Torsional Fretting Wear Behavior of PVD TiCN Coated CuNiAl Blade Bearing in Oil and Artificial Seawater

Abstract

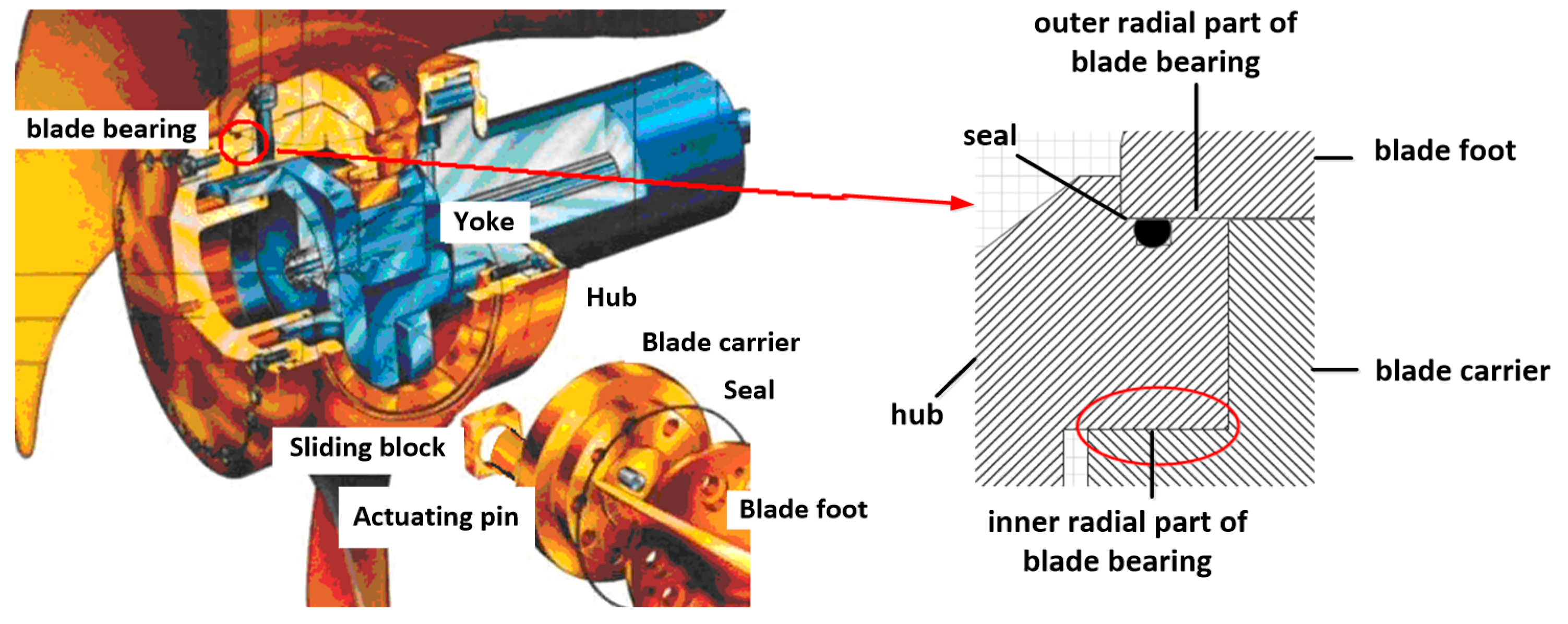

:1. Introduction

2. Experimental Method and Materials

2.1. Specimens

2.2. Fretting Tests

2.3. Analysis Methods

3. Results and Discussion

3.1. Microstructure

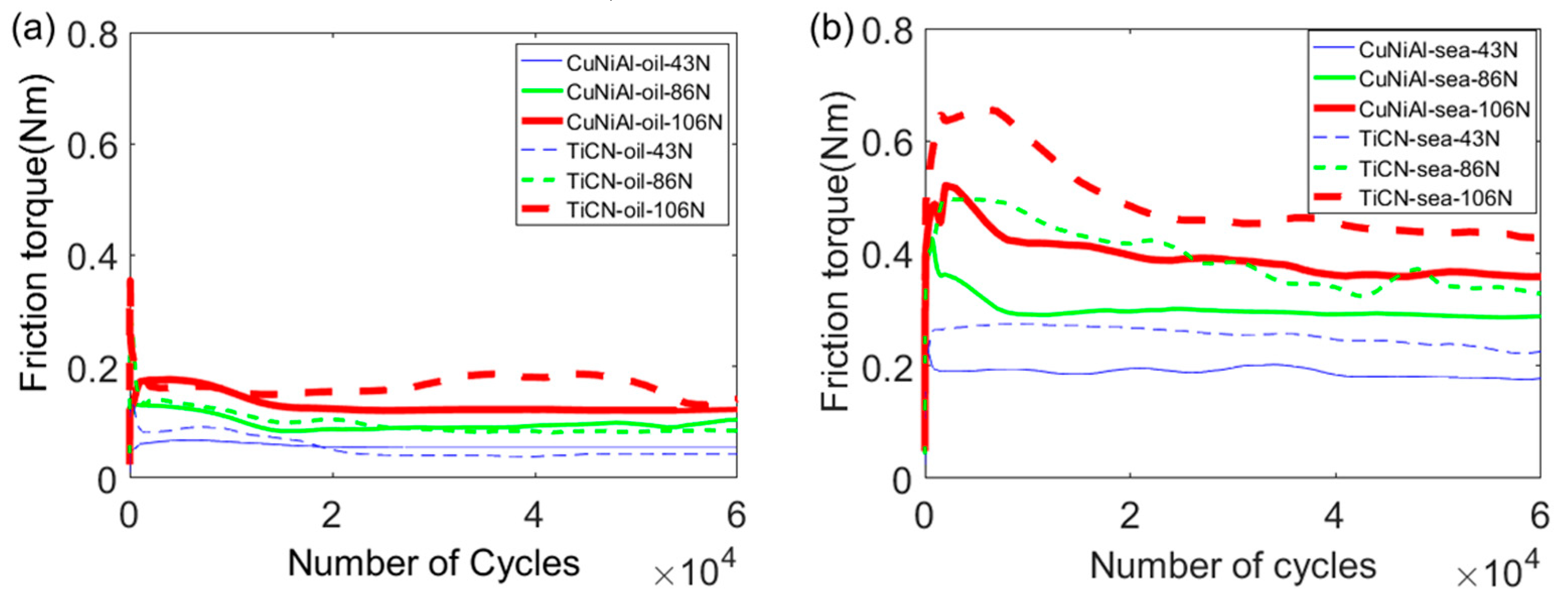

3.2. Friction Behavior

3.3. Wear Behavior

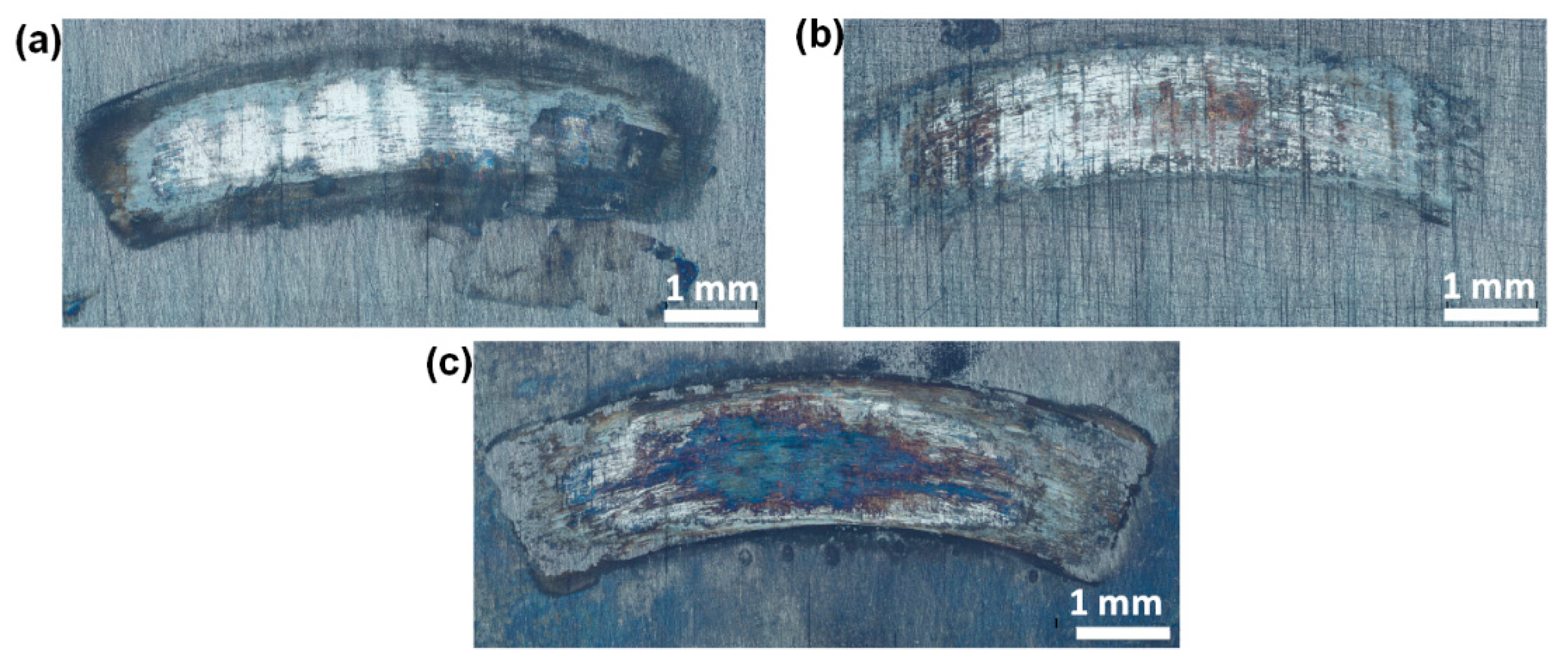

3.4. Wear Scar Observation

3.5. Tribochemical Behaviors

4. Conclusions

- The friction torque of CuNiAl was lower than that of TiCN coating in artificial seawater. This was because the CuNiAl produced more wear debris, which played the role of a solid lubricant to reduce the friction.

- Compared with CuNiAl, the TiCN coating reduced the wear volume by 97.6% and 62.3% in oil and artificial seawater, respectively, which was mainly attributed to an increase in surface hardness.

- In oil, the sulfates and phosphates can prevent adhesion between the friction pair and reduce the friction and wear. The worn surface was characterized by polishing wear. In artificial seawater, the wear mechanism was a combination of cracks, delamination and corrosion wear.

- Through comprehensive research on the friction and wear properties, the PVD TiCN coating was determined to more suitable for the alleviation of fretting wear, which happens under the oil lubrication (such as the blade bearing).

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, H.Y.; Blunt, L.A.; Jiang, X.Q.; Fleming, L.T.; Barrans, S.M. The influence of bone cement type on production of fretting wear on the femoral stem surface: A preliminary study. Clin. Biomech. 2012, 27, 666–672. [Google Scholar] [CrossRef] [PubMed]

- Zhai, W.Z.; Lu, W.L.; Zhang, P.; Wang, J.; Liu, X.J.; Zhou, L.P. Wear-triggered self-healing behavior on the surface of nanocrystalline nickel aluminum bronze/Ti 3 SiC 2 composites. Appl. Surf. Sci. 2018, 436, 1038–1049. [Google Scholar] [CrossRef]

- Gallego, L.; Fulleringer, B.; Deyber, S.; Nelias, D. Multiscale computation of fretting wear at the blade/disk interface. Tribol. Int. 2010, 43, 708–718. [Google Scholar] [CrossRef]

- Zhai, W.Z.; Lu, W.L.; Chen, Y.M.; Liu, X.J.; Zhou, L.P.; Lin, D. Gas-atomized copper-based particles encapsulated in graphene oxide for high wear-resistant composites. Compos. Part. B-Eng. 2019, 157, 131–139. [Google Scholar] [CrossRef]

- Zhai, W.Z.; Lu, W.L.; Liu, X.J.; Zhou, L.P. Nanodiamond as an effective additive in oil to dramatically reduce friction and wear for fretting steel/copper interfaces. Tribol. Int. 2019, 129, 75–81. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Wei, J.; Batchelor, A.W. Some considerations on the mitigation of fretting damage by the application of surface-modification technologies. J. Mater. Process. Tech. 2000, 99, 231–245. [Google Scholar] [CrossRef]

- Polcar, T.; Novák, R.; Široký, P. The tribological characteristics of TiCN coating at elevated temperatures. Wear 2006, 260, 40–49. [Google Scholar] [CrossRef]

- Wu, P.Q.; Chen, H.; Van Stappen, M.; Stals, L.; Celis, J.P. Comparison of fretting wear of uncoated and PVD TiN coated high-speed steel under different testing conditions. Surf. Coat. Tech. 2000, 127, 114–119. [Google Scholar] [CrossRef]

- Sung, J.H.; Kim, T.H.; Kim, S.S. Fretting damage of TiN coated zircaloy-4 tube. Wear 2001, 250, 658–664. [Google Scholar] [CrossRef]

- Larbi, A.B.C.; Tlili, B. Fretting wear of multilayered PVD TiAlCN/TiAlN/TiAl on AISI 4140 steel. Surf. Coat. Tech. 2006, 201, 1511–1518. [Google Scholar] [CrossRef]

- Wu, P.Q.; Mohrbacher, H.; Celis, J.P. The fretting behaviour of PVD TiN coatings in aqueous solutions. Wear 1996, 201, 171–177. [Google Scholar] [CrossRef]

- Zheng, J.F.; Yang, S.; Shen, M.X.; Mo, J.L.; Zhu, M.H. Study on rotational fretting wear under a ball-on concave contact configuration. Wear 2011, 271, 1552–1562. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, W.; Liu, X.; Zhai, W.; Zeng, W. Torsional fretting and torsional sliding wear behaviors of CuNiAl against 42CrMo4 under dry condition. Tribol. Int. 2018, 118, 11–19. [Google Scholar] [CrossRef]

- Godjevac, M. Wear and Friction in a Controllable Pitch Propeller. Doctoral Dissertation, TU Delft, Delft University of Technology, 2010. [Google Scholar]

- Godjevac, M.; Van Beek, T.; Grimmelius, H.T.; Tinga, T.; Stapersma, D. Prediction of fretting motion in a controllable pitch propeller during service. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2009, 223, 541–560. [Google Scholar] [CrossRef]

- Su, Y.L.; Yao, S.H.; Leu, Z.L.; Wei, C.S.; Wu, C.T. Comparison of tribological behavior of three films—TiN, TiCN and CrN—grown by physical vapor deposition. Wear 1997, 213, 165–174. [Google Scholar] [CrossRef]

- Karlsson, L.; Hultman, L.; Sundgren, J.E. Influence of residual stresses on the mechanical properties of TiCxN1–x (x= 0, 0.15, 0.45) thin films deposited by arc evaporation. Thin. Solid. Films. 2000, 371, 167–177. [Google Scholar] [CrossRef]

- Wei, C.; Lin, J.F.; Jiang, T.H.; Ai, C.F. Tribological characteristics of titanium nitride and titanium carbonitride multilayer films: Part II. The effect of coating sequence on tribological properties. Thin. Solid. Films. 2001, 381, 104–118. [Google Scholar] [CrossRef]

- Guu, Y.Y.; Lin, J.F.; Ai, C.F. The tribological characteristics of titanium nitride, titanium carbonitride and titanium carbide coatings. Thin. Solid. Films. 1997, 302, 193–200. [Google Scholar] [CrossRef]

- Surviliene, S.; Bellozor, S.; Kurtinaitiene, M.; Safonov, V.A. Protective properties of the chromium–titanium carbonitride composite coatings. Surf. Coat. Tech. 2004, 176, 193–201. [Google Scholar] [CrossRef]

- Vancoille, E.; Celis, J.P.; Roos, J.R. Dry sliding wear of TiN based ternary PVD coatings. Wear 1993, 165, 41–49. [Google Scholar] [CrossRef]

- Lu, W.L.; Zhang, P.; Liu, X.J.; Zhai, W.Z.; Zhou, M.Z.; Luo, J.; Zeng, W.H.; Jiang, X.Q. Influence of surface topography on torsional fretting wear under flat-on-flat contact. Tribol. Int. 2017, 109, 367–372. [Google Scholar] [CrossRef]

- Lu, W.; Zhai, W.; Zhang, P.; Zhou, M.; Liu, X.; Zhou, L. Effect of different levels of free water in oil on the fretting wear of nickel-aluminum bronze based composites. Wear 2017, 390, 376–384. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, W.L.; Liu, X.J.; Zhou, M.Z.; Zhai, W.Z.; Zhang, G.P.; Zeng, W.H.; Jiang, X.Q. Torsional fretting wear behavior of CuNiAl against 42CrMo4 under flat on flat contact. Wear 2017, 380, 6–14. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, W.L.; Liu, X.J.; Zhai, W.Z.; Zhou, M.Z.; Jiang, X.Q. A comparative study on torsional fretting and torsional sliding wear of CuNiAl under different lubricated conditions. Tribol. Int. 2018, 117, 78–86. [Google Scholar] [CrossRef]

- Zhai, W.Z.; Shi, X.L.; Yang, K.; Huang, Y.C.; Zhou, L.P.; Lu, W.L. Tribological Behaviors of Ni 3 Al Intermetallics with MoO 3 Multilayer Ribbon Crystal Prepared by Spark Plasma Sintering. Acta. Metall. Sin. 2016, 30, 576–584. [Google Scholar] [CrossRef]

- Lan, P.X.; Meyer, J.L.; Vaezian, B.; Polycarpou, A.A. Advanced polymeric coatings for tilting pad bearings with application in the oil and gas industry. Wear. 2016, 354, 10–20. [Google Scholar] [CrossRef]

- Lan, P.X.; Polychronopoulou, K.; Zhang, Y.F.; Polycarpou, A.A. Three-body abrasive wear by (silica) sand of advanced polymeric coatings for tilting pad bearings. Wear 2017, 382, 40–50. [Google Scholar] [CrossRef]

- Lan, P.X.; Meyer, J.L.; Economy, J.; Polycarpou, A.A. Unlubricated Tribological Performance of Aromatic Thermosetting Polyester (ATSP) Coatings Under Different Temperature Conditions. Tribol. Lett. 2016, 61, 10. [Google Scholar] [CrossRef]

- Zhai, W.Z.; Shi, X.L.; Yang, K.; Huang, Y.C.; Zhou, L.P.; Lu, W.L. Mechanical and tribological behaviors of the tribo-layer with nanocrystalline structure during sliding contact: Experiments and model assessment. Compos. Part. B-Eng. 2017, 108, 354–363. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Zhou, F.; Chen, K.M.; Wang, M.L.; Qian, T. Friction and wear properties of TiCN coatings sliding against SiC and steel balls in air and water. Thin. Solid. Films. 2011, 519, 4830–4841. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.X.; Li, J.L.; Li, H.; Wu, X.D.; Chen, J.M. Tribological behaviours of PVD TiN and TiCN coatings in artificial seawater. Surf. Coat. Tech. 2013, 226, 40–50. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Neville, A.; Morina, A.; Haque, T.; Voong, M. Compatibility between tribological surfaces and lubricant additives—how friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 2007, 40, 1680–1695. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Bigerelle, M.; Mathia, T.G.; Dubois, A.; Dubar, L. Dynamic evolution of interface roughness during friction and wear processes. Scanning 2014, 36, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Shi, W.J.; Luo, X.H.; Zhang, Z.T.; Liu, Y.S.; Lu, W.L. Influence of external load on the frictional characteristics of rotary model using a molecular dynamics approach. Comp. Mater. Sci. 2016, 122, 201–209. [Google Scholar] [CrossRef]

- Lu, W.L.; Zhang, G.P.; Liu, X.J.; Zhou, L.P.; Chen, L.Z.; Jiang, X.Q. Prediction of Surface Topography at the End of Sliding Running-In Wear Based on Areal Surface Parameters. Tribol. T. 2014, 57, 553–560. [Google Scholar] [CrossRef]

- Kubiak, K.J.; Mathia, T.G.; Fouvry, S. Interface roughness effect on friction map under fretting contact conditions. Tribol. Int. 2010, 43, 1500–1507. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Luo, X.; Sun, Y. Torsional Fretting Wear Properties of Thermal Oxidation-Treated Ti3SiC2 Coatings. Coatings 2018, 8, 324. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, X.J.; Lu, W.L.; Zhai, W.Z.; Zhou, M.Z.; Wang, J. Fretting wear behavior of CuNiAl against 42CrMo4 under different lubrication conditions. Tribol. Int. 2018, 117, 59–67. [Google Scholar] [CrossRef]

- Holmberg, K.; Matthews, A.; Ronkainen, H. Coatings tribology—contact mechanisms and surface design. Tribol. Int. 1998, 31, 107–120. [Google Scholar] [CrossRef]

- Ding, H.Y.; Dai, Z.D.; Zhou, F.; Zhou, G.H. Sliding friction and wear behavior of TC11 in aqueous condition. Wear 2007, 263, 117–124. [Google Scholar] [CrossRef]

- Jia, Z.F.; Chen, T.D.; Wang, J.; Ni, J.J.; Li, H.Y.; Shao, X. Synthesis, characterization and tribological properties of Cu/reduced graphene oxide composites. Tribol. Int. 2015, 88, 17–24. [Google Scholar] [CrossRef]

- Liu, X.Q.; Zhou, F.; Liang, Y.M.; Liu, W.M. Tribological performance of phosphonium based ionic liquids for an aluminum-on-steel system and opinions on lubrication mechanism. Wear 2006, 261, 1174–1179. [Google Scholar] [CrossRef]

- Piao, H.; McIntyre, N.S. Oxidation studies of Au-Al alloys using x-ray photoelectron spectroscopy (XPS) and x-ray absorption near-edge structure (XANES). Surf. Interface. Anal. 2010, 31, 874–880. [Google Scholar] [CrossRef]

- Cho, M.H.; Bahadur, S.; Pogosian, A.K. Friction and wear studies using Taguchi method on polyphenylene sulfide filled with a complex mixture of MoS2, Al2O3 and other compounds. Wear 2005, 258, 1825–1835. [Google Scholar] [CrossRef]

- Squarcialupi, M.C.; Bernardini, G.P.; Faso, V.; Atrei, A.; Rovida, G. Characterisation by XPS of the corrosion patina formed on bronze surfaces. J. Cult. Herit. 2002, 3, 199–204. [Google Scholar] [CrossRef]

- Cui, G.J.; Bi, Q.L.; Zhu, S.Y.; Yang, J.; Liu, W.M. Tribological properties of bronze–graphite composites under sea water condition. Tribol. Int. 2012, 53, 76–86. [Google Scholar] [CrossRef]

- Li, W.S.; Wang, Z.P.; Lu, Y.; Yuan, L.H. Corrosion wear behavior of Al-bronzes in 3.5% NaCl solution. J. Mater. Eng. Perform. 2006, 15, 102–110. [Google Scholar] [CrossRef]

- Cui, G.J.; Bi, Q.L.; Yang, J.; Liu, W.M. The bronze–silver self-lubricating composite under sea water condition. Tribol. Int. 2013, 60, 83–92. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Wang, J. Torsional Fretting Wear Behavior of PVD TiCN Coated CuNiAl Blade Bearing in Oil and Artificial Seawater. Coatings 2019, 9, 140. https://doi.org/10.3390/coatings9020140

Zhang P, Wang J. Torsional Fretting Wear Behavior of PVD TiCN Coated CuNiAl Blade Bearing in Oil and Artificial Seawater. Coatings. 2019; 9(2):140. https://doi.org/10.3390/coatings9020140

Chicago/Turabian StyleZhang, Po, and Jian Wang. 2019. "Torsional Fretting Wear Behavior of PVD TiCN Coated CuNiAl Blade Bearing in Oil and Artificial Seawater" Coatings 9, no. 2: 140. https://doi.org/10.3390/coatings9020140

APA StyleZhang, P., & Wang, J. (2019). Torsional Fretting Wear Behavior of PVD TiCN Coated CuNiAl Blade Bearing in Oil and Artificial Seawater. Coatings, 9(2), 140. https://doi.org/10.3390/coatings9020140