Micro- and Nanofibrillated Cellulose Coatings as Barriers Against Water and Oil in Food Packaging Paper: A Sustainable Alternative to Plastic Coatings

Abstract

:1. Introduction

The Coating Process as an Operation Developing Specific Desired Properties of Paper

2. Materials and Methods

2.1. Materials

- Grammage [g/m2]: 60.

- Thickness: 78.

- Breaking length: 6450 m.

- Bendtsen roughness: 523 mL/min.

- Consistency: 5% (note that in papermaking, “consistency” typically refers to fiber concentration, not total solids content).

- Water retention value (WRV): 810%.

- Cellulose content: above 99.5%.

- Alpha-cellulose content: above 80%.

- Hemicellulose content: below 0.1% (undetectable).

- Lignin content: below 0.1% (undetectable).

- Average degree of polymerization: 420.

- Dynamic viscosity: 820–860 mPa·s.

2.2. Methods

2.2.1. Coating Process

- Coating speed: 15 m/min.

- Pressure of the coating rod: 100 N/m.

- Paper tension: 100 N/m.

- Heating plate temperatures: 100 °C for the first section, 120 °C for the second section, and 130 °C for the third section.

- Drying hot air temperature: 70 °C.

- Hot airflow: 150 m3/min.

2.2.2. Evaluation of Coated Paper Properties

Smoothness

- The Bendtsen method, according to ISO 8791-2:2013. The measurement was performed by a Bendtsen Roughness & AP Tester at 5000 mL/min from Messmer Buchel (Veenendaal, The Netherlands).

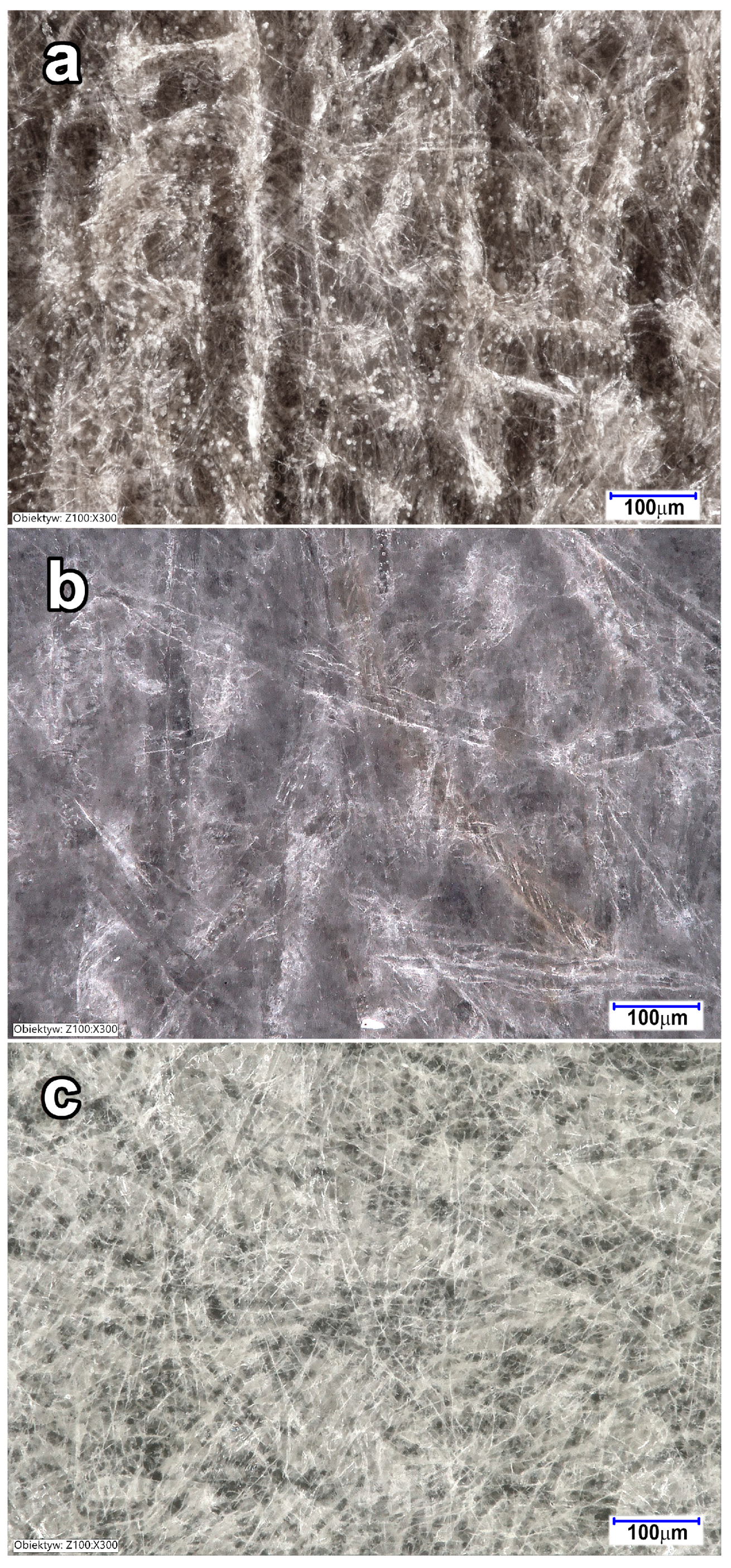

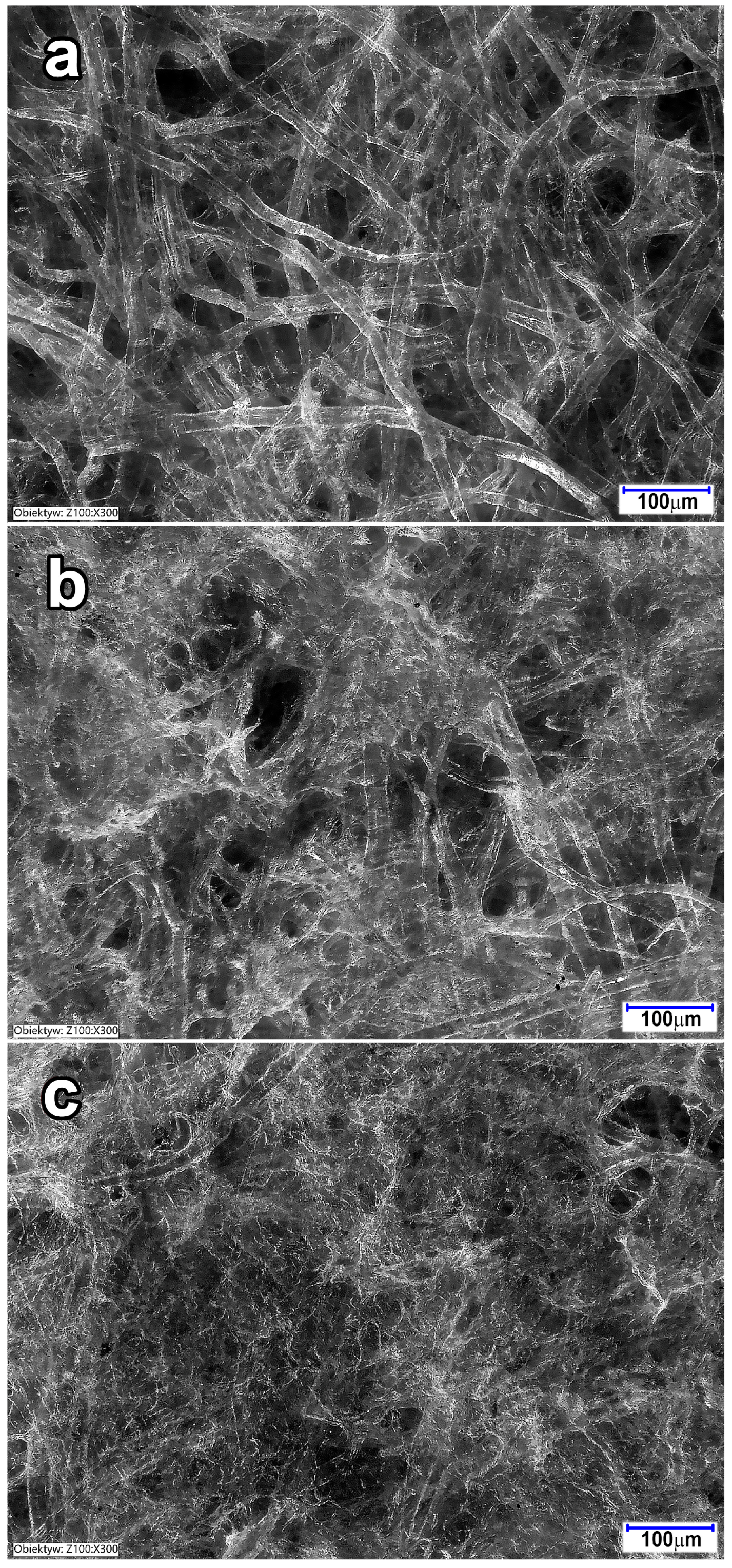

- A microscopic surface analysis, according to ISO 25178:2021. Measurements were conducted using the VHX-7000 digital microscope from Keyence (Osaka, Japan) equipped with a VHZ100UR lens and an OP-72404 lighting attachment. The same microscope was also used to assess the surface condition of the paper after the coating process with M-NFC.

Absorbency

Wettability Analysis

3. Results

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| M-NFC | micro- and nanofibrillated cellulose |

| PE | polyethylene |

| PP | polypropylene |

| WBBC | water-based barrier coatings |

| PVA | polyvinyl alcohol |

| FDA | Food and Drug Administration |

| BFR | Bundesinstitut für Risikobewertung |

| TPS | thermoplastic starch |

| PLA | polylactic acid |

| PBS | polyethylene succinate |

| PHAs | polyhydroxyalkanoates |

| BDO | 1-4-butanediol |

| PHB | polyhydroxybutyrate |

| PHBV | polyhydroxybutyrate vinyl |

| PHBH | polyhydroxybutylohydroxyl |

| MFC | microfibrillated cellulose |

| MD/CD | machine direction |

| CD | cross direction |

| WRV | water retention value |

References

- Lamenta, Z.A.; Grzybowska, K. Impact of the European Green Deal on Business Operations—Preliminary Benchmarking. Sustainability 2023, 15, 7780. [Google Scholar] [CrossRef]

- Kiessling, T.; Hinzmann, M.; Mederake, L.; Dittmann, S.; Brennecke, D.; Böhm-Beck, M.; Knickmeier, K.; Thiel, M. What potential does the EU Single-Use Plastics Directive have for reducing plastic pollution at coastlines and riversides? An evaluation based on citizen science data. Waste Manag. 2023, 164, 106–118. [Google Scholar] [CrossRef]

- European Parliament. How the EU Wants to Achieve a Circular Economy by 2050. Available online: https://www.europarl.europa.eu/topics/en/article/20210128STO96607/how-the-eu-wants-to-achieve-a-circular-economy-by-2050 (accessed on 3 October 2024).

- European Commision. European Green Deal: Putting an End to Wasteful Packaging, Boosting Reuse and Recycling. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_7155?fbclid=IwAR17DTjpv2Z22Wf8tQ73xYvoQ7yjuvXVeT8kZhrYDEri9eMkrz4XJrS-eAA (accessed on 30 August 2024).

- Unver, H. The European Green Deal and Sustainable Business Growth. Visions Europe. Available online: https://visionsforeurope.eu/v4e-articles/the-european-green-deal-and-sustainable-business-growth/ (accessed on 2nd December 2024).

- Zhou, Y.; Wang, X.; Zhang, L.; Li, Y.; Liu, J.; Zhang, Y.; Zhang, X.; Zhang, Y.; Wang, Y.; Zhang, Y. A novel bio-based flame retardant for cotton fabrics: Preparation, characterization, and flame retardancy. Int. J. Biol. Macromol. 2023, 231, 128916. [Google Scholar] [CrossRef]

- Smook, G.A. Handbook for Pulp and Paper Technology; Angus Wilde Publications: Vancouver, BC, Canada, 1996. [Google Scholar]

- Samyn, P. Wetting and hydrophobic modification of cellulose surfaces for paper applications. J. Mater. Sci. 2013, 48, 6455–6498. [Google Scholar] [CrossRef]

- Yang, L.; Liu, J.; Gu, L. Detailed insights to liquid absorption and liquid-paper interaction. In Advances in Pulp and Paper Research, Cambridge 2013; I’Anson, S.J., Ed.; FRC: Manchester, UK, 2018; pp. 585–598. [Google Scholar] [CrossRef]

- Huq, T.; Salmieri, S.; Khan, A.; Khan, R.A.; Le Tien, C.; Riedl, B.; Fraschini, C.; Bouchard, J.; Uribe-Calderon, J.; Kamal, M.R.; et al. Nanocrystalline cellulose (NCC) reinforced alginate-based biodegradable nanocomposite film. Carbohydr. Polym. 2012, 90, 1757–1763. [Google Scholar] [CrossRef]

- Basak, S.; Dangate, M.S.; Samy, S. Oil- and water-resistant paper coatings: A review. Prog. Org. Coat. 2023, 186, 107938. [Google Scholar] [CrossRef]

- Fardim, P. Paper and Surface Chemistry–Part 2: Coating and Printability; SSRN: Rochester, NY, USA, 2002. [Google Scholar]

- Cordt, C.; Daeg, J.; Elle, O.; Geissler, A.; Biesalski, M. Innovative Paper Coatings: Regenerative Superhydrophobicity through Self-Structuring Aqueous Wax-Polymer Dispersions. Coatings 2024, 14, 1028. [Google Scholar] [CrossRef]

- Liu, W.; Liu, H.; Liu, K.; Du, H.; Liu, Y.; Si, C. Paper-based products as promising substitutes for plastics in the context of bans on non-biodegradables. BioResources 2020, 15, 7309–7312. [Google Scholar] [CrossRef]

- Oloyede, O.O.; Lignou, S. Sustainable paper-based packaging: A consumer’s perspective. Foods 2021, 10, 1035. [Google Scholar] [CrossRef] [PubMed]

- Teck Kim, Y.; Min, B.; Won Kim, K. General Characteristics of Packaging Materials for Food System. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2014; pp. 13–35. [Google Scholar] [CrossRef]

- Kumar, P.; Kishore, A.; Tripathi, S.; Lavanya; Chaudhary, V.; Gaikwad, K.K. Innovative strategies to improve the properties of paper with bio-sourced material and its application in food packaging: A review. Biomass Convers. Biorefin. 2024, 14, 178–200. [Google Scholar] [CrossRef]

- Gurav, S.; Bereznitski, A.; Heidweiller, A.; Kandachar, P. Mechanical properties of paper-pulp packaging. Compos. Sci. Technol. 2003, 63, 1325–1334. [Google Scholar] [CrossRef]

- European Paper Recycling Council (EPRC). The Paper Value Chain Reached a 70.5% Recycling Rate in 2022. CEPI 2023. Available online: https://www.cepi.org/press-release-the-paper-value-chain-reached-a-705-recycling-rate-in-2022/ (accessed on 25 November 2024).

- World Economic Forum. Top 25 Recycling Facts and Statistics for 2022. World Economic Forum 2022. Available online: https://www.weforum.org/agenda/2022/06/recycling-global-statistics-facts-plastic-paper/ (accessed on 14 November 2024).

- Deshwal, G.K.; Panjagari, N.R.; Alam, T. An overview of paper and paper-based food packaging materials: Health safety and environmental concerns. J. Food Sci. Technol. 2019, 56, 4391–4403. [Google Scholar] [CrossRef] [PubMed]

- Lipkiewicz, A.; Małachowska, E.; Dubowik, M.; Przybysz, P. Impact of shredding degree on papermaking potential of recycled waste. Sci. Rep. 2021, 11, 96325. [Google Scholar] [CrossRef] [PubMed]

- Kunam, P.K.; Ramakanth, D.; Akhila, K.; Gaikwad, K.K. Bio-based materials for barrier coatings on paper packaging. Biomass Convers. Biorefin. 2024, 14, 12637–12652. [Google Scholar] [CrossRef] [PubMed]

- Bajpai, P. Coating. In Biermann’s Handbook of Pulp and Paper; Academic Press: Cambridge, MA, USA, 2018; pp. 159–176. [Google Scholar] [CrossRef]

- Webb, H.K.; Arnott, J.; Crawford, R.; Ivanova, E. Plastic degradation and its environmental implications with special reference to poly(ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef]

- Chaudhuri, S. Paper Cups Become a Target in the Fight Against Plastic. Wall Street J. 2018. Available online: https://www.wsj.com/articles/scrutiny-of-paper-coffee-cups-stacks-up-1540810800 (accessed on 31 October 2018).

- Triantafillopoulos, N.; Koukoulas, A.A. The future of single-use paper coffee cups: Current progress and outlook. BioResources 2020, 15, 7260–7287. [Google Scholar] [CrossRef]

- de Resende, T.M.; da Costa, M.M. Biopolymers of sugarcane. In Sugarcane Biorefinery, Technology and Perspectives; Santos, F., Rabelo, S.C., De Matos, M., Eichler, P., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 229–254. ISBN 9780128142363. [Google Scholar] [CrossRef]

- Chen, R.S.; Chai, Y.H.; Olugu, E.U.; Salleh, M.N.; Ahmad, S. Evaluation of mechanical performance and water absorption properties of modified sugarcane bagasse high-density polyethylene plastic bag green composites. Polym. Polym. Compos. 2021, 29 (Suppl. S9), S1134–S1143. [Google Scholar] [CrossRef]

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-Based Polymers with Potential for Biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef]

- Eriksson, M. The Influence of Pigment Additives on the Barrier Properties of Dispersion Coatings. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2022. (TRITA-CBH-GRU). Available online: https://kth.diva-portal.org/smash/record.jsf?pid=diva2%3A1692262&dswid=6045 (accessed on 21 October 2024).

- Sharma, K.M. Surface Phenomena and Additives in Water-Based Coatings and Printing Technology; Springer Science & Business Media: New York, NY, USA, 2013; p. 6. [Google Scholar]

- Bakker, S.; Aarts, J.; Esteves, A.C.C.; Metselaar, G.A.; Schenning, A.P.H.J. Water Barrier Properties of Resin-Stabilized Waterborne Coatings for Paperboard. Macromol. Mater. Eng. 2022, 307, 2100829. [Google Scholar] [CrossRef]

- Mujtaba, M.; Lipponen, J.; Ojanen, M.; Puttonen, S.; Vaittinen, H. Trends and challenges in the development of bio-based barrier coating materials for paper/cardboard food packaging; a review. Sci. Total Environ. 2022, 10, 158328. [Google Scholar] [CrossRef]

- Rastogi, V.K.; Samyn, P. Bio-Based Coatings for Paper Applications. Coatings 2015, 5, 887–930. [Google Scholar] [CrossRef]

- Jahangiri, F.; Mohanty, A.K.; Misra, M. Sustainable biodegradable coatings for food packaging: Challenges and opportunities. Green Chem. 2024, 26, 4934–4974. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, M.; Tian, Y.; Jin, Z. Starch-based biodegradable packaging materials: A review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- Surendren, A.; Mohanty, A.K.; Liu, Q.; Misra, M. A review of biodegradable thermoplastic starches, their blends and composites: Recent developments and opportunities for single-use plastic packaging alternatives. Green Chem. 2022, 24, 22. [Google Scholar] [CrossRef]

- Li, H.; Qi, Y.; Zhao, Y.; Chi, J.; Cheng, S. Starch and its derivatives for paper coatings: A review. Prog. Org. Coat. 2019, 135, 213–227. [Google Scholar] [CrossRef]

- Khan, B.; Niazi, M.B.K.; Samin, G.; Jahan, Z. Thermoplastic Starch: A Possible Biodegradable Food Packaging Material—A Review. J. Food Process Eng. 2016, 40, e12447. [Google Scholar] [CrossRef]

- Ni, S.; Zhang, H.; Dai, H.; Xiao, H. Starch-Based Flexible Coating for Food Packaging Paper with Exceptional Hydrophobicity and Antimicrobial Activity. Polymers 2018, 10, 1260. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass Production, Processing, Industrial Applications, and End of Life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Sundar, N.; Ananda Kumar, S.; Pavithra, A.; Ghosh, S. Studies on Semi-crystalline Poly Lactic Acid (PLA) as a Hydrophobic Coating Material on Kraft Paper for Imparting Barrier Properties in Coated Abrasive Applications. Prog. Org. Coat. 2020, 145, 105682. [Google Scholar] [CrossRef]

- Abdenour, C.; Eesaee, M.; Stuppa, C.; Chabot, B.; Barnabé, S.; Bley, J.; Tolnai, B.; Guy, N.; Nguyen-Tri, P. Water Vapor and Air Barrier Performance of Sustainable Paper Coatings Based on PLA and Xanthan Gum. Mater. Today Commun. 2023, 36, 106626. [Google Scholar] [CrossRef]

- Rhim, J.W.; Kim, J.H. Properties of Poly(lactide)-Coated Paperboard for the Use of 1-Way Paper Cup. J. Food Sci. 2009, 74, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Thurber, H.; Curtzwiler, G.W. Suitability of Poly(butylene succinate) as a Coating for Paperboard Convenience Food Packaging. Int. J. Biobased Plast. 2020, 2, 1–12. [Google Scholar] [CrossRef]

- Hamdani, S.S.; Emch, H.; Isherwood, J.; Khan, A.; Kumar, V.; Alford, A.; Wyman, I.; Sharma, R.; Mayekar, P.; Bher, A.; et al. Waterborne Poly(Butylene Succinate)-Coated Paper for Sustainable Packaging Applications. Nat. Commun. 2022, 13, 33064. [Google Scholar] [CrossRef]

- Kathuria, A.; Zhang, S. Sustainable and Repulpable Barrier Coatings for Fiber-Based Materials for Food Packaging: A Review. Front. Mater. 2022, 9, 929501. [Google Scholar] [CrossRef]

- Israni, N.; Shivakumar, S. Polyhydroxyalkanoates in packaging. In Biotechnological Applications of Polyhydroxyalkanoates; Kalia, V.C., Ed.; Springer: Singapore, 2019; pp. 363–388. [Google Scholar] [CrossRef]

- Tyagi, P.; Salem, K.S.; Hubbe, M.A.; Pal, L. Advances in barrier coatings and film technologies for achieving sustainable packaging of food products—A review. Trends Food Sci. Technol. 2021, 115, 461–485. [Google Scholar] [CrossRef]

- Pracella, M.; Mura, C.; Galli, G. Polyhydroxyalkanoate Nanocomposites with Cellulose Nanocrystals as Biodegradable Coating and Packaging Materials. ACS Appl. Nano Mater. 2021, 4, 1234–1245. [Google Scholar] [CrossRef]

- Yeo, J.C.C.; Muiruri, J.K.; Fei, X.; Wang, T.; Zhang, X.; Xiao, Y.; Thitsartarn, W.; Tanoto, H.; He, C.; Li, Z. Innovative biomaterials for food packaging: Unlocking the potential of polyhydroxyalkanoate (PHA) biopolymers. Biomater. Adv. 2024, 163, 213929. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and New Opportunities on Barrier Performance of Biodegradable Polymers for Sustainable Packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Stublić, K.; Ranilović, J.; Ocelić Bulatović, V.; Kučić Grgić, D. Advancing Sustainability: Utilizing Bacterial Polyhydroxyalkanoate for Food Packaging. Processes 2024, 12, 1886. [Google Scholar] [CrossRef]

- Viswanathan, S.S. Wax-based artificial superhydrophobic surfaces and coatings. Colloids Surf. A Physicochem. Eng. Asp. 2020, 602, 125132. [Google Scholar] [CrossRef]

- Yadav, S.; Khan, A.; Hamdani, S.S.; Rabnawaz, M. Degradable Polymeric Waxes for Paper Coating Applications. ACS Appl. Polym. Mater. 2024, 3, 03072. [Google Scholar] [CrossRef]

- Woch, J.; Małachowska, E.; Korasiak, K.; Lipkiewicz, A.; Dubowik, M.; Chrobak, J.; Iłowska, J.; Przybysz, P. Barrier Dispersion-Based Coatings Containing Natural and Paraffin Waxes. Molecules 2022, 27, 930. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Hamdani, S.S.; Duncan, E.; Rabnawaz, M. High-Performance Synthetic Waxes for a Sustainable Packaging. ACS Sustain. Chem. Eng. 2024, 4, 04229. [Google Scholar] [CrossRef]

- Nowacka, M.; Rybak, K.; Wiktor, A.; Mika, A.; Boruszewski, P.; Woch, J.; Przybysz, K.; Witrowa-Rajchert, D. The quality and safety of food contact materials—Paper and cardboard coated with paraffin emulsion. Food Control 2018, 93, 183–190. [Google Scholar] [CrossRef]

- Fei, T.; Walker, J.A.; Vickerman, K.L.; Stanley, L.M.; Jarboe, D.; Wang, T. Synthesis and characterization of soybean oil-based waxes and their application as paraffin substitute for corrugated coating. J. Ind. Eng. Chem. 2018, 58, 113–122. [Google Scholar] [CrossRef]

- Tambe, C.; Graiver, D.; Narayan, R. Moisture resistance coating of packaging paper from biobased silylated soybean oil. Prog. Org. Coat. 2016, 101, 270–278. [Google Scholar] [CrossRef]

- Lee, E.J.; Lim, K.-H. Preparation of eco-friendly wax-coated paper and its rheological and water-resistant characteristics. Korean J. Chem. Eng. 2021, 38, 2479–2492. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Khelifi, B.; Bras, J. Impact of different coating processes of microfibrillated cellulose on the mechanical and barrier properties of paper. J. Mater. Sci. 2014, 49, 2879–2893. [Google Scholar] [CrossRef]

- Mascarenhas, A.R.P.; Scatolino, M.V.; Dias, M.C.; Martins, M.A.; de Melo, R.R.; Mendonça, M.C.; Tonoli, G.H.D. Association of cellulose micro/nanofibrils and silicates for cardboard coating: Technological aspects for packaging. Ind. Crops Prod. 2022, 188, 115667. [Google Scholar] [CrossRef]

- Sharma, M.; Aguado, R.; Murtinho, D.; Valente, A.J.M.; Ferreira, P.J.T. Micro-/Nanofibrillated Cellulose-Based Coating Formulations: A Solution for Improving Paper Printing Quality. Nanomaterials 2022, 12, 2853. [Google Scholar] [CrossRef]

- Chen, H.; Wang, B.; Li, J.; Ying, G.; Chen, K. High-strength and super-hydrophobic multilayered paper based on nano-silica coating and micro-fibrillated cellulose. Carbohydr. Polym. 2022, 288, 119371. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Koppolu, V.R.; Bousfield, D.; Toivakka, M. Substrate role in coating of microfibrillated cellulose suspensions. Cellulose 2017, 24, 1247–1260. [Google Scholar] [CrossRef]

- Mayrhofer, A.; Kopacic, S.; Bauer, W. Extensive Characterization of Alginate, Chitosan and Microfibrillated Cellulose Cast Films to Assess their Suitability as Barrier Coating for Paper and Board. Polymers 2023, 15, 3336. [Google Scholar] [CrossRef]

- Li, T.; Chen, C.; Brozena, A.H.; Zhu, J.Y.; Xu, L.; Driemeier, C.; Dai, J.; Rojas, O.J.; Isogai, A.; Wågberg, L.; et al. Developing fibrillated cellulose as a sustainable technological material. Nature 2021, 590, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Mármol, G.; Gauss, C.; Fangueiro, R. Potential of Cellulose Microfibers for PHA and PLA Biopolymers Reinforcement. Molecules 2020, 25, 4653. [Google Scholar] [CrossRef] [PubMed]

- Martins, N.C.T.; Freire, C.S.R.; Neto, C.P.; Silvestre, A.J.D.; Causio, J.; Baldi, G.; Sadocco, P.; Trindade, T. Antibacterial Paper Based on Composite Coatings of Nanofibrillated Cellulose and ZnO. Colloids Surf. A Physicochem. Eng. Asp. 2013, 417, 111–119. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Manship, B.; Bras, J.; Sillard, C.; Marais, S. Antibacterial Paperboard Packaging Using Microfibrillated Cellulose. J. Food Sci. Technol. 2015, 52, 5590–5600. [Google Scholar] [CrossRef] [PubMed]

- Balan, T.; Guezennec, C.; Nicu, R.; Ciolacu, F.; Bobu, E. Improving Barrier and Strength Properties of Paper by Multi-Layer Coating with Bio-Based Additives. Cellulose Chem. Technol. 2015, 49, 607–615. [Google Scholar]

- Huq, T.; Khan, A.; Brown, D.; Dhayagude, N.; He, Z.; Ni, Y. Sources, Production and Commercial Applications of Fungal Chitosan: A Review. J. Bioresour. Bioprod. 2022, 7, 85–98. [Google Scholar] [CrossRef]

- Krol, L.F.; Beneventi, D.; Alloin, F.; Chaussy, D. Microfibrillated Cellulose-SiO2 Composite Nanopapers Produced by Spray Deposition. J. Mater. Sci. 2015, 50, 4095–4103. [Google Scholar] [CrossRef]

- Jia, M.; Zhang, X.; Weng, J.; Zhang, J.; Zhang, M. Protective Coating of Paper Works: ZnO/Cellulose Nanocrystal Composites and Analytical Characterization. J. Cult. Herit. 2019, 38, 64–74. [Google Scholar] [CrossRef]

- Pang, X.; Chen, Y.Z.; Zhang, Z.J. Study on the Antibacterial Paper Coated by ZnO/MFC for Food Packaging. Appl. Mech. Mater. 2015, 731, 457–461. [Google Scholar] [CrossRef]

- Du, J.; Tang, J.; Xu, S.; Ge, J.; Dong, Y.; Li, H.; Jin, M. ZnO Nanoparticles: Recent Advances in Ecotoxicity and Risk Assessment. Drug Chem. Toxicol. 2018, 43, 322–333. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Bras, J. Microfibrillated Cellulose Coatings as New Release Systems for Active Packaging. Carbohydr. Polym. 2014, 103, 528–537. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Guo, Z.; Chen, S.; Dong, H.; Zhang, X.; Qin, Y.; Yao, C.; Xu, F. High-Barrier, Strong, and Antibacterial Paper Fabricated by Coating Acetylated Cellulose and Cinnamaldehyde for Food Packaging. Cellulose 2021, 28, 4371–4384. [Google Scholar] [CrossRef]

- Wang, B.; Zhao, M.Z.; Huang, L.Y.; Zhang, L.J.; Yu, X.J.; Liu, Y.; Li, J. Exploring Cinnamaldehyde: Preparation Methods, Biological Functions, Efficient Applications, and Safety. Food Rev. Int. 2024, 41, 615–642. [Google Scholar] [CrossRef]

| Property | WBBC-Coated | Silicon-Coated | PE-Coated |

|---|---|---|---|

| Grammage [g/m2] | 42 | 57 | 44 |

| Thickness [µm] | 56 | 50 | 52 |

| Breaking length MD/CD [m] | 4750/2800 | 4900/2450 | 3550/1400 |

| Bendtsen roughness [mL/min] | 216 | 51 | 38 |

| Sample | Bendtsen Roughness (ISO 8791-2), mL/min | Optical Roughness, Sa (ISO 25178), µm | Water Absorbency Cobb60, g/m2 | Castor Oil Absorbency, Cobb–Unger, g/m2 |

|---|---|---|---|---|

| WBB-coated | 216 | 8.45 | 12.2 | 14.8 |

| (21) | (0.33) | (2.7) | (2.0) | |

| Silicon-coated | 51 | 1.47 | 0.8 | 1.1 |

| (4) | (0.30) | (0.6) | (0.2) | |

| PE-coated | 38 | 3.23 | 0.4 | 0.8 |

| (4) | (0.17) | (0.2) | (0.2) | |

| Base paper | 523 | 7.37 | 33.4 | 46.2 |

| (33) | (0.73) | (2.9) | (2.3) | |

| M-NFC-coated 1.2 g/m2 | 318 | 6.44 | 19.5 | 30.3 |

| (51) | (1.28) | (6.9) | (7.4) | |

| M-NFC-coated 1.8 g/m2 | 265 | 4.67 | 14.1 | 16.2 |

| (70) | (1.37) | (4.5) | (4.6) | |

| M-NFC-coated 2.9 g/m2 | 185 | 3.22 | 10.5 | 9.6 |

| (75) | (0.31) | (2.0) | (2.0) |

| Sample | Contact Angle, ° | Dispersive Free Surface Energy, mN/m | Polar Free Surface Energy, mN/m | ||

|---|---|---|---|---|---|

| Water | Isopropanol | Castor Oil | |||

| WBB-coated | 127.46 | 30.36 | 77.58 | 33.63 | 5.01 |

| (0.06) | (0.06) | (0.16) | |||

| Silicon-coated | 110.43 | 23.11 | 80.17 | 26.65 | 0.15 |

| (0.09) | (0.08) | (0.12) | |||

| PE-coated | 80.45 | 24.27 | 76.48 | 11.80 | 13.28 |

| (0.09) | (0.21) | (0.16) | |||

| Base paper | 116.51 | 9.45 | 88.91 | 32.91 | 1.77 |

| (0.03) | (0.02) | (0.13) | |||

| M-NFC-coated 1.2 g/m2 | 113.44 | 9.11 | 86.65 | 31.14 | 0.91 |

| (0.08) | (0.04) | (0.07) | |||

| M-NFC-coated 1.8 g/m2 | 111.64 | 8.21 | 87.41 | 30.18 | 0.54 |

| (0.12) | (0.08) | (0.12) | |||

| M-NFC-coated 2.9 g/m2 | 111.44 | 7.31 | 86.88 | 29.92 | 0.44 |

| (0.07) | (0.05) | (0.13) | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubowik, M.; Przybysz, K.; Dańczak, J.; Lipkiewicz, A.; Gajadhur, M.; Górska, B.; Pawłowska, E.; Drozd, R.; Przybysz, P. Micro- and Nanofibrillated Cellulose Coatings as Barriers Against Water and Oil in Food Packaging Paper: A Sustainable Alternative to Plastic Coatings. Coatings 2025, 15, 270. https://doi.org/10.3390/coatings15030270

Dubowik M, Przybysz K, Dańczak J, Lipkiewicz A, Gajadhur M, Górska B, Pawłowska E, Drozd R, Przybysz P. Micro- and Nanofibrillated Cellulose Coatings as Barriers Against Water and Oil in Food Packaging Paper: A Sustainable Alternative to Plastic Coatings. Coatings. 2025; 15(3):270. https://doi.org/10.3390/coatings15030270

Chicago/Turabian StyleDubowik, Marcin, Kamila Przybysz, Jacek Dańczak, Aneta Lipkiewicz, Marta Gajadhur, Beata Górska, Ewelina Pawłowska, Robert Drozd, and Piotr Przybysz. 2025. "Micro- and Nanofibrillated Cellulose Coatings as Barriers Against Water and Oil in Food Packaging Paper: A Sustainable Alternative to Plastic Coatings" Coatings 15, no. 3: 270. https://doi.org/10.3390/coatings15030270

APA StyleDubowik, M., Przybysz, K., Dańczak, J., Lipkiewicz, A., Gajadhur, M., Górska, B., Pawłowska, E., Drozd, R., & Przybysz, P. (2025). Micro- and Nanofibrillated Cellulose Coatings as Barriers Against Water and Oil in Food Packaging Paper: A Sustainable Alternative to Plastic Coatings. Coatings, 15(3), 270. https://doi.org/10.3390/coatings15030270