Fatigue and Mechanical Behavior of Ti-6Al-4V Alloy with CrN and TiN Coating Deposited by Magnetic Filtered Cathodic Vacuum Arc Process

Abstract

:1. Introduction

2. Materials and Methods

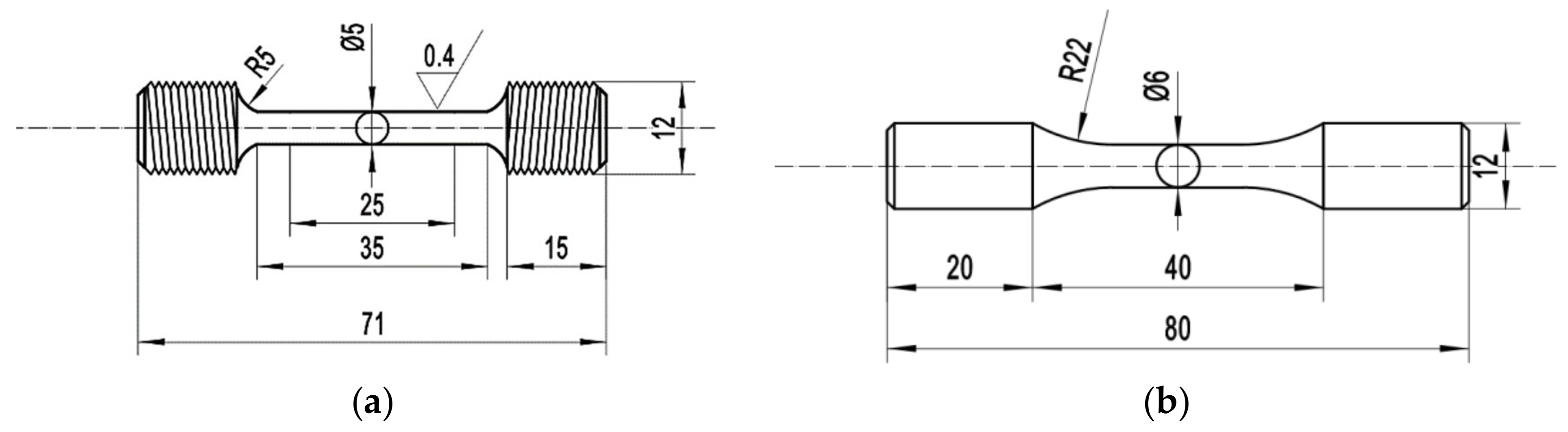

2.1. Sample Preparation

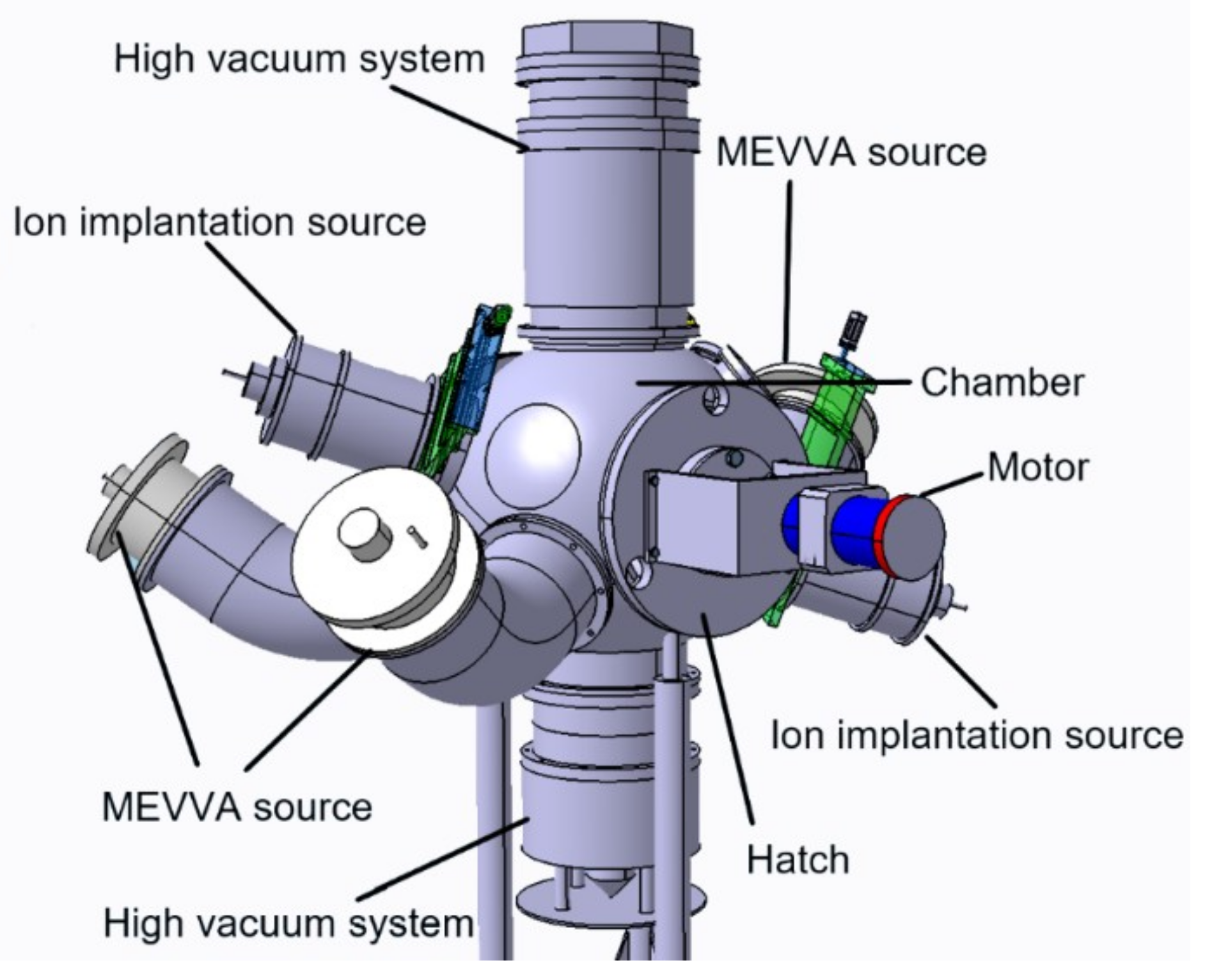

2.2. Magnetic Filtered Cathoic Vacuum Arc (MFCVA) Setup

2.3. Coating Deposition and Characterization

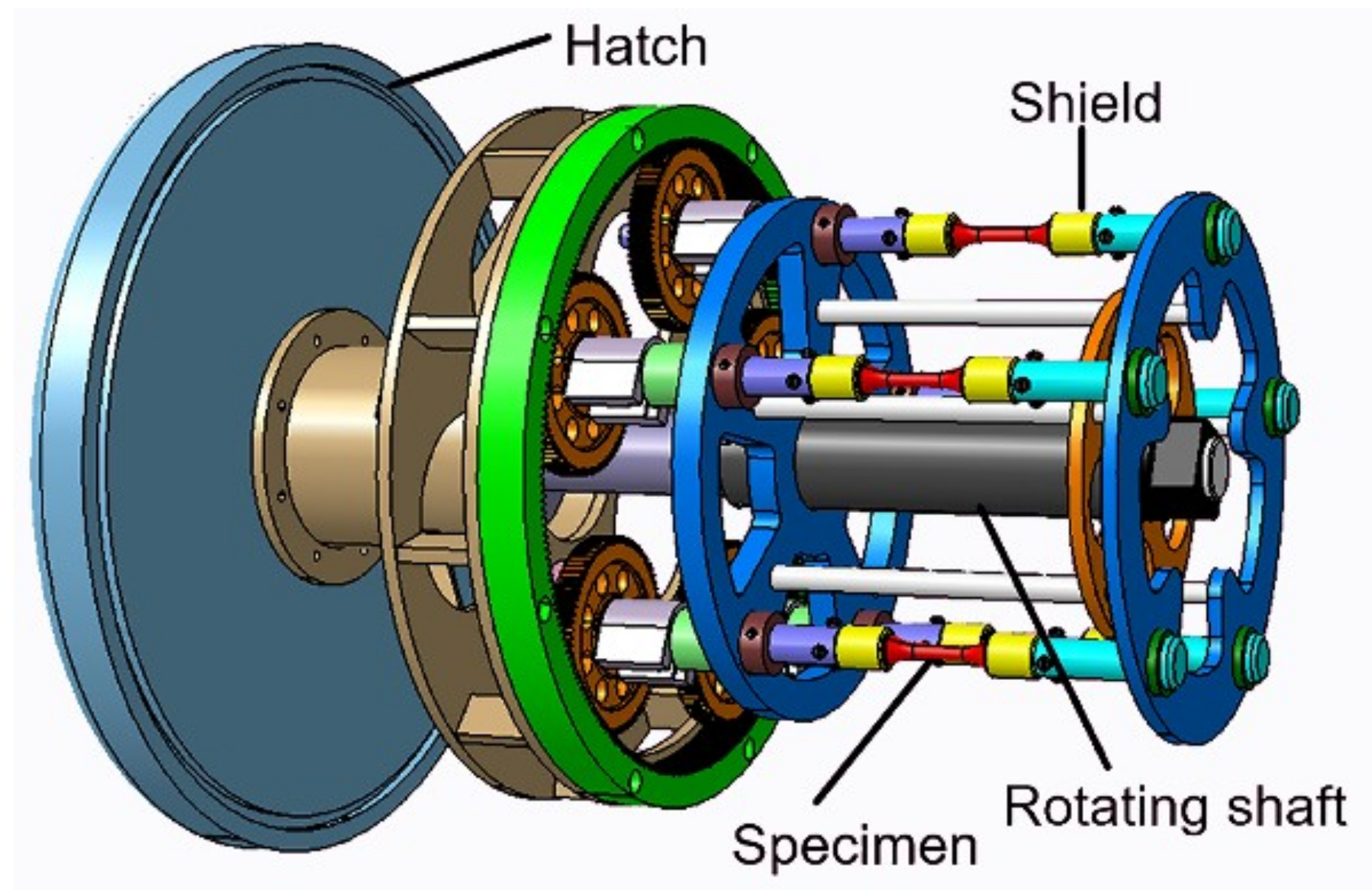

2.3.1. Deposition and Characterization of Coating Thickness Uniformity on Dog-Bone Shape Sample

2.3.2. CrN and TiN Coating Deposition

2.3.3. Coating Characterization

2.4. Fatigue and Mechanical Tests

3. Results and Discussion

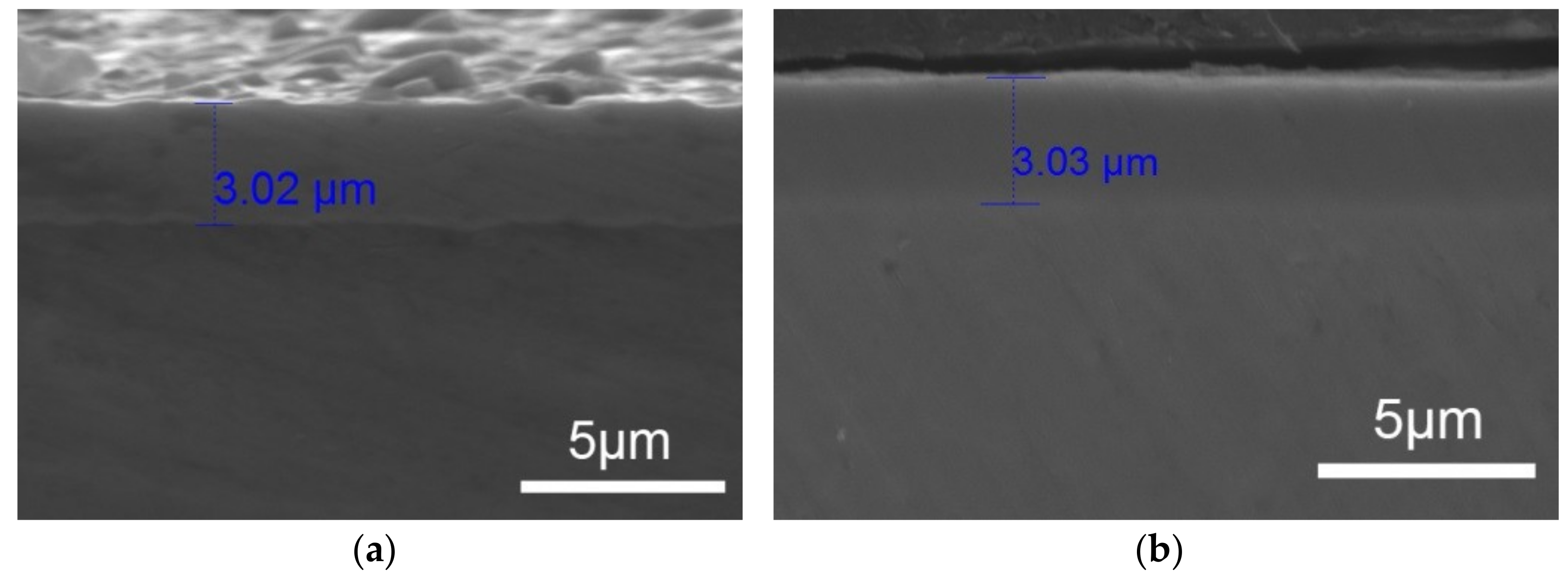

3.1. Thickness Uniformity of Coating on Dog-Bone Shape Samples

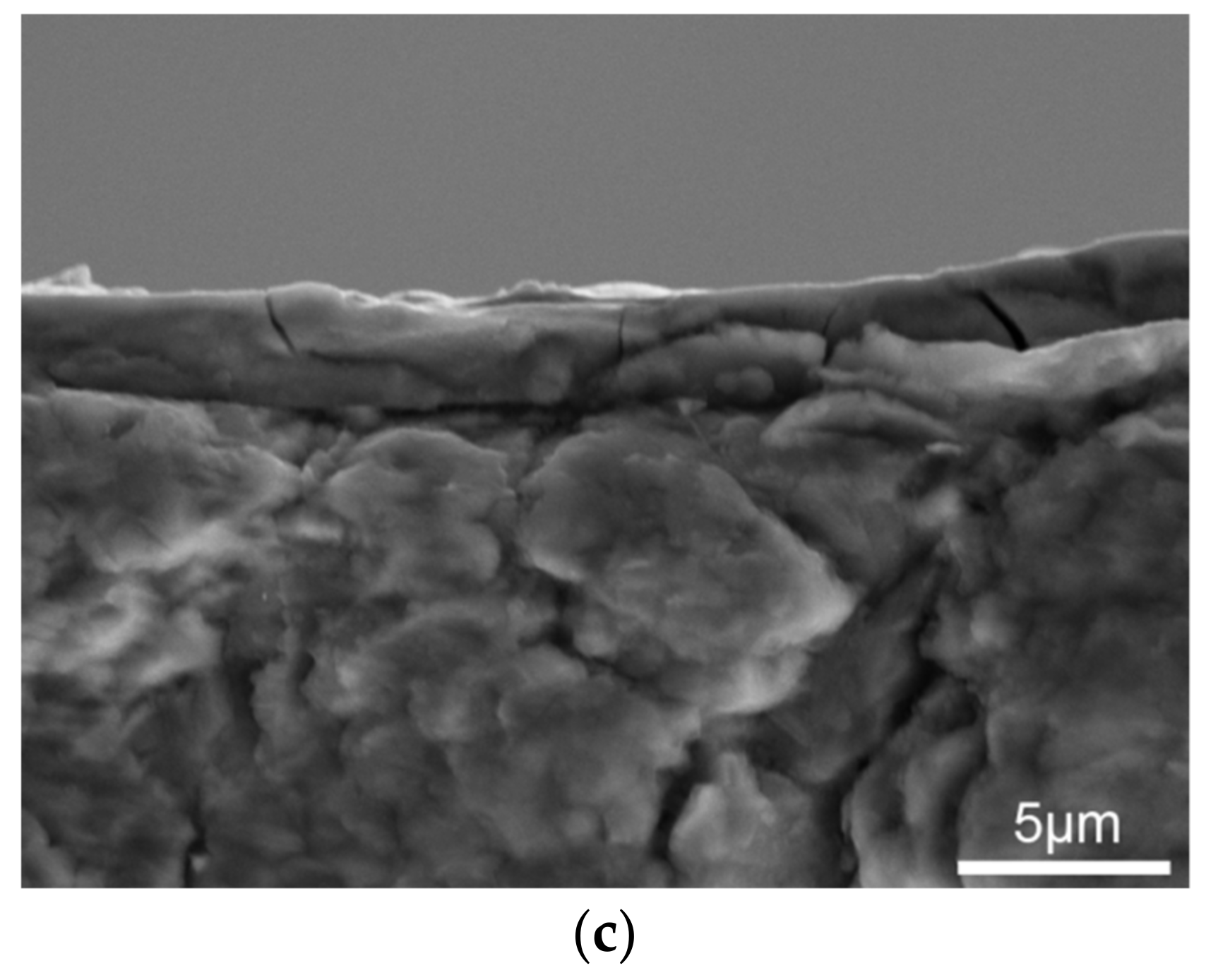

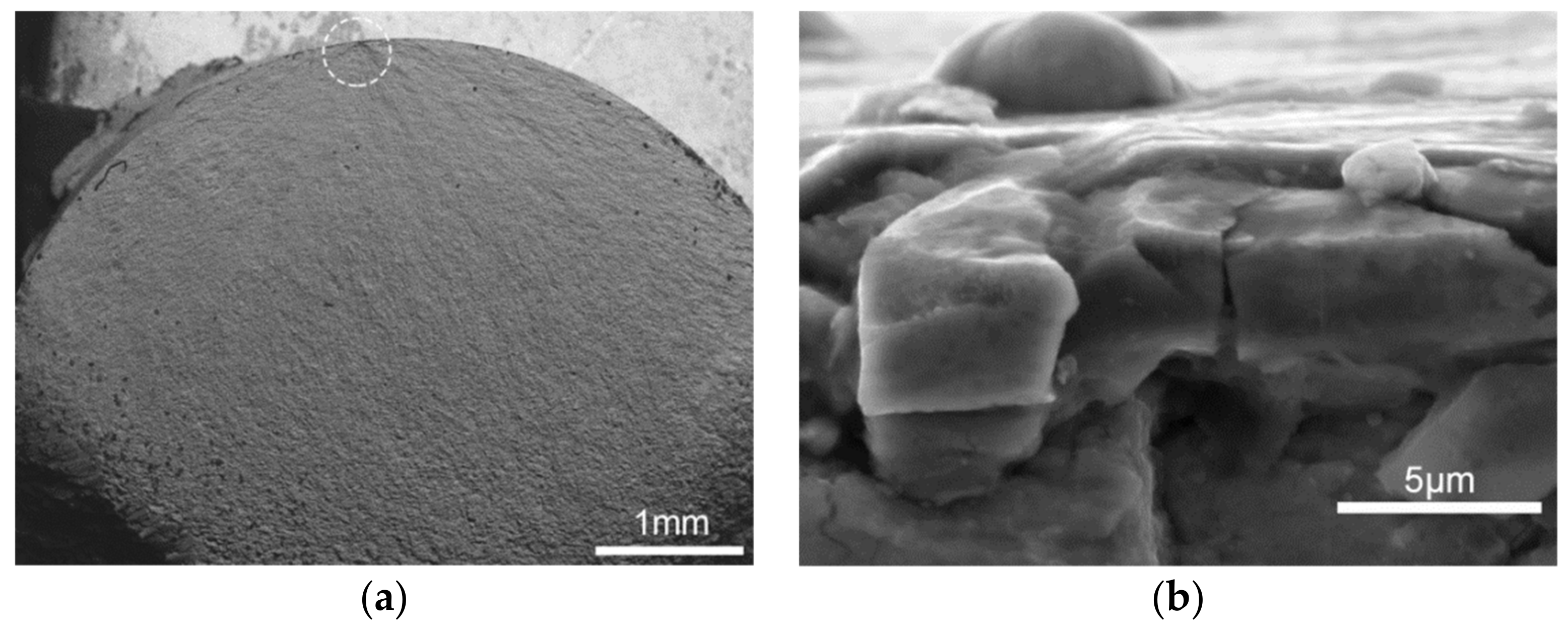

3.2. Characterization of the Coating

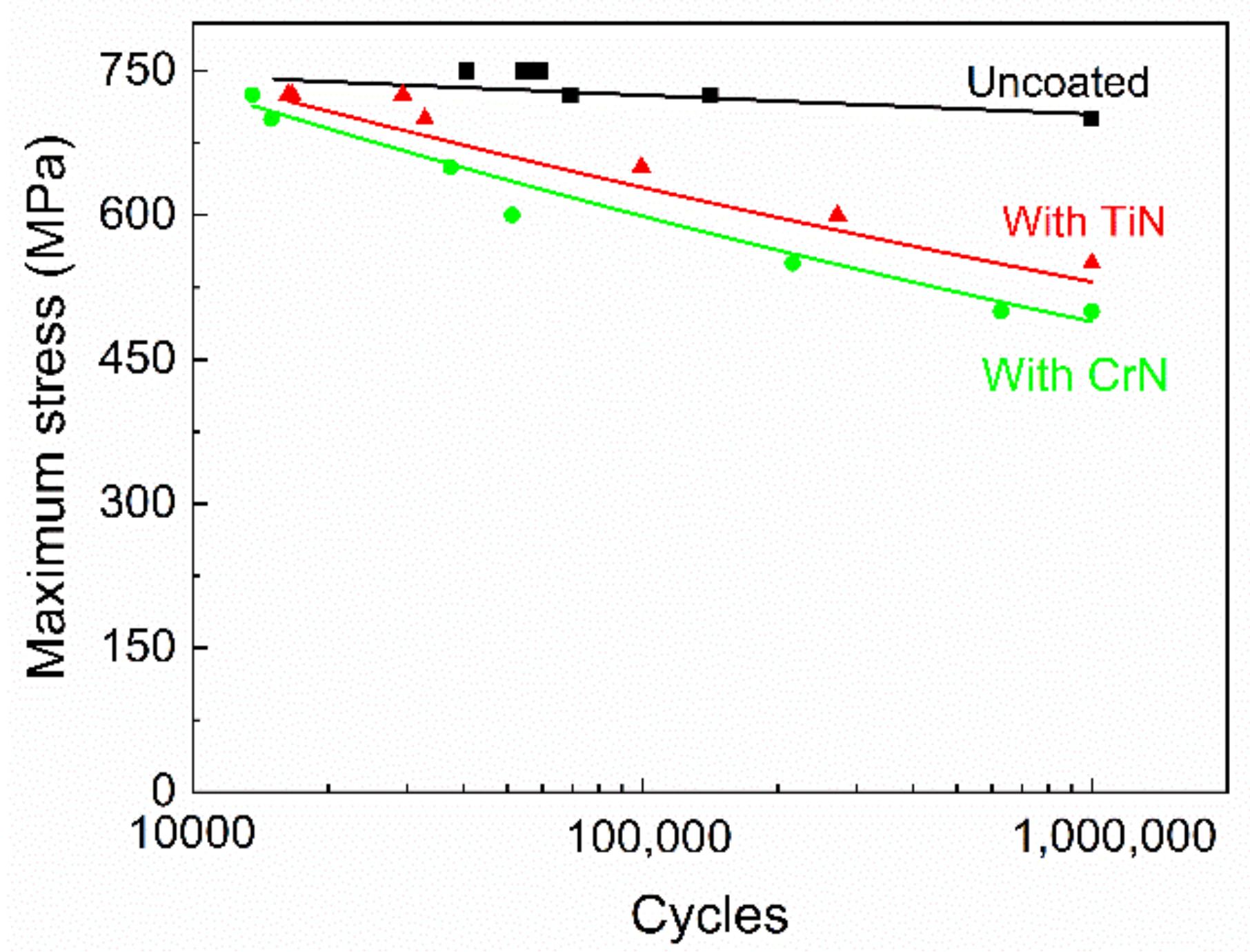

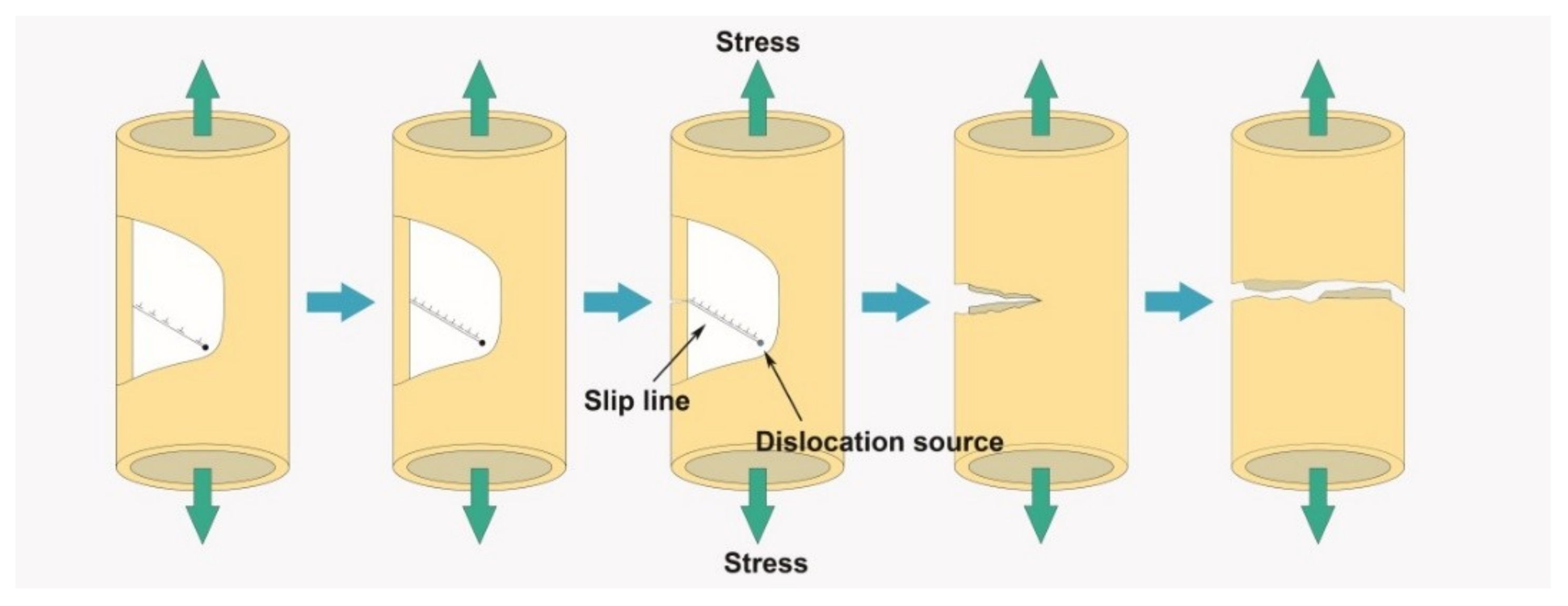

3.3. Fatigue Behavior and Discussion

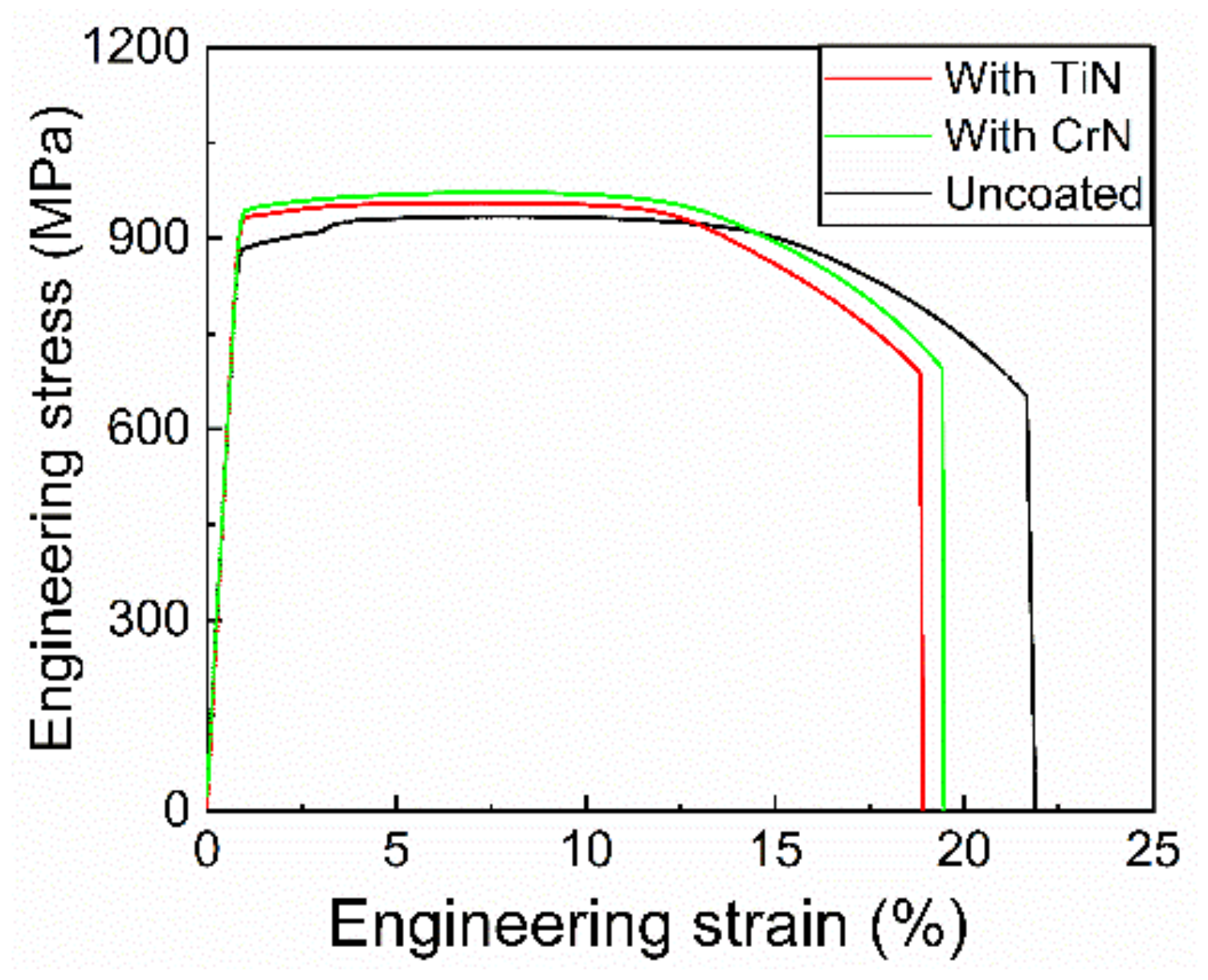

3.4. Mechanical Properties and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shahmir, H.; Langdon, T.G. Using heat treatments, high-pressure torsion and post-deformation annealing to optimize the properties of Ti-6Al-4V alloys. Acta Mater. 2017, 141, 419–426. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.H.; Kou, H.C.; Tang, B.; Fan, J.K.; Chen, Y.; Li, J.S. Stress relaxation induced morphological evolution and texture weakening of α phase in Ti-6Al-4V alloy. Mater. Lett. 2019, 236, 148–151. [Google Scholar] [CrossRef]

- Nabhani, M.; Razavi, R.S.; Barekat, M. Corrosion study of laser cladded Ti-6Al-4V alloy in different corrosive environments. Eng. Fail. Anal. 2019, 97, 234–241. [Google Scholar] [CrossRef]

- Geng, M.; He, G.; Sun, Z.; Chen, J.; Yang, Z.; Li, Y. Corrosion damage mechanism of TiN/ZrN nanoscale multilayer anti-erosion coating. Coatings 2018, 8, 400. [Google Scholar] [CrossRef]

- Chen, J.; Geng, M.; Li, Y.; Yang, Z.; Chai, Y.; He, G. Erosion Resistance and damage mechanism of TiN/ZrN nanoscale multilayer coating. Coatings 2019, 9, 64. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, J.; Meng, X.; Li, J. Evaluation of fatigue resistance of a gradient CrNx coating applied to turbine blades. Mater. Sci. Eng. A 2010, 527, 1436–1443. [Google Scholar] [CrossRef]

- Gelfi, M.; La Vecchia, G.M.; Lecis, N.; Troglio, S. Relationship between through-thickness residual stress of CrN-PVD coatings and fatigue nucleation sites. Surf. Coat. Technol. 2005, 192, 263–268. [Google Scholar] [CrossRef]

- Deng, J.; Wu, F.; Lian, Y.; Xing, Y.; Li, S. Erosion wear of CrN, TiN, CrAlN, and TiAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 35, 10–16. [Google Scholar] [CrossRef]

- Akbari, A.; Riviere, J.P.; Templier, C.; Le Bourhis, E. Structural and mechanical properties of IBAD deposited nanocomposite Ti-Ni-N coatings. Surf. Coat. Technol. 2006, 200, 6298–6302. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, F.; Wang, C.; Yuen, M.-F.; Wang, M.; Qian, T.; Matsumoto, M.; Yan, J. Comparison of tribological and electrochemical properties of TiN, CrN, TiAlN and a-C:H coatings in simulated body fluid. Mater. Chem. Phys. 2015, 158, 74–81. [Google Scholar] [CrossRef]

- Guo, T.; Qiao, L.; Pang, X.; Volinsky, A.A. Brittle film-induced cracking of ductile substrates. Acta Mater. 2015, 99, 273–280. [Google Scholar] [CrossRef]

- Bandyopadhyay, R.; Mello, A.W.; Kapoor, K.; Reinhold, M.P.; Broderick, T.F.; Sangid, M.D. On the crack initiation and heterogeneous deformation of Ti-6Al-4V during high cycle fatigue at high R ratios. J. Mech. Phys. Solids 2019, 129, 61–82. [Google Scholar] [CrossRef]

- Ren, Y.M.; Lin, X.; Guo, P.F.; Yang, H.O.; Tan, H.; Chen, J.; Li, J.; Zhang, Y.Y.; Huang, W.D. Low cycle fatigue properties of Ti-6Al-4V alloy fabricated by high-power laser directed energy deposition: Experimental and prediction. Int. J. Fatigue 2019, 127, 58–73. [Google Scholar] [CrossRef]

- Costa, M.Y.P.; Venditti, M.L.R.; Cioffi, M.O.H.; Voorwald, H.J.C.; Guimarães, V.A.; Ruas, R. Fatigue behavior of PVD coated Ti-6Al-4V alloy. Int. J. Fatigue 2011, 33, 759–765. [Google Scholar] [CrossRef]

- Bai, Y.; Xi, Y.; Gao, K.; Yang, H.; Pang, X.; Yang, X.; Volinsky, A.A. Brittle coating effects on fatigue cracks behavior in Ti alloys. Int. J. Fatigue 2019, 125, 432–439. [Google Scholar] [CrossRef]

- Costa, M.Y.P.; Cioffi, M.O.H.; Venditti, M.L.R.; Voorwald, H.J.C. Fatigue fracture behavior of Ti-6Al-4V PVD coated. Procedia Eng. 2010, 2, 1859–1864. [Google Scholar] [CrossRef]

- Lee, C.M.; Chu, J.P.; Chang, W.Z.; Lee, J.W.; Jang, J.S.C.; Liaw, P.K. Fatigue property improvements of Ti-6Al-4V by thin film coatings of metallic glass and TiN: A comparison study. Thin Solid Films 2014, 561, 33–37. [Google Scholar] [CrossRef]

- AQSIQ. Metallic Materials-tensile Testing–Part 1: Method of Test at Room Temperatures GB/T228.1; Standards Press of China: Beijing, China, 2010. (in Chinese) [Google Scholar]

- AQSIQ. Metallic Materials-Fatigue Testing–Rotating bar bending method GB/T4337; Standards Press of China: Beijing, China, 2015. (in Chinese) [Google Scholar]

- Belov, D.S.; Blinkov, I.V.; Sergevnin, V.S.; Smirnov, N.I.; Volkhonskii, A.O.; Bondarev, A.V.; Lobova, T.A. Abrasive, hydroabrasive, and erosion wear behaviour of nanostructured (Ti,Al)N-Cu and (Ti,Al)N-Ni coatings. Surf. Coat. Technol. 2018, 338, 1–13. [Google Scholar] [CrossRef]

- Sha, C.; Munroe, P.; Zhou, Z.; Xie, Z. Effect of Ni content on the microstructure and mechanical behaviour of CrAlNiN coatings deposited by closed field unbalanced magnetron sputtering. Surf. Coat. Technol. 2019, 357, 445–455. [Google Scholar] [CrossRef]

- Bartosik, M.; Rumeau, C.; Hahn, R.; Zhang, Z.L.; Mayrhofer, P.H. Fracture toughness and structural evolution in the TiAlN system upon annealing. Sci. Rep. 2017, 7, 16476. [Google Scholar] [CrossRef]

- Ibrahim, R.N.; Rahmat, M.A.; Oskouei, R.H.; Singh Raman, R.K. Monolayer TiAlN and multilayer TiAlN/CrN PVD coatings as surface modifiers to mitigate fretting fatigue of AISI P20 steel. Eng. Fract. Mech. 2015, 137, 64–78. [Google Scholar] [CrossRef]

- Pei, L.; Lu, C.; Zhao, X.; Zhang, L.; Cheng, K.; Michal, G.; Tieu, K. Brittle versus ductile behaviour of nanotwinned copper: A molecular dynamics study. Acta Mater. 2015, 89, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Guo, T.; Chen, Y.; Cao, R.; Pang, X.; He, J.; Qiao, L. Cleavage cracking of ductile-metal substrates induced by brittle coating fracture. Acta Mater. 2018, 152, 77–85. [Google Scholar] [CrossRef]

- Fertig, R.S.; Baker, S.P. Dislocation dynamics simulations of dislocation interactions and stresses in thin films. Acta Mater. 2010, 58, 5206–5218. [Google Scholar] [CrossRef]

- Bertin, B.; Durinck, J.; Colin, J. Dislocation emission and crack propagation during thin film buckling on substrate. Int. J. Solids Struct. 2019. [Google Scholar] [CrossRef]

- Guo, T.; He, J.; Pang, X.; Volinsky, A.A.; Su, Y.; Qiao, L. High temperature brittle film adhesion measured from annealing-induced circular blisters. Acta Mater. 2017, 138, 1–9. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, J.Y.; Li, J.; Wang, Y.Q.; Liu, G.; Sun, J. Length-scale-dependent cracking and buckling behaviors of nanostructured Cu/Cr multilayer films on compliant substrates. Acta Mater. 2015, 100, 344–358. [Google Scholar] [CrossRef]

- Huang, C.; Gao, X. Development of a phase field method for modeling brittle and ductile fracture. Comput. Mater. Sci. 2019, 169, 109089. [Google Scholar] [CrossRef]

- Cramer, T.; Wanner, A.; Gumbsch, P. Energy dissipation and path instabilities in dynamic fracture of silicon single crystals. Phys. Rev. Lett. 2000, 85, 788–791. [Google Scholar] [CrossRef]

- Ye, T.; Suo, Z.; Evans, A.G. Thin film cracking and the roles of substrate and interface. Int. J. Solids Struct. 1992, 29, 2639–2648. [Google Scholar] [CrossRef]

| Coating Type | Step | Source | Bias Voltage | Arc Current | Duration | Nitrogen Flow Rate | Temperature |

|---|---|---|---|---|---|---|---|

| TiN coating | Ion implantation | Ti (99.95%) | 10 kV | – | 40 min | – | 400 °C |

| Coating deposition | Ti (99.95%) | 250 V | 115 A | 70 min | 50 sccm | 500 °C |

| Step | Source | Bias Voltage | Arc Current | Duration | Nitrogen Flow Rate | Temperature |

|---|---|---|---|---|---|---|

| Ion implantation | Cr (99.95%) | 8 kV | – | 50 min | – | 300 °C |

| Buffer layer deposition | Cr (99.95%) | 40 V | 120 A | 40 min | – | 400 °C |

| Coating deposition | Cr (99.95%) | 40 V | 120 A | 720 min | 18 sccm | 400 °C |

| Step | Source | Bias Voltage | Arc Current | Duration | Nitrogen Flow Rate | Temperature |

|---|---|---|---|---|---|---|

| Ion implantation | Ti (99.95%) | 10 kV | – | 40 min | – | 400 °C |

| Buffer layer | Ti (99.95%) | 250 V | 110 A | 30 min | – | 600 °C |

| Coating deposition | Ti (99.95%) | 250 V | 110 A | 70 min | 35 sccm | 600 °C |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Chen, J.; He, G.; Yang, G. Fatigue and Mechanical Behavior of Ti-6Al-4V Alloy with CrN and TiN Coating Deposited by Magnetic Filtered Cathodic Vacuum Arc Process. Coatings 2019, 9, 689. https://doi.org/10.3390/coatings9100689

Zhang Z, Chen J, He G, Yang G. Fatigue and Mechanical Behavior of Ti-6Al-4V Alloy with CrN and TiN Coating Deposited by Magnetic Filtered Cathodic Vacuum Arc Process. Coatings. 2019; 9(10):689. https://doi.org/10.3390/coatings9100689

Chicago/Turabian StyleZhang, Zhaolu, Jiao Chen, Guangyu He, and Guanjun Yang. 2019. "Fatigue and Mechanical Behavior of Ti-6Al-4V Alloy with CrN and TiN Coating Deposited by Magnetic Filtered Cathodic Vacuum Arc Process" Coatings 9, no. 10: 689. https://doi.org/10.3390/coatings9100689

APA StyleZhang, Z., Chen, J., He, G., & Yang, G. (2019). Fatigue and Mechanical Behavior of Ti-6Al-4V Alloy with CrN and TiN Coating Deposited by Magnetic Filtered Cathodic Vacuum Arc Process. Coatings, 9(10), 689. https://doi.org/10.3390/coatings9100689