Hybrid Nanostructured Antireflection Coating by Self-Assembled Nanosphere Lithography

Abstract

:1. Introduction

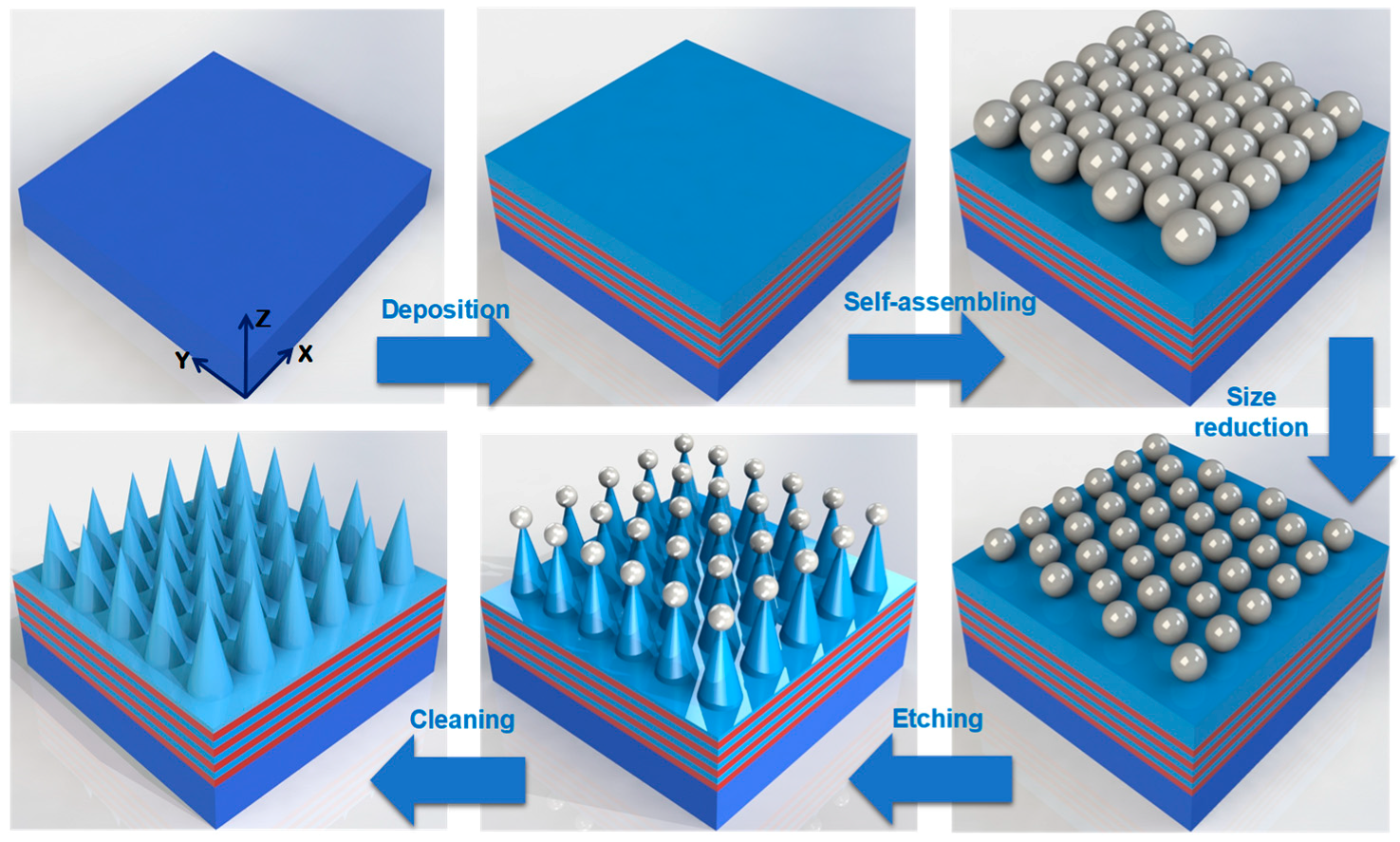

2. Materials and Methods

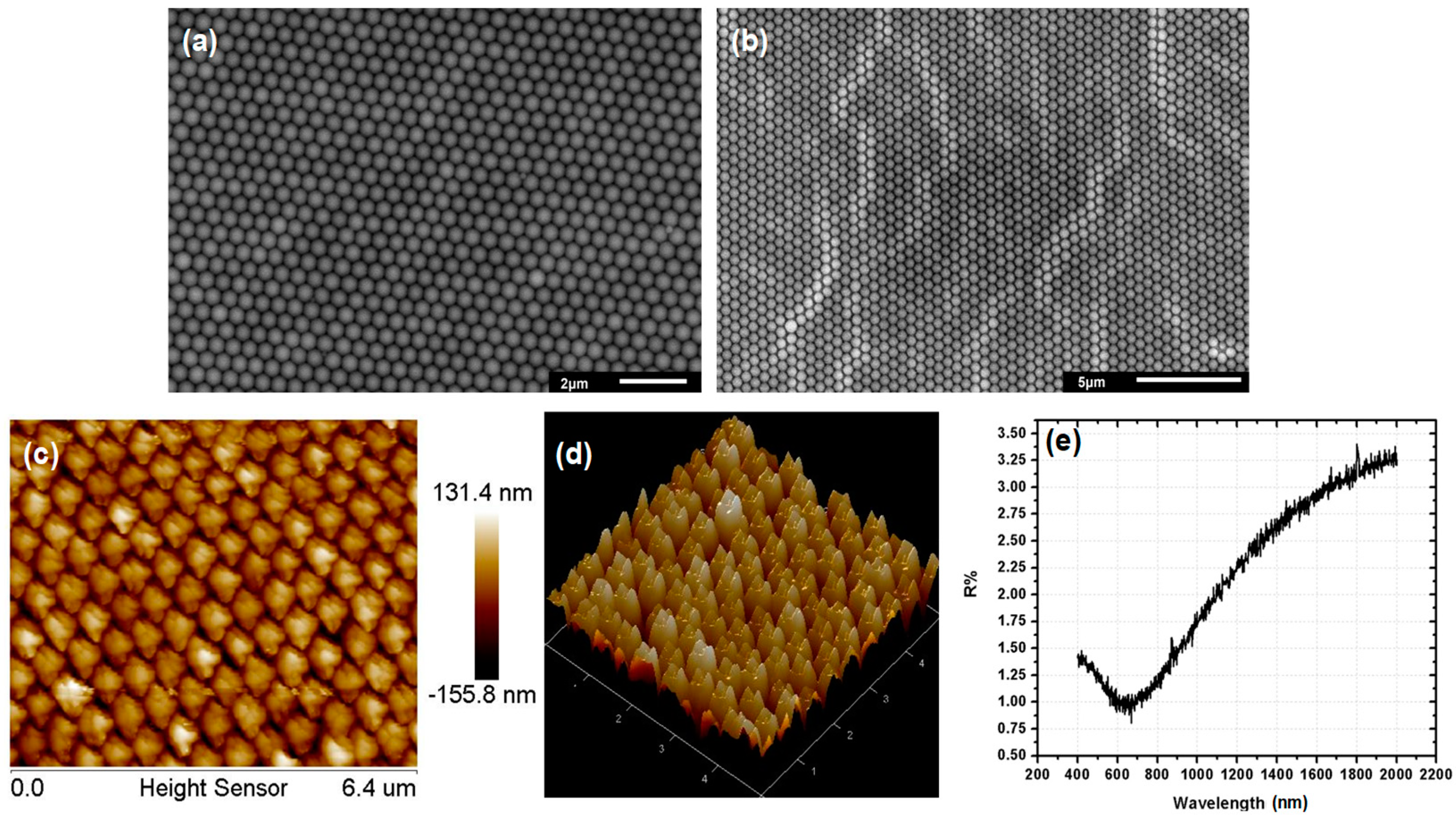

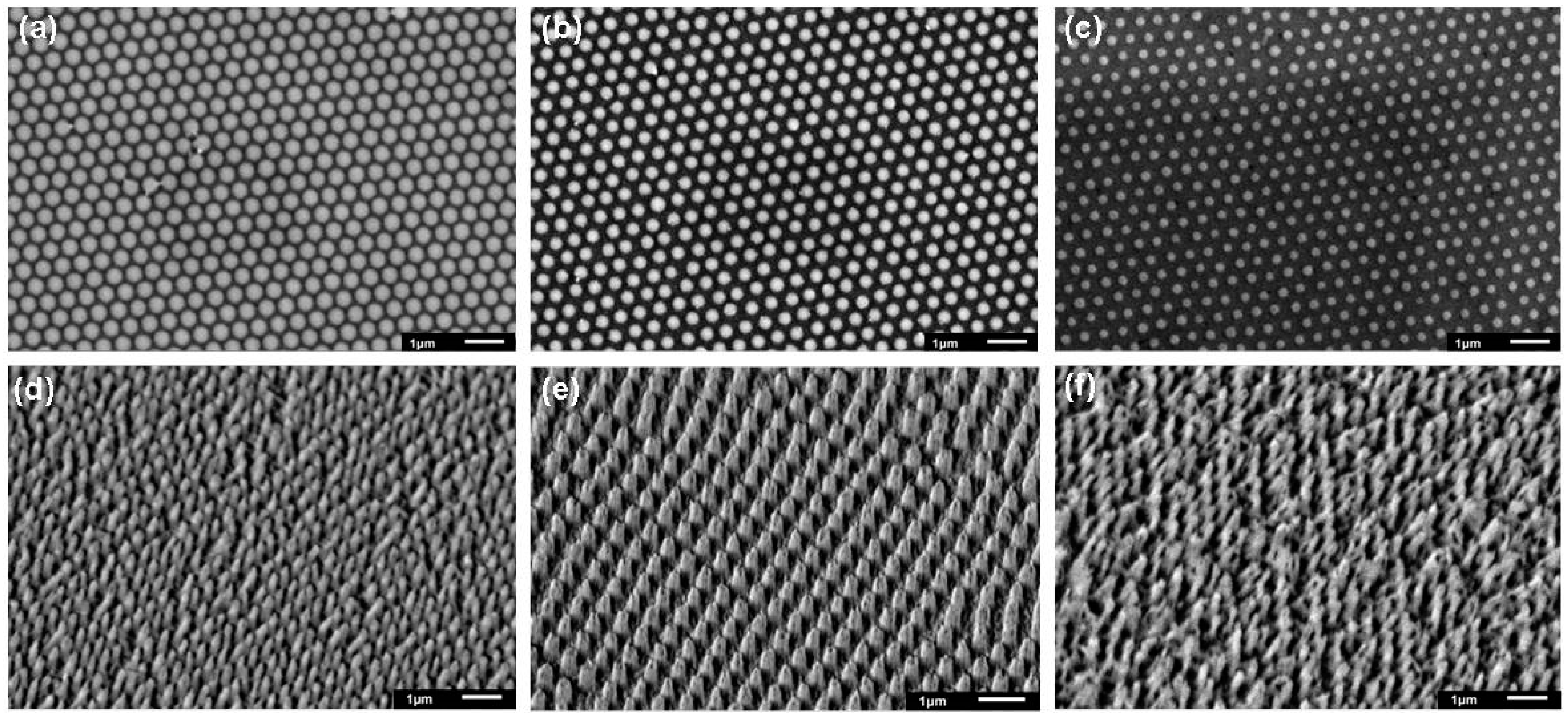

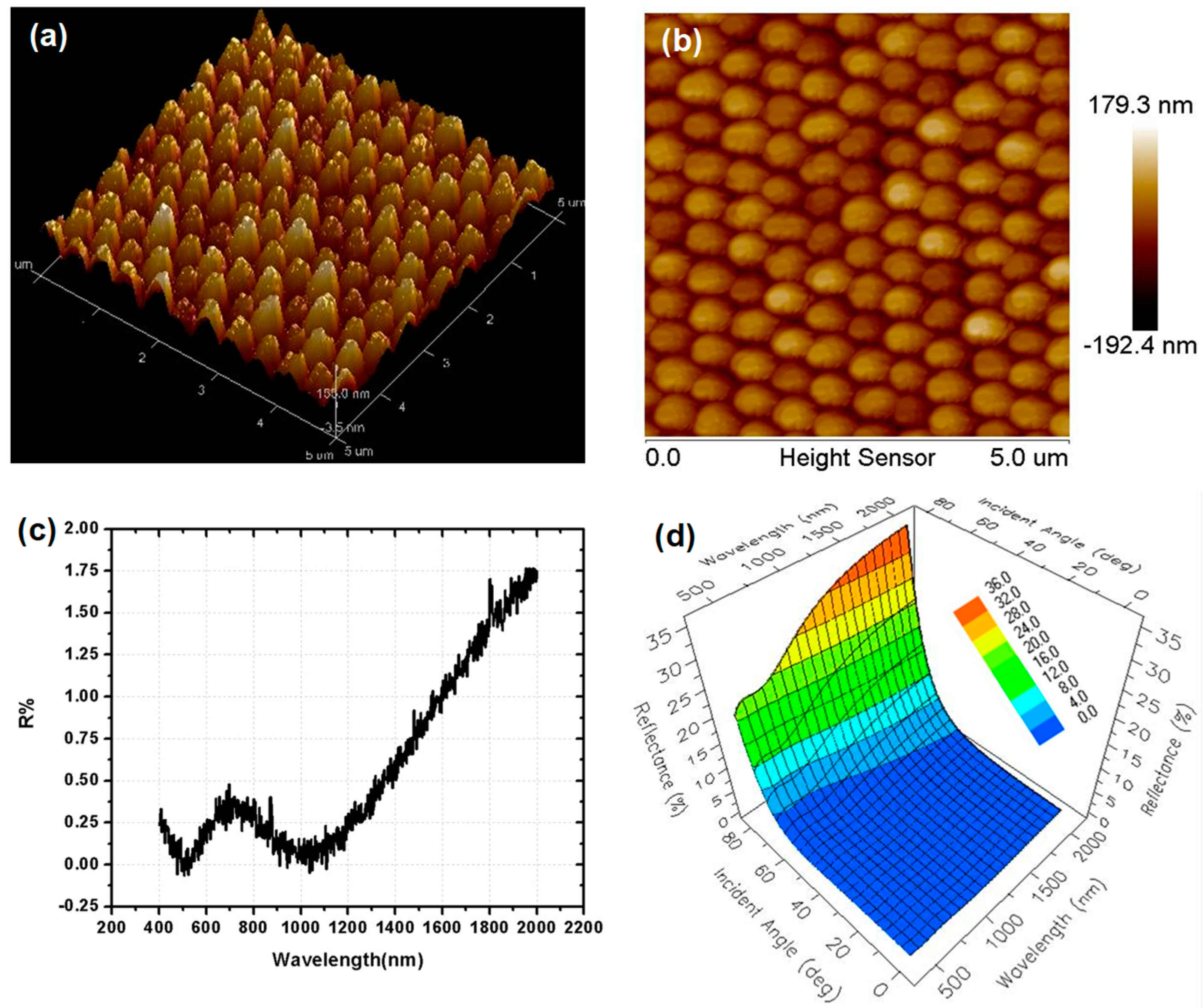

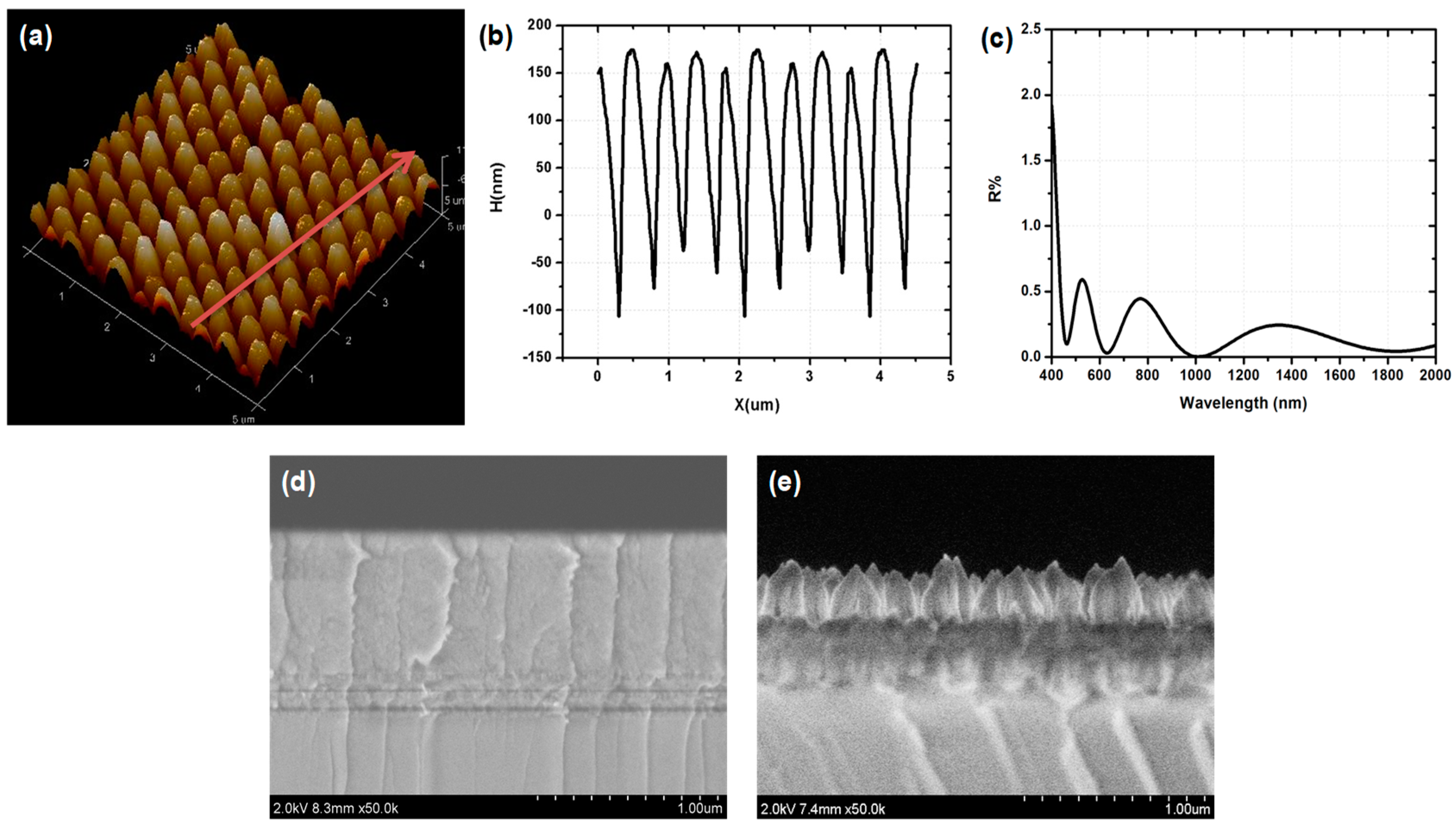

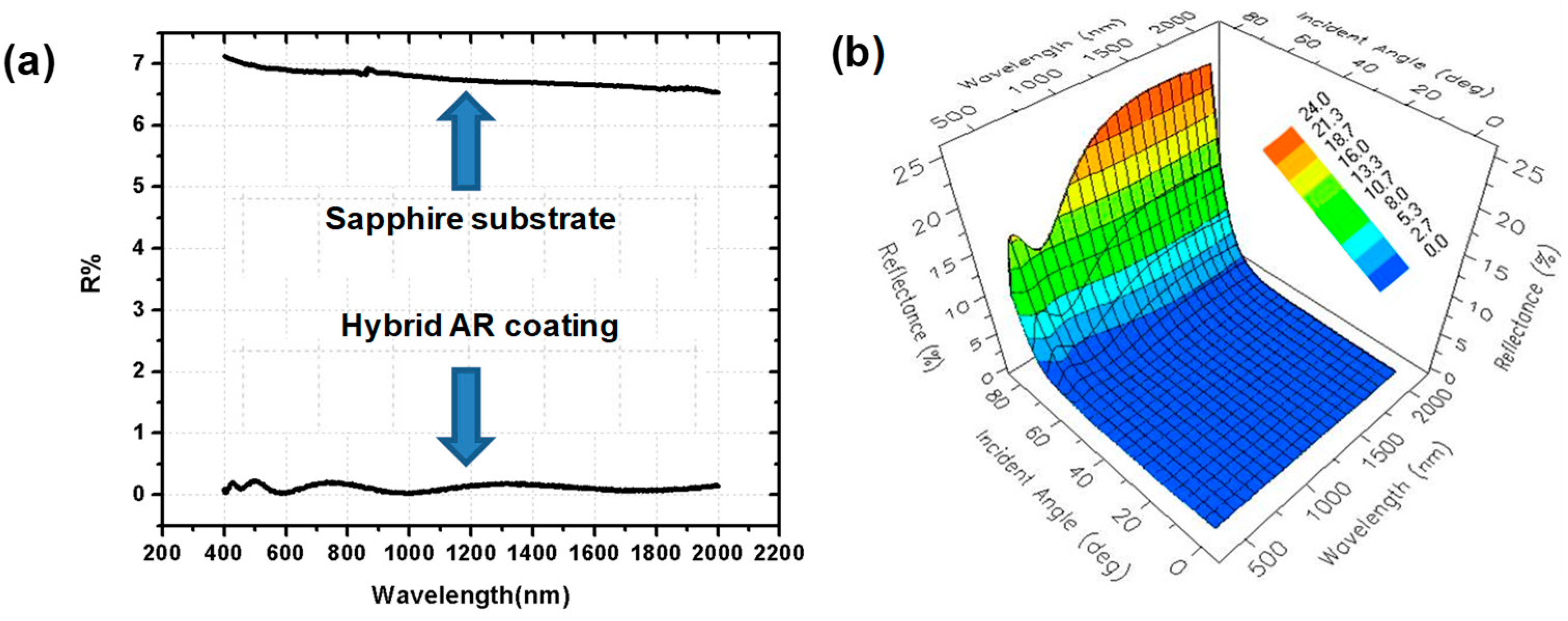

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Macleod, H.A. Thin-Film Optical Filters, 4th ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Walheim, S. Nanophase-separated polymer films as high-performance antireflection coatings. Science 1999, 283, 520–522. [Google Scholar] [CrossRef] [PubMed]

- Deng, C.; Ki, H. Pulsed laser deposition of refractive-index-graded broadband antireflection coatings for silicon solar cells. Sol. Energy Mater. Sol. Cells 2016, 147, 37–45. [Google Scholar] [CrossRef]

- Uzum, A.; Kuriyama, M.; Kanda, H.; Kimura, Y.; Tanimoto, K.; Ito, S. Non-vacuum processed polymer composite antireflection coating films for silicon solar cells. Energies 2016, 9, 633. [Google Scholar] [CrossRef]

- Makableh, Y.; Vasan, R.; Sarker, J.; Nusir, A.; Seal, S.; Manasreh, M.; Nusir, A. Enhancement of GaAs solar cell performance by using a ZnO sol–gel anti-reflection coating. Sol. Energy Mater. Sol. Cells 2014, 123, 178–182. [Google Scholar] [CrossRef]

- Cui, H.; Pillai, S.; Campbell, P.; Green, M. A novel silver nanoparticle assisted texture as broadband antireflection coating for solar cell applications. Sol. Energy Mater. Sol. Cells 2013, 109, 233–239. [Google Scholar] [CrossRef]

- Salman, K.A.; Omar, K.; Hassan, Z. Effective conversion efficiency enhancement of solar cell using ZnO/PS antireflection coating layers. Sol. Energy 2012, 86, 541–547. [Google Scholar] [CrossRef]

- Kosten, E.D.; Atwater, J.H.; Parsons, J.; Polman, A.; Atwater, H.A. Highly efficient GaAs solar cells by limiting light emission angle. Light. Sci. Appl. 2013, 2, e45. [Google Scholar] [CrossRef]

- Wang, B.; Price, J.S.; Giebink, N.C. Durable broadband ultralow index fluoropolymer antireflection coatings for plastic optics. Optica 2017, 4, 239. [Google Scholar] [CrossRef]

- Chang, Y.-J.; Chen, Y.-T. Broadband omnidirectional antireflection coatings for metal-backed solar cells optimized using simulated annealing algorithm incorporated with solar spectrum. Opt. Express 2011, 19, A875. [Google Scholar] [CrossRef]

- Victoria, M.; Domínguez, C.; Antón, I.; Sala, G. Antireflective coatings for multijunction solar cells under wide-angle ray bundles. Opt. Express 2012, 20, 8136. [Google Scholar] [CrossRef]

- Sarkar, S.; Pradhan, S.K. Silica-based antireflection coating by glancing angle deposition. Surf. Eng. 2019, 1, 1–4. [Google Scholar] [CrossRef]

- Ma, J.; Ai, Y.; Kang, L.; Liu, W.; Ma, Z.; Song, P.; Zhao, Y.; Yang, F.; Wang, X. A novel nano-cone cluster microstructure with anti-reflection and superhydrophobic properties for photovoltaic devices. Nano Res. Lett. 2018, 13, 332. [Google Scholar] [CrossRef] [PubMed]

- Pisco, M.; Galeotti, F.; Quero, G.; Grisci, G.; Micco, A.; Mercaldo, L.V.; Veneri, P.D.; Cutolo, A.; Cusano, A. Nano-sphere lithography for optical fiber tip nanoprobes. Light Sci. Appl. 2017, 6, e16229. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, M.M.; Tsui, K.-H.; Leung, S.-F.; Zhang, Q.; He, J.; Yao, Y.; Li, D.; Fan, Z. Highly efficient flexible perovskite solar cell with anti-reflection and self-cleaning nanostructures. ACS Nano 2015, 9, 10287–10295. [Google Scholar] [CrossRef] [PubMed]

- Hou, C.C.; Chen, H.M.; Zhang, J.C.; Zhuo, N.; Huang, Y.Q.; Hogg, R.A.; Childs, D.T.; Ning, J.Q.; Wang, Z.G.; Liu, F.Q.; et al. Near-infrared and mid-infrared semiconductorbroadband light emitters. Light Sci. Appl. 2018, 7, 17170. [Google Scholar] [CrossRef] [PubMed]

- Shao, T.; Tang, F.; Sun, L.; Ye, X.; He, J.; Yang, L.; Zheng, W. Fabrication of antireflective nanostructures on a transmission grating surface using a one-step self-masking method. Nanomaterials 2019, 9, 180. [Google Scholar] [CrossRef] [PubMed]

- Zhu, A.Y.; Chen, W.T.; Zaidi, A.; Huang, Y.W.; Khorasaninejad, M.; Sanjeev, V.; Qiu, C.W.; Capasso, F. Giant intrinsic chiro-optical activity in planar dielectric nanostructures. Light Sci. Appl. 2018, 7, 17158. [Google Scholar] [CrossRef]

- Cui, A.; Liu, Z.; Li, J.; Shen, T.H.; Xia, X.; Li, Z.; Gong, Z.; Li, H.; Wang, B.; Li, J.; et al. Directly patterned substrate-free plasmonic ‘‘nanograter’’ structures with unusual Fano resonances. Light Sci. Appl. 2015, 4, e308. [Google Scholar] [CrossRef]

- Jang, H.J.; Kim, Y.J.; Yoo, Y.J.; Lee, G.J.; Kim, M.S.; Chang, K.S.; Song, Y.M. Double-sided anti-reflection nanostructures on optical convex lenses for imaging applications. Coatings 2019, 9, 404. [Google Scholar] [CrossRef]

- Jian, L.Y.; Wu, C.N.; Lee, H.Y.; Heo, J.; Lee, C.T. Performance improvement of III–V compound solar cells using nanomesh electrode and nanostructured antireflection structures. Sol. Energ. 2019, 188, 51–54. [Google Scholar] [CrossRef]

- Chen, J.; Chang, W.-L.; Huang, C.; Sun, K. Biomimetic nanostructured antireflection coating and its application on crystalline silicon solar cells. Opt. Express 2011, 19, 14411. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.Y.; Gao, J.B.; Gao, J.S.; Yang, H.G.; Wang, X.Y.; Wang, T.T.; Shen, Z.F.; Liu, Z.; Liu, H.; Zhang, J.; et al. Microcavity electrodynamics of hybrid surface Plasmon polariton modes in high-quality multilayer trench gratings. Light Sci. Appl. 2018, 7, 14. [Google Scholar] [CrossRef] [PubMed]

- Sobahan, K.; Park, Y.J.; Kim, J.J.; Hwangbo, C.K. Nanostructured porous SiO2 films for antireflection coatings. Opt. Commun. 2011, 284, 873–876. [Google Scholar] [CrossRef]

- Guo, C.F.; Sun, T.; Cao, F.; Liu, Q.; Ren, Z. Metallic nanostructures for light trapping in energy-harvesting devices. Light. Sci. Appl. 2014, 3, e161. [Google Scholar]

- Yang, J.; Luo, F.; Kao, T.S.; Li, X.; Ho, G.W.; Teng, J.; Luo, X.; Hong, M. Design and fabrication of broadband ultralow reflectivity black Si surfaces by laser micro/nanoprocessing. Light Sci. Appl. 2014, 3, e185. [Google Scholar] [CrossRef]

- Chen, X.; Jia, B.; Zhang, Y.; Gu, M. Exceeding the limit of plasmonic light trapping in textured screen-printed solar cells using Al nanoparticles and wrinkle-like graphene sheets. Light Sci. Appl. 2013, 2, e92. [Google Scholar] [CrossRef]

- Ko, Y.H.; Yu, J.S. Design of hemi-urchin shaped ZnO nanostructures for broadband and wide-angle antireflection coatings. Opt. Express 2011, 19, 297–305. [Google Scholar] [CrossRef] [PubMed]

- Hedayati, M.K.; Etrich, C.; Faupel, F.; Elbahri, P.D.-I.M.; Fahr, S.; Rockstuhl, C. The hybrid concept for realization of an ultra-thin plasmonic metamaterial antireflection coating and plasmonic rainbow. Nanoscale 2014, 6, 6037–6045. [Google Scholar] [CrossRef] [Green Version]

- Baek, S.-H.; Kim, S.-B.; Shin, J.-K.; Kim, J.H. Preparation of hybrid silicon wire and planar solar cells having ZnO antireflection coating by all-solution processes. Sol. Energy Mater. Sol. Cells 2012, 96, 251–256. [Google Scholar] [CrossRef]

- Fazio, B.; Artoni, P.; Iatì, M.A.; D’andrea, C.; Faro, M.J.L.; Del Sorbo, S.; Pirotta, S.; Gucciardi, P.G.; Musumeci, P.; Vasi, C.S.; et al. Strongly enhanced light trapping in a two-dimensional silicon nanowire random fractal array. Light Sci. Appl. 2016, 5, e16062. [Google Scholar] [CrossRef]

- Dai, D.; Bauters, J.; Bowers, J.E. Passive technologies for future large-scale photonic integrated circuits on silicon: Polarization handling, light non-reciprocity and loss reduction. Light Sci. Appl. 2012, 1, e1. [Google Scholar] [CrossRef]

- Lee, K.; Lee, J.; Mazor, B.A.; Forrest, S.R. Transforming the cost of solar-to-electrical energy conversion: Integrating thin-film GaAs solar cells with non-tracking mini-concentrators. Light Sci. Appl. 2015, 4, e288. [Google Scholar] [CrossRef]

- Fan, Q.; Wang, Z.; Cui, Y. Optimal design of an antireflection coating structure for enhancing the energy-conversion efficiency of a silicon nanostructure solar cell. RCS Adv. 2018, 8, 34793–34807. [Google Scholar] [CrossRef] [Green Version]

- Askar, K.; Wang, J.; Leo, S.-Y.; Kim, C.; Fenton, A.M.; Jiang, P.; Jiang, B. Scalable parallel self-assembly of nanoparticle anti-reflection coatings. Thin Solid Films 2017, 621, 156–164. [Google Scholar] [CrossRef]

- Siddique, R.H.; Mertens, J.; Hölscher, H.; Vignolini, S. Scalable and controlled self-assembly of aluminum-based random plasmonic metasurfaces. Light. Sci. Appl. 2017, 6, e17015. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.Y.; Lin, K.Y.; Tsai, H.P.; He, Y.X.; Yang, H. Self-assembled dual-sided hemispherical nano-dimple-structured broadband antireflection coatings. Appl. Phys. Lett. 2017, 109, 221601. [Google Scholar] [CrossRef]

- Kang, Y.H.; Oh, S.S.; Kim, Y.-S.; Choi, C.-G. Fabrication of antireflection nanostructures by hybrid nano-patterning lithography. Microelectron. Eng. 2010, 87, 125–128. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: New York, NY, USA, 1985. [Google Scholar]

- Ji, S.; Song, K.; Nguyen, T.B.; Kim, N.; Lim, H. Optimal moth eye nanostructure array on transparent glass towards broadband antireflection. ACS Appl. Mater. Interfaces 2013, 5, 10731–10737. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Song, C.; Li, Q.; Xiang, X.; Yang, H.; Wang, X.; Gao, J. Hybrid Nanostructured Antireflection Coating by Self-Assembled Nanosphere Lithography. Coatings 2019, 9, 453. https://doi.org/10.3390/coatings9070453

Li Z, Song C, Li Q, Xiang X, Yang H, Wang X, Gao J. Hybrid Nanostructured Antireflection Coating by Self-Assembled Nanosphere Lithography. Coatings. 2019; 9(7):453. https://doi.org/10.3390/coatings9070453

Chicago/Turabian StyleLi, Zizheng, Chi Song, Qiang Li, Xiangjun Xiang, Haigui Yang, Xiaoyi Wang, and Jinsong Gao. 2019. "Hybrid Nanostructured Antireflection Coating by Self-Assembled Nanosphere Lithography" Coatings 9, no. 7: 453. https://doi.org/10.3390/coatings9070453