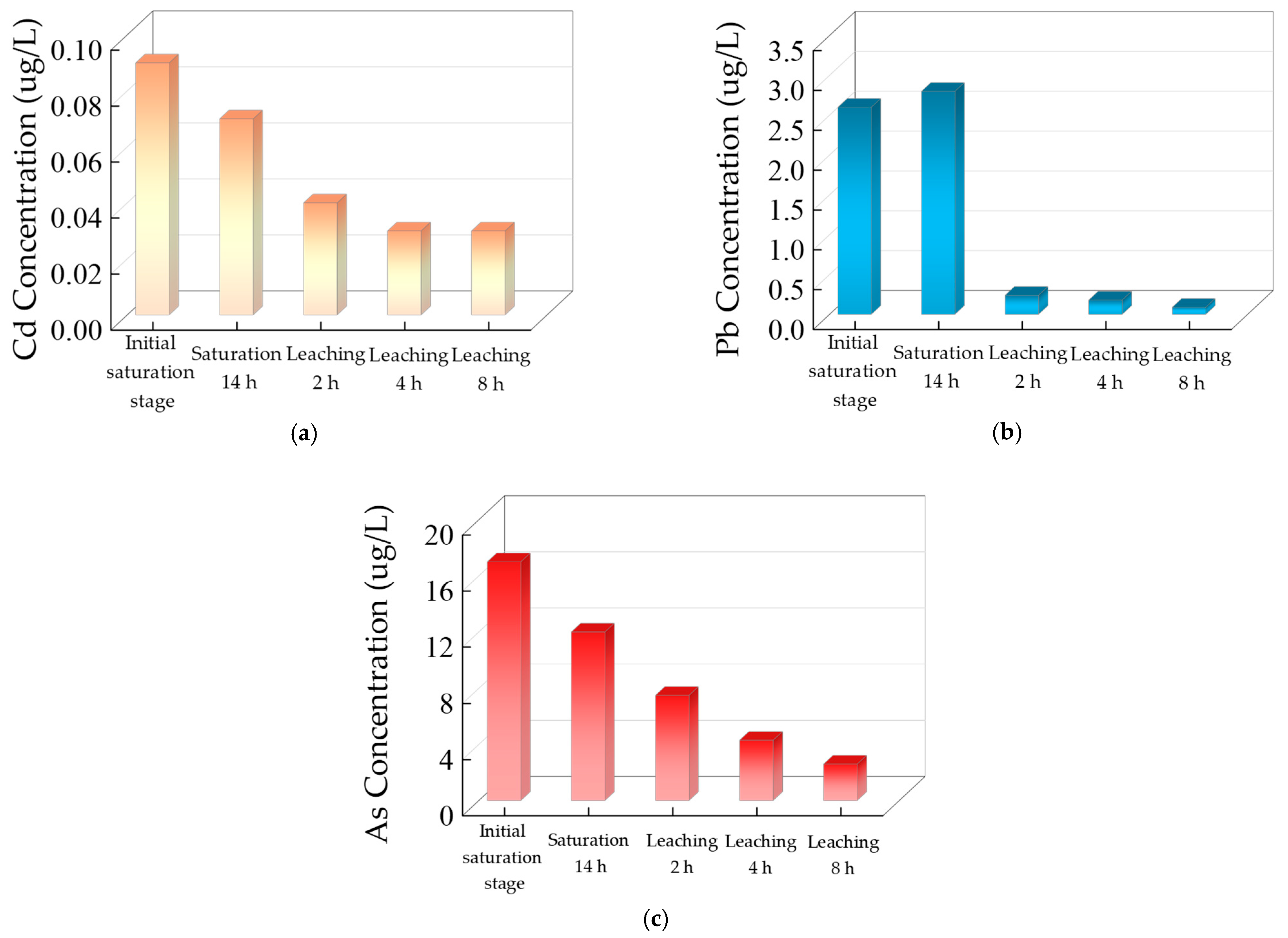

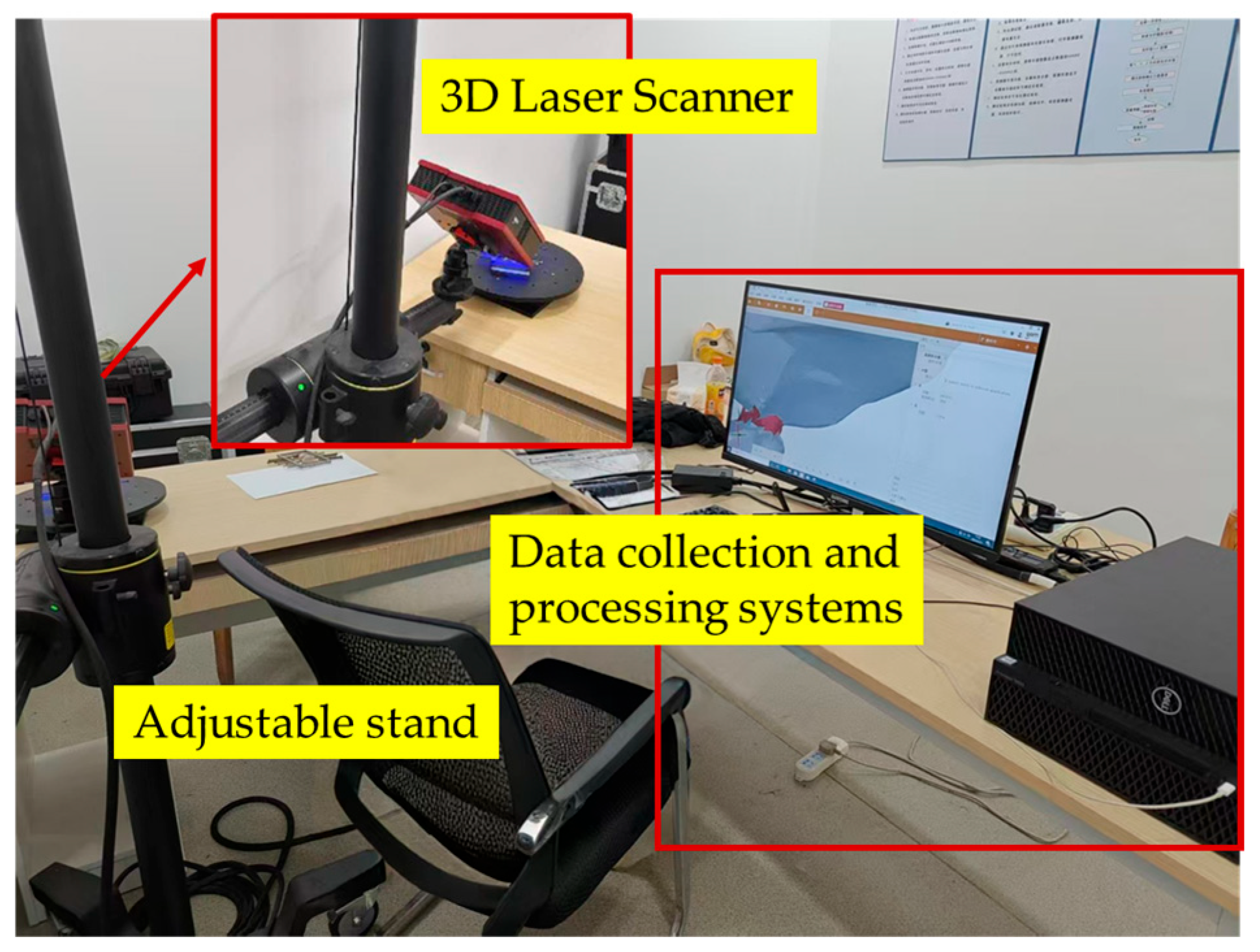

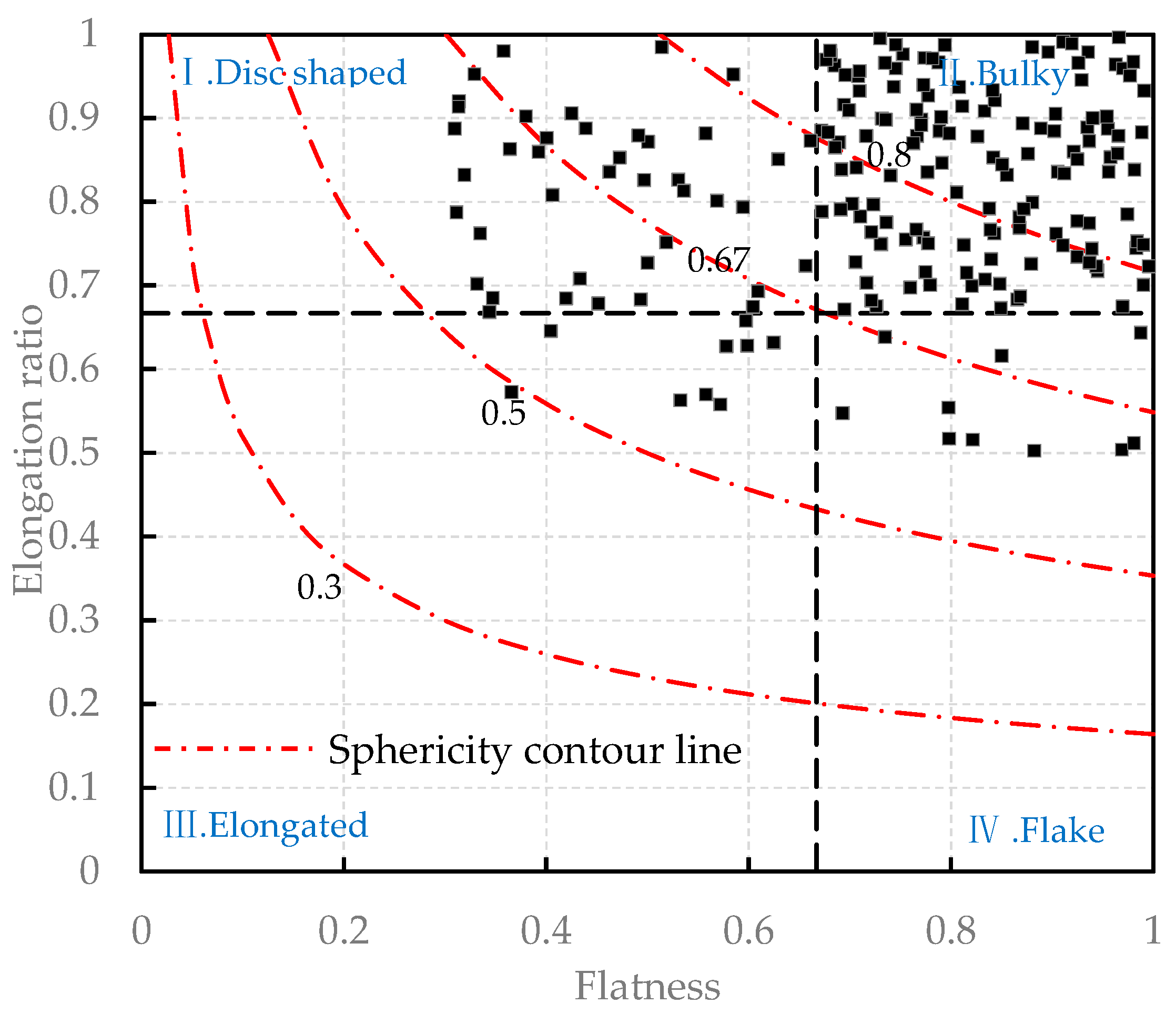

2.1. Materials

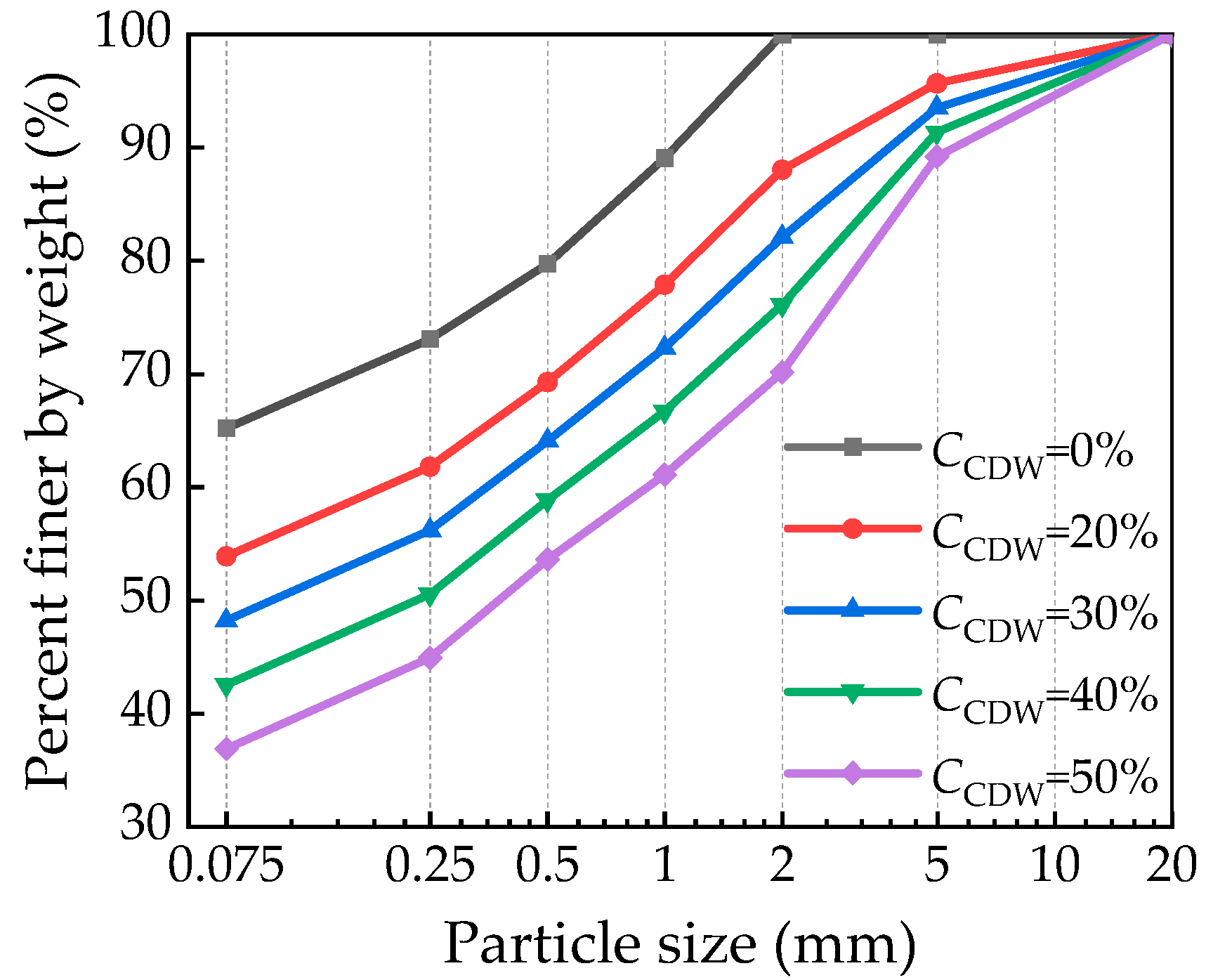

2.2. Determination of the Optimal Gradation of the Stabilized Soil

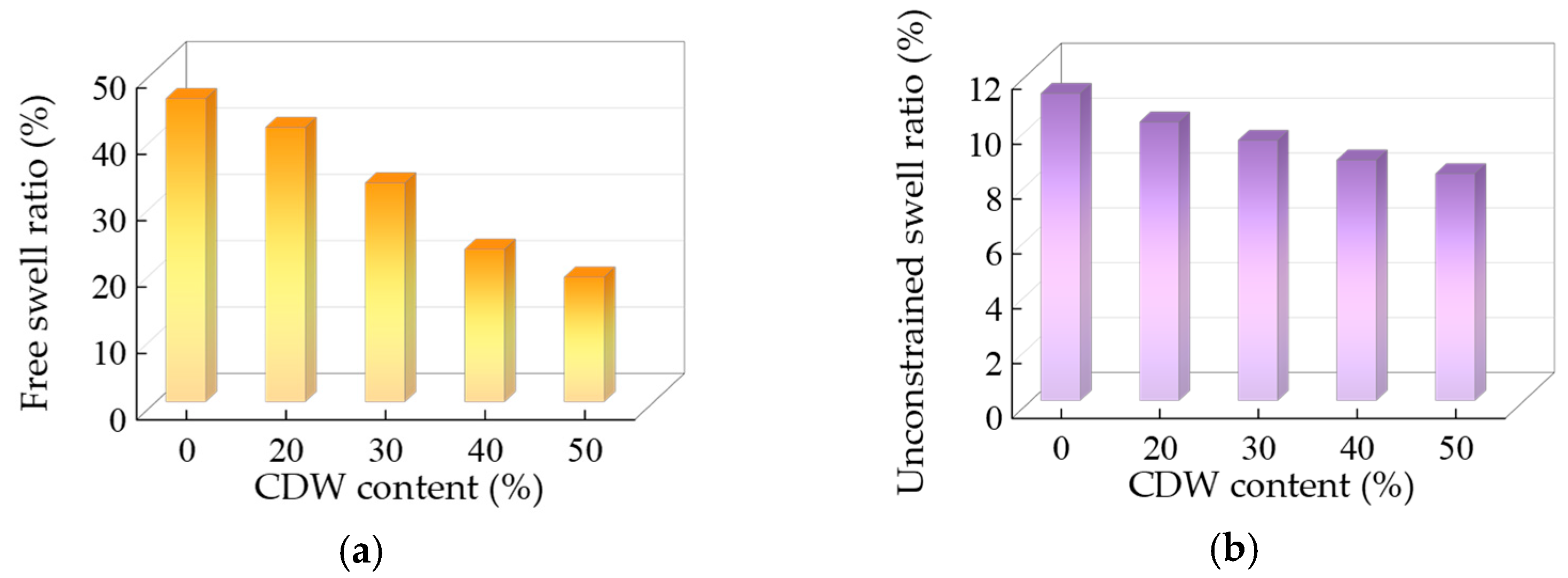

2.2.1. Influence of CDW Content on Swelling Behavior

2.2.2. Influence of CDW Content on Physical Properties

- i.

- Atterberg limits showed an overall decline. From 0% to 50% CDW, the liquid limit decreased from 42.3% to 23.1%, the plastic limit decreased from 24.8% to 17.4%, and the plasticity index decreased from 17.5 to 5.7, indicating reduced plasticity and moisture sensitivity.

- ii.

- Compaction characteristics first increased and then decreased. The maximum dry density ranged from 1.68 to 1.77 g·cm−3 and reached a peak value of 1.77 g·cm−3 at 40% CDW, which is about 5.4% higher than that of untreated soil. The optimum moisture content decreased from 14.8% to 8.8%, i.e., a reduction of 40.5%. This pattern suggests that a moderate content promotes a dense coarse skeleton, whereas excessive content leaves insufficient fines to fill voids, so the density declines.

- iii.

- Bearing capacity improved markedly and exhibited an optimum. Soaked CBR increased with content and then slightly decreased, reaching 25.1% at 40% CDW, which is about 5.23 times that of untreated soil, and then slightly falling to 23.4% at 50% CDW. The slight decrease can be inferred from existing studies to result from fine deficiency and localized particle breakage [26]. Considering both swelling suppression and structural capacity, 40% CDW was adopted as the optimum content for subsequent tests.

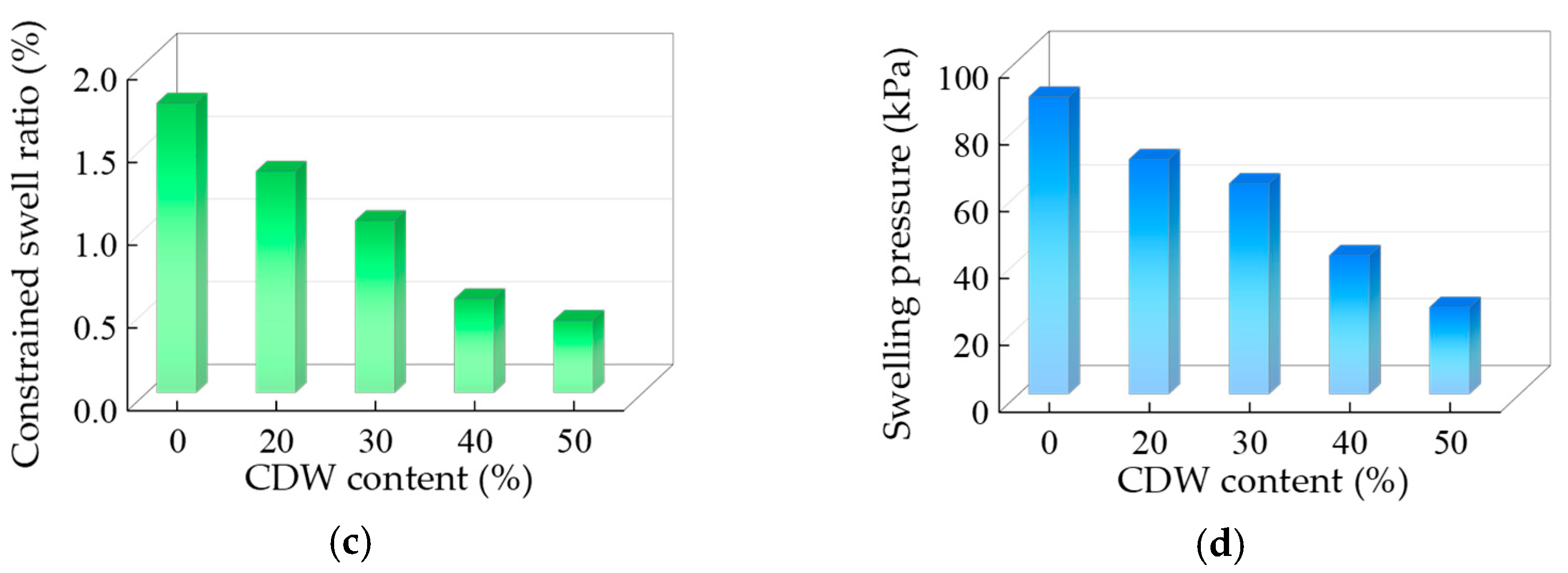

2.3. Wetting and Drying Protocol and Resilient Modulus Testing

- i.

- Humidification: the specimen was sealed in a controlled humidity environment until its mass stabilized, which required about 48 h.

- ii.

- Air drying: natural drying at 25 °C until the mass returned to the value measured before humidification.

- iii.

- Equalization: sealing for 24 h to equilibrate the internal moisture state.

3. Results and Discussion

3.1. Effect of Stress State on Resilient Modulus

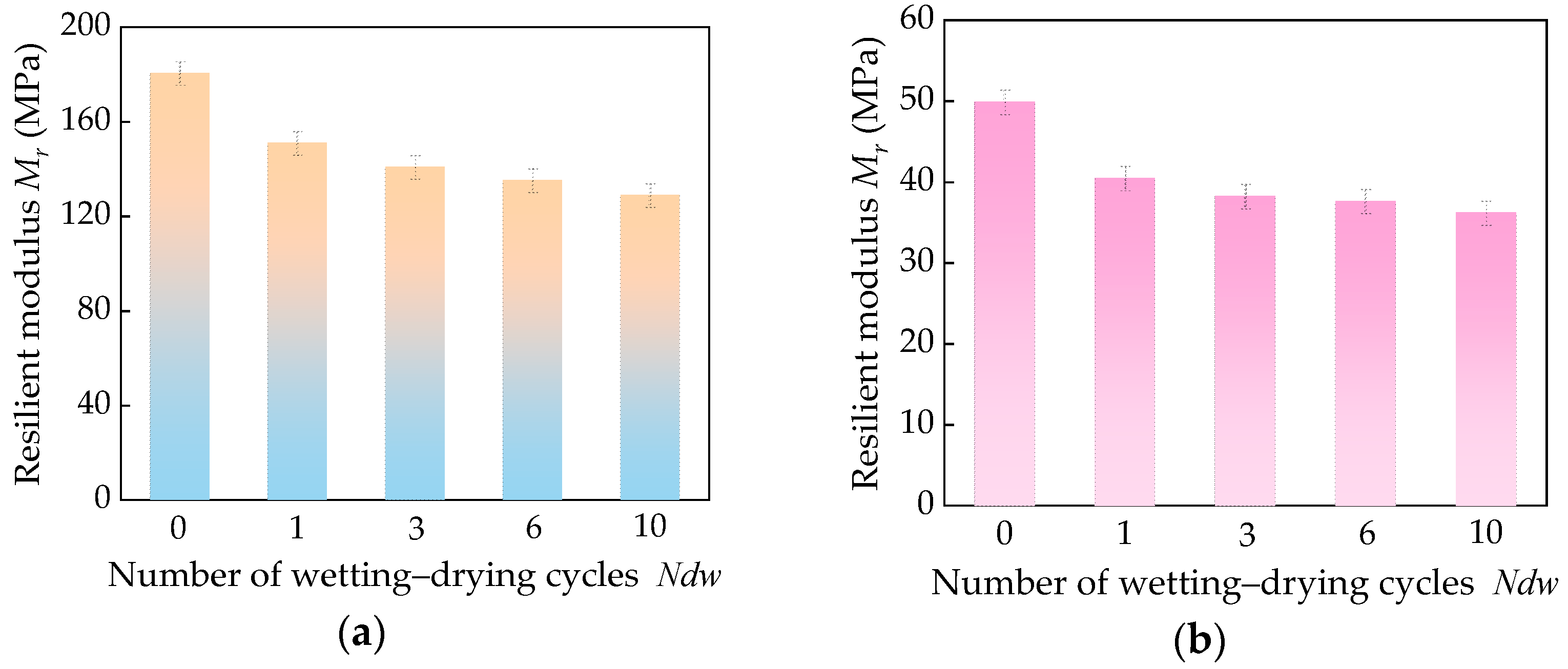

3.2. Effect of Environmental History on Resilient Modulus

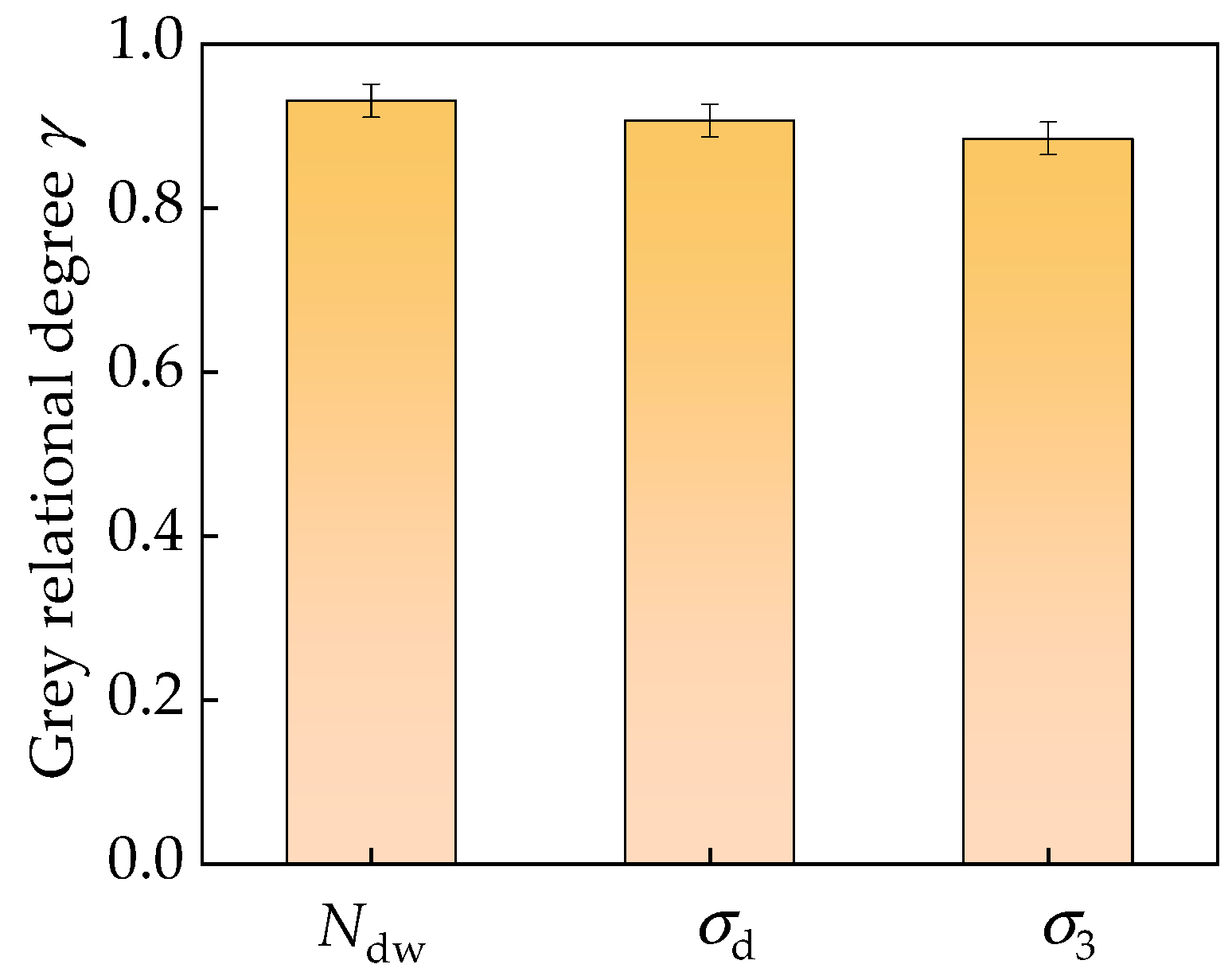

3.3. Sensitivity of Dynamic Resilient Modulus to Influencing Factors

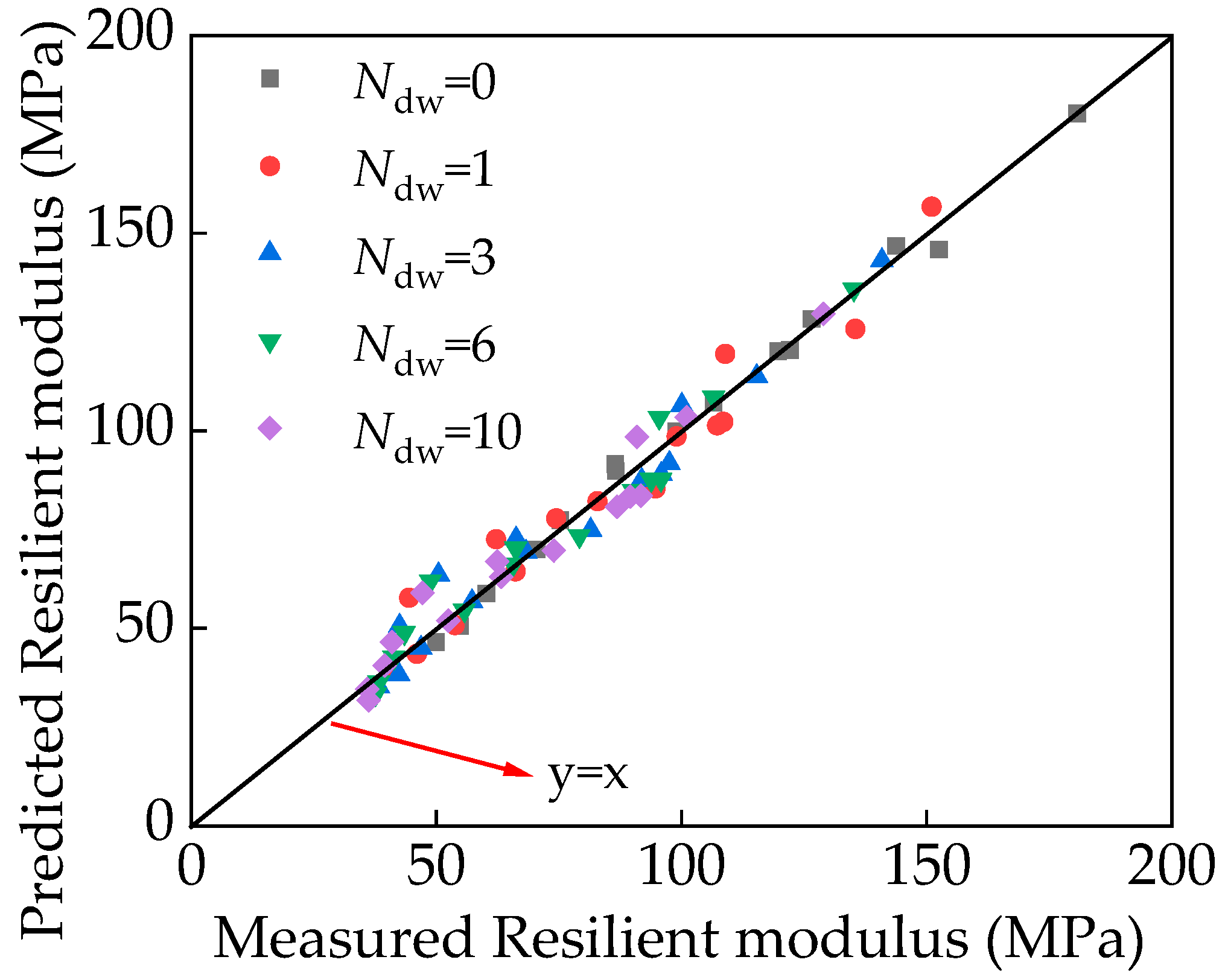

3.4. Model Analysis

4. Conclusions

- (1)

- An optimal CDW content of about 40% was identified, effectively reducing swelling potential while improving compaction and bearing capacity. This mix proportion provides a practical guideline for material selection in subgrade construction.

- (2)

- The resilient modulus exhibited typical stress dependence: it increased monotonically with confining pressure and deviatoric stress, with stronger hardening observed under higher deviatoric stress. These findings confirm that appropriate stress conditions can be used to enhance the stiffness performance of stabilized subgrades.

- (3)

- Wetting–drying cycles induced stiffness degradation, with a rapid initial drop followed by a gradual decline. Higher confining pressure delayed this deterioration, suggesting that adequate overburden or compaction control in the field could mitigate stiffness loss.

- (4)

- Grey relational analysis identified the number of wetting–drying cycles as the dominant factor, followed by deviatoric stress and confining pressure. This ranking underscores the importance of moisture management over purely mechanical considerations.

- (5)

- By incorporating the experimental results into the Lytton model, a modified prediction framework was established. The fitted parameters achieved a high degree of accuracy (R2 ≥ 0.95) across all conditions, and robustness verification demonstrated strong agreement between predicted and measured resilient modulus values. This indicates that the model is reliable and suitable for engineering applications.

- (6)

- For long-term pavement service, CDW-stabilized subgrades should be constructed at the optimal content with strict control of moisture and compaction. Maintenance strategies should focus on early cycle moisture fluctuations, which exert the greatest impact on stiffness, and apply predictive models that couple stress dependence with cyclic degradation for reliable service life evaluation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Mr | Resilient Modulus |

| CDW | Construction and Demolition Waste |

| CBR | California Bearing Ratio |

| Ndw | Number of Wetting and Drying Cycles |

| σd | Peak Cyclic Deviator Stress |

| εr | Peak Resilient Axial Strain |

| σ3 | Confining pressure |

| r | Principal Stress Ratio |

| γ | Grey Relational Degree |

| The Comparison Sequence Normalized to a Dimensionless Form by Initial Value Processing | |

| The Reference Sequence Normalized to a Dimensionless Form by Standardization | |

| k | Index of the Working Condition |

| i | Index of the Influencing Factor |

| ξi (k) | Grey Relational Coefficient |

| Δmin | Minimum of all Proximity Values |

| Δmax | Maximum of all Proximity Values |

| ρ | Distinguishing Coefficient |

| n | Total Number of Working Conditions |

References

- Ai, X.M.; Yi, J.Y.; Zhao, H.; Chen, S.Q.; Luan, H.; Zhang, L.D.; Feng, D.C. An empirical predictive model for the dynamic resilient modulus based on the static resilient modulus and California bearing ratio of cement- and lime-stabilised subgrade soils. Road Mater. Pavement Des. 2021, 22, 2818–2837. [Google Scholar] [CrossRef]

- Zhang, J.H.; Peng, J.H.; Zeng, L.; Li, J.; Li, F. Rapid estimation of resilient modulus of subgrade soils using performance-related soil properties. Int. J. Pavement Eng. 2021, 22, 732–739. [Google Scholar] [CrossRef]

- Yang, X.J.; Wang, J.M.; Hou, D.G.; Zhu, C.; He, M.C. Effect of dry-wet cycling on the mechanical properties of rocks: A laboratory-scale experimental study. Processes 2018, 6, 199. [Google Scholar] [CrossRef]

- Shi, G.M.; Li, X.Y.; Guo, Z.K.; Zhang, Z.Z.; Zhang, Y.Y. Effect of mica content on shear strength of the Yili loess under the dry-wet cycling condition. Sustainability 2022, 14, 9569. [Google Scholar] [CrossRef]

- Bai, Y.; Ye, W.J.; Wu, Y.T.; Chen, Y.Q. Multiscale analysis of the strength deterioration of loess under the action of drying and wetting cycles. Adv. Mater. Sci. Eng. 2021, 2021, 6654815. [Google Scholar] [CrossRef]

- Zheng, J.L.; Zhang, R.; Yang, H.P. Highway subgrade construction in expansive soil areas. J. Mater. Civ. Eng. 2009, 21, 154–162. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, Z.N.; Zheng, J.L.; Lei, G. Utilisation of expansive soils as highway embankment materials in humid environments. Int. J. Pavement Eng. 2022, 23, 2176–2190. [Google Scholar] [CrossRef]

- Yuan, J.B.; He, Y.; Liu, J.H. Construction of weak expansive red clay on dongxin expressway in Hunan Province, China. J. Perform. Constr. Facil. 2016, 30, C4015001. [Google Scholar] [CrossRef]

- Puppala, A.J. Performance evaluation of infrastructure on problematic expansive soils: Characterization challenges, innovative stabilization designs, and monitoring methods. J. Geotech. Geoenviron. Eng. 2021, 147, 04021053. [Google Scholar] [CrossRef]

- Snethen, D.R.; Townsend, F.C.; Johnson, L.D.; Patrick, D.M.; Vedros, P.J. A Review of Engineering Experiences with Expansive Soils in Highway Subgrades; Federal Highway Administration, Offices of Research and Development: Washington, DC, USA, 1975. [Google Scholar]

- Murali, K.; Ashok, S.; Giridharan, N.; Pandiarasan, K.; Logesh, P. A review on stabilization of expansive soil with various admixtures. Int. J. Sci. Res. Publ. 2018, 8, 7629. [Google Scholar] [CrossRef]

- Gaikwad, M.V.; Singh, S.K.; Suryavanshi, N.T.; Survase, K.P.; Yadav, S.R.; Pujari, M.C.; Basate, O.S. Reviewing the enhancement of expansive soil through different waste material blending. World J. Adv. Eng. Technol. Sci. 2024, 11, 158–166. [Google Scholar] [CrossRef]

- Sambre, T.; Endait, M.; Patil, S. Sustainable soil stabilization of expansive soil subgrades through lime-fly ash admixture. Discov. Civ. Eng. 2024, 1, 65. [Google Scholar] [CrossRef]

- Yu, D.F.; Duan, H.B.; Song, Q.B.; Li, X.Y.; Zhang, H.; Zhang, H.; Liu, Y.C.; Shen, W.J.; Wang, J.B. Characterizing the environmental impact of metals in construction and demolition waste. Environ. Sci. Pollut. Res. 2018, 25, 13823–13832. [Google Scholar] [CrossRef] [PubMed]

- Lauritzen, E.K. Construction, Demolition and Disaster Waste Management: An Integrated and Sustainable Approach; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Duan, X.; Wang, Y.; Yang, D.; Zeng, W.; Du, Y.; Li, N. Evaluation of road performance and carbon emission accounting analysis of recycled aggregates from construction and demolition waste. Sci. Rep. 2025, 15, 29395. [Google Scholar] [CrossRef]

- Paula Junior, A.C.; Jacinto, C.; Turco, C.; Fernandes, J.; Teixeira, E.; Mateus, R. Analysis of the effect of incorporating construction and demolition waste on the environmental and mechanical performance of earth-based mixtures. Constr. Build. Mater. 2022, 330, 127244. [Google Scholar] [CrossRef]

- Cabalar, A.; Zardikawi, O.; Abdulnafaa, M. Utilisation of construction and demolition materials with clay for road pavement subgrade. Road Mater. Pavement Des. 2019, 20, 702–714. [Google Scholar] [CrossRef]

- Kianimehr, M.; Shourijeh, P.T.; Binesh, S.M.; Mohammadinia, A.; Arulrajah, A. Utilization of recycled concrete aggregates for light-stabilization of clay soils. Constr. Build. Mater. 2019, 227, 116792. [Google Scholar] [CrossRef]

- Islam, S.; Islam, J.; Hoque, N.M.R. Improvement of consolidation properties of clay soil using fine-grained construction and demolition waste. Heliyon 2022, 8, e11029. [Google Scholar] [CrossRef] [PubMed]

- Zaharieva, R.; Evlogiev, D.; Kerenchev, N.; Stanimirova, T. Modification of quaternary clays using recycled fines from construction and demolition waste. Processes 2022, 10, 1062. [Google Scholar] [CrossRef]

- Liu, C.H.; Hung, C. Reutilization of solid wastes to improve the hydromechanical and mechanical behaviors of soils—A state-of-the-art review. Sustain. Environ. Res. 2023, 33, 17. [Google Scholar] [CrossRef]

- JTG 3430-2020; Test Methods of Soils for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- JTG/T 3610-2019; Technical Specifications for Construction of Highway Subgrades. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019.

- Ahmadi, M.; Shire, T.; Mehdizadeh, A.; Disfani, M. DEM modelling to assess internal stability of gap-graded assemblies of spherical particles under various relative densities, fine contents and gap ratios. Comput. Geotech. 2020, 126, 103710. [Google Scholar] [CrossRef]

- Zhang, F.S.; Li, M.L.; Peng, M.; Chen, C.; Zhang, L.M. Three-dimensional DEM modeling of the stress-strain behavior for the gap-graded soils subjected to internal erosion. Acta Geotech. 2019, 14, 487–503. [Google Scholar] [CrossRef]

- Niu, Z.L.; Xu, J.; Li, Y.F.; Wang, Z.F.; Wang, B. Strength deterioration mechanism of bentonite modified loess after wetting-drying cycles. Sci. Rep. 2022, 12, 3130. [Google Scholar] [CrossRef]

- Hao, R.H.; Zhang, Z.Z.; Guo, Z.Z.; Huang, X.B.; Lv, Q.L.; Wang, J.H.; Liu, T.C. Investigation of changes to triaxial shear strength parameters and microstructure of Yili loess with drying-wetting cycles. Materials 2022, 15, 255. [Google Scholar] [CrossRef]

- Zhao, Y.B.; Yang, C.Q.; Qu, F.; Wu, Z.R.; Ding, K.J.; Liang, Z.S. Effect of wet-dry cycles on the mechanical performances and microstructure of pisha sandstone. Molecules 2023, 28, 2533. [Google Scholar] [CrossRef] [PubMed]

- Gu, C.; Gu, Z.Q.; Cai, Y.Q.; Wang, J.; Ling, D.S. Dynamic modulus characteristics of saturated clays under variable confining pressure. Can. Geotech. J. 2017, 54, 729–735. [Google Scholar] [CrossRef]

- Chu, C.F.; Zhan, M.H.; Feng, Q.; Li, D.; Xu, L.; Zha, F.S.; Deng, Y.F. Effect of drying-wetting cycles on engineering properties of expansive soils modified by industrial wastes. Adv. Mater. Sci. Eng. 2020, 2020, 5602163. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Z.P.; Ren, X.; Li, F.T.; Zhang, F. Dynamic modulus and damping ratio of compacted loess under long-term traffic loading. Road Mater. Pavement Des. 2022, 23, 1731–1745. [Google Scholar] [CrossRef]

- Zhang, F.Z.; Chen, X.P. Influence of repeated drying and wetting cycles on mechanical behaviors of unsaturated soil. Chin. J. Geotech. Eng. 2010, 32, 41–46. [Google Scholar]

- Tang, C.S.; Bin, S.; Chun, L. Study on desiccation cracking behaviour of expansive soil. J. Eng. Geol. 2012, 20, 663–673. [Google Scholar]

- Singer, M.; Southard, R.; Warrington, D.; Janitzky, P. Stability of synthetic sand-clay aggregates after wetting and drying cycles. Soil Sci. Soc. Am. J. 1992, 56, 1843–1848. [Google Scholar] [CrossRef]

- An, R.; Kong, L.W.; Zhang, X.W.; Li, C.S. Effects of dry-wet cycles on three-dimensional pore structure and permeability characteristics of granite residual soil using X-ray micro computed tomography. J. Rock Mech. Geotech. Eng. 2022, 14, 851–860. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, H.R.; Wang, G.Y.; Yang, Y.Q.; Ouyang, M. Development characteristics and mechanism of crack in expansive soil under wet-dry cycling. Appl. Sci. 2024, 14, 6499. [Google Scholar] [CrossRef]

- Zhou, W.; Cheng, J.L.; Zhang, G.K.; Li, H.B.; Cheng, Y.G.; Ma, G.; Ji, X. Effects of wetting-drying cycles on the breakage characteristics of slate rock grains. Rock Mech. Rock Eng. 2021, 54, 6323–6337. [Google Scholar] [CrossRef]

- Wu, H.; Shao, S.; Shao, S.J.; Zhang, S.Y.; Wang, Z.C. Variations in dynamic shear modulus of loess exposed to dry-wet cycles from Xi’an area, China. Soil Dyn. Earthq. Eng. 2023, 173, 108126. [Google Scholar] [CrossRef]

- Abbey, S.J.; Amakye, S.Y.O.; Eyo, E.U.; Booth, C.A.; Jeremiah, J.J. Wet-Dry Cycles and Microstructural Characteristics of Expansive Subgrade Treated with Sustainable Cementitious Waste Materials. Materials 2023, 16, 3124. [Google Scholar] [CrossRef]

- Zhang, J.H.; Zhang, A.S.; Li, J.; Li, F.; Peng, J.H. Gray correlation analysis and prediction on permanent deformation of subgrade filled with construction and demolition materials. Materials 2019, 12, 3035. [Google Scholar] [CrossRef]

| Specific Gravity | Liquid Limit (%) | Plastic Limit (%) | Maximum Dry Density (g/cm3) | Optimum Moisture Content (%) | Free Swell Index (%) | Clay Content (%) | Silt Content (%) | Sand Content (%) |

|---|---|---|---|---|---|---|---|---|

| 2.7 | 42.3 | 24.8 | 1.68 | 14.8 | 46.7 | 25.4 | 39.8 | 34.8 |

| Natural Moisture Content (%) | Specific Gravity | Coefficient of Uniformity | Coefficient of Curvature | Fine Content (%) | Sand Content (%) | Gravel Content (<20 mm) (%) |

|---|---|---|---|---|---|---|

| 13.5 | 2.26 | 2.45 | 0.79 | 8.5 | 31.8 | 59.7 |

| Seq. No. | Confining Pressure, σ3 (kPa) | Contact Stress, 0.2σ3 (kPa) | Cyclic Deviator Stress, σd (kPa) | Principal Stress Ratio, r = σ1/σ3 | No. of Cycles |

|---|---|---|---|---|---|

| 0 (Preloading) | 30 | 6 | 60 | 3 | 1000 |

| 1 | 15 | 3 | 8 | 1.5 | 100 |

| 2 | 30 | 6 | 15 | 1.5 | 100 |

| 3 | 45 | 9 | 23 | 1.5 | 100 |

| 4 | 60 | 12 | 30 | 1.5 | 100 |

| 5 | 80 | 16 | 40 | 1.5 | 100 |

| 6 | 15 | 3 | 15 | 2 | 100 |

| 7 | 30 | 6 | 30 | 2 | 100 |

| 8 | 45 | 9 | 45 | 2 | 100 |

| 9 | 60 | 12 | 60 | 2 | 100 |

| 10 | 80 | 16 | 80 | 2 | 100 |

| 11 | 15 | 3 | 30 | 3 | 100 |

| 12 | 30 | 6 | 60 | 3 | 100 |

| 13 | 45 | 9 | 90 | 3 | 100 |

| 14 | 60 | 12 | 120 | 3 | 100 |

| 15 | 80 | 16 | 160 | 3 | 100 |

| Ndw | k1 | k2 | k3 | R2 | RMSE | Correlation |

|---|---|---|---|---|---|---|

| 0 | 0.66 | 0.58 | 0.34 | 0.98 | 3.12 | Excellent |

| 1 | 0.53 | 0.50 | 0.65 | 0.95 | 4.98 | Excellent |

| 3 | 0.46 | 0.49 | 0.76 | 0.96 | 4.22 | Excellent |

| 6 | 0.45 | 0.52 | 0.64 | 0.96 | 4.22 | Excellent |

| 10 | 0.43 | 0.52 | 0.65 | 0.95 | 4.98 | Excellent |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Huang, C. Stiffness Degradation of Expansive Soil Stabilized with Construction and Demolition Waste Under Wetting–Drying Cycles. Coatings 2025, 15, 1154. https://doi.org/10.3390/coatings15101154

Xu H, Huang C. Stiffness Degradation of Expansive Soil Stabilized with Construction and Demolition Waste Under Wetting–Drying Cycles. Coatings. 2025; 15(10):1154. https://doi.org/10.3390/coatings15101154

Chicago/Turabian StyleXu, Haodong, and Chao Huang. 2025. "Stiffness Degradation of Expansive Soil Stabilized with Construction and Demolition Waste Under Wetting–Drying Cycles" Coatings 15, no. 10: 1154. https://doi.org/10.3390/coatings15101154

APA StyleXu, H., & Huang, C. (2025). Stiffness Degradation of Expansive Soil Stabilized with Construction and Demolition Waste Under Wetting–Drying Cycles. Coatings, 15(10), 1154. https://doi.org/10.3390/coatings15101154