Effect of Particle In-Flight Behavior on the Microstructure and Fracture Toughness of YSZ TBCs Prepared by Plasma Spraying

Abstract

1. Introduction

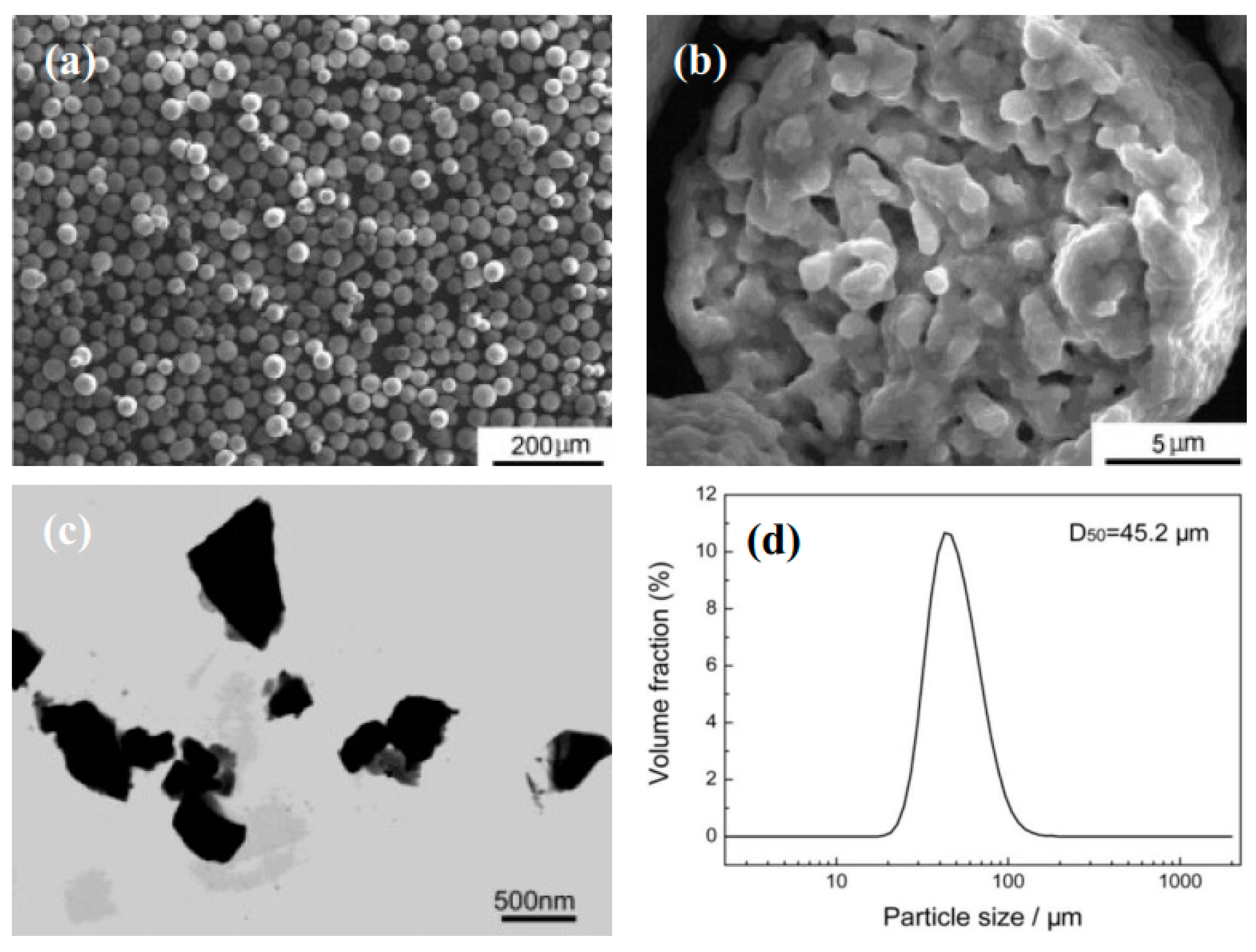

2. Experimental Materials and Methods

3. Result and Discussion

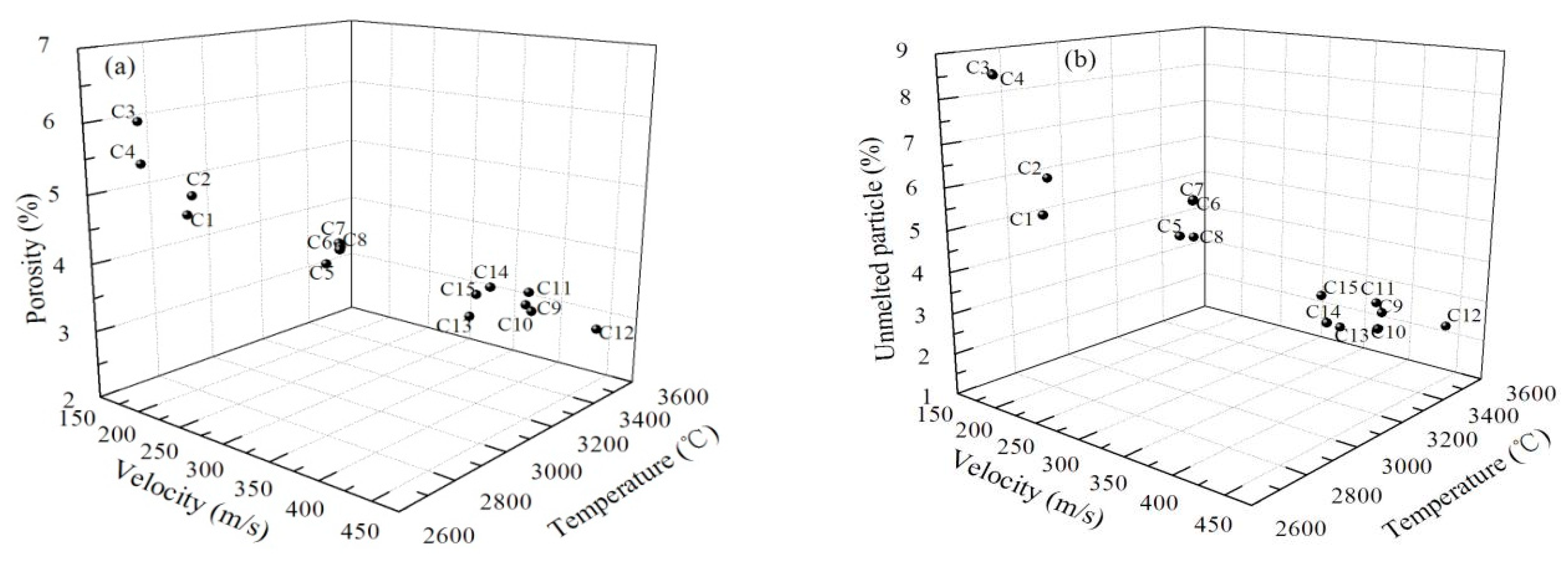

3.1. Influence of Flying Particle Characteristics on the Microstructure of Deposited Coatings

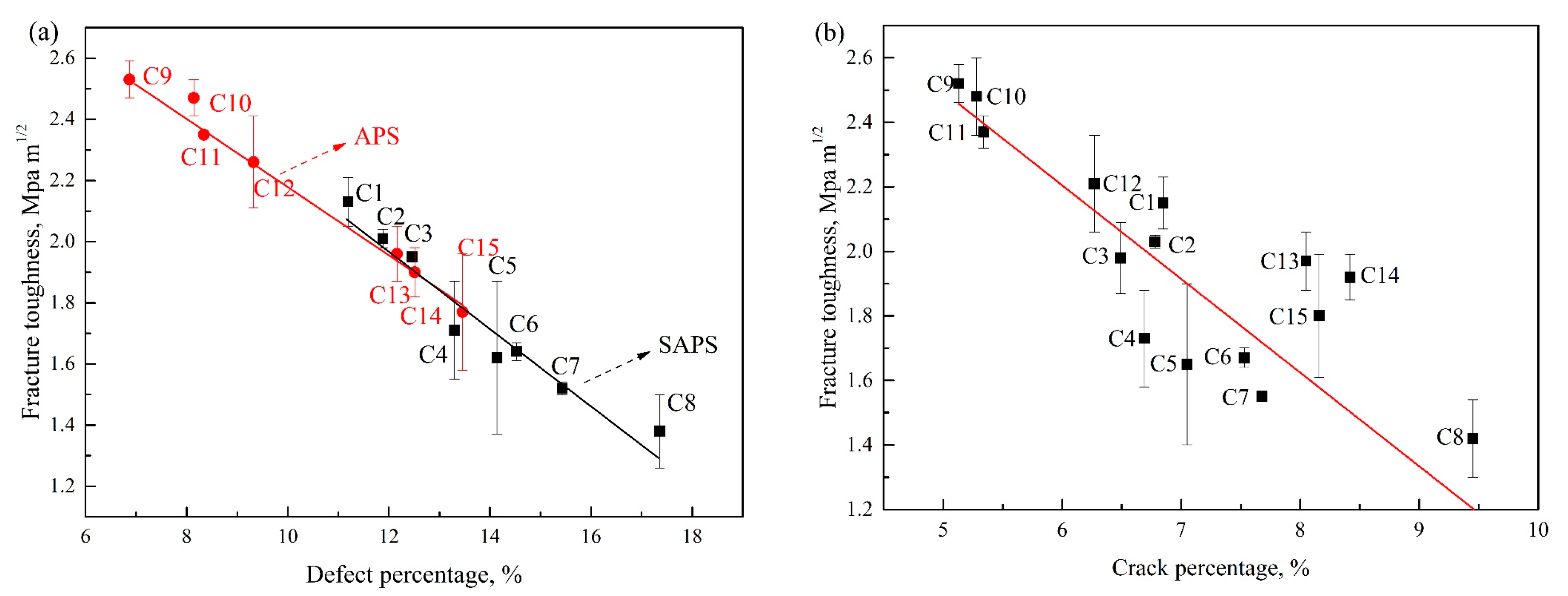

3.2. Influence of Microstructure on the Fracture Toughness of Deposited Coatings

4. Conclusions

- The temperature and velocity of in-flight particles of the SAPS-TBCs were higher than that of the APS-TBCs, resulting in the SAPS-TBCs having a denser microstructure with less structural defects and superior fracture toughness.

- The correlation among the in-flight particle behavior, microstructure, and mechanical properties were established in SAPS-TBCs and APS-TBCs. It was found that with a higher temperature and velocity of particles in-flight, the structural defects decreased and furthermore the mechanical properties were enhanced (and vice versa).

- The experimental results indicated that a relative high crack percentage, in a reasonable and proper content, may lower improved fracture toughness.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bobzin, K.; Öte, M.; Linke, T.F.; Sommer, J.; Liao, X. Influence of process parameter on grit blasting as a pretreatment process for thermal spraying. J. Therm. Spray Technol. 2015, 25, 3–11. [Google Scholar] [CrossRef]

- Berger, L.M. Hardmetals as thermal spray coatings. Powder Metall. 2013, 50, 205–214. [Google Scholar] [CrossRef]

- Hardwicke, C.U.; Lau, Y.-C. Advances in thermal spray coatings for gas turbines and energy generation: A review. J. Therm. Spray Technol. 2013, 22, 564–576. [Google Scholar] [CrossRef]

- Zhu, L.; Huang, W.; Cheng, H.; Cao, X. Thermal shock resistance of stabilized zirconia/metal coat on polymer matrix composites by thermal spraying process. J. Therm. Spray Technol. 2014, 23, 1312–1322. [Google Scholar] [CrossRef]

- Chen, Y.; Tessarini, S.; Sampath, S. Integrated study of APS YSZ coatings with different spray angle. J. Therm. Spray Technol. 2013, 22, 110–115. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Sun, X.G.; He, J.Q.; Pan, Z.Y.; Wang, C.H. Thermal shock behavior of 8YSZ and double-ceramic-layer La2Zr2O7/8YSZ thermal barrier coatings fabricated by atmospheric plasma spraying. Ceram. Int. 2012, 38, 3595–3606. [Google Scholar] [CrossRef]

- Lamuta, C.; Girolamo, G.D.; Pagnotta, L. Microstructural, mechanical and tribological properties of nanostructured YSZ coatings produced with different APS process parameters. Ceram. Int. 2015, 41, 8904–8914. [Google Scholar] [CrossRef]

- Kromer, R.; Costil, S.; Cormier, J.; Berthe, L.; Peyre, P.; Courapied, D. Laser patterning pretreatment before thermal spraying: A technique to adapt and control the surface topography to thermomechanical loading and materials. J. Therm. Spray Technol. 2016, 25, 401–410. [Google Scholar] [CrossRef]

- Chandra, S.; Fauchais, P. Formation of solid splats during thermal spray deposition. J. Therm. Spray Technol. 2009, 18, 148–180. [Google Scholar] [CrossRef]

- Sobhanverdi, R.; Akbari, A. Porosity and microstructural features of plasma sprayed yttria stabilized zirconia thermal barrier coatings. Ceram. Int. 2015, 41, 14517–14528. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Balasubramanian, V.; Rajendran, R. Developing empirical relationships to estimate porosity and Young’s modulus of plasma sprayed YSZ coatings. Appl. Surf. Sci. 2014, 296, 31–46. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.B. Yttria-stabilized zirconia thermal barrier coatings: A review. Surf. Rev. Lett. 2006, 13, 535–544. [Google Scholar] [CrossRef]

- Carpio, P.; Rayón, E.; Salvador, M.D.; Lusvarghi, L.; Sánchez, E. Mechanical properties of double-layer and graded composite coatings of YSZ obtained by atmospheric plasma spraying. J. Therm. Spray Technol. 2016, 25, 778–787. [Google Scholar] [CrossRef]

- Manero, A.; Sofronsky, S.; Knipe, K.; Meid, C.; Wischek, J.; Okasinski, J.; Almer, J.; Karlsson, A.M.; Raghavan, S.; Bartsch, M. Monitoring local strain in a thermal barrier coating system under thermal mechanical gas turbine operating conditions. JOM 2015, 67, 1528–1539. [Google Scholar] [CrossRef]

- Ramachandran, C.S.; Balasubramanian, V.; Ananthapadmanabhan, P.V. Multiobjective optimization of atmospheric plasma spray process parameters to deposit yttria-stabilized zirconia coatings using response surface methodology. J. Therm. Spray Technol. 2011, 20, 590–607. [Google Scholar] [CrossRef]

- Bakan, E.; Mack, D.E.; Mauer, G.; Vaßen, R. Gadolinium zirconate/YSZ thermal barrier coatings: Plasma spraying, microstructure, and thermal cycling behavior. J. Am. Ceram. Soc. 2015, 97, 4045–4051. [Google Scholar] [CrossRef]

- Frommherz, M.; Scholz, A.; Oechsner, M.; Bakan, E.; Vaßen, R. Gadolinium zirconate/YSZ thermal barrier coatings: Mixed-mode interfacial fracture toughness and sintering behavior. Surf. Coat. Technol. 2016, 286, 119–128. [Google Scholar] [CrossRef]

- Dwivedi, G.; Wentz, T.; Sampath, S.; Nakamura, T. Assessing process and coating reliability through monitoring of process and design relevant coating properties. J. Therm. Spray Technol. 2010, 19, 695–712. [Google Scholar] [CrossRef]

- Oksa, M.; Metsäjoki, J. Optimizing NiCr and FeCr HVOF coating structures for high temperature corrosion protection applications. J. Therm. Spray Technol. 2015, 24, 436–453. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, M. Sensors in spray processes. J. Therm. Spar Technol. 2010, 19, 668–694. [Google Scholar] [CrossRef]

- Breede, A.; Kahali Moghaddam, M.; Brauner, C.; Lang, W.; Herrmann, A.S. Online process monitoring and control by dielectric sensors for a composite main spar. Mater. Sci. Forum 2015, 825–826, 936–943. [Google Scholar] [CrossRef]

- Cho, J.Y.; Zhang, S.H.; Cho, T.Y.; Yoon, J.H.; Joo, Y.K.; Hur, S.K. The processing optimization and property evaluations of HVOF Co-base alloy T800 coating. J. Mater. Sci. 2009, 44, 6348–6355. [Google Scholar] [CrossRef]

- Bakan, E.; Mack, D.E.; Mauer, G.; Mücke, R.; Vaßen, R. Porosity-property relationships of plasma-sprayed Gd2Zr2O7/YSZ thermal barrier coatings. J. Am. Ceram. Soc. 2015, 98, 2647–2654. [Google Scholar] [CrossRef]

- Oksa, M.; Turunen, E.; Suhonen, T.; Varis, T.; Hannula, S.P. Optimization and characterization of high velocity oxy-fuel sprayed coatings: Techniques, materials, and applications. Coatings 2011, 1, 17–52. [Google Scholar] [CrossRef]

- Liu, K.; Ma, J.; Bai, Y. Particle in-flight behavior and its determining the microstructure and mechanical properties of zirconia based thermal barrier coatings. In Proceedings of the 4th Annual International Conference on Material Engineering and Application (ICMEA 2017), Wuhan, China, 15–17 December 2017. [Google Scholar]

- Vardelle, M.; Vardelle, A.; Leger, A.C.; Fauchais, P.; Gobin, D. Influence of particle parameters at impact on splat formation and solidification in plasma spraying process. J. Therm. Spray Technol. 1994, 4, 50–58. [Google Scholar] [CrossRef]

| Coating Type | Process Type | Current (A) | Primary Gas Ar (slpm) | Secondary Gas H2 (slpm) | Voltage (V) | Spray Distance D (mm) | Powder Feeding Rate (g·min−1) |

|---|---|---|---|---|---|---|---|

| C1 | APS | 454 | 42.3 | 27.0 | 74.5 | 70 | 40 |

| C2 | APS | 605 | 44.7 | 25.0 | 75.6 | 70 | 40 |

| C3 | APS | 651 | 47.0 | 12.5 | 72.6 | 70 | 40 |

| C4 | APS | 648 | 51.7 | 15.0 | 73.8 | 70 | 40 |

| C5 | APS | 660 | 37.6 | 11.8 | 73.0 | 100 | 40 |

| C6 | APS | 753 | 40.0 | 12.9 | 74.6 | 100 | 40 |

| C7 | APS | 814 | 35.3 | 12.9 | 74.0 | 100 | 40 |

| C8 | APS | 808 | 35.3 | 13.2 | 73.9 | 100 | 40 |

| C9 | SAPS | 504 | 65.0 | 19.5 | 118 | 90 | 35 |

| C10 | SAPS | 472 | 75.0 | 21.0 | 124 | 90 | 35 |

| C11 | SAPS | 487 | 70.0 | 21.0 | 123 | 90 | 35 |

| C12 | SAPS | 546 | 65.5 | 22.5 | 131 | 110 | 35 |

| C13 | SAPS | 356 | 60.3 | 15.0 | 125 | 90 | 35 |

| C14 | SAPS | 366 | 65.0 | 15.4 | 131 | 90 | 35 |

| C15 | SAPS | 312 | 65.2 | 16.7 | 133 | 90 | 35 |

| Coating Type | Temperature (°C) | Velocity (m/s) |

|---|---|---|

| C1 | 2843 ± 4 | 180 ± 2 |

| C2 | 2854 ± 4 | 183 ± 1 |

| C3 | 2689 ± 3 | 182 ± 2 |

| C4 | 2692 ± 1 | 183 ± 1 |

| C5 | 3213 ± 2 | 229 ± 1 |

| C6 | 3280 ± 4 | 226 ± 4 |

| C7 | 3264 ± 5 | 230 ± 1 |

| C8 | 3264 ± 2 | 231 ± 3 |

| C9 | 3414 ± 1 | 401 ± 2 |

| C10 | 3419 ± 2 | 406 ± 1 |

| C11 | 3420 ± 3 | 402 ± 4 |

| C12 | 3524 ± 5 | 451 ± 2 |

| C13 | 3245 ± 4 | 381 ± 1 |

| C14 | 3242 ± 2 | 388 ± 2 |

| C15 | 3251 ± 2 | 400 ± 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Ren, E.; Hu, M.; Liu, K. Effect of Particle In-Flight Behavior on the Microstructure and Fracture Toughness of YSZ TBCs Prepared by Plasma Spraying. Coatings 2018, 8, 309. https://doi.org/10.3390/coatings8090309

Xiao Y, Ren E, Hu M, Liu K. Effect of Particle In-Flight Behavior on the Microstructure and Fracture Toughness of YSZ TBCs Prepared by Plasma Spraying. Coatings. 2018; 8(9):309. https://doi.org/10.3390/coatings8090309

Chicago/Turabian StyleXiao, Yanqiu, Erzhou Ren, Mingyang Hu, and Kun Liu. 2018. "Effect of Particle In-Flight Behavior on the Microstructure and Fracture Toughness of YSZ TBCs Prepared by Plasma Spraying" Coatings 8, no. 9: 309. https://doi.org/10.3390/coatings8090309

APA StyleXiao, Y., Ren, E., Hu, M., & Liu, K. (2018). Effect of Particle In-Flight Behavior on the Microstructure and Fracture Toughness of YSZ TBCs Prepared by Plasma Spraying. Coatings, 8(9), 309. https://doi.org/10.3390/coatings8090309