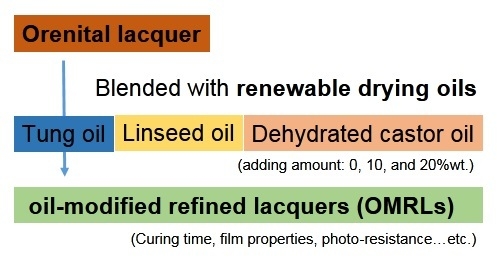

3.1. Properties of the Oil-Modified Refined Lacquer Coatings

During the refining process of the oriental lacquer, the timing of the addition of drying oil to lacquer was very important. As an example for TO, when the water content of the oriental lacquer reached 30%, 20%, and 10%, TO was added to the given batch to achieve an oil/oriental lacquer weight ratio of 20/100. Then, refining continued until the water content was reduced to 3.5%. This process led to the TO-modified RL. The time for hardened drying (HD) was measured. Results showed that when the water content of the oriental lacquer was at 30%, 20%, and 10%, the HD of the RL was 13.5, 11.0, and 7.0 h, respectively. This finding indicated that the suitable point for adding the drying oil to lacquer during refining occurred when its water content reached 10%.

The viscosity and drying time of the RL with different types of drying oil and weight ratios are listed in

Table 1. The RL had a viscosity of 2927 cps, whereas the viscosities of all three drying oils were lower. LO (L100) had the lowest viscosity at only 55 cps. More than 70% of the fatty acids of TO (T100) is eleostearic acid, which contains three highly reactive conjugated double bonds for easy oxidative addition in an aerobic environment, which in turn increases the molecular weight of TO and gives it a viscosity of 257 cps. The ricinoleic acid in raw castor oil dehydrates at high temperatures to form two types of linoleic acids, one with conjugated double bonds and the other with nonconjugated double bonds. At 174 cps, the viscosity of DCO (D100) was slightly lower than that of TO. After the blending and refining process of the oriental lacquer with different types of drying oil, T10 and D10 (with an oil/oriental lacquer weight ratio of 10/100) both had viscosities higher than RL, and the viscosity of T10 was also greater than that of D10, indicating that drying oils acted as more than diluents for RL. In particular, the conjugated double bonds in the unsaturated fatty acids of TO and DCO could undergo autooxidation or with the unsaturated side chains of urushiols as the oriental lacquer was refined with these drying oils. This led to an overall increase in molecular weight and viscosity of the OMRL. On the other hand, in L10, although the fatty acids of LO contained 40% linolenic acid and a large number of double bonds, all of the double bonds were nonconjugated and did not undergo significant oxidative addition during the refining process. Thus, the OMRL that was obtained did not have a high viscosity. When the ratio of the drying oils reached 20/100, oxidative addition still had the effects highlighted above. However, once an excess of low-viscosity drying oil was introduced to the process, it began to dilute the RL and ultimately reduced the OMRL viscosity. The addition of the drying oil, which enhanced the workability and utilization of OMRL, made it possible to use ordinary coating brushes instead of those made from human hair for the application of RL.

The drying times of the coated specimens at 25 °C and 80% RH are also given in

Table 1. As described in previous research [

4,

8,

16], in the initial drying stages of traditional oriental lacquer, laccase reacts with oxygen and promotes free radical polymerization to produce phenoxy radicals from urushiols, which are also known as urushiol semiquinone radicals. This drying stage corresponds to DF in the curing test. These radicals are then disproportionated to produce urushiol quinones: This is the TF drying stage. When urushiols are polymerized into urushiol quinones and lose their antioxidant activity, their side chains oxidize and polymerize to produce densely crosslinked film in the HD drying stage. The DF and HD drying times of RL measured in this study were 3.5 and 7 h, respectively, consistent with previously reported results. As the oxidative polymerization and complete hardening of drying oils can take weeks or even months, none of the drying oils used here reached the HD stage within one day. The TO with conjugated double bonds took at least 96 h to harden. The oxidative addition and polymerization of drying oils also require atmospheric oxygen: However, because oxygen diffused into the interior of the wet film, an oxygen concentration gradient was formed between the film surface and the interior, leading to different drying rates throughout the film. When the surface dried too quickly, it toughened and blocked oxygen penetration into the interior, resulting in incomplete drying inside the film. OMRL containing drying oils is also potentially subject to such uneven drying.

In DCO-modified RLs, the TF and HD time was shortened as more DCO was added and became shorter than those of the RL. This is because the low viscosity of the oil-modified RL allows oxygen to easily permeate into the coating, promoting the laccase-catalyzed polymerization and reducing the TF time. The abundant conjugated double bonds also participate in the oxidative polymerization of urushiol side chains, thus decreasing the time it takes to reach the HD stage.

The DF and TF times of TO-modified refined lacquers were shorter than RL, but the HD time was the same (7.0 h). This was due to the three highly reactive conjugated double bonds on the eleostearic acid of TO, which increased the viscosity of the coating material during the early drying, hardening the surface of the film and blocking oxygen penetration. Thus, the ability of laccase to catalyze oxidation polymerization was reduced, which was not beneficial to the drying of the RL.

For the LO-modified refined lacquers, the DF and TF times of L10 and L20 were shorter than those of RL, but the HD time varied with the amount of LO added. The HD time of L20 was only 5.5 h, whereas that of L10 was 8.0 h. This was due to the high content of linolenic acid, which was characterized by nonconjugated double bonds, in the fatty acids of LO and a reactivity that fell between that of TO and DCO. As a result, the HD time of the RL was shortened only when the proportion of drying oil/oriental lacquer reached 20/100.

3.2. Properties of OMRL Films

After the RLs blended with the three respective drying oils hardened into films at 25 °C and 80% RH in a constant temperature and humidity chamber, they were placed in an air-conditioned environment at 26 °C and 60% RH for 3 weeks. The film properties, including the hardness, mass retention,

Tg, bending resistance, tensile strength, and elongation at break, were then determined (as shown in

Table 2).

The RL film had a hardness of 104 s, whereas the other OMRL films all exhibited lower hardness. The values for T10 and T20, the TO-modified RLs, were 81 and 80 s, respectively; D10 and D20, the DCO-modified RLs, had hardness values of 83 and 52 s, respectively; and L10 and L20, the LO-modified refined lacquers, had hardness values of 61 and 33 s. Previous literature [

27] has used a multianalytical approach and has reported that the catechol acts as an antioxidant, inhibiting the oxidation reactions of linseed oil, and is accompanied by an increase in the occurrence of propagation and termination reactions leading to crosslinking. However, in our study, the oils were added when the water content of the RL reached 10%. At this stage, over 50% of catechol monomers had been transformed into oligomers and polymers [

4], which weakened the antioxidant of RL. As is evident from our results, the highly reactive eleostearic acid in the TO-modified RLs readily formed cyclic peroxide with oxygen and decomposed into either oxygen or peroxy radicals, initiating polymerization and the rapid drying of the RL into a film. When TO was blended with the oriental lacquer, the fast-oxidative polymerization inhibited the catalytic polymerization by laccase, but still enabled the formation of a highly crosslinked film or a film with a tough surface [

9]. For linolenic acid in LO, which contains nonconjugated double bonds, the oxidative polymerization required dehydrogenation by methylene, after which it reacted with oxygen to form hydroperoxide and decomposed into either oxygen or peroxy radicals, initiating the crosslinking reaction. Therefore, the drying time of LO-modified RLs was longer [

14]. The oxidative polymerization of LO also competed with the catalyzed polymerization by laccase, lowering the crosslink density of the dried film and giving rise to a softer film. The DCO contained both conjugated and nonconjugated double bonds, and thus the film hardness of the DCO-modified RLs was between that of the TO and the LO-modified RLs.

The mass retention for each RL composition is listed in

Table 2. Except for the pure drying oils (T100, L100, and D100), from which isolated films could not be obtained. The highest mass retention was seen for RL (91.6%), whereas all the other OMRLs containing 10% oils showed similar and lower values. Although the mass retention of pure drying oils could not be measured, the crosslink density of the films of LO and DCO-modified RLs were found to decrease as the LO or DCO content increased. This indicated the possible slowing effect that the antioxidant activity of urushiols had on the oxidative polymerization of drying oils, or the competition between the crosslinking that occurred during the oxidative polymerization of the drying oils and the catalyzed polymerization by laccase, which lowered the crosslink density in the film. However, when the TO content was increased from 10% to 20%, a small increase in mass retention (from 86.4% to 87.1%) was observed in the TO-modified RLs because TO is composed of unsaturated fatty acids with highly reactive conjugated double bonds that are unaffected by the antioxidant activity of urushiols. Although it inhibited the catalyzed polymerization by laccase, the oxidative polymerization of TO still formed crosslinked structures as TO underwent rapid oxidative polymerization with urushiol side chains, giving the film its high mass retention. Due to the abundance of conjugated double bonds in the fatty acids of DCO, the mass retention in films formed by DCO-modified RLs was slightly higher than in their LO counterparts.

Figure 2 shows the DMA results of the films and the

Tg values of the films as given by the peaks of the tan δ plots shown in

Table 2. As intact films of the three pure drying oils could not be obtained, the standard method of film chips covered in aluminum was used to measure the

Tg of the films. The RL film had the highest

Tg at 80.2 °C, indicating a high degree of crosslinking, as is also reflected in the mass retention results. The

Tg of the various OMRLs decreased as the drying oil proportion increased, with the highest

Tg recorded in D10 at 66.6 °C, whereas T10 and L10 had similar

Tg values of 55.0 °C and 59.9 °C, respectively. These results were also consistent with the mass retention. In addition, the film of TO-OMRL showed narrower tan δ peaks than the LO-OMRL and DCO-OMRL films did, which indicates that the network structure of the TO-OMRL films was more homogeneous than the other ones.

The results above show that OMRL, composed of long chain fatty acids, had lower rigidity than the RL. The crosslinking reaction was still possible for the films of TO-modified RLs as the highly reactive eleostearic acid in TO could still undergo oxidative polymerization despite the antioxidant activity of urushiols. Therefore, the mass retention of the films increased even as the quantity of TO increased from 10% to 20%, and the decrease in Tg was smaller (from 55.0 to 44.5 °C). The iodine value of LO was higher than that of DCO, which indicates that the crosslinking density in films of LO-modified RLs should be higher than that of their DCO counterparts, whose fatty acids were completely oxidized and polymerized. However, the mass retention and DMA tests showed opposite results, which suggests that the laccase-catalyzed polymerization of oriental lacquer competed effectively with the oxidative polymerization of the drying oils, resulting in incomplete oxidative polymerization. On the other hand, the DCO consisted of fatty acids with highly reactive double bonds, giving the RL films a higher mass retention and Tg. The high hardness, mass retention, and Tg values exhibited by the films of DCO-modified RLs also indicate the presence of both conjugated and nonconjugated double bonds in the fatty acids of DCO, which formed highly crosslinked films despite the possibility of laccase-catalyzed polymerization.

The bending resistance test results showed that the film formed by the RL was hard and brittle and was broken using a 10 mm-diameter steel bar. Films of pure drying oils all demonstrated good bending resistance during a 2–3 mm-diameter steel shaft test. The addition of TO, LO, and DCO greatly improved the bending resistance of the OMRL films. A higher bending resistance was observed as more drying oils were added, as seen for D10 and D20, which were tested using 6 and 4 mm-diameter steel bars, respectively. This finding shows the enhanced flexibility of OMRL films as compared to traditional RL films.

The tensile strength and elongation at break for the films are shown in

Figure 3. The T100, L100, and D100 films were so low in strength that intact films could not be isolated. The tensile strength of the RL film was around 27.6 MPa. The tensile strengths of the OMRL films all decreased with an increase in the proportion of drying oil, as drying oils reduced the crosslinking density of the films. Among the OMRLs, films of TO-modified RLs showed the highest tensile strength of 20.7 MPa (T10), whereas the films of LO and DCO-modified RLs had similar tensile strengths of approximately 13.0 (D10) and 15.2 MPa (L10). With the addition of 10% or 20% drying oil, the DCO-modified RLs had the lowest tensile strengths. Although these films had the highest crosslinking density, they had poor homogeneity as both conjugated and nonconjugated fatty acids participated in the oxidative polymerization as the films dried, in addition to the laccase-catalyzed polymerization. This suggestion is supported by the observation that D10 showed the broadest peak in the DMA test results (

Figure 2c).

The elongation at break for RL was only about 12%, but it increased for the OMRL films as more drying oils were added. The best results were obtained for LO-modified RLs, which had an elongation at break of 34.2% for L20. The unsaturated fatty acids of LO contain nonconjugated double bonds and show low reactivity in oxidation polymerization. Thus, films of LO-modified RLs are not exhibit dense crosslinking and possess soft and flexible as a result.

The impact resistance, adhesion, abrasion resistance, and gloss of OMRL films are listed in

Table 3. Because pure drying oils penetrated into the wooden test boards after application, they could not be tested for impact resistance. The RL film was hard and brittle, but it withstood the impact of a fall from 5 cm. The OMRL films all showed reasonably high impact resistance of about 10–20 cm, with the highest exhibited by T20, L20, and D20. Both RL and pure drying oils (T100, L100, and D100) showed an excellent adhesion of grade 10, but the adhesion of OMRL was low and decreased with an increasing content of drying oil. Among the various OMRLs, the adhesion of LO and DCO-modified RL dropped most significantly. The oxidative polymerization of drying oils depended on the penetration of atmospheric oxygen into the wet film, but oxygen permeation was impeded with increasing film thickness and coating material viscosity, resulting in an oxygen concentration gradient in the wet film. The oxygen concentration at the film’s surface was higher, which led to oxidative polymerizations rates that varied between the surface and the bottom of the film. This effect was more substantial when the fatty acids in the drying oils were not very reactive.

The abrasion resistance of OMRL films is also shown in

Table 3. The weight loss due to abrasion for an RL film after 1000 test cycles was 13.2 mg. The weight loss of OMRL films increased with increasing content of drying oil. With the exception of the L10 film (a weight loss of 11.5 mg), the other OMRL films all lost more weight (approximately 13.7–32.2 mg) than the RL. D20 film had the highest weight after the abrasion test at 32.2 mg, whereas that of the D10 film was closest to RL at 13.7 mg. The results of the abrasion resistance test were consistent with the tensile stress-strain curves of

Figure 3 [

28], which show the smallest area-under-curve for the D20 film. The 60° gloss of RL film had a value of 26%, whereas OMRL films all showed greatly improved gloss, particularly L20, which had a gloss value of 82%. The films of TO and DCO-modified RLs showed little difference in this respect, and all had high gloss values, such as 52% and 54% for T20 and D20, respectively. Drying oils reduced the viscosity of the RLs, facilitating flattening of the film and the release of air bubbles, which made the film surface smoother after drying. The OMRL films with drying oils had a high gloss and were lustrous in appearance, and hence are well suited for their special end-uses.

According to a previous study, aging of the RL films is detrimental to their properties. For example, Lu et al. [

29] reported that a chemical reaction occurred quickly (48 h) on the surface of the oriental lacquer film after UV irradiation, and an Fe

2+ ion-containing lacquer film deteriorated more quickly than a kurome lacquer film. Another study [

30] showed that aging (within 1000 days) increased strength and reduced the ductility of the oriental lacquer films. A further study [

31] examined the effects of aging and moisture on the dynamic viscoelastic properties of oriental lacquer films. This study showed that the film’s

Tg shifted to higher temperatures, the maximum loss tangent (tan δ) decreased, and the storage modulus increased after aging over 1000 days at room temperature. We focused on changes in appearance of films during the UV irradiation. The lightfastness values of the OMRL films before and after the color fading test are given in

Figure 4. The color difference (∆

E*) of RL and OMRL films increased with prolonged exposure under ultraviolet light irradiation, accounting for the color changes of the films. The ∆

E* values of RL during the first 72 h were lower than those of the pure drying oils (T100, L100, and D100), but steadily rose after 72 h of irradiation. Conversely, the drying oils did not show any increase. This was because RL contains a large number of aromatic rings that are easily converted into quinones and undergo photodegradation, thus increasing ∆

E*. The ∆

E* of drying oils did not increase appreciably but still had values of 11–17, with the highest observed in TO and the lowest in DCO. This was related to the unreacted or newly formed conjugated double bonds in the films, as these conjugated double bonds absorb light and are common chromophores. The OMRL films with 10% drying oil added showed ∆

E* variations similar to the pure drying oils, with ∆

E* values in the following order: TO-modified RL > LO-modified RL > DCO-modified RL. When the proportion of drying oil increased to 20%, the ∆

E* of the TO-modified RLs decreased significantly. The order of ∆

E* became LO-modified RL > DCO-modified RL > TO-modified RL. As TO was blended with oriental lacquer, rapid oxidative polymerization inhibited and dominated the laccase-catalyzed polymerization, forming highly crosslinked films. Fewer conjugated double bonds were left in the film, reducing ∆

E*. Generally speaking, the ∆

E* values of OMRLs were higher than RL, as the colors of the OMRL films were lighter, resulting in greater color changes. In the lightfastness test, the ∆

E* values of OMRL films were found to stabilize at 96 h, whereas those of RL continued to rise. Lightfastness tests of longer duration or with a higher irradiation intensity are needed to draw firmer conclusions about the lightfastness of oil modified lacquer films.

According to our experimental results, the OMRL containing 10% tung oil had better film flexibility and gloss than the RL films and possessed superior hardness, which are desirable properties for finishing of wooden furniture. Even if the OMRL contained 20% linseed oil it had low film tensile strength of film, but it had the highest gloss, lowest viscosity and fast curing time, which are properties that are desirable for artistic applications, for example, colored paintings.