Influence of Particle Velocity When Propelled Using N2 or N2-He Mixed Gas on the Properties of Cold-Sprayed Ti6Al4V Coatings

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials

2.2. Cold-Spray Process

2.3. Microstructural and Mechanical Characterisation

2.4. Finite Element Modelling

3. Results and Discussion

3.1. Particle Velocity Analysis

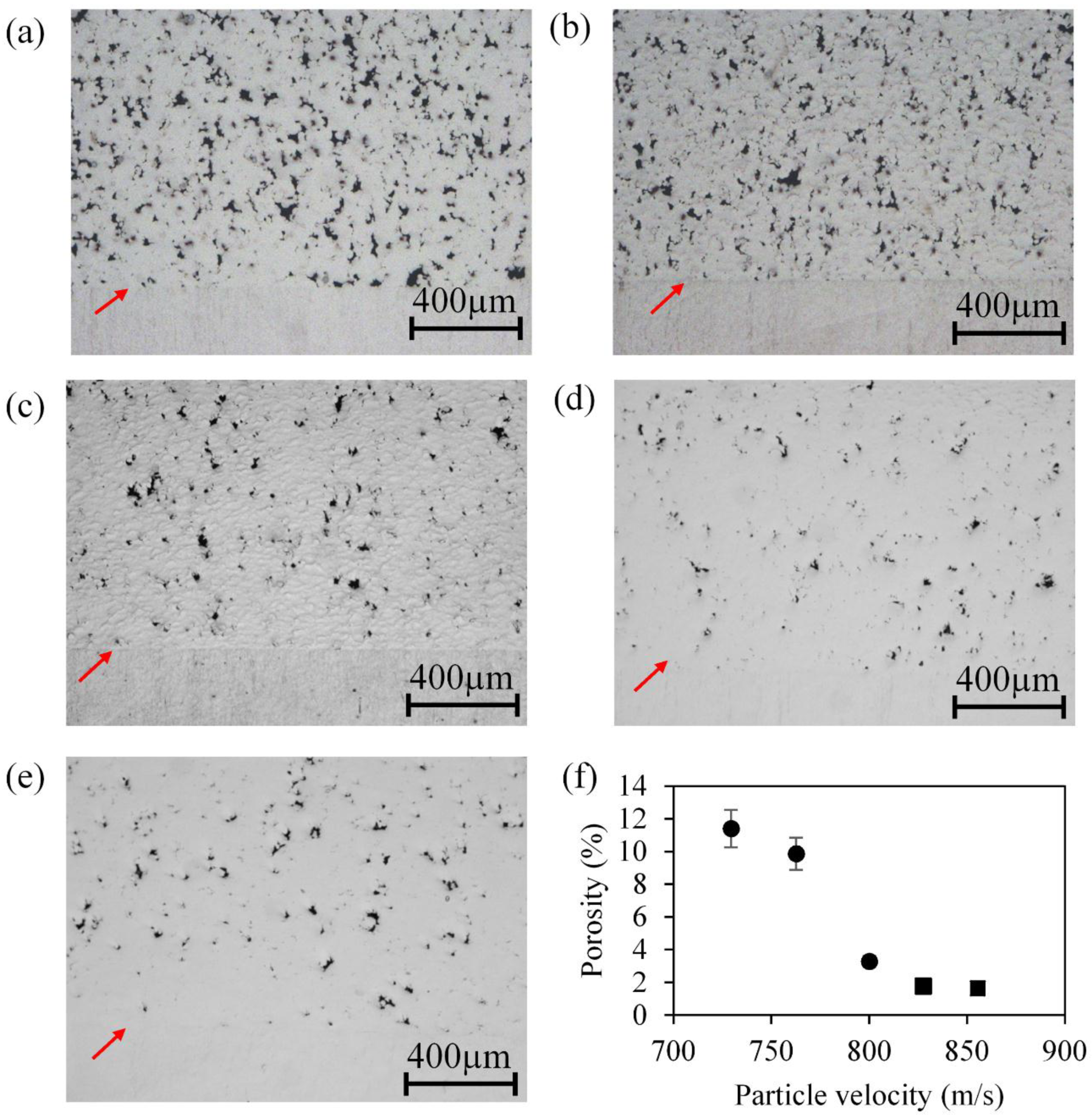

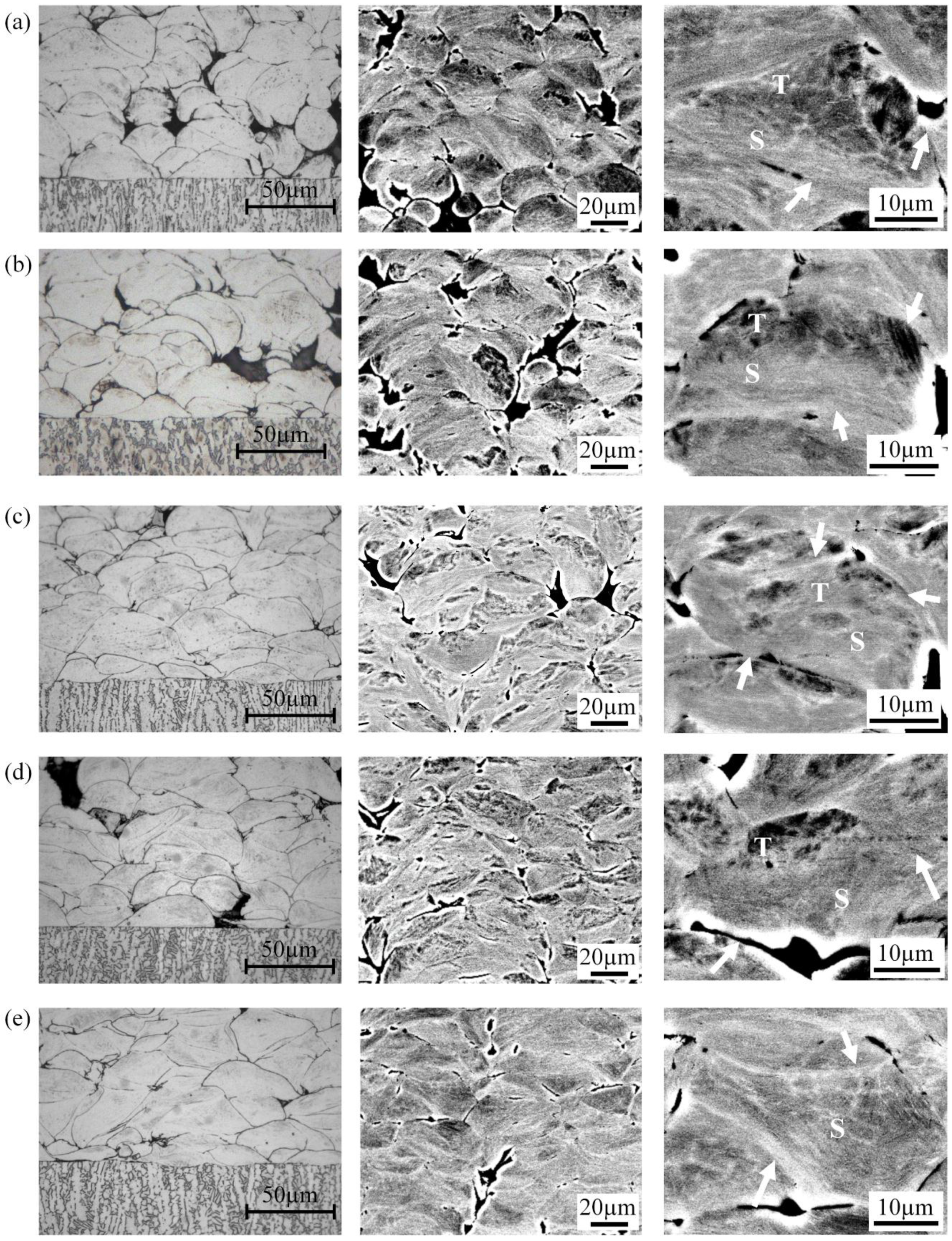

3.2. Cross-Section Analysis

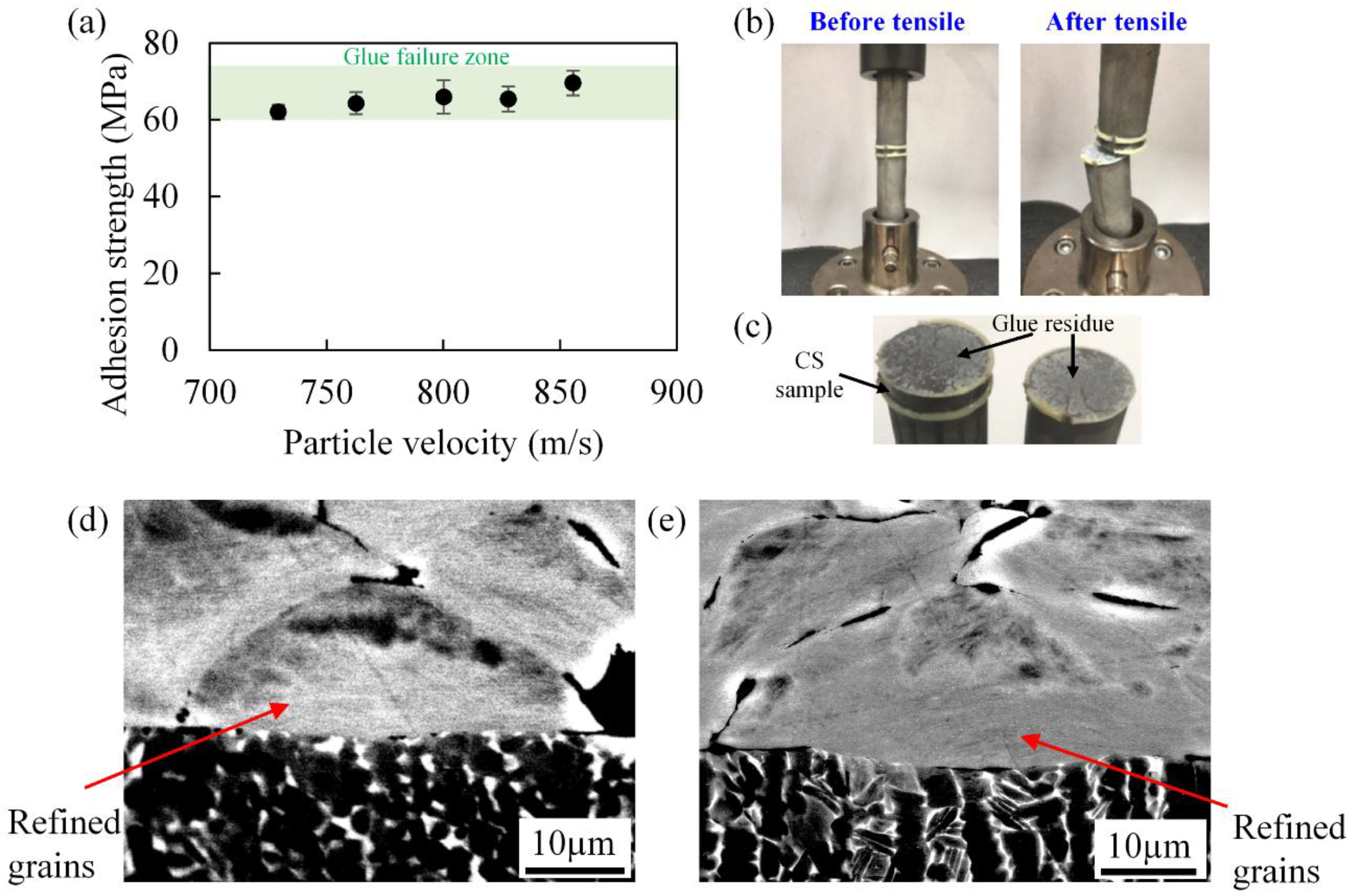

3.3. Adhesion Strength

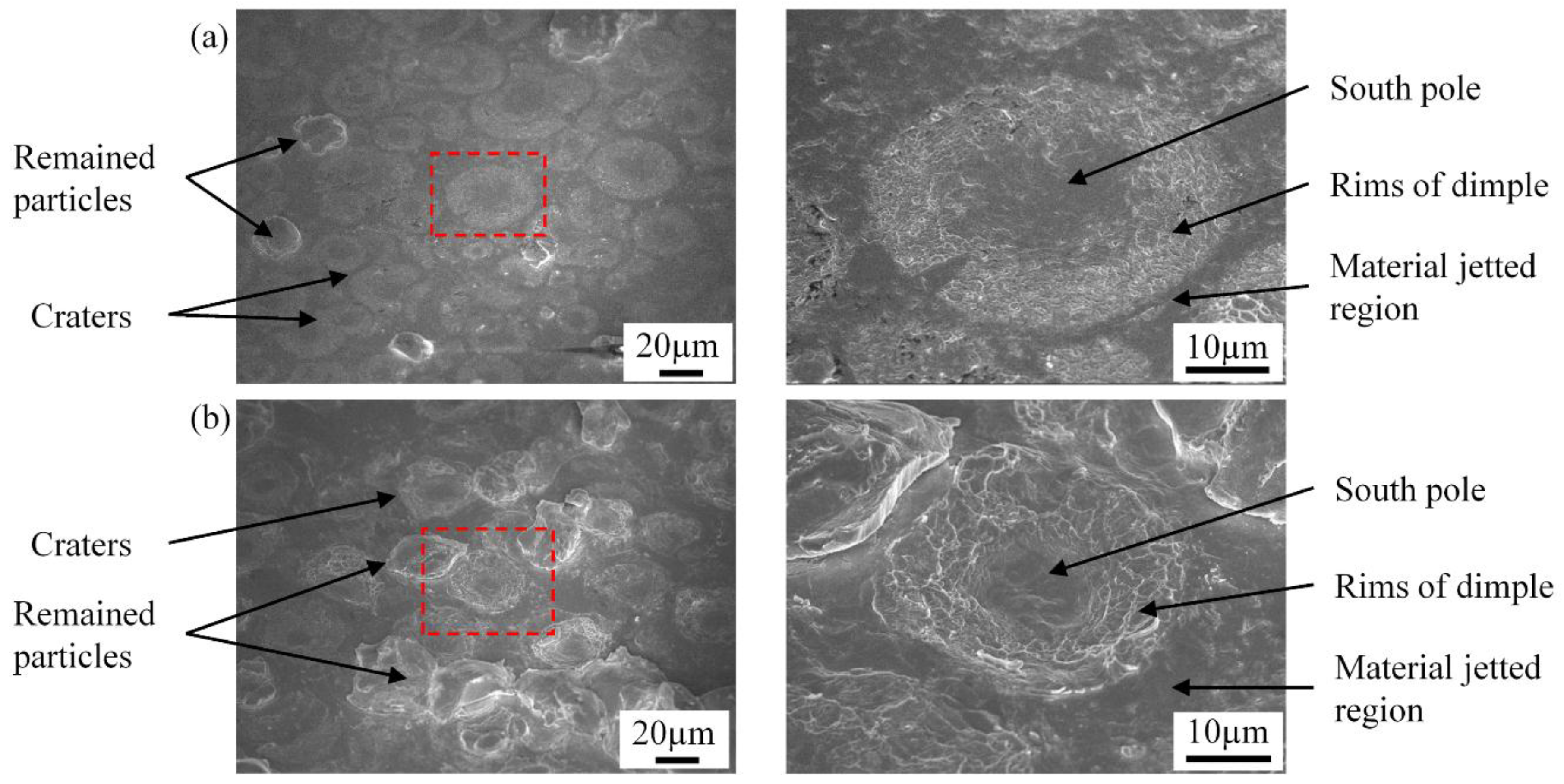

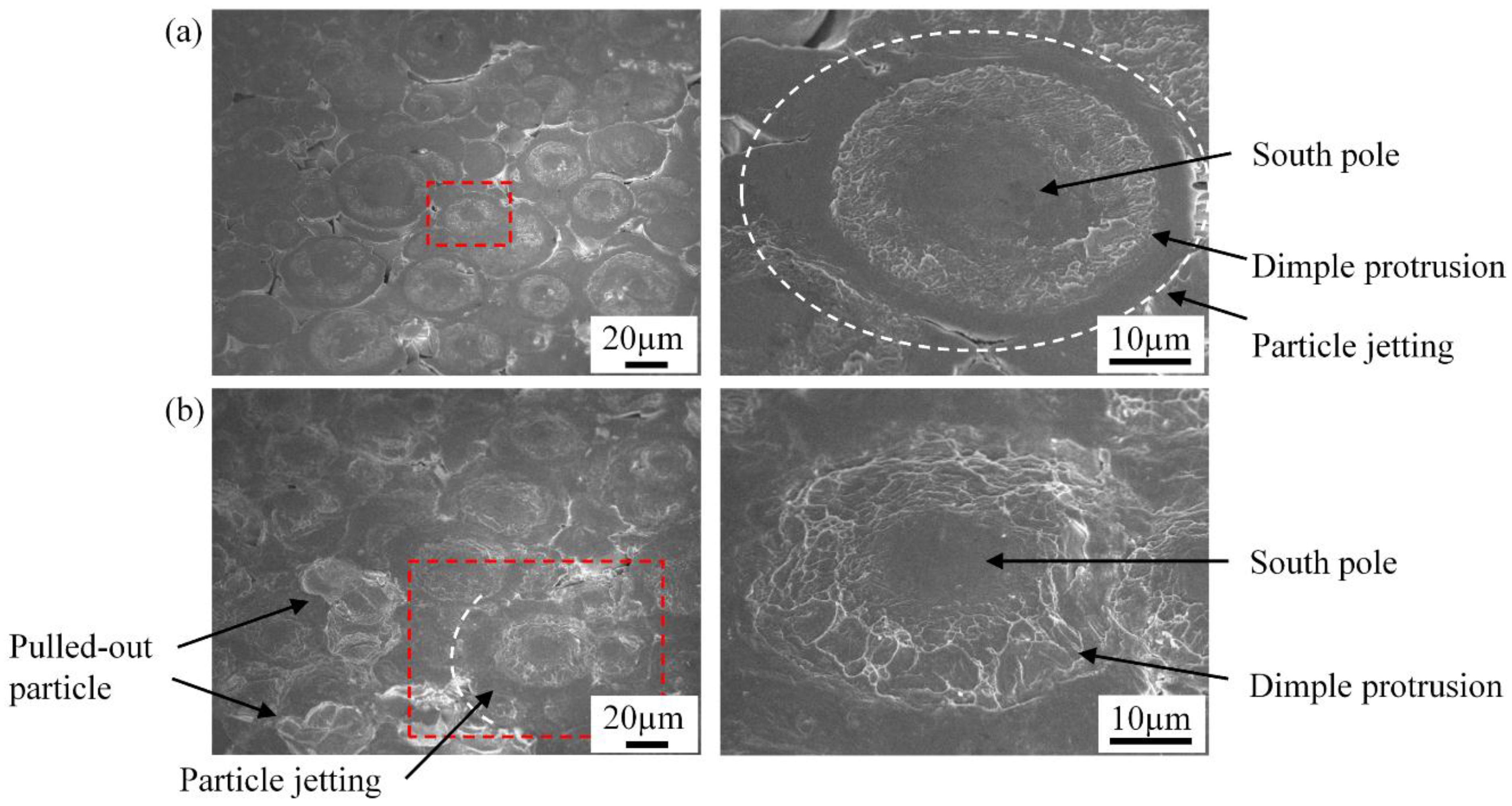

3.4. Fractography

3.5. Finite Element Model

4. Conclusions

- The addition of He gas into N2 gas efficiently increased the particle velocities without a significant reduction in particle temperature, which contributed to the thermal softening and plastic deformation of the sprayed particles;

- The porosity content in the Ti64 coatings dropped from about 11 to 1.6% with increasing particle velocity from 730 to 855 m/s;

- The coating/substrate interfaces of all the coatings were intimate without macroscopic cracks. The percentage of smooth regions (consisted of refined nanograins) of the coatings increased with higher particle velocity as compared to the textured regions (consisted of martensite laths) due to the severe particle deformation that helped with particle refinement;

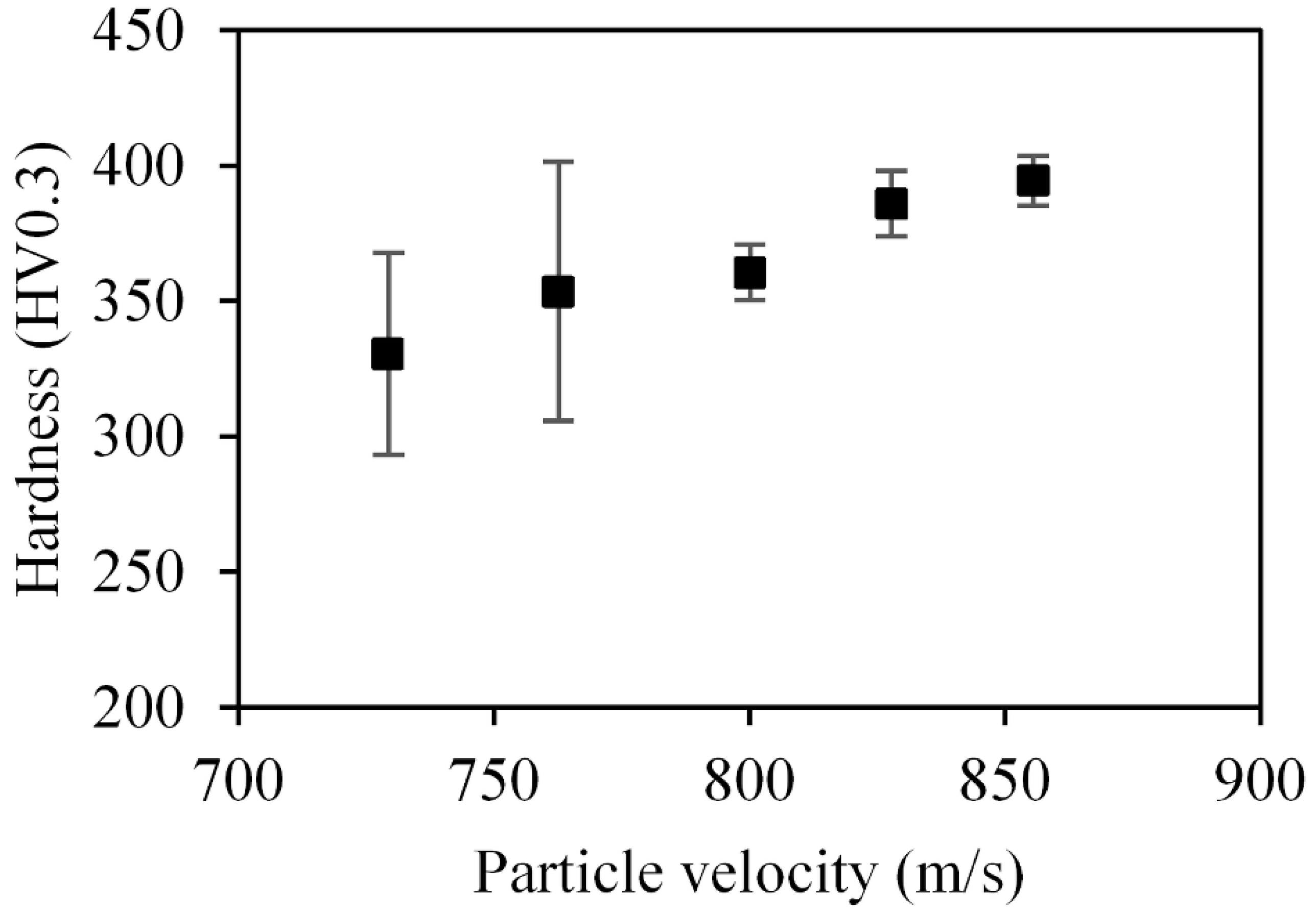

- The microhardness of the coatings increased with higher particle velocity due to a higher fraction of refined grains (grain boundary strengthening) within the splats;

- The adhesion strengths of all the coatings deposited across the velocity range exceeded 60 MPa, as the tests failed at the glue regions, which showed that an effective coating with an appreciable adhesion strength, albeit with a higher porosity level, could be formed even with a particle velocity lower than the calculated critical velocity. This could be attributed to the velocity distribution of particles where a fraction of particles could have velocities higher than the respective critical velocities to form a strong bonding with the substrate, coupled with the optimum deposition parameters;

- Fractographic analyses revealed that the dimple fractures were more prominent in the coatings deposited at higher particle impact velocities due to the more severe cohesive failure within particles;

- The FEM indicated more plastic deformation and higher temperatures at the peripheries of the particle with a higher impact velocity (e.g., 855 m/s), which correlated well with the experimental observation of the mechanical response of the coatings;

- The use of an N2-He gas mixture as the propellant gas was more cost effective for producing high quality coatings.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Kalla, G. CO2-laser beam welding of structural steel with a thickness up to 20 mm. Rev. Métall. 1996, 93, 1303–1310. [Google Scholar] [CrossRef]

- Wang, X.B. Temperature distribution in adiabatic shear band for ductile metal based on Johnson-Cook and gradient plasticity models. Trans. Nonferrous Met. Soc. Chin. 2006, 16, 333–338. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Sami, M.; Nickel, J.; Coban, A.; Said, S.A.M. Introduction into the electron beam welding of austenitic 321-type stainless steel. J. Mater. Process. Technol. 1998, 82, 13–20. [Google Scholar] [CrossRef]

- Champagne, V.K. The Cold Spray Materials Deposition Process: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Papyrin, A.; Kosarev, V.; Klinkov, S.; Alkhimov, A.; Fomin, V.M. Cold Spray Technology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Dykhuizen, R.C.; Smith, M.F.; Gilmore, D.L.; Neiser, R.A.; Jiang, X.; Sampath, S. Impact of high velocity cold spray particles. J. Therm. Spray Technol. 1999, 8, 559–564. [Google Scholar] [CrossRef]

- Vlcek, J.; Gimeno, L.; Huber, H.; Lugscheider, E. A systematic approach to material eligibility for the cold-spray process. J. Therm. Spray Technol. 2005, 14, 125–133. [Google Scholar] [CrossRef]

- McCune, R.C.; Papyrin, A.N.; Hall, J.N.; Riggs, W.L.I.; Zajchowski, P.H. An exploration of the cold gas-dynamic spray method for several materials systems. In Proceedings of the 8th National Thermal Spray Conference, Houston, TX, USA, 11–15 September 1995; p. 795. [Google Scholar]

- Kosarev, V.F.; Klinkov, S.V.; Alkhimov, A.P.; Papyrin, A.N. On some aspects of gas dynamics of the cold spray process. J. Therm. Spray Technol. 2003, 12, 265–281. [Google Scholar] [CrossRef]

- Schmidt, T.; Gaertner, F.; Kreye, H. New developments in cold spray based on higher gas and particle temperatures. J. Therm. Spray Technol. 2006, 15, 488–494. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; DeRosset, W.S.; Helfritch, D. Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process. Mater. Des. 2004, 25, 681–688. [Google Scholar] [CrossRef]

- Bae, G.; Kumar, S.; Yoon, S.; Kang, K.; Na, H.; Kim, H.J.; Lee, C. Bonding features and associated mechanisms in kinetic sprayed titanium coatings. Acta Mater. 2009, 57, 5654–5666. [Google Scholar] [CrossRef]

- Bae, G.; Xiong, Y.; Kumar, S.; Kang, K.; Lee, C. General aspects of interface bonding in kinetic sprayed coatings. Acta Mater. 2008, 56, 4858–4868. [Google Scholar] [CrossRef]

- Alkhimov, A.P.; Klinkov, S.V.; Kosarev, V.F.; Papyrin, A.N. Gas-dynamic spraying study of a plane supersonic two-phase jet. J. Appl. Mech. Tech. Phys. 1997, 38, 324–330. [Google Scholar] [CrossRef]

- Dykhuizen, R.C.; Smith, M.F. Gas dynamic principles of cold spray. J. Therm. Spray Technol. 1998, 7, 205–212. [Google Scholar] [CrossRef]

- Gilmore, D.L.; Dykhuizen, R.C.; Neiser, R.A.; Smith, M.F.; Roemer, T.J. Particle velocity and deposition efficiency in the cold spray process. J. Therm. Spray Technol. 1999, 8, 576–582. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Kim, K.; Watanabe, M.; Kawakita, J.; Kuroda, S. Grain refinement in a single titanium powder particle impacted at high velocity. Scr. Mater. 2008, 59, 768–771. [Google Scholar] [CrossRef]

- Luo, X.T.; Li, C.X.; Shang, F.L.; Yang, G.J.; Wang, Y.Y.; Li, C.J. High velocity impact induced microstructure evolution during deposition of cold spray coatings: A review. Surf. Coat. Technol. 2014, 254, 11–20. [Google Scholar] [CrossRef]

- Cavaliere, P.; Silvello, A. Processing parameters affecting cold spay coatings performances. Int. J. Adv. Manuf. Technol. 2014, 71, 263–277. [Google Scholar] [CrossRef]

- Perton, M.; Costil, S.; Wong, W.; Poirier, D.; Irissou, E.; Legoux, J.G.; Blouin, A.; Yue, S. Effect of pulsed laser ablation and continuous laser heating on the adhesion and cohesion of cold sprayed Ti-6Al-4V coatings. J. Therm. Spray Technol. 2012, 21, 1322–1333. [Google Scholar] [CrossRef]

- Sun, W.; Tan, A.W.Y.; Bhowmik, A.; Marinescu, I.; Song, X.; Zhai, W.; Li, F.; Liu, E. Deposition characteristics of cold sprayed Inconel 718 particles on Inconel 718 substrates with different surface conditions. Mater. Sci. Eng. A 2018, 720, 75–84. [Google Scholar] [CrossRef]

- Sun, W.; Tan, A.W.Y.; Khun, N.W.; Marinescu, I.; Liu, E. Effect of substrate surface condition on fatigue behavior of cold sprayed Ti6Al4V coatings. Surf. Coat. Technol. 2017, 320, 452–457. [Google Scholar] [CrossRef]

- Bhattiprolu, V.S.; Johnson, K.W.; Ozdemir, O.C.; Crawford, G.A. Influence of feedstock powder and cold spray processing parameters on microstructure and mechanical properties of Ti-6Al-4V cold spray depositions. Surf. Coat. Technol. 2018, 335, 1–12. [Google Scholar] [CrossRef]

- Binder, K.; Gottschalk, J.; Kollenda, M.; Gärtner, F.; Klassen, T. Influence of impact angle and gas temperature on mechanical properties of titanium cold spray deposits. J. Therm. Spray Technol. 2011, 20, 234–242. [Google Scholar] [CrossRef]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a generalized parameter window for cold spray deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gärtner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From particle acceleration to impact and bonding in cold spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef]

- Huang, R.; Fukanuma, H. Study of the influence of particle velocity on adhesive strength of cold spray deposits. J. Therm. Spray Technol. 2012, 21, 541–549. [Google Scholar] [CrossRef]

- List, A.; Gärtner, F.; Mori, T.; Schulze, M.; Assadi, H.; Kuroda, S.; Klassen, T. Cold spraying of amorphous Cu50Zr50 alloys. J. Therm. Spray Technol. 2015, 24, 108–118. [Google Scholar] [CrossRef]

- Kumar, S.; Bae, G.; Kang, K.; Yoon, S.; Lee, C. Effect of powder state on the deposition behaviour and coating development in kinetic spray process. J. Phys. D Appl. Phys. 2009, 42, 075305. [Google Scholar] [CrossRef]

- Marrocco, T.; McCartney, D.G.; Shipway, P.H.; Sturgeon, A.J. Production of titanium deposits by cold-gas dynamic spray: Numerical modeling and experimental characterization. J. Therm. Spray Technol. 2006, 15, 263–272. [Google Scholar] [CrossRef]

- Wong, W.; Irissou, E.; Ryabinin, A.N.; Legoux, J.-G.; Yue, S. Influence of helium and nitrogen gases on the properties of cold gas dynamic sprayed pure titanium coatings. J. Therm. Spray Technol. 2011, 20, 213–226. [Google Scholar] [CrossRef]

- Li, C.-J.; Li, W.-Y.; Liao, H. Examination of the critical velocity for deposition of particles in cold spraying. J. Therm. Spray Technol. 2006, 15, 212–222. [Google Scholar] [CrossRef]

- Meyer, M.; Yin, S.; Lupoi, R. Particle in-flight velocity and dispersion measurements at increasing particle feed rates in cold spray. J. Therm. Spray Technol. 2017, 26, 60–70. [Google Scholar] [CrossRef]

- Yin, S.; Liu, Q.; Liao, H.L.; Wang, X.F. Effect of injection pressure on particle acceleration, dispersion and deposition in cold spray. Comput. Mater. Sci. 2014, 90, 7–15. [Google Scholar] [CrossRef]

- Zahiri, S.H.; Yang, W.; Jahedi, M. Characterization of cold spray titanium supersonic jet. J. Therm. Spray Technol. 2009, 18, 110–117. [Google Scholar] [CrossRef]

- Li, W.Y.; Liao, H.; Douchy, G.; Coddet, C. Optimal design of a cold spray nozzle by numerical analysis of particle velocity and experimental validation with 316L stainless steel powder. Mater. Des. 2007, 28, 2129–2137. [Google Scholar] [CrossRef]

- Ozdemir, O.C.; Widener, C.A.; Helfritch, D.; Delfanian, F. Estimating the effect of helium and nitrogen mixing on deposition efficiency in cold spray. J. Therm. Spray Technol. 2016, 25, 660–671. [Google Scholar] [CrossRef]

- Wu, X.K.; Zhou, X.L.; Wang, J.G.; Zhang, J.S. Numerical investigation on acceleration of gaseous mixture of nitrogen and helium on particles during cold spraying. J. Mater. Eng. 2010, 8, 12–15. [Google Scholar]

- Irissou, E.; Ilinca, F.; Wong, W.; Legoux, J.; Yue, S. Investigation on the effect of helium-to-nitrogen ratio as propellent gas mixture on the processing of titanium coating using cold gas dynamic spray. In Proceedings of the International Thermal Spray Conference (ITSC 2011), Hamburg, Germany, 27–29 September 2011; Volume 276, pp. 88–93. [Google Scholar]

- Khun, N.W.; Tan, A.W.Y.; Bi, K.J.W.; Liu, E. Effects of working gas on wear and corrosion resistances of cold sprayed Ti-6Al-4V coatings. Surf. Coat. Technol. 2016, 302, 1–12. [Google Scholar] [CrossRef]

- Sun, W.; Tan, A.W.Y.; Marinescu, I.; Toh, W.Q.; Liu, E. Adhesion, tribological and corrosion properties of cold-sprayed CoCrMo and Ti6Al4V coatings on 6061-T651 Al alloy. Surf. Coat. Technol. 2017, 326, 291–298. [Google Scholar] [CrossRef]

- Goldbaum, D.; Shockley, J.M.; Chromik, R.R.; Rezaeian, A.; Yue, S.; Legoux, J.G.; Irissou, E. The effect of deposition conditions on adhesion strength of Ti and Ti6Al4V cold spray splats. J. Therm. Spray Technol. 2011, 21, 288–303. [Google Scholar] [CrossRef]

- Vidaller, M.V.; List, A.; Gaertner, F.; Klassen, T.; Dosta, S.; Guilemany, J.M. Single impact bonding of cold sprayed Ti-6Al-4V powders on different substrates. J. Therm. Spray Technol. 2015, 24, 644–658. [Google Scholar] [CrossRef]

- Vo, P.; Irissou, E.; Legoux, J.G.; Yue, S. Mechanical and microstructural characterization of cold-sprayed Ti-6Al-4V after heat treatment. J. Therm. Spray Technol. 2013, 22, 954–964. [Google Scholar] [CrossRef]

- Luo, X.T.; Wei, Y.K.; Wang, Y.; Li, C.J. Microstructure and mechanical property of Ti and Ti6Al4V prepared by an in situ shot peening assisted cold spraying. Mater. Des. 2015, 85, 527–533. [Google Scholar] [CrossRef]

- Birt, A.M.; Champagne, V.K.; Sisson, R.D.; Apelian, D. Microstructural analysis of cold-sprayed Ti-6Al-4V at the micro- and nano-scale. J. Therm. Spray Technol. 2015, 24, 1277–1288. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, C.; Guo, X.; Xu, J.; Li, C.J.; Liao, H.; Coddet, C.; Khor, K.A. Ti and Ti-6Al-4V coatings by cold spraying and microstructure modification by heat treatment. Adv. Eng. Mater. 2007, 9, 418–423. [Google Scholar] [CrossRef]

- Aydin, H.; Alomair, M.; Wong, W.; Vo, P.; Yue, S. Cold sprayability of mixed commercial purity Ti plus Ti6Al4V metal powders. J. Therm. Spray Technol. 2017, 26, 360–370. [Google Scholar] [CrossRef]

- Garrido, M.A.; Sirvent, P.; Poza, P. Evaluation of mechanical properties of Ti6Al4V cold sprayed coatings. Sur. Eng. 2018, 34, 399–406. [Google Scholar] [CrossRef]

- ASTM B822-10 Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by Light Scattering; ASTM International: West Conshohocken, PA, USA, 2010.

- Tan, A.W.Y.; Sun, W.; Phang, Y.P.; Dai, M.; Marinescu, I.; Dong, Z.; Liu, E. Effects of traverse scanning speed of spray nozzle on the microstructure and mechanical properties of cold-sprayed Ti6Al4V coatings. J. Therm. Spray Technol. 2017, 26, 1484–1497. [Google Scholar] [CrossRef]

- Kinetic Spray Solutions. Available online: https://kinetic-spray-solutions.com/ (accessed on 19 January 2018).

- Coddet, P.; Verdy, C.; Coddet, C.; Debray, F. Effect of cold work, second phase precipitation and heat treatments on the mechanical properties of copper-silver alloys manufactured by cold spray. Mater. Sci. Eng. A 2015, 637, 40–47. [Google Scholar] [CrossRef]

- ASTM C633-13 Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings; ASTM International: West Conshohocken, PA, USA, 2013.

- Rahmati, S.; Ghaei, A. The use of particle/substrate material models in simulation of cold-gas dynamic-spray process. J. Therm. Spray Technol. 2014, 23, 530–540. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Champagne, V.K.; Nelson, K.A.; Schuh, C.A. Adiabatic shear instability is not necessary for adhesion in cold spray. Acta Mater. 2018, 158, 430–439. [Google Scholar] [CrossRef]

- Bae, G.; Jang, J.I.; Lee, C. Correlation of particle impact conditions with bonding, nanocrystal formation and mechanical properties in kinetic sprayed nickel. Acta Mater. 2012, 60, 3524–3535. [Google Scholar] [CrossRef]

- Song, X.; Everaerts, J.; Zhai, W.; Zheng, H.; Tan, A.W.Y.; Sun, W.; Li, F.; Marinescu, I.; Liu, E.; Korsunsky, A.M. Residual stresses in single particle splat of metal cold spray process – Numerical simulation and direct measurement. Mater. Lett. 2018, 230, 152–156. [Google Scholar] [CrossRef]

- Lek, J.Y.; Bhowmik, A.; Tan, A.W.-Y.; Sun, W.; Song, X.; Zhai, W.; Buenconsejo, P.J.; Li, F.; Liu, E.; Lam, Y.M.; et al. Understanding the microstructural evolution of cold sprayed Ti-6Al-4V coatings on Ti-6Al-4V substrates. Appl. Surf. Sci. 2018, 459, 492–504. [Google Scholar] [CrossRef]

- Guetta, S.; Berger, M.H.; Borit, F.; Guipont, V.; Jeandin, M.; Boustie, M.; Ichikawa, Y.; Sakaguchi, K.; Ogawa, K. Influence of particle velocity on adhesion of cold-sprayed splats. J. Therm. Spray Technol. 2009, 18, 331–342. [Google Scholar] [CrossRef]

- Saleh, M.; Luzin, V.; Spencer, K. Analysis of the residual stress and bonding mechanism in the cold spray technique using experimental and numerical methods. Surf. Coat. Technol. 2014, 252, 15–28. [Google Scholar] [CrossRef]

- Zhu, L.; Jen, T.-C.; Pan, Y.-T.; Chen, H.-S. Particle bonding mechanism in cold gas dynamic spray: A three-dimensional approach. J. Therm. Spray Technol. 2017, 26, 1859–1873. [Google Scholar] [CrossRef]

- Xie, W.; Alizadeh-Dehkharghani, A.; Chen, Q.; Champagne, V.K.; Wang, X.; Nardi, A.T.; Kooi, S.; Muftu, S.; Lee, J.H. Dynamics and extreme plasticity of metallic microparticles in supersonic collisions. Sci. Rep. 2017, 7, 5073. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Yue, S.; Song, J. Quantitative prediction of critical velocity and deposition efficiency in cold-spray: A finite-element study. Scr. Mater. 2015, 107, 83–87. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, C.; Li, C.J.; Liao, H. Modeling aspects of high velocity impact of particles in cold spraying by explicit finite element analysis. J. Therm. Spray Technol. 2009, 18, 921. [Google Scholar] [CrossRef]

- Ghelichi, R.; Bagherifard, S.; Guagliano, M.; Verani, M. Numerical simulation of cold spray coating. Surf. Coat. Technol. 2011, 205, 5294–5301. [Google Scholar] [CrossRef]

- Brunig, M.; Driemeier, L. Numerical simulation of Taylor impact tests. Int. J. Plast. 2007, 23, 1979–2003. [Google Scholar] [CrossRef]

- Manes, A.; Lumassi, D.; Giudici, L.; Giglio, M. An experimental–numerical investigation on aluminium tubes subjected to ballistic impact with soft core 7.62 ball projectiles. Thin Walled Struct. 2013, 73, 68–80. [Google Scholar] [CrossRef]

- Lesuer, D. Experimental investigation of material models for Ti-6Al-4V and 2024-T3; Lawrence Livermore National Laboratory: Livermore, CA, USA, 2000; pp. 1–36. [Google Scholar]

- Maev, R.G.; Leshchynsky, V. Cold gas dynamic spray, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Alkhimov, A.P.; Kosarev, V.F.; Klinkov, S.V. The features of cold spray nozzle design. J. Therm. Spray Technol. 2001, 10, 375–381. [Google Scholar] [CrossRef]

- Haynes, W.M. Handbook of Chemistry and Physics, 92nd ed.; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Mineral Commodity Summaries 2012; U.S. Geological Survey: Reston, VA, USA, 2012.

- Blose, R.E.; Walker, B.H.; Walker, R.M.; Froes, S.H. New opportunities to use cold spray process for applying additive features to titanium alloys. Met. Powder Rep. 2006, 61, 30–37. [Google Scholar] [CrossRef]

- Khun, N.W.; Tan, A.W.Y.; Sun, W.; Liu, E. Wear and corrosion resistance of thick Ti-6Al-4V coating deposited on Ti-6Al-4V substrate via high-pressure cold spray. J. Therm. Spray Technol. 2017, 26, 1393–1407. [Google Scholar] [CrossRef]

- Tan, A.W.Y.; Sun, W.; Khun, N.W.; Marinescu, I.; Dong, Z.; Liu, E. Potential of cold spray as additive manufacturing for Ti6Al4V. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing (Pro-AM 2016), Nanyang, Singapore, 16–19 May 2016; pp. 403–408. [Google Scholar]

- Jung, H.B.; Park, J.I.; Park, S.H.; Kim, H.-J.; Lee, C.-h.; Han, J.-W. Effect of the expansion ratio and length ratio on a gas-particle flow in a converging-diverging cold spray nozzle. Met. Mater. Int. 2009, 15, 967–970. [Google Scholar] [CrossRef]

- Morgan, R.; Fox, P.; Pattison, J.; Sutcliffe, C.; O’Neill, W. Analysis of cold gas dynamically sprayed aluminium deposits. Mater. Lett. 2004, 58, 1317–1320. [Google Scholar] [CrossRef]

- Goldbaum, D.; Chromik, R.R.; Brodusch, N.; Gauvin, R. Microstructure and mechanical properties of Ti cold-spray splats determined by electron channeling contrast imaging and nanoindentation mapping. Microsc. Microanal. 2015, 21, 570–581. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.Y.; Shen, T.D.; Quan, M.X.; Wei, W.D. Hall-Petch relationship in nanocrystalline titanium produced by ball-milling. J. Mater. Sci. Lett. 1993, 12, 1818–1820. [Google Scholar] [CrossRef]

- Pawlowski, L. Chapter 8: Properties of coatings. In The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons: Chichester, UK, 2008. [Google Scholar]

- Tan, A.W.-Y.; Sun, W.; Bhowmik, A.; Lek, J.Y.; Marinescu, I.; Li, F.; Khun, N.W.; Dong, Z.; Liu, E. Effect of coating thickness on microstructure, mechanical properties and fracture behaviour of cold sprayed Ti6Al4V coatings on Ti6Al4V substrates. Surf. Coat. Technol. 2018, 349, 303–317. [Google Scholar] [CrossRef]

- Dodd, B.; Bai, Y. Adiabatic shear localization: Frontiers and Advances, 2nd ed.; Elsevier: London, UK, 2012. [Google Scholar]

- Huang, R.; Ma, W.; Fukanuma, H. Development of ultra-strong adhesive strength coatings using cold spray. Surf. Coat. Technol. 2014, 258, 832–841. [Google Scholar] [CrossRef]

| Author (et al.) | Ref. | Gas Type (P, T) | Porosity (%) | Microhardness (HV) | Adhesion Strength (MPa) |

|---|---|---|---|---|---|

| Bhattiprolu | [25] | He (41, 425) | 0.9 | 415 | >65 |

| He (41, 500) | 1.16 | 400 | 50 ± 12 | ||

| Vo | [46] | N2 (40, 800) | 12 | 350 | – |

| He (40 ,350) | 1 | 357 | – | ||

| Luo | [47] | N2 (28, 550) | 15.7 | 210 | – |

| He (28, 550) | 2.7 | 363 | – | ||

| Birt | [48] | N2 (38.5, 760) | 11.3 | 214.1 * | – |

| N2-73 vol.% He (36, 790) | 2.1 | 517 * | – | ||

| Li | [49] | Air (28, 520) | 22.3 | – | – |

| Aydin | [50] | N2 (40, 800) | 6.7 | 385 | – |

| Garrido | [51] | N2 (40, 800) | 18.1 | 328.3 | – |

| N2 (50, 1000) | 3.83 | 361 | – | ||

| Perton | [22] | N2 (40, 800) | 7.5 | 860 | >80 |

| Working Gas (vol.%) | Gas Pressure (MPa) | Gas Temperature (°C) | Measured Particle Velocity (m/s) | |

|---|---|---|---|---|

| Nitrogen | Helium | |||

| 100 | – | 4.5 | 800 | ~730 |

| 100 | – | 900 | ~760 | |

| 100 | – | 1000 | ~800 | |

| 90 | 10 | 1000 | ~827 | |

| 80 | 20 | 1000 | ~855 | |

| Nomenclature | Symbol | Unit | Value |

|---|---|---|---|

| Density | ρ | kg/m2 | 4428 |

| Specific Heat | c | J/(kg·K) | Temperature Dependent * |

| Melting Temperature | Tm | K | 1878 |

| Liquidus Temperature | TL | K | 1877 |

| Solidus Temperature | TS | K | 1933 |

| Young’s Modulus | E | GPa | Temperature Dependent * |

| Poisson’s Ratio | ν | Dimensionless | 0.33 |

| Thermal Conductivity | k | W/(m·K) | 0 |

| Latent Heat of Fusion | Lf | J/kg | 365000 |

| Inelastic Heat Fraction | η | Dimensionless | 0.9 |

| Johnson–Cook Plasticity Model | MPa | 862 | |

| MPa | 331 | ||

| Dimensionless | 0.34 | ||

| Dimensionless | 0.012 | ||

| Dimensionless | 0.8 | ||

| K | 298 | ||

| s−1 | 1 | ||

| Johnson–Cook Dynamic Failure Model | Dimensionless | −0.09 | |

| Dimensionless | 0.25 | ||

| Dimensionless | −0.5 | ||

| Dimensionless | 0.014 | ||

| Dimensionless | 3.87 | ||

| K | 298 | ||

| s−1 | 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, A.W.-Y.; Lek, J.Y.; Sun, W.; Bhowmik, A.; Marinescu, I.; Song, X.; Zhai, W.; Li, F.; Dong, Z.; Boothroyd, C.B.; et al. Influence of Particle Velocity When Propelled Using N2 or N2-He Mixed Gas on the Properties of Cold-Sprayed Ti6Al4V Coatings. Coatings 2018, 8, 327. https://doi.org/10.3390/coatings8090327

Tan AW-Y, Lek JY, Sun W, Bhowmik A, Marinescu I, Song X, Zhai W, Li F, Dong Z, Boothroyd CB, et al. Influence of Particle Velocity When Propelled Using N2 or N2-He Mixed Gas on the Properties of Cold-Sprayed Ti6Al4V Coatings. Coatings. 2018; 8(9):327. https://doi.org/10.3390/coatings8090327

Chicago/Turabian StyleTan, Adrian Wei-Yee, Jun Yan Lek, Wen Sun, Ayan Bhowmik, Iulian Marinescu, Xu Song, Wei Zhai, Feng Li, Zhili Dong, Chris B. Boothroyd, and et al. 2018. "Influence of Particle Velocity When Propelled Using N2 or N2-He Mixed Gas on the Properties of Cold-Sprayed Ti6Al4V Coatings" Coatings 8, no. 9: 327. https://doi.org/10.3390/coatings8090327

APA StyleTan, A. W.-Y., Lek, J. Y., Sun, W., Bhowmik, A., Marinescu, I., Song, X., Zhai, W., Li, F., Dong, Z., Boothroyd, C. B., & Liu, E. (2018). Influence of Particle Velocity When Propelled Using N2 or N2-He Mixed Gas on the Properties of Cold-Sprayed Ti6Al4V Coatings. Coatings, 8(9), 327. https://doi.org/10.3390/coatings8090327