Effect of Different ZrN Addition on Microstructure and Wear Properties of Titanium Based Coatings by Laser Cladding Technique

Abstract

:1. Introduction

2. Materials and Methods

3. Results

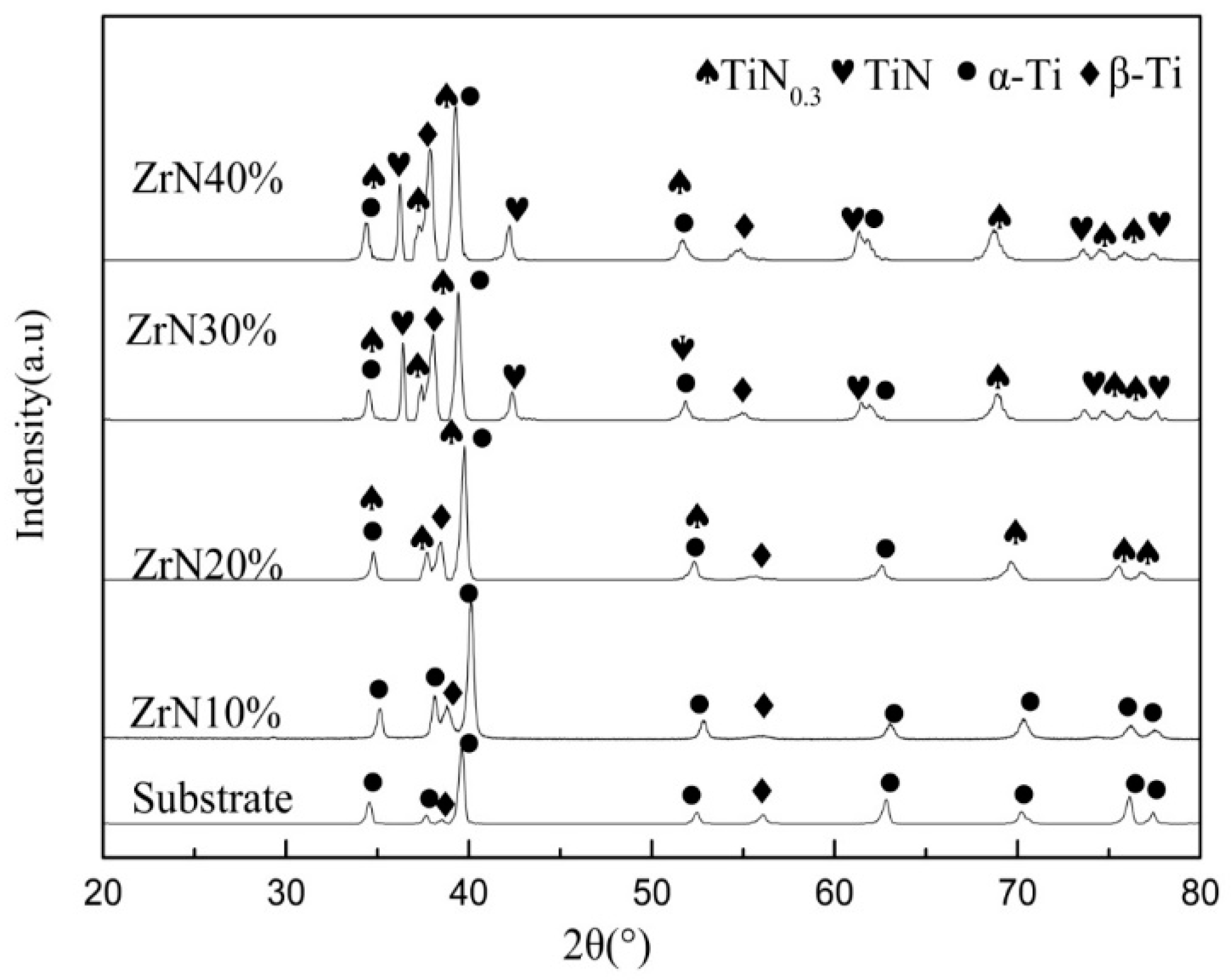

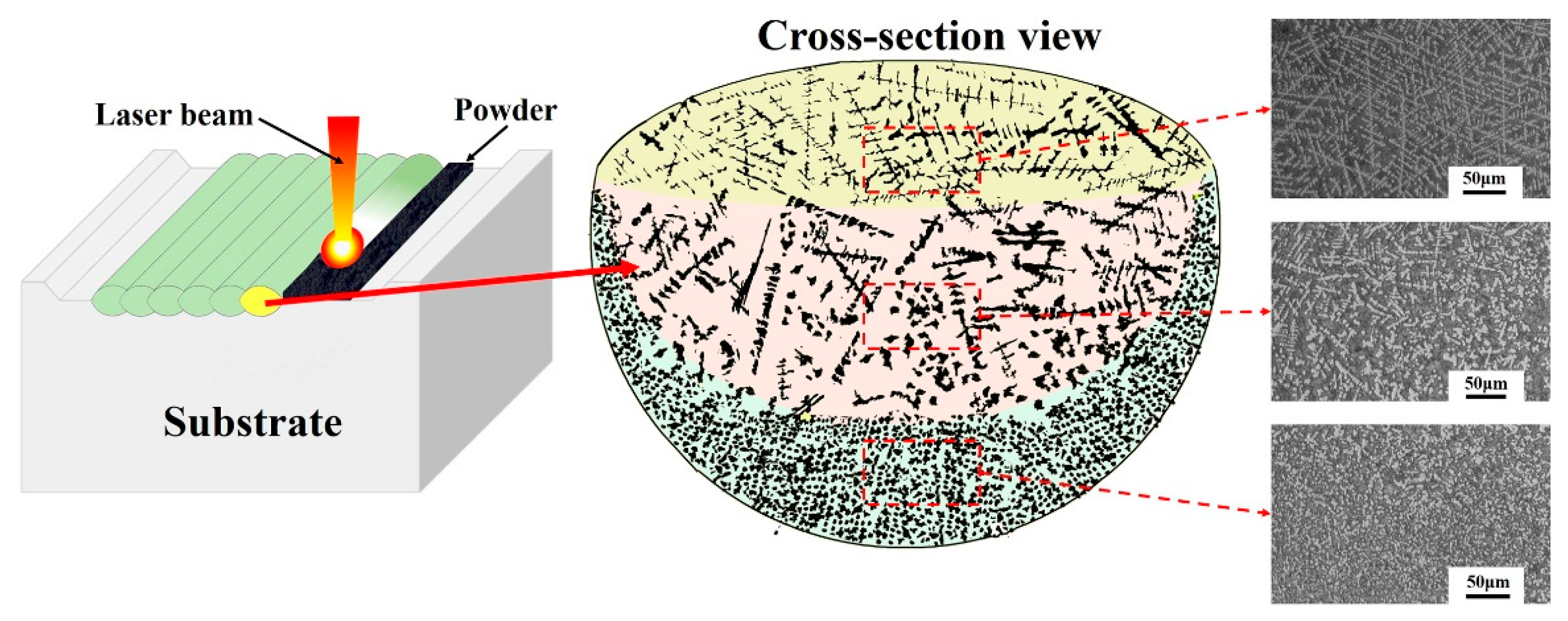

3.1. Microstructures and Compositions

3.2. Microhardness and Wear Resistance

4. Discussion

4.1. Microstructure Evolution at Different ZrN Additions

4.2. Effect of Different ZrN Addition on the Friction and Wear Properties of Coatings

5. Conclusions

- New precipitation such as TiN0.3 and TiN are in situ precipitated in the coating when the addition of ZrN exceeds 20 wt.%. TiNx based precipitates have dendritic morphology at the top of the coating, and which change to a spherical shape at the bottom of the molten pool.

- As the ZrN contents increase, the hardness of the coating increases significantly. The increase in microhardness of the coating is mainly due to the in situ formation of TiNx reinforcing phase and solid solution strengthening of elements such as Zr and N.

- The enhanced microhardness of the coatings could improve the wear properties, and high amount of ZrN addition (20 wt.% ZrN) will lead to embrittlement of the coatings; then, their wear resistance degrades.

Author Contributions

Funding

Conflicts of Interest

References

- Christoph, L.; Manfred, P. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Köln, Germany, 2003. [Google Scholar]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Bruni, S.; Martinesi, M.; Stio, M.; Treves, C.; Bacci, T.; Borgioli, F. Effects of surface treatment of Ti–6Al–4V titanium alloy on biocompatibility in cultured human umbilical vein endothelial cells. Acta Biomater. 2005, 1, 223–234. [Google Scholar] [CrossRef] [PubMed]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.Z.; Zhang, Y.K.; Luo, K.Y.; Zhong, J.W.; Cui, C.Y.; Kong, D.J.; Guan, H.B.; Qian, X.M. Effects of different shocked paths on fatigue property of 7050-T7451 aluminum alloy during two-sided laser shock processing. Mater. Des. 2011, 32, 480–486. [Google Scholar] [CrossRef]

- Saleh, A.F.; Abboud, J.H.; Benyounis, K.Y. Surface carburizing of Ti–6Al–4V alloy by laser melting. Opt. Lasers Eng. 2010, 48, 257–267. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Höche, D.; Kaspar, J.; Schaaf, P. Laser nitriding and carburization of materials. In Laser Surface Engineering; Woodhead Publishing: Sawston, Cambridge, UK, 2014; pp. 33–58. [Google Scholar]

- Liu, J.; Li, L. Study on cross-section clad profile in coaxial single-pass cladding with a low-power laser. Opt. Laser Technol. 2005, 37, 478–482. [Google Scholar] [CrossRef]

- Wu, P.; Du, H.M.; Chen, X.L.; Li, Z.Q.; Bai, H.L.; Jiang, E.Y. Influence of WC particle behavior on the wear resistance properties of Ni–WC composite coatings. Wear 2004, 257, 142–147. [Google Scholar] [CrossRef]

- Savalani, M.M.; Ng, C.C.; Li, Q.H.; Man, H.C. In situ formation of titanium carbide using titanium and carbon-nanotube powders by laser cladding. Appl. Surf. Sci. 2012, 258, 3173–3177. [Google Scholar] [CrossRef]

- Lifang, C.; Zhang, Y.; Likai, S. Microstructure and formation mechanism of titanium matrix composites coating on Ti-6Al-4V by laser cladding. Rare Met. 2007, 26, 342–346. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, Z.; Li, Y.; Zhu, W.; Wen, X.; Wang, X. Microstructure and hardness characteristic of in-situ synthesized TiB coating by laser cladding on TC4 titanium alloy. Infrared Laser Eng. 2012, 41, 2694–2698. (In Chinese) [Google Scholar]

- Shishkovsky, I.; Smurov, I. Titanium base functional graded coating via 3D laser cladding. Mater. Lett. 2012, 73, 32–35. [Google Scholar] [CrossRef]

- Tavares, C.J.; Rebouta, L.; Almeida, B.; Sousa, J.B.E. Structural characterization of multilayered sputtered TiN/ZrN coatings. Surf. Coat. Technol. 1998, 100–101, 65–71. [Google Scholar] [CrossRef]

- Lin, Y.C.; Lin, Y.C.; Chen, Y.C. Evolution of the microstructure and tribological performance of Ti–6Al–4V cladding with TiN powder. Mater. Des. (1980–2015) 2012, 36, 584–589. [Google Scholar] [CrossRef]

- Deng, J.; Liu, J.; Zhao, J.; Song, W. Wear mechanisms of PVD ZrN coated tools in machining. Int. J. Refract. Met. Hard Mater. 2008, 26, 164–172. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Floroian, L.; Craciun, D.; Socol, G.; Dorcioman, G.; Socol, M.; Badea, M.; Craciun, V. Titanium implants’ surface functionalization by pulsed laser deposition of TiN, ZrC and ZrN hard films. Appl. Surf. Sci. 2017, 417, 175–182. [Google Scholar] [CrossRef]

- Dias, F.C.; Silva, C.R.; Muterlle, P.V.; Henriques, V.A.; Araújo, J.A. Wear resistance of Ti-40Zr alloy with TiN and ZrN multilayer coatings. Adv. Mater. Res. 2014, 936, 1056–1065. [Google Scholar] [CrossRef]

- Yang, C.; Cheng, X.; Tang, H.; Tian, X.; Liu, D. Influence of microstructures and wear behaviors of the microalloyed coatings on TC11 alloy surface using laser cladding technique. Surf. Coat. Technol. 2018, 337, 97–103. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Jiang, Y.; Zhou, R. Microstructure and high temperature oxidation resistance of in-situ synthesized TiN/Ti3Al intermetallic composite coatings on Ti6Al4V alloy by laser cladding process. J. Alloy. Compd. 2016, 670, 268–274. [Google Scholar] [CrossRef]

- Nie, G.Z.; Zhong, C.L.; Luo, L.E.; Zhou, R.L.; Liu, Q. Microstructure and oxidation resistance of TiN coatings. Adv. Mater. Res. 2013, 750–752, 2092–2095. [Google Scholar] [CrossRef]

- Yu, S.; Zeng, Q.; Oganov, A.R.; Frapper, G.; Zhang, L. Phase stability, chemical bonding and mechanical properties of titanium nitrides: A first-principles study. Phys. Chem. Chem. Phys. 2015, 17, 11763–11769. [Google Scholar] [CrossRef]

- Sridar, S.; Kumar, R.; Kumar, K.C.H. Thermodynamic modelling of Ti-Zr-N system. Calphad 2017, 56, 102–107. [Google Scholar] [CrossRef]

- Gurrappa, I.; Manova, D.; Gerlach, J.W.; Mändl, S.; Rauschenbach, B. Influence of nitrogen implantation on the high temperature oxidation of titanium-base alloys. Surf. Coat. Technol. 2006, 201, 3536–3546. [Google Scholar] [CrossRef]

- Bai, X.; Colegrove, P.; Ding, J.; Zhou, X.; Diao, C.; Bridgeman, P.; Roman Hönnige, J.; Zhang, H.; Williams, S. Numerical analysis of heat transfer and fluid flow in multilayer deposition of PAW-based wire and arc additive manufacturing. Int. J. Heat Mass Transfer 2018, 124, 504–516. [Google Scholar] [CrossRef]

- Wang, Z.J.; Luo, S.; Song, H.W.; Deng, W.D.; Li, W.Y. Simulation of microstructure during laser rapid forming solidification based on cellular automaton. Math. Prob. Eng. 2014, 2014, 627528. [Google Scholar] [CrossRef]

- David, S.A.; Vitek, J.M. Correlation between solidification parameters and weld microstructures. Int. Mater. Rev. 1989, 34, 213–245. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elastic moduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Suresh, S.; Giannakopoulos, A.E. A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 1998, 46, 5755–5767. [Google Scholar] [CrossRef]

| Position | Zr wt.% | Ti wt.% | Al wt.% |

|---|---|---|---|

| A | 22.10 | 77.54 | 0.36 |

| B | 30.65 | 68.64 | 0.71 |

| TC11Titaniumalloy matrix | 11.61 | 82.32 | 6.07 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, S.; Wang, J.; Yu, M.; Tang, H. Effect of Different ZrN Addition on Microstructure and Wear Properties of Titanium Based Coatings by Laser Cladding Technique. Coatings 2019, 9, 261. https://doi.org/10.3390/coatings9040261

Li X, Liu S, Wang J, Yu M, Tang H. Effect of Different ZrN Addition on Microstructure and Wear Properties of Titanium Based Coatings by Laser Cladding Technique. Coatings. 2019; 9(4):261. https://doi.org/10.3390/coatings9040261

Chicago/Turabian StyleLi, Xiaodong, Shasha Liu, Jiawei Wang, Mengxiao Yu, and Haibo Tang. 2019. "Effect of Different ZrN Addition on Microstructure and Wear Properties of Titanium Based Coatings by Laser Cladding Technique" Coatings 9, no. 4: 261. https://doi.org/10.3390/coatings9040261

APA StyleLi, X., Liu, S., Wang, J., Yu, M., & Tang, H. (2019). Effect of Different ZrN Addition on Microstructure and Wear Properties of Titanium Based Coatings by Laser Cladding Technique. Coatings, 9(4), 261. https://doi.org/10.3390/coatings9040261