Niobium-Containing DLC Coatings on Various Substrates for Strain Gauges

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

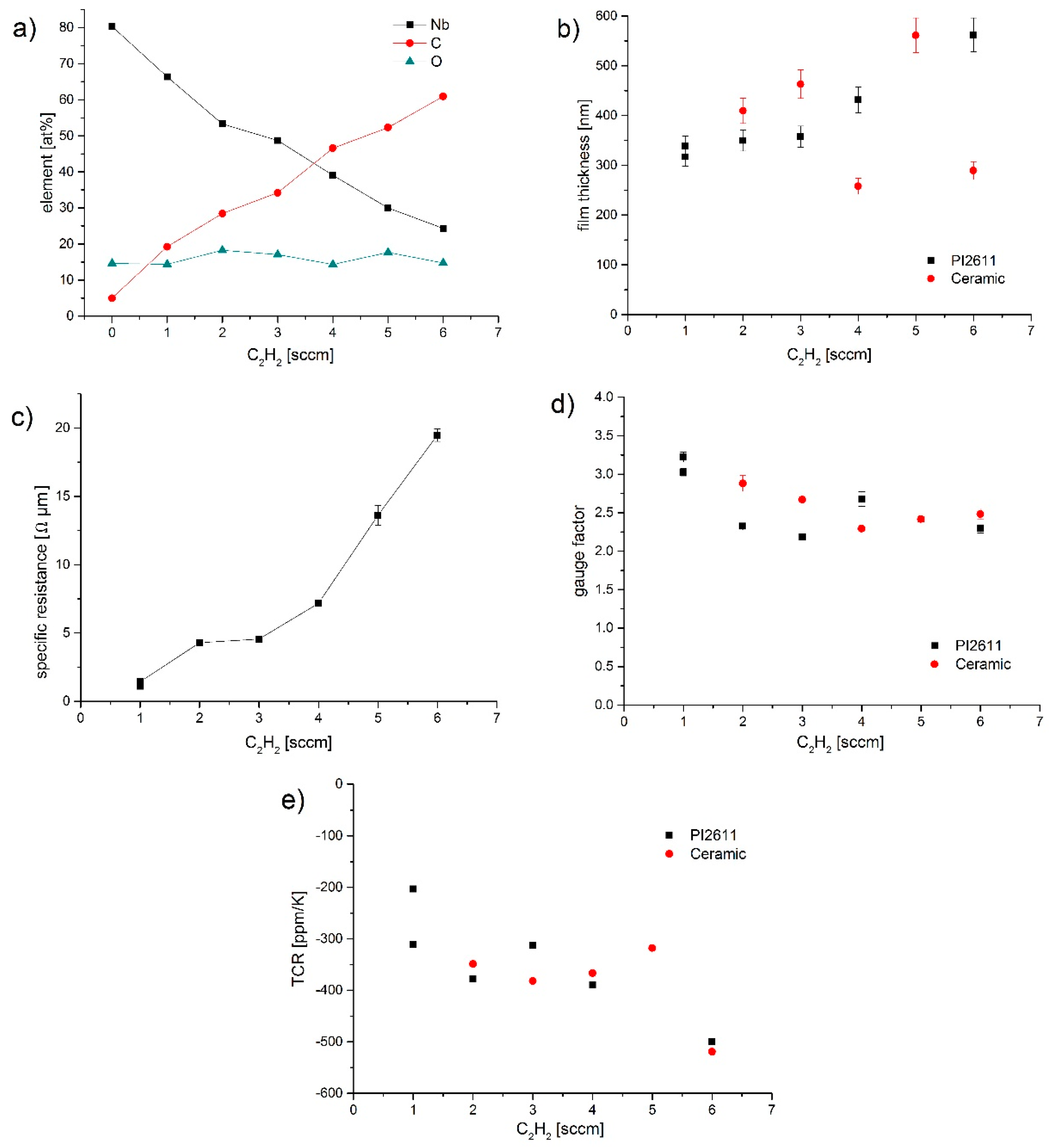

3.1. Electrical Properties and Morphology

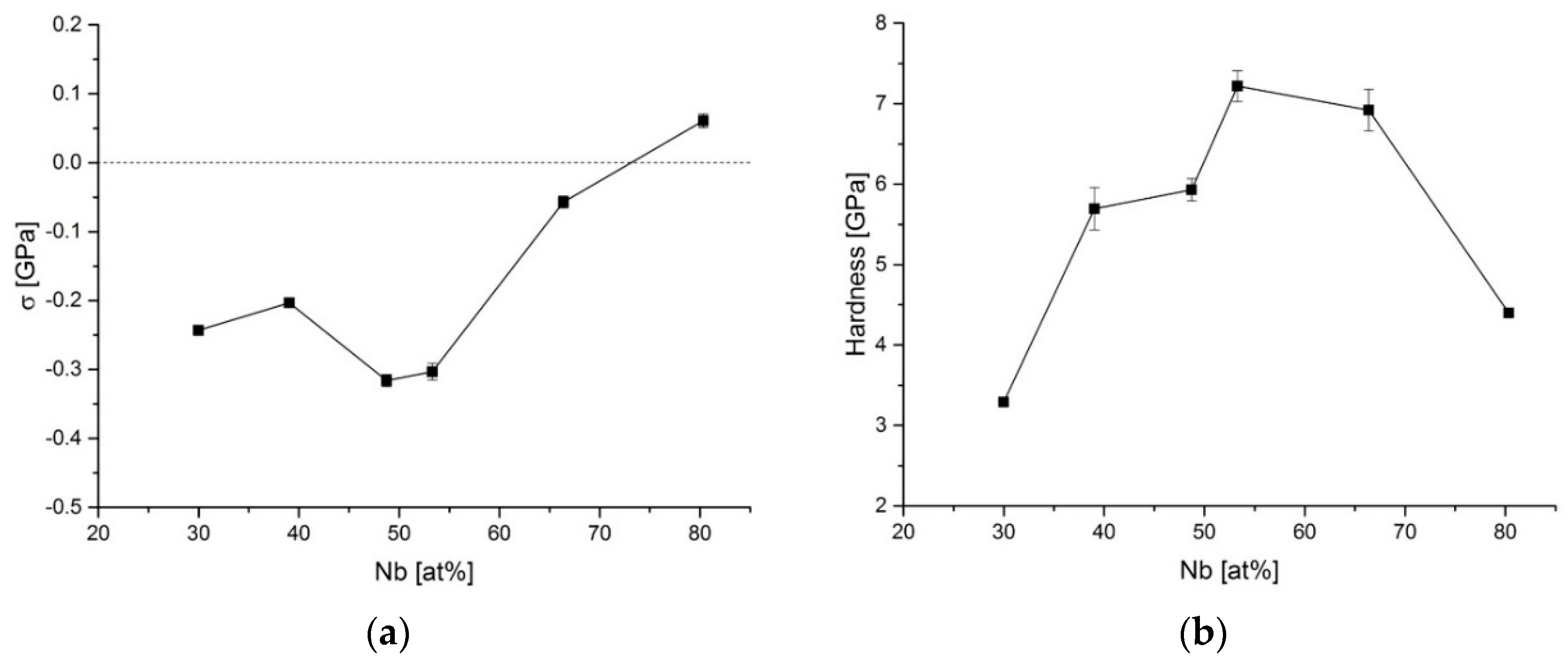

3.2. Stress and Hardness of a-C:H:Nb

3.3. Thermally-Induced Intrinsic Stress

3.4. Surface Roughness of the Substrates

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lago, N.; Yoshida, K.; Koch, K.P.; Navarro, X. Assessment of biocompatibility of chronically implanted polyimide and platinum intrafascicular electrodes. IEEE Trans. Biomed. Eng. 2007, 54, 281–290. [Google Scholar] [CrossRef] [PubMed]

- Stieglitz, T.; Beutel, H.; Schuettler, M.; Meyer, J.-U. Micromachined, polyimide-based devices for flexible neural interfaces. Biomed. Microdevices 2000, 2, 283–294. [Google Scholar] [CrossRef]

- González, C.; Rodrı́guez, M. A flexible perforated microelectrode array probe for action potential recording in nerve and muscle tissues. J. Neurosci. Methods 1997, 72, 189–195. [Google Scholar] [CrossRef]

- Bouabibsa, I.; Lamri, S.; Sanchette, F. Structure, mechanical and tribological properties of Me-doped diamond-like carbon (DLC) (Me = Al, Ti, or Nb) hydrogenated amorphous carbon coatings. Coatings 2018, 8, 370. [Google Scholar] [CrossRef]

- Ding, J.C.; Dai, W.; Zhang, T.F.; Zhao, P.; Yun, J.M.; Kim, K.H.; Wang, Q.M. Microstructure and Properties of Nb-Doped Diamond-Like Carbon Films Deposited by High Power Impulse Magnetron Sputtering. Thin Solid Films 2018, 663, 159–167. [Google Scholar] [CrossRef]

- Köberle, H. Struktur und Elektrische LeitfäHigkeit von HF-Plasma-erzeugten Metallhaltigen Kohlenwasserstoffschichten. Ph.D. Thesis, University of Hamburg, Hamburg, Germany, 1989. [Google Scholar]

- Heckmann, U.; Bandorf, R.; Gerdes, H.; Lübke, M.; Schnabel, S.; Brauer, G. New materials for sputtered strain gauges. Procedia Chem. 2009, 1, 64–67. [Google Scholar] [CrossRef]

- Schultes, G.; Koppert, R.; Goettel, D.; Freitag-Weber, O.; Probst, A.C.; Werner, U. New perspectives for pressure and force sensors thin films combining high gauge factor and low TCR. In Smart Sensors, Actuators, and MEMS IV, Proceedings of SPIE Europe Microtechnologies for the New Millennium, Dresden, Germany, 4–6 May 2009; Schmid, U., Ed.; SPIE: Bellingham, WA, USA, 2009. [Google Scholar]

- Schultes, G.; Schmid-Engel, H.; Schwebke, S.; Werner, U. Granular metal–carbon nanocomposites as piezoresistive sensor films—Part 1: Experimental results and morphology. J. Sens. Sens. Syst. 2018, 7, 1–11. [Google Scholar] [CrossRef]

- Grein, M.; Bandorf, R.; Schiffmann, K.; Bräuer, G. Material structure and piezoresistive properties of niobium containing diamond-like-carbon films. Surf. Coat. Technol. 2019, 357, 273–279. [Google Scholar] [CrossRef]

- Thornton, J.A.; Hoffman, D. Stress-related effects in thin films. Thin Solid Films 1989, 171, 5–31. [Google Scholar] [CrossRef]

- Neuville, S.; Matthews, A. A perspective on the optimisation of hard carbon and related coatings for engineering applications. Thin Solid Films 2007, 515, 6619–6653. [Google Scholar] [CrossRef]

- Ordonez, J.S.; Boehler, C.; Schuettler, M.; Stieglitz, T. Long-term adhesion studies of polyimide to inorganic and metallic layers. MRS Proc. 2012, 1466. [Google Scholar] [CrossRef]

- Tai, F.-C.; Lee, S.-C.; Wei, C.-H. Spin-coating polyimide film on hydrogenated DLC film surface prepared by ion beam deposition method. Mater. Trans. 2006, 47, 1869–1873. [Google Scholar] [CrossRef]

- Von Der Heide, C.; Grein, M.; Dietzel, A. Femtosecond laser-contoured micro-strain gages. Microelectron. Eng. 2019, 214, 81–86. [Google Scholar] [CrossRef]

- Saha, R.; Nix, W.D. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Robertson, J. Properties and prospects for non-crystalline carbons. J. Non-Cryst. Solids 2002, 299, 798–804. [Google Scholar] [CrossRef]

- Anders, A. A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films 2010, 518, 4087–4090. [Google Scholar] [CrossRef]

- Zhang, K.; Wen, M.; Cheng, G.; Li, X.; Meng, Q.; Lian, J.; Zheng, W. Reactive magnetron sputtering deposition and characterization of niobium carbide films. Vacuum 2014, 99, 233–241. [Google Scholar] [CrossRef]

- El Mel, A.A.; Bouts, N.; Grigore, E.; Gautron, E.; Granier, A.; Angleraud, B.; Tessier, P.-Y. Shape control of nickel nanostructures incorporated in amorphous carbon films: From globular nanoparticles toward aligned nanowires. J. Appl. Phys. 2012, 111, 114309. [Google Scholar] [CrossRef]

- Zehnder, T. Nanostructural and mechanical properties of nanocomposite nc-TiC/a-C:H films deposited by reactive unbalanced magnetron sputtering. J. Appl. Phys. 2004, 95, 4327. [Google Scholar] [CrossRef]

- Champi, A.; Lacerda, R.; Viana, G.; Marques, F. Thermal expansion dependence on the sp2 concentration of amorphous carbon and carbon nitride. J. Non-Cryst. Solids 2004, 338, 499–502. [Google Scholar] [CrossRef]

- Marques, F.C.; Lacerda, R.G.; Champi, A.; Stolojan, V.; Cox, D.C.; Silva, S.R.P. Thermal expansion coefficient of hydrogenated amorphous carbon. Appl. Phys. Lett. 2003, 83, 3099. [Google Scholar] [CrossRef]

- Wang, J.; Sugimura, Y.; Evans, A.; Tredway, W. The mechanical performance of DLC films on steel substrates. Thin Solid Films 1998, 325, 163–174. [Google Scholar] [CrossRef]

- Nelson, J.B.; Riley, D.P. The thermal expansion of graphite from 15 °C to 800 °C: Part I. Experimental. Proc. Phys. Soc. 1945, 57, 477–486. [Google Scholar] [CrossRef]

- Kempter, C.; Storms, E. Thermal expansion of some niobium carbides. J. Less Common Met. 1967, 13, 443–447. [Google Scholar] [CrossRef]

| Substrate | Gauge Factor | TCR (ppm/K) | Specific Resistance (Ω µm) | Sputter Unit |

|---|---|---|---|---|

| Industrial polyimide (Kapton HN) | 1.9–39.7 | −3900~+250 | 1.5–1560 | IC300, BAS 450 PM |

| Spin-coated polyimide (PI 2611) | 2.2–3.2 | −500~−200 | 3.3–34.6 | BAS 450 PM |

| Ceramic, Al2O3 polished | 2.3–2.9 | −520~−320 | – | BAS450 PM |

| Material | Thermal Expansion Coefficient (ppm/K) | ΔCTE between Substrate and Coating (ppm/K) | References |

|---|---|---|---|

| Polyimide, Kapton HN | 20 | 14–18 | Manufacturer specification |

| Polyimide, HD Microsystems PI 2611 | 3 | 1–3 | Manufacturer specification |

| Glass, borofloat | 3.25 | 1.25–2.75 | Manufacturer specification |

| Ceramic, Al2O3 | 7.2 | 1.2–5.2 | Manufacturer specification |

| Hard a-C:H | 1.5–7 | – | [23,24] |

| Graphite, Perpendicular to the basal plane | 27−1.5 | – | [25] |

| Graphite, Parallel to the basal plane Average | 8 | – | |

| NbxCy | 5.89–6.23 | – | [26] |

| a-C:H:Nb | 2–6 | – | assumption of this work |

| Substrate | Ra before Coating (µm) | Ra after Coating (µm) | Gauge Factor | TCR (ppm/K) |

|---|---|---|---|---|

| Industrial polyimide (Kapton HN) | 0.065 ± 0.028 | 0.420 ± 0.150 | 10.2 ± 0.45 | +110 |

| Spin-coated polyimide (PI 2611) | 0.023 ± 0.013 | 0.007 ± 0.004 | 3.22 ± 0.06 | −203 |

| Ceramic, Al2O3, polished | 0.007 ± 0.002 | 0.030 ± 0.017 | 2.68 ± 0.01 | −203 |

| Ceramic, Al2O3, rough | 0.080 ± 0.035 | 0.140 ± 0.030 | 2.48 ± 0.04 | −413 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grein, M.; Gerstenberg, J.; von der Heide, C.; Bandorf, R.; Bräuer, G.; Dietzel, A. Niobium-Containing DLC Coatings on Various Substrates for Strain Gauges. Coatings 2019, 9, 417. https://doi.org/10.3390/coatings9070417

Grein M, Gerstenberg J, von der Heide C, Bandorf R, Bräuer G, Dietzel A. Niobium-Containing DLC Coatings on Various Substrates for Strain Gauges. Coatings. 2019; 9(7):417. https://doi.org/10.3390/coatings9070417

Chicago/Turabian StyleGrein, Maria, Jessica Gerstenberg, Chresten von der Heide, Ralf Bandorf, Günter Bräuer, and Andreas Dietzel. 2019. "Niobium-Containing DLC Coatings on Various Substrates for Strain Gauges" Coatings 9, no. 7: 417. https://doi.org/10.3390/coatings9070417

APA StyleGrein, M., Gerstenberg, J., von der Heide, C., Bandorf, R., Bräuer, G., & Dietzel, A. (2019). Niobium-Containing DLC Coatings on Various Substrates for Strain Gauges. Coatings, 9(7), 417. https://doi.org/10.3390/coatings9070417