Abstract

Polymer composite coatings exhibit excellent mechanical properties, chemical resistance, and self-lubricating characteristics, providing an effective solution to address the failure of transmission components under harsh operating conditions, including high-speed, high-pressure, and oil-deficient environments, which often lead to excessive friction and limited bearing performance. This study fabricated three polyamide-imide (PAI) composite coatings modified with monodisperse surface-modified nano-silica (SiO2) via direct spraying and compared their physicochemical parameters. The tribological performance of the three coatings was evaluated using ring-block high-speed friction and wear tester under continuous loading conditions. The tests were conducted using diesel engine oil CI4-5W40, supplemented with oil-soluble cerium dioxide (CeO2) nanoparticles as an energy-efficient and restorative additive, as the lubricating medium. The experimental results demonstrated that the PAI composite coating exhibited a load-bearing capacity exceeding 1000 N (66 MPa). The wear mechanism analysis reveals that CeO2 nanoparticles embedded in the coating surface form a cobblestone-like protective layer. This unique microstructure compensates for the surface pits generated by PAI matrix transfer and minimizes direct contact between the coating and steel ring. Additionally, the synergistic interaction between short carbon fiber (SCF) and the tribofilm contributes to the exceptional tribological properties of the coating, including coefficients of friction as low as 0.04 and wear rates below 0.41 × 10−8 mm3/N·m. The experimental findings could provide an experimental and theoretical foundation for the application of coatings under conditions involving finished lubricants.

1. Introduction

Due to their excellent thermal stability, chemical resistance, and self-lubricating properties, polymer composite coatings have emerged as a critical solution for mitigating tribological failures in transmission components under extreme operating conditions, particularly at boundary conditions such as high speed and high pressure, oil starvation, etc., thereby enhancing their operational safety, reliability, and long lifespan [1,2,3]. Among polymers, polyimide (PI) is a leading engineering plastic known for its excellent mechanical strength, highly designable structure, self-lubricating properties, and strong adhesion to metal, making it an ideal binding agent matrix for self-lubricating nanocomposite coatings [4,5,6,7]. However, a significant challenge persists in enhancing the performance of PI composite coatings to achieve superior stability and prolonged lubrication under high-load operating conditions while maintaining ultralow wear rates, minimal friction coefficients, and high load-bearing capacity.

To address the challenges associated with PI coatings, the incorporation of fillers featuring nanostructures of varying dimensions into PI has emerged as the predominant enhancement strategy in the field, such as 0D nanoparticles (LaF3 [8], ZnO [9,10,11], Al2O3 [12,13], etc.), 1D reinforcing fibers (glass fiber (GF) [14], carbon fiber (CF) [15], etc.), and 2D solid lubricants (MoS2 [16,17], graphene [18], polytetrafluoroethylene (PTFE) [19], etc.). The synergistic incorporation of multiple nanofillers significantly enhances the tribological and mechanical properties of coatings [20,21]. This improvement is achieved through the complementary effects of different dimensional nanoparticles: 0D nanoparticles provide surface polishing and repair capabilities, 1D nanomaterials enhance load-bearing capacity and wear resistance, and 2D nanomaterials contribute to lubrication and tribofilm formation. Yan et al. [22] developed epoxy (EP) composite coatings incorporating SiO2 and graphene oxide (GO) as reinforcing fillers. The synergistic effects between the combination of the shielding and lubricating of GO with the rolling bearing capability of SiO2 significantly enhanced the wear resistance and anti-corrosion of coating. Lan et al. [21] employed SiO2 and CF to augment the mechanical properties of ultra-high-molecular-weight polyethylene (UHMWPE) composites, including hardness and compressive strength. Additionally, they achieved macroscopic super-lubricity and ultralow wear under water lubrication conditions. Chen et al. [23] synthesized a ZnO/h-BN hybrid material via a surface modification method to enhance its interfacial bonding with EP. The resulting composite coating demonstrated exceptional tribological properties under high-load and high-speed conditions. Yang et al. [24] grafted MoS2 onto CF, which significantly enhanced the interfacial bonding between the nanofillers and PI. The CF effectively dispersed the coating stress, while the MoS2 exhibited excellent lubricating properties. This synergistic effect resulted in improved load-bearing capacity and wear resistance of the PI composites. Song et al. [25] incorporated short glass fiber (SGF), PTFE, and SiO2 into PI to enhance the thermal stability and hardness of the PI composites. The synergistic effect of these three nanofillers endowed the PI composites with exceptional tribological properties under high-speed and high-pressure conditions.

The mechanical and tribological properties of polymeric materials can be significantly enhanced by incorporating various types of nanofillers. However, the utilization of three distinct types of nanofillers to improve the tribological performance of PI coatings has been rarely reported in the literature. In addition, surface modification of nanoparticles represents a crucial strategy for enhancing their homogeneous dispersion and interfacial bond within polymer matrices, which is a critical consideration in the development of nanofiller-reinforced polymers.

Furthermore, the application of lubricating media during the friction process represents another crucial approach for enhancing the tribological performance and load-bearing capacity of coatings [11]. Tu et al. [19] demonstrated that PAI composite coatings show superior tribological performance under oil lubrication, owing to their excellent compatibility with ester-based lubricants. This compatibility enables stable oil film formation at the interface, significantly lowering both friction coefficient and wear rate. Ye et al. [26] observed that liquid paraffin exhibits high viscosity and favorable wettability with PI, leading to the formation of a robust boundary lubrication layer during frictional interactions. This layer imparts enhanced friction reduction and wear resistance properties to PI coatings. In addition, the incorporation of nano-additives into the lubricating medium can significantly enhance its load-carrying capacity and tribological properties [27,28].

As a rare earth compound, CeO2 exhibits high reactivity due to the presence of two variable valence states, Ce3+ and Ce4+, which impart CeO2 with robust adsorption capabilities and facilitate the formation of tribofilms during friction processes [29]. Furthermore, when utilized as a lubricant additive, CeO2 demonstrates exceptional friction reduction performance, wear resistance, and load-bearing capacity. Lei et al. [30] incorporated CeO2 and zinc dialkyl dithiophosphate (ZDDP) as nano-additives into polyalphaolefin (PAO6). The CeO2 nanoparticles facilitated the formation of a tribofilm, and in combination with ZDDP, they synergistically developed a highly anti-wear and load-bearing tribofilm at the contact interface, providing excellent tribological performance. Mohamed et al. [31] dispersed CeO2 as an additive within a fully synthetic engine oil (CW-30). Their findings demonstrated that CeO2 forms a protective layer during friction, promoting the formation of a stable tribofilm that significantly enhances interfacial friction reduction and wear resistance properties. Shen et al. [32] incorporated isobutylene sulfide (SIB) and CeO2 as additives in a titanium composite grease. During the friction process, SIB and CeO2 synergistically polished the surfaces and complemented one another, leading to the formation of a tribofilm, which provided friction reduction and anti-wear properties for the grease. The incorporation of CeO2 nano-additives during the friction process exhibits multiple functionalities, including polishing the surface, the formation of a tribofilm, and the embeds forming a protective layer at the contact interface. These functionalities collectively contribute to the enhancement of load-bearing capacity and tribological performance of the coatings.

Based on the aforementioned analysis, polyamide-imide (PAI), renowned for its exceptional adhesion to metal substrates, is employed as the binder in this study. To enhance the dispersion and embedding of PAI, amino-modified SiO2 (SiO2-NH2) was introduced into its chain segment. Furthermore, the PAI coating was synergistically reinforced with the incorporation of BN and SCF. CeO2 nanoparticles were added as energy-efficient and regenerative additives to the CI4-5W40 lubricant base of the formulated oil. These nanoparticles, in conjunction with the lubricant base, collectively imparted remarkable load-bearing capacity exceeding 1000 N (66 MPa) to the PAI coating. Analysis of the wear mechanism reveals that during friction, CeO2 forms a cobblestone-like protective layer, which is synergistic with the SCF and the tribofilm, and provides exceptional friction reduction (friction coefficient of 0.04) and wear resistance performance (wear rate, 0.41 × 10−8 mm3/N·m) for the PAI composite coating. This will provide an important experimental foundation and theoretical basis for the design of axle shaft coatings and lubricating oils for diesel engines in the future.

2. Materials and Methods

2.1. Materials

The PAI resin (solid content, 37%) was commercially obtained from the Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, China. BN powder with a particle size of 50 nm was purchased from Beijing Deco Island Gold Science and Technology Co., Ltd. (Beijing, China); SiO2-NH2 was provided by the pilot base of Henan University (named SiO2) with a particle size of about 20 nm, China; SCF was supplied by Nantong Senyou Carbon Fiber Co., Ltd. (Nantong, China), D: 4–7 μm, L: 20–50 μm; N, N-Dimethylformamide (DMF) was purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China); CI4-5W40 diesel oil was obtained from Liaoning Kunlun Lubrication Technology Co., Ltd. (Anshan, China). Petroleum ether was provided by Tianjin Fuyu Fine Chemical Co., Ltd. (Tianjin, China). CeO2 was prepared in the laboratory. The materials used were used as received and were not further processed.

2.2. Preparation of Composite Coatings

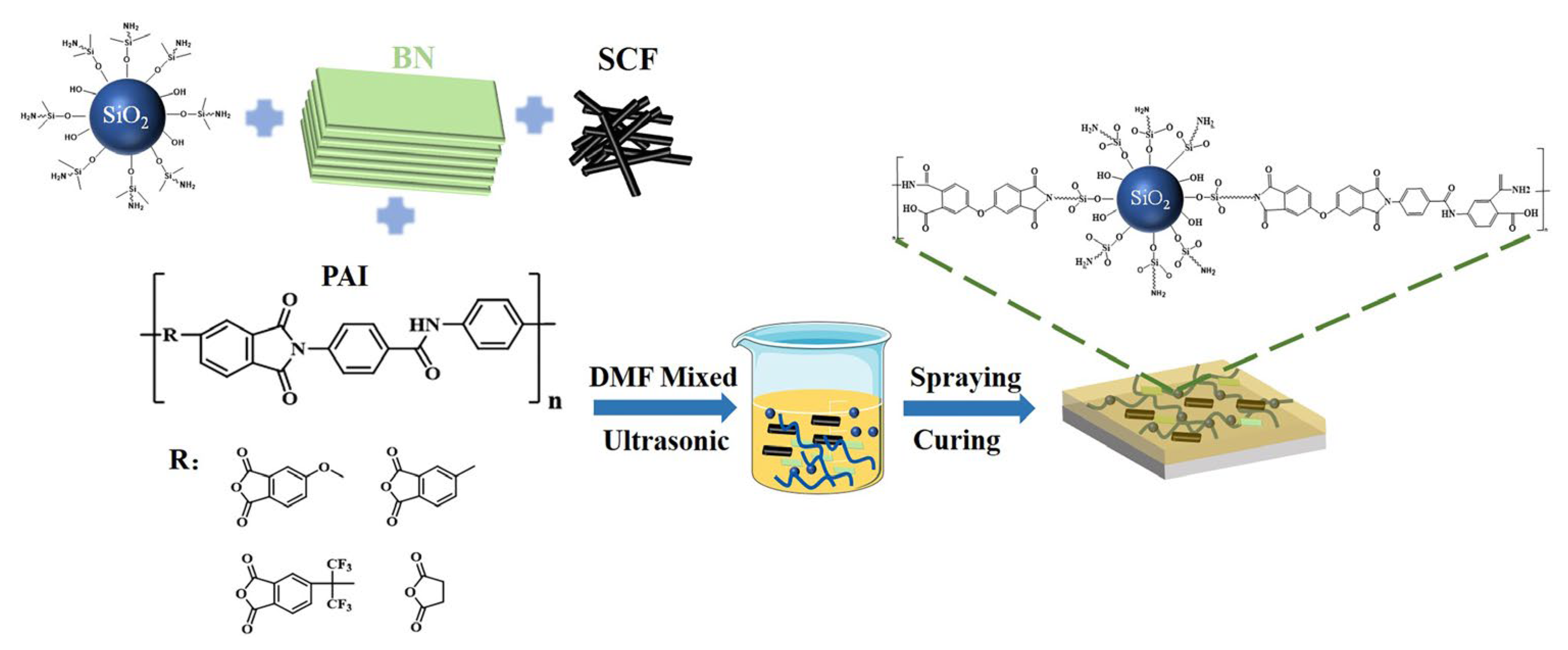

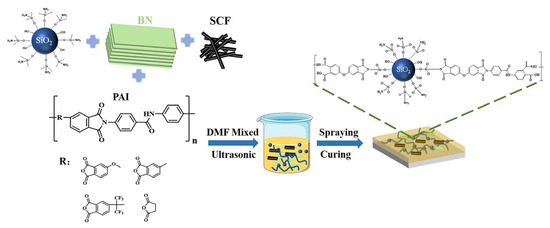

Scheme 1 illustrates the preparation process of PAI/BN/SiO2/SCF composite coating. The constituent materials, including SCF, SiO2, BN, and PAI, were dispersed in DMF solvent to prepare the suspension according to the weight percent listed in Table 1. The suspension was then subjected to ultrasonication and magnetic stirring to ensure its homogeneity. Subsequently, PAI composite coating was prepared by spraying the suspension on a GCr15 steel block under 0.2 MPa pressure using compressed air spraying technology, followed by programmed temperature rise and curing in an oven, specifically, hold at 80 °C for 8 h, hold at 150 °C for 1 h, hold at 200 °C for 1 h, hold at 250 °C for 1 h, and finally ramp up to 300 °C hold for 1 h, then end. For comparative analysis, there are three different contents of the coating materials listed in Table 1 and prepared by the same method. These coatings were subjected to testing under diverse oil lubrication conditions. For the convenience of subsequent discussions, the pure PAI coating is named NP coating, the PAI/BN/SiO2 composite coating is named PBS composite coating, and the PAI/BN/SiO2/SCF composite coating is named PBSF composite coating.

Scheme 1.

The preparation process of PBSF composite coating.

Table 1.

Mass fraction of nanofillers contained in different composite coatings.

2.3. Tribology Tests

Tribological tests were carried out by a high-speed ring-block friction and wear tester (MRH-3, Jinan Yihua Tribological Testing Technology Co., Ltd. (Jinan, China)). The surfaces of the dyadic GCr15 steel rings were polished with 1200 C and 2000 C sandpaper before the tests, and then ultrasonically cleaned with petroleum ether for 30 min after the surfaces were polished. Subsequently, the coating and steel ring assembly were mounted onto the tribometer for a friction test. The friction experiments were conducted utilizing a continuous loading method (100 N, 200 N, 300 N, 400 N, 500 N, 1000 N), each load was carried out for 30 min, and at the end of each load, unloaded and then reloaded to the next experimental load. Each experiment was repeated three times; the friction coefficient was the average value of the stationary phase under each load. CI4-5W40 (named CW) and CI4-5W40 + CeO2 (named CW + CeO2) lubricating medium was dripped onto the contact surfaces using a micro syringe pump (LSP01-1A, Baoding Lange Constant Flow Pump Co., Ltd. (Baoding, China)) so that the contact surfaces of the coating and the steel ring were always covered with the lubricant. In addition, the wear rate was calculated according to the following wear formula [18,19,33,34]:

where WR is the wear rate (mm3/Nm), V is the total friction volume (mm3), L is the overall sliding distance (m), and F is the normal load (N). The experimental conditions and sample parameters are shown in Table 2.

Table 2.

Experimental parameters and conditions.

2.4. Characterization Methods

Transmission electron microscopy (TEM, JEOL, JEM-2100, Tokyo, Japan) was used to analyze the morphology and particle size of SiO2. The functional groups of the SiO2 were characterized using Fourier transform infrared spectroscopy (FT-IR, VERTEX 70, Bruker Spectroscopy Instruments, Ettlingen, Germany). A scanning electron microscope (SEM, Gemini SEM 500, Gal Zeiss, Stuttgart, Germany) combined with an energy dispersive spectrometer (EDS; Oxford Instruments, Abingdon, UK) was used to characterize and analyze the morphology of the SiO2, PAI composite coating cross-section, and worn surface. The surface hardness of the coatings was measured by a micro-hardness tester (HVS-1000CCD, Shanghai Benson Instrument and Equipment Co., Ltd. (Shanghai, China) with an experimental load of 1 kg (9.8 N/kg). The surface roughness of the coating was evaluated through a three-dimensional profilometer optical profiler (Contour-K1, Bruker, Billerica, MA, USA). The surface morphology of both the coating and steel ring was characterized using an ultra-depth-of-field three-dimensional optical microscope (LY-WN-YN, Chengdu Liyang Precision Electromechanical Co., Ltd., Chengdu, China).

3. Results and Discussion

3.1. Characterization of SiO2 Morphology and Structure

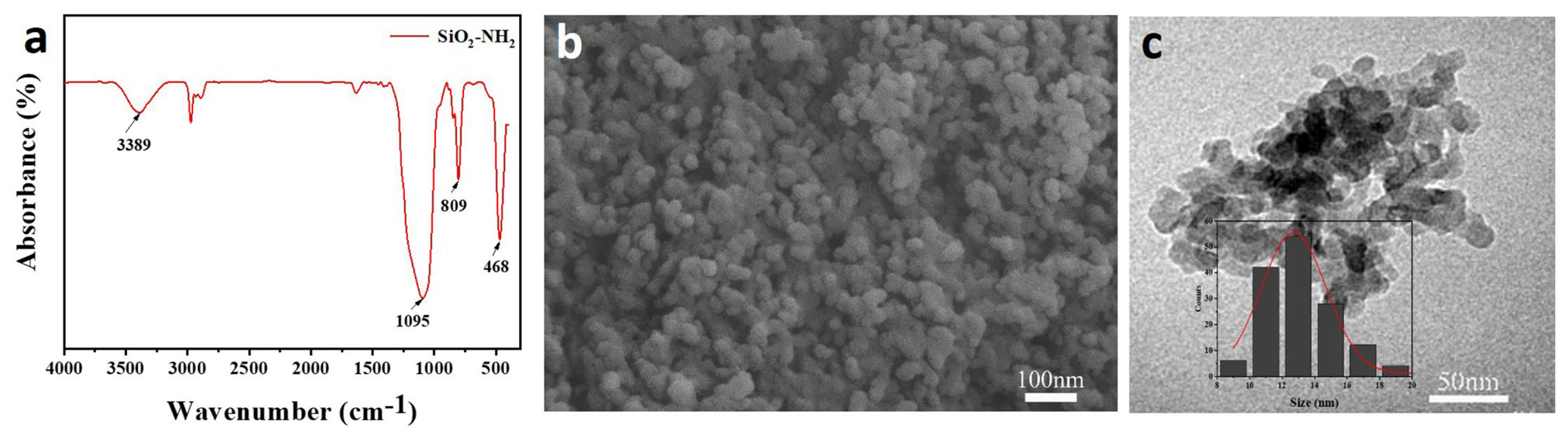

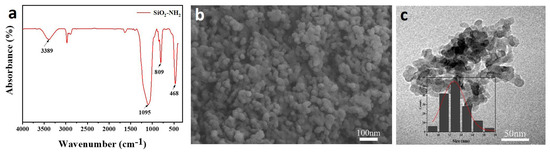

The structural and morphological characterization of SiO2 nanoparticles is shown in Figure 1. As demonstrated in the FT-IR spectrum of SiO2 in Figure 1a, the absorption peak at 3389 cm−1 is attributed to the -NH- stretching vibration. The stretching vibrational peaks of Si-O-Si and Si-O appear at 1095 cm−1 and 809 cm−1, 468 cm−1, respectively. The morphological characteristics of nanoparticles significantly influence their physicochemical properties. Specifically, SiO2 nanoparticles exhibit a spherical morphology with an average diameter of 13 nm, demonstrating slight agglomeration tendencies attributed to the presence of polar -NH- functional groups on their surfaces (Figure 1b,c).

Figure 1.

Morphology and structural characterization of SiO2: (a) FT-IR spectrum; (b) SEM image; (c) TEM image and size distribution.

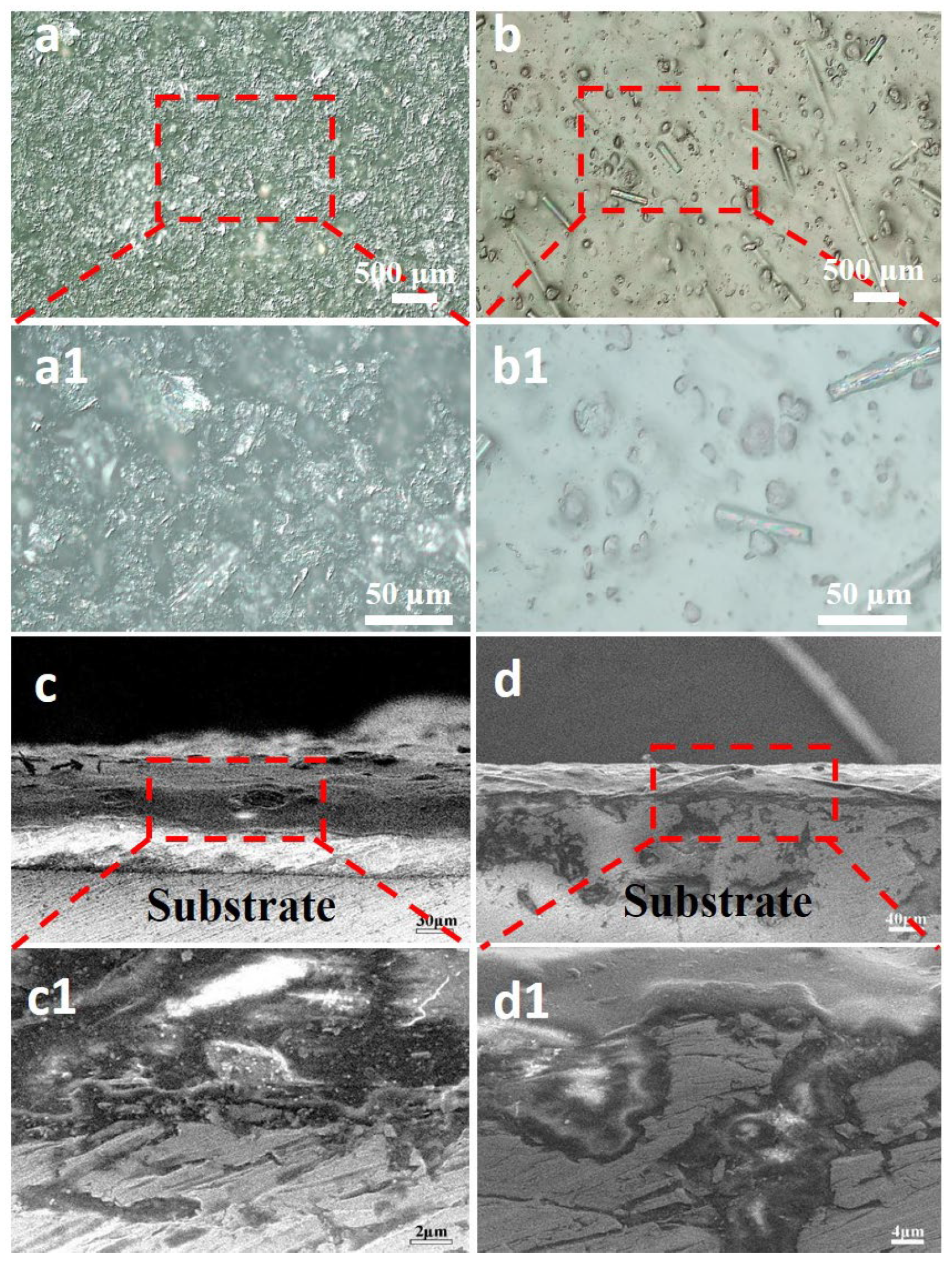

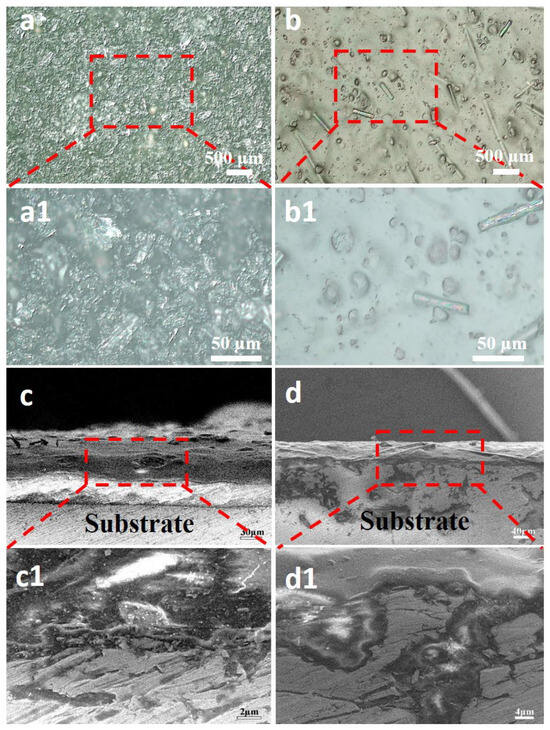

Surface morphology influences the tribological properties of coatings. As illustrated in Figure 2, optical photographs of the surface and SEM images of cross-sections of the PBS and PBSF composite coatings are presented. From Figure 2a,(a1),b,(b1), it is evident that the surfaces of the PBS and PBSF composite coatings exhibit a smooth and dense morphology. The nanoparticles exhibit a strong bond with the PAI substrate, and the dense surface contributes to the enhancement of the coating hardness (NP: 14.5 HV, PBS: 14.7 HV, PBSF: 18.7 HV), the hardness of the PBSF composite coating is increased by 29% relative to NP. Despite the dense surface of the composite coating, its surface roughness increases with nanofiller content (NP: Ra = 0.5 μm, PBS: Ra = 1.2 μm, PBSF: Ra = 1.5 μm). The cross-section SEM images of both the PBS and PBSF composite coatings demonstrate a uniform coating thickness of approximately 30 μm, exhibiting excellent homogeneity and enhanced substrate adhesion. The absence of nanofiller exposure at the coating–substrate interface indicates optimal reinforcement dispersion and effective embedding within the matrix (Figure 2c,(c1),d,(d1)).

Figure 2.

Surface and cross-section of PBS and PBSF composite coatings: (a,a1) surface morphology of PBS composite coating; (b,b1) surface morphology of PBSF composite coating; (c,c1) cross-section of PBS composite coating; (d,d1) cross-section of PBSF composite coating.

3.2. Tribological Properties Under Different Lubrication Conditions

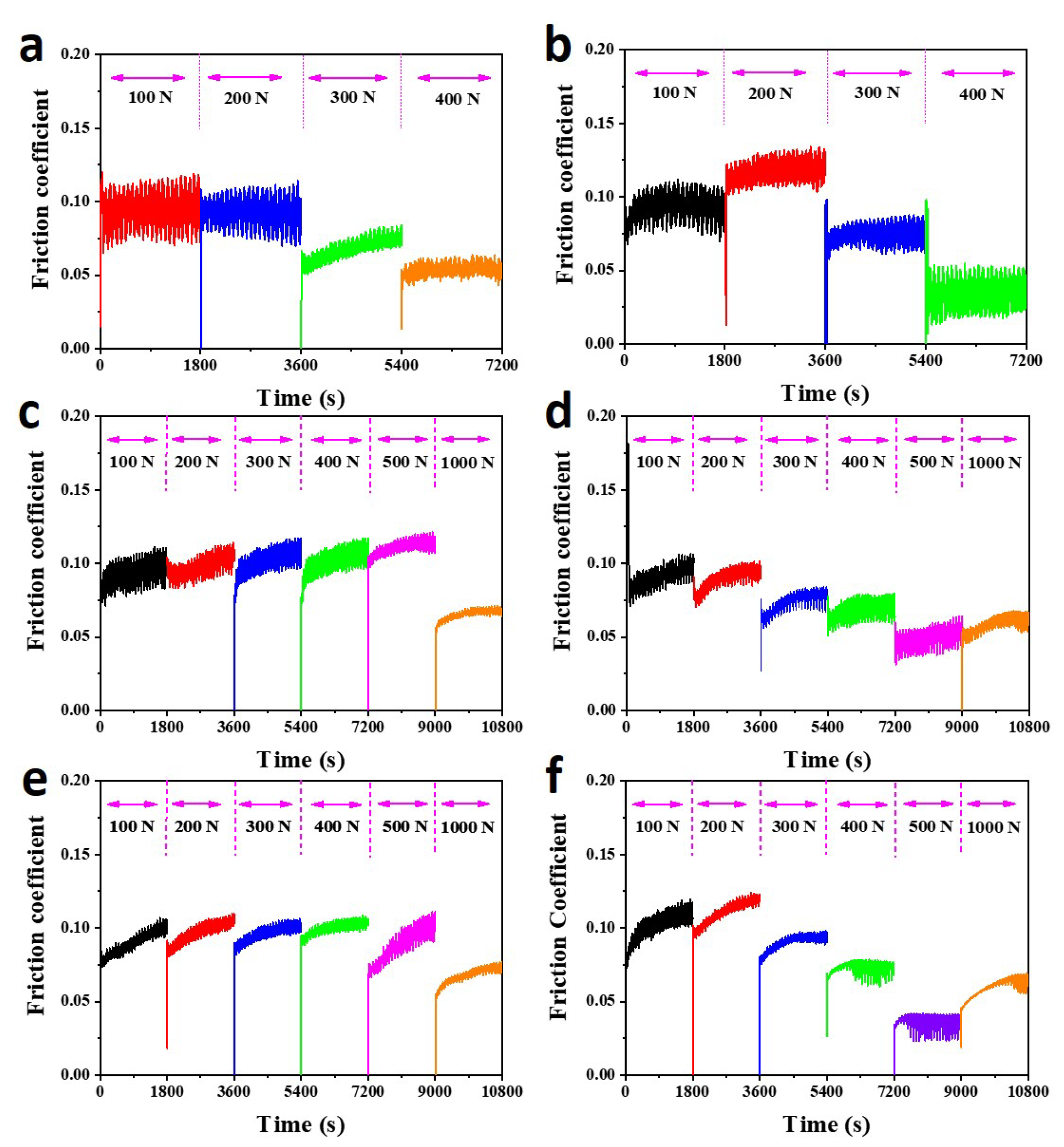

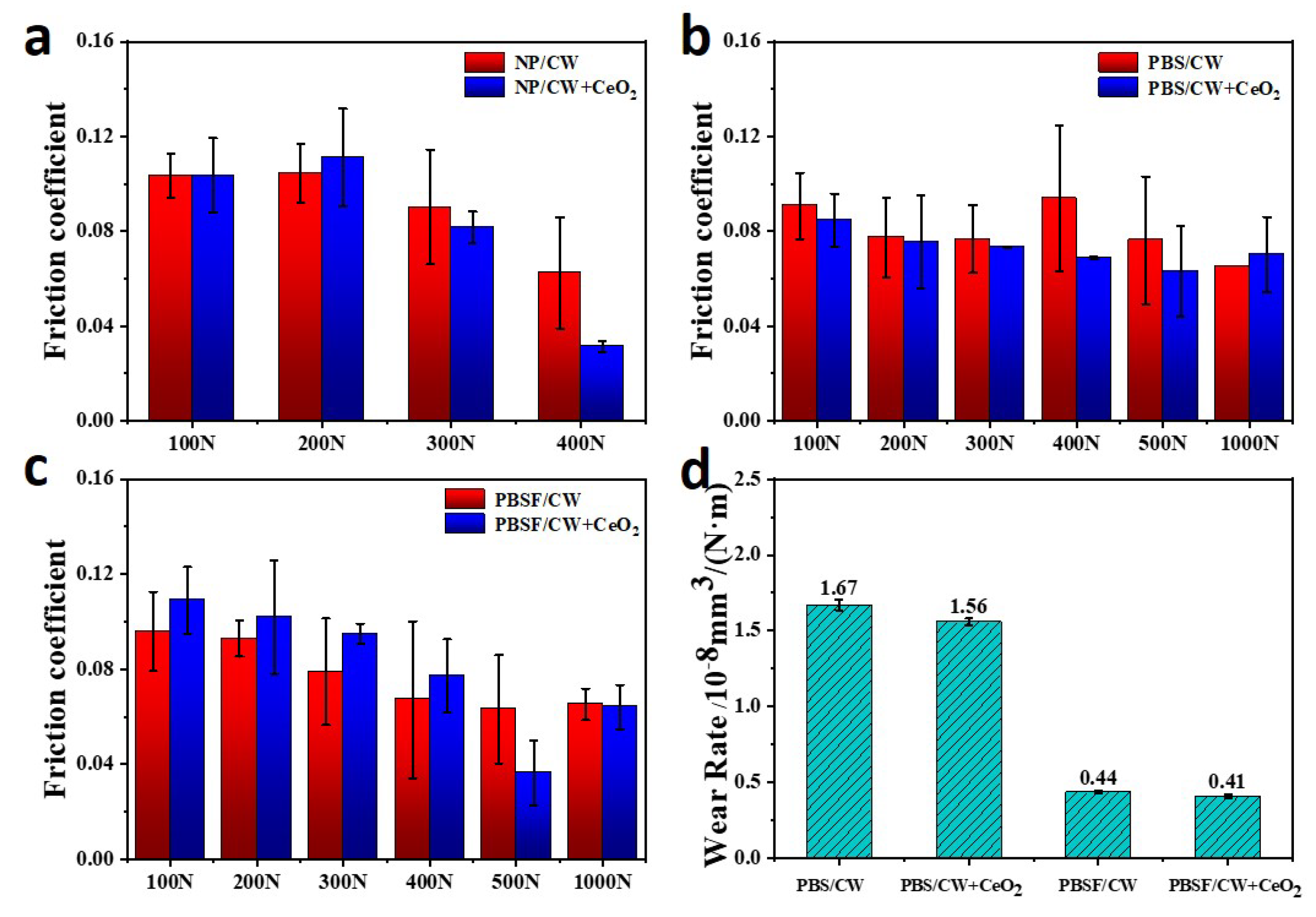

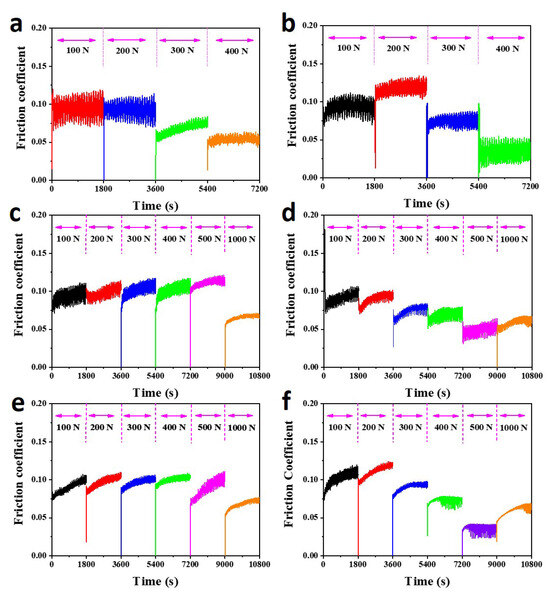

Figure 3 illustrates the variation in friction coefficient curves in different lubrication conditions. The friction coefficient exhibits a decreasing trend with applied load, accompanied by a corresponding reduction in curve fluctuation amplitude, indicating enhanced tribological stability and friction reduction performance under high load conditions. In addition, it has been demonstrated that CW + CeO2 provides superior friction reduction in comparison with CW lubrication conditions. However, at 200 N, the resistance of the lubricating medium is increased due to the mosaic effect of CeO2, increasing the coefficient of friction, but at 300 N and upwards, the load is higher, the resistance decreases and the coefficient of friction decreases. The friction coefficients under the lubrication condition of CW + CeO2 are about 0.03 under 400 N load. The coefficient of friction of the PBS composite coatings showed a gradual increase with time for each load experimental range under CW lubrication conditions. The coefficient of friction finally stabilized at around 0.1 when the load was less than 500 N. The friction coefficients were reduced to about 0.05 when the load was increased to 1000 N (Figure 3c). It was demonstrated that optimal friction reduction is attained with PBS coatings under high loads. Under CW + CeO2 lubrication conditions (Figure 3d), the friction coefficients exhibited a consistent decreasing trend with increasing applied load, reaching remarkably low values of approximately 0.05 at both the 500 N and 1000 N loading conditions. The results demonstrate that the friction reduction in PBS coatings exhibits significant load dependence. Figure 3e,f display the variation in friction coefficient curves of PBSF composite coatings, the trend of friction coefficient of PBSF coatings is consistent with the trend of friction coefficient of PBS coatings, but the fluctuation degree of friction coefficient curves is smaller than that of PBS coatings. Under CW + CeO2 lubrication conditions, the lowest friction coefficient can reach 0.04. The friction reduction effect of CW + CeO2 is superior to that of CW. Comparative analysis of PBS and PBSF compositions and lubricating media revealed that SCF and CeO2 have a significant influence on the tribological behavior of the coatings and play a key role in the friction mechanism.

Figure 3.

Friction coefficient curves of PAI composite coatings under different lubrication conditions: (a) NP/CW; (b) NP/CW + CeO2; (c) PBS/CW; (d) PBS/CW + CeO2; (e) PBSF/CW; (f) PBSF/CW + CeO2.

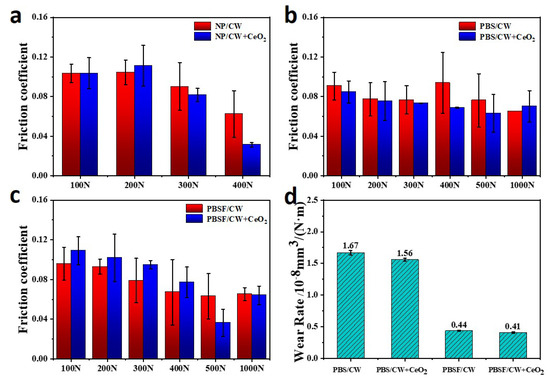

Figure 4 presents the average coefficient of friction and wear rate for various coatings under different lubrication conditions. As illustrated in Figure 4a–c, the coefficient of friction of the three PAI coatings generally show decreases gradually with increasing load under the same lubrication conditions. For the PBS composite coating under CW lubrication conditions, when the applied load is less than 400 N, the oil film primarily functions as an isolator. Consequently, the force exerted on the coating surface is minimal. As the load gradually increases to 300 N, the force acting on the coating surface intensifies, leading to an increased transfer of coating material onto the mating surface, where it forms a transfer film. This transfer film, in conjunction with the lubricating medium, synergistically reduces the coefficient of friction of the coating. And when the load is greater than 400 N, the formation of the oil film is destroyed, reducing its enhancement effect, increasing the contact area between the coating and the steel ring, resulting in an increase in the coefficient of friction, as the load continues to increase, more matrix is transferred to the surface of the dyadic steel ball to form a transfer film, the formation of the transfer film reduces the coefficient of friction of the composite coatings, and continues to be reduced to the end of the experiment; the coefficient of friction is at a minimum at 1000 N. And when CeO2 is added, the load-bearing capacity of CW is improved, and the oil film formed by CW will not rupture when the load is less than 400 N, and its rupture load is increased to 1000 N. However, the PBSF coating exhibits higher friction coefficients under CW + CeO2 lubrication compared to CW alone at loads below 400 N, primarily attributed to the synergistic effect of surface-embedded CeO2 nanoparticles and exposed SCF, which collectively increase frictional resistance, leading to a higher coefficient of friction under CW + CeO2 lubrication conditions at low loads. At elevated loads of 500 N and 1000 N, the mechanical crushing of both CeO2 and SCF results in a smoother friction interface, consequently reducing the overall frictional resistance and coefficient of friction. However, under CW + CeO2 lubrication conditions, the higher load of 1000 N destroys the transfer film formed at low loads and the coefficient of friction increases, with the lowest coefficient of friction at 500 N. The wear rates of PBS and PBSF composite coatings under different lubrication conditions were calculated and statistically obtained, as shown in Figure 4d. For the same coating composition, the enhanced wear resistance performance observed in CW + CeO2 lubrication can be attributed to the effective embedment of CeO2 nanoparticles from the lubricant onto the coating surface, which subsequently fills the microstructural defects and surface pores generated during friction. Under identical lubrication conditions, SCF enhances the surface hardness of the coating, with the exposed SCF bearing the majority of the load during the friction process. Consequently, the PBSF coating exhibits enhanced wear resistance. Under CW + CeO2 conditions, the synergistic interaction between CeO2 and SCF significantly enhances the load-bearing capacity of PBSF coatings under frictional conditions, resulting in the PBSF coating having the lowest wear coefficient of 0.41 × 10−8 mm3/N·m.

Figure 4.

Average coefficient of friction and wear rate under different lubrication conditions: (a) NP; (b) PBS; (c) PBSF; (d) wear rate.

Based on the above analysis of the friction coefficient and wear rate of the coatings, it can be concluded that the incorporation of nanofillers into the PAI matrix significantly enhances the load-carrying capacity, friction reduction, and anti-wear.

3.3. Wear Surface Morphology Analysis

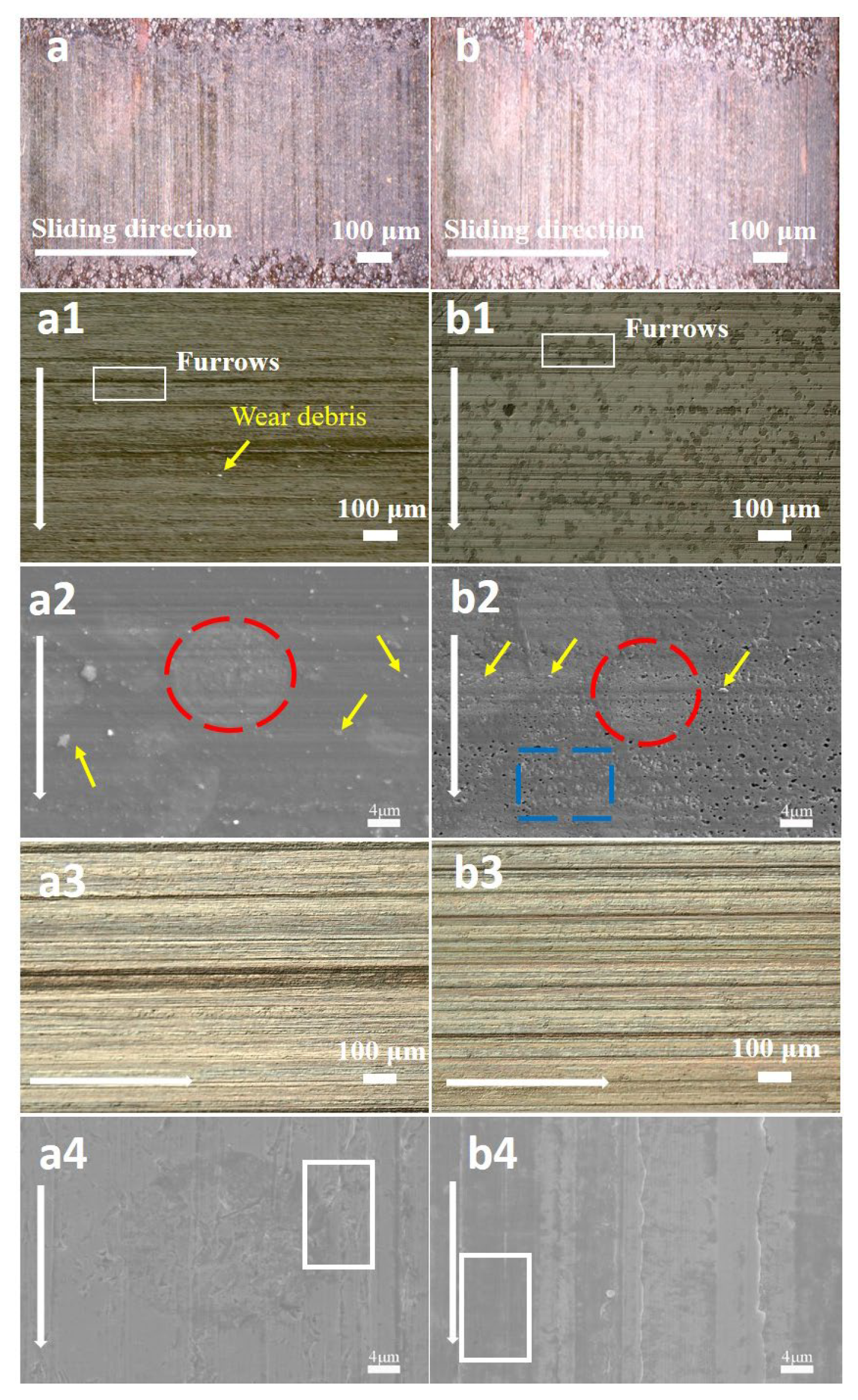

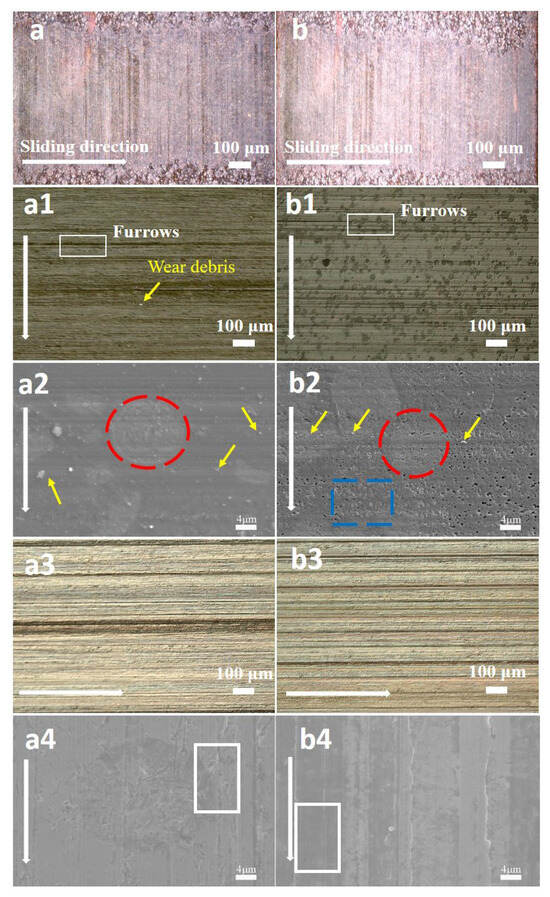

Figure 5 displays the morphology analysis of the coating surface and the steel ring surface after the wear of the PBS composite coating. Figure 5(a–a4) and Figure 5(b–b4) demonstrate the surface of PBS composite coatings after friction under CW and CW + CeO2 lubrication conditions, respectively, where the white arrow represents the sliding direction during friction. As shown in Figure 5a,(a1),b,(b1), the abrasion marks on the wear surface of the coating are concentrated and continuous, and there are obvious furrows and wear debris on the surface of the coating, the wear mode is abrasive wear. The coating has deeper abrasion marks and more wear debris under CW lubrication conditions, the results indicate a relatively high degree of coating wear. There are many pits on the surface in Figure 5(b1). As evidenced by the SEM images presented in Figure 5(a2,b2), the coating surface exhibits numerous points of white wear debris (yellow arrow) and irregular aggregates (red dashed box). In addition, spherical nanoparticles are present in Figure 5(b2) (blue dashed box), in contrast to the variations observed under different lubrication media, the initial analysis suggests that CeO2 nanoparticles were embedded onto the coating surface during the friction process, this improves the wear resistance of the coating [35]. As demonstrated in Figure 5(b3), the steel ring surface exhibits a uniform distribution of furrows with relatively mild wear compared to that observed in Figure 5(a3), where the formation of a transfer film preferentially occurs on the worn regions of the steel ring surface [36], and the formation of the transfer film significantly improves the tribological properties of the coating. The SEM image reveals the formation of a transfer film on the steel ring surface, as indicated within the white rectangular box. Notably, the transfer film observed in Figure 5(a4) exhibits a relatively small coverage area and displays a characteristic corrugated morphology with partial delamination on the surface. The transfer film observed in Figure 5(b4) demonstrates a significantly larger and more continuous coverage area, which contributes to the remarkable enhancement of the coating tribological properties. This observation is consistent with the corresponding improvements in the friction reduction and wear resistance of the coatings, as previously discussed.

Figure 5.

Optical photographs and SEM images of wear surfaces of PBS coatings under different lubrication conditions: (a–a4) CW lubrication conditions; (b–b4) CW + CeO2 lubrication conditions; (a,b,a1,b1) optical photographs of coated surfaces; (a2,b2) SEM maps of the coated surfaces; (a3,b3) optical photographs of the steel ring; (a4,b4) SEM maps of the surfaces of the steel ring.

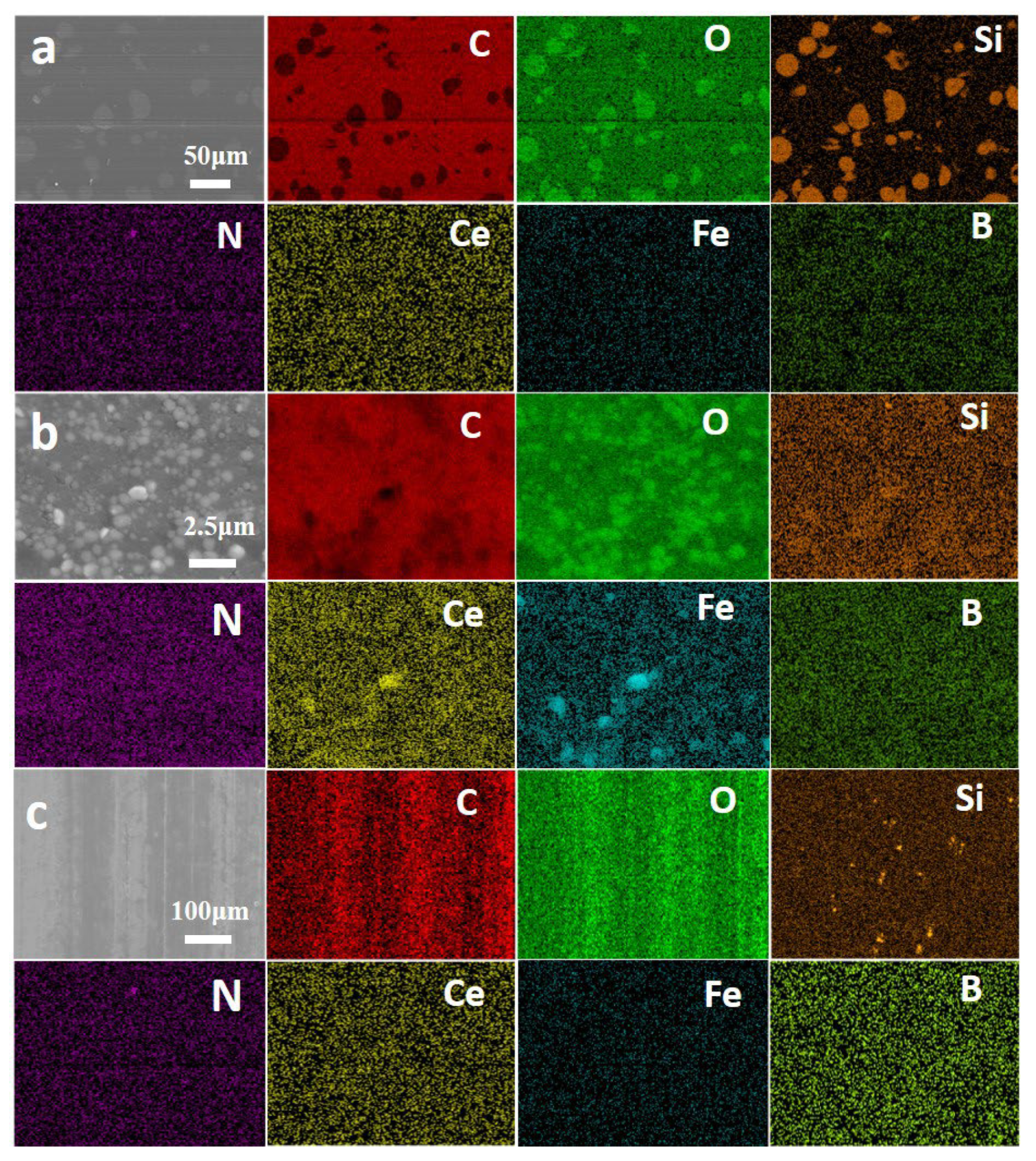

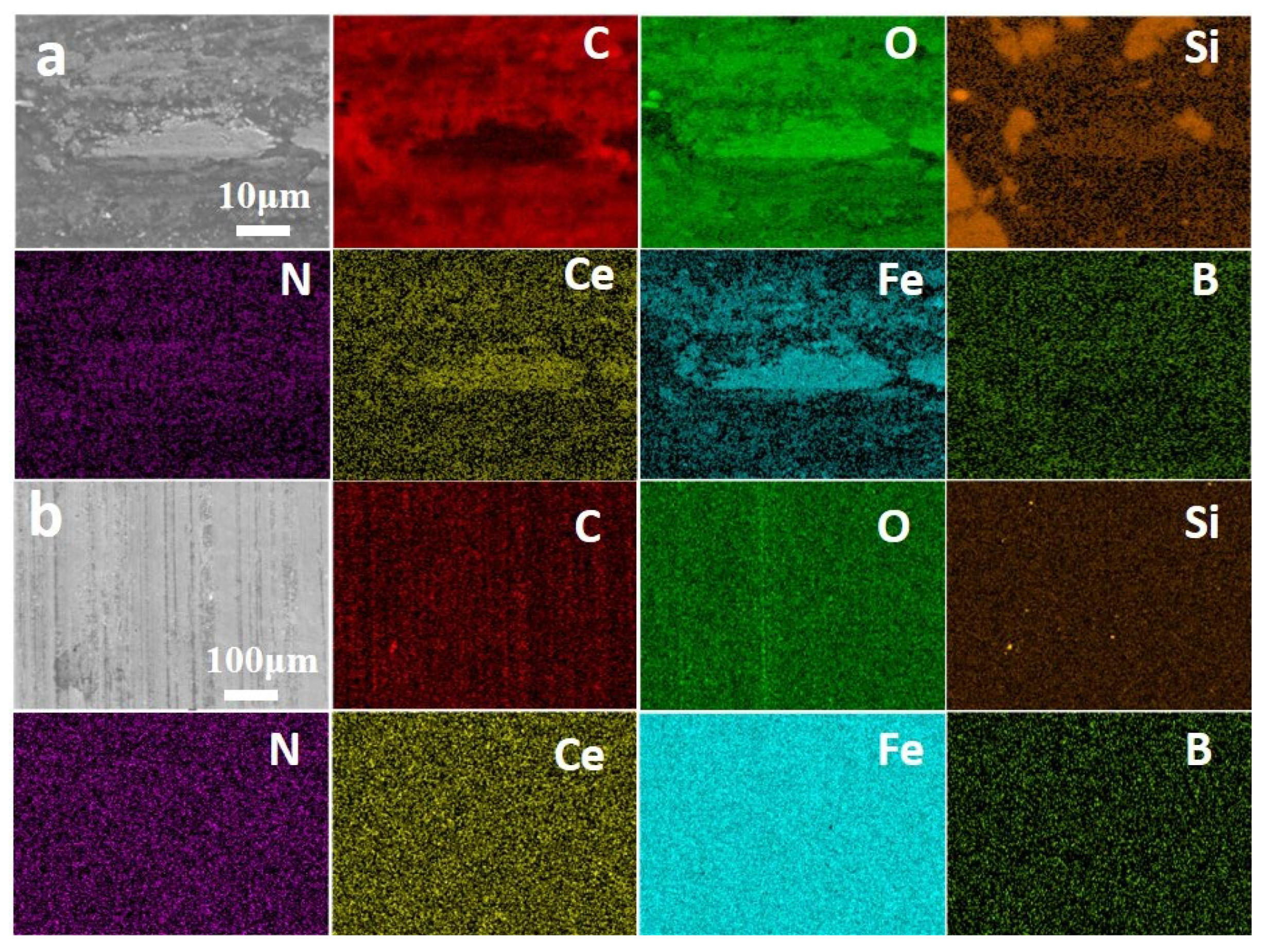

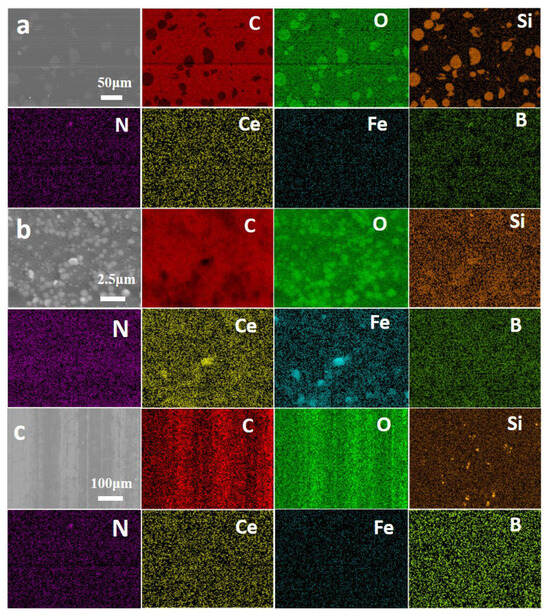

EDS mapping analysis of the wear surfaces of coatings and rings provides a deeper understanding of the wear mechanism. Figure 6a,b show the wear surface of PBS coating under CW + CeO2 lubrication conditions; the distribution of O and Si elements in the EDS mapping element distribution is consistent with the distribution of irregular aggregates on the coating surface, and the identification of irregular aggregates as SiO2 agglomerates. During the friction process, the SiO2 nanoparticles within the coating undergo sliding under the influence of frictional shear forces, thereby contributing to a reduction in the coating’s coefficient of friction. However, when these nanoparticles agglomerate and form a ‘third phase’, they significantly compromise the continuity of the coating matrix, ultimately leading to a deterioration in the coating’s wear resistance [35]. From the distribution of C elements, it can be seen that the presence of -NH- on the surface of SiO2 will cross-link with and become embedded in the PAI matrix, and the coating becomes denser, which contributes to the enhancement of the coating load-bearing capacity and tribological properties. The elemental mapping analysis in Figure 6b, particularly the distribution patterns of Ce and O, confirms that the spherical particles are CeO2. This phenomenon can be attributed to the embedment of CeO2 nanoparticles from the lubricating oil onto the coating surface, facilitated by the combined effects of gravitational force and frictional shear during the sliding process. CeO2 aggregates on the surface of the coating, forming a cover layer similar to a cobblestone pavement, and the formation of the cover layer provides the coating with excellent friction reduction and anti-wear properties. As illustrated in Figure 6c, the presence of C, Si, and O enrichment on the surface of steel rings. The presence of the Si element, originating from SiO2 within the PAI matrix, confirms the transfer of PAI matrix material to the steel ring surface, leading to the formation of a transfer film during the friction process. Additionally, the lubricating medium undergoes tribochemical reactions induced by frictional heat generation, resulting in the subsequent enrichment of C and O elements on the contact surface. The enrichment of the elements B, N, and Ce is not significant, indicating that only a slight transfer of the coating takes place during the friction process, which is mainly formed by the carbonation of the lubricant, being the main components of the transfer film. The synergistic interaction between the transfer film, which contains C, O, and Si elements, and the CeO2 overlayer on the coating surface collectively contributes to the enhanced load-bearing capacity and superior friction reduction and anti-wear properties of the coating.

Figure 6.

EDS mapping of PBS coatings on the surface of the coatings and steel rings after wear under CW + CeO2 lubrication conditions: (a,b) surface of the coating; (c) surface of the steel rings.

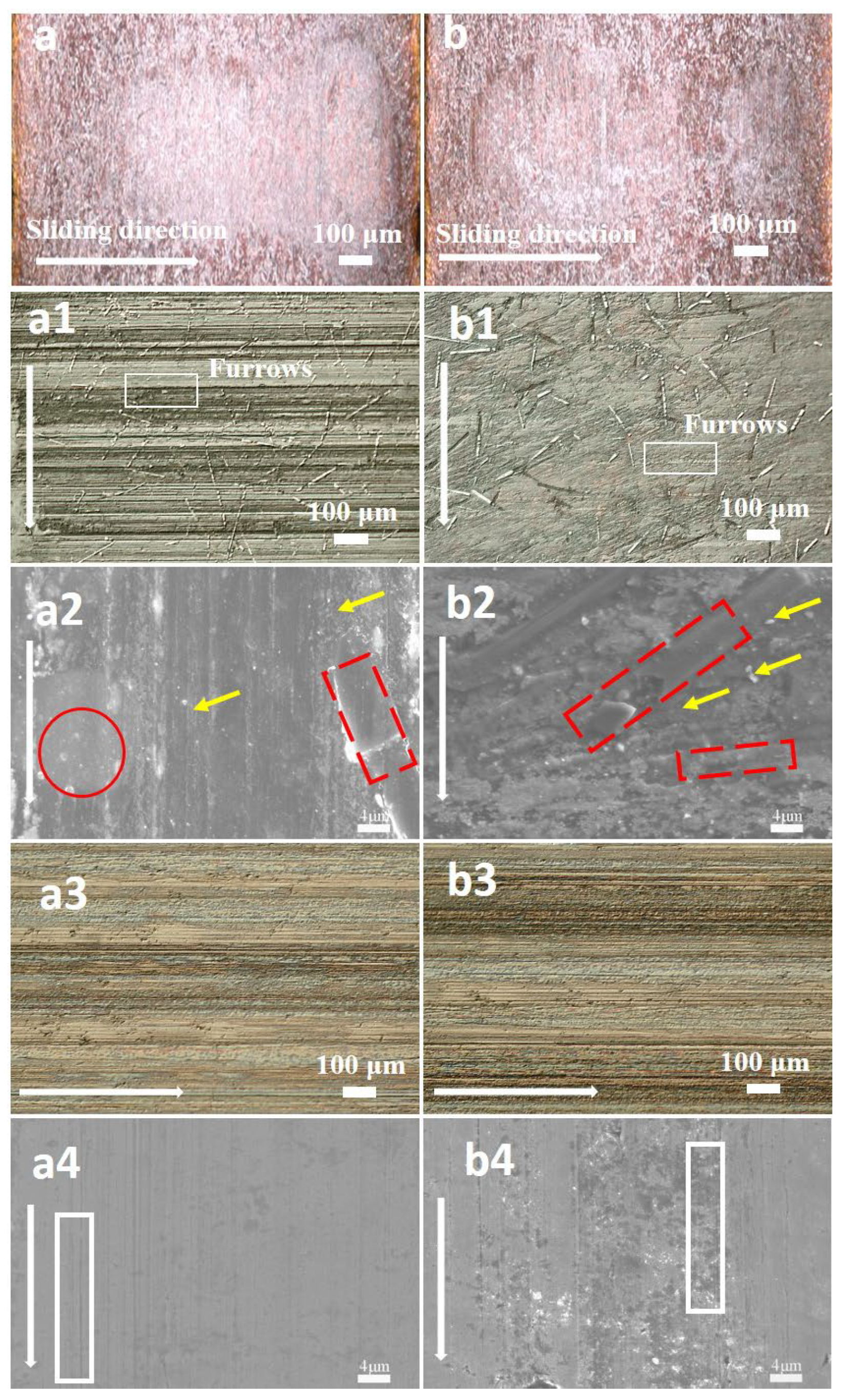

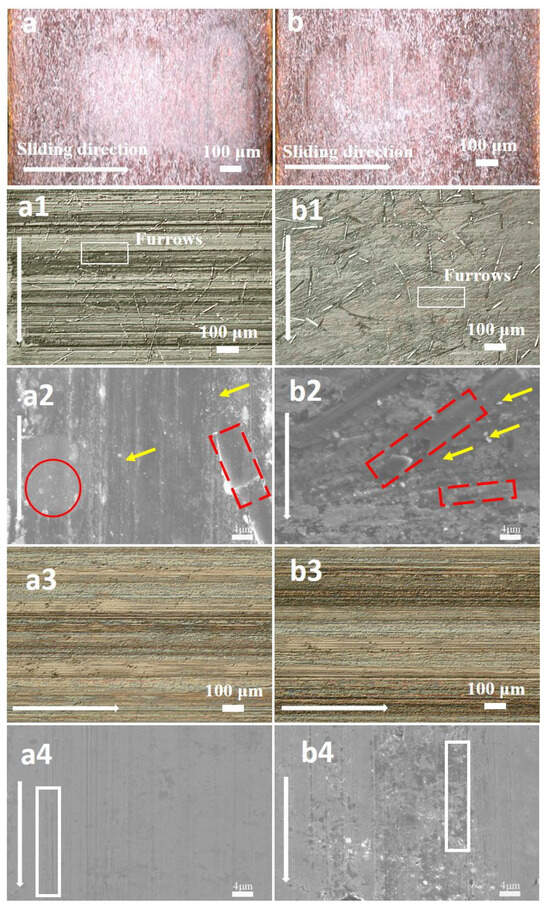

Figure 7 illustrates the morphology analysis of the coating surface and the steel ring surface after the wear of the PBSF composite coating. The coating surface exhibits numerous fractured and delaminated SCF, with the degree of fiber damage in Figure 7(b1) being significantly less severe compared to Figure 7(a1), abrasive wear is the main mode of wear. These SCFs play a crucial role in determining the tribological behavior of the coating [14]. The high-strength SCF demonstrates excellent wear resistance when exposed to the wear surface, while simultaneously enhancing the coating’s hardness and mechanical strength [37]. This reinforcement mechanism indirectly contributes to friction reduction and improves the overall stability of the coating during the friction process [35,38,39]. As shown in Figure 7a,b, the abrasion marks on the surface of the PBSF composite coating are shallower and smaller in area compared to the PBS composite coating (Re. Figure 5a,b), and show smaller wear area under CW + CeO2 lubrication conditions. SEM images of the PBSF composite coating surface, as shown in Figure 7(a2,b2), indicate the presence of several distinct features: wear debris (yellow arrows), and fractured and spalled SCF (red rectangular dashed boxes). In addition, in Figure 7(b2), the formation of a CeO2 cover layer can be identified, which exhibits a unique cobblestone-like morphology. This protective layer effectively reduces direct contact between the steel ring and the coating surface while simultaneously encapsulating the SiO2 nanoparticles embedded within the matrix. The CeO2 overlay for cobblestone-like predominantly shares the applied load and effectively mitigates stress concentration around the SCF, thereby preventing fiber fragmentation. This stress dissipation mechanism fundamentally explains the exceptional anti-wear performance demonstrated by the PBSF composite coating under CW + CeO2 lubrication conditions. The presence of furrows on the surface of the steel ring, which are uniformly distributed and large in Figure 7(a3,b3), can be attributed to the increased surface roughness of the coating resulting from exposed SCF, which consequently leads to larger furrow formation during the friction process. In addition, the superior thermal conductivity of SCF facilitates efficient heat transfer from the friction interface to the PAI matrix, thereby minimizing tribochemical reactions at the contact surface and resulting in reduced formation of transfer films on the steel ring counterface [34]. As a result, the transfer films in Figure 7(a4,b4) are not obvious. Although the transfer film formed by the PBSF composite coating is not as complete as that of the PBS composite coating, the friction reduction and anti-wear performance of the coating are significantly enhanced due to the presence of SCF. In particular, when CeO2 is present in the lubrication medium, a cobblestone pavement cover layer is formed on the surface of the coating, and the synergistic enhancement of CeO2 and SCF and the presence of the cover layer provide the coating with excellent tribological properties and load-bearing capacity.

Figure 7.

Optical photographs and SEM images of wear surfaces of PBSF coatings under different lubrication conditions: (a–a4) CW lubrication conditions; (b–b4) CW + CeO2 lubrication conditions; (a,b,a1,b1) optical photographs of coated surfaces; (a2,b2) SEM maps of the coated surfaces; (a3,b3) optical photographs of the steel ring; (a4,b4) SEM maps of the surfaces of the steel ring.

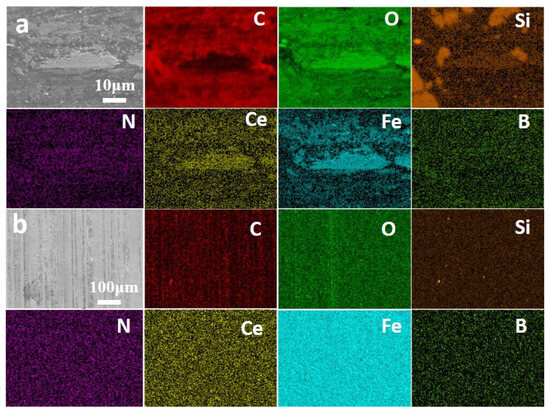

Figure 8 demonstrates the EDS analysis of the coating surface and the surface of the steel ring after friction of the PBSF composite coating under CW + CeO2 lubrication conditions. Figure 8a shows the surface of the PBSF composite coating with a covering layer of CeO2 on the surface of the coating, and the white material is Fe and its oxides. According to the distribution of C and O elements, it can be concluded that CeO2 predominantly aggregates around the SCF and contributes to load sharing with the SCF. The formation of a CeO2 covering layer on the surface, along with its synergistic interaction with SCF, significantly enhances the friction reduction and anti-wear properties of the coating, which is consistent with the SEM imaging observations. Furthermore, the distribution of Si elements indicates that SiO2 also tends to agglomerate during the friction process. However, its presence was not distinctly observed due to the dominant surface coverage provided by the CeO2 layer. As shown in Figure 8b, only a small enrichment of C and O elements was observed on the surface of the rings, indicating that the friction reduction and anti-wear mechanisms of the coating under these conditions are primarily attributed to the synergistic enhancement effect of the cobblestone-like CeO2 and the SCF, which collectively form a protective cover layer. The presence of the protective layer minimizes direct contact between the coating and the steel ring, thereby enhancing the friction reduction and anti-wear properties of the coating.

Figure 8.

EDS mapping of PBSF coatings on the surface of the coatings and steel rings after wear under CW + CeO2 lubrication conditions. (a,b) surface of the coating.

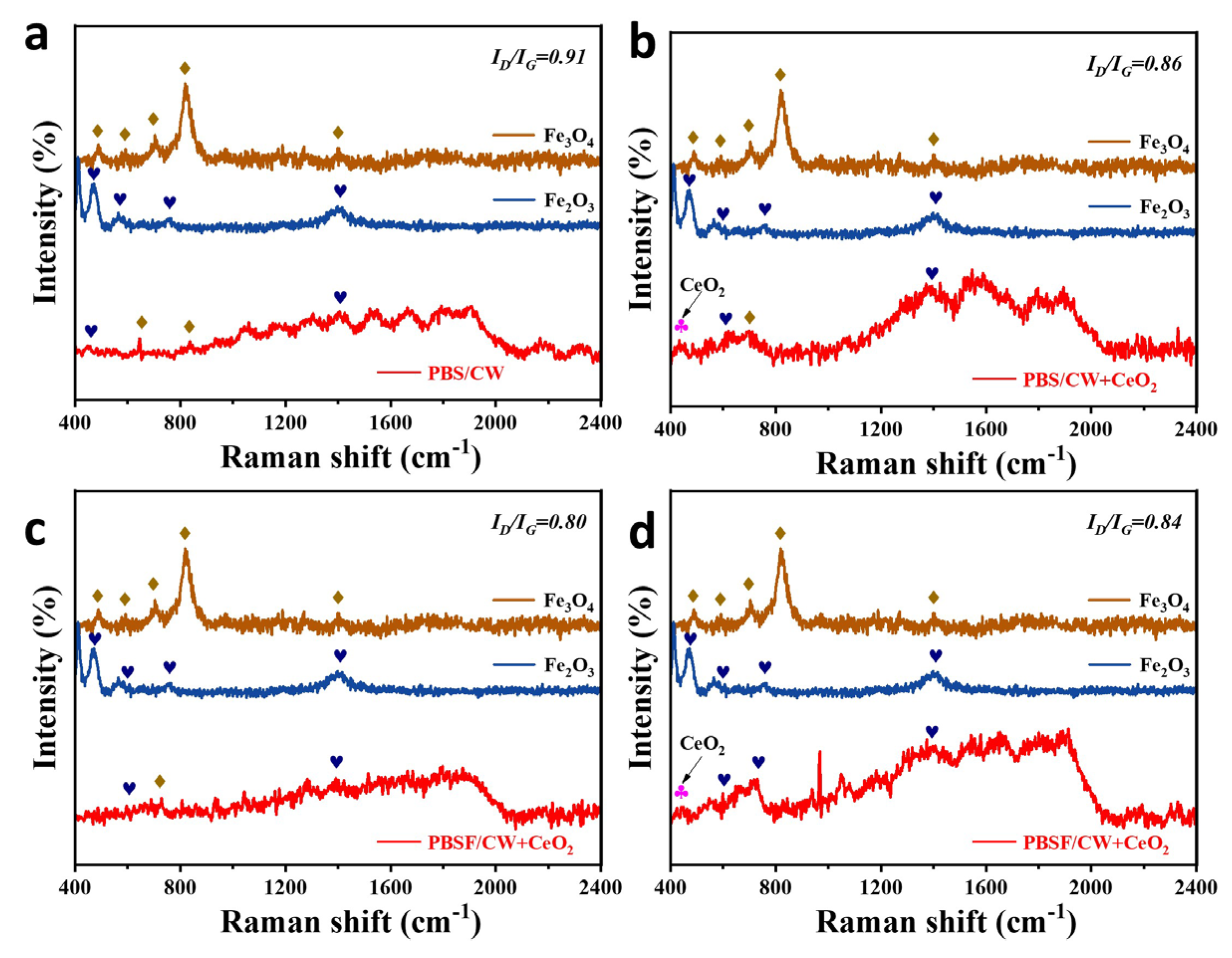

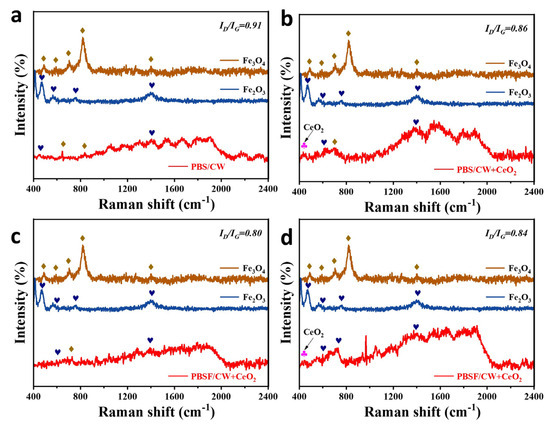

The Raman spectral analysis of the steel ring surface is shown in Figure 9. The ID/IG ratio clearly indicates the degree of defects/ordering in the carbon material, and the composition of the friction film is analyzed to determine the lubrication mechanism [40,41]. From the Raman spectra of the steel ring, the characteristic vibrational peaks of Fe2O3 and Fe3O4 can be observed from the Raman spectra of the steel ring, indicating that the surface of the steel ring oxidizes to form an iron oxide layer due to frictional heat generation during friction. Furthermore, Raman peaks attributable to CeO2 were identified on the ring surfaces under both CW/CeO2 lubrication conditions. This observation indicates that CeO2 nanoparticles present in the lubricating oil were successfully transferred onto the ring surface during the friction process. Throughout the friction process, the contact interface underwent repeated exposure to frictional stress and instantaneous heat generation. Consequently, both the transferred PAI matrix and the oil underwent carbonization at the interface between the coating and the steel ring. Notably, the ID/IG ratios for all four lubrication systems were below unity, suggesting that ordered carbon predominantly comprised the tribofilm composition. Compared to the PBS composite coating, the PBSF composite coating exhibits a smaller ID/IG value. This observation suggests that the superior thermal conductivity of SCF facilitates the reduction in disordered carbon formation through tribochemical reactions within the PBSF coating. Concurrently, it promotes the transfer of more ordered carbon from the PAI matrix to the contact surface. Furthermore, under the PBS/CW + CeO2 lubrication condition, the formation of a protective CeO2 layer significantly diminishes the transfer of the matrix material to the steel ring, resulting in a lower ID/IG value under CW lubrication. In contrast, PBSF coatings exhibit different tribological behavior due to SCF incorporation. The fractured SCF fragments migrate to the steel ring surface during sliding, while the surface roughness induced by both CeO2 nanoparticles and SCF creates severe abrasive wear, as evidenced by the extensive plow furrows observed in Figure 7(b2). This synergistic effect consequently results in substantially higher ID/IG values compared to PBS coatings.

Figure 9.

Raman spectra of the surface of the steel ring after friction with PBS and PBSF composite coatings under different lubrication conditions: (a) PBS/CW; (b) PBS/CW + CeO2; (c) PBSF/CW; (d) PBSF/CW + CeO2.

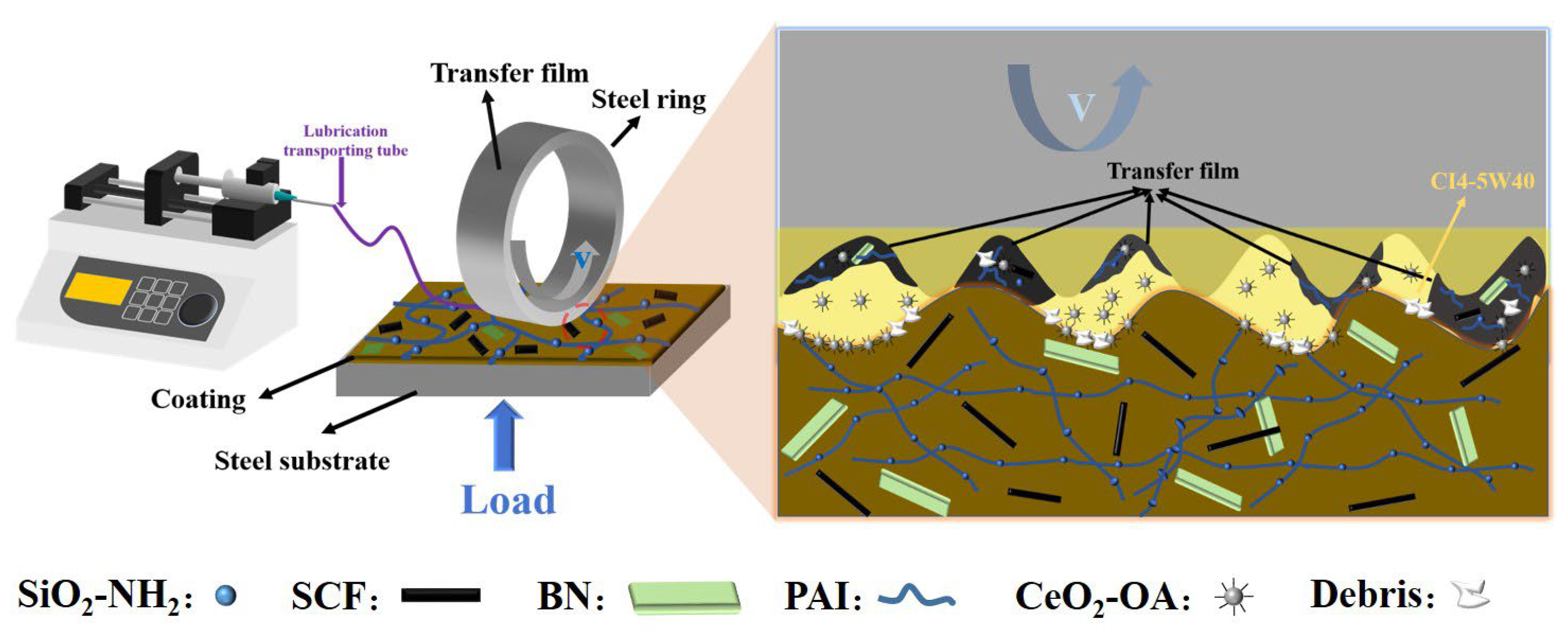

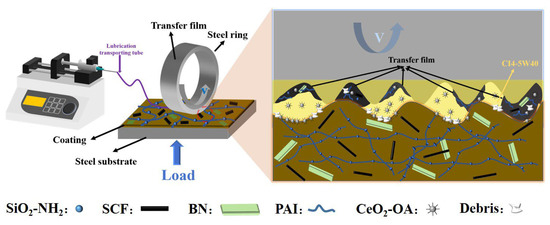

Through analysis of the aforementioned experimental results, the wear mechanism underlying the PBSF/CW + CeO2 lubrication system has been proposed, as shown in Figure 10. During the initial stage of the tribological test, the lubricant medium formed a continuous oil film that effectively covered both the rough coating surface and the steel ring counterface, thereby significantly reducing direct contact. Nevertheless, the steel ring is in direct contact with the exposed SCF and micro-convex bodies on the coated surface and is gradually smoothed to form wear debris under frictional shear force, the friction experiment belongs to the run-in period. Moreover, a portion of the PAI matrix containing nanofillers is transferred onto the steel ring surface, resulting in the formation of a transfer film. As the progression of the tribological test, CeO2 nanoparticles in the lubricant are progressively embedded onto the coating surface through frictional shear forces, effectively filling the microstructural voids generated during the PAI matrix subsequent material transfer. A small amount of CeO2 was also transferred to the surface of the steel ring and compacted, contributing to the formation of the tribofilm. In addition, a cobblestone-like cover layer was formed around the SCF, thereby reducing the stress concentration of the SCF and preventing it from being crushed. Furthermore, the frictional heat generated during the process facilitates the formation of a tribofilm through tribochemical reactions between a small amount of lubricating medium and SCF, which preferentially adheres to the surface coating of the steel ring at the wear site. The cobblestone-like CeO2 cover layer on the coating surface, combined with the tribofilm formed on the steel ring surface, provides the coating with excellent load-bearing capacity, friction reduction, and wear resistance.

Figure 10.

Wear mechanism of PBSF composite coatings under CW + CeO2 lubrication conditions.

4. Conclusions

In this study, three PAI composite coatings incorporating different nanofillers were fabricated using a direct spraying method. The effects of continuous variable loading and various lubricating media on the tribological properties of these composite coatings were systematically investigated. Through comparative analysis of the physicochemical and tribological properties of the three coating materials under different lubrication conditions, the following conclusions were drawn:

- The presence of -NH2- groups on the SiO2 surface, which can be embedded into the PAI coating during the curing process, synergistically enhances the surface hardness of the coating when combined with SCF and BN nanofillers. The PBSF composite coating demonstrates a 29% improvement in surface hardness compared to the pure PAI coating.

- Friction experiments demonstrate that the nanofillers significantly enhance the stability of the coefficient of friction and the load-carrying capacity of the PAI coatings, achieving a load-bearing capacity exceeding 1000 N. Furthermore, the energy-efficient repair additive CeO2 further improves the friction reduction performance of the coatings, exhibiting the most effective friction reduction under high-load conditions. The PBSF composite coatings exhibit the lowest coefficient of friction of 0.04 under CW + CeO2 lubrication conditions, with a wear rate of 0.41 × 10−8 mm3/N·m.

- The wear mechanism of PBSF under CW + CeO2 lubrication conditions reveals that CeO2 forms a cobblestone-like overlayer on the coating surface under the influence of gravity and frictional shear forces, which partially bears the load and reduces stress concentration on SCF. Additionally, a portion of the PAI matrix and the lubricating medium form a tribofilm on the steel ring surface. The synergistic interaction of the cobblestone-like CeO2 overlayer, SCF, and tribofilm provides the PBSF composite coating with exceptional friction reduction, wear resistance, and high load-bearing performance.

Finally, for the convenience of readers, we give the names of the compounds mentioned in our paper and their abbreviations, as shown in Table 3.

Table 3.

The names of the compounds involved in the paper and their abbreviations.

Author Contributions

W.Y. and M.N.: writing—original draft preparation; L.B.: investigation, C.D.: funding acquisition; C.G.: formal analysis; P.Z.: project administration; S.Z. and Y.Z.: supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Henan Province of China, grant number 222300420124; the Open Project of State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, grant number LSL-2207; the Postgraduate Education Reform and Quality Improvement Project of Henan Province, grant number YJS2025GZZ28; the Open Project of China International Science and Technology Cooperation Base on Intelligent Equipment Manufacturing in Special Service Environment, grant number ISTC2022KF02; and the National Natural Science Foundation of China, grant number, 52475186.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, Y.; Zhang, D.; Wei, X.; Zhong, S.; Wang, J. Enhanced tribological properties of polymer composite coating containing graphene at room and elevated temperatures. Coatings 2018, 8, 91. [Google Scholar] [CrossRef]

- Tavakoli, S.; Nemati, S.; Kharaziha, M.; Akbari-Alavijeh, S. Embedding CuO nanoparticles in PDMS-SiO2 coating to improve antibacterial characteristic and corrosion resistance. Colloid Interface Sci. Commun. 2019, 28, 20–28. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, M.; Yuan, J.; Guo, F.; Men, X. Friction and wear behaviors of MoS2-multi-walled carbon nanotube hybrid reinforced polyurethane composite coating. Friction 2018, 7, 316–326. [Google Scholar] [CrossRef]

- Naderi-Samani, H.; Shoja Razavi, R.; Loghman-Estarki, M.R.; Ramazani, M.; Barekat, M.; Mishra, A.K.; Fattahi, H. The effects of Cloisite 20A content on the adhesion strength and corrosion behavior of poly(amide-imide)/cloisite 20A nanocomposite coatings. Compos. Part B Eng. 2019, 175, 107154. [Google Scholar] [CrossRef]

- Xi, Z.; Wan, H.; Chen, L.; Zhou, H.; Chen, J. Strengthening mechanism of in-situ synthesized Cu2S nanoparticles on tribological performance of polyamide-imide bonded solid lubricating coatings. Prog. Org. Coat. 2022, 166, 106807. [Google Scholar] [CrossRef]

- Li, G.; Ma, Y.; Wan, H.; Chen, L.; An, Y.; Ye, Y.; Zhou, H.; Chen, J. Flake aluminum reinforced polyamideimide-polytetrafluoroethylene bonded solid lubricating composite coating for wear resistance and corrosion protection. Eur. Polym. J. 2021, 152, 110485. [Google Scholar] [CrossRef]

- Wu, J.; Yin, X.; Mu, L.; Feng, X.; Lu, X.; Shi, Y. Hollow IF-MoS2/r-GO nanocomposite filled polyimide coating with improved mechanical, thermal and tribological properties. Coatings 2020, 11, 25. [Google Scholar] [CrossRef]

- Li, B.; Jiang, X.; Wan, H.; Chen, L.; Ye, Y.; Zhou, H.; Chen, J. Optimum hydrophilic modification of lanthanum trifluoride nanoparticles and their application in enhancing tribological properties of eco-friendly water-based bonded solid lubricating coatings. Tribol. Int. 2018, 125, 1–11. [Google Scholar] [CrossRef]

- Kesler, D.; Ariyawansa, B.P.; Rathnayake, H. Mechanical Properties and Synergistic Interfacial Interactions of ZnO Nanorod-Reinforced Polyamide–Imide Composites. Polymers 2023, 15, 1522. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, R.; Zhou, X.; Wang, H.; Hu, Y.; Nie, D.; Bao, D. Numerical modelling on the effect of temperature on MOCVD growth of ZnO using diethylzinc and tertiarybutanol. Coatings 2022, 12, 1991. [Google Scholar] [CrossRef]

- Fan, L.; Cao, J.; Suo, X.; Liu, L.; Xu, H.; Wang, S. The Tribological properties of polyimide/polyamide-imide/epoxy coating filled by WS2 and ZnO under dry, water, and sediment conditions. J. Macromol. Sci. Part B 2023, 63, 242–259. [Google Scholar] [CrossRef]

- Qi, H.; Zhang, G.; Zheng, Z.; Yu, J.; Hu, C. Tribological properties of polyimide composites reinforced with fibers rubbing against Al2O3. Friction 2020, 9, 301–314. [Google Scholar] [CrossRef]

- Cao, J.; Wang, Y.; Liu, G.; Shang, Q.; Wang, B.; Sun, J.; Bai, Y.; Liu, M.; Yu, F.; Ma, G.; et al. Surface modification of nano-Al2O3 with silane coupling agent and its effect on the compressive strength of PI/Al2O3 Composites. Coatings 2023, 14, 27. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T. Friction and wear of fiber reinforced polyimide composites. Wear 2013, 301, 122–129. [Google Scholar] [CrossRef]

- Tang, H.; Zhou, H.; Cheng, X. Friction process analysis of carbon fiber-carbon nanotube multiscale hybrid reinforced epoxy with excellent tribological performance. Tribol. Int. 2022, 171, 107559. [Google Scholar] [CrossRef]

- Yuan, H.; Yang, S.; Liu, X.; Wang, Z.; Ma, L.; Hou, K.; Yang, Z.; Wang, J. Polyimide-based lubricating coatings synergistically enhanced by MoS2@HCNF hybrid. Compos. Part A Appl. Sci. Manuf. 2017, 102, 9–17. [Google Scholar] [CrossRef]

- Saxena, M.; Sharma, A.K.; Srivastava, A.K.; Singh, R.K.; Dixit, A.R.; Nag, A.; Hloch, S. Microwave-assisted synthesis, characterization and tribological properties of a g-C3N4/MoS2 nanocomposite for low friction coatings. Coatings 2022, 12, 1840. [Google Scholar] [CrossRef]

- Yan, J.; Wu, C.; Hou, J.; Zhang, X.; Liu, Y.; Zhang, Y.; Li, P.; Che, H.; Xing, Z.; Wang, Y. Tribological properties of polyimide coatings filled with graphene oxide and MXene composite nanofillers. Tribol. Int. 2023, 189, 109000. [Google Scholar] [CrossRef]

- Tu, C.; Cao, J.; Huang, H.; Yan, C.; Al-Maqbol, A.; Wang, X. The investigation of microstructure and tribological properties of PTFE/PI-PAI composite coating added with VN. Surf. Coat. Technol. 2022, 432, 128092. [Google Scholar] [CrossRef]

- Liao, C.; Zhang, Z.; Yang, M.; Yuan, J.; Liu, M.; He, Y.; Li, P.; Jiang, W.; Liu, W. The cooperatively crosslinking between GO-COOH/TiO2 @PAO microcapsules and polyimide to improve the mechanical and tribological properties of PEEK/PI composites. Tribol. Int. 2024, 191, 109209. [Google Scholar] [CrossRef]

- Lan, J.; Mo, C.; Chen, X.; Hu, T.; Li, X.; Zhang, C. Carbon fiber/nano SiO2 reinforced polyelectrolyte-graft UHMWPE for water lubricated superlubricity. Tribol. Int. 2025, 202, 110303. [Google Scholar] [CrossRef]

- Yan, J.; Rong, Y.; Zhang, Y.; Zhou, S.; Huang, J.; Zhao, G.; Liu, Y. Wear and corrosion resistance of textured and functionally particle-enhanced multilayer dual-biomimetic polymer coatings. Tribol. Int. 2025, 202, 110335. [Google Scholar] [CrossRef]

- Chen, B.; Dong, Z.; Li, J.; Zhang, M.; Zhang, K. ZnO nanowires-decorated h-BN hybrid for enhancing the tribological properties of epoxy resin. Prog. Org. Coat. 2021, 161, 106493. [Google Scholar] [CrossRef]

- Yang, J.; Xiao, Q.; Lin, Z.; Li, Y.; Jia, X.; Song, H. Growth of ultra-dense MoS2 nanosheets on carbon fibers to improve the mechanical and tribological properties of polyimide composites. Friction 2020, 9, 1150–1162. [Google Scholar] [CrossRef]

- Song, J.; Yu, Y.; Zhao, G.; Qiu, J.; Ding, Q. Comparative study of tribological properties of insulated and conductive polyimide composites. Friction 2019, 8, 507–516. [Google Scholar] [CrossRef]

- Ye, X.; Liu, X.; Yang, Z.; Wang, Z.; Wang, H.; Wang, J.; Yang, S. Tribological properties of fluorinated graphene reinforced polyimide composite coatings under different lubricated conditions. Compos. Part A Appl. Sci. Manuf. 2016, 81, 282–288. [Google Scholar] [CrossRef]

- Yan, Q.; Ma, H.; Zhang, D.; Wen, P.; Fan, M. Oleic acid modified oxide graphene/triazine-based covalent-organic frameworks composite: Cooperation between heterostructure and electrical double layer to enhance tribological performances. Tribol. Int. 2023, 178, 108066. [Google Scholar] [CrossRef]

- Wu, B.; Song, H.; Li, C.; Song, R.; Zhang, T.; Hu, X. Enhanced tribological properties of diesel engine oil with Nano-Lanthanum hydroxide/reduced graphene oxide composites. Tribol. Int. 2020, 141, 105951. [Google Scholar] [CrossRef]

- Zhao, Z.; Ma, Y.; Wan, H.; Ye, Y.; Chen, L.; Zhou, H.; Chen, J. Preparation and tribological behaviors of polyamide-imide/polytetrafluoroethylene lubricating coatings reinforced by in-situ synthesized CeO2 nanoparticles. Polym. Test. 2021, 96, 107100. [Google Scholar] [CrossRef]

- Lei, X.; Zhang, Y.; Zhang, S.; Yang, G.; Zhang, C.; Zhang, P. Study on the mechanism of rapid formation of ultra-thick tribofilm by CeO2 nano additive and ZDDP. Friction 2022, 11, 48–63. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H. Exploring the lubrication mechanism of CeO2 nanoparticles dispersed in engine oil by bis(2-ethylhexyl) phosphate as a novel antiwear additive. Tribol. Int. 2022, 165, 107321. [Google Scholar] [CrossRef]

- Shen, T.; Wang, D.; Yun, J.; Liu, Q.; Liu, X.; Peng, Z. Tribological properties and tribochemical analysis of nano-cerium oxide and sulfurized isobutene in titanium complex grease. Tribol. Int. 2016, 93, 332–346. [Google Scholar] [CrossRef]

- De Oliveira, P.R.; Sukumaran, A.K.; Benedetti, L.; John, D.; Stephens, K.; Chu, S.-H.; Park, C.; Agarwal, A. Novel polyimide-hexagonal boron nitride nanocomposites for synergistic improvement in tribological and radiation shielding properties. Tribol. Int. 2023, 189, 108936. [Google Scholar] [CrossRef]

- Wang, S.; Jia, F.; Wang, X.; Hu, L.; Sun, Y.; Yin, G.; Zhou, T.; Feng, Z.; Kumar, P.; Liu, B. Fabrication of ZnO Nanoparticles Modified by Uniformly Dispersed Ag Nanoparticles: Enhancement of Gas Sensing Performance. ACS Omega 2020, 5, 5209–5218. [Google Scholar] [CrossRef]

- Zhang, G.; Chang, L.; Schlarb, A.K. The roles of nano-SiO2 particles on the tribological behavior of short carbon fiber reinforced PEEK. Compos. Sci. Technol. 2009, 69, 1029–1035. [Google Scholar] [CrossRef]

- Zhang, G.; Wetzel, B.; Jim, B.; Oesterle, W. Impact of counterface topography on the formation mechanisms of nanostructured tribofilm of PEEK hybrid nanocomposites. Tribol. Int. 2015, 83, 156–165. [Google Scholar] [CrossRef]

- Lv, M.; Zheng, F.; Wang, Q.; Wang, T.; Liang, Y. Friction and wear behaviors of carbon and aramid fibers reinforced polyimide composites in simulated space environment. Tribol. Int. 2015, 92, 246–254. [Google Scholar] [CrossRef]

- Song, J.; Yu, Y.; Zhao, G.; Qiu, J.; Ding, Q. Improved tribological properties of polyimide composites by micro–nano reinforcement. J. Appl. Polym. Sci. 2019, 136, 47900. [Google Scholar] [CrossRef]

- Li, J.; Qu, J.; Zhang, Y. Wear properties of brass and PTFE–matrix composite in traveling wave ultrasonic motors. Wear 2015, 338–339, 385–393. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Zheng, W. Ultrathin flexible graphene film: An excellent thermal conducting material with efficient EMI shielding. Adv. Funct. Mater. 2014, 24, 4542–4548. [Google Scholar] [CrossRef]

- Yu, P.; He, R.; Li, G.; Guo, Y.; Myshkin, N.K.; Zhang, G. Novel Nanocomposites Reinforced with Layered Double Hydroxide Platelets: Tribofilm Growth Compensating for Lubrication Insufficiency of Oil Films. ACS Sustain. Chem. Eng. 2022, 10, 4929–4942. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).