Abstract

It is well known that an effective way to improve the quality attributes of food is the use of coatings. Moreover, there is evidence of the use of dairy byproducts to design coatings to improve the shelf life of food products. This study was conducted to explore the effectiveness of a film forming solution containing whey protein–pectin complex enzymatically reticulated by transglutaminase (TGase) applied as a coating on eggshells to preserve the internal quality of eggs stored under environmental conditions (25 ± 1 °C and 35% HR) during 15 days storage. Eggs properties tested included yolk index, albumen and yolk pH, albumen CO2 content, water loss, shell strength, and microbial permeability through the shell. The results showed that the coating maintained a higher yolk index and albumen carbon dioxide content, reduced the weight loss and increased both albumen and yolk pH values with respect to the uncoated eggs. All coated eggshells showed greater strength than those of uncoated eggs. Moreover, by using Blue Lake dye penetration method we demonstrated that the coating reduced the Blue Lake dye penetration confirming the effectiveness of the coating on the reduction of post-wash bacterial penetration. These results suggest that the studied coating can be useful to preserve internal egg quality but also to reduce the breakage of eggshell and egg microbial contamination. Based on this result we can conclude that the coating made with whey protein–pectin crosslinked by TGase could be an effective strategy to increase the shelf life of eggs preserved in environmental conditions and to reduce economic losses due to the eggs breakage during their marketing.

1. Introduction

Chicken eggs are one of the most common foods all over the world. In 2016, Mexico ranked the fourth place on egg production worldwide, there was an approximate production of 2,653,000 tons of fresh eggs, and the main production was in the region of Jalisco (50%) [1,2]. According to FAO [3], eggs are considered a fundamental foodstuff for developing countries. The main activities involved in egg marketing include collecting, packaging, transporting, storing, and selling. During these operations, it is common for the eggshell to fracture or suffer a total rupture causing an economic loss for the producers. Moreover, sometimes it is difficult to control the environmental conditions in which the fresh eggs are conserved. Once the chicken egg is laid, the deterioration process starts due to a reduction in moisture content and a loss of carbon dioxide (CO2). These parameters are involved in the quality of the albumen and yolk [4,5,6,7] and can favor the penetration of microorganisms from the shell causing a microbial deterioration of the egg [7,8].

One strategy to enhance the shelf-life of fresh eggs is to keep them at refrigeration temperatures (4–8 °C), but in some regions that is not possible. An alternative to solve this problem is the use of edible coatings applied to fresh egg surfaces that can improve the egg´s shell mechanical properties and through the sealing of the eggshell pores, reduce the permeability to moisture, gases, and microorganisms [6,7,8,9,10,11,12,13]. It is well known that the chemical–physical properties of edible coatings strongly depend on their composition. Thus, an effective coating deserves to be selected according to the ability to counteract the phenomena responsible to the deterioration of food products. Lipid coatings show a high water barrier and poor mechanical properties. Moreover, their disadvantage is the development of rancidity. Hydrocolloid (polysaccharides and proteins) based-coatings promotes a higher water permeability due to their hydrophilicity but possess good mechanical and gases barrier properties. However, different physical, chemical, and biochemical modifications of the biopolymers used to make coatings can be useful to improve their barrier and mechanical properties [14,15]. Among the different coatings, hydrocolloid edible coatings represent the main egg coatings.

Whey proteins [9,16,17], soy proteins [8,9,17,18], and chitosan [7,10,19,20] have been proposed as an improvement of both barrier properties and mechanical strength of eggshells.

Since we previously demonstrated that edible whey protein/pectin films obtained in the presence of the enzyme transglutaminase (EC 2.3.2.13) possess good water vapor and gases barrier properties [17,21,22,23,24,25,26,27,28], we decided to study their effectiveness as a coating to preserve the quality parameters of fresh eggs.

Therefore, in this study, eggs were coated with whey proteins–pectin based films crosslinked by transglutaminase to observe their effect on quality parameters like weight loss, yolk index, pH of both yolk and albumen, and CO2 loss during 15 days of egg preservation in environmental conditions. In addition, both the strength of shell and the microbial permeability through the shell of the coated eggs were investigated. All the obtained results with the coated eggs were compared with those of the untreated eggs.

2. Materials and Methods

2.1. Materials

Commercial whey protein isolate (WPI) was obtained by Nature’s Best (Hauppauge, NY, USA). Erioglaucine disodium salt (Blue Lake dye), Low methoxyl pectin (Pec) from Citrus fruits, sorbitol and all other reagents were purchased from Sigma (Steinheim, Germany). mTGase (ACTIVA WM), derived from the culture of Streptoverticillium sp., was supplied by Ajinomoto Co. (Tokyo, Japan). The commercial preparation of ACTIVA-WM contains 1% of mTGase and 99% maltodextrin with a specific activity of 92 U/g of powder. Fresh chicken eggs were bought at a local market (medium size, 55 mm height, 42 mm width ±2 mm; 55 g weight ±2 g).

2.2. Methods

2.2.1. Film Forming Solution (FFS)

FFS was prepared as described by Di Pierro et al. [24] by dissolving the WPI (1.2 g) and sorbitol (0.6 g) in 25 mL of distilled water and stirring for 2 h. Simultaneously, Pec (1.2 g) was dissolved in 25 mL of distilled water and stirred for 2 h at room temperature to ensure the complete solubilization. After that, WPI and sorbitol solution was heated under stirring at 80 °C for 25 min to denature the proteins and Pec solution previously heated at 80 °C was added to obtain a WPI/Pec ratio of 4:1 (w:w). The FFS was let cool at room temperature under continuous stirring. The pH of the solution was adjusted to 5.1 by using HCl 0.1 N, and then transglutaminase (8 U/g of WPI) was added, and the solution was stirred for 16 h at room temperature. The obtained coating solution was used within one hour to coat the eggs.

2.2.2. Egg Coating

New-laid eggs were washed by dipping the eggs in distilled water containing 100 ppm of sodium hypochlorite (Clorox, Mexico City, Mexico) for 3 min, rinsed for 1 min in distilled water and dried at room temperature for 10 min. After that, the washed eggs were divided into two groups of 50 eggs. The coated egg group was dipped for 1 min in the coating solution and the uncoated, in distilled water. After dipping, all the samples were dried for 10 min with their small-end down at room temperature. All the eggs were placed in an egg tray with their small-end down and stored at environmental condition (25 ± 1 °C and 35% ± 4% RH) for 15 days.

2.2.3. Eggs Quality Parameters

Weight Loss (%)

Five marked eggs from each group were weighed at day 0 and after 7 and 15 days. The weight loss (%) of a whole egg was calculated as the weight difference in the percentage of an egg during storage compared to its whole weight at day 0 and given as an average value ± standard deviation.

Egg Yolk Index (YI)

Yolk index was determined as described by DSM manual. [29]. Five marked eggs were opened at scheduled days (0, 7, 15) and the yolk separated from the egg white by using an egg yolk white separator and the yolk was placed onto a plane surface covered with aluminum foil. The height (H) and the diameter, taken at two positions, D1 and 90° respect to D1 (D2), were measured by using a vernier calliper (Mitutoyo 530-312, Mitutoyo, Kawasaki, Japan). The egg yolk index was calculated as follows:

pH Measurement

The yolk and albumen separated for the egg yolk index were also selected for pH analysis. The pH was measured using a model pH500 Oakton Instruments pH meter (Oakton Instruments, Singapore).

Albumen CO2 Content

Five marked eggs of each group were opened at 0, 7, and 15 days of storage and the albumen were used to calculate the amount of CO2. The CO2 content was measured by using the methodology developed by Keener et al. [30]. A measured amount of albumen was placed into a 250 mL glass jar containing a 30 mL glass vial with 12 mL of 0.15 N standardized NaOH. The 250 mL glass jar was sealed with a screw-cap lid modified on the top with a 1.5 cm rubber septum. Next, via a rubber septum, a syringe was used for to inject 15 mL of acid phosphate solution into albumen to convert the carbonate into albumen in CO2 which was driven into the 12 mL of standardized NaOH and converted in sodium carbonate. After 24 h at 37 °C, the vials were removed from the jars, and for carbon dioxide determination, 3 mL of 1 N BaCl2 and one drop of phenolphthalein indicator were added to the 30 mL vial to convert sodium carbonate in NaCl and insoluble BaCO3. At the end, the remaining NaOH in the solution was titrated by using 0.15 N standardized HCl. Knowing that one mEq of NaOH reacts with 22 mg of CO2, the amount of CO2 in the albumen was calculated as follow:

2.2.4. Eggshell Thickness

The test was configured as described by Xie et al. [9]. All the eggshells obtained in the previous experiment were washed with distilled water and the inner membrane removed. The obtained eggshell was dried overnight at 25 °C. After that, the eggshell thickness was measured by using a micrometer (± 0.3 μm accuracy) (Mitutoyo M10-25, Kawasaki, Japan). The thickness was evaluated at ten random positions in each eggshell sample, and the mean value was calculated for each shell. Results were expressed as the mean of the mean thickness of each shell ± standard deviation.

2.2.5. Eggshell Strength

The strength of whole eggs was determined in accord to Rhim et al. [18]. Each whole egg was mounted on a platform with a 1.5 cm diameter circular hole at center in which the eggs were inserted by their small ends. The eggs were compressed at their large end with a flat cylinder (55 mm diameter) mounted on an Instron universal testing instrument model No. 5543A (Instron Engineering Corp., Norwood, MA, USA) equipped with a 2 kN load cell. The test was performed at 5 mm min−1 constant speed in compression mode. The maximum force required to break the eggshell was recorded and expressed as shell strength (N).

2.2.6. Eggshell Permeability to Blue Lake Dye

The ability of the coating to stop the bacterial penetration into eggs were made as described by Xie et al. [9]. The bacterial penetration was simulated by using the Blue Lake dye an insoluble dye with an average diameter of particle size of 0.6 mm which is slightly smaller than most bacteria [31]. Kim et al. [32] reported that Blue Lake dye penetration corresponds to Salmonella enteriditis behavior on eggs. Coated and uncoated eggs were immersed in 0.25% Blue Lake dye in 0.1% Triton X-100 solution for 2 min and then incubated at room temperature up to 1 h. Hence, eggs were broken, and dots were counted on the entire shell membranes.

2.2.7. Statistical Analysis

JMP software 5.0 (SAS Institute, Cary, NC, USA) was used for all statistical analyses. Mean values ± standard deviation is reported from three independent experiments.

3. Results and Discussion

The main problems encountered in storing eggs are represented by weight loss, deterioration of the interior quality (an increase of albumen and yolk pH), and microbial contamination [4,5,33].

3.1. Weight Loss

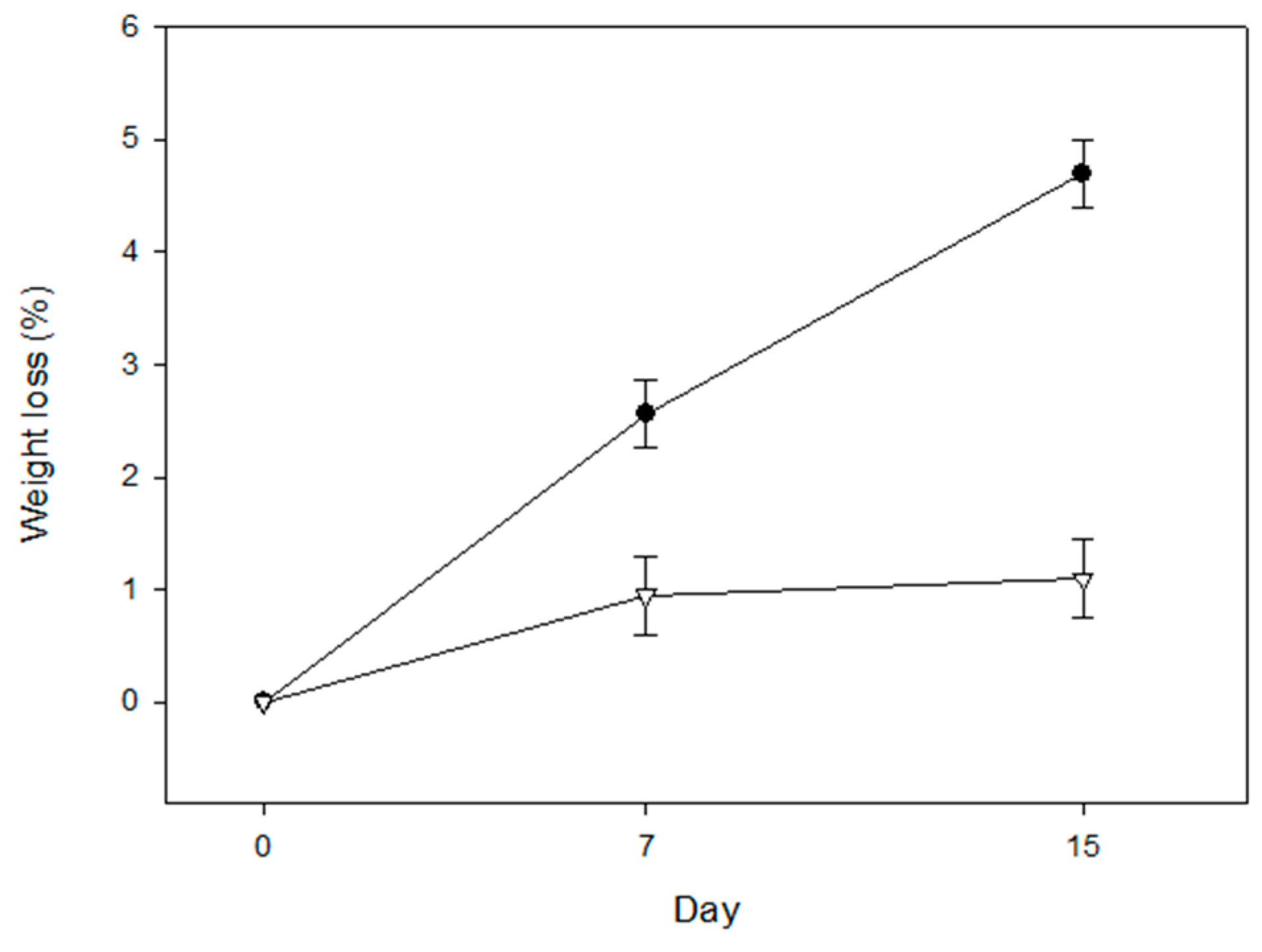

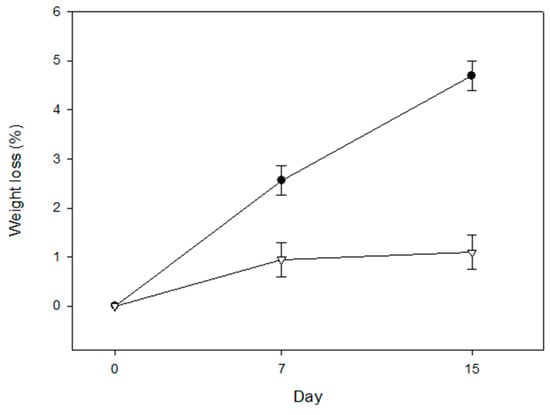

Weight loss of eggs during storage is mainly caused by evaporation of water and loss of carbon dioxide from the albumen through the porous shells or micro-breakages of eggshell [17]. Different weight losses for uncoated eggs were reported in the literature, these changes may be due to the variability among the storage period, temperature, humidity, egg size, and shell porosity that can affect the results obtained with coated eggs. For this reason, it is very important to compare the effectiveness of different coatings only with the ones reported in the literature that showed similar water loss on uncoated eggs. Additionally, a weight loss of 2%–3% in market eggs is not noticeable by the consumers [33,34]. The results reported in Figure 1 showed a linear weight loss increase during storage at 25 °C both in uncoated and coated eggs with the lowest slope in coated eggs. Uncoated eggs lost around 4.7% ± 0.3% weight after 15 days of storage at 25 °C while coated eggs showed a much lower weight loss (1.1% ± 0.35%) at the same storage time. This study demonstrates that whey protein–pectin coating crosslinked by transglutaminase (TGase) was able to make a more effective barrier against the loss of components through the eggshells during the 15 days of storage compared with the results reported by Caner [16] using whey proteins alone (2.1% respect to 3.4% for uncoated samples at 15 days), Xu et al. [8] using a solution of soy protein and montmorillonite (SPI/MMT) (2.7% respect to 4.2% for uncoated samples at 15 days), Suresh et al. [7] using only chitosan (2.3% respect to 3.1% for uncoated samples at 15 days), and recently, Xu et al. [35] using three consecutive layers of chitosan (2.0% respect to 2.6% for uncoated eggs at 16 days).

Figure 1.

Weight loss of uncoated (●) and coated (∇) samples.

3.2. CO2 Loss and pH Value

It is well known that between the two parameters affecting the eggs weight loss, the CO2 loss is the main effect on the quality of eggs. When CO2 is lost, the pH of the albumen increases and, an increase in pH causes some denaturation of proteins affecting the quality of the eggs [34]. Moreover, the rise of the pH leads to the thinning of the albumen and to a reduction on the viscosity of the albumen because of the rupture of the ovomucin-lysozyme complex [8,10,19]. The results in Table 1 show that there was about 12% CO2 loss in the albumen of the uncoated eggs after two weeks while in the coated eggs only 6% of CO2 was lost confirming the good barrier properties of our coating. This reduction on the release of CO2 through the eggshell mediated by the coating counteracts the increase of the pH occurring in both albumen and yolk of uncoated eggs. These results demonstrate that the presence of coating creates a barrier against CO2 loss, enhancing the shelf-life of the product and are in agreement with the results obtained by Biladau et al. [17] who used whey protein isolates and soy protein isolates as coatings. The same behavior was also observed by Xu et al. [35] by applying three consecutive layers of chitosan coating on the eggs shell.

Table 1.

Albumen CO2 content, albumen and Yolk pH of uncoated and coated samples.

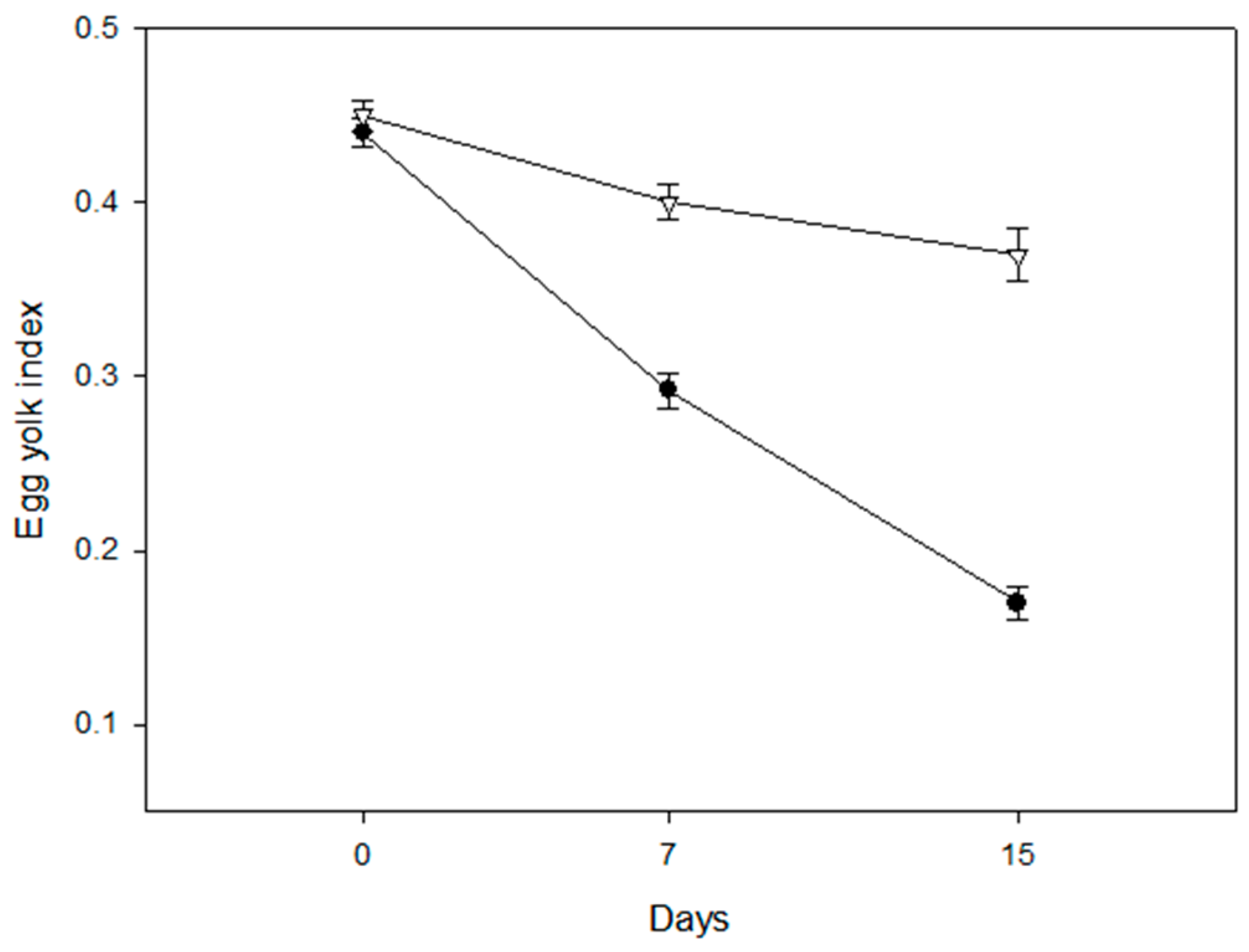

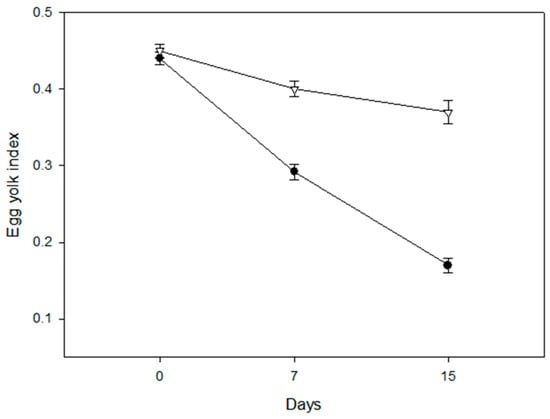

3.3. Yolk Index

Yolk index (YI) is related with a progressive deterioration of the vitelline membrane and liquefaction of the yolk caused by diffusion of water from the albumen when it loses its structure and can be used as an indicator of freshness [20,36,37,38]. The yolk index of fresh, high-quality eggs is about 0.45, while the storage time and conditions (humidity and temperature) have a significant effect on YI decreasing. Hence, the higher the yolk index is, the better the yolk quality is [11,19]. Figure 2 shows that the YI of uncoated eggs decreases linearly (from 0.44 to 0.17) during 15 days of storage at ambient condition. The YI of coated eggs also decreases during the storage but at a lower rate with respect to uncoated eggs. In fact, coated eggs showed a YI value (0.37) more than twice the YI of uncoated eggs (0.17) at 15 days of storage.

Figure 2.

Egg yolk index of uncoated (●) and coated (∇) samples.

These results show that our coatings are able to preserve the quality of yolk in eggs stored for 15 days, as they effectively reduced the rate of water and CO2 loss from the albumen through the eggshell to inhibit albumen liquefaction and water uptake of the yolk. Compared with the previous study by Suresh et al. [7] the yolk index of coated eggs (0.37) was similar to chitosan-coated eggs (0.37) or SPI/MMT coating (0.38) [8]. However, if we compare YI of coated eggs against the uncoated eggs, the coatings had a more positive effect on the yolk index (Uncoated = 0.17, Coated = 0.37) with respect to the chitosan (Uncoated = 0.34, Coated = 0.36) or SPI/MMT (Uncoated = 0.36, Coated = 0.38) coatings. These observed differences probably are due to the lower environmental humidity of our region (mean RH = 35%).

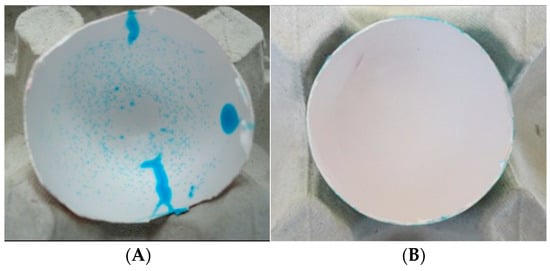

3.4. Egg Shell Parameters and Bacterial Penetration

To evaluate the physical effect of coating on the eggshell, we evaluated the shell strength by a compression test and the barrier properties to stop bacterial penetration into eggshells by use of Blue Lake dye [9,32]. As shown in Table 2, in the coated eggs a little increase was observed in the eggs shell thickness compared with uncoated eggs. However, a 42% increase in shell strength was observed in coated eggs. These results confirm that a very small increase in thickness may have a large effect on shell strength results [9,18].

Table 2.

Eggshell thickness, strength and dye dots of uncoated and coated eggs.

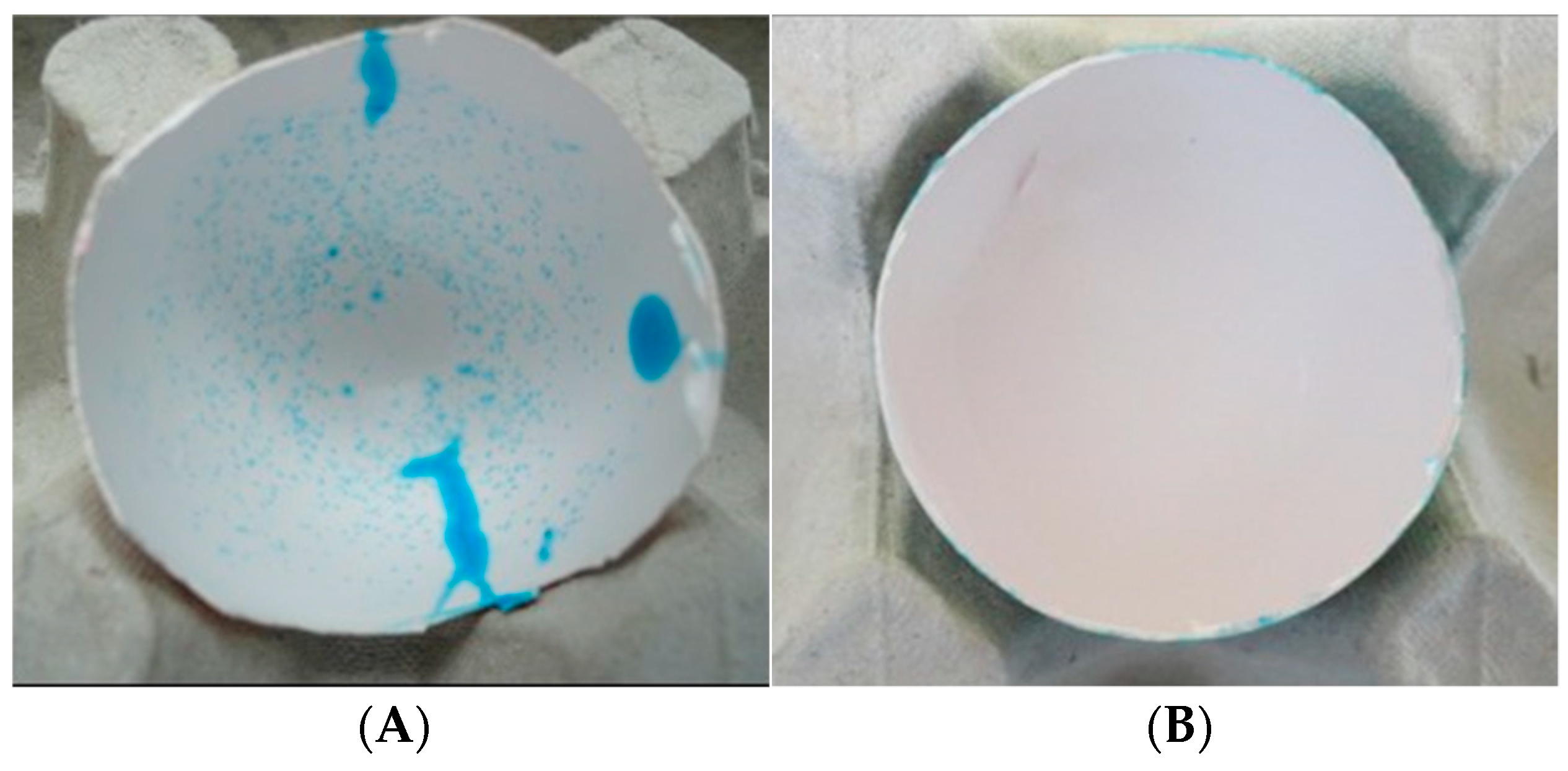

Moreover, as shown in Figure 3, the uncoated eggs showed very high permeation toward Blue Lake (Figure 3A). Conversely, no dots are highlighted on the internal surface of coated eggs (Figure 3B). In fact, if we count the dots on ten samples, we can see that the dots on the coated eggs are significantly lower with respect to the uncoated eggs (Table 1). These results confirm the ability of the coating to stop the penetration of the microorganisms and confirm the usefulness of the coating to protect the eggshell from breakage during the processing and handling.

Figure 3.

Internal eggshell of uncoated eggs (A) and coated eggs (B) after incubation in a solution containing Blue Lake dye.

4. Conclusions

The results revealed that eggs coated with our whey protein–pectin blend crosslinked by TGase showed an increase the shelf life of fresh washed eggs stored in environmental conditions (25 ± 1 °C and 35% ± 4% RH). The preservation effects of coating on eggs are predominantly attributed to the barrier properties of coatings that close the pores of eggshell and reduce both the weight loss and CO2 loss preserving the eggs quality parameters for up to 15 days of preservation. The reduction on the eggshell porosity can affect the bacterial penetration as demonstrated by the reduction of the permeability to the Blue Lake dye that simulates the dimensions of Salmonella enteriditis. Moreover, the presence of the coating increases the strength of eggshell protecting the eggs from the shell breakage during processing and handling. Based on this study, the proposed whey proteins–pectin blend crosslinked by TGase could be a good candidate as a coating material for preserving egg quality during storage without refrigeration.

Author Contributions

Conceptualization, C.A.D.S., P.D.P. and G.R.M.; Methodology, P.D.P. and G.R.M.; Validation, P.D.P. and C.R.G.; Formal Analysis, C.A.D.S., P.D.P., G.R.M., C.R.G. and M.A.M.; Investigation, C.A.D.S., G.R.M. and M.A.M.; Writing-Original Draft Preparation, C.A.D.S., G.R.M.; Writing-Review & Editing, P.D.P., G.R.M. and C.R.G.; Project Administration, P.D.P.; Funding Acquisition, P.D.P. and C.R.G.

Funding

This research was funded by the Italian Ministry of Foreign Affairs and International Cooperation through the Executive Program of Scientific and Technological Cooperation between Italy and United States of Mexico 2018–2020 (Progetto Grande Rrilevanza, 2018).

Conflicts of Interest

The authors declare no conflict of interest.

References

- 4To Informe De Labores 2015–2016; Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación (SAGARPA): Ciudad de México, Mexico, 2016; Available online: https://www.gob.mx/cms/uploads/attachment/file/254118/CuartoInformeDeLabores_SAGARPA.pdf (accessed on 28 November 2018). (In Mexican)

- Leading egg producing countries worldwide in 2016 (in number of eggs in billions). Available online: https://www.statista.com/statistics/263971/top-10-countries-worldwide-in-egg-production (accessed on 27 November 2018).

- Egg Marketing: A Guide for the Production and Sale of Eggs; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2003.

- Stadelman, W.J.; Cotterill, O.J. The preservation of quality in shell eggs. In Egg Science and Technology, 3rd ed.; AVI Publishing Company: Westport, CT, USA, 1986; pp. 499–521. [Google Scholar]

- Stadelman, W.J.; Cotterill, O.J. Quality identification of shell eggs. In Egg Science and Technology, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 55–82. [Google Scholar]

- Nongtaodum, S.; Jangchud, A.; Jangchud, K.; Dhamvithee, P.; No, H.K.; Prinyawiwatkul, W. Oil coating affects internal quality and sensory acceptance of selected attributes of raw eggs during storage. J. Food Sci. 2013, 78, S329–S335. [Google Scholar] [CrossRef] [PubMed]

- Suresh, P.V.; Raj, K.R.; Nidheesh, T.; Pal, G.K.; Sakhare, P.Z. Application of chitosan for improvement of quality and shelf life of table eggs under tropical room conditions. J. Food Sci. Technol. 2015, 52, 6345–6354. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Zhang, H.; Lv, X.; Chi, Y.; Wu, Y.; Shao, H. Internal quality of coated eggs with soy protein isolate and montmorillonite: effects of storage conditions. Int. J. Food Prop. 2017, 20, 1921–1934. [Google Scholar] [CrossRef]

- Xie, L.; Hettiarachchy, N.S.; Ju, Z.Y.; Meullenet, J.; Wang, H.; Slavik, M.F.; Janes, M.E. Edible film coating to minimize eggshell breakage and reduce post-wash bacterial contamination measured by dye penetration in eggs. J. Food Sci. 2002, 67, 280–284. [Google Scholar] [CrossRef]

- Caner, C.; Cansiz, Ö. Chitosan coating minimises eggshell breakage and improves egg quality. J. Sci. Food Agric. 2008, 88, 56–61. [Google Scholar] [CrossRef]

- Yuceer, M.; Caner, C. Antimicrobial lysozyme–chitosan coatings affect functional properties and shelf life of chicken eggs during storage. J. Sci. Food Agric. 2014, 94, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Alleoni, A.C.C.; Antunes, A.J. Internal quality of eggs coated with whey protein concentrate. Sci. Agric. 2004, 61, 276–280. [Google Scholar] [CrossRef]

- Edirisinghe, E.D.M.T.; Jayasinghe, J.M.P.; Himali, S.M.C.; Abeyrathne, E.D.N.S. Effect of Beeswax and Gammalu (Pterocarpus marsupium) Latex Coating on Internal and Sensory Attributes of Chicken Eggs Stored at Room Temperature. Int. J. Res. Agric. Sci. 2017, 4, 76–81. [Google Scholar]

- Coltelli, M.-B.; Wild, F.; Bugnicourt, E.; Cinelli, P.; Lindner, M.; Schmid, M.; Weckel, V.; Müller, K.; Rodriguez, P.; Staebler, A.; et al. State of the Art in the Development and Properties of Protein-Based Films and Coatings and Their Applicability to Cellulose Based Products: An Extensive Review. Coatings 2016, 6, 1. [Google Scholar] [CrossRef]

- Zink, J.; Wyrobnik, T.; Prinz, T.; Schmid, M. Physical, chemical and biochemical modifications of protein-based films and coatings: An extensive review. Int. J. Mol. Sci. 2016, 17, 1376. [Google Scholar] [CrossRef] [PubMed]

- Caner, C. Whey protein isolate coating and concentration effects on egg shelf life. J. Sci. Food Agric. 2005, 85, 2143–2148. [Google Scholar] [CrossRef]

- Biladeau, A.M.; Keener, K.M. The effects of edible coatings on chicken egg quality under refrigerated storage. Poult. Sci. 2009, 88, 1266–1274. [Google Scholar] [CrossRef] [PubMed]

- Rhim, J.-W.; Weller, C.L.; Gennadios, A. Effects of soy protein coating on shell strength and quality of shell eggs. Food Sci. Biotechnol. 2004, 13, 455–459. [Google Scholar]

- Wardy, W.; Torrico, D.D.; Herrera Corredor, J.A.; No, H.K.; Zhang, X.; Xu, Z.; Prinyawiwatkul, W. Soybean oil-chitosan emulsion affects internal quality and shelf-life of eggs stored at 25 and 4 °C. Int. J. Food Sci. Technol. 2013, 48, 1148–1156. [Google Scholar] [CrossRef]

- Bhale, S.; No, H.K.; Prinyawiwatkul, W.; Farr, A.J.; Nadarajah, K.; Meyers, S.P. Chitosan coating improves shelf life of eggs. J. Food Sci. 2003, 68, 2378–2383. [Google Scholar] [CrossRef]

- Di Pierro, P.; Chico, B.; Villalonga, R.; Mariniello, L.; Damiao, A.E.; Masi, P.; Porta, R. Chitosan−whey protein edible films produced in the absence or presence of transglutaminase: Analysis of their mechanical and barrier properties. Biomacromolecules 2006, 7, 744–749. [Google Scholar] [CrossRef] [PubMed]

- Di Pierro, P.; Chico, B.; Villalonga, R.; Mariniello, L.; Masi, P.; Porta, R. Transglutaminase-catalyzed preparation of chitosan–ovalbumin films. Enzyme Microb. Technol. 2007, 40, 437–441. [Google Scholar] [CrossRef]

- Porta, R.; Mariniello, L.; Di Pierro, P.; Sorrentino, A.; Giosafatto, C.V.L. Transglutaminase crosslinked pectin-and chitosan-based edible films: A review. Crit. Rev. Food Sci. Nutr. 2011, 51, 223–238. [Google Scholar] [CrossRef] [PubMed]

- Di Pierro, P.; Rossi Marquez, G.; Mariniello, L.; Sorrentino, A.; Villalonga, R.; Porta, R. Effect of transglutaminase on the mechanical and barrier properties of whey protein/pectin films prepared at complexation pH. J. Agric. Food Chem. 2013, 61, 4593–4598. [Google Scholar] [CrossRef] [PubMed]

- Rossi-Marquez, G.; Di Pierro, P.; Esposito, M.; Mariniello, L.; Porta, R. Application of Transglutaminase-Crosslinked Whey Protein/Pectin Films as Water Barrier Coatings in Fried and Baked Foods. Food Bioprocess Technol. 2014, 7, 447–455. [Google Scholar] [CrossRef]

- Porta, R.; Di Pierro, P.; Sabbah, M.; Regalado-Gonzales, C.; Mariniello, L.; Kadivar, M.; Arabestani, A. Blend films of pectin and bitter vetch (Vicia ervilia) proteins: Properties and effect of transglutaminase. Innov. Food Sci. Emerg. Technol. 2016, 36, 245–251. [Google Scholar] [CrossRef]

- Rossi Marquez, G.; Di Pierro, P.; Mariniello, L.; Esposito, M.; Giosafatto, C.V.; Porta, R. Fresh-cut fruit and vegetable coatings by transglutaminase-crosslinked whey protein/pectin edible films. LWT Food Sci. Technol. 2017, 75, 124–130. [Google Scholar] [CrossRef]

- Sabbah, M.; Giosafatto, C.V.L.; Esposito, M.; Di Pierro, P.; Mariniello, L.; Porta, R. Transglutaminase Cross-Linked Edible Films and Coatings for Food Applications. In Enzymes in Food Biotechnology; Academic Press: New York, NY, USA, 2019; pp. 369–388. [Google Scholar]

- DSM Egg Quality Manual; DSM Nutritional Products Ltd.: Basel, Switzerland. Available online: https://www.dsm.com/content/dam/dsm/anh/en_US/documents/DSM-egg-quality-manual.PDF (accessed on 28 November 2018).

- Keener, K.M.; LaCrosse, J.D.; Babson, J.K. Chemical method for determination of carbon dioxide content in egg yolk and egg albumen. Poult. Sci. 2001, 80, 983–987. [Google Scholar] [CrossRef] [PubMed]

- De Zuniga, A.G.; Anderson, M.E.; Marshall, R.T.; Iannotti, E.L. A model system for studying the penetration of microorganisms into meat. J. Food Prot. 1991, 54, 256–258. [Google Scholar] [CrossRef]

- Kim, J.W.; Slavik, M.F. Changes in eggshell surface microstructure after washing with cetylpyridinium chloride or trisodium phosphate. J. Food Prot. 1996, 59, 859–863. [Google Scholar] [CrossRef]

- Lucisano, M.; Hidalgo, A.; Comelli, E.M.; Rossi, M. Evolution of chemical and physical albumen characteristics during the storage of shell eggs. J. Agric. Food Chem. 1996, 44, 1235–1240. [Google Scholar] [CrossRef]

- Marketing quality eggs. In Egg Marketing: A Guide for the Production and Sales of Eggs; Agricultural Services Bulletin n.150; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2003; pp. 29–41.

- Xu, D.; Wang, J.; Ren, D.; Wu, X. Effects of Chitosan Coating Structure and Changes during Storage on Their Egg Preservation Performance. Coatings 2018, 8, 317. [Google Scholar] [CrossRef]

- Stadelman, W.J. The preservation of quality in shell eggs. In Egg Science and Technology, 4th ed.; CRC Press: New York, NY, USA, 1995; pp. 67–79. [Google Scholar]

- Scott, T.A.; Silversides, F.G. The effect of storage and strain of hen on egg quality. Poult. Sci. 2000, 79, 1725–1729. [Google Scholar] [CrossRef] [PubMed]

- Silversides, F.G.; Scott, T.A. Effect of storage and layer age on quality of eggs from two lines of hens. Poult. Sci. 2001, 80, 1240–1245. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).