Thermal Stability of YSZ Coatings Deposited by Plasma Spray–Physical Vapor Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation and Heat Treatment of PS–PVD Coating

2.2. Coating Characterization

3. Results and Discussion

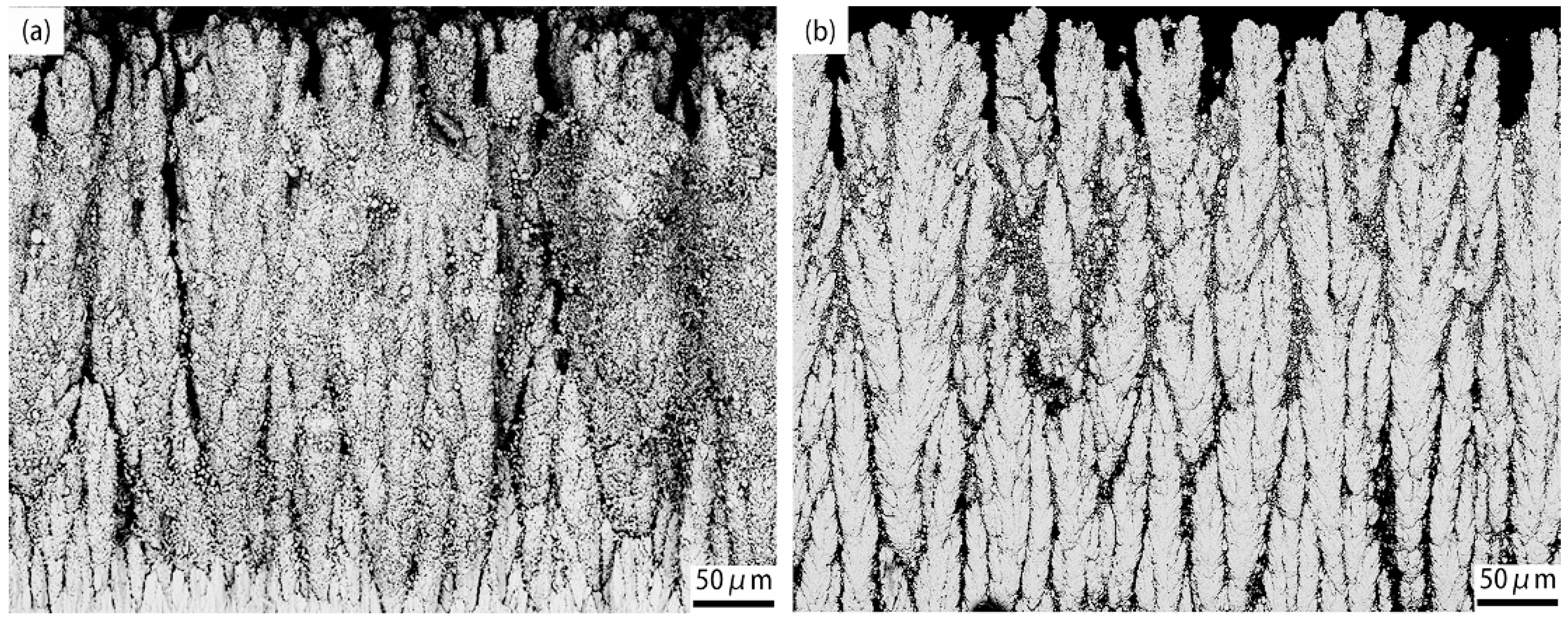

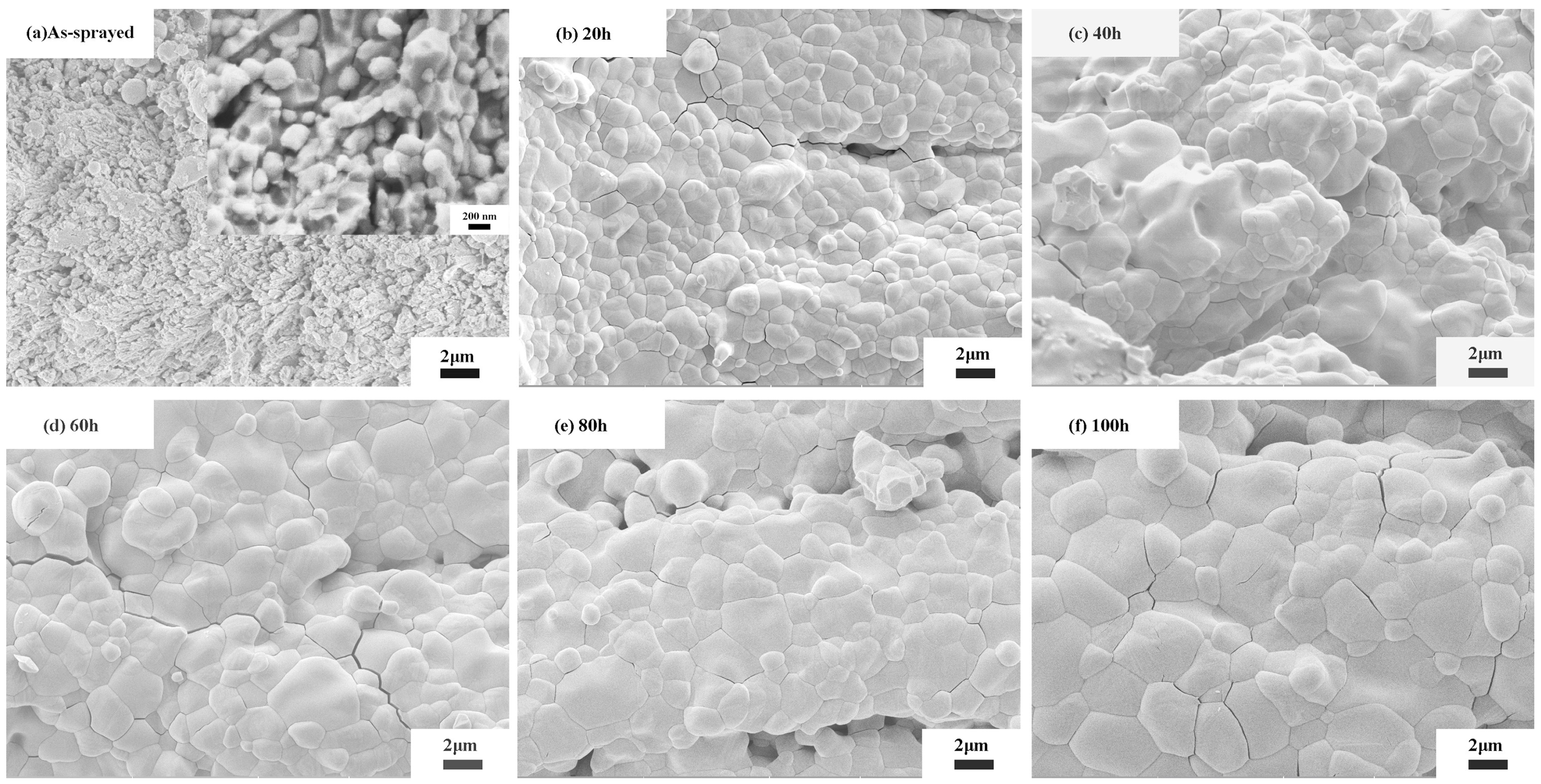

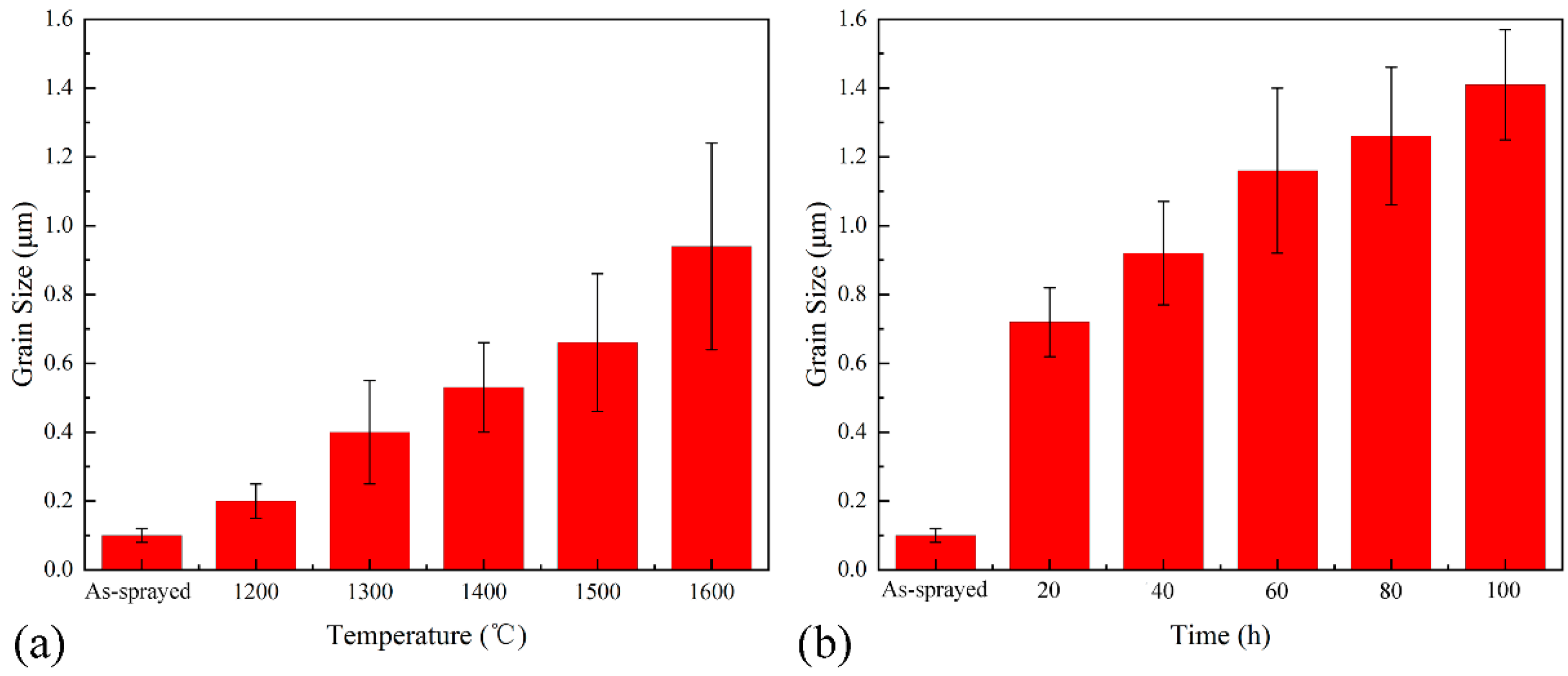

3.1. Microstructure

3.2. Phase Transformation

3.3. Mechanical Properties

4. Conclusions

- After thermal exposure, the columnar structure degraded and micro pores were generated in the columns, resulting in a close contact of columns as a result of sintering effect.

- After high-temperature exposure for a long time, the initial t-ZrO2 phase of PS–PVD YSZ TBCs evolved gradually into m-ZrO2 and cracks form between the grain boundaries with increasing exposure temperature caused by the formation and accumulation of m-ZrO2 phase.

- The significant improvement of hardness and Young’s modulus of the coatings were attributed to a stiffer structure caused by the sintering effect during the thermal exposure at 1200–1300 °C for 24 h and 1550 °C for 20–100 h. For coatings exposed at different temperatures for 24 h, the hardness and Young’s modulus decreased in the range of 1300–1500 °C, which is caused by the generation of micro cracks accompanied with the formation of m-ZrO2 phase.

Author Contributions

Funding

Conflicts of Interest

References

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Ganvir, A.; Markocsan, N.; Joshi, S. Influence of isothermal heat treatment on porosity and crystallite size in axial suspension plasma sprayed thermal barrier coatings for gas turbine applications. Coatings 2017, 7, 4. [Google Scholar] [CrossRef]

- Parks, W.P.; Hoffman, E.E.; Lee, W.Y.; Wright, I.G. Thermal barrier coatings issues in advanced land-based gas turbines. J. Therm. Spray Technol. 1997, 6, 187–192. [Google Scholar] [CrossRef] [Green Version]

- Smialek, J.L.; Miller, R.A. Revisiting the birth of 7YSZ thermal barrier coatings: Stephan Stecura †. Coatings 2018, 8, 225. [Google Scholar] [CrossRef]

- Montavon, G. Recent developments in thermal spraying for improved coating characteristics and new applications/process controls and spray processes. High Temp. Mater. Process. 2004, 8, 45–93. [Google Scholar] [CrossRef]

- Hass, D.D.; Slifka, A.J.; Wadley, H.N.G. Low thermal conductivity vapor deposited zirconia microstructures. Acta Mater. 2001, 49, 973–983. [Google Scholar] [CrossRef]

- Peichl, A.; Beck, T.; Vohringer, O. Behaviour of an EB–PVD thermal barrier coating system under thermal-mechanical fatigue loading. Surf. Coat. Technol. 2003, 162, 113–118. [Google Scholar] [CrossRef]

- Schulz, U.; Menzebach, M.; Leyens, C.; Yang, Y.Q. Influence of substrate material on oxidation behavior and cyclic lifetime of EB–PVD TBC systems. Surf. Coat. Technol. 2001, 146, 117–123. [Google Scholar] [CrossRef]

- Rezanka, S.; Mauer, G.; Vaßen, R. Improved thermal cycling durability of thermal barrier coatings manufactured by PS–PVD. J. Therm. Spray Technol. 2013, 23, 182–189. [Google Scholar] [CrossRef]

- Mauer, G.; Hospach, A.; Vaßen, R. Process development and coating characteristics of plasma spray-PVD. Surf. Coat. Technol. 2013, 220, 219–224. [Google Scholar] [CrossRef]

- Mauer, G.; Vaßen, R. Plasma spray–PVD: Plasma characteristics and impact on coating properties. J. Phys. Conf. Ser. 2012, 406, 012005. [Google Scholar] [CrossRef]

- Hospach, A.; Mauer, G.; Vaßen, R.; Stöver, D. Characteristics of ceramic coatings made by thin film low pressure plasma spraying (LPPS–TF). J. Therm. Spray Technol. 2012, 21, 435–440. [Google Scholar] [CrossRef]

- Hospach, A.; Mauer, G.; Vaßen, R.; Stöver, D. Columnar-structured thermal barrier coatings (TBCs) by thin film low-pressure plasma spraying (LPPS–TF). J. Therm. Spray Technol. 2010, 20, 116–120. [Google Scholar] [CrossRef]

- Paul, S.; Cipitria, A.; Tsipas, S.A.; Clyne, T.W. Sintering characteristics of plasma sprayed zirconia coatings containing different stabilisers. Surf. Coat. Technol. 2009, 203, 1069–1074. [Google Scholar] [CrossRef]

- Choi, S.R.; Zhu, D.M.; Miller, R.A. Effect of sintering on mechanical properties of plasma-sprayed zirconia-based thermal barrier coatings. J. Am. Ceram. Soc. 2005, 88, 2859–2867. [Google Scholar] [CrossRef]

- Zhu, D.M.; Miller, R.A. Sintering and creep behavior of plasma-sprayed zirconia- and hafnia-based thermal barrier coatings. Surf. Coat. Technol. 1998, 108, 114–120. [Google Scholar] [CrossRef]

- Clarke, D.R.; Levi, C.G. Materials design for the next generation thermal barrier coatings. Annu. Rev. Mater. Res. 2003, 33, 383–417. [Google Scholar] [CrossRef]

- Ren, X.; Pan, W. Mechanical properties of high-temperature-degraded yttria-stabilized zirconia. Acta Mater. 2014, 69, 397–406. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Luo, J.; Adak, S.; Stevens, R. Microstructure evolution and grain growth in the sintering of 3Y-TZP ceramics. J. Mater. Sci. 1998, 33, 5301–5309. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, L.; Yang, J.; Li, D.; Zhong, X.; Zhao, H.; Shao, F.; Tao, S. Thermal aging behavior of axial suspension plasma-sprayed yttria-stabilized zirconia (YSZ) thermal barrier coatings. J. Therm. Spray Technol. 2015, 24, 338–347. [Google Scholar] [CrossRef]

- He, W.; Mauer, G.; Gindrat, M.; Wäger, R.; Vaßen, R. Investigations on the nature of ceramic deposits in plasma spray–physical vapor deposition. J. Therm. Spray Technol. 2016, 26, 83–92. [Google Scholar] [CrossRef]

- Kulkarni, A.; Goland, A.; Herman, H.; Allen, A.J.; Dobbins, T.; DeCarlo, F.; Ilavsky, J.; Long, G.G.; Fang, S.; Lawton, P. Advanced neutron and X-ray techniques for insights into the microstructure of EB–PVD thermal barrier coatings. Mater. Sci. Eng. A 2006, 426, 43–52. [Google Scholar] [CrossRef]

- Dalach, P.; Ellis, D.E.; van de Walle, A. First-principles thermodynamic modeling of atomic ordering in yttria-stabilized zirconia. Phys. Rev. B 2010, 82, 144117. [Google Scholar] [CrossRef]

- Huang, W.; Yang, J.; Wang, C.; Zou, B.; Meng, X.; Wang, Y.; Cao, X.; Wang, Z. Effects of Zr/Ce molar ratio and water content on thermal stability and structure of ZrO2–CeO2 mixed oxides prepared via sol–gel process. Mater. Res. Bull 2012, 47, 2349–2356. [Google Scholar] [CrossRef]

- Stefanic, G.; Music, S.; Popovic, S.; Sekulic, A. FT-IR and laser Raman spectroscopic investigation of the formation and stability of low temperature t-ZrO2. J. Mol. Struct. 1997, 408, 391–394. [Google Scholar] [CrossRef]

- Guo, S. Young’s moduli of zirconia top-coat and thermally grown oxide in a plasma-sprayed thermal barrier coating system. Scripta Mater. 2004, 50, 1401–1406. [Google Scholar] [CrossRef]

- Guo, S.Q.; Kagawa, Y. Effect of thermal exposure on hardness and Young’s modulus of EB–PVD yttria-partially-stabilized zirconia thermal barrier coatings. Ceram. Int. 2006, 32, 263–270. [Google Scholar] [CrossRef]

- Zotov, N.; Bartsch, M.; Eggeler, G. Thermal barrier coating systems—Analysis of nanoindentation curves. Surf. Coat. Technol. 2009, 203, 2064–2072. [Google Scholar] [CrossRef]

- Thompson, J.A.; Clyne, T.W. The effect of heat treatment on the stiffness of zirconia top coats in plasma-sprayed TBCs. Acta Mater. 2001, 49, 1565–1575. [Google Scholar] [CrossRef]

- Jang, B.K.; Matsubara, H. Influence of porosity on hardness and Young’s modulus of nanoporous EB–PVD TBCs by nanoindentation. Mater. Lett. 2005, 59, 3462–3466. [Google Scholar] [CrossRef]

| Items | Preheating Parameters | Coating Parameters |

|---|---|---|

| Plasma gas flow rate (slpm) | Ar: 50, He: 110 | Ar: 35, He: 60 |

| Power (kW) | 64 | 130 |

| Current (A) | 1400 | 2600 |

| Feed rate (g/min) | – | 5 |

| Spray distance (mm) | 800 | 900 |

| Oxygen flow rate (splm) | – | 2 |

| Carrier gas (slpm) | Ar: 6 | Ar: 8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Z.; Yang, J.; Shao, F.; Zhong, X.; Zhao, H.; Zhuang, Y.; Ni, J.; Tao, S. Thermal Stability of YSZ Coatings Deposited by Plasma Spray–Physical Vapor Deposition. Coatings 2019, 9, 464. https://doi.org/10.3390/coatings9080464

Cheng Z, Yang J, Shao F, Zhong X, Zhao H, Zhuang Y, Ni J, Tao S. Thermal Stability of YSZ Coatings Deposited by Plasma Spray–Physical Vapor Deposition. Coatings. 2019; 9(8):464. https://doi.org/10.3390/coatings9080464

Chicago/Turabian StyleCheng, Zefei, Jiasheng Yang, Fang Shao, Xinghua Zhong, Huayu Zhao, Yin Zhuang, Jinxing Ni, and Shunyan Tao. 2019. "Thermal Stability of YSZ Coatings Deposited by Plasma Spray–Physical Vapor Deposition" Coatings 9, no. 8: 464. https://doi.org/10.3390/coatings9080464

APA StyleCheng, Z., Yang, J., Shao, F., Zhong, X., Zhao, H., Zhuang, Y., Ni, J., & Tao, S. (2019). Thermal Stability of YSZ Coatings Deposited by Plasma Spray–Physical Vapor Deposition. Coatings, 9(8), 464. https://doi.org/10.3390/coatings9080464