Abstract

The running-in behavior and the associated transient friction characteristics of a piston ring with different surface treatments are experimentally evaluated using a custom-made engine testing apparatus. Results are reported for a series of running-in and steady-state experiments on piston rings with different combinations of coated and textured surfaces. Comparisons are provided between five different types of piston rings: (1) with no textures; (2) with textures only; (3) with coating only; (4) first textured and then coated; and (5) first coated and then textured. A combination of the texturing and coating showed 12.5% improvement in the frictional behavior and up to 50% improvement in break-in time compared to cases when only one surface treatment was applied.

1. Introduction

Manufacturers of internal combustion engines continuously face the challenging task of finding means to reduce fuel consumption and emissions in an attempt to improve the engine efficiency. Research shows that frictional loss in an internal combustion engine is the most important factor in determining the fuel economy and performance of a vehicle. Typically, a single passenger car uses an average of 89.82 gallons of fuel per year to overcome friction, which amounts to $206.6 according to the average gas price in the United States in 2017 [1]. Quantitatively, about 33% of fuel in a car is used to overcome friction [1], and 50% of the friction losses in an internal combustion engine is due to the piston/cylinder system, of which 70–80% comes from the piston rings [2]. Therefore, improving the tribological behavior of piston rings can have a major impact on the engine performance with concomitant benefits of reducing fuel and oil consumption.

One method for improving piston rings’ performance is to take advantage of recent developments in surface texturing and coating technology. Surface texturing involves creating micro patterns on one of the contacting surfaces, while surface coating requires depositing a thin layer of a suitable material on one or both surfaces to improve the component’s friction and wear characteristics. The performance of textured surfaces is affected by the geometric characteristic of textures and studies have shown that dimensional uncertainties due to manufacturing tolerances can affect the performance of textures [3,4].

Relevant to improving engine performance, Ryk and Etsion [4] were one of the first groups to conduct an experimental study on the hydrodynamics of a textured piston ring. They designed a test rig capable of keeping the lubrication rate constant to measure the friction between a section of the ring and a section of the cylinder liner. The dimples created on the piston rings had a diameter of 100 mm, depth of 10 mm, and area ratio of 20%. As a result, a friction reduction of 20% to 30% was observed. In a later work [5,6], a design was proposed wherein only a portion of the piston ring was textured. Comparison with non-textured surfaces revealed that a 25% reduction in the friction can be achieved by partial texturing. In a subsequent study, Etsion and Sher [7] compared the fuel efficiency and emission of engines equipped with partially textured and non-textured barrel shape piston rings installed in an engine and reported a 4% reduction in the fuel consumption. The effect of texturing circular dimples with different diameters and depths on the piston ring surface was studied by Bolander and Sadeghi [8]. Based on their results, textured piston rings with shallow dimples yielded a lower friction compared to deeper grooves. In a recent study, Shen and Khonsari [9] proposed a textured design with a micro trapezoidal shaped oil pocket on the inlet and outlet of the ring face. They suggested that during the reciprocating motion of the piston, the pockets perform akin to small step-bearings and can generate additional load-carrying capacity with improved frictional behavior, without compromising the blow-by characteristics.

The existing literature also contains studies of different coating materials for piston ring applications [10,11,12,13]. Many researchers have focused on diamond-like carbon coatings (DLC) that are known to have a low propensity for tribochemical reactions and adhesive wear. In general, these properties result in a lower coefficient of friction compared to the metallic layer or hard coatings [14]. Plasma coatings for application on piston rings have also been investigated and promising results have been reported [10]. With the capability of reducing friction, coatings have been shown to improve the thermal performance of pistons. For example, Buyukkaya [11] showed that the application of a ceramic coating would, in some cases, lead to 48% improvement in the thermal conductivity of pistons.

Experimental tests dealing with surface texture alone have revealed that sharp edges created around the circumference of the dimples tend to scratch the mating surface. This is particularly crucial when thermally- and mechanically-induced waviness is generated on the surface and, as a result, the sharp edges tend to orient themselves along the surface undulations and further contribute to cutting and scratching, particularly during the running-in stage [15]. One technique to overcome such a drawback is to treat the textured surfaces with the coating. Examination of the available publications in the open literature reveals, however, that the transient behavior of piston rings during the running-in stage has not been thoroughly investigated, particularly in applications involving the use of a combination of coating and surface texturing. In this paper, we investigate the effect of texturing and coating and the sequence of each of these surface treatments on the tribological performance of oil control rings. Results are presented for different combination scenarios of surface textures and coatings including the breaking-in time, transient, and the steady-state frictional characteristics.

2. Materials and Methods

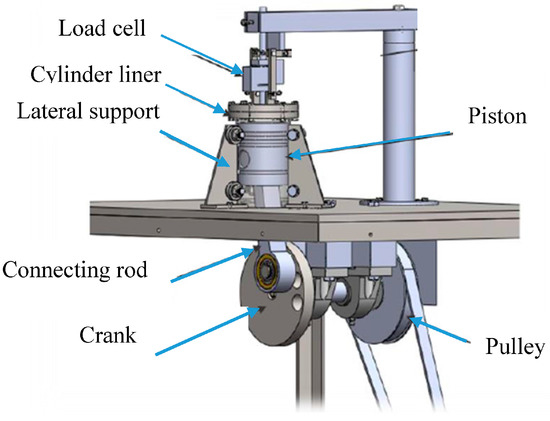

2.1. Experimental Setup

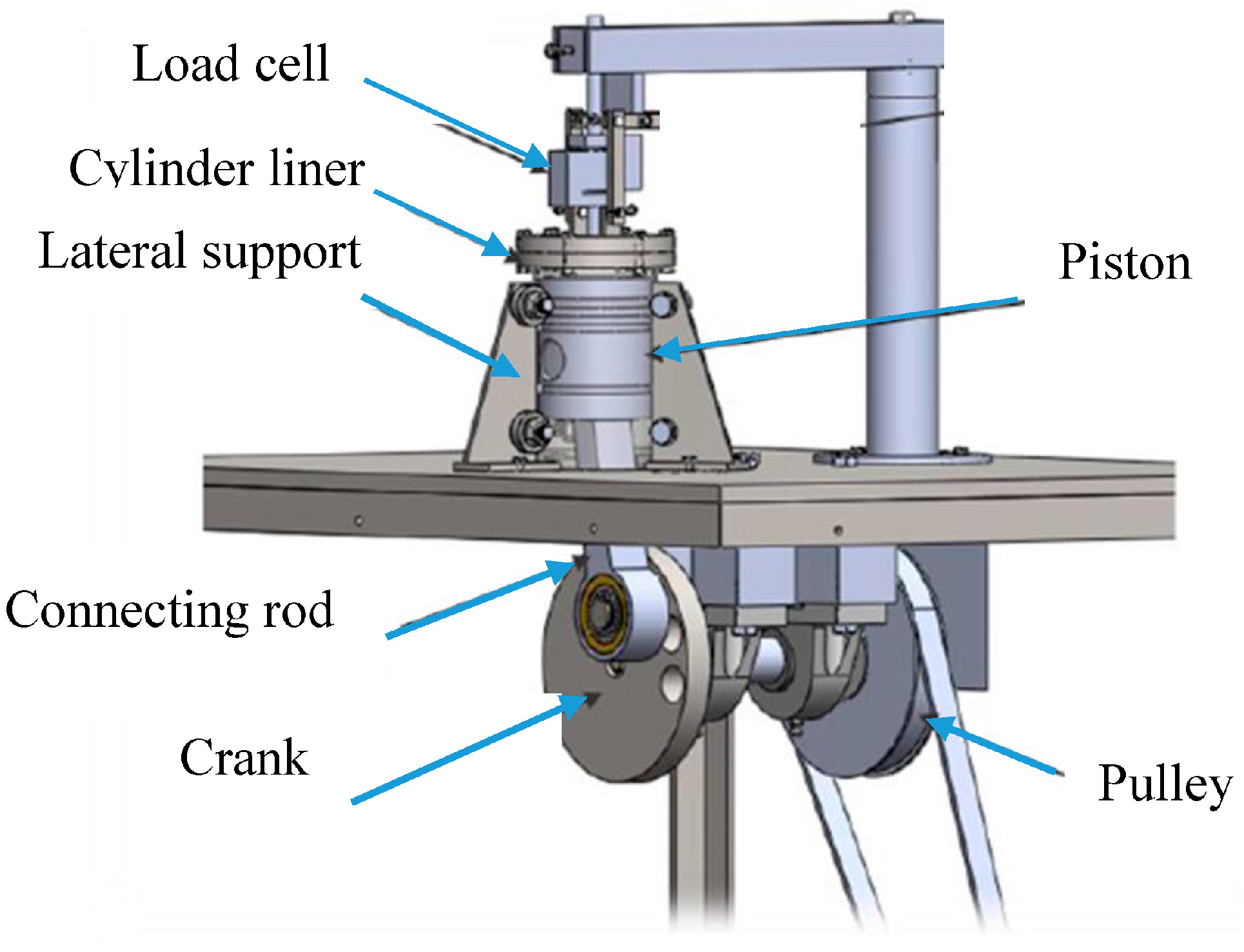

A custom-built engine testing apparatus with a reciprocating piston instrumented for friction measurement was used to conduct the experiments. The apparatus was equipped with a diesel engine piston, piston rings, cylinder liner, and connecting rod. An electric motor drives the crankshaft through a set of pulleys. Rotation of crankshaft creates a reciprocating movement of the piston assembly. The pulley drive ratio is 3.4:2.5. A larger pulley connected to the crankshaft also functions as a flywheel to smooth the motion of the piston. To achieve smooth motion in the axial direction, the cylinder liner should remain in the center position. For this purpose, each lateral support is equipped with two ball bearings. Figure 1 shows the schematic of the test rig.

Figure 1.

Schematic of the test setup.

Similar to the lubrication system of a real engine, a nozzle sprays the lubricant on the lower surface of the piston and cylinder liner. Holes in the piston deliver the lubricant to the cylinder wall and lubrication is regulated by the oil control rings [16]. A full description of the experimental setup can be found in [16].

2.2. Sample Preparation

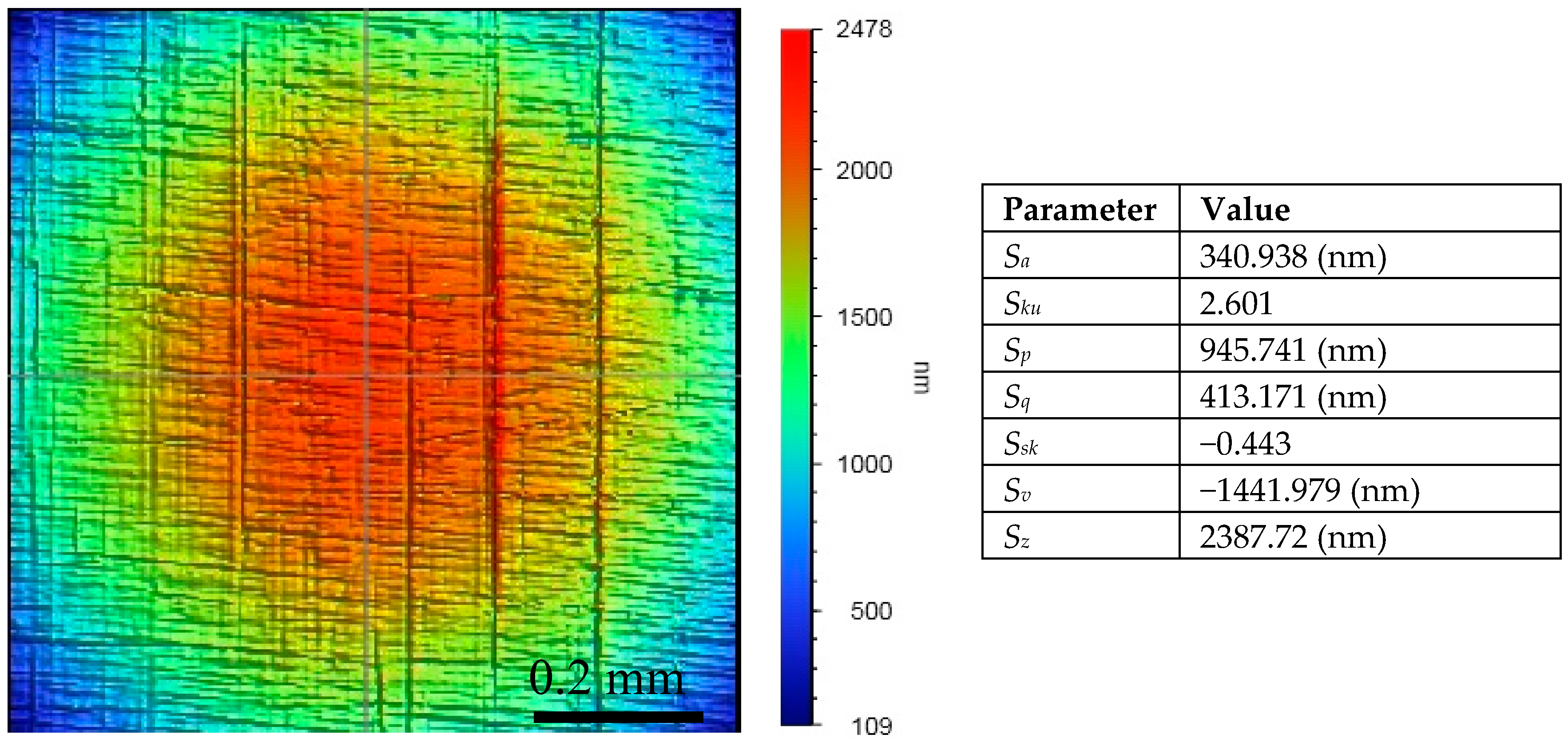

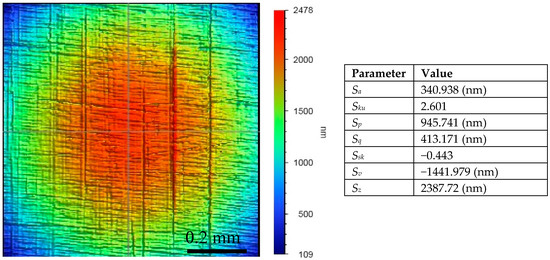

The piston ring-pack consists of three compression rings and two oil control rings. The reason for using piston rings from a diesel engine is that their axial ring width is larger than those in a gasoline engine. Therefore, relatively large pockets can be created on the ring surface in order to make the effects of lasered pockets easier to fabricate and measure. Further, in a diesel engine, the ring’s tension force and the number of compression rings are greater. This can lead to higher and more noticeable piston ring friction. The micro-pockets and coating are machined only on the sliding surface of the oil control rings. This surface is made of cast iron with a diameter of 99 mm and a width of 2.36 mm. An optical surface profile of an untreated compression ring along with surface roughness parameters are given in Figure 2.

Figure 2.

Surface profile of an untreated pressure ring. Surface roughness parameters are given in the right table.

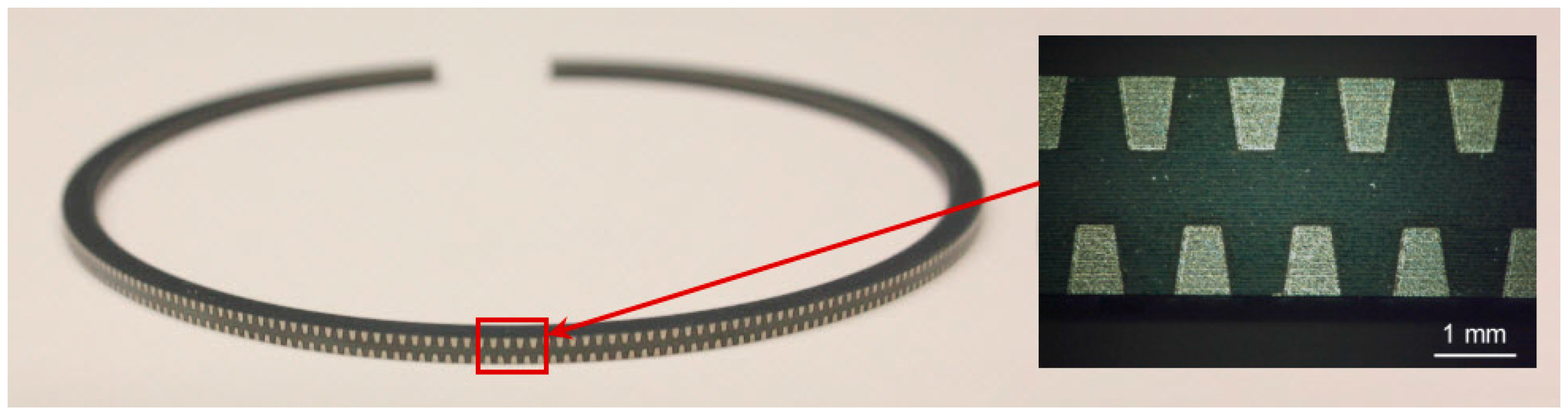

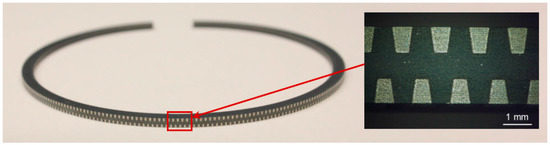

A fiber laser with a wavelength of 1064 nm was used to fabricate micro-textures. The shape and distribution of the pockets are first designed using CAD software and then imported into the laser texturing device. Figure 3 shows the surface of a laser pocketed compression ring. The geometric parameters of the pockets are listed in Table 1. The optimal range of the pocket size was selected based on a previous study [9].

Figure 3.

Image of pocketed compression ring [14].

Table 1.

Geometric parameters of lasered pockets [14].

Untampered plasma coating has a number of benefits, such as improving the adhesion and wetting of surfaces. It is convenient and lightweight and can be applied via a handheld device. It is also available in the robotic mountable option to improve productivity and repeatability. Since it uses “cold plasma”, it is suitable to treat temperature-sensitive substrates. In a recent study, the effect of this specific coating on the surface energy and wettability of eight different samples was investigated [17]. Lack of research on this coating material was the motivation behind choosing this type of coating.

In this research, a Piezobrush® PZ2 (Relyon Plasma GmbH, Regensburg, Germany) was used for coating the samples. This instrument uses a Piezoelectric Direct Discharge technology to transfer the low voltage input into the high AC voltage. As a result, a strong electric field is produced that dissociates and ionizes the ambient process gas (air) and deposits a thin layer of material on the surface of the specimen. The advantages of this method are that the coating can be easily and inexpensively applied at a rapid rate. A previous study demonstrated that for this type of coating, the spraying distance and its angle are the most important parameters that influence the hardness, porosity, and coating roughness of the plasma spraying [18]. Accordingly, in the current study, the coatings were sprayed an angle of 45° at a distance of 12 cm, and each segment of the rings was coated for 3 min. Rings were rotated at a constant speed to ensure the identical thickness of the coatings all around the rings.

3. Results and Discussion

In this section, the experimental results obtained from the friction tests are presented and discussed. Five sets of piston rings were tested. The first set was coated with the plasma gun, the next set was textured only without coating, the third set was coated identical to the first set but then textured, and the fourth set was textured and then coated, just like set numbers 1 and 3. Finally, the fifth set was neither coated nor textured for reference purposes. The sample’s specifications are reported in Table 2.

Table 2.

Sample’s specifications.

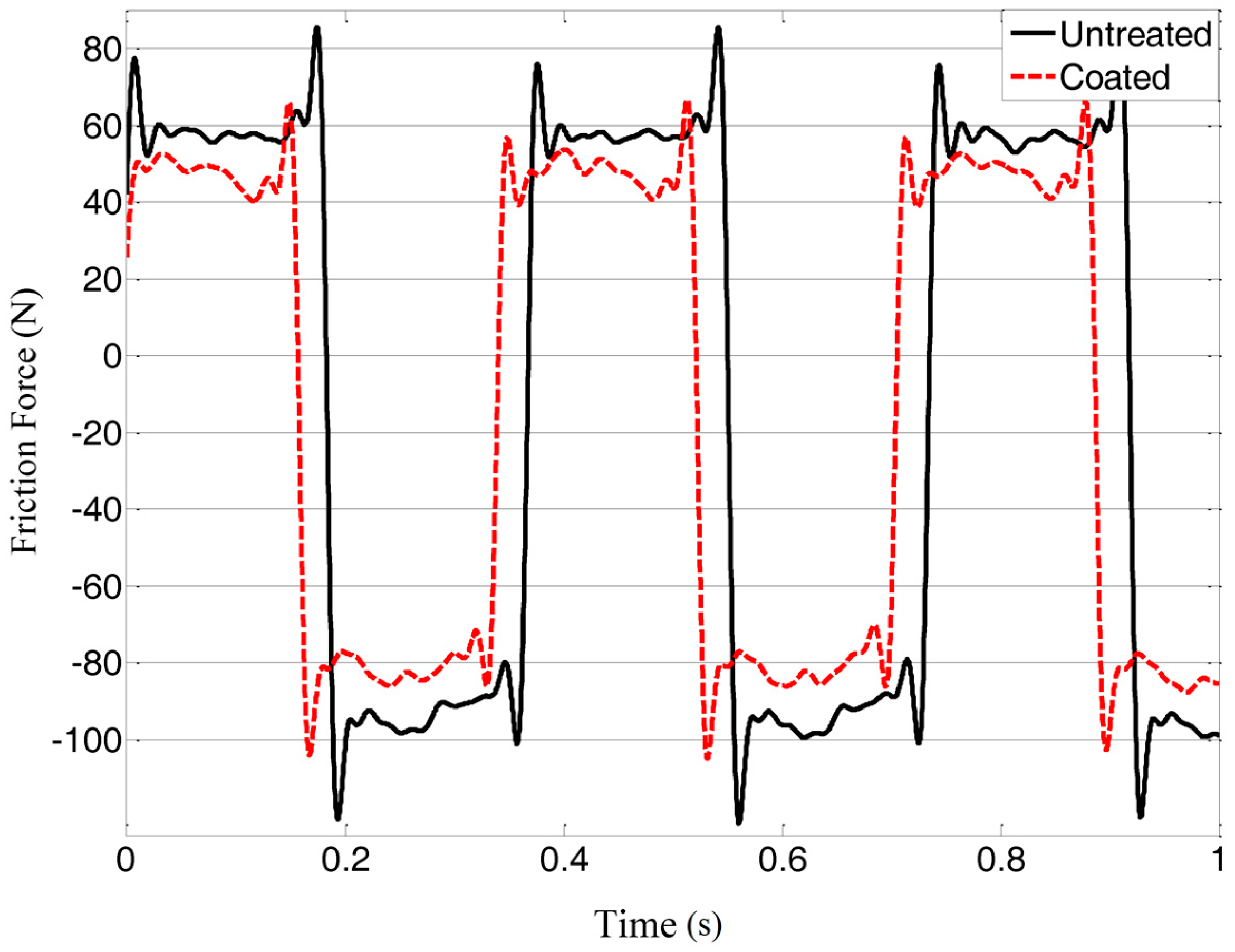

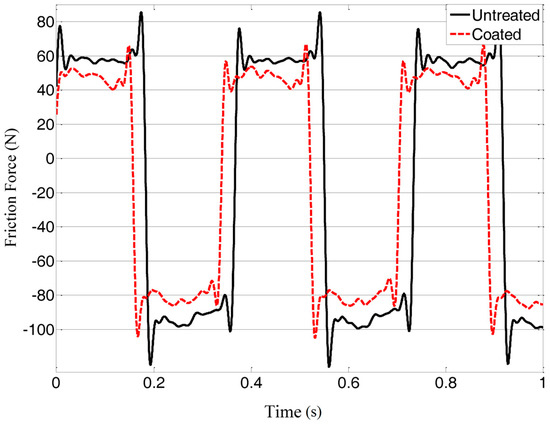

Prior to recoding data, the rings were run at a relatively low speed (100 rpm) for some time (between 1 and 2 h) or until the friction coefficient stabilized. The goal for such a procedure was to ensure that the friction between the piston rings and piston skirt had completed its running-in state, stabilized, and entered into the steady state. After the running-in process, the friction tests were performed under various crank speeds ranging from 100 to 900 rpm. As an example, a comparison between the friction force for coated rings and untreated rings at 360 rpm is presented in Figure 4.

Figure 4.

Comparison of observed friction force of coated and untreated piston rings.

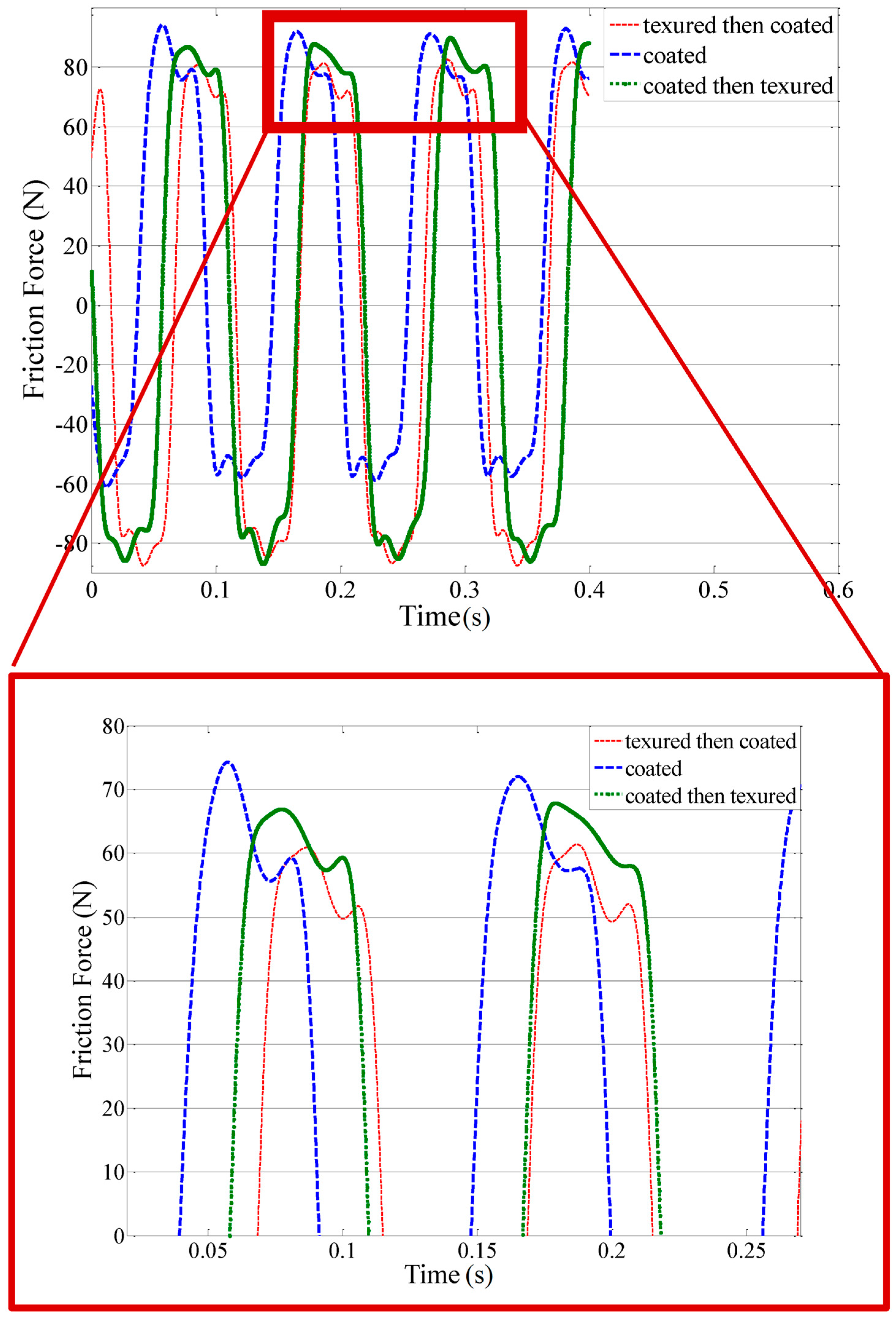

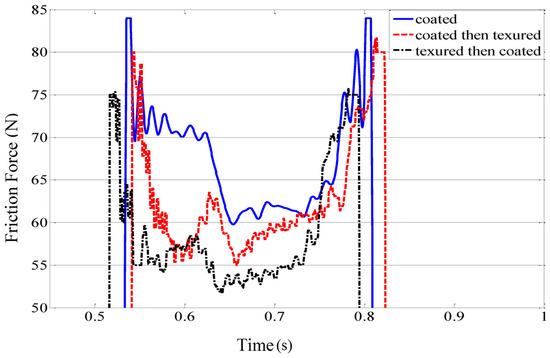

A magnified picture of a friction force graph versus time for coated, textured then coated, and coated then textured rings at 120 rpm is presented in Figure 5.

Figure 5.

Magnified picture of friction force versus time at 120 rpm for coated, coated and textured, and textured and coated rings.

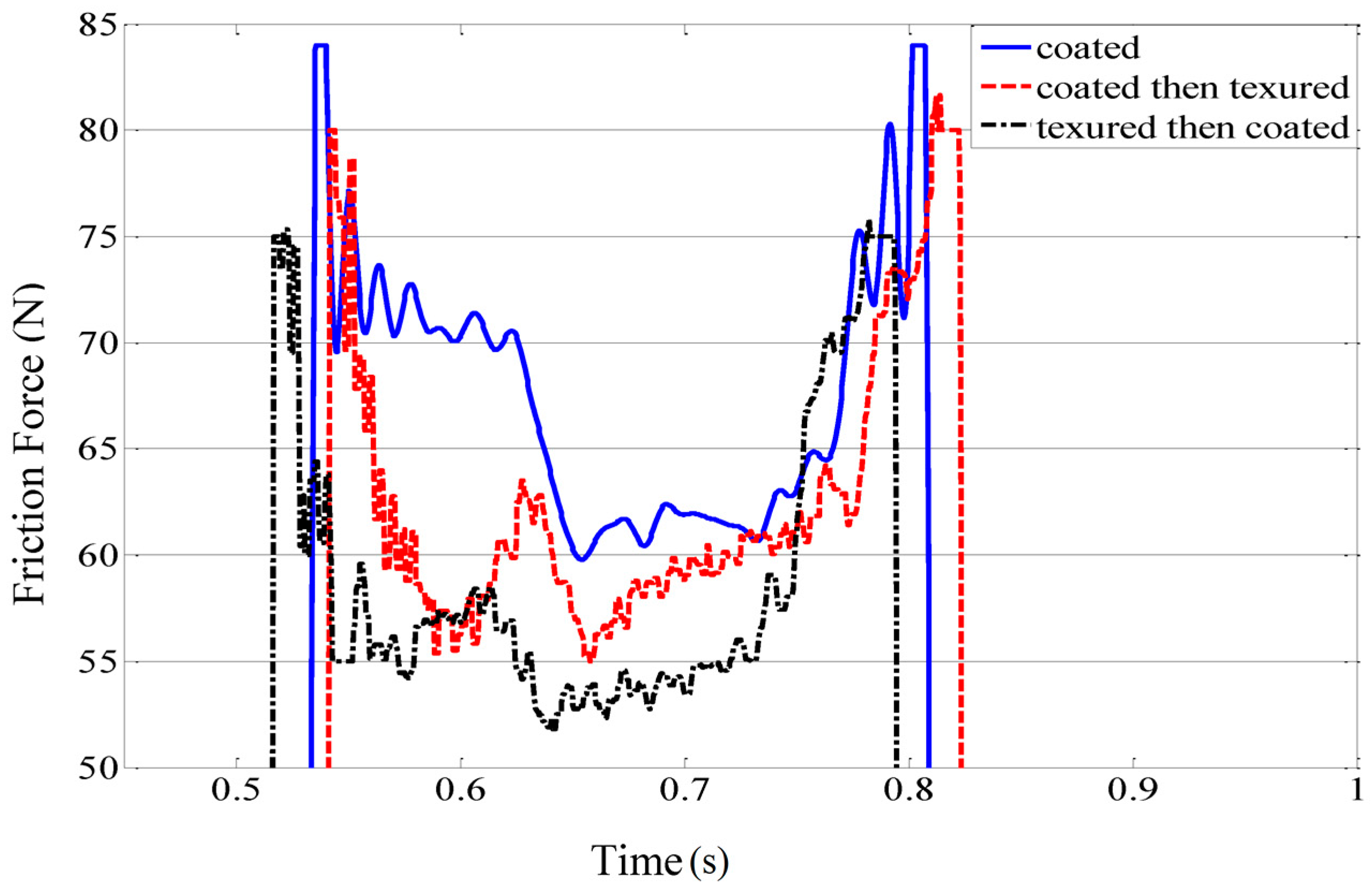

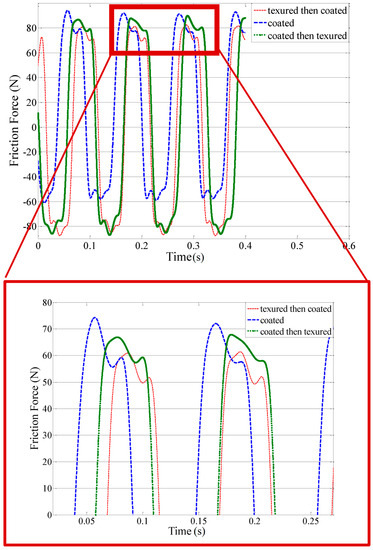

A comparison graph similar to Figure 5 but at higher speed (600 rpm) is presented in Figure 6 to ensure that the trends are repeatable.

Figure 6.

Magnified picture of friction force versus time at speed of 600 rpm for coated, coated and textured, and textured and coated rings.

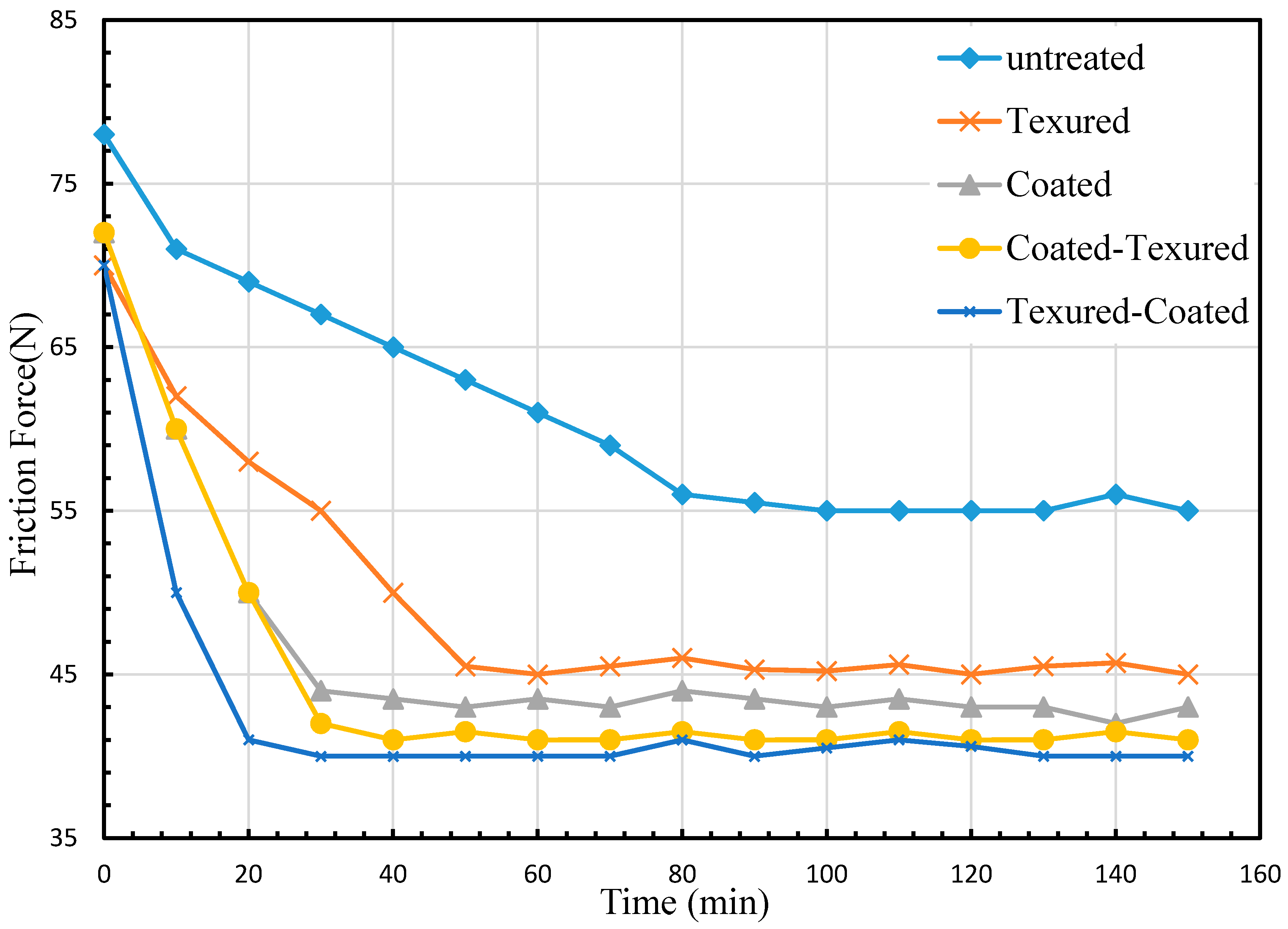

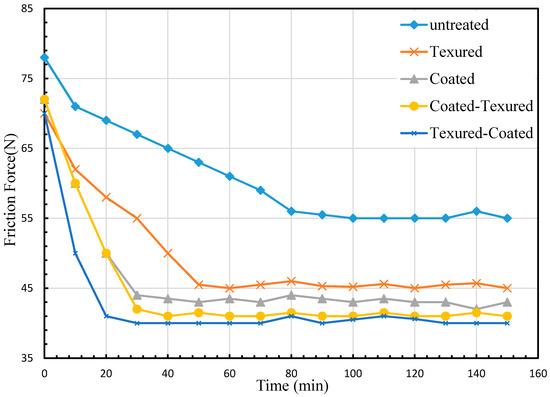

The data collection method is similar to that reported in [15]. For each test condition, the friction force data of 10 reciprocating cycles were collected with 100 data points per cycle. Results were filtered using a low pass filter in order to reduce high-frequency noise in the signal. Then, the averaged friction force was used to represent the result of each test, calculated by averaging the absolute values of the friction force over 10 reciprocating cycles [15]. Figure 7 presents the behavior of different sets during the running-in state.

Figure 7.

Running-in behavior of textured, coated, coated-textured, and textured-coated piston rings.

As can be seen in Figure 6, while the trend of the results for all five cases is similar, the running-in behavior, such as the running-in duration, and the steady-state friction for these piston rings are quite different. It took close to 50 min for an uncoated textured ring set to reach to the steady state, while for the coated sample this stage was completed in only 30 min. More importantly, the coated-textured piston rings (Sample 3) had the lowest friction force in both the running-in and steady-state stages. A lower friction force translates to less power loss, with the added advantage of reaching the steady-state stage significantly (60%) sooner than the uncoated sample. The piston ring whose surface was textured without coating (Sample 2) showed the highest friction force. Results of Figure 7 are presented in Table 3 in a comparable fashion.

Table 3.

A comparison between the running-in behaviors of different ring sets.

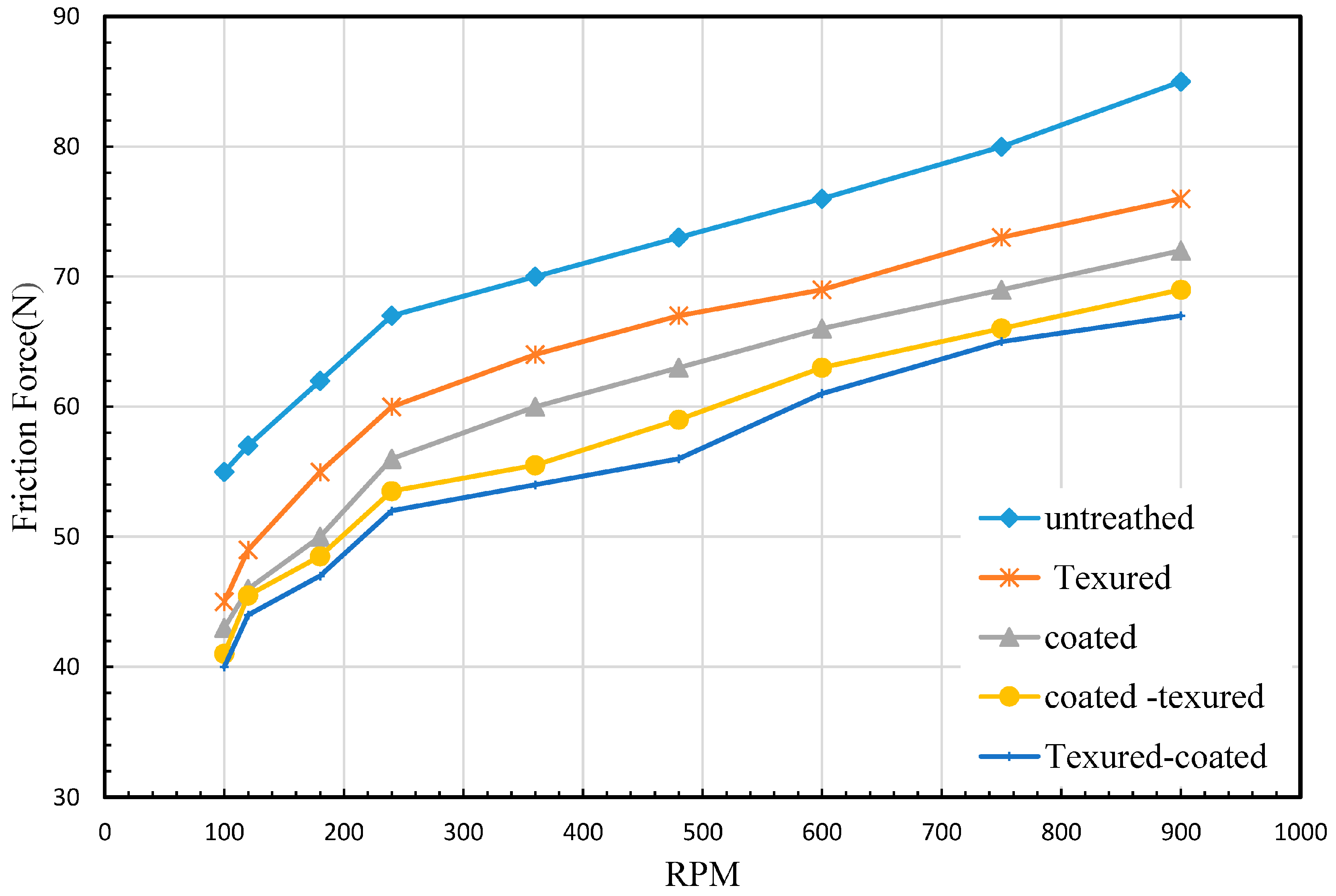

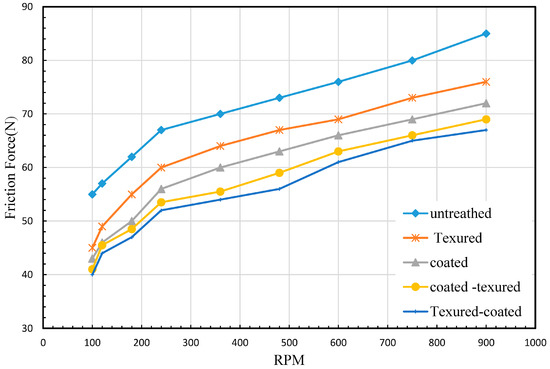

Figure 8 shows the friction force as a function of speed for different ring sets. Untreated piston rings experienced the highest friction force followed by those that were textured only. On the other hand, the combination of coating and texturing not only reduced the running-in time but also yielded the lowest frictional forces in an engine. A 15% reduction in the friction force was observed where traditional rings were replaced by rings that were textured and coated. The close second best behavior was observed when the rings were coated and then textured.

Figure 8.

Frictional behavior of piston ring sets under after various surface treatments.

Clearly, significant savings in power loss can be obtained by surface treatment via coating and texturing, both of which reduce the running-in time, the transient, as well as the steady-state friction. By texturing first and then coating the piston ring, the performance can be optimized. Future research should be directed to examine the coating lifetime during long-term tests.

4. Conclusions

Plasma coating and micro-pockets with optimal geometries were selected based on a previous study [15] and fabricated on the running surface of compression rings using a laser. The results show that the combination of coating and texturing not only reduced the running-in time but also yielded the lowest piston ring frictional force in an engine test. Specifically, a 15% reduction in friction force was observed where the piston rings were textured and then coated. The close second best behavior was observed when the rings were coated and then textured. At higher speeds, the difference between the rings sets with coating and texturing was reduced. Texturing and coating alone would also improve frictional behavior as well. The friction test results showed that the combination of coating and laser texturing yielded a reduction of 11%‒15% in the total friction between the cylinder liner and piston assembly over a wide range of speed. Also noteworthy is the favorable results of 40% reduction in the break-in duration when the combination of coating and texturing was applied.

Acknowledgments

This work was conducted at LSU Center for Rotating Machinery. The assistance of Cong Shen in the design of the original engine test rig and texture configuration is gratefully acknowledged.

Author Contributions

A. Akbarzadeh and M. M. Khonsari conceived the original idea and designed the experiment. A. Akbarzadeh carried out the experiments and analyzed the data. M. M. Khonsari supervise the project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Joshi, D.S.; Shah, A.V.; Gosai, D.C. Importance of Tribology in Internal Combustion Engine: A Review. Int. Res. J. Eng. Technol. 2015, 2, 803–809. [Google Scholar]

- Mo, F.; Shen, C.; Zhou, J.; Khonsari, M.M. Statistical Analysis of the Influence of Imperfect Texture Shape and Dimensional Uncertainty on Surface Texture Performance. IEEE Access 2017, 5, 27023–27035. [Google Scholar] [CrossRef]

- Mo, F.; Shen, C.; Zhou, J.; Khonsari, M.M. Statistical analysis of surface texture performance with provisions with uncertainty in texture dimensions. IEEE Access 2017, 5, 5388–5398. [Google Scholar] [CrossRef]

- Ryk, G.; Kligerman, Y.; Etsion, I.; Shinkarenko, A. Experimental investigation of partial laser surface texturing for piston-ring friction reduction. Tribol. Trans. 2005, 48, 583–588. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Bolander, N.W.; Sadeghi, F. Surface modification for piston ring and liner. In IUTAM Symposium on Elastohydrodynamics and Micro-Elastohydrodynamics, Proceedings of the IUTAM Symposium held in Cardiff, UK, 1–3 September 2004; Snidle, R.W., Evans, H.P., Eds.; Springer: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Shen, C.; Khonsari, M. Texture shape optimization for seal-like parallel surfaces: Theory and experiment. Tribol. Trans. 2016, 59, 698–706. [Google Scholar] [CrossRef]

- Barbezat, G. Advanced thermal spray technology and coating for lightweight engine blocks for the automotive industry. Surf. Coat. Technol. 2005, 200, 1990–1993. [Google Scholar] [CrossRef]

- Buyukkaya, E.; Cerit, M. Thermal analysis of a ceramic coating diesel engine piston using 3-D finite element method. Surf. Coat. Technol. 2007, 202, 398–402. [Google Scholar] [CrossRef]

- Kennedy, M.; Hoppe, S.; Esser, J. Piston ring coating reduces gasoline engine friction. MTZ Worldw. 2012, 73, 40–43. [Google Scholar] [CrossRef]

- Kennedy, M.; Hoppe, S.; Esser, J. Lower friction losses with new piston ring coating. MTZ Worldw. 2014, 75, 24–29. [Google Scholar] [CrossRef]

- Scheibe, H.J.; Leonhardt, M.; Leson, A.; Meyer, C.F.; Stucky, T.; Weihnacht, V. Abscheidung superharter Kohlenstoffschichten mittels Laser-Arco® auf dem Weg vom Labor in die industrielle Serienfertigung. Vak. Forsch. Prax. 2008, 20, 26–31. [Google Scholar] [CrossRef]

- Qiu, Y.; Khonsari, M. Experimental investigation of tribological performance of laser textured stainless steel rings. Tribol. Int. 2011, 44, 635–644. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M. Tribological and sealing performance of laser pocketed piston rings in a diesel engine. Tribol. Lett. 2016, 64, 26. [Google Scholar] [CrossRef]

- Nettesheim, S. Evaluating the Activation Capacity of Atmospheric Plasma Systems; Plasma Technical Note; Relyon Plasma GmbH: Regensburg, Germany, 2016. [Google Scholar]

- Sarikaya, O. Effect of some parameters on microstructure and hardness of alumina coatings prepared by the air plasma spraying process. Surf. Coat. Technol. 2005, 190, 388–393. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).