Review of Preparation, Performance, and Application of Chromium-Carbide-Based Cermets

Abstract

1. Introduction

2. Preparation and Performance of Chromium-Carbide-Based Cermets

2.1. Bulk Cr3C2-Ni Cermets (Vacuum Sintering Technology)

2.2. Cr3C2-NiCr Coatings

2.2.1. Plasma Spray Technology

2.2.2. High-Velocity Oxygen Fuel Spray Technology

2.2.3. Laser Cladding Technology

3. Application of Chromium-Carbide-Based Cermets

3.1. Seals

3.2. Ball Valve and Seats

3.3. High-Temperature Furnace Tube Wall

3.4. High-Temperature Molds

4. Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Sarjas, H.; Surzhenkov, A.; Juhani, K.; Antonov, M.; Adoberg, E.; Kulu, P.; Vuoristo, P. Abrasive-erosive wear of thermally sprayed coatings from experimental and commercial Cr3C2-Based Powders. J. Therm. Spray Technol. 2017, 26, 2020–2029. [Google Scholar] [CrossRef]

- Lu, H.; Shang, J.; Jia, X.; Li, Y.; Li, F.; Li, J.; Nie, Y. Erosion and corrosion behavior of shrouded plasma sprayed Cr3C2-NiCr coating. Surf. Coat. Technol. 2020, 388, 125534. [Google Scholar] [CrossRef]

- Mathapati, M.; Doddamani, M.; Ramesh, M. High-temperature erosive behavior of plasma sprayed Cr3C2-NiCr/cenosphere coating. J. Mater. Eng. Perform. 2018, 27, 1592–1600. [Google Scholar] [CrossRef]

- Li, Y.; Gao, Y.; Xiao, B. The electronic, mechanical properties and theoretical hardness of chromium carbides by first-principles calculations. J. Alloys Compd. 2011, 509, 5242–5249. [Google Scholar] [CrossRef]

- Hu, J.B.; Jian, X.G.; Yang, T.; Peng, X.Y. Investigation on the interface characteristic between WC(001) and diamond(111) by first-principles calculation. Diam. Relat. Mater. 2022, 123, 108864. [Google Scholar] [CrossRef]

- Benarji, K.; Kumar, Y.R.; Jinoop, A.N.; Paul, C.P.; Bindra, K.S. Effect of WC Composition on the Microstructure and Surface Properties of Laser Directed Energy Deposited SS 316-WC Composites. J. Mater. Eng. Perform. 2021, 30, 6732–6742. [Google Scholar] [CrossRef]

- Xu, Q.Z.; Ai, X.; Zhao, J.; Gong, F.; Pang, J.M.; Wang, Y.T. Effects of metal binder on the microstructure and mechanical properties of Ti(C, N)-based cermets. J. Alloys Compd. 2015, 644, 663–672. [Google Scholar] [CrossRef]

- Zhang, P.; Sun, W.C.; Yang, Q.H.; Li, P.; She, X.L. Effects of Ni/Co metal binder phase on mechanical properties of Ti(C, N)-based cermets. Mater. Sci. Forum 2014, 809, 438–442. [Google Scholar] [CrossRef]

- Chen, M.; Xiong, W.; Zhang, G.; Fan, C. Effect of Ni3Al binder on microstructure and properties of Ti(C,N)-based cermets. Cem. Carbide 2014, 31, 15–22. [Google Scholar]

- Lindahl, P.; Rolander, U.; Andren, H.O. Atom-probe analysis of the binder phase in TiC-TiN-Mo2C-(Co/Ni) cermets. Int. J. Refract. Met. Hard Mater. 1993, 12, 115–119. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. High temperature erosion-oxidation of Cr3C2-NiCr thermal spray coatings under simulated turbine conditions. Corros. Sci. 2013, 70, 203–211. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. The role of microstructure in the high temperature oxidation mechanism of Cr3C2-NiCr composite coatings. Corros. Sci. 2009, 51, 1172–1180. [Google Scholar] [CrossRef]

- Jonda, E.; Szala, M.; Sroka, M.; Latka, L.; Walczak, M. Investigations of cavitation erosion and wear resistance of cermet coatings manufactured by HVOF spraying. Appl. Surf. Sci. 2023, 608, 155071. [Google Scholar] [CrossRef]

- Nakano, K.; Takagi, K. Sinter-bonding behavior of Cr3C2 base cermets on steels. Adv. Powder Metal. Part. Mater. 1996, 3, 432–437. [Google Scholar]

- Brondaya, E.V.; Klimenko, V.N.; Maslyuk, V.A.; Radomysel, I.D. Effect of phosphorus additions on the sintering temperature and properties of chromium carbide-nickel alloys. Sov. Powder Metall. Met. Ceram. 1971, 10, 698–701. [Google Scholar] [CrossRef]

- Tkachenko, Y.G.; Klimenko, V.N.; Gorbatov, I.N.; Maslyuk, V.A.; Yurchenko, D.Z. Friction and wear of chromium-carbide-nickel alloys at temperatures of 20–1000 °C. Sov. Powder Metall. Met. Ceram. 1978, 17, 864–867. [Google Scholar] [CrossRef]

- Klimenko, V.N.; Kayuk, V.G.; Maslyuk, V.A. Densification kinetics of chromium carbide and its alloys in hot pressing. Sov. Powder Metall. Met. Ceram. 1983, 22, 60–63. [Google Scholar] [CrossRef]

- Duran, C.; Eroglu, S. Liquid-phase sintering and properties of Cr3C2/NiCr cermets. J. Mater. Process. Technol. 1998, 74, 69–73. [Google Scholar] [CrossRef]

- Hussainova, I.; Pirso, J.; Antonov, M.; Juhani, K.; Letunovits, S. Erosion and abrasion of chromium carbide based cermets produced by different methods. Wear 2007, 263, 905–911. [Google Scholar] [CrossRef]

- Juhani, K.; Pirso, J.; Letunovits, S.; Viljus, M. Phase evolution, microstructure characteristics and properties of Cr3C2-Ni cermets prepared by reactive sintering. Int. J. Mater. Prod. Technol. 2011, 40, 75–91. [Google Scholar] [CrossRef]

- Kayuk, V.; Masljk, V.; Kostenko, A. Tribological properties of hard alloys based on chromium carbide. Powder Metall. Met. Ceram. 2003, 42, 257–261. [Google Scholar] [CrossRef]

- Hussainova, I.; Pirso, J.; Viljus, M. Processing and tribological properties of chromium carbide based cermets. Processing of World Congress on Powder Metallurgy and Particulate Materials. USA. Met. Powder Ind. Fed. 2002, 6, 166–173. [Google Scholar]

- Juhani, K.; Pirso, J.; Viljus, M.; Letunovits, S. Impact wear of chromium carbide based cermets. Mater. Sci. 2008, 14, 341–344. [Google Scholar]

- Hussainova, I.; Jasiuk, I.; Sardela, M.; Antonov, M. Micromechanical properties and erosive wear performance of chromium carbide based cermets. Wear 2009, 267, 152–159. [Google Scholar] [CrossRef]

- Zhai, W.; Pu, B.; Sun, L.; Wang, Y.; Dong, H.; Gao, Q.; He, L.; Gao, Y. Influence of molybdenum content and load on the tribological behaviors of in-situ Cr3C2-20wt.% Ni composites. J. Alloys Compd. 2020, 826, 154180. [Google Scholar] [CrossRef]

- Shi, M.; Xue, Z.L.; Liang, H.P.; Yan, Z.P.; Liu, X.; Zhang, S.H. High velocity oxygen fuel sprayed Cr3C2-NiCr coatings against Na2SO4 hot corrosion at different temperatures. Ceram. Int. 2020, 46, 23629–23635. [Google Scholar] [CrossRef]

- Dzhurinskiy, D.; Babu, A.; Pathak, P.; Elkin, A.; Dautov, S.; Shornikov, P. Microstructure and wear properties of atmospheric plasma-sprayed Cr3C2-NiCr composite coatings. Surf. Coat. Technol. 2021, 428, 127904. [Google Scholar] [CrossRef]

- Chong, K.; Zou, Y.; Wu, D.; Tang, Y.; Zhang, Y. Pulsed laser remelting supersonic plasma sprayed Cr3C2-NiCr coatings for regulating microstructure, hardness and corrosion properties. Surf. Coat. Technol. 2021, 418, 127258. [Google Scholar] [CrossRef]

- Hebbale, A.M.; Tak, M.; Bathe, R. Microstructural studies of composite (Cr3C2-NiCr) laser clads developed on preheated substrate T91. Trans. Indian Inst. Met. 2021, 74, 593–600. [Google Scholar] [CrossRef]

- Sharma, A.; Vijay, A.; Sadeghi, F. Finite element modeling of fretting wear in anisotropic composite coatings: Application to HVOF Cr3C2-NiCr coating. Tribol. Int. 2021, 155, 106765. [Google Scholar] [CrossRef]

- Kevin, P.S.; Tiwari, A.; Seman, S.; Mohamed, S.A.B.; Jayaganthan, R. Erosion-Corrosion protection due to Cr3C2-NiCr cermet coating on stainless steel. Coatings 2020, 10, 1042. [Google Scholar] [CrossRef]

- Jonda, E.; Latka, L.; Pakiela, W. Microstructure and selected properties of Cr3C2-NiCr coatings obtained by HVOF on magnesium alloy substrates. Materials 2020, 13, 2775. [Google Scholar] [CrossRef]

- Zhao, H.; Luo, L.; Guo, F.; Zhao, X.; Xiao, P. High-temperature tribological behavior of Mo and BaF2 added Cr3C2-NiCr matrix composite. Ind. Lubr. Tribol. 2020, 72, 136–145. [Google Scholar] [CrossRef]

- Su, H.; Hu, H.; Chen, S.; Zhang, G.; Zhang, C. Tribological properties of atmospheric plasma sprayed Cr3C2-NiCr/20% nickel-coated graphite self-lubricating coatings. Ceram. Int. 2024, 50, 38040–38050. [Google Scholar] [CrossRef]

- Marcano, Z.; Lesage, J.; Chicot, D.; Mesmacque, G.; Puchi, C.E. Microstructure and adhesion of Cr3C2-NiCr vacuum plasma sprayed coatings. Surf. Coat. Technol. 2008, 202, 4406–4410. [Google Scholar] [CrossRef]

- Guilemany, J.; Espallargas, N.; Suegama, P.; Benedetti, A. Comparative study of Cr3C2-NiCr coatings obtained by HVOF and hard chromium coatings. Corros. Sci. 2006, 48, 2998–3013. [Google Scholar] [CrossRef]

- Hong, S.; Qin, J.Y.; Lin, J.R.; Wu, Y.P.; Li, J.H.; Zheng, Y. Influences of sand concentration and flow velocity on hydro-abrasive erosion behaviors of HVOF sprayed Cr3C2-NiCr and WC-Cr3C2-Ni coatings. J. Mater. Res. Technol. 2022, 21, 1507–1518. [Google Scholar] [CrossRef]

- Matthews, S.; O’Neil, F. The effect of carbide decomposition and carbon loss on the steady state composition of WC-Cr3C2-Ni composite coatings at 900 °C. Int. J. Refract. Met. Hard Mater. 2024, 120, 106634. [Google Scholar] [CrossRef]

- Aldrich, D.E.; Fan, Z.; Mummery, P. Processing, microstructure, and physical properties of interpenetrating Al2O3/Ni composites. J. Mater. Sci. Technol. 2000, 16, 747–752. [Google Scholar] [CrossRef]

- Niki, E.; Masato, K. Mechanical and physical properties of the Extruded TiC-Ni cermets. J. Jpn. Inst. Met. 1963, 27, 588–592. [Google Scholar] [CrossRef]

- Doi, H.; Fujiwara, Y.; Miyake, K.; Oosawa, Y. A systematic investigation of elastic moduli of WC-Co alloys. Metall. Mater. Trans. B 1970, 1, 1417–1425. [Google Scholar] [CrossRef]

- Huang, H.; Mccormick, P.G. Effect of milling conditions on the synthesis of chromium carbides by mechanical alloying. J. Alloys Compd. 1997, 256, 258–262. [Google Scholar] [CrossRef]

- Deng, J.X.; Can, T.K.; Sun, J.L. Microstructure and mechanical properties of hot-pressed Al2O3/TiC ceramic composites with the additions of solid lubricants. Ceram. Int. 2005, 31, 249–256. [Google Scholar] [CrossRef]

- Jiang, W.; Jin, F.L.; Park, S.J. Thermo-mechanical behaviors of epoxy resins reinforced with nano-Al2O3 particles. J. Ind. Eng. Chem. 2012, 18, 594–596. [Google Scholar] [CrossRef]

- Choi, C.J. Preparation of ultrafine TiC-Ni cermet powders by mechanical alloying. J. Mater. Process. Technol. 2000, 104, 127–132. [Google Scholar] [CrossRef]

- Kwon, H.; Sch, C.; Kim, W. Preparation of a highly toughened (Ti,W)C-20Ni cermet through in situ formation of solid solution and WC whiskers. Ceram. Int. 2015, 41, 4223–4226. [Google Scholar] [CrossRef]

- Chermant, J.L.; Osterstock, F. Fracture and fracture of WC-Co composites. J. Mater. Sci. 1976, 11, 1939–1951. [Google Scholar] [CrossRef]

- Ban, Z.G.; Shaw, L.L. Synthesis and processing of nanostructured WC-Co materials. J. Mater. Sci. 2002, 37, 3397–3403. [Google Scholar] [CrossRef]

- Gomari, S.; Sharafi, S. Microstructural characterization of nanocrystalline chromium carbides synthesized by high energy ball milling. J. Alloys Compd. 2010, 490, 26–30. [Google Scholar] [CrossRef]

- Fu, J.X.; Li, X.D.; Hwang, W.S. Study of the coefficient of thermal expansion for steel Q235. Adv. Mater. Res. 2011, 194–196, 326–330. [Google Scholar] [CrossRef]

- Guillermet, A.F. Predictive approach to thermodynamic properties of the metastable Cr3C carbide. Int. J. Thermophys. 1991, 12, 919–936. [Google Scholar] [CrossRef]

- Chang, Y.A.; Naujock, D. The relative stabilities of Cr23C6, Cr7C3, and Cr3C2 and the phase relationships in ternary Cr-Mo-C system. Metall. Mater. Trans. B 1972, 3, 1693–1698. [Google Scholar] [CrossRef]

- Small, M.; Ryba, E. Calculation and evaluation of the Gibbs energies of formation of Cr3C2, Cr7C3, and Cr23C6. Metall. Trans. A 1981, 12, 1389–1396. [Google Scholar] [CrossRef]

- Coltters, R.G.; Belton, G.R. High temperature thermodynamic properties of the chromium carbides Cr7C3 and Cr3C2 determined using a galvanic cell technique. Metall. Trans. B 1984, 15, 517–521. [Google Scholar] [CrossRef]

- Xiao, B.; Xing, J.D.; Feng, J.; Li, Y.F.; Zhou, C.T.; Su, W.; Xie, X.J.; Chen, Y.H. Theoretical study on the stability and mechanical property of Cr7C3. Phys. B Condens. Matter 2008, 403, 2273–2281. [Google Scholar] [CrossRef]

- Pirso, J.; Viljus, M.; Letunovits, S.; Juhani, K. Reactive carburizing sintering—A novel production method for high quality chromium carbide-nickel cermets. Int. J. Refract. Met. Hard Mater. 2006, 24, 263–270. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, Y.; Zhou, R. First-principles study on stability and mechanical properties of Cr7C3. Rare Met. Mater. Eng. 2014, 43, 2903–2907. [Google Scholar]

- Zhai, W.; Gao, Y.; Sun, L.; Wang, Y.; Niwa, K.; Hasegawa, M. High pressure in-situ synthesis and physical properties of Cr3C2-Ni cermets. Ceram. Int. 2017, 43, 17202–17205. [Google Scholar] [CrossRef]

- Sun, L.; Ji, X.; Zhao, L.; Zhai, W.; Xu, L.; Dong, H.; Liu, Y.; Peng, J. First principles investigation of binary chromium carbides Cr7C3, Cr3C2 and Cr23C6, electronic structures, mechanical properties and thermodynamic properties under pressure. Materials 2022, 15, 558. [Google Scholar] [CrossRef]

- Nakano, K.; Lonue, M.; Takagi, K. Effect of WB addition on sinter ability Cr3C2-Ni cermets. Jpn. Soc. Powder Powder Met. 1995, 42, 432–437. [Google Scholar] [CrossRef][Green Version]

- Detroye, M.; Reniers, F. Synthesis and characterization of chromium carbides. Appl. Surf. Sci. 1997, 120, 85–93. [Google Scholar] [CrossRef]

- Jow, L.H. Investigation of Al2O3/Cr3C2 composites prepared by pressureless sintering. Ceram. Int. 1999, 25, 141–144. [Google Scholar]

- Ghaleb, N.; Gar, B. Dynamic SIMS study of Cr3C2, Cr7C3 and Cr23C6. Appl. Surf. Sci. 1998, 134, 194–196. [Google Scholar]

- Romero, J.; Lousa, A. Nanometric chromium/chrumium carbides multilayers for tribological application. Surf. Coat. Technol. 2003, 163, 392–397. [Google Scholar] [CrossRef]

- Juhani, K.; Pirso, J.; Viljus, M. The influence of sinter/HIP sintering on the properties of chromium carbide based cermets. Hard Mater. 2007, 1, 209–213. [Google Scholar]

- Zhai, W.; Sun, L.; Dong, H.; Wang, Y.; He, L. Effect of temperature on the friction and wear behaviors of Cr3C2-20wt.%Ni cermets. Mater. Res. Express 2019, 6, 1065c3. [Google Scholar] [CrossRef]

- Zhai, W.; Pu, B.; Sun, L.; Dong, H.; Wang, Y.; He, L.; Gao, Y. Influence of Ni content on the microstructure and mechanical properties of chromium carbide-nickel composites. Ceram. Int. 2020, 46, 8754–8760. [Google Scholar] [CrossRef]

- Zhai, W.; Zhang, K.; Gao, Y.; Sun, L.; Xu, L.; Wang, Y.; Dong, H.; Wang, S.; Gao, Q. Preparation and oxidation kinetics behavior of bulk Cr3C2-20wt%Ni cermets. Ceram. Int. 2021, 47, 6573–6583. [Google Scholar] [CrossRef]

- Sun, L.; Hui, W.; Xu, L.; Zhai, W.; Dong, H.; Wang, Y.; He, L.; Peng, J. Interface characterization and mechanical properties of Mo-added chromium carbide-nickel composite. Ceram. Int. 2020, 46, 27071–27079. [Google Scholar] [CrossRef]

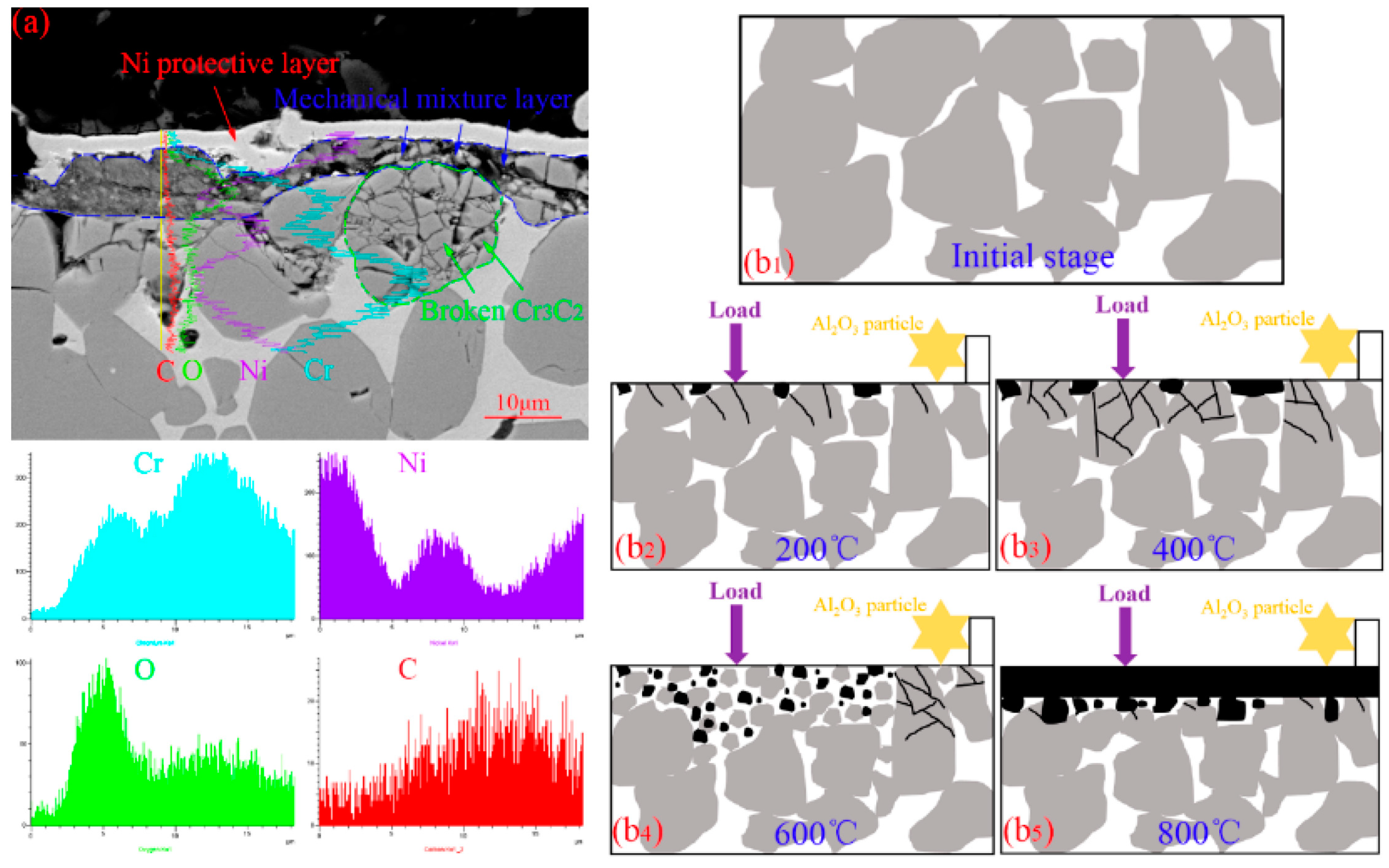

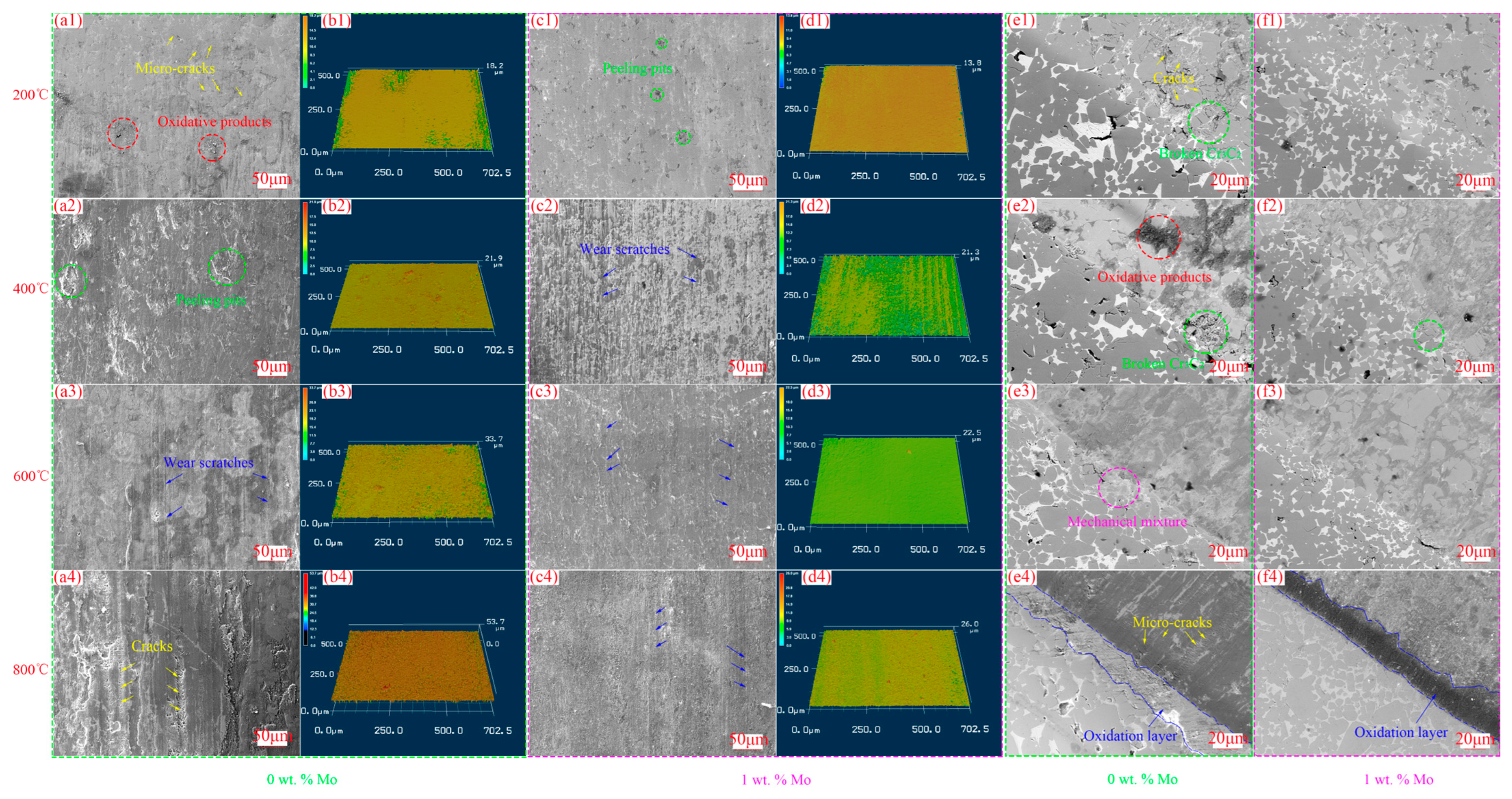

- Sun, L.; Zhai, W.; Dong, H.; Wang, Y.; He, L. Improvement of high temperature wear behavior of in-situ Cr3C2-20wt.%Ni cermet by adding Mo. Crystals 2020, 10, 682. [Google Scholar] [CrossRef]

- Van, T.N.; Nguyen, T.A.; Thu, Q.L.; Thi, H.P. Influence of plasma spraying parameters on microstructure and corrosion resistance of Cr3C2-25NiCr cermet carbide coating. Anti-Corros. Methods Mater. 2019, 66, 336–342. [Google Scholar]

- Ghosh, D.; Mitra, S.K. Plasma sprayed Cr3C2-Ni-Cr coating for oxidation protection of 2.25Cr-1Mo steel. Surf. Eng. 2015, 31, 342–348. [Google Scholar] [CrossRef]

- Li, H.; Cheng, X.N.; Xie, C.S.; Lu, P.C. Microstructure and the high temperature friction and wear behavior of Cr3C2-NiCr coating on CuCo2Be alloy by plasma spraying. Rare Met. Mater. Eng. 2014, 43, 2011–2016. [Google Scholar]

- Li, H.; Jiao, L.; Lu, P.C.; Zhang, Y. Friction and wear pproperties of plasma sprayed Cr3C2-NiCr/NiAl composite coating on CuCo2Be alloy at different temperatures. Rare Met. Mater. Eng. 2018, 47, 588–593. [Google Scholar]

- Mou, H.L.; Zhao, H.C.; Ma, G.Z.; Cai, Z.H.; Guo, W.L.; Liu, M.; Wang, H.D. Quality control of NiCr-Cr3C2-hBN@Ni coating on thin-walled GH4169 alloy surface prepared by plasma spraying. J. Alloys Compd. 2024, 992, 174523. [Google Scholar]

- Babu, A.; Dzhurinskiy, D.; Dautov, S.; Shornikov, P. Structure and electrochemical behavior of atmospheric plasma sprayed Cr3C2-NiCr cermet composite coatings. Int. J. Refract. Met. Hard Mater. 2023, 111, 106105. [Google Scholar] [CrossRef]

- Ozkan, D. Structural characteristics and wear, oxidation, hot corrosion behaviors of HVOF sprayed Cr3C2-NiCr hardmetal coatings. Surf. Coat. Technol. 2023, 457, 129319. [Google Scholar] [CrossRef]

- Sauceda, S.; Lascano, S.; Núñez, J.; Parra, C.; Arévalo, C.; Béjar, L. Effect of HVOF processing parameters on Cr3C2-NiCr hard coatings deposited on AISI 4140 steel. Eng. Sci. Technol.-Int. J. 2023, 39, 101342. [Google Scholar] [CrossRef]

- Alroy, R.J.; Kamaraj, M.; Sivakumar, G. Influence of processing condition and post-spray heat treatment on the tribological performance of high velocity air-fuel sprayed Cr3C2-25NiCr coatings. Surf. Coat. Technol. 2023, 463, 129498. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. The role of microstructure in the mechanism of high velocity erosion of Cr3C2-NiCr thermal spray coatings: Part 1—As-sprayed coatings. Surf. Coat. Technol. 2009, 203, 1086–1093. [Google Scholar] [CrossRef]

- Matthews, S.; James, B.; Hyland, M. The role of microstructure in the mechanism of high velocity erosion of Cr3C2-NiCr thermal spray coatings: Part 2—Heat treated coatings. Surf. Coat. Technol. 2009, 203, 1094–1100. [Google Scholar] [CrossRef]

- Du, J.Y.; Li, Y.L.; Li, F.Y.; Ran, X.J.; Zhang, X.Y.; Qi, X.X. Research on the high temperature oxidation mechanism of Cr3C2-NiCrCoMo coating for surface remanufacturing. J. Mater. Res. Technol. 2021, 10, 565–579. [Google Scholar] [CrossRef]

- Du, J.Y.; Li, F.Y.; Li, Y.L.; Lu, H.Y.; Qi, X.X.; Yang, B.J.; Li, C.; Yu, P.L.; Cao, Y.H. High temperature oxidation behavior and interface diffusion of Cr3C2-NiCrCoMo/nano-CeO2 composite coatings. J. Alloys Compd. 2022, 905, 164177. [Google Scholar] [CrossRef]

- Du, J.Y.; Qi, X.X.; Lu, H.Y.; Hua, Y.; Li, Y.L.; Li, F.Y. Interaction mechanisms and high-temperature erosion-oxidation performance of Cr3C2-NiCrCoMo/nano-TiC coatings. Ceram. Int. 2024, 50, 19945–19962. [Google Scholar] [CrossRef]

- Mou, H.L.; Zhao, H.C.; Tian, H.G.; Ma, G.Z.; Liu, M.; Wang, H.D.; Xie, F.K.; Cai, Z.H. Effects of hBN content and particle size on microstructure, mechanical and tribological properties of NiCr-Cr3C2-hBN coatings. Surf. Coat. Technol. 2024, 478, 130330. [Google Scholar]

- Zhai, W.Y.; Nan, J.J.; Sun, L.; Wang, Y.R.; Wang, S.Q. Preparation, microstructure, and interface quality of Cr3C2-NiCr cladding layer on the surface of Q235 steel. Coatings 2023, 13, 676. [Google Scholar] [CrossRef]

- Mieczyslaw, S.; Wojciech, Z.; Katarzyna, S.S.; Anna, G. Influence of laser treatment on the corrosion resistance of Cr3C2-25(Ni20Cr) cermet coating. Materials 2021, 14, 4078. [Google Scholar] [CrossRef]

- Pan, C.G.; Wang, H.C.; Wang, H.F.; Chang, Q.M.; Wang, H.J. Microstructure and thermal physical parameters of Ni60-Cr3C2 composite coating by laser cladding. J. Wuhan Univ. Technol. 2010, 25, 991–995. [Google Scholar] [CrossRef]

- Zang, C.C.; Wang, Y.Z.; Zhang, Y.D.; Li, J.H.; Zeng, H.; Zhang, D.Q. Microstructure and wear-resistant properties of NiCr-Cr3C2 coating with Ni45 transition layer produced by laser cladding. Rare Met. 2015, 34, 491–497. [Google Scholar] [CrossRef]

- Venkatesh, L.; Samajdar, I.; Tak, M.; Doherty, R.D.; Gundakaram, R.C.; Prasad, K.S.; Joshi, S.V. Microstructure and phase evolution in laser clad chromium carbide-NiCrMoNb. Appl. Surf. Sci. 2015, 357, 2391–2401. [Google Scholar] [CrossRef]

- Wang, D.; Wang, W.Q.; Chen, X.G.; Chi, C.T.; Wang, M.S.; Han, X.; Xie, Y.J. Influence of Cr addition on the interface purification of vacuum brazed NiCr-Cr3C2 coatings on single crystal superalloy. Surf. Coat. Technol. 2017, 325, 200–209. [Google Scholar] [CrossRef]

- Lou, D.Y.; Yang, S.K.; Mei, S.; Liu, Q.; Cheng, J.; Yang, Q.B.; Liu, D.; He, C.L. The effect of laser scanning speed on microstructure and performance of Cr3C2-NiCr cermet fabricated by in-situ laser cladding. Mater. Sci. 2021, 27, 167–174. [Google Scholar] [CrossRef]

- Cao, S.L.; Liang, J.; Wang, L.Q.; Zhou, J.S. Effects of NiCr intermediate layer on microstructure and tribological property of laser cladding Cr3C2 reinforced Ni60A-Ag composite coating on copper alloy. Opt. Laser Technol. 2021, 142, 106963. [Google Scholar] [CrossRef]

- Wu, H.Y.; Kong, D.J. Effects of laser power on friction–wear performances of laser thermal sprayed Cr3C2-NiCr composite coatings at elevated temperatures. Opt. Laser Technol. 2019, 117, 227–238. [Google Scholar] [CrossRef]

- Vila, M.; Carrapichano, J.M.; Gomes, J.R.; Camargo, S.S., Jr.; Achete, C.A.; Silva, R.F. Ultra-high performance of DLC-coated Si3N4 rings for mechanical seals. Wear 2008, 265, 940–944. [Google Scholar] [CrossRef]

- Shihab, T.A.; Shlapak, L.S.; Namer, N.S.; Prysyazhnyuk, P.M.; Ivanov, O.O.; Burda, M.J. Increasing of durability of mechanical seals of oil and gas centrifugal pumps using tungsten-free cermet with Cu-Ni-Mn binder. J. Phys. Conf. Ser. 2021, 1741, 012031. [Google Scholar] [CrossRef]

- Yang, M.S.; Liu, X.B.; Fan, J.W.; He, X.M.; Shi, S.H.; Fu, G.Y.; Wang, M.D.; Chen, S.F. Microstructure and wear behaviors of laser clad NiCr/Cr3C2-WS2 high temperature self-lubricating wear-resistant composite coating. Appl. Surf. Sci. 2012, 258, 3757–3762. [Google Scholar] [CrossRef]

- Zhou, Z.; Duan, D.; Li, S.; Sun, D.; Yong, J.; Jiang, Y.; He, W.; Xu, J. Microstructure and high-temperature properties of Cr3C2-25NiCr nanoceramic coatings prepared by HVAF. Coatings 2023, 13, 1741. [Google Scholar] [CrossRef]

- Poirier, D.; Legoux, J.; Lima, R. Engineering HVOF-Sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties, and High Temperature Wear Performance. J. Therm. Spray Technol. 2013, 22, 280–289. [Google Scholar] [CrossRef]

- Jia, B.; Xu, W.; Li, J.; Liu, X.; Ji, L.; Sun, C.; Li, J.; Li, H. Enhancement of thermal stability and high-temperature oxidation resistance of chromium oxide-based films by addition of rare earth element Y. J. Mater. Sci. Technol. 2024, 188, 105–115. [Google Scholar] [CrossRef]

- Bhatia, R.; Sidhu, H.S.; Sidhu, B.S. High temperature behavior of Cr3C2-NiCr coatings in the actual Coal-Fired boiler environment. Met. Mater. Soc. 2015, 2, 70–86. [Google Scholar] [CrossRef]

- Huang, K.; Zheng, Z.; Lin, C.; Huang, W.; Zhang, J.; Chen, X.; Xiao, J.; Xu, J. Microstructure characterization and high-temperature wear behavior of plasma nitriding mold steel. Surf. Coat. Technol. 2024, 492, 131210. [Google Scholar] [CrossRef]

- Wang, X.; Gao, X.; Zhang, Z.; Cheng, L.; Ma, H.; Yang, W. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. J. Eur. Ceram. Soc. 2021, 41, 4671–4688. [Google Scholar] [CrossRef]

- Ganji, O.; Sajjadi, S.A.; Yang, Z.G.; Mirjalili, M.; Najari, M.R. On the formation and properties of chromium carbide and vanadium carbide coatings produced on W1 tool steel through thermal reactive diffusion (TRD). Ceram. Int. 2020, 46, 25320–25329. [Google Scholar] [CrossRef]

- Minouei, H.; Meratian, M.; Fathi, M.H.; Ghazvinizadeh, H. Biphasic calcium phosphate coating on cobalt-base surgical alloy during investment casting. J. Mater. Sci.-Mater. Med. 2011, 22, 2449–2455. [Google Scholar] [CrossRef]

| Ceramic Particle | Melting Point/°C | Density/g·mm−3 | Thermal Expansion Coefficient/10−6·°C−1 | Elasticity Modulus/GPa | Hardness/HV |

|---|---|---|---|---|---|

| Al2O3 [43,44] | 2054 | 3.95 | 8.4 | 360 | 1800~2200 |

| TiC [45,46] | 3140 | 4.93 | 7.7 | 430 | 2000~3000 |

| WC [47,48] | 2870 | 15.63 | 3.8 | 710 | 2000~3000 |

| Cr3C2 [42,49] | 1890 | 6.68 | 10.3 | 410 | 1600~2000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, W.; Wei, Y.; Sun, L.; Lv, J. Review of Preparation, Performance, and Application of Chromium-Carbide-Based Cermets. Coatings 2025, 15, 393. https://doi.org/10.3390/coatings15040393

Zhai W, Wei Y, Sun L, Lv J. Review of Preparation, Performance, and Application of Chromium-Carbide-Based Cermets. Coatings. 2025; 15(4):393. https://doi.org/10.3390/coatings15040393

Chicago/Turabian StyleZhai, Wenyan, Yujing Wei, Liang Sun, and Jiaao Lv. 2025. "Review of Preparation, Performance, and Application of Chromium-Carbide-Based Cermets" Coatings 15, no. 4: 393. https://doi.org/10.3390/coatings15040393

APA StyleZhai, W., Wei, Y., Sun, L., & Lv, J. (2025). Review of Preparation, Performance, and Application of Chromium-Carbide-Based Cermets. Coatings, 15(4), 393. https://doi.org/10.3390/coatings15040393