A Review on Drilling of Multilayer Fiber-Reinforced Polymer Composites and Aluminum Stacks: Optimization of Strategies for Improving the Drilling Performance of Aerospace Assemblies

Abstract

:1. Introduction

2. Drilling Performance of Aerospace Assemblies

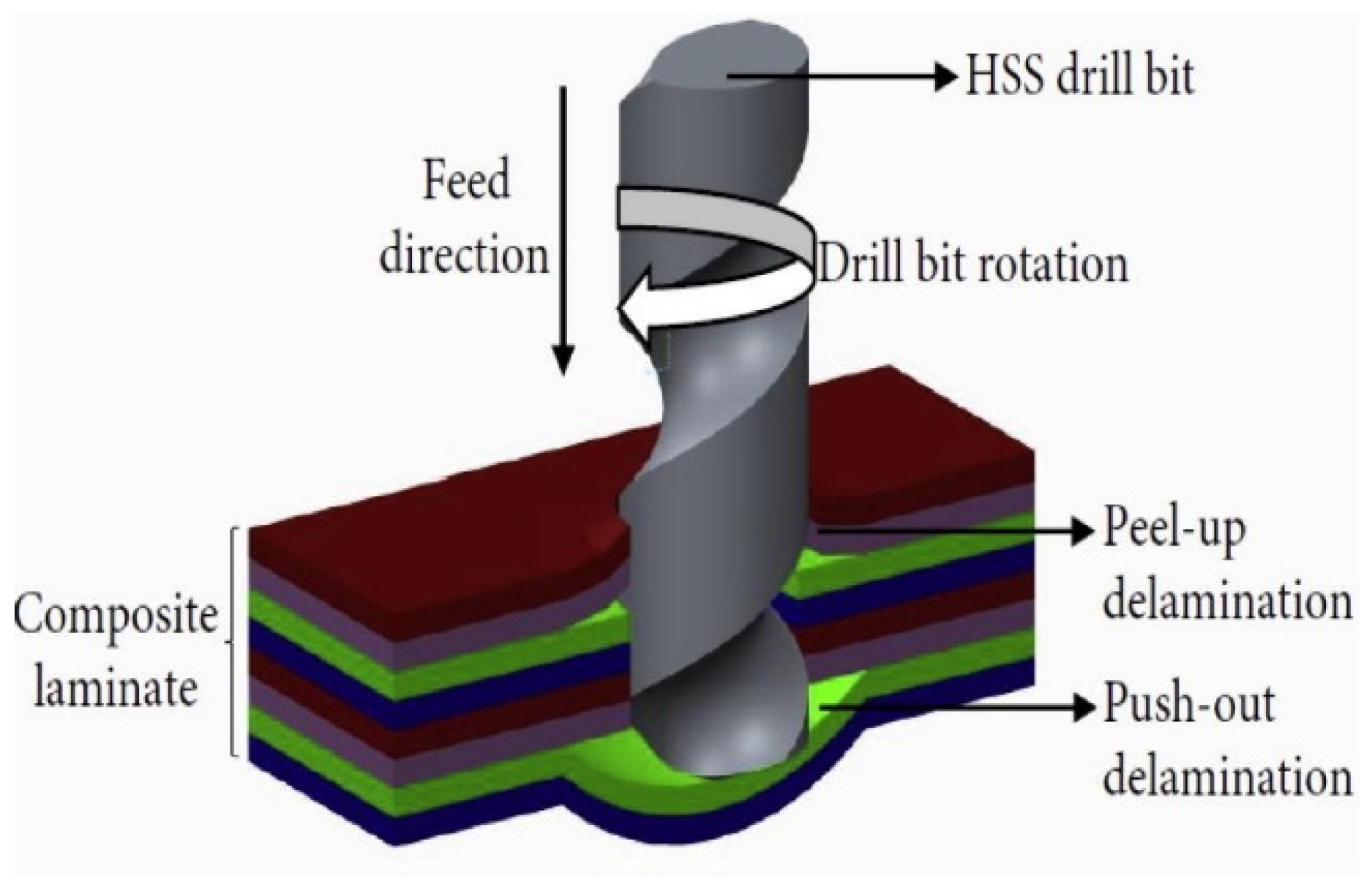

2.1. Delamination in FRPs

2.2. Surface Roughness in FRPs and Aluminum

2.3. Hole Size and Geometrical Accuracy in FRPs and Aluminum

2.4. Burr Height in Aluminum

2.5. Drilling Forces

2.6. Drilling Temperatures

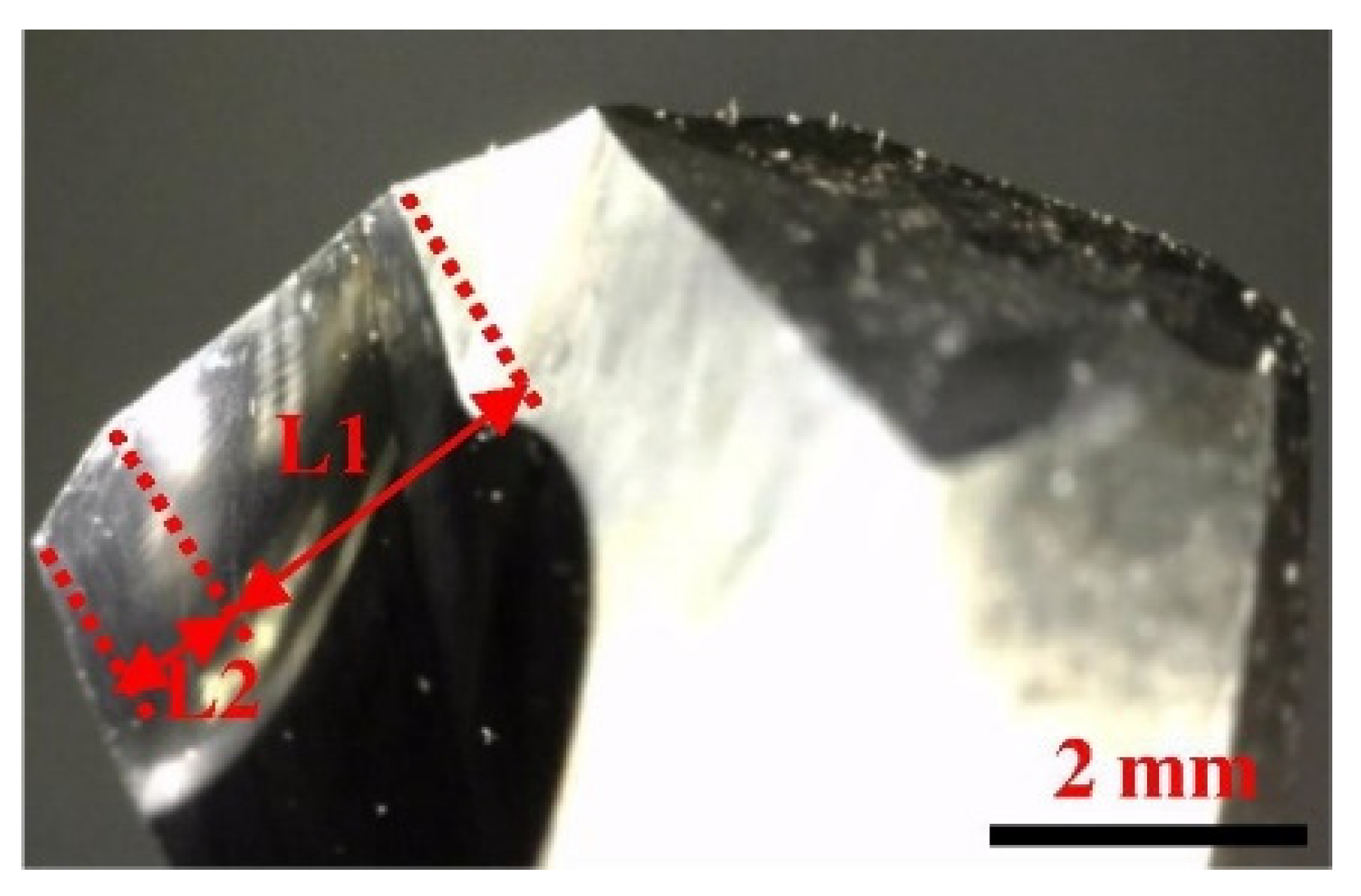

2.7. Tool Wear

2.8. Chip Formation

3. Optimization of Strategies for High-Performance Drilling of Multi-Material Stacks

3.1. Selection of Cutting Parameters

3.2. Selection of Cutting Tool

3.2.1. Tool Material and Coating Type

3.2.2. Morphologies and Geometries

3.2.3. Tool Wear

3.3. Selection of Cutting Process

3.3.1. Alternative Methods

3.3.2. Cooling Strategies

4. Conclusions and Future Scope

- Hybrid composite stacks, including CFRP/Al assemblies and FML composites, are increasingly employed in the manufacturing of structural components in the aerospace and aeronautics industries due to their enhanced mechanical and physical properties. Additionally, these new hybrid materials are usually bolted or riveted and thus required to be drilled in a single-shot operation and under dry conditions for both environmental and economic considerations. Unfortunately, laminated composites and aluminum alloys exhibit different properties, which complicate their simultaneous drilling and induce crippling issues such as severe tool wear, heat-induced damage, drilled-hole deviations or metal burr formation.

- Delamination, fiber breakage and hole wall damage due to metal chip transport through the FRP layer, exit burrs in the aluminum layer and hole size and geometrical errors in both constituents are the main hole defects induced by the drilling of CFRP/Al stacks and FML composites. The achievement of better drilling performance of aerospace assemblies requires monitoring and assessing both offline and online parameters with well-known devices such as optical microscopes, surface profilometers, coordinate measuring machines, piezoelectric dynamometers or thermocouples. Offline parameters, such as delamination, hole wall surface roughness, hole circularity error, hole size deviation and burr height, inform on the overall quality of the drilled hole, while online parameters, such as both cutting force temperatures, constitute major indicators related to drilling defects or tool wear.

- The stringent requirements of the aerospace industry for the drilled-hole quality of CFRP/Al stacks and FML composites are required to suppress exit aluminum burrs, minimize drilled-hole wall surface roughness and peripherical hole delamination and control the hole diameter deviation and geometrical accuracy. Numerous investigations have shown that the cutting parameters, cutting tool and cutting environment significantly influence the overall drilling performance, and optimized strategies or alternative drilling techniques should be developed to achieve high-quality delamination-free drilled holes.

- Cutting parameters represent key factors in the drilling of hybrid composite stacks since they directly impact delamination, hole surface roughness, dimensional accuracy, burr formation, drilling forces, thermal aspects, tool wear and chip formation and thus influence the drilling performance of aerospace assemblies. Generally, the feed rate was found to significantly influence cutting forces, metal chip morphology, drilled-hole wall roughness and the hole diameter of each constituent, while the choice of spindle speed had a negligible effect when drilling CFRP/Al stacks. Moreover, a reduction in the delamination extent and a rise in cutting temperature were observed when increasing cutting speed or decreasing the feed rate. Conversely, spindle speed and feed speed significantly influence cutting forces, drilled-hole wall surface roughness and burr size when drilling GLARE composites. Hence, the combination of low feed speed and low or moderate spindle speed is recommended to achieve minimum roughness, better surface finish and good hole quality, while cutting forces can be minimized when drilling with higher spindle speed.

- Tool characteristics and tool coating are other key factors in the drilling of CFRP/Al stacks and FML composites, which need to be carefully selected in order to drill high-quality holes and enhance tool life without increasing manufacturing costs. Cemented and tungsten carbide tools are preferred to HSS tools due to their better performance, even at high temperatures. The deposition of a coating layer generally delays tool wear and extends tool life. Nano- and diamond-coated drills cause a significant reduction in thrust forces and achieve lower hole wall surface roughness, while TiAlCrN and AlTiSiN-G coatings are inefficient in terms of tool wear prevention. Moreover, wear mechanisms are different depending on the type of tool coating. TiAlN-coated tools are essentially affected by abrasion, while DLC-coated drills exhibit chipping, edge rounding and abrasion. DLC coating allows the achievement of a lower delamination factor than TiAlN coating.

- Drill bit morphologies and geometries also affect hole surface quality, delamination and tool performance. Double cone, brad and spur and step drills allow thrust forces to be reduced. The brad and spur drill can also improve hole accuracy and achieve lower surface roughness, while a double cone drill is found to decrease the hole wall surface roughness compared to the conventional twist drill. Nevertheless, the conventional twist drill remains the tool commonly used when drilling CFRP/Al stacks and FML composites. Hence, significant efforts are made to optimize the characteristic angles of the twist drill to promote high-quality holes. The point angle influences thrust force and delamination. Lower values of this angle reduce delamination damage but increase thrust forces. Smaller thrust forces are produced when decreasing the clearance and chisel edge angles, while smoother surface roughness is achieved when increasing the chisel edge angle or decreasing the clearance angle. The combination of a 45° chisel edge angle, 7° primary clearance angle and 130° point angle is recommended to achieve minimum thrust force and the best hole surface roughness when drilling CFRP/AA7075-T6 stacks in a single-shot process.

- Vibration-assisted drilling and orbital drilling are two emerging drilling techniques for CFRP/Al stacks and FML composites, and promising results are found concerning the reduction in the delamination extent, the lessening of thrust forces, the decrease in cutting temperatures and the improvement of the fragmentation and evacuation of metal chips. For the VAD process, the vibration amplitude constitutes the key parameter influencing the overall drilled-hole quality and tool wear, while frequency seems to play no role.

- The performance of MQL and cryogenic cooling is still too little studied in the context of CFRP/Al stack and FML composite drilling. However, the few studies conducted show that tool wear is delayed and hole diameter deviations are reduced by MQL cooling strategies, while it seems to have a negative impact on the occurrence of entry delamination. Cryogenic cooling was exclusively investigated by one research team when drilling GLARE composites, and excellent results were found.

- This literature review shows that few investigations still exist on drilling temperatures or tool wear progression when drilling CFRP/Al stacks, while studies on the influence of cutting parameters are numerous. Further investigations should be performed on the optimization of the tool geometry by focusing on the relationship between cutting mechanisms, induced defects and the functional of the main geometrical characteristics of the drill. Furthermore, the drilling of CARALL and GLARE composites is not sufficiently studied, and more research projects in this area should be developed in the future.

- Numerical studies on the drilling of CFRP/Al stacks and FML composites are not discussed in the present article since this extensive review study focused only on the significant contributions of experimental investigations and studies. However, the authors are convinced that the selection of strategies for high-performance drilling of multi-material stacks could be optimized more efficiently by combining numerical methodologies with experimental studies. Few numerical studies on the drilling of CFRP/Al stacks and FML composites are currently available in the scientific literature, and this is a promising line of thought for forthcoming research works.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khashaba, U.A. Drilling of polymer matrix composites: A review. J. Compos. Mater. 2012, 47, 1817–1832. [Google Scholar] [CrossRef]

- Kuo, C.L.; Soo, S.L.; Aspinwall, D.K.; Carr, C.; Bradley, S.; M’Saoubi, R.; Leahy, W. Development of single step drilling technology for multilayer metallic-composite stacks using uncoated and PVD coated carbide tools. J. Manuf. Process. 2018, 31, 286–300. [Google Scholar] [CrossRef]

- Xu, J.; Mkaddem, A.; El Mansori, M. Recent advances in drilling hybrid FRP/Ti composite: A state-of-the-art review. Compos. Struct. 2016, 135, 316–338. [Google Scholar] [CrossRef]

- Liang, X.; Wu, D.; Gao, Y.; Chen, K. Investigation on the non-coaxiality in the drilling of carbon-fibre-reinforced plastic and aluminium stacks. Int. J. Mach. Tools Manuf. 2018, 125, 1–10. [Google Scholar] [CrossRef]

- Singh, A.P.; Sharma, M.; Singh, I. A review of modelling and control during drilling of fiber reinforced plastic composites. Compos. B Eng. 2013, 47, 118–125. [Google Scholar] [CrossRef]

- Mouritz, A.P. Introduction to Aerospace Materials; Woodhead Publishing: Sawaston, UK, 2012. [Google Scholar]

- Zitoune, R.; Krishnaraj, V.; Collombet, F. Study of drilling of composite material and aluminium stack. Compos. Struct. 2010, 92, 1246–1255. [Google Scholar] [CrossRef]

- Ashrafi, S.A.; Sharif, S.; Farid, A.A.; Yahya, M.Y. Performance evaluation of carbide tools in drilling CFRP-Al stacks. J. Compos. Mater. 2014, 48, 2071–2084. [Google Scholar] [CrossRef]

- Vlot, A.; Gunnink, J.W. Fibre Metal Laminates: An Introduction, 1st ed.; Kluwer Academic Publishers: Dordrecht, The Netherland, 2001. [Google Scholar]

- Wu, G.; Yang, J.M. The mechanical behavior of GLARE laminates for aircraft structures. JOM 2005, 57, 72–79. [Google Scholar] [CrossRef]

- Bonhin, E.P.; David-Müzel, S.; de Sampaio Alves, M.C.; Botelho, E.C.; Ribeiro, M.V. A review of mechanical drilling on fiber metal laminates. J. Compos. Mater. 2020, 55, 843–869. [Google Scholar] [CrossRef]

- Kuo, C.L.; Soo, S.L.; Aspinwall, D.K.; Thomas, W.; Bradley, S.; Pearson, D.; M’Saoubi, R.; Leahy, W. The effect of cutting speed and feed rate on hole surface integrity in single-shot drilling of metallic-composite stacks. Procedia CIRP 2014, 13, 405–410. [Google Scholar] [CrossRef] [Green Version]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Nosrati, A. Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: A review. Int. J. Adv. Manuf. Technol. 2019, 105, 2289–2308. [Google Scholar] [CrossRef]

- Klocke, F.; Eisenblätter, G. Dry cutting. CIRP Ann. 1997, 46, 519–526. [Google Scholar] [CrossRef]

- Batzer, S.; Haan, D.; Rao, P.; Olson, W.; Sutherland, J. Chip morphology and hole surface texture in the drilling of cast aluminum alloys. J. Mater. Process. Technol. 1998, 79, 72–78. [Google Scholar] [CrossRef]

- Sreejith, P.; Ngoi, B. Dry machining: Machining of the future. J. Mater. Process. Technol. 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Dixit, U.S.; Sarma, D.K.; Davim, J.P. Environmentally Friendly Machining; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Liu, D.; Tang, Y.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Shyha, I.S.; Aspinwall, D.K.; Soo, S.L.; Bradley, S. Drill geometry and operating effects when cut-ting small diameter holes in CFRP. Int. J. Mach. Tools Manuf. 2009, 49, 1008–1114. [Google Scholar] [CrossRef]

- Abrão, A.M.; Faria, P.E.; Rubio, J.C.C.; Reis, P.; Davim, J.P. Drilling of fiber reinforced plastics: A review. J. Mater. Process. Technol. 2007, 186, 1–7. [Google Scholar] [CrossRef]

- Dandekar, C.R.; Shin, Y.C. Modeling of machining of composite materials: A review. Int. J. Mach. Tools Manuf. 2012, 57, 102–121. [Google Scholar] [CrossRef]

- Ben Soussia, A.; Mkaddem, A.; El Mansori, M. Rigorous treatment of dry cutting of FRP—Interface consumption concept: A review. Int. J. Mech. Sci. 2014, 83, 1–29. [Google Scholar] [CrossRef]

- Che, D.; Saxena, I.; Han, P.; Guo, P.; Ehmann, K.F. Machining of Carbon Fiber Reinforced Plastics/Polymers: A literature review. J. Manuf. Sci. Eng. 2014, 136, 34001. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, K.K. An approach towards damage free machining of CFRP and GFRP composite material: A review. Adv. Compos. Mater. 2015, 24, 49–63. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W.-M. High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann. 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Shetty, N.; Shahabaz, S.M.; Sharma, S.S.; Shetty, S.D. A review on finite element method for machining of composite materials. Compos. Struct. 2017, 176, 790–802. [Google Scholar] [CrossRef]

- Karataş, M.A.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Panchagnula, K.K.; Palaniyandi, K. Drilling on fiber reinforced polymer/nanopolymer composite laminates: A review. J. Mater. Res. Technol. 2018, 7, 180–189. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Review on machinability of fiber reinforced polymers: A drilling approach. Silicon 2018, 10, 2295–2305. [Google Scholar] [CrossRef]

- Wang, G.-D.; Melly, S.K. Three-dimensional finite element modeling of drilling CFRP composites using Abaqus/CAE: A review. Int. J. Adv. Manuf. Technol. 2018, 94, 599–614. [Google Scholar] [CrossRef]

- Geng, D.; Liu, Y.; Shao, Z.; Lu, Z.; Cai, J.; Li, X.; Jiang, X.; Zhang, D. Delamination formation, evaluation and suppression during drilling of composite laminates: A review. Compos. Struct. 2019, 216, 168–186. [Google Scholar] [CrossRef]

- John, K.M.; Kumaran, S.T.; Kurniawan, R.; Park, K.M.; Byeon, J.H. Review on the methodologies adopted to minimize the material damages in drilling of carbon fiber reinforced plastic composites. J. Reinf. Plast. Compos. 2019, 38, 351–368. [Google Scholar] [CrossRef]

- Cepero-Mejias, F.; Curiel-Sosa, J.L.; Blazquez, A.; Yu, T.T.; Kerrigan, K.; Phadnis, V.A. Review of recent developments and induced damage assessment in the modelling of the machining of long fibre reinforced polymer composites. Compos. Struct. 2020, 240, 112006. [Google Scholar] [CrossRef]

- Zadafiya, K.; Bandhu, D.; Kumari, S.; Chatterjee, S.; Abhishek, K. Recent trends in drilling of carbon fiber reinforced polymers (CFRPs): A state-of-the-art review. J. Manuf. Process. 2021, 69, 7–68. [Google Scholar] [CrossRef]

- Wang, X.; Wang, F.; Gu, T.; Jia, Z.; Shi, Y. Computational simulation of the damage response for machining long fibre reinforced plastic (LFRP) composite parts: A review. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106296. [Google Scholar] [CrossRef]

- Poor, D.; Geier, N.; Pereszlai, C.; Xu, J. A critical review of the drilling of CFRP composites: Burr formation, characterisation and challenges. Compos. B Eng. 2021, 223, 109155. [Google Scholar] [CrossRef]

- Du, J.; Geng, M.; Ming, W.; He, W.; Ma, J. Simulation machining of fiber-reinforced composites: A review. Int. J. Adv. Manuf. Technol. 2021, 117, 1–15. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, H.; Xu, J.; Fu, Y.; Yan, C. Recent advances in hole making of FRP/metal stacks: A review. Trans. Nanjing Univ. Aeronaut. Astronaut. 2019, 36, 361–375. [Google Scholar]

- Kim, D.; Ramulu, M. Drilling process optimization for graphite/bismaleimide–titanium alloy stacks. Compos. Struct. 2004, 63, 101–114. [Google Scholar] [CrossRef]

- Feito, N.; Muñoz-Sánchez, A.; Díaz-Álvarez, A.; Miguelez, M.H. Multi-objective optimization analysis of cutting parameters when drilling composite materials with special geometry drills. Compos. Struc. 2019, 225, 111187. [Google Scholar] [CrossRef]

- Gu, W.; Xu, H.; Liu, J.; Yue, Z. Effect of drilling process on fatigue life of open holes. Tsinghua Sci. Technol. 2009, 14, 54–57. [Google Scholar] [CrossRef]

- Liu, J.; Xu, H.; Zhai, H.; Yue, Z. Effect of detail design on fatigue performance of fastener hole. Mater. Des. 2010, 31, 976–980. [Google Scholar] [CrossRef]

- Wang, G.-D.; Melly, S.K.; Li, N.; Peng, T.; Li, Y. Research on milling strategies to reduce delamination damage during machining of holes in CFRP/Ti stack. Compos. Struc. 2018, 200, 679–688. [Google Scholar] [CrossRef]

- El-Sonbaty, I.; Khashaba, U.A.; Machaly, T. Factors affecting the machinability of GFR/epoxy composites. J. Compos. Struct. 2004, 63, 329–338. [Google Scholar] [CrossRef]

- Khashaba, U.A.; El-Sonbaty, I.; Selmy, A.I.; Megahed, A.A. Machinability analysis in drilling woven GFR/epoxy composites: Part I—Effect of machining parameters. Compos. A Appl. Sci. Manuf. 2010, 41, 391–400. [Google Scholar] [CrossRef]

- Kavad, B.V.; Pandey, A.B.; Tadavi, M.V.; Jakharia, H.C. A review paper on effects of drilling on glass fiber reinforced plastic. Proc. Technol. 2014, 14, 457–464. [Google Scholar] [CrossRef]

- Park, K.-H.; Beal, A.; Kim, D.; Kwon, P.; Lantrip, J. Tool wear in drilling of composite/titanium stacks using carbide and polycrystalline diamond tools. Wear 2011, 271, 2826–2835. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Janssen, R. Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum Alloys. CIRP Ann. 2002, 51, 87–90. [Google Scholar] [CrossRef]

- Montoya, M.; Calamaz, M.; Gehin, D.; Girot, F. Evaluation of the performance of coated and uncoated carbide tools in drilling thick CFRP/aluminium alloy stacks. Int. J. Adv. Manuf. Technol. 2013, 68, 2111–2120. [Google Scholar] [CrossRef]

- Ismail, S.O.; Dhakal, H.N.; Popov, I.; Beaugrand, J. Comprehensive study on machinability of sustainable and conventional fibre reinforced polymer composites. Eng. Sci. Technol. Int. J. 2016, 19, 2043–2052. [Google Scholar] [CrossRef]

- Caprino, G.; Tagliaferri, V. Damage development in drilling glass fiber reinforced plastics. Int. J. Mach. Tools Manuf. 1995, 35, 817–829. [Google Scholar] [CrossRef]

- Murphy, C.; Byrne, G.; Gilchrist, M.D. The performance of coated tungsten carbide drills when machining carbon fibre-reinforced epoxy composite materials. Proc. Inst. Mech. Eng. Part B 2002, 216, 143–152. [Google Scholar] [CrossRef]

- Davim, J.; Reis, P. Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos. Struct. 2003, 59, 481–487. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Davim, J.P. Prediction and minimization of delamination in drilling of medium density fiberboard (MDF) using response surface methodology and Taguchi design. Mater. Manuf. Process. 2008, 23, 377–384. [Google Scholar] [CrossRef]

- Rubio, J.C.; Abrão, A.M.; Faria, P.E.; Correia, A.E.; Davim, J.P. Effects of high speed in the drilling of glass fibre reinforced plastic: Evaluation of the delamination factor. Int. J. Mach. Tools Manuf. 2008, 48, 715–720. [Google Scholar] [CrossRef]

- Rajamurugan, T.V.; Shanmugam, K.; Palanikumar, K. Analysis of delamination in drilling glass fiber reinforced polyester composites. Mater. Des. 2013, 45, 80–87. [Google Scholar] [CrossRef]

- Gaugel, S.; Sripathy, P.; Haeger, A.; Meinhard, D.; Bernthaler, T.; Lissek, F.; Kaufeld, M.; Knoblauch, V.; Schneider, G. A comparative study on tool wear and laminate damage in drilling of carbon-fiber reinforced polymers (CFRP). Compos. Struct. 2016, 155, 173–183. [Google Scholar] [CrossRef]

- Haeger, A.; Schoen, G.; Lissek, F.; Meinhard, D.; Kaufeld, M.; Schneider, G.; Schuhmacher, S.; Knoblauch, V. Non-destructive detection of drilling-induced delamination in CFRP and its effect on mechanical properties. Procedia Eng. 2016, 149, 130–142. [Google Scholar] [CrossRef]

- Hrechuk, A.; Bushlya, V.; Ståhl, J. Hole-quality evaluation in drilling fiber-reinforced composites. Compos. Struct. 2018, 204, 378–387. [Google Scholar] [CrossRef]

- Khashaba, U.A. Delamination in drilling GFR-thermoset composites. Compos. Struct. 2004, 63, 313–327. [Google Scholar] [CrossRef]

- Davim, J.; Rubio, J.; Abrão, A. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos. Sci. Technol. 2007, 67, 1939–1945. [Google Scholar] [CrossRef]

- Faraz, A.; Biermann, D.; Weinert, K. Cutting edge rounding: An innovative tool wear criterion in drilling CFRP composite laminates. Int. J. Mach. Tools. Manuf. 2009, 49, 1185–1196. [Google Scholar] [CrossRef]

- Durão, L.M.; Gonçalves, D.J.; Tavares, J.M.R.; de Albuquerque, V.H.C.; Vieira, A.A.; Marques, A.T. Drilling tool geometry evaluation for reinforced composite laminates. Compos. Struct. 2010, 92, 1545–1550. [Google Scholar] [CrossRef]

- Durão, L.M.; Tavares, M.R.; de Albuquerque, V.H.C. Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos. Struct. 2013, 96, 576–583. [Google Scholar] [CrossRef] [Green Version]

- Silva, D.; Teixeira, J.P.; Machado, C.M. Methodology analysis for evaluation of drilling induced damage in composites. Int. J. Adv. Manuf. Technol. 2014, 71, 1919–1928. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int. J. Mach. Tools Manuf. 2004, 44, 1085–1090. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C.C. Computerized tomography and C-scan for measuring drilling-induced delamination in composite material using twist drill and core drill. Key. Eng. Mater. 2007, 339, 16–20. [Google Scholar] [CrossRef]

- Tsao, C.C.; Kuo, K.L.; Hsu, I.C. Evaluation of a novel approach to a delamination factor after drilling composite laminates using a core–saw drill. Int. J. Adv. Manuf. Technol 2012, 59, 617–622. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H.; Chen, Y.C. Delamination reduction in drilling composite materials by active backup force. CIRP Ann. Manuf. Technol. 2012, 61, 91–94. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Mi, S.; An, Q.; Chen, M. Study of drilling-induced defects for CFRP composites using new criteria. Compos. Struct. 2018, 201, 1076–1087. [Google Scholar] [CrossRef]

- Chen, W.C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int. J. Mach. Tools. Manuf. 1997, 37, 1097–1108. [Google Scholar] [CrossRef]

- Saoudi, J.; Zitoune, R.; Mezlini, S.; Gururaja, S.; Seitier, P. Critical thrust force predictions during drilling: Analytical modeling and X-ray tomography quantification. Compos. Struct. 2016, 153, 886–894. [Google Scholar] [CrossRef]

- Xu, J.; An, Q.; Cai, X.; Chen, M. Drilling machinability evaluation on new developed high-strength T800S/250F CFRP laminates. Int. J. Precis. Eng. Manuf. 2013, 14, 1687–1696. [Google Scholar] [CrossRef]

- Mohan, N.S.; Kulkarni, S.M.; Ramachandra, A. Delamination analysis in drilling process of glass fiber reinforced plastic (GFRP) composite materials. J. Mater. Process. Technol. 2007, 186, 265–271. [Google Scholar] [CrossRef]

- Nagarajan, V.A.; Selwin Rajadurai, J.; Annil Kumar, T.A. Digital image analysis to evaluate delamination factor for wind turbine composite laminate blade. Compos. B. Eng. 2012, 43, 3153–3159. [Google Scholar] [CrossRef]

- Hassan, M.H.; Abdullah, J.; Franz, G. Multi-objective optimization in single-shot drilling of CFRP/Al stacks using customized twist drill. Materials 2022, 15, 1981. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. An experimental study on drilling of unidirectional GLARE fibre metal laminates. Compos. Struct. 2015, 133, 794–808. [Google Scholar] [CrossRef]

- Palanikumar, K.; Karunamoorthy, L.; Karthikeyan, R. Assessment of factors influencing surface roughness on the ma-chining of glass fiber-reinforced polymer composites. Mater. Des. 2006, 27, 862–871. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynac, Y.; Bagci, E. Evaluation of drilled hole quality in Al 2024 alloy. Int. J. Adv. Manuf. Technol. 2008, 37, 1051–1060. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Kumar, M.S.; Zitoune, R.; Davim, J. Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos. Part B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Sui, S.; Song, G.; Sun, C.; Zhu, Z.; Guo, K.; Sun, J. Experimental investigation on the performance of novel double cone integrated tool in one-shot drilling of metal stacks. Int. J. Adv. Manuf. Technol. 2020, 109, 523–534. [Google Scholar] [CrossRef]

- Mahdi, A.; Turki, Y.; Habak, M.; Salem, M.; Bouaziz, Z. Experimental study of thrust force and surface quality when drilling hybrid stacks. Int. J. Adv. Manuf. Technol. 2020, 107, 3981–3994. [Google Scholar] [CrossRef]

- Jia, Z.-Y.; Zhang, C.; Wang, F.-J.; Fu, R.; Chen, C. Multi-margin drill structure for improving hole quality and dimensional consistency in drilling Ti/CFRP stacks. J. Mater. Process. Technol. 2020, 276, 116405. [Google Scholar] [CrossRef]

- Ghidossi, P.; El Mansori, M.; Pierron, F. Edge machining effects on the failure of polymer matrix composite coupons. Compos. A 2004, 35, 989–999. [Google Scholar] [CrossRef]

- König, W.; Graß, P. Quality definition and assessment in drilling of fibre reinforced thermosets. CIRP Ann. 1989, 38, 119–124. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Chen, Y.-H.; An, Q.-L.; Cai, X.-J.; Ming, W.-W.; Chen, M. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill. Int. J. Precis. Eng. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Tian, W.; Liao, W. Experimental studies on the performance of different structure tools in drilling CFRP/Al alloy stacks. Int. J. Adv. Manuf. Technol. 2015, 81, 241–251. [Google Scholar] [CrossRef]

- Shilpa, M.K.; Yendapalli, V. Surface roughness estimation techniques for drilled surfaces: A review. Mater. Today Proc. 2022, 52, 1082–1091. [Google Scholar] [CrossRef]

- Zitoune, R.; Krishnaraj, V.; Almabouacif, B.S.; Collombet, F.; Sima, M.; Jolin, A. Influence of machining parameters and new nano-coated tool on drilling performance of CFRP/Aluminium sandwich. Compos. Part B Eng. 2012, 43, 1480–1488. [Google Scholar] [CrossRef]

- Shyha, I.S.; Soo, S.L.; Aspinwall, D.K.; Bradley, S.; Perry, R.; Harden, P.; Dawson, S. Hole quality assessment following drilling of metallic-composite stacks. Int. J. Mach. Tools Manuf. 2011, 51, 569–578. [Google Scholar] [CrossRef]

- Zitoune, R.; Cadorin, R.; Elambouacif, B.S.; Collombet, F.; Krishnaraj, V.; Bougherara, H. Influence of the double cone drill geometry on the holes quality during drilling multi-stack made of CFRP/Al. Int. J. Mater Mech. Manuf. 2014, 2, 292–296. [Google Scholar]

- Meshreki, M.; Damir, A.; Sadek, A.; Attia, M.H. Investigation of drilling of CFRP-Aluminum stack under different cooling modes. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar]

- Zitoune, R.; Krishnaraj, V.; Collombet, F.; Le Roux, S. Experimental and numerical analysis on drilling of carbon fibre reinforced plastic and aluminium stacks. Compos. Struct. 2016, 146, 148–158. [Google Scholar] [CrossRef]

- Hassan, M.H.; Abdullah, J.; Mahmud, A.S.; Supran, A. Effects of twist drill geometry and drilling parameters on CFRP-aluminum stack up in single shot drilling. SciFed Mater. Res. Lett. 2018, 2, 1–14. [Google Scholar]

- Bañon, F.; Sambruno, A.; Fernández-Vidal, S.; Fernández-Vidal, S.R. One-shot drilling analysis of stack CFRP/UNS A92024 bonding by adhesive. Materials 2019, 12, 160. [Google Scholar] [CrossRef] [PubMed]

- Janakiraman, A.; Pemmasani, S.; Sheth, S.; Kannan, C. Experimental investigation and parametric optimization on hole quality assessment during drilling of CFRP/GFRP/Al stacks. J. Inst. Eng. India Ser. C 2020, 101, 291–302. [Google Scholar] [CrossRef]

- Hassan, M.; Abdullah, J.; Franz, G.; Shen, C.; Mahmoodian, R. Effect of twist drill geometry and drilling parameters on hole quality in single-shot drilling of CFRP/Al7075-T6 Composite Stack. J. Compos. Sci. 2021, 5, 189. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S. An Investigation of burrs, chip formation, hole size, circularity and delamination during drilling operation of GLARE using ANOVA. Compos. Struct. 2017, 159, 745–760. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, C.H.; Choi, H.S. Effect of drilling parameters on hole quality and delamination of hybrid GLARE laminate. Compos. Struct. 2018, 185, 684–698. [Google Scholar] [CrossRef]

- Giasin, K.; Gorey, G.; Byrne, C.; Sinke, J.; Brousseau, E. Effect of machining parameters and cutting tool coating on hole quality in dry drilling of fibre metal laminates. Compos. Struct. 2019, 212, 159–174. [Google Scholar] [CrossRef]

- Bolar, G.; Sridhar, A.K.; Ranjan, A. Drilling and helical milling for hole making in multi-material carbon reinforced aluminum laminates. Int. J. Lightweight Mater. Manuf. 2022, 5, 113–125. [Google Scholar] [CrossRef]

- Kuo, C.; Li, Z.; Wang, C. Multi-objective optimisation in vibration-assisted drilling of CFRP/Al stacks. Compos. Struct. 2017, 173, 196–209. [Google Scholar] [CrossRef]

- D’Orazio, A.; El Mehtedi, M.; Forcellese, A.; Nardinocchi, A.; Simoncini, M. Tool wear and hole quality in drilling of CFRP/AA7075 stacks with DLC and nanocomposite TiAlN coated tools. J. Manuf. Process. 2017, 30, 582–592. [Google Scholar] [CrossRef]

- Ekici, E.; Motorcu, A.R.; Yildirim, E. An experimental study on hole quality and different delamination approaches in the drilling of CARALL, a new FML composite. FME Trans. 2021, 49, 950–961. [Google Scholar] [CrossRef]

- Zhang, H.; Dang, J.; An, Q.; Cai, X.; Chen, M. Study on the drilling performances of a newly developed CFRP/invar co-cured material. J. Manuf. Process. 2021, 66, 669–678. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. The effects of minimum quantity lubrication and cryogenic liquid nitrogen cooling on drilled hole quality in GLARE fibre metal laminates. Mater. Des. 2016, 89, 996–1006. [Google Scholar] [CrossRef]

- Giasin, K.; Hawxwell, J.; Sinke, J.; Dhakal, H.; Köklü, U.; Brousseau, E. The effect of cutting tool coating on the form and dimensional errors of machined holes in GLARE fibre metal laminates. Int. J. Adv. Manuf. Technol. 2020, 107, 2817–2832. [Google Scholar] [CrossRef]

- Seeholzer, L.; Voss, R.; Marchetti, L.; Wegener, K. Experimental study: Comparison of conventional and low-frequency vibration-assisted drilling (LF-VAD) of CFRP/aluminium stacks. Int. J. Adv. Manuf. Technol. 2019, 104, 433–449. [Google Scholar] [CrossRef]

- Zou, F.; Dang, J.; An, Q.; Chen, M. Mechanism and feasibility study of low frequency vibration assisted drilling of a newly developed CFRP/Al co-cured material. J. Manuf. Process. 2021, 68, 115–127. [Google Scholar] [CrossRef]

- Rivero, A.; Aramendi, G.; Herranz, S.; Lopez de Lacalle, L.N. An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int. J. Adv. Manuf. Technol. 2006, 28, 1–11. [Google Scholar] [CrossRef]

- Devitte, C.; Souza, G.S.C.; Souza, A.J.; Tita, V. Optimization for drilling process of metal composite aeronautical structures. Sci. Eng. Compos. 2021, 28, 264–275. [Google Scholar] [CrossRef]

- Costa, E.S.; da Silva, M.B.; Machado, A.R. Burr produced on the drilling process as a function of tool wear and lubricant-coolant conditions. J. Braz. Soc. Mech. Sci. Eng. 2009, 31, 57–63. [Google Scholar] [CrossRef]

- Avila, M.C.; Gardner, J.D.; Reich-Weiser, C.; Vijayaraghavan, A.; Dornfeld, D. Strategies for burr minimization and cleanability in aerospace and automotive manufacturing. SAE Trans. J. Aerosp. 2006, 114, 1073–1081. [Google Scholar]

- Bu, Y.; Liao, W.H.; Tian, W.; Shen, J.X.; Hu, J. An analytical model for exit burrs in drilling of aluminum materials. Int. J. Adv. Manuf. Tech. 2016, 85, 2783–2796. [Google Scholar] [CrossRef]

- Min, S.; Kim, J.; Dornfeld, D.A. Development of a drilling burr control chart for low alloy steel, AISI 4118. J. Mater. Process. Technol. 2001, 113, 4–9. [Google Scholar] [CrossRef]

- Rezende, B.A.; Silveira, M.L.; Vieira, L.M.G.; Abrão, A.M.; Faria, P.E.; Rubio, J.C.C. Investigation on the effect of drill geometry and pilot holes on thrust force and burr height when drilling an aluminium/PE sandwich material. Materials 2016, 9, 774. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Liao, W.; Zheng, K.; Liu, J.; Feng, J. Investigation on exit burr in robotic rotary ultrasonic drilling of CFRP/aluminum stacks. Int. J. Mech. Sci. 2019, 151, 868–876. [Google Scholar] [CrossRef]

- Möhring, H.-C.; Kimmelmann, M.; Eschelbacher, S.; Güzel, K.; Gauggel, C. Process monitoring on drilling fiber-reinforced plastics and aluminium stacks using acoustic emissions. Procedia Manuf. 2018, 18, 58–67. [Google Scholar] [CrossRef]

- Kimmelmann, M.; Duntschew, J.; Schluchter, I.; Möhring, H.-C. Analysis of burr formation mechanisms when drilling CFRP-aluminium stacks using acoustic emission. Procedia Manuf. 2019, 40, 64–69. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Rivero, A.; Lamikiz, A. Mechanistic model for drills with double point-angle edges. Int. J. Adv. Manuf. Technol. 2009, 40, 447–457. [Google Scholar] [CrossRef]

- Zitoune, R.; Collombet, F. Numerical prediction of the thrust force responsible of delamination during the drilling of the long-fibre composite structures. Compos. A Appl. Sci. 2007, 38, 858–866. [Google Scholar] [CrossRef]

- Pardo, A.; Majeed, M.; Heinemann, R. Process signals characterisation to enable adaptive drilling of aerospace stacks. Procedia CIRP 2020, 88, 479–484. [Google Scholar] [CrossRef]

- Fernández-Vidal, S.R.; Fernández-Vidal, S.; Batista, M.; Salguero, J. Tool wear mechanism in cutting of stack CFRP/UNS A97075. Materials 2018, 11, 1276. [Google Scholar] [CrossRef]

- Soo, S.L.; Abdelhafeez, A.M.; Li, M.; Hood, R.; Lim, C.M. The drilling of carbon fibre composite-aluminium stacks and its effect on hole quality and integrity. Proc. Inst. Mech. Eng. B Manag. Eng. Manufact. 2019, 233, 1323–1331. [Google Scholar] [CrossRef]

- Bonnet, C.; Poulachon, G.; Rech, J.; Girard, Y.; Costes, J.P. CFRP drilling: Fundamental study of local feed force and consequences on hole exit damage. Int. J. Mach. Tools Manuf. 2015, 94, 57–64. [Google Scholar] [CrossRef]

- Zhong, B.; Zou, F.; An, Q.; Chen, M.; Zhang, H.; Xie, C. Experimental study on drilling process of a newly developed CFRP/Al/CFRP co-cured material. J. Manuf. Process. 2022, 75, 476–484. [Google Scholar] [CrossRef]

- Sridhar, A.K.; Bolar, G.; Padmaraj, N.H. Comprehensive experimental investigation on drilling multi-material carbon fiber reinforced aluminum laminates. J. King Saud Univ. Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Boughdiri, I.; Giasin, K.; Mabrouki, T.; Zitoune, R. Effect of cutting parameters on thrust force, torque, hole quality and dust generation during drilling of GLARE 2B laminate. Compos. Struct. 2021, 261, 113562. [Google Scholar] [CrossRef]

- Fujishima, M.; Ohno, K.; Nishikawa, S.; Nishimura, K.; Sakamoto, M.; Kawai, K. Study of sensing technologies for machine tools. CIRP J. Manuf. Sci. Technol. 2016, 14, 71–75. [Google Scholar] [CrossRef]

- Benezech, L.; Landon, Y.; Rubio, W. Study of manufacturing defects and tool geometry optimisation for multi-material stack drilling. Adv. Mat. Res. 2011, 423, 1–11. [Google Scholar] [CrossRef]

- Neugebauer, R.; Ben-Hanan, U.; Ihlenfeldt, S.; Wabner, M.; Stoll, A. Acoustic emission as a tool for identifying drill position in fiber-reinforced plastic and aluminum stacks. Int. J. Mach. Tools Manuf. 2012, 57, 20–26. [Google Scholar] [CrossRef]

- Wertheim, R.; Ben-Hanan, U.; Ihlenfeldt, S.; Stoll, A.; Treppe, F.; Wabner, M. Acoustic emission for controlling drill position in fiber-reinforced plastic and metal stacks. CIRP Ann. Manuf. Technol. 2012, 61, 75–78. [Google Scholar] [CrossRef]

- El Bouami, S.; Habak, M.; Velasco, R.; Dos Santos, B.; Franz, G.; Vantomme, P. Tool geometry optimization for drilling CFRP/Al-Li stacks with a lightning strike protection. AIP Conf. Proc. 2017, 1896, 090009. [Google Scholar]

- Bleicher, F.; Wiesinger, G.; Kumpf, C.; Finkeldei, D.; Baumann, C.; Lechner, C. Vibration assisted drilling of CFRP/metal stacks at low frequencies and high amplitudes. Prod. Eng. 2018, 12, 289–296. [Google Scholar] [CrossRef]

- Wang, G.-D.; Kirwa, M.S.; Li, N. Experimental studies on a two-step technique to reduce damage during milling of large diameter holes in CFRP/Al stack delamination. Compos. Struct. 2018, 188, 330–339. [Google Scholar] [CrossRef]

- Dang, J.; Zou, F.; Cai, X.; An, Q.; Ming, W.; Chen, M. Experimental investigation on mechanical drilling of a newly developed CFRP/Al co-cured material. Int. J. Adv. Manuf. Technol. 2020, 106, 993–1004. [Google Scholar] [CrossRef]

- Sato, M.; Tanaka, H.; Yamamoto, K. Temperature variations in drilling of CFRP/aluminum and CFRP/titanium stacks. Int. J. Autom. Technol. 2016, 10, 348–355. [Google Scholar] [CrossRef]

- Park, J.-M.; Kwon, D.-J.; Wang, Z.-J.; Gu, G.-Y.; DeVries, K.L. A new strategy of carbon fiber reinforced plastic drilling evaluation using thermal measurement. J. Compos. Mater. 2013, 47, 2005–2011. [Google Scholar] [CrossRef]

- Yashiro, T.; Ogawa, T.; Sasahara, H. Temperature measurement of cutting tool and machined surface layer in milling of CFRP. Int. J. Mach. Tools Manuf. 2013, 70, 63–69. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. An embedded multi-sensor system on the rotating dynamometer for real-time condition monitoring in milling. Int. J. Adv. Manuf. Technol. 2018, 95, 811–823. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Almaskari, F.; Hafeez, F. Thermal aspects in machining CFRPs: Effect of cutter type and cutting parameters. Int. J. Adv. Manuf. Technol. 2019, 100, 2569–2582. [Google Scholar] [CrossRef]

- Pinillos, U.A.; Fernández-Vidal, S.R.; Calamaz, M.; Girot Mata, F.A. Wear mechanisms and wear model of carbide tools during dry Drilling of CFRP/TiAl6V4 Stacks. Materials 2019, 12, 2843. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, L.; Chen, M.; Ren, F. Experimental study on mechanical drilling of carbon/epoxy composite-Ti6Al4V stacks. Mater. Manuf. Process. 2019, 34, 715–725. [Google Scholar] [CrossRef]

- Moghaddas, M.A.; Yi, A.Y.; Graff, K.F. Temperature measurement in ultrasonic-assisted drilling process. Int. J. Adv. Manuf. Technol. 2019, 103, 187–199. [Google Scholar] [CrossRef]

- Kolesnyk, V.; Kryvoruchko, D.; Hatala, M.; Mital, D.; Hutyrova, Z.; Duplak, J.; Alowa, M. The effect of cutting temperature on carbide drilling life in the process of CFRP/steel stacks drilling. Manuf. Technol. 2015, 15, 357–362. [Google Scholar] [CrossRef]

- Sanda, A.; Arriola, I.; Navas, V.G.; Bengoetxea, I.; Gonzalo, O. Ultrasonically assisted drilling of carbon fibre reinforced plastics and Ti6Al4V. J. Manuf. Process. 2016, 22, 169–176. [Google Scholar] [CrossRef]

- Wei, Y.; An, Q.; Ming, W.; Chen, M. Effect of drilling parameters and tool geometry on drilling performance in drilling carbon fiber-reinforced plastic/titanium alloy stacks. Adv. Mech. Eng. 2016, 8, 1687814016670281. [Google Scholar] [CrossRef]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M.H. Low-frequency vibration-assisted drilling of hybrid CFRP/Ti6Al4V stacked material. Int. J. Adv. Manuf. Technol. 2018, 98, 2801–2817. [Google Scholar] [CrossRef]

- Onawumi, P.Y.; Roy, A.; Silberschmidt, V.V.; Merson, E. Ultrasonically assisted drilling of aerospace CFRP/Ti stack. Procedia CIRP 2018, 77, 383–386. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Duan, Y. Effect of drilling area temperature on drilling of carbon fiber reinforced polymer composites due to temperature-dependent properties. Int. J. Adv. Manuf. Technol. 2018, 96, 2943–2951. [Google Scholar] [CrossRef]

- An, Q.; Dang, J.; Li, J.; Wang, C.; Chen, M. Investigation on the cutting responses of CFRP/Ti stacks: With special emphasis on the effects of drilling sequences. Compos. Struct. 2020, 253, 112794. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Chen, M.; El Mansori, M.; Davim, J.P. On the analysis of temperatures, surface morphologies and tool wear in drilling CFRP/Ti6Al4V stacks under different cutting sequence strategies. Compos. Struct. 2020, 234, 111708. [Google Scholar] [CrossRef]

- Angelone, R.; Caggiano, A.; Improta, I.; Nele, L.; Teti, R. Characterization of hole quality and temperature in drilling of Al/CFRP stacks under different process condition. Procedia CIRP 2019, 79, 319–324. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S. Evaluation of workpiece temperature during drilling of GLARE fiber metal laminates using infrared techniques: Effect of cutting parameters, fiber orientation and spray mist application. Materials 2016, 9, 622. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, D.; Qin, L.; Yan, L. Feasibility study of the rotary ultrasonic elliptical machining of carbon fiber reinforced plastics (CFRP). Int. J. Mach. Tools Manuf. 2012, 53, 141–150. [Google Scholar] [CrossRef]

- Wang, X.; Kwon, P.Y.; Sturtevant, C.; Lantrip, J. Tool wear of coated drills in drilling CFRP. J. Manuf. Process. 2013, 15, 127–135. [Google Scholar] [CrossRef]

- Fang, N.; Dewhurst, P. Slip-line modeling of built-up edge formation in machining. Int. J. Mech. Sci. 2005, 47, 1079–1098. [Google Scholar] [CrossRef]

- List, G.; Nouari, M.; Gehin, D.; Gomez, S.; Manaud, P.; Le Petitcorps, Y.; Girot, F. Wear behaviour of cemented carbide tools in dry machining of aluminium alloy. Wear 2005, 259, 1177–1189. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F.; Gehin, G. Effect of machining parameters and coating on wear mechanisms in dry drilling of aluminium alloys. Int. J. Mach. Tools. Manuf. 2005, 45, 1436–1442. [Google Scholar] [CrossRef]

- Jeong, M.-J.; Lee, S.-W.; Jang, W.-K.; Kim, H.-J.; Seo, Y.-H.; Kim, B.-H. Prediction of drill bit breakage using an infrared sensor. Sensors 2021, 21, 2808. [Google Scholar] [CrossRef]

- Wika, K.; Sharman, A.; Goulbourne, D.; Ridgway, K. Impact of Number of Flutes and Helix Angle on Tool Performance and Hole Quality in Drilling Composite/Titanium Stacks; SAE Technical Paper 2011-01-2744; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S. Manufacturing Processes for Engineering Materials, 5th ed.; Pearson: London, UK, 2008. [Google Scholar]

- Arola, D.D.; Ramulu, M.; Wang, D. Chip formation in orthogonal trimming of graphite/epoxy composite. Compos. A Appl. Sci. Manuf. 1998, 27, 121–133. [Google Scholar] [CrossRef]

- Kim, D.; Ramulu, M.; Pedersen, W. Machinability of titanium/graphite hybrid composites in drilling. Trans. NAMRI/SME 2005, 33, 445–452. [Google Scholar]

- El Bouami, S.; Habak, M.; Franz, G.; Velasco, R.; Vantomme, P. Effect of tool geometry and cutting parameters on delamination and thrust forces in drilling CFRP/Al-Li. AIP Conf. Proc. 2016, 1769, 080012. [Google Scholar]

- Krishnaraj, V.; Zitoune, R.; Collombet, F. Study of drilling of multi-material (CFRP/Al) using Taguchi and statistical techniques. Usak Univ. J. Mater. Sci. 2012, 2, 95–109. [Google Scholar]

- Bayraktar, S.; Turgut, Y. Determination of delamination in drilling of carbon fiber reinforced carbon matrix composites/Al 6013-T651 stacks. Measurement 2020, 154, 107493. [Google Scholar] [CrossRef]

- Pawar, O.A.; Gaikhe, Y.S.; Tewari, A.; Sundaram, R.; Joshi, S.S. Analysis of hole quality in drilling GLARE fiber metal laminates. Compos. Struct. 2015, 123, 350–365. [Google Scholar] [CrossRef]

- Ekici, E.; Motorcu, A.R.; Uzun, G. Multi-objective optimization of process parameters for drilling fiber-metal laminate using a hybrid GRAPCA approach. FME Trans. 2021, 49, 356–366. [Google Scholar] [CrossRef]

- Bonhin, E.P.; David-Müzel, S.; Guidi, E.S.; Botelho, E.C.; Ribeiro, M.V. Influence of drilling parameters on thrust force and burr on fiber metal laminate Al 2024-T3/glass fiber reinforced epoxy. Procedia CIRP 2021, 101, 338–341. [Google Scholar] [CrossRef]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. A review: Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Geier, N.; Davim, J.P.; Szalay, T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review. Compos. A Appl. Sci. Manuf. 2019, 125, 105552. [Google Scholar] [CrossRef]

- Bertollo, N.; Walsh, W.R. Drilling of bone: Practicality, limitations and complications associated with surgical drill-Bits. Biomech. Appl. 2011, 4, 53–83. [Google Scholar]

- Zhang, L.; Wang, L.; Wang, X. Study on vibration drilling of fiber reinforced plastics with hybrid variation parameters method. Compos. Part. A Appl. Sci. Manuf. 2003, 34, 237–244. [Google Scholar]

- Wang, X.; Wang, L.J.; Tao, J.P. Investigation on thrust in vibration drilling of fiber reinforced plastics. J. Mater. Process. Technol. 2004, 148, 239–244. [Google Scholar] [CrossRef]

- Sadek, A.; Attia, M.H.; Meshreki, M.; Shi, B. Characterization and optimization of vibration-assisted drilling of fibre reinforced epoxy laminates. CIRP Ann. Manuf. Technol. 2013, 62, 91–94. [Google Scholar] [CrossRef]

- Debnath, K.; Singh, I. Low-frequency modulation-assisted drilling of carbon-epoxy composite laminates. J. Manuf. Process. 2017, 25, 262–273. [Google Scholar] [CrossRef]

- Makhdum, F.; Phadnis, V.A.; Roy, A.; Silberschmidt, V.V. Effect of ultrasonically-assisted drilling on carbon-fibre-reinforced plastics. J. Sound Vib. 2014, 333, 5939–5952. [Google Scholar] [CrossRef]

- Laporte, S.; De Castelbajac, C. Major breakthrough in multi material drilling, using low frequency axial vibration assistance. SAE Int. J. Mater. Manuf. 2013, 6, 11–18. [Google Scholar] [CrossRef]

- Pecat, O.; Brinksmeier, E. Low damage drilling of CFRP/titanium compound materials for fastening. Procedia CIRP 2014, 13, 1–7. [Google Scholar] [CrossRef]

- Pecat, O.; Brinksmeier, E. Tool wear analyses in low frequency vibration assisted drilling of CFRP/Ti6Al4V stack material. Procedia CIRP 2014, 14, 142–147. [Google Scholar] [CrossRef]

- Lonfier, J.; De Castelbajac, C. A comparison between regular and vibration-assisted drilling in CFRP/Ti6Al4V stack. SAE Int. J. Mater. Manuf. 2015, 8, 18–26. [Google Scholar] [CrossRef]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M.H. Surface and microstructure characterization of low-frequency vibration-assisted drilling of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2019, 103, 1443–1457. [Google Scholar] [CrossRef]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M.H. An investigation into tool wear and hole quality during low-frequency vibration-assisted drilling of CFRP/Ti6Al4V stack. J. Mater. Process. Technol. 2019, 3, 3030063. [Google Scholar] [CrossRef] [Green Version]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M.H. Elimination of delamination and burr formation using high-frequency vibration-assisted drilling of hybrid CFRP/Ti6Al4V stacked material. Int. J. Adv. Manuf. Technol. 2019, 105, 859–873. [Google Scholar] [CrossRef]

- Li, C.; Xu, J.; Chen, M.; An, Q.; El Mansori, M.; Ren, F. Tool wear processes in low frequency vibration assisted drilling of CFRP/Ti6Al4V stacks with forced air-cooling. Wear 2019, 426–427, 1616–1623. [Google Scholar] [CrossRef]

- Shao, Z.; Jiang, X.; Geng, D.; Li, S.; Zhang, D. Feasibility study on ultrasonic-assisted drilling of CFRP/Ti stacks by single-shot under dry condition. Int. J. Adv. Manuf. Technol. 2019, 105, 1259–1273. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Chen, M.; Ren, F. A comparison between vibration assisted and conventional drilling of CFRP/Ti6Al4V stacks. Mater. Manuf. 2019, 34, 1182–1193. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Y.; Xu, J.; Ladonne, M.; Lonfier, J.; Fu, Y. Tool wear mechanism in low-frequency vibration–assisted drilling of CFRP/Ti stacks and its individual layer. Int. J. Adv. Manuf. Technol. 2019, 104, 2539–2551. [Google Scholar] [CrossRef]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M.H. The effect of MQL on tool wear progression in low-frequency vibration-assisted drilling of CFRP/Ti6Al4V stack material. J. Manuf. Mater. Process. 2021, 5, 50. [Google Scholar] [CrossRef]

- Shao, Z.; Jiang, X.; Geng, D.; Liu, Y.; Zhou, Z.; Li, S.; Zhang, D.; Zheng, W. The interface temperature and its influence on surface integrity in ultrasonic-assisted drilling of CFRP/Ti stacks. Compos. Struct. 2021, 266, 113803. [Google Scholar] [CrossRef]

- Voss, R.; Henerichs, M.; Rupp, S.; Kuster, F.; Wegener, K. Evaluation of bore exit quality for fibre reinforced plastics including delamination and uncut fibres. CIRP J. Manuf. Sci. Technol. 2016, 12, 56–66. [Google Scholar] [CrossRef]

- Wang, G.D.; Suntoo, D.; Li, N.; Peng, T.; Li, Y. Experimental research in CFRP/Ti stack through different helical milling strategies. Int. J. Adv. Manuf. Technol. 2018, 98, 3251–3267. [Google Scholar] [CrossRef]

- Denkena, B.; Boehnke, D.; Dege, J.H. Helical milling of CFRP–titanium layer compounds. CIRP J. Manuf. Sci. Technol. 2008, 1, 64–69. [Google Scholar] [CrossRef]

- Sadek, A.; Meshreki, M.; Attia, M.H. Characterization and optimization of orbital drilling of woven carbon fiber reinforced epoxy laminates. CIRP Ann. Manuf. Technol. 2012, 61, 123–126. [Google Scholar] [CrossRef]

- Qin, X.; Wang, B.; Wang, G.; Li, H.; Jiang, Y.; Zhang, X. Delamination analysis of the helical milling of carbon fiber-reinforced plastics by using the artificial neural network model. J. Mech. Sci. Technol. 2014, 28, 713–719. [Google Scholar] [CrossRef]

- Voss, R.; Henerichs, M.; Kuster, F. Comparison of conventional drilling and orbital drilling in machining carbon fibre reinforced plastics (CFRP). CIRP Ann. Manuf. Technol. 2016, 65, 137–140. [Google Scholar] [CrossRef]

- Geier, N.; Szalay, T. Optimisation of process parameters for the orbital and conventional drilling of uni-directional carbon fibre-reinforced polymers (UD-CFRP). Measurement 2017, 110, 319–334. [Google Scholar] [CrossRef]

- He, G.; Li, H.; Jiang, Y.; Qin, X.; Zhang, X.; Guan, Y. Helical milling of CFRP/Ti-6Al-4V stacks with varying machining parameters. Trans. Tianjin Univ. 2015, 21, 56–63. [Google Scholar] [CrossRef]

- Wang, H.; Qin, X.; Li, H.; Tan, Y. A comparative study on helical milling of CFRP/Ti stacks and its individual layers. Int. J. Adv. Manuf. Technol. 2016, 86, 1973–1983. [Google Scholar] [CrossRef]

- Zhou, L.; Ke, Y.; Dong, H.; Chen, Z.; Gao, K. Hole diameter variation and roundness in dry orbital of CFRP/Ti stacks drilling. Int. J. Adv. Manuf. Technol. 2016, 87, 811–824. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, L.; Fang, Q.; Sun, Z.; Qu, W. Study on tool deflection compensation method based on cutting force observer for orbital drilling of CFRP/Ti stacks. J. Manuf. Mater. Process. 2022, 75, 450–460. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. Evaluation of cryogenic cooling and minimum quantity lubrication effects on machining GLARE laminates using design of experiments. J. Clean. Prod. 2016, 135, 533–548. [Google Scholar] [CrossRef]

- Giasin, K.; Dad, A.; Brousseau, E.; Pimenov, D.; Mia, M.; Morkavuk, S.; Koklu, U. The effects of through tool cryogenic machining on the hole quality in GLARE fibre metal laminates. J. Manuf. Process. 2021, 64, 996–1012. [Google Scholar] [CrossRef]

- Biermann, D.; Iovkov, I.; Blum, H.; Rademacher, A.; Taebi, K.; Suttmeier, F.T.; Klein, N. Thermal aspects in deep hole drilling of aluminium cast alloy using twist drills and MQL. Procedia CIRP 2012, 3, 245–250. [Google Scholar] [CrossRef]

- Chatha, S.S.; Pal, A.; Singh, T. Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. J. Clean. Prod. 2016, 137, 537–545. [Google Scholar] [CrossRef]

- Zhu, Z.; He, B.; Chen, J. Evaluation of tool temperature distribution in MQL drilling of aluminum 2024-T351. J. Manuf. Process 2020, 56, 757–765. [Google Scholar] [CrossRef]

- Nagaraj, A.; Uysal, A.; Jawahir, I.S. An Investigation of process performance when drilling carbon fiber reinforced polymer (CFRP) composite under dry, cryogenic and MQL environments. Procedia Manuf. 2020, 43, 551–558. [Google Scholar] [CrossRef]

- Fernández-Pérez, J.; Cantero, J.L.; Díaz-Álvarez, J.; Miguélez, M.H. Hybrid composite-metal stack drilling with different minimum quantity lubrication levels. Materials 2019, 12, 448. [Google Scholar] [CrossRef]

- Min, J.; Xu, J.; Ming, C.; El Mansori, M. Effects of different cooling methods on the specific energy consumption when drilling CFRP/Ti6Al4V stacks. Procedia Manuf. 2020, 43, 95–102. [Google Scholar]

- Xia, T.; Kaynak, Y.; Arvin, C.; Jawahir, I.S. Cryogenic cooling induced process performance and surface integrity in drilling CFRP composite material. Int. J. Adv. Manuf. Technol. 2016, 82, 605–616. [Google Scholar] [CrossRef]

- Kumaran, S.T.; Ko, T.J.; Li, C.; Yu, Z.; Uthayakumar, M. Rotary ultrasonic machining of woven CFRP composite in a cryogenic environment. J. Alloys Compd. 2017, 698, 984–993. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.; Balan, A.S.S. A novel approach to predict the delamination factor for dry and cryogenic drilling of CFRP. J. Mater. Process. Technol. 2018, 262, 521–531. [Google Scholar] [CrossRef]

- Morkavuk, S.; Köklü, U.; Bağcı, M.; Gemic, L. Cryogenic machining of carbon fiber reinforced plastic (CFRP) composites and the effects of cryogenic treatment on tensile properties: A comparative study. Compos. Part B-Eng. 2018, 147, 1–11. [Google Scholar] [CrossRef]

- Xu, J.; Ji, M.; Chen, M.; El Mansori, M. Experimental investigation on drilling machinability and hole quality of CFRP/Ti6Al4V stacks under different cooling conditions. Int. J. Adv. Manuf. Technol. 2020, 109, 1527–1539. [Google Scholar] [CrossRef]

- Rodríguez, A.; Calleja, A.; Lacalle, L.; Pereira, O.; Rodríguez, G. Drilling of CFRP-Ti6Al4V stacks using CO2-cryogenic cooling. J. Manuf. Process. 2021, 64, 58–66. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franz, G.; Vantomme, P.; Hassan, M.H. A Review on Drilling of Multilayer Fiber-Reinforced Polymer Composites and Aluminum Stacks: Optimization of Strategies for Improving the Drilling Performance of Aerospace Assemblies. Fibers 2022, 10, 78. https://doi.org/10.3390/fib10090078

Franz G, Vantomme P, Hassan MH. A Review on Drilling of Multilayer Fiber-Reinforced Polymer Composites and Aluminum Stacks: Optimization of Strategies for Improving the Drilling Performance of Aerospace Assemblies. Fibers. 2022; 10(9):78. https://doi.org/10.3390/fib10090078

Chicago/Turabian StyleFranz, Gérald, Pascal Vantomme, and Muhammad Hafiz Hassan. 2022. "A Review on Drilling of Multilayer Fiber-Reinforced Polymer Composites and Aluminum Stacks: Optimization of Strategies for Improving the Drilling Performance of Aerospace Assemblies" Fibers 10, no. 9: 78. https://doi.org/10.3390/fib10090078

APA StyleFranz, G., Vantomme, P., & Hassan, M. H. (2022). A Review on Drilling of Multilayer Fiber-Reinforced Polymer Composites and Aluminum Stacks: Optimization of Strategies for Improving the Drilling Performance of Aerospace Assemblies. Fibers, 10(9), 78. https://doi.org/10.3390/fib10090078