Insights on the Role of Copper Addition in the Corrosion and Mechanical Properties of Binary Zr-Cu Metallic Glass Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Electrochemical Measurements

2.3. Material Characterization

2.4. Mechanical Test

3. Results

3.1. Structural Characterization

3.2. Electrochemical Corrosion Behavior

3.3. Corrosion Morphology and Composition Characterization

3.4. XPS Analysis

3.5. The Cu Content Impact on Mechanical Properties and impedance

4. Discussion

5. Conclusions

- The Zr-Cu glassy coatings displayed a typical amorphous state with some traces of crystallinity for the Zr-90 at.% Cu sample composed of the pure Cu phase.

- The metallic glassy coatings exhibited different corrosion resistance and corroded surface morphologies with respect to copper content. The corrosion current density increased and the EIS impedance of the Zr-Cu glassy coatings decreased by increasing the copper content.

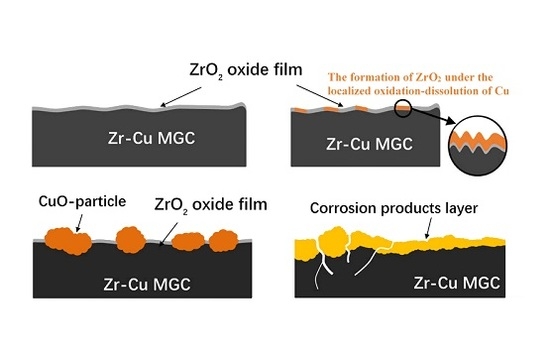

- The ZrO2 formed on the surface benefited the formation of passive film, but the protection performance depended on the coverage degree of the ZrO2 oxide on the surface. The competition between the oxidation of Zr atoms (ZrO2 film generation) and the oxidation–dissolution of Cu atoms assumed the most important role in the electrochemical behavior of the Zr-Cu systerm. It also determined the interface micro-configuration.

- The best mechanical properties of Zr-Cu have been achieved at the values of 70–80 at.% Cu. However, the Zr-30 at.% Cu sample had the best corrosion resistance and displayed a stable passivation ability at a large polarization potential range. In addition, the evolution of free volume affected both the mechanical properties and corrosion behavior of the Zr-Cu glassy coating.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Qiao, J.W.; Jia, H.L.; Liaw, P.K. Metallic glass matrix composites. Mater. Sci. Eng. R 2016, 100, 1–69. [Google Scholar] [CrossRef]

- Wang, W.H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. R 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Ashby, M.F.; Greer, A.L. Metallic glasses as structural materials. Scr. Mater. 2006, 54, 321–326. [Google Scholar] [CrossRef]

- Hashimoto, K. Chapter 24—Chemical properties. In Amorphous Metallic Alloys; Elsevier: Amsterdam, The Netherlands, 1983; pp. 471–486. [Google Scholar]

- Naka, M.; Hashimoto, K.; Masumoto, T. Corrosion behavior of amorphous and crystalline Cu50Ti50 and Cu50Zr50 alloys. J. Non-Cryst. Solids 1978, 30, 29–36. [Google Scholar] [CrossRef]

- Turn, J.C.; Latanision, R.M. The influence of structure on the corrosion of glassy copper-zirconium alloys. Natl. Assoc. Corros. Eng. 1983, 39, 271–279. [Google Scholar] [CrossRef]

- Bala, H.; Szymura, S. Acid corrosion of amorphous and crystalline Cu-Zr alloys. Appl. Surf. Sci. 1988, 35, 41–51. [Google Scholar] [CrossRef]

- Gostin, P.F.; Eigel, D.; Grell, D.; Eckert, J.; Kerscher, E.; Gebert, A. Comparing the pitting corrosion behavior of prominent Zr-based bulk metallic glasses. J. Mater. Res. 2015, 30, 233–241. [Google Scholar] [CrossRef]

- Axinte, E. Metallic glasses from “alchemy” to pure science: Present and future of design, processing and applications of glassy metals. Mater. Des. 2012, 35, 518–556. [Google Scholar] [CrossRef]

- Lu, B.F.; Li, J.F.; Kong, L.T.; Zhou, Y.H. Correlation between mechanical behavior and glass forming ability of Zr-Cu metallic glasses. Intermetallics 2011, 19, 1032–1035. [Google Scholar] [CrossRef]

- Schuh, C.A.; Hufnagel, T.C.; Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 2007, 55, 4067–4109. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.J.; Djemia, P.; Mompiou, F.; Abadias, G.; Raskin, J.P.; Pardoen, T. Extrinsic mechanical size effects in thin ZrNi metallic glass films. Acta Mater. 2015, 90, 232–241. [Google Scholar] [CrossRef]

- Guo, L.J. Recent progress in nanoimprint technology and its applications. J Phys. D Appl. Phys. 2004, 37, 123–141. [Google Scholar] [CrossRef]

- Kobata, J.; Miura, K.; Amiya, K.; Fukuda, Y.; Saotome, Y. Nanoimprinting of Ti–Cu-based thin-film metallic glasses deposited by unbalanced magnetron sputtering. J. Alloys Compd. 2017, 15, 132–136. [Google Scholar] [CrossRef]

- Chu, J.P.; Jang, J.S.C.; Huang, J.C.; Chou, H.S.; Yang, Y.; Ye, J.C.; Wang, Y.C.; Lee, J.W.; Liu, F.X.; Liaw, P.K.; et al. Thin film metallic glasses: Unique properties and potential applications. Thin Solid Films 2012, 520, 5097–5122. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.J.; Pardoen, T.; Raskin, J.J.; Mompiou, F. Compositional-induced structural change in ZrxNi100−x thin film metallic glasses. J. Alloys Compd. 2014, 615, 12–16. [Google Scholar] [CrossRef]

- Apreutesei, M.; Steyer, P.; Joly-Pottuz, L.; Billard, A.; Qiao, J.; Cardinal, S.; Sanchette, F.; Pelletier, J.M.; Esnouf, C. Microstructural, thermal and mechanical behavior of co-sputtered binary Zr-Cu thin film metallic glasses. Thin Solid Films 2014, 561, 53–59. [Google Scholar] [CrossRef]

- Zeman, P.; Zítek, M.; Zuzjaková, Š.; Čerstvý, R. Amorphous Zr-Cu thin-film alloys with metallic glass behavior. J. Alloys Compd. 2017, 696, 1298–1306. [Google Scholar] [CrossRef]

- Kondoh, K.; Fujita, J.; Umeda, J.; Serikawa, T. Estimation of compositions of Zr-Cu binary sputtered film and its characterization. Adv. Mater. Sci. Eng. 2008, 4, 1–5. [Google Scholar] [CrossRef]

- Lu, H.B.; Li, Y.; Wang, F.H. Corrosion behavior and porous structure formation of sputtered Cu-Zr nanostructured films. J. Alloys Compd. 2008, 465, 139–144. [Google Scholar] [CrossRef]

- Apreutesei, M.; Boissy, C.; Mary, N.; Arab Pour Yazdi, M.; Billard, A.; Steyer, P. Binary Zr-Ni/Co metallic glass films: Role of the structural state on their durability. Acta Mater. 2015, 89, 305–314. [Google Scholar] [CrossRef]

- Del Re, M.; Gouttebaron, R.; Dauchot, J.P.; Leclère, P.; Terwagne, G.; Hecq, M. Study of ZrN layers deposited by reactive magnetron sputtering. Surf. Coat. Technol. 2003, 175, 240–245. [Google Scholar] [CrossRef]

- Yu, S.H.; Yang, W.H.; Li, L.X.; Zhang, W.F. Improved chemical stability of ITO transparent anodes with a SnO2 buffer layer for organic solar cells. Sol. Energy Mater. Sol. Cells 2016, 144, 652–656. [Google Scholar] [CrossRef]

- Apreutesei, M.; Steyer, P.; Billard, A.; Joly-Pottuz, L.; Esnouf, C. Zr-Cu thin film metallic glasses: An assessment of the thermal stability and phases’ transformation mechanisms. J. Alloys Compd. 2015, 619, 284–292. [Google Scholar] [CrossRef]

- Zhang, D.Q.; Gao, L.X.; Zhou, G.D. Inhibition of copper corrosion by bis-(1,1′-benzotriazoly)-α,ω-diamide compounds in aerated sulfuric acid solution. Appl. Surf. Sci. 2006, 252, 4975–4981. [Google Scholar] [CrossRef]

- Gebert, A.; Gostin, P.F.; Schultz, L. Effect of surface finishing of a Zr-based bulk metallic glass on its corrosion behavior. Corros. Sci. 2010, 52, 1711–1720. [Google Scholar] [CrossRef]

- Merl, D.K.; Panjan, P.; Kovac, J. Corrosion and surface study of sputtered Al-W coatings with a range of tungsten contents. Corros. Sci. 2013, 69, 359–368. [Google Scholar] [CrossRef]

- KkochNim, O.; Ihsan-UI-Haq, T.; SooHoon, A.; HyukSang, K. Effects of Cu on the passive film stability of Fe-20Cr-xCu (x = 0, 2, 4 wt.%) alloys in H2SO4 solution. Electrochim. Acta 2013, 88, 170–176. [Google Scholar] [CrossRef]

- Park, K.W.; Jang, J.; Wakeda, M.; Shibutani, Y.; Lee, J.C. Atomic packing density and its influence on the properties of Cu-Zr amorphous alloys. Scr. Mater. 2007, 57, 805–808. [Google Scholar] [CrossRef]

- Qin, F.X.; Wang, X.M.; Xie, G.Q.; Wada, K.; Song, M.; Furuya, K.; Asami, K.; Inoue, A. Microstructure and electrochemical behavior of Ti-coated Zr55Al10Ni5Cu30 bulk metallic glass. Intermetallics 2009, 17, 945–950. [Google Scholar] [CrossRef]

- Paunovic, M.; Schlesinger, M. Equilibrium Electrode Potential. In Fundamentals of Electrochemical Deposition, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 2006. [Google Scholar]

- Tan, M.; Liu, Q.; Zhang, N.; Hu, H.; Li, B.; Kang, X. Characterization of the surface film on Zr-based bulk metallic glass using X-ray photoelectron spectroscopy (XPS) and scanning electron microscopy (SEM). J. Alloys Compd. 2011, 509, 5926–5930. [Google Scholar] [CrossRef]

- Amin, M.A.; Khaled, K.F. Copper corrosion inhibition in O2-saturated H2SO4 solutions. Corros. Sci. 2010, 52, 1194–1204. [Google Scholar] [CrossRef]

- Kang, K.H.; Park, K.W.; Lee, J.C.; Fleury, E.; Lee, B.J. Correlation between plasticity and other materials properties of Cu-Zr bulk metallic glasses: An atomistic simulation study. Acta Mater. 2011, 59, 805–811. [Google Scholar] [CrossRef]

- Chen, L.Y.; Setyawan, A.D.; Kato, H.; Inoue, A.; Zhang, G.Q.; Saida, J.; Wang, X.D.; Cao, Q.P.; Jiang, J.Z. Free-volume-induced enhancement of plasticity in a monolithic bulk metallic glass at room temperature. Scr. Mater. 2008, 59, 75–78. [Google Scholar] [CrossRef]

- Cao, Q.P.; Jin, J.B.; Ma, Y.; Cao, X.Z.; Wang, B.Y.; Qu, S.X.; Wang, X.D.; Zhang, D.X.; Jiang, J.Z. Enhanced plasticity in Zr-Cu-Ag-Al-Be bulk metallic glasses. J. Non-Cryst. Solids 2015, 412, 35–44. [Google Scholar] [CrossRef]

- Apreutesei, M.; Billard, A.; Steyer, P. Crystallization and hardening of Zr-40 at.% Cu thin film metallic glass: Effects of isothermal annealing. Mater. Des. 2015, 86, 555–563. [Google Scholar] [CrossRef]

- Tailleart, N.R.; Huang, R.; Aburada, T.; Horton, D.J.; Scully, J.R. Effect of thermally induced relaxation on passivity and corrosion of an amorphous Al-Co-Ce alloy. Corros. Sci. 2012, 59, 238–248. [Google Scholar] [CrossRef]

- Jayaraj, J.; Gebert, A.; Schultz, L. Passivation behaviour of structurally relaxed Zr48Cu36Ag8Al8 metallic glass. J. Alloys Compd. 2009, 479, 257–261. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, J.; Zhu, Q.; Wang, Y.; Apreutesei, M.; Wang, H.; Steyer, P.; Chamas, M.; Billard, A. Insights on the Role of Copper Addition in the Corrosion and Mechanical Properties of Binary Zr-Cu Metallic Glass Coatings. Coatings 2017, 7, 223. https://doi.org/10.3390/coatings7120223

Tang J, Zhu Q, Wang Y, Apreutesei M, Wang H, Steyer P, Chamas M, Billard A. Insights on the Role of Copper Addition in the Corrosion and Mechanical Properties of Binary Zr-Cu Metallic Glass Coatings. Coatings. 2017; 7(12):223. https://doi.org/10.3390/coatings7120223

Chicago/Turabian StyleTang, Junlei, Qiuhong Zhu, Yingying Wang, Mihai Apreutesei, Hu Wang, Philippe Steyer, Mohamad Chamas, and Alain Billard. 2017. "Insights on the Role of Copper Addition in the Corrosion and Mechanical Properties of Binary Zr-Cu Metallic Glass Coatings" Coatings 7, no. 12: 223. https://doi.org/10.3390/coatings7120223

APA StyleTang, J., Zhu, Q., Wang, Y., Apreutesei, M., Wang, H., Steyer, P., Chamas, M., & Billard, A. (2017). Insights on the Role of Copper Addition in the Corrosion and Mechanical Properties of Binary Zr-Cu Metallic Glass Coatings. Coatings, 7(12), 223. https://doi.org/10.3390/coatings7120223