Natural Fiber-Reinforced Mycelium Composite for Innovative and Sustainable Construction Materials

Abstract

:1. Introduction

1.1. Sustainable Building Materials

1.2. Mycelium as a Construction Material

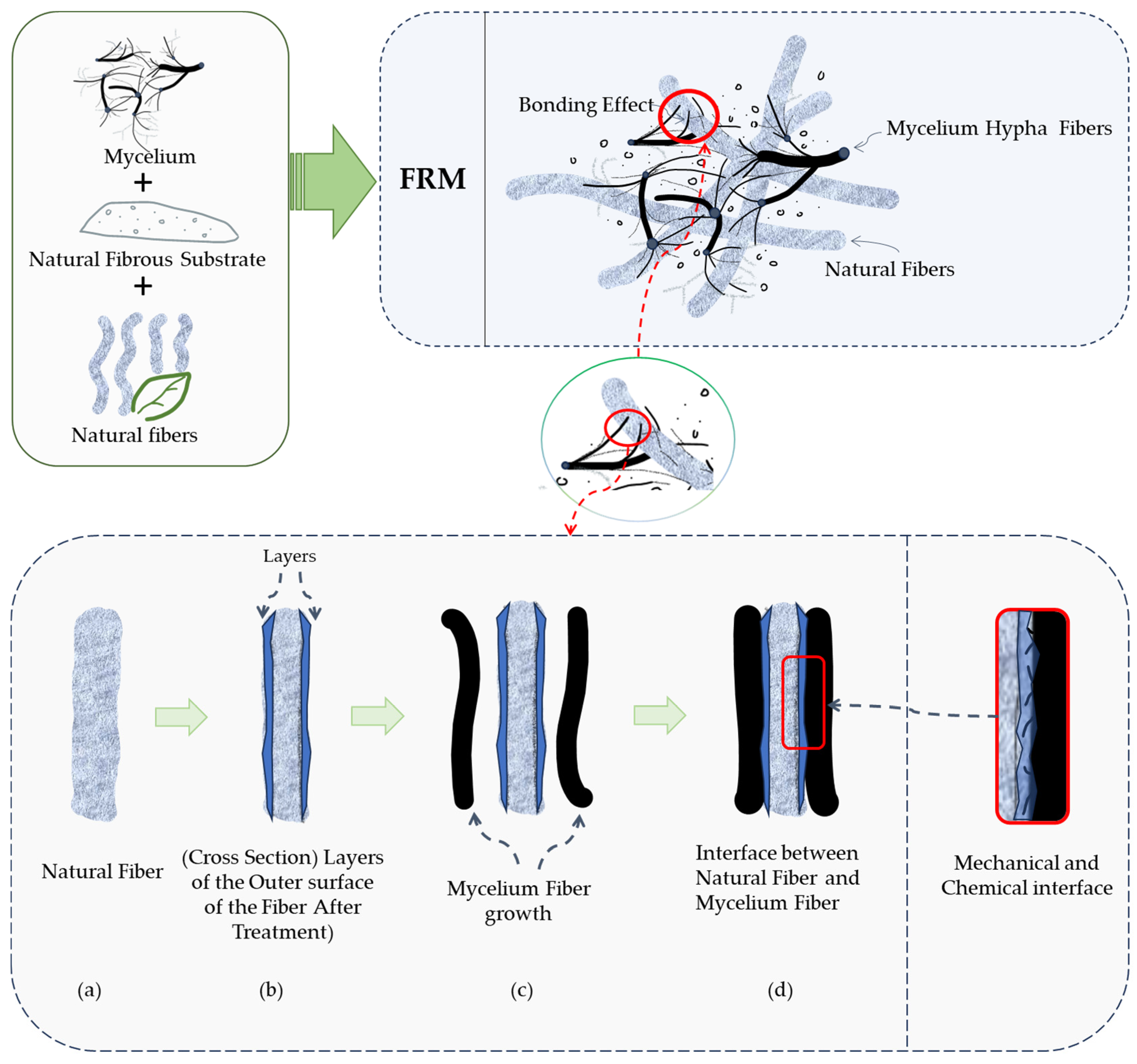

1.3. FRM as a Composite Material

Natural Fiber Reinforcement for Architectural Heritage and Self-Healing Structures

1.4. Mechanical Properties of the FRM

2. Adhesive Features in FRMs Composites

2.1. Improving Adhesive Characteristics of Mycelium

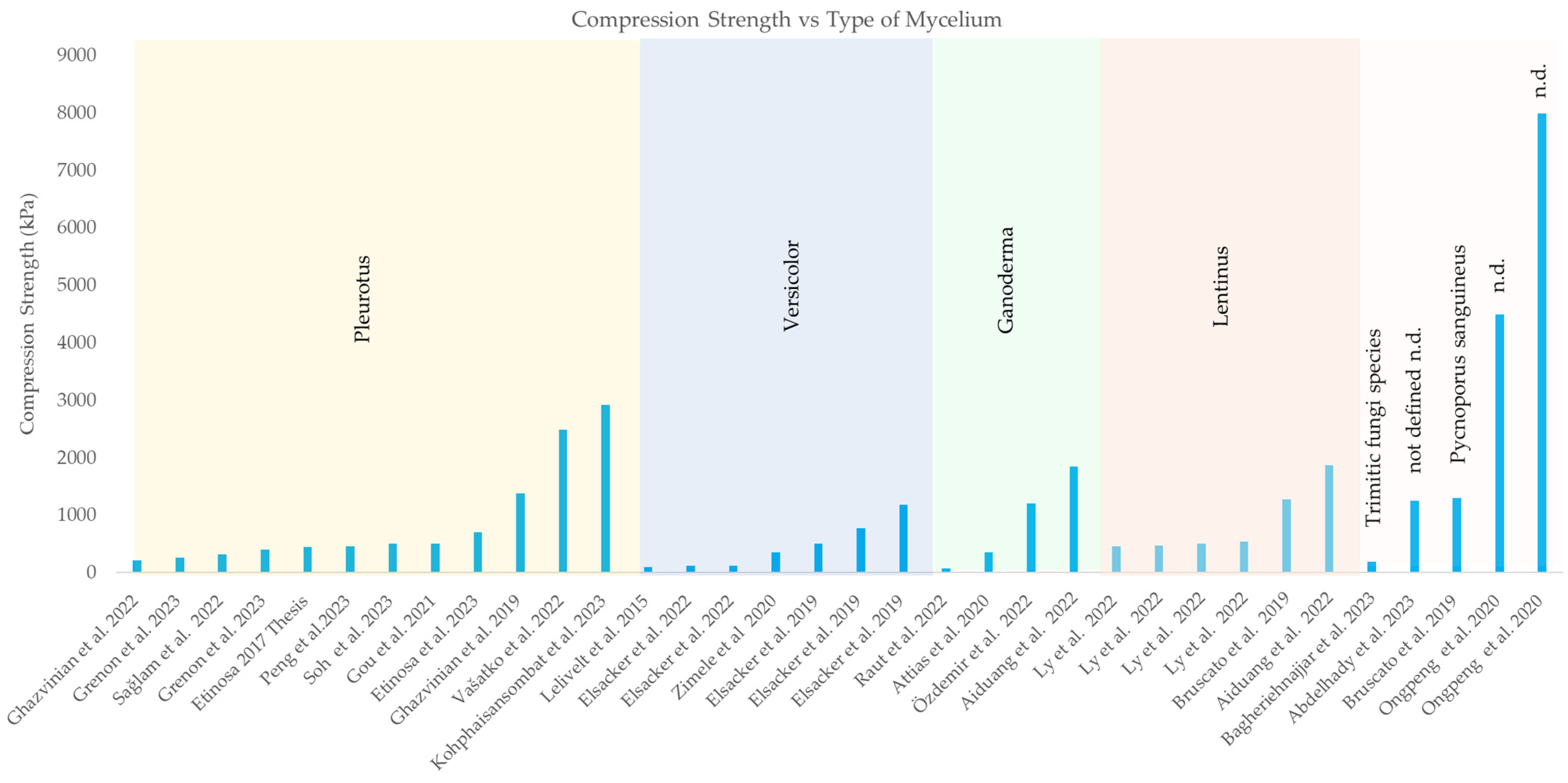

2.1.1. Type of Mycelium

2.1.2. Growing Conditions

2.1.3. Substrate Selection

2.1.4. Genetic Engineering

2.1.5. Additives

2.1.6. Manufacturing Processes and Treatments

2.1.7. Analytical Tools

2.2. The FRM Composite

2.2.1. Fiber Type Selection

2.2.2. Fiber Preparation and Surface Modification

2.2.3. Combining Mycelium and NFs

- Mycelium materials are fully biological and sustainable while other traditional composites often use synthetic polymers.

- Mycelium materials are biodegradable and can be grown using less energy and have lower environmental impact compared to the production of synthetic polymers.

- In mycelium materials, which contain hyphae—a dynamic growing variable—the precise mix proportion is not initially precisely known, unlike in traditional composites where the mix proportion is defined at the outset.

- Traditional composites offer higher strength and durability than mycelium-based materials. However, mycelium composites are continuously being improved and may find appropriate applications where lower mechanical properties are acceptable.

- Traditional composites often require high-temperature processing and chemical additives, whereas mycelium materials grow at room temperature and use biological processes.

2.2.4. Fiber Distribution and Bonding

2.3. Problems in the Addition of NFs in MBCs

3. A Comparative Review of The Mechanical Properties of FRM Composites

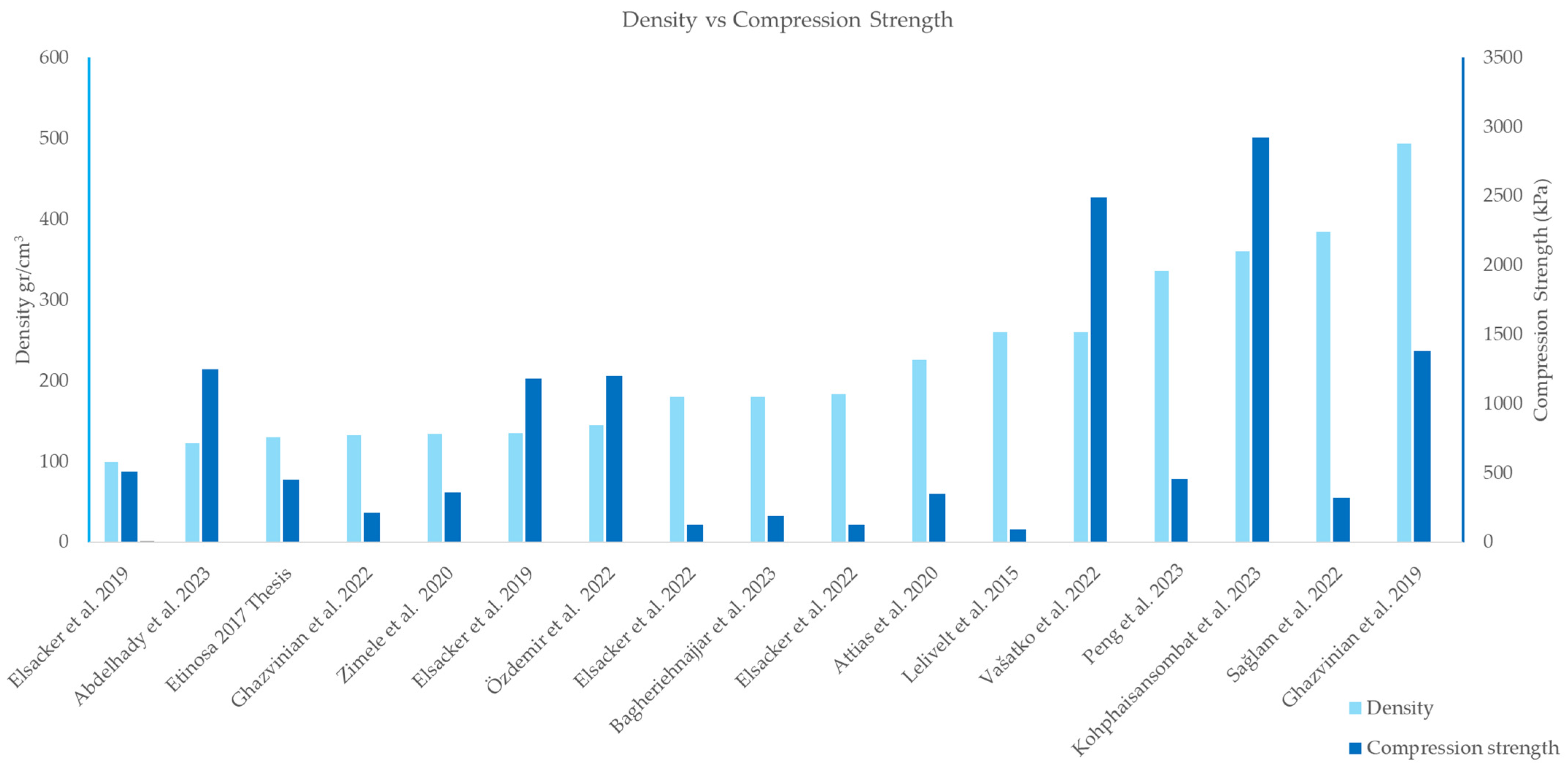

3.1. Density

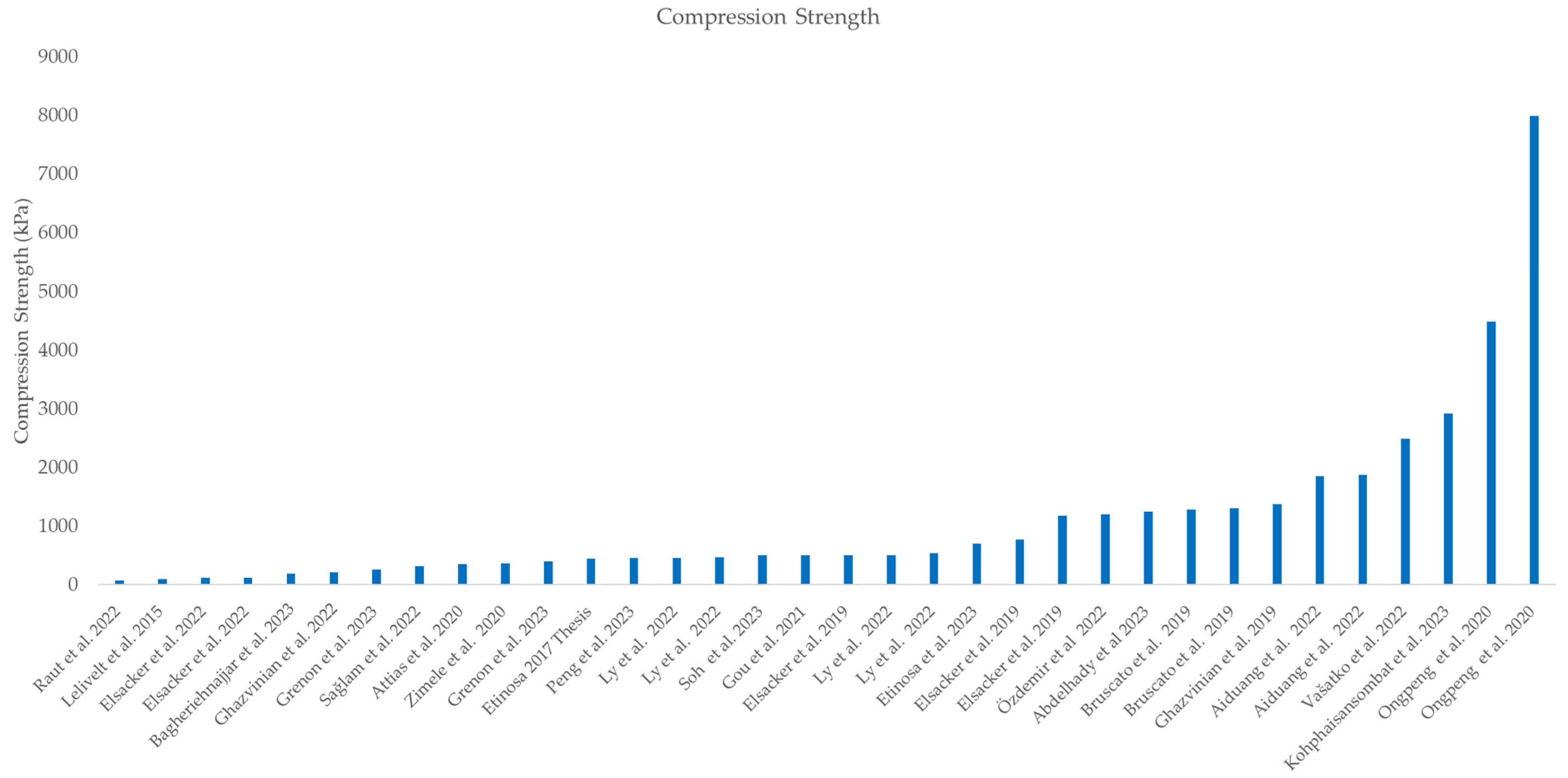

3.2. Compressive Strength

Effect of the NFs on the Compression Strength of FRM

3.3. Flexural Strength

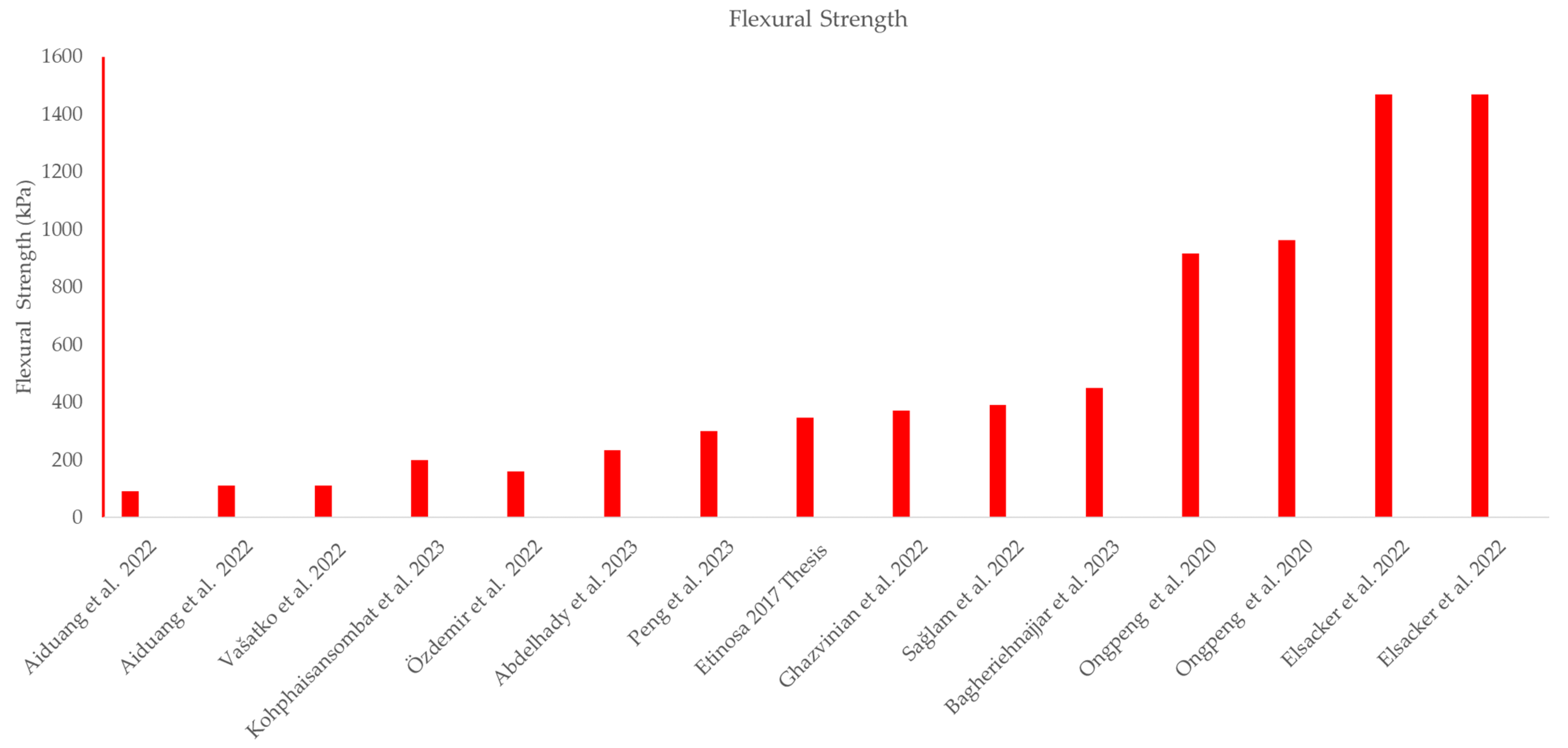

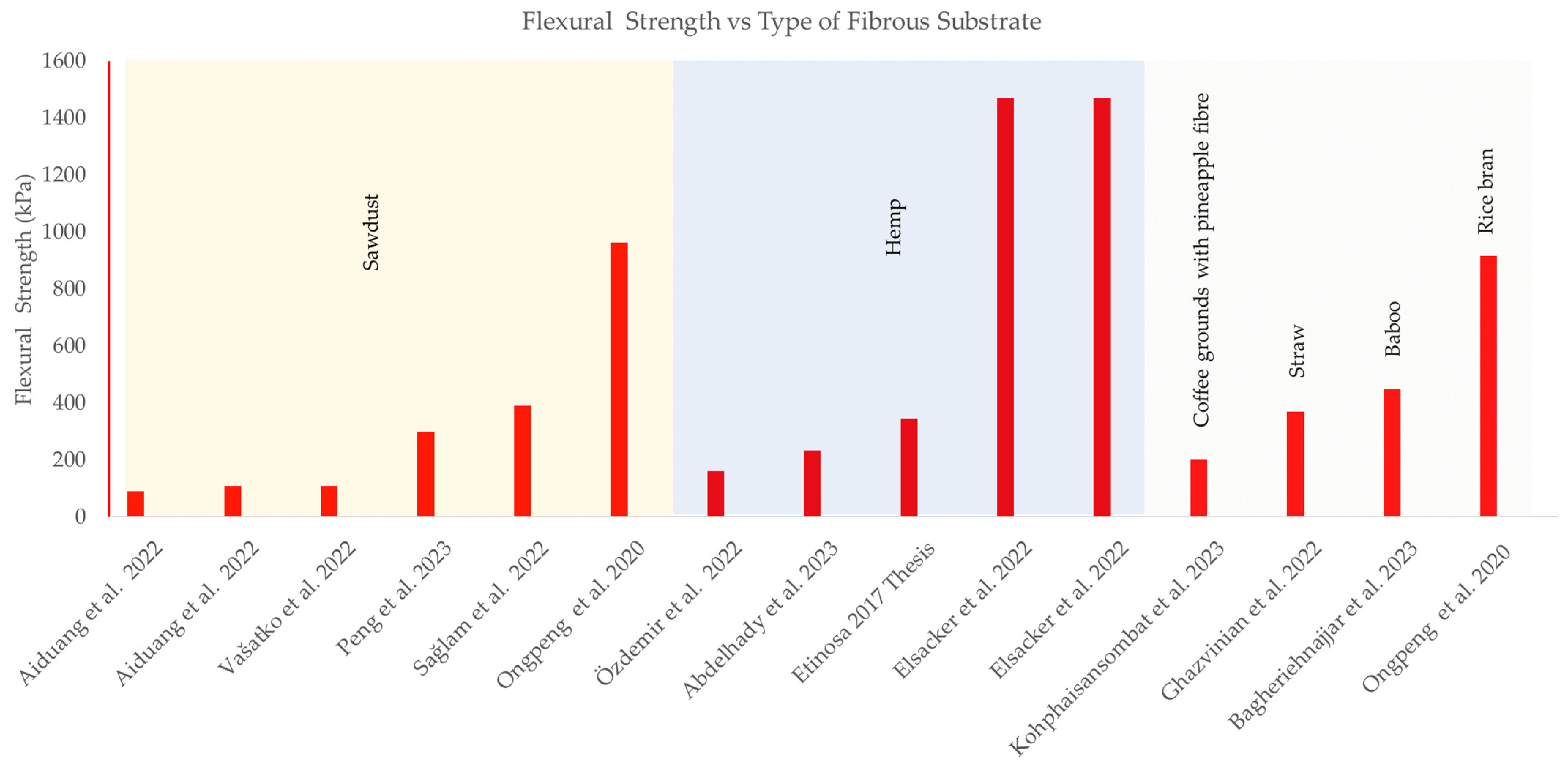

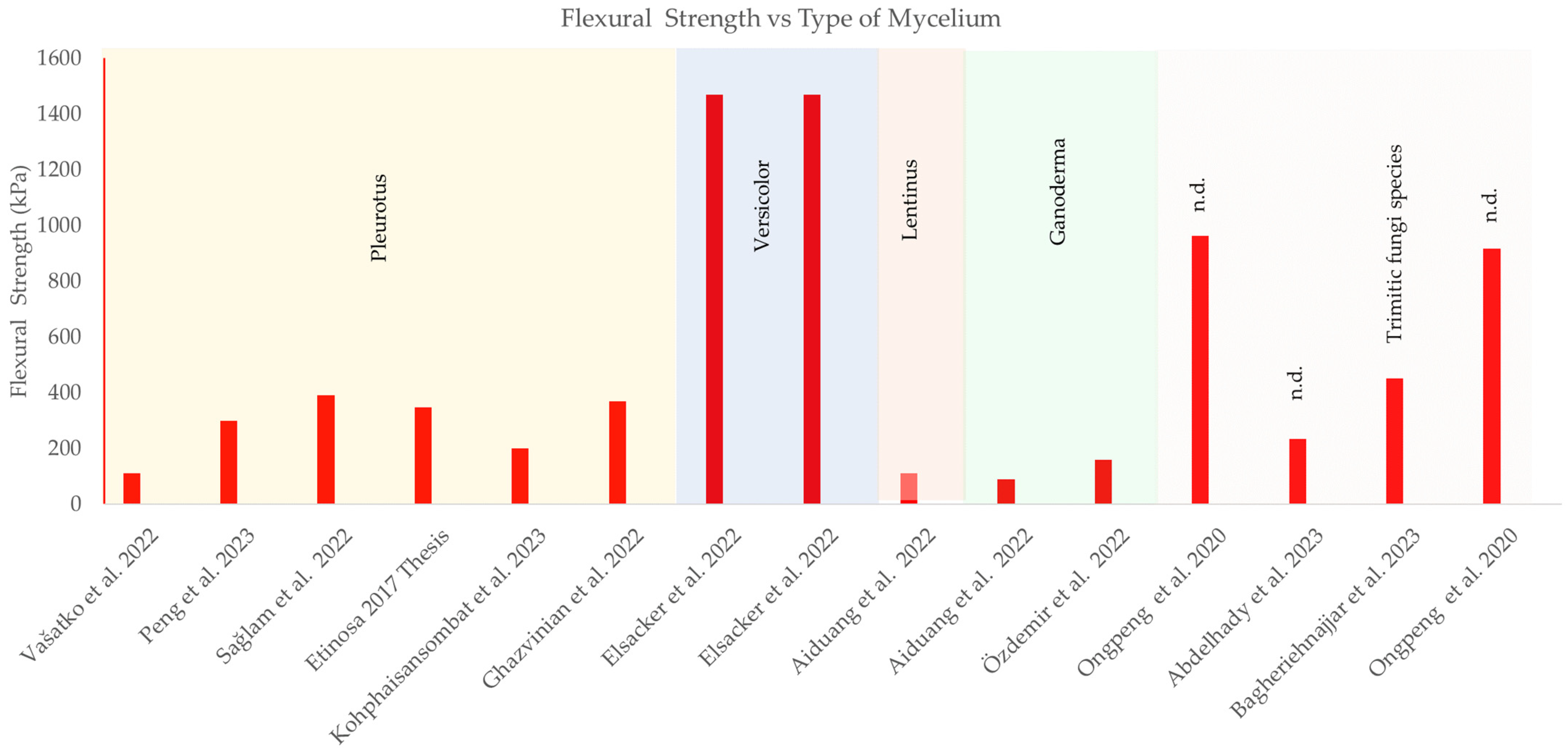

Impact of NFs on the Flexural Strength of FRM

4. Discussion—Setbacks and Future

5. Conclusions

- Despite the extensive research on NF treatments and substrate modifications with known materials, the literature does not clearly demonstrate an easy method to enhance the mechanical properties of mycelium composites. The primary reason for this is the complex, multifactorial nature of the type of mycelium and the type of fibrous substrate.

- Mycelium materials differ from traditional fiber composites as they are fully biological, sustainable, biodegradable, and have lower environmental impact. The mix proportion in mycelium materials, containing hyphae, is not precisely known initially, unlike traditional composites. FRM composites provide a sustainable alternative to traditional materials, offering customizable mechanical properties, especially in compression and flexural strength.

- Factors like porosity, fillers and reinforcements influence the relationship between density and compressive strength in mycelium bio-composites. Higher density from high-strength reinforcements can significantly increase the composite’s compressive strength. Adjustments in the ratio of reinforcing fibers can lead to more robust FRM composites with higher compressive strength values compared to other studies using different techniques or materials.

- The addition of an optimized quantity of NFs to FRMs positively impacts their flexural strength.

- Utilizing simulation and machine learning tools can help understand and predict optimal adhesive properties in mycelium-based materials, enhancing their application in various fields, including the construction realm.

- The development of standardized design codes for mycelium composites would not only facilitate their widespread adoption but also pave the way for innovative and eco-friendly structural solutions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| NF | Natural Fiber |

| FRM | Fiber-Reinforced Mycelium |

| MBCs | Mycelium-based Bio-Composites |

References

- Volk, R.; Schröter, M.; Saeidi, N.; Steffl, S.; Javadian, A.; Hebel, D.E.; Schultmann, F. Life Cycle Assessment of Mycelium-Based Composite Materials. Resour. Conserv. Recycl. 2024, 205, 107579. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered Mycelium Composite Construction Materials from Fungal Biorefineries: A Critical Review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Nasr, Y.; El Zakhem, H.; Hamami, A.E.A.; El Bachawati, M.; Belarbi, R. Comprehensive Review of Innovative Materials for Sustainable Buildings’ Energy Performance. Energies 2023, 16, 7440. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium Based Composites: A Review of Their Bio-Fabrication Procedures, Material Properties and Potential for Green Building and Construction Applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

- Thomoglou, A.K.; Voutetaki, M.E.; Fantidis, J.G.; Chalioris, C.E. Novel Natural Bee Brick with a Low Energy Footprint for “Green” Masonry Walls: Mechanical Properties. Eng. Proc. 2024, 60, 9. [Google Scholar] [CrossRef]

- Filipova, I.; Irbe, I.; Spade, M.; Skute, M.; Dāboliņa, I.; Baltiņa, I.; Vecbiskena, L. Mechanical and Air Permeability Performance of Novel Biobased Materials from Fungal Hyphae and Cellulose Fibers. Materials 2021, 14, 136. [Google Scholar] [CrossRef]

- Sayfutdinova, A.R.; Cherednichenko, K.A.; Rakitina, M.A.; Dubinich, V.N.; Bardina, K.A.; Rubtsova, M.I.; Petrova, D.A.; Vinokurov, V.A.; Voronin, D.V. Natural Fibrous Materials Based on Fungal Mycelium Hyphae as Porous Supports for Shape-Stable Phase-Change Composites. Polymers 2023, 15, 4504. [Google Scholar] [CrossRef]

- Jonnala, S.N.; Gogoi, D.; Devi, S.; Kumar, M.; Kumar, C. A Comprehensive Study of Building Materials and Bricks for Residential Construction. Constr. Build. Mater. 2024, 425, 135931. [Google Scholar] [CrossRef]

- Lou, Z.; Han, X.; Liu, J.; Ma, Q.; Yan, H.; Yuan, C.; Yang, L.; Han, H.; Weng, F.; Li, Y. Nano-Fe3O4/Bamboo Bundles/Phenolic Resin Oriented Recombination Ternary Composite with Enhanced Multiple Functions. Compos. B Eng. 2021, 226, 109335. [Google Scholar] [CrossRef]

- Han, H.; Lou, Z.; Wang, Q.; Xu, L.; Li, Y. Introducing Rich Heterojunction Surfaces to Enhance the High-Frequency Electromagnetic Attenuation Response of Flexible Fiber-Based Wearable Absorbers. Adv. Fiber Mater. 2024, 6, 739–757. [Google Scholar] [CrossRef]

- Almpani-Lekka, D.; Pfeiffer, S.; Schmidts, C.; Seo, S.-i. A Review on Architecture with Fungal Biomaterials: The Desired and the Feasible. Fungal Biol. Biotechnol. 2021, 8, 17. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, Physical and Chemical Characterisation of Mycelium-Based Composites with Different Types of Lignocellulosic Substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosc. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Heisel, F.; Hebel, D.E. Pioneering Construction Materials through Prototypological Research. Biomimetics 2019, 4, 56. [Google Scholar] [CrossRef]

- Mbabali, H.; Lubwama, M.; Yiga, V.A.; Were, E.; Kasedde, H. Development of Rice Husk and Sawdust Mycelium-Based Bio-Composites: Optimization of Mechanical, Physical and Thermal Properties. J. Inst. Eng. (India) Ser. D 2024, 105, 97–117. [Google Scholar] [CrossRef]

- Rigobello, A.; Colmo, C.; Ayres, P. Effect of Composition Strategies on Mycelium-Based Composites Flexural Behaviour. Biomimetics 2022, 7, 53. [Google Scholar] [CrossRef]

- Arifin, Y.H.; Yusuf, Y. Mycelium Fibers as New Resource for Environmental Sustainability. Procedia Eng. 2013, 53, 504–508. [Google Scholar] [CrossRef]

- Adamu, M.; Alanazi, F.; Ibrahim, Y.E.; Alanazi, H.; Khed, V.C. A Comprehensive Review on Sustainable Natural Fiber in Cementitious Composites: The Date Palm Fiber Case. Sustainability 2022, 14, 6691. [Google Scholar] [CrossRef]

- Rocha, D.L.; Júnior, L.U.D.T.; Marvila, M.T.; Pereira, E.C.; Souza, D.; de Azevedo, A.R.G. A Review of the Use of Natural Fibers in Cement Composites: Concepts, Applications and Brazilian History. Polymers 2022, 14, 2043. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and Biocomposites. Carbohydr. Polym. 2007, 71, 343–364. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Harussani, M.M.; Syafri, E. A Short Review of Recent Engineering Applications of Natural Fibres. IOP Conf. Ser. Earth Environ. Sci. 2022, 1097, 012033. [Google Scholar] [CrossRef]

- Sharma, R.; Sumbria, R. Mycelium Bricks and Composites for Sustainable Construction Industry: A State-of-the-Art Review. Innov. Infrastruct. Solut. 2022, 7, 298. [Google Scholar] [CrossRef]

- Naoum, M.C.; Sapidis, G.M.; Papadopoulos, N.A.; Voutetaki, M.E. An Electromechanical Impedance-Based Application of Realtime Monitoring for the Load-Induced Flexural Stress and Damage in Fiber-Reinforced Concrete. Fibers 2023, 11, 34. [Google Scholar] [CrossRef]

- Naoum, M.C.; Papadopoulos, N.A.; Voutetaki, M.E.; Chalioris, C.E. Structural Health Monitoring of Fiber-Reinforced Concrete Prisms with Polyolefin Macro-Fibers Using a Piezoelectric Materials Network under Various Load-Induced Stress. Buildings 2023, 13, 2465. [Google Scholar] [CrossRef]

- Imanzadeh, S.; Jarno, A.; Hibouche, A.; Bouarar, A.; Taibi, S. Ductility Analysis of Vegetal-Fiber Reinforced Raw Earth Concrete by Mixture Design. Constr. Build. Mater. 2020, 239, 117829. [Google Scholar] [CrossRef]

- Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G.; Alver, N. Acoustic Emission for Evaluating the Reinforcement Effectiveness in Steel Fiber Reinforced Concrete. Appl. Sci. 2021, 11, 3850. [Google Scholar] [CrossRef]

- Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G. Acoustic Monitoring for the Evaluation of Concrete Structures and Materials. In Acoustic Emission and Related Non-Destructive Evaluation Techniques in the Fracture Mechanics of Concrete; Elsevier: Amsterdam, The Netherlands, 2021; pp. 257–280. [Google Scholar] [CrossRef]

- Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G. Acoustic Emission of Fire Damaged Fiber Reinforced Concrete. In Proceedings of the Smart Materials and Nondestructive Evaluation for Energy Systems 2016, Las Vegas, NV, USA, 21–23 March 2016; pp. 320–328. [Google Scholar] [CrossRef]

- Ardra, R.; Karthik, S.; Padmakumar, T.G.; Kishnan, R.; Shukla, S.K.; Sathyan, D. Mycelium-Infused Geopolymer Bricks for Non-Load-Bearing Walls: Experimental Investigation and Life Cycle Assessment. Innov. Infrastruct. Solut. 2024, 9, 72. [Google Scholar] [CrossRef]

- Verma, N.; Jujjavarapu, S.E.; Mahapatra, C. Green Sustainable Biocomposites: Substitute to Plastics with Innovative Fungal Mycelium Based Biomaterial. J. Environ. Chem. Eng. 2023, 11, 110396. [Google Scholar] [CrossRef]

- Grenon, V.; Maref, W.; Ouellet-Plamondon, C.M. Multi-Property Characterization of an Experimental Material Composed of Pleurotus Ostreatus Mycelium and Ash Wood Chips Compared with Glass Wool and Hemp Wool. Constr. Build. Mater. 2023, 409, 133941. [Google Scholar] [CrossRef]

- Bitting, S.; Derme, T.; Lee, J.; Van Mele, T.; Dillenburger, B.; Block, P. Challenges and Opportunities in Scaling up Architectural Applications of Mycelium-Based Materials with Digital Fabrication. Biomimetics 2022, 7, 44. [Google Scholar] [CrossRef] [PubMed]

- Soh, E.; Le Ferrand, H. Woodpile Structural Designs to Increase the Stiffness of Mycelium-Bound Composites. Mater. Des. 2023, 225, 111530. [Google Scholar] [CrossRef]

- Bagheriehnajjar, G.; Yousefpour, H.; Rahimnejad, M. Multi-Objective Optimization of Mycelium-Based Bio-Composites Based on Mechanical and Environmental Considerations. Constr. Build. Mater. 2023, 407, 133346. [Google Scholar] [CrossRef]

- Wu, J.; Chen, C.; Zhang, H.; Xia, L.; Huang, Y.; Huang, H.; Wang, Y.; Qian, D.; Wang, J.; Wang, X.; et al. Eco-Friendly Fiberboard Production without Binder Using Poplar Wood Shavings Bio-Pretreated by White Rot Fungi Coriolus Versicolor. Constr. Build. Mater. 2020, 236, 117620. [Google Scholar] [CrossRef]

- Vailati, M.; Mercuri, M.; Angiolilli, M.; Gregori, A. Natural-Fibrous Lime-Based Mortar for the Rapid Retrofitting of Heritage Masonry Buildings. Fibers 2021, 9, 68. [Google Scholar] [CrossRef]

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical Performance of Natural Fiber-Reinforced Composites for the Strengthening of Masonry. Compos. B Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Damsin, B.; Van Wylick, A.; Peeters, E.; De Laet, L. Mechanical Characteristics of Bacterial Cellulose-Reinforced Mycelium Composite Materials. Fungal Biol. Biotechnol. 2021, 8, 18. [Google Scholar] [CrossRef] [PubMed]

- Van Wylick, A.; Monclaro, A.V.; Elsacker, E.; Vandelook, S.; Rahier, H.; De Laet, L.; Cannella, D.; Peeters, E. A Review on the Potential of Filamentous Fungi for Microbial Self-Healing of Concrete. Fungal Biol. Biotechnol. 2021, 8, 16. [Google Scholar] [CrossRef]

- Dessi-Olive, J. Strategies for Growing Large-Scale Mycelium Structures. Biomimetics 2022, 7, 129. [Google Scholar] [CrossRef]

- Modanloo, B.; Ghazvinian, A.; Matini, M.; Andaroodi, E. Tilted Arch; Implementation of Additive Manufacturing and Bio-Welding of Mycelium-Based Composites. Biomimetics 2021, 6, 68. [Google Scholar] [CrossRef]

- Javadian, A.; Le Ferrand, H.; Hebel, D.E.; Saeidi, N. Application of Mycelium-Bound Composite Materials in Construction Industry: A Short Review. SOJ Mater. Sci. Eng. 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Sayfutdinova, A.; Samofalova, I.; Barkov, A.; Cherednichenko, K.; Rimashevskiy, D. Structure and Properties of Cellulose/Mycelium Biocomposites. Polymers 2022, 14, 1519. [Google Scholar] [CrossRef]

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A.B. Fabrication Factors Influencing Mechanical, Moisture- and Water-Related Properties of Mycelium-Based Composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Atta, O.M.; Yang, G. Synthesis and Applications of Fungal Mycelium-Based Advanced Functional Materials. J. Bioresour. Bioprod. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Yang, L.; Qin, Z. Mycelium-Based Wood Composites for Light Weight and High Strength by Experiment and Machine Learning. Cell Rep. Phys. Sci. 2023, 4, 101424. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Gürsoy, B. Mycelium-Based Composite Graded Materials: Assessing the Effects of Time and Substrate Mixture on Mechanical Properties. Biomimetics 2022, 7, 48. [Google Scholar] [CrossRef] [PubMed]

- Sydor, M.; Bonenberg, A.; Doczekalska, B.; Cofta, G. Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers 2022, 14, 145. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Wei, Y.; Hadigheh, S.A. Variations in the Properties of Engineered Mycelium-Bound Composites (MBCs) under Different Manufacturing Conditions. Buildings 2024, 14, 155. [Google Scholar] [CrossRef]

- Jagadesh, P.; Amirtavarshini, K.S.; Isleem, H.F.; Thomoglou, A.K.; Voutetaki, M.E. Development of Models for Mechanical Properties of Engineered Cementitious Composites. In Production, Properties, and Applications of Engineered Cementitious Composites; Praveenkumar, S., Davim, J., Eds.; IGI Global: Hershey, PA, USA; pp. 106–142. [CrossRef]

- Shakir, M.A.; Ahmad, M.I.; Yusup, Y.; Rafatullah, M. From Waste to Wealth: Converting Rubber Wood Sawdust into Green Mycelium-Based Composite. Biomass Convers. Biorefin. 2023, 1–19. [Google Scholar] [CrossRef]

- Shakir, M.A.; Ahmad, M.I.; Yusup, Y.; Wabaidur, S.M.; Siddiqui, M.R.; Alam, M.; Rafatullah, M. Sandwich Composite Panel from Spent Mushroom Substrate Fiber and Empty Fruit Bunch Fiber for Potential Green Thermal Insulation. Buildings 2023, 13, 224. [Google Scholar] [CrossRef]

- Sağlam, S.S.; Özer, N.; Özgünler, S.A. Experimental Study on the Production of Mycelium-Based Biocomposites. In Proceedings of the International Architectural Sciences and Applications Symposium, Naples, Italy, 14–15 September 2023; Available online: https://www.researchgate.net/publication/378496944 (accessed on 31 October 2023).

- Nguyen, M.T.; Solueva, D.; Spyridonos, E.; Dahy, H. Mycomerge: Fabrication of Mycelium-Based Natural Fiber Reinforced Composites on a Rattan Framework. Biomimetics 2022, 7, 42. [Google Scholar] [CrossRef]

- Sharma, M.; Verma, S.; Chauhan, G.; Arya, M.; Kumari, A. Mycelium-Based Biocomposites: Synthesis and Applications. Environ. Sustain. 2024. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium Bio-Composites in Industrial Design and Architecture: Comparative Review and Experimental Analysis. J. Clean. Prod. 2020, 246, 119037. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Biala, E.; Ostermann, M. Mycostructures—Growth-driven fabrication processes for architectural elements from mycelium composites. Archit. Struct. Constr. 2022, 2, 509–519. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A Review of Coir Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Gulati, D.; Sain, M. Fungal-Modification of Natural Fibers: A Novel Method of Treating Natural Fibers for Composite Reinforcement. J. Polym. Environ. 2006, 14, 347–352. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Farrokhsiar, P.; Vieira, F.; Pecchia, J.; Gursoy, B. Mycelium-Based Bio-Composites For Architecture: Assessing the Effects of Cultivation Factors on Compressive Strength. In Proceedings of the eCAADe + SIGraDi 2019 Conference, Porto, Portugal, 11–13 September 2019. [Google Scholar]

- Lelivelt, R.; Lindner, G.; Teuffel, P.; Lamers, H. The Production Process and Compressive Strength of Mycelium-based Materials. In Proceedings of the First International Conference on Bio-Based Building Materials, Clermont Ferrand, France, 22–55 June 2015; pp. 1–6. Available online: https://research.tue.nl/en/publications/the-production-process-and-compressive-strength-of-mycelium-based (accessed on 1 January 2015).

- Aiduang, W.; Jatuwong, K.; Jinanukul, P.; Suwannarach, N.; Kumla, J.; Thamjaree, W.; Teeraphantuvat, T.; Waroonkun, T.; Oranratmanee, R.; Lumyong, S. Sustainable Innovation: Fabrication and Characterization of Mycelium-Based Green Composites for Modern Interior Materials Using Agro-IndustrialWastes and Different Species of Fungi. Polymers 2024, 16, 550. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M.; Chen, L. Interface and Bonding Mechanisms of Plant Fibre Composites: An Overview. Compos. Part B Eng. 2016, 101, 31–45. [Google Scholar] [CrossRef]

- Etinosa, O.P. Design and Testing of Mycelium Biocomposite. Master’s Thesis, African University of Science and Technology, Galadima, Nigeria, 2019. [Google Scholar]

- Bruscato, C.; Malvessi, E.; Brandalise, R.N.; Camassola, M. High Performance of Macrofungi in the Production of Mycelium-Based Biofoams Using Sawdust—Sustainable Technology for Waste Reduction. J. Clean. Prod. 2019, 234, 225–232. [Google Scholar] [CrossRef]

- Zimele, Z.; Irbe, I.; Grinins, J.; Bikovens, O.; Verovkins, A.; Bajare, D. Novel Mycelium-Based Biocomposites (Mbb) as Building Materials. J. Renew. Mater. 2020, 8, 1067–1076. [Google Scholar] [CrossRef]

- Ongpeng, J.M.C.; Inciong, E.; Sendo, V.; Soliman, C.; Siggaoat, A. Using Waste in Producing Bio-Composite Mycelium Bricks. Appl. Sci. 2020, 10, 5303. [Google Scholar] [CrossRef]

- Gou, L.; Li, S.; Yin, J.; Li, T.; Liu, X. Morphological and Physico-Mechanical Properties of Mycelium Biocomposites with Natural Reinforcement Particles. Constr. Build. Mater. 2021, 304, 124656. [Google Scholar] [CrossRef]

- Răut, I.; Călin, M.; Vuluga, Z.; Oancea, F.; Paceagiu, J.; Radu, N.; Doni, M.; Alexandrescu, E.; Purcar, V.; Gurban, A.M.; et al. Fungal Based Biopolymer Composites for Construction Materials. Materials 2021, 14, 2906. [Google Scholar] [CrossRef] [PubMed]

- Elsacker, E.; De Laet, L.; Peeters, E. Functional Grading of Mycelium Materials with Inorganic Particles: The Effect of Nanoclay on the Biological, Chemical and Mechanical Properties. Biomimetics 2022, 7, 57. [Google Scholar] [CrossRef] [PubMed]

- Ly, L.; Jitjak, W. Biocomposites from Agricultural Wastes and Mycelia of a Local Mushroom, Lentinus squarrosulus (Mont.) Singer. Open Agric. 2022, 7, 634–643. [Google Scholar] [CrossRef]

- Özdemir, E.; Saeidi, N.; Javadian, A.; Rossi, A.; Nolte, N.; Ren, S.; Dwan, A.; Acosta, I.; Hebel, D.E.; Wurm, J.; et al. Wood-Veneer-Reinforced Mycelium Composites for Sustainable Building Components. Biomimetics 2022, 7, 39. [Google Scholar] [CrossRef]

- Aiduang, W.; Kumla, J.; Srinuanpan, S.; Thamjaree, W.; Lumyong, S.; Suwannarach, N. Mechanical, Physical, and Chemical Properties of Mycelium-Based Composites Produced from Various Lignocellulosic Residues and Fungal Species. J. Fungi 2022, 8, 1125. [Google Scholar] [CrossRef]

- Vašatko, H.; Gosch, L.; Jauk, J.; Stavric, M. Basic Research of Material Properties of Mycelium-Based Composites. Biomimetics 2022, 7, 51. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Yi, J.; Yang, X.; Xie, J.; Chen, C. Development and Characterization of Mycelium Bio-Composites by Utilization of Different Agricultural Residual Byproducts. J. Bioresour. Bioprod. 2023, 8, 78–89. [Google Scholar] [CrossRef]

- Etinosa, P.O.; Salifu, A.A.; Azeko, S.T.; Obayemi, J.D.; Onche, E.O.; Aina, T.; Soboyejo, W.O. Self-Organized Mycelium Biocomposites: Effects of Geometry and Laterite Composition on Compressive Behavior. J. Mech. Behav. Biomed. Mater. 2023, 142, 105831. [Google Scholar] [CrossRef] [PubMed]

- Kohphaisansombat, C.; Jongpipitaporn, Y.; Laoratanakul, P.; Tantipaibulvut, S.; Euanorasetr, J.; Rungjindamai, N.; Chuaseeharonnachai, C.; Kwantong, P.; Somrithipol, S.; Boonyuen, N. Fabrication of Mycelium (Oyster Mushroom)-Based Composites Derived from Spent Coffee Grounds with Pineapple Fibre Reinforcement. Mycology 2023. [Google Scholar] [CrossRef]

- Etinosa, P.O.; Salifu, A.A.; Osafo, S.; Eluu, S.C.; Obayemi, J.D.; Soboyejo, W.O. Fracture and Toughening of Mycelium-Based Biocomposites. Mater. Des. 2024, 237, 112592. [Google Scholar] [CrossRef]

- Picco, C.M.; Suarez, N.E.; Regenhardt, S.A. Exploring the Impact of Substrate Composition and Process Parameters on Biomaterial Derived from Fungus Mycelium (Pleurotus ostreatus) and Agricultural Wastes. MRS Adv. 2024, 9, 33–38. [Google Scholar] [CrossRef]

- Van Wylick, A.; Elsacker, E.; Yap, L.; Peeters, E.; De Laet, L. Mycelium Composites and Their Biodegradability: An Exploration on the Disintegration of Mycelium-Based Materials in Soil. In Proceedings of the 4th International Conference on Bio-Based Building Materials, Barcelona, Spain, 16–18 June 2021; Available online: www.scientific.net (accessed on 5 January 2022).

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Morphology and Mechanics of Fungal Mycelium. Sci. Rep. 2017, 7, 13070. [Google Scholar] [CrossRef]

| Type of Mycelium | Fiber Substrate | Density (kg/m3) | Flexural Strength (KPa) | Compression Strength (kPa) | Reference | Studies |

|---|---|---|---|---|---|---|

| Coriolus Versicolor | Wood chips, hemp hurd, fiber | 260 | 93 | [65] | Lelivelt et al., 2015 | |

| Pleurotus ostreatus | Wood chips and hemp fiber | 130 | 347 | 452 | [68] | Etinosa 2017 Thesis |

| Trametes versicolor | Hemp | 99 | 510 | [13] | Elsacker et al., 2019 | |

| Trametes versicolor | Chopped hemp | 770 | [13] | Elsacker et al., 2019 | ||

| Trametes versicolor | Chopped flax | 135 | 1180 | [13] | Elsacker et al., 2019 | |

| Lentinus velutinus | Sawdust and wheat bran | 1280 | [69] | Bruscato et al., 2019 | ||

| Pycnoporus sanguineus | Sawdust and wheat bran | 1300 | [69] | Bruscato et al., 2019 | ||

| Pleurotus Ostreatus | Sawdust 90% and wheat 10% | 493 | 1380 | [64] | Ghazvinian et al., 2019 | |

| Ganoderma sessile | Wheat straw | 226 | 350 | [57] | Attias et al., 2020 | |

| Trametes versicolor | Hemp | 134 | 360 | [70] | Zimele et al., 2020 | |

| not defined | Rice bran | 916 | 4490 | [71] | Ongpeng et al., 2020 | |

| not defined | Sawdust | 962 | 7990 | [71] | Ongpeng et al., 2020 | |

| Pleurotus ostreatus | Cotton stalk, wheat bran | 508 | [72] | Gou et al., 2021 | ||

| Ganoderma lucidum | Wheat straws | 70 | [73] | Raut et al., 2022 | ||

| Trametes versicolor | Hemp and 1.5% nanoclay | 180 | 1470 | 123 | [74] | Elsacker et al., 2022 |

| Trametes versicolor | Hemp and 2.5% nanoclay | 183 | 1470 | 123 | [74] | Elsacker et al., 2022 |

| Pleurotus ostreatus | Straw | 132 | 370 | 210 | [48] | Ghazvinian et al., 2022 |

| Pleurotus ostreatus | Beech Sawdust | 384 | 390 | 320 | [54] | Sağlam et al., 2022 |

| Lentinus squarrosulus | Rice husk | 460 | [75] | Ly et al., 2022 | ||

| Lentinus squarrosulus | Coconut husk | 470 | [75] | Ly et al., 2022 | ||

| Lentinus squarrosulus | Hemp | 510 | [75] | Ly et al., 2022 | ||

| Lentinus squarrosulus | Rice straw | 540 | [75] | Ly et al., 2022 | ||

| Ganoderma lucidum | Wood veneer and hemp hurds | 145 | 160 | 1200 | [76] | Özdemir et al., 2022 |

| Ganoderma williamsianum | Sawdust | 90 | 1850 | [77] | Aiduang et al., 2022 | |

| Lentinus sajorcaju | Sawdust | 110 | 1870 | [77] | Aiduang et al., 2022 | |

| Pleurotus ostreatus | Beech Sawdust | 260 | 110 | 2490 | [78] | Vašatko et al., 2022 |

| Trimitic fungi species | Baboo | 180 | 450 | 190 | [35] | Bagheriehnajjar et al., 2023 |

| Pleurotus ostreatus | Small particle size ash wood chips | 261 | [32] | Grenon et al., 2023 | ||

| Pleurotus ostreatus | Ash wood chips | 399 | [32] | Grenon et al., 2023 | ||

| Pleurotus ostreatus fungi | Sawdust | 336 | 300 | 456 | [79] | Peng et al., 2023 |

| Pleurotus ostreatus spawn | Bamboo | 500 | [34] | Soh et al., 2023 | ||

| Pleurotus Ostreatus | Hemp hurds | 700 | [80] | Etinosa et al., 2023 | ||

| Pleurotus Ostreatus | Coffee grounds with pineapple fiber | 360 | 200 | 2920 | [81] | Kohphaisansombat et al., 2023 |

| not defined | Hemp | 122 | 234 | 1246 | [72] | Abdelhady et al., 2023 |

| Substrates | Fungal Species | Compression Strength * (MPa) | Flexural Strength * (MPa) |

|---|---|---|---|

| Sawdust | Ganoderma fornicatum | 1.71 ± 0.03 b | 0.07 ± 0.00 bc |

| Ganoderma williamsianum | 1.85 ± 0.01 a | 0.09 ± 0.02 ab | |

| Lentinus sajor-caju | 1.87 ± 0.03 a | 0.11 ± 0.02 a | |

| Schizophyllum commune | 1.59 ± 0.02 c | 0.06 ± 0.01 c | |

| Corn husk | Ganoderma fornicatum | 0.59 ± 0.01 b | 0.19 ± 0.01 b |

| Ganoderma williamsianum | 0.62 ± 0.01 a | 0.28 ± 0.03 a | |

| Lentinus sajor-caju | 0.62 ± 0.02 a | 0.32 ± 0.02 a | |

| Schizophyllum commune | 0.58 ± 0.02 b | 0.18 ± 0.04 b | |

| Rice straw | Ganoderma fornicatum | 0.33 ± 0.01 a | 0.10 ± 0.02 b |

| Ganoderma williamsianum | 0.36 ± 0.02 a | 0.15 ± 0.03 a | |

| Lentinus sajor-caju | 0.33 ± 0.04 a | 0.16 ± 0.02 a | |

| Schizophyllum commune | 0.25 ± 0.03 b | 0.07 ± 0.01 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voutetaki, M.E.; Mpalaskas, A.C. Natural Fiber-Reinforced Mycelium Composite for Innovative and Sustainable Construction Materials. Fibers 2024, 12, 57. https://doi.org/10.3390/fib12070057

Voutetaki ME, Mpalaskas AC. Natural Fiber-Reinforced Mycelium Composite for Innovative and Sustainable Construction Materials. Fibers. 2024; 12(7):57. https://doi.org/10.3390/fib12070057

Chicago/Turabian StyleVoutetaki, Maristella E., and Anastasios C. Mpalaskas. 2024. "Natural Fiber-Reinforced Mycelium Composite for Innovative and Sustainable Construction Materials" Fibers 12, no. 7: 57. https://doi.org/10.3390/fib12070057

APA StyleVoutetaki, M. E., & Mpalaskas, A. C. (2024). Natural Fiber-Reinforced Mycelium Composite for Innovative and Sustainable Construction Materials. Fibers, 12(7), 57. https://doi.org/10.3390/fib12070057