An Investigation of the Polishing Behavior of Calcined Bauxite Aggregate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Methods

2.2.1. PSV Test

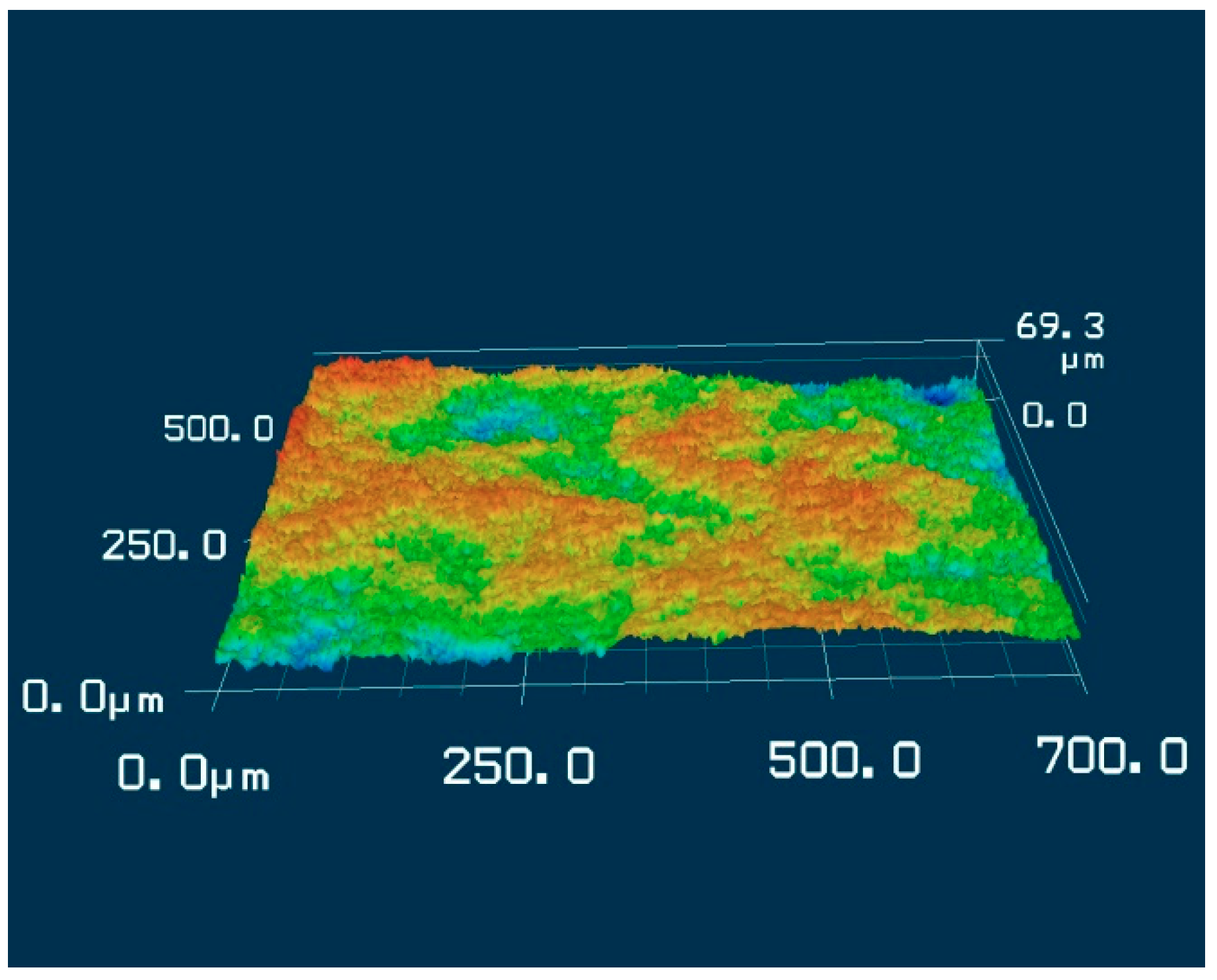

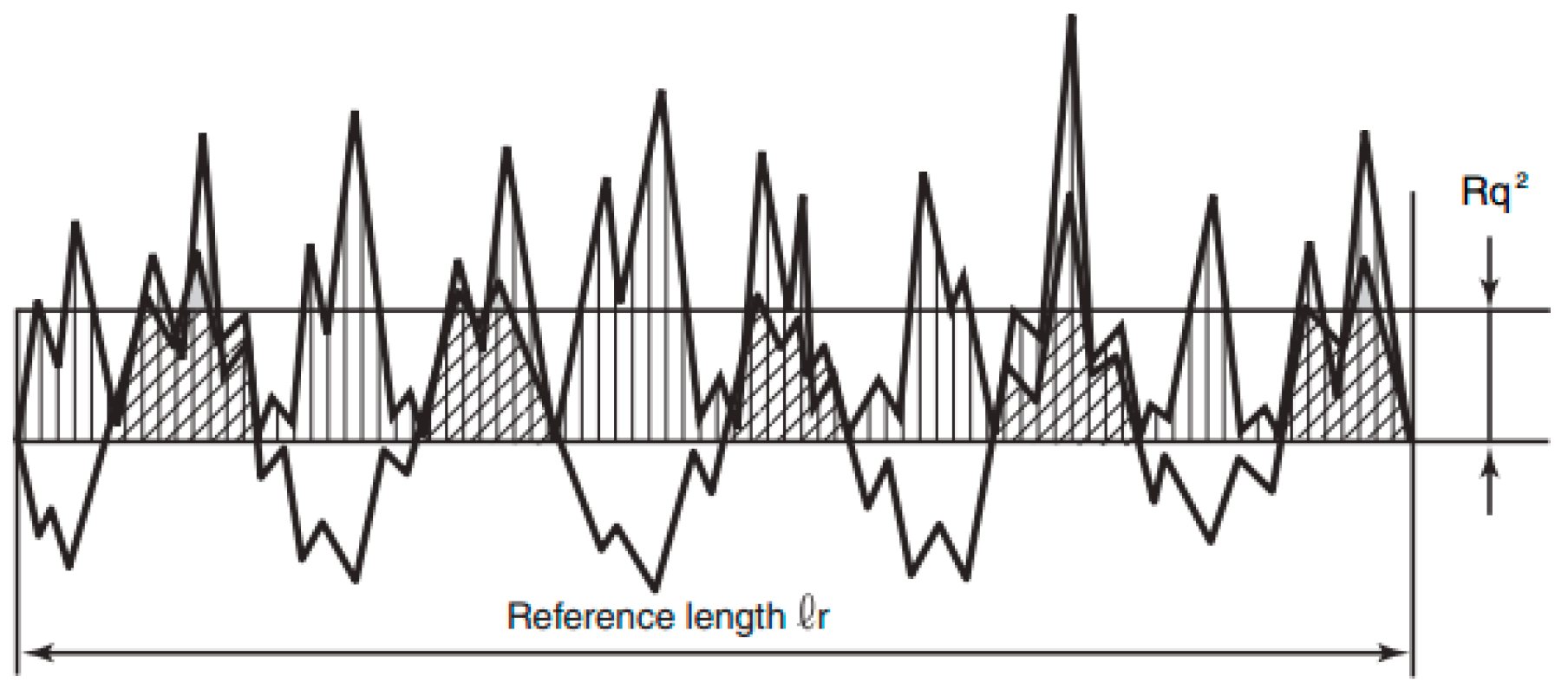

2.2.2. Profile Roughness Measurement

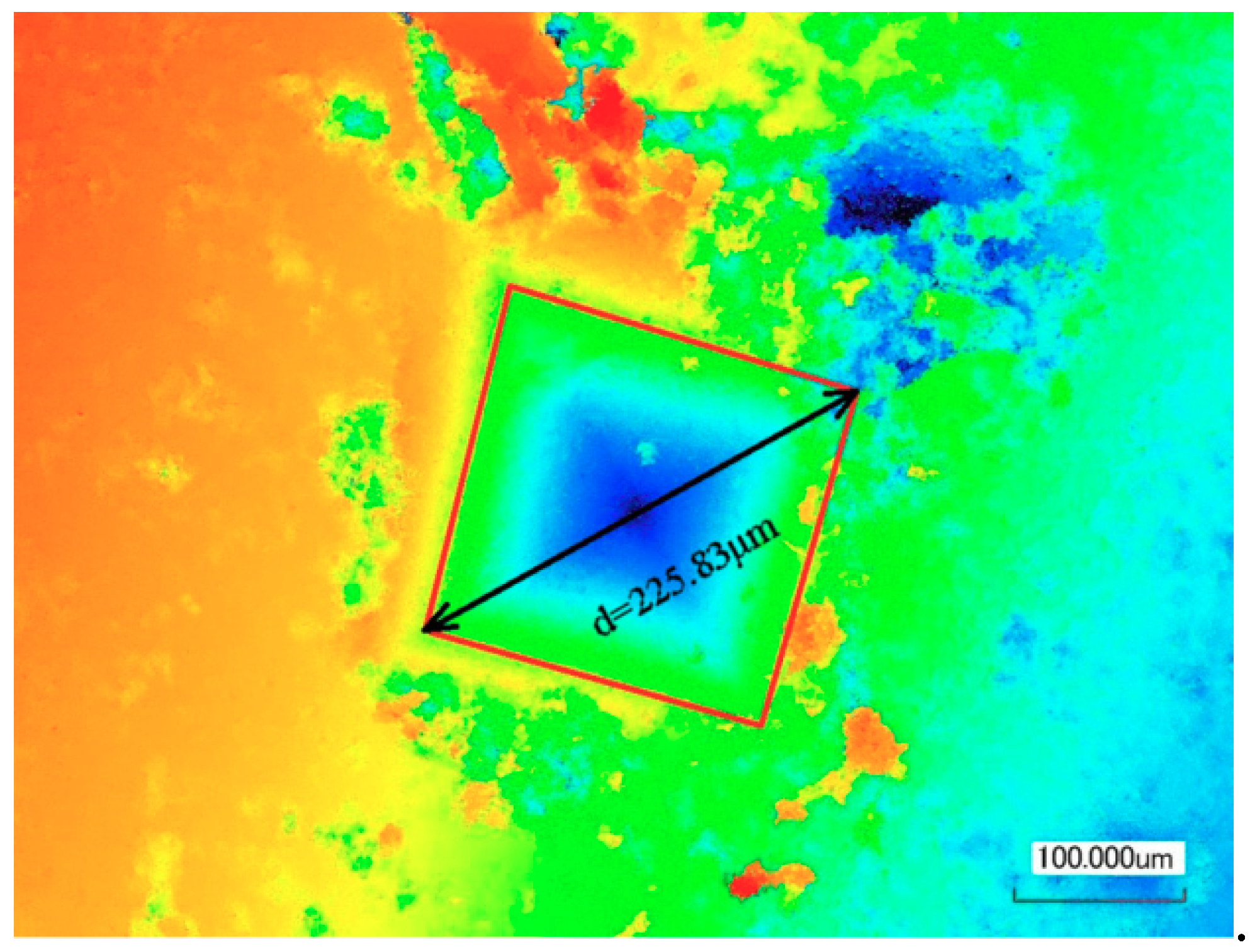

2.2.3. Vickers Hardness Test

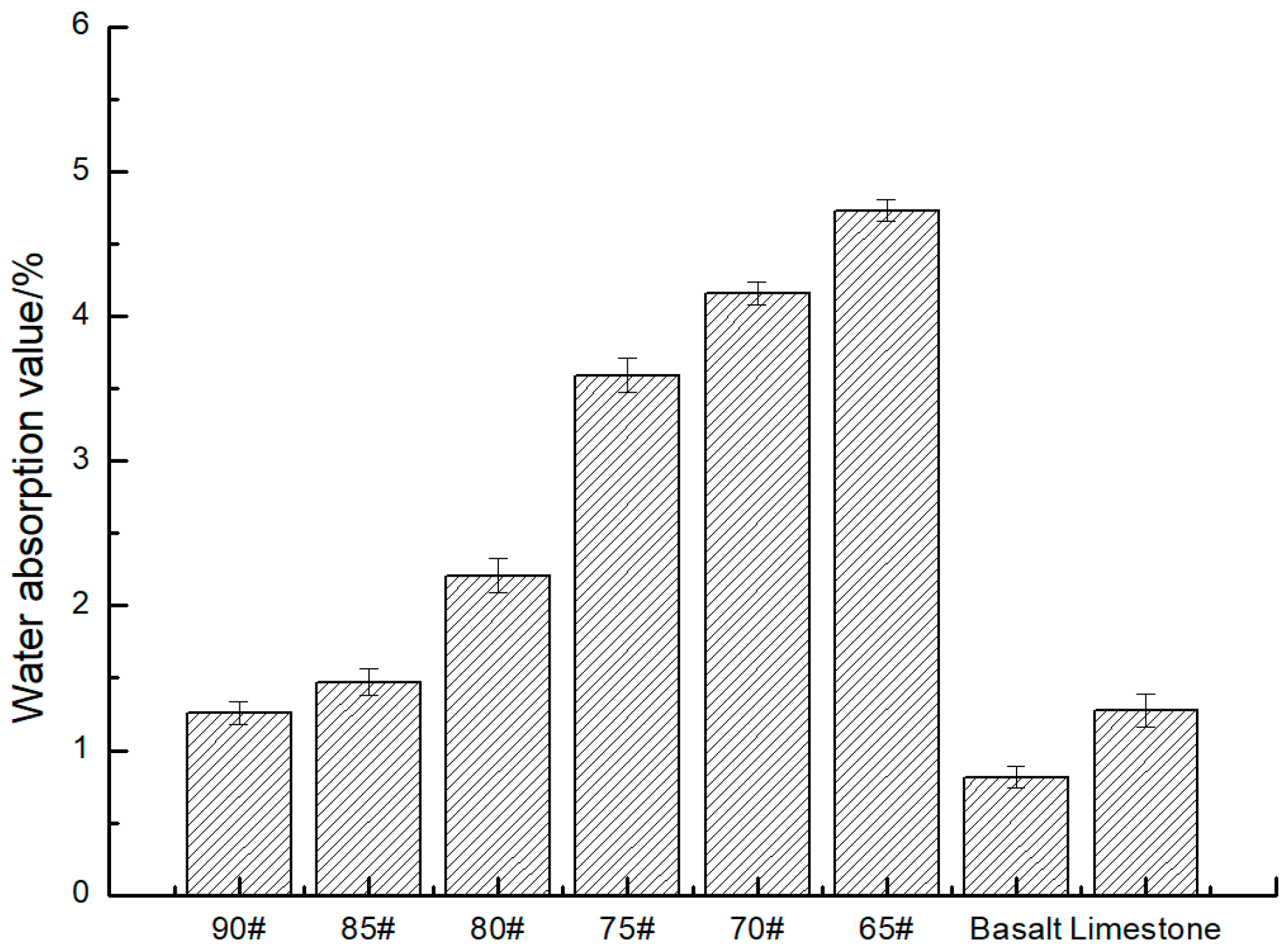

2.2.4. Water Absorption Test

2.2.5. X-ray Diffraction Analyses

2.2.6. Micromorphology

2.2.7. Crushing Value Test

2.2.8. L.A. Abrasion Test

3. Results and Discussion

3.1. Variation of PSV of Different Grades of Calcined Bauxite

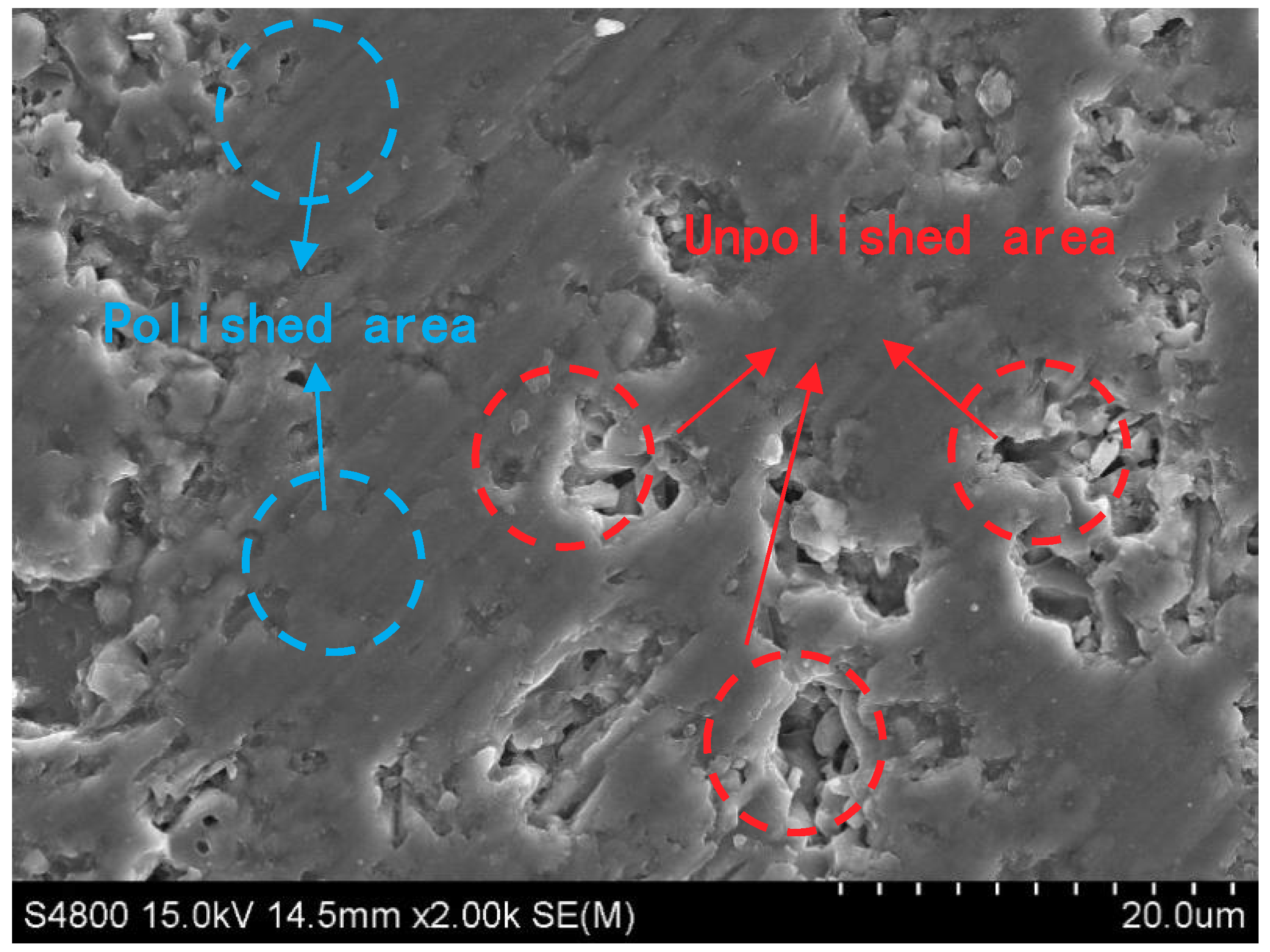

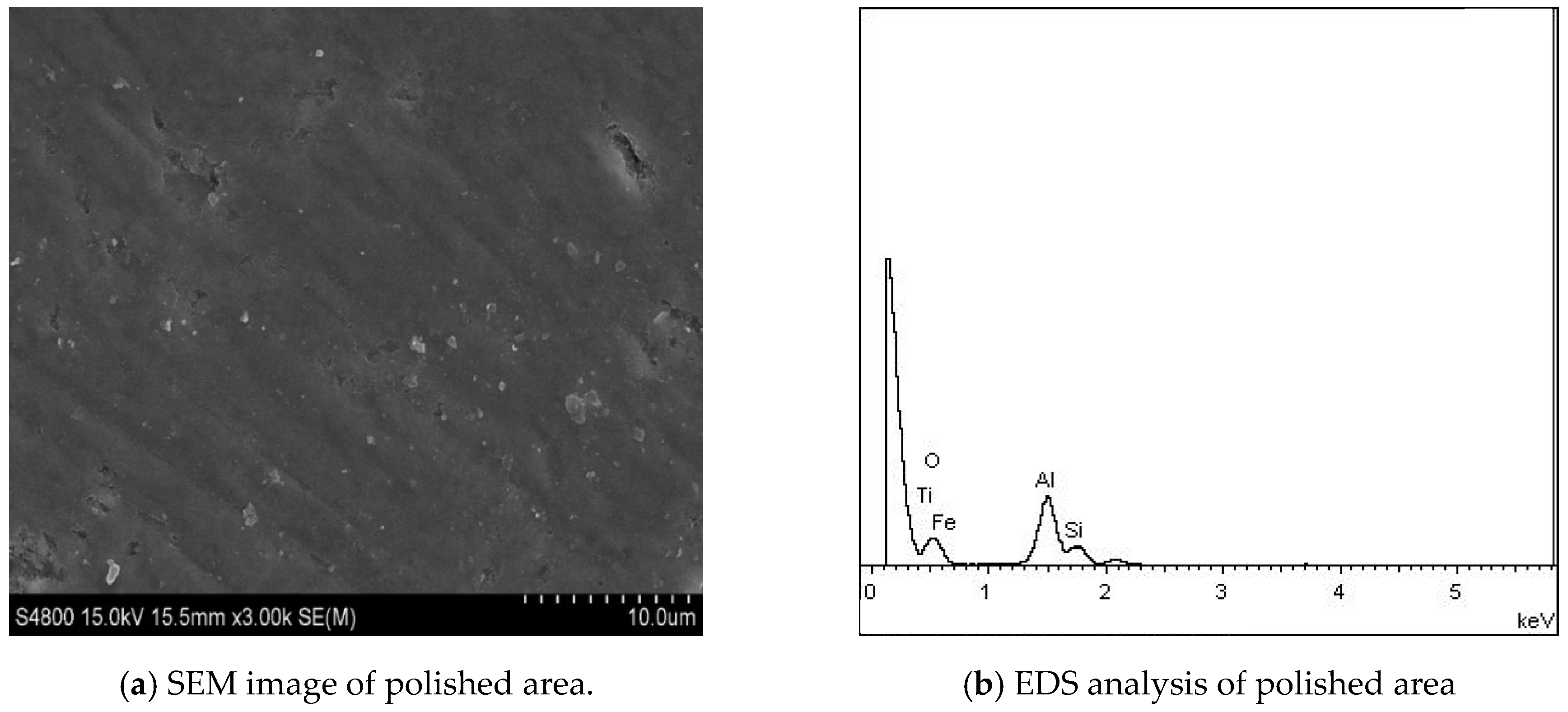

3.2. Polishing Mechanism of Calcined Bauxite Aggregate

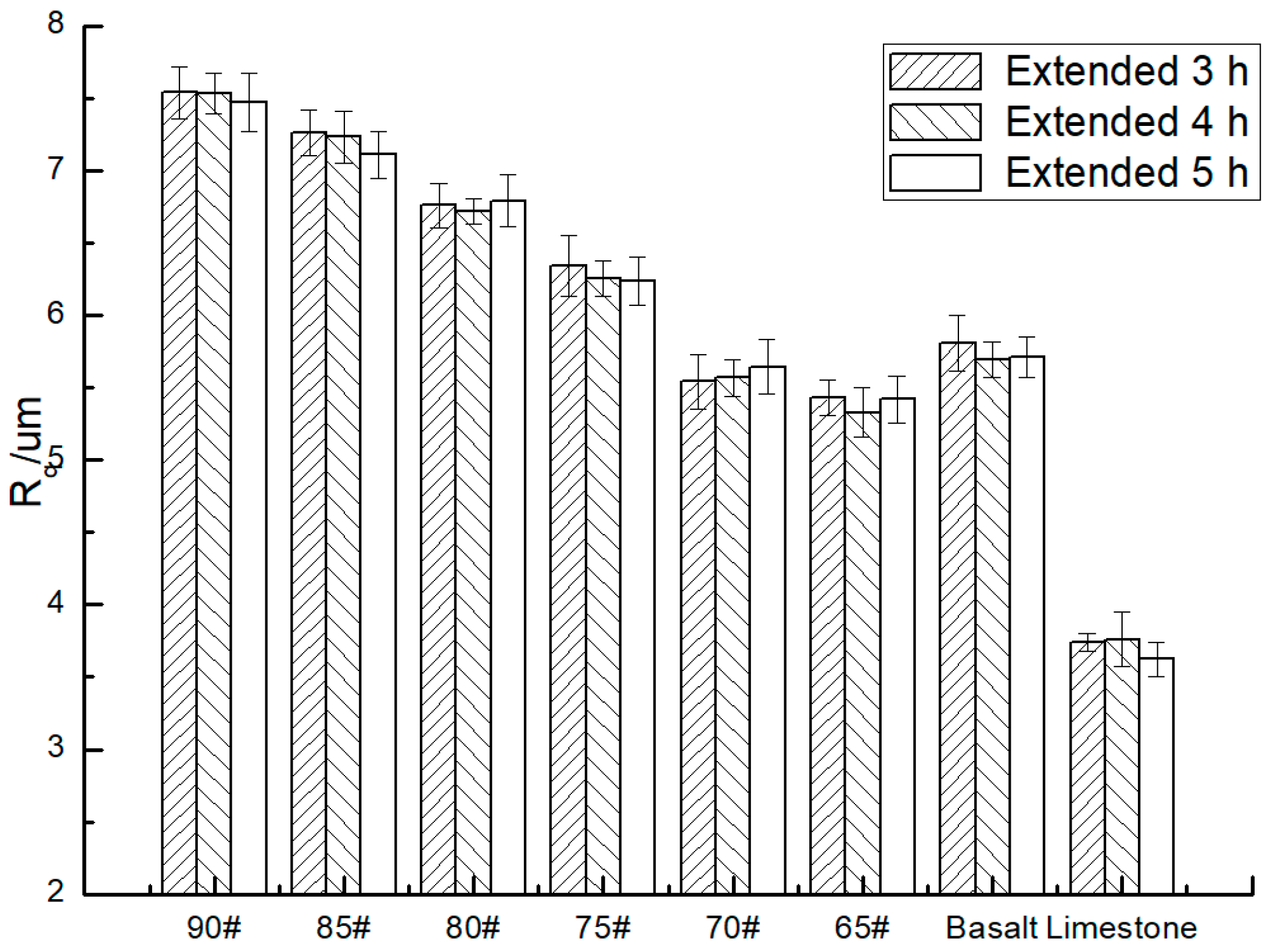

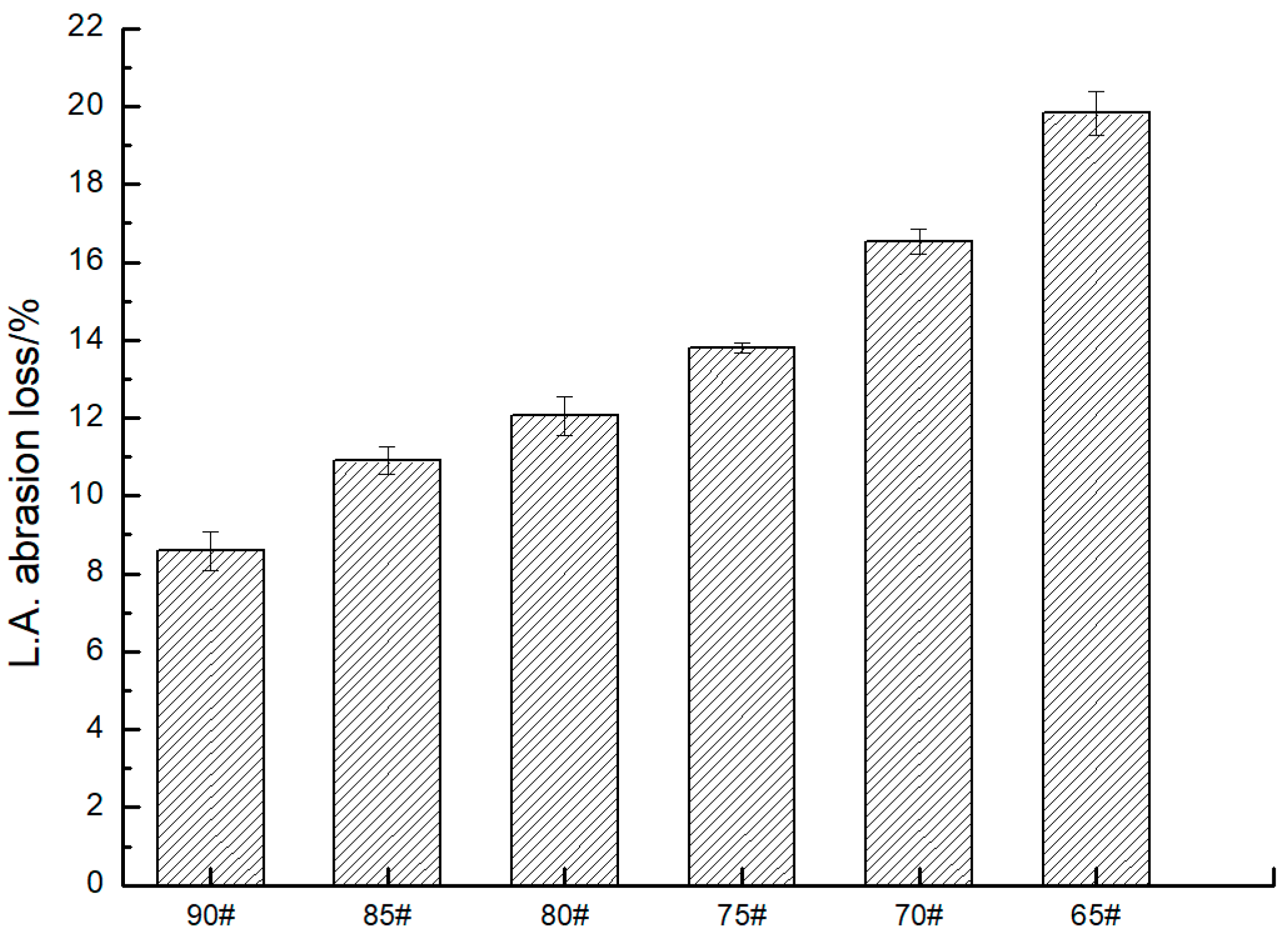

3.3. Effect of C/M on the Polishing Behavior of Calcined Bauxite

4. Conclusions

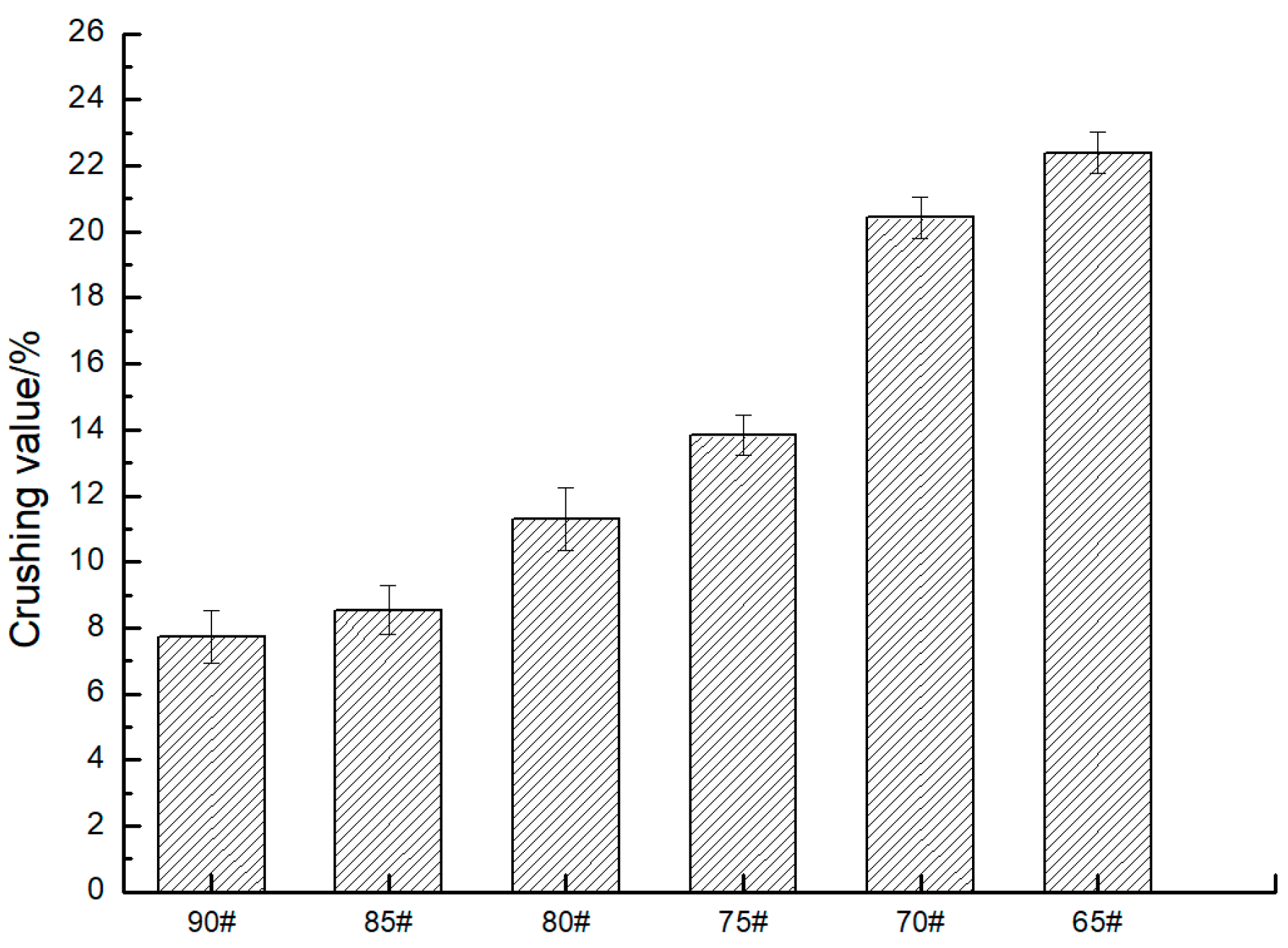

- Calcined bauxite above 75# (C/M ≥ 1) satisfies the requirements of polishing resistance, abrasion resistance, and crushing resistance, so could be used in the ultra-thin friction course. Compared with basalt, 80# calcined bauxite (C/M ≥ 3) has better long-term skid resistance, even though the pavement surface is subject to heavier traffic.

- The higher microhardness of the corundum and the larger hardness difference between the corundum and the mullite are the main reasons for the better long-term skid resistance of high-grade calcined bauxite.

- The microhardness of the aggregate is not only related to the hardness of minerals in the aggregate, but also to the cohesion in the aggregate. Higher cohesion of lower porosity is beneficial for the microhardness of aggregates.

- C/M is a good indicator for evaluating the calcined bauxite aggregate using in pavement surface coatings. There is a power law relationship between C/M and physical properties (PSV, L.A. abrasion loss, and crushing value). Considering the diminishing returns of higher-grade calcined bauxite, it is necessary to select the appropriate C/M of calcined bauxite before use in pavement surface coatings such as ultra-thin friction course, HSFT, or another skid resistance function layer.

Author Contributions

Funding

Conflicts of Interest

References

- Mitchell, M.R.; Link, R.E.; Luce, A.; Mahmoud, E.; Masad, E.; Chowdhury, A. Relationship of Aggregate Microtexture to Asphalt Pavement Skid Resistance. J. Test. Eval. 2007, 35, 578–588. [Google Scholar] [CrossRef]

- Geng, L.; Ma, T.; Zhang, J.H.; Huang, X.M.; Hu, P.S. Research on Performance of a Dense Graded Ultra-Thin Wearing Course Mixture. Appl. Sci. 2017, 7, 800. [Google Scholar] [CrossRef]

- Feng, D.C.; Yi, J.Y.; Wang, D.S. Performance and Thermal Evaluation of Incorporating Waste Ceramic Aggregates in Wearing Layer of Asphalt Pavement. J. Mater. Civ. Eng. 2013, 25, 857–863. [Google Scholar] [CrossRef]

- Sernas, O.; Vorobjovas, V.; Sneideraitiene, L.; Vaitkus, A. Evaluation of Asphalt Mix with Dolomite Aggregates for Wearing Layer. Transp. Res. Proc. 2016, 14, 732–737. [Google Scholar] [CrossRef]

- Dews, S.J.; Bishop, R.J. Factors affecting the skid-resistance of calcined bauxite. J. Chem. Technol. Biotechnol. 2010, 22, 1117–1124. [Google Scholar] [CrossRef]

- Humaira, Z. Performance of Local Aggregate in High Friction Surface Treatment. Master’s Thesis, Science, Kansas State University, Manhattan, KS, USA, 2016. [Google Scholar]

- AASHTO. AASHTO PP 79-14 Standard Practice for High Friction Surface Treatment for Asphalt and Concrete Pavements; AASHTO: Washington, DC, USA, 2018. [Google Scholar]

- Debasish, M.; Debaraj, M.; Ho, P.K. A laboratory scale study on arsenic(V) removal from aqueous medium using calcined bauxite ore. J. Environ. Sci. 2008, 20, 683–689. [Google Scholar] [CrossRef]

- Li, S.; Xiong, R.; Yu, D.; Zhao, G.; Cong, P.; Jiang, Y. Friction Surface Treatment Selection: Aggregate Properties, Surface Characteristics, Alternative Treatments and Safety Effects; Report No. FHWA/IN/JTRP-2017/09; Purdue University: West Lafayette, IN, USA, 2017. [Google Scholar]

- NDRC. Bauxite Clinker; YB/T 5179-2005; NDRC: Beijing, China, 2005.

- Johnson, M.; Bayliss, C. Improving global sustainability in bauxite mining. Alum. Int. Today 2018, 31, 13–14. [Google Scholar]

- Heitzman, M.; Turner, P.; Greer, M. High Friction Surface Treatment Alternative Aggregates Study; NCAT Report 15-04; National Center for Asphalt Technology at Auburn University: Auburn, AL, USA, 2015. [Google Scholar]

- Senga, Y.; Dony, A.; Colin, J.; Hamlat, S.; Berthaud, Y. Study of the skid resistance of blends of coarse aggregates with different polish resistances. Constr. Build. Mater. 2013, 48, 901–907. [Google Scholar] [CrossRef]

- MOT. Test Methods of Aggregate for Highway Engineering; JTG E42; MOT: Beijing, China, 2005.

- Descantes, Y.; Hamard, E. Parameters influencing the polished stone value (PSV) of road surface aggregates. Constr. Build. Mater. 2015, 100, 246–254. [Google Scholar] [CrossRef]

- Guan, B.W.; Wu, J.Y.; Xie, C.; Fang, J.H.; Zheng, H.L.; Chen, H.X. Influence of Macrotexture and Micro texture on the Skid Resistance of Aggregates. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Qian, Z.Y.; Meng, L.J. Study on micro-texture and skid resistance of aggregate during polishing. Front. Struct. Civ. Eng. 2017, 11, 346–352. [Google Scholar] [CrossRef]

- AQSIQ. Technical Specification for Construction of Ultra-Thin Friction Course of Bituminous Pavement; DB33/T 2113; AQSIQ: Hangzhou, China, 2018.

- MOT. Technical Specification for Construction of Highway Asphalt Pavements; JTG-F40; MOT: Beijing, China, 2005.

- Wang, D.; Chen, X.; Xie, X.; Stanjek, H.; Oeser, M.; Steinauer, B. A study of the laboratory polishing behavior of granite as road surfacing aggregate. Constr. Build. Mater. 2015, 89, 25–35. [Google Scholar] [CrossRef]

- Woodward, D.; Friel, S. Predicting the wear of high friction surfacing aggregate. Coatings 2017, 7, 71. [Google Scholar] [CrossRef]

- Ismail, A.; Elmaghraby, M. Effect of limestone composition and microstructure on the strength of aggregates and concretes. Int. Ceram. Rev. 2015, 64, 28–32. [Google Scholar] [CrossRef]

- Wang, D.W.; Chen, X.H.; Oeser, M.; Stanjek, H.; Steinauer, B. Study of micro-texture and skid resistance change of granite slabs during the polishing with the Aachen Polishing Machine. Wear 2014, 318, 1–11. [Google Scholar] [CrossRef]

- Rembis, M. Mineral and textural variability of selected lower silesian basaltoids and its role in controlling the physical and mechanical properties of the aggregates produced. Gospod. Surowcami Miner.-Miner. Resour. Manag. 2011, 27, 29–49. [Google Scholar]

| Grade | Al2O3 | SiO2 | TiO2 | TFe2O3 | MgO | CaO | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| 90# | 90.14 | 3.32 | 4.47 | 1.55 | 0.15 | 0.17 | 0.17 | <0.01 |

| 85# | 84.36 | 9.35 | 3.87 | 1.78 | 0.17 | 0.35 | 0.11 | <0.01 |

| 80# | 81.29 | 12.84 | 3.51 | 1.01 | 0.13 | 0.08 | 0.06 | <0.01 |

| 75# | 75.51 | 19.59 | 3.29 | 1.12 | 0.16 | 0.3 | 0.18 | <0.01 |

| 70# | 70.53 | 25.31 | 2.32 | 1.45 | 0.22 | 0.17 | 0.14 | 0.03 |

| 65# | 66.32 | 29.12 | 2.02 | 1.54 | 0.19 | 0.21 | 0.16 | 0.04 |

| Type | Specific Gravity (g/cm3) | Crushing Value (%) | L.A. Abrasion (%) |

|---|---|---|---|

| Basalt | 2.87 | 11.52 | 12.92 |

| Limestone | 2.68 | 22.69 | 20.13 |

| Standard specification | ≥2.6 | ≤26 | ≤28 |

| Type | Standard Time | Extended 5 h | ||

|---|---|---|---|---|

| Average (BPN) | St. Dev. | Average (BPN) | St. Dev. | |

| 90# | 55.5 | 1.11 | 51.3 | 1.29 |

| 85# | 52.5 | 1.66 | 47.8 | 1.79 |

| 80# | 49.5 | 1.50 | 44.3 | 1.92 |

| 75# | 44.8 | 1.92 | 39.3 | 1.48 |

| 70# | 41.3 | 1.48 | 36.0 | 1.58 |

| 65# | 36.8 | 0.83 | 32.3 | 2.05 |

| Basalt | 44.5 | 0.50 | 39.5 | 1.50 |

| Limestone | 38.5 | 0.50 | 30.8 | 1.76 |

| Type | Average (kg/mm2) | St. Dev. |

|---|---|---|

| 90# | 1721 | 82 |

| 85# | 1350 | 48 |

| 80# | 1248 | 54 |

| 75# | 817 | 69 |

| 70# | 687 | 74 |

| 65# | 458 | 44 |

| Basalt | 683 | 40 |

| Limestone | 397 | 26 |

| Type of Aggregate | Mineral Components | Mohs Hardness |

|---|---|---|

| Calcined bauxite | Corundum | 8.5–9 |

| Mullite | 6–7 | |

| Basalt | Plagioclase | 6–6.5 |

| Augite | 5.5–6 | |

| Olivine | 6.5–7 | |

| Limestone | Calcite | 3–4 |

| Dolomite | 3–4 |

| Grade | Mineral Components (%) | C/M | |

|---|---|---|---|

| Corundum (C) | Mullite (M) | ||

| 90# | 86 | 14 | 6.14 |

| 85# | 78 | 22 | 3.55 |

| 80# | 76 | 24 | 3.17 |

| 75# | 50 | 50 | 1.00 |

| 70# | 36 | 64 | 0.56 |

| 65# | 27 | 73 | 0.37 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Guan, B.; Liu, J.; Wu, J.; Liu, J.; Xie, C.; Xiong, R. An Investigation of the Polishing Behavior of Calcined Bauxite Aggregate. Coatings 2019, 9, 760. https://doi.org/10.3390/coatings9110760

Yang F, Guan B, Liu J, Wu J, Liu J, Xie C, Xiong R. An Investigation of the Polishing Behavior of Calcined Bauxite Aggregate. Coatings. 2019; 9(11):760. https://doi.org/10.3390/coatings9110760

Chicago/Turabian StyleYang, Fa, Bowen Guan, Jingyi Liu, Jiayu Wu, Jianan Liu, Chao Xie, and Rui Xiong. 2019. "An Investigation of the Polishing Behavior of Calcined Bauxite Aggregate" Coatings 9, no. 11: 760. https://doi.org/10.3390/coatings9110760

APA StyleYang, F., Guan, B., Liu, J., Wu, J., Liu, J., Xie, C., & Xiong, R. (2019). An Investigation of the Polishing Behavior of Calcined Bauxite Aggregate. Coatings, 9(11), 760. https://doi.org/10.3390/coatings9110760