Hydrothermal Aging and Humidity Exposure of Carbon and Basalt Fibers and Life Time Prediction †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Dry Fiber Bundles

2.2. Sample Preparation and Conditioning

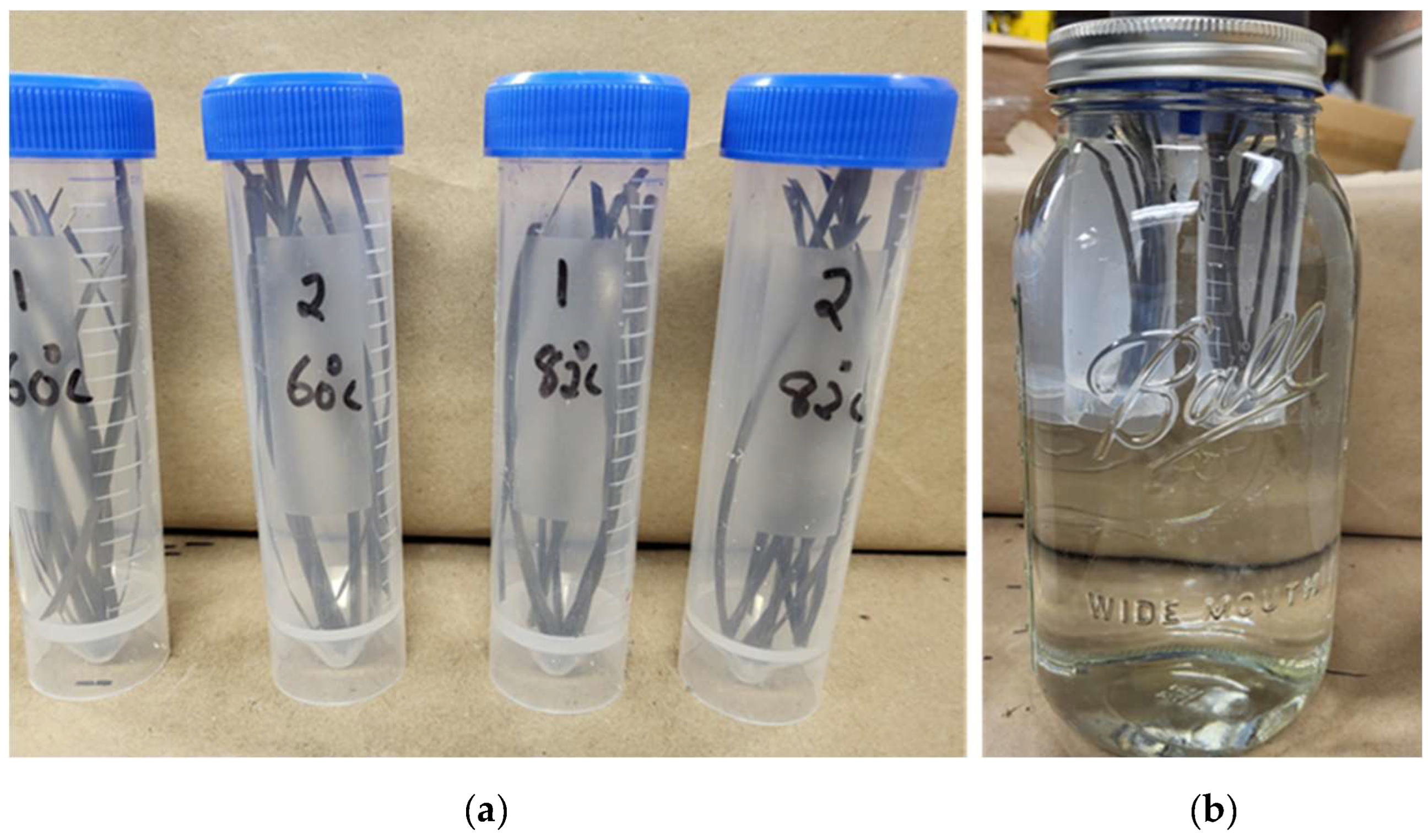

2.2.1. Hydrothermal Aging

2.2.2. Exposure to Humidity

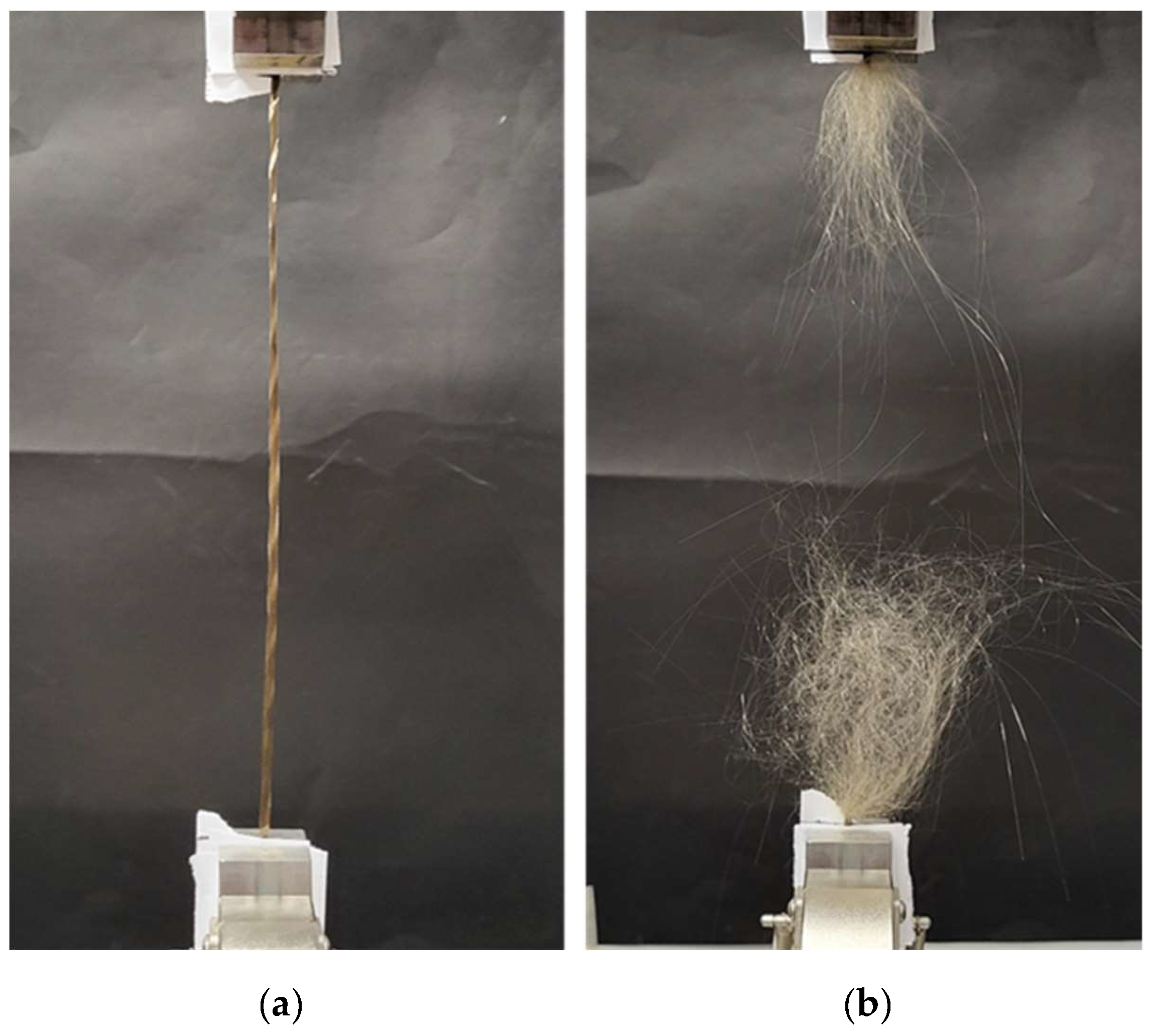

2.2.3. Assessment of Damage Caused by Sample Preparation

2.3. Tensile Testing

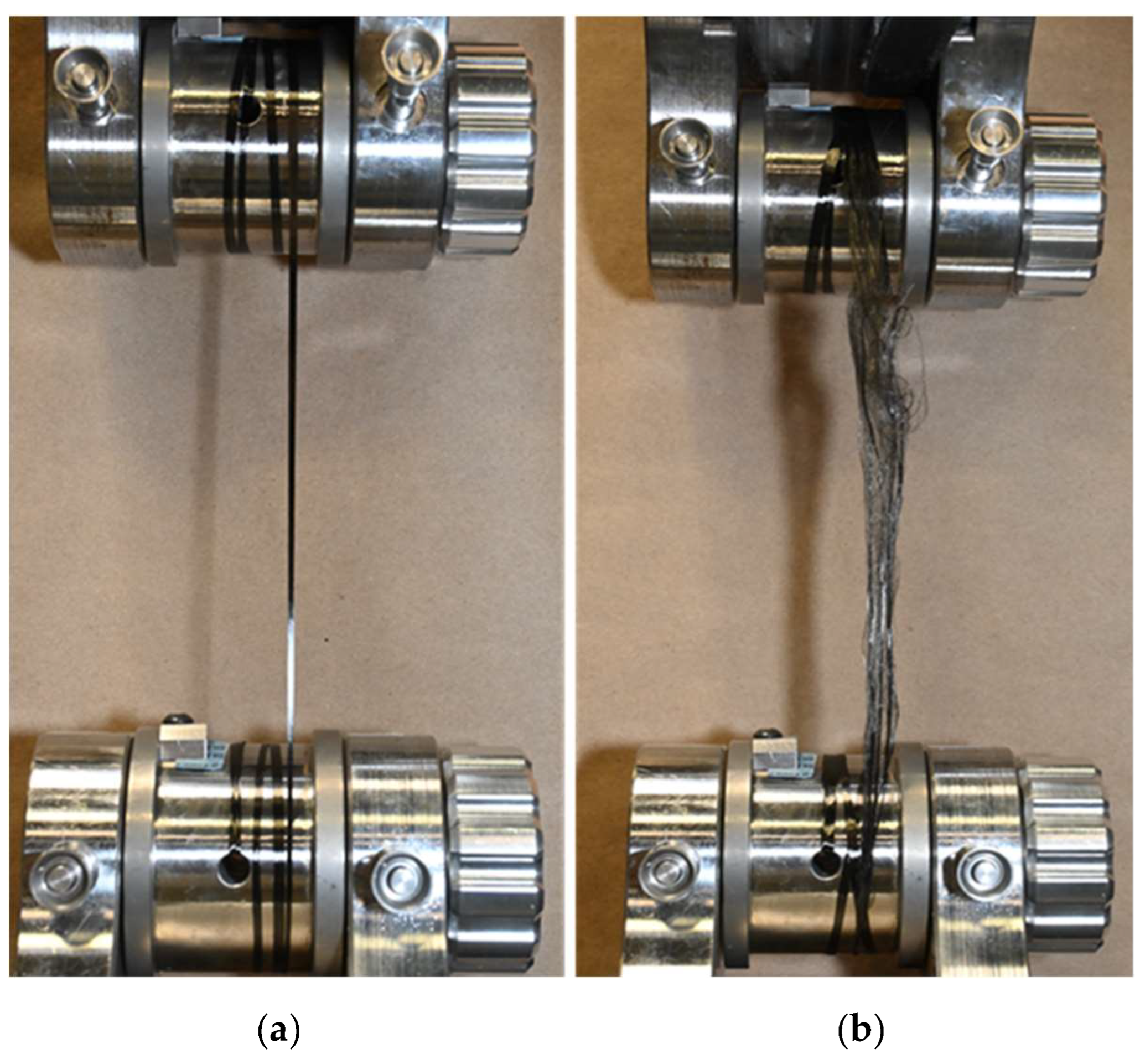

2.3.1. Capstan Grips

2.3.2. Tabbing Method

2.4. Mass Spectroscopy

2.5. Fourier-Transform Infrared Spectroscopy

2.6. Scanning Electron Microscopy

3. Results and Discussion

3.1. Variations in Fiber Strength

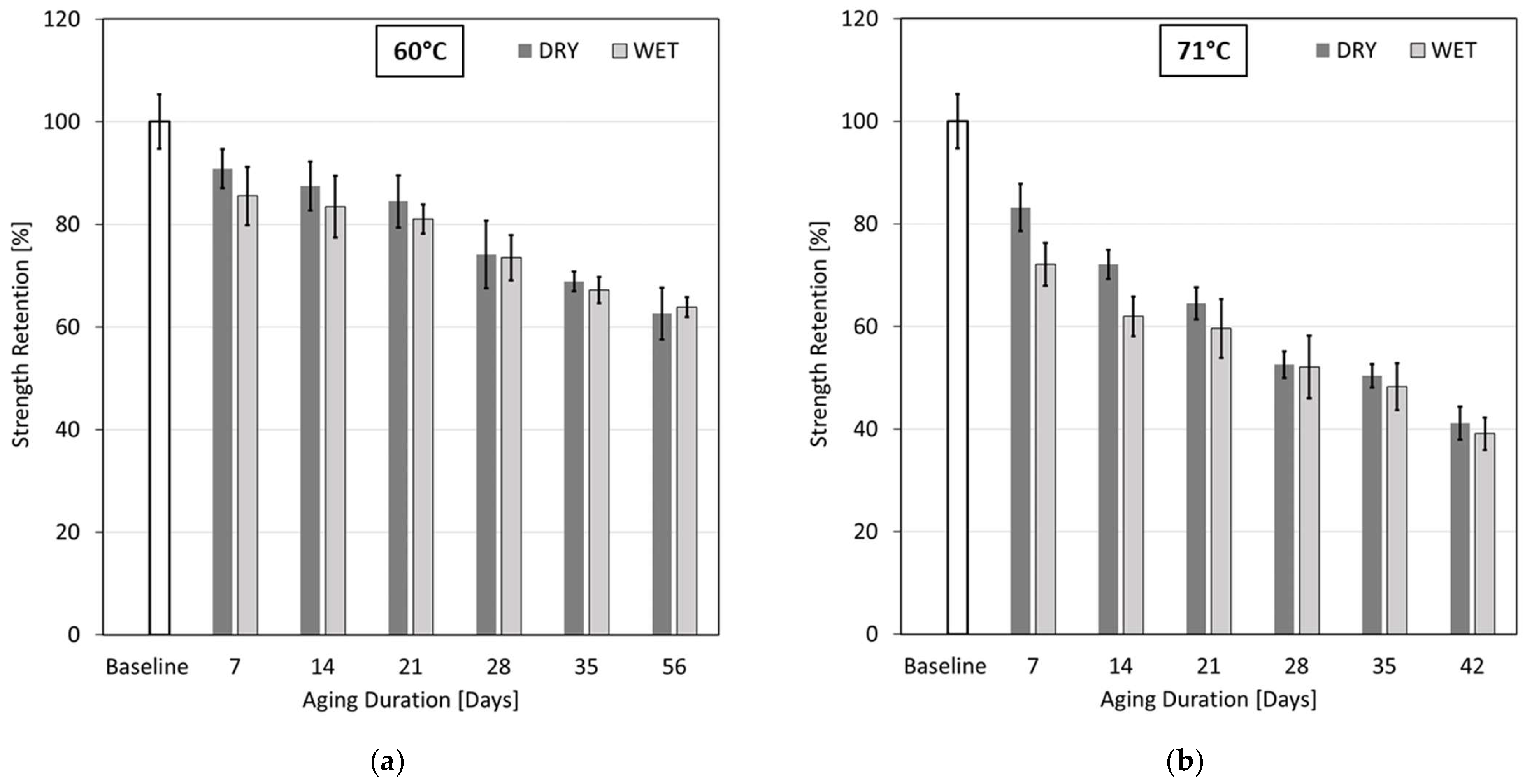

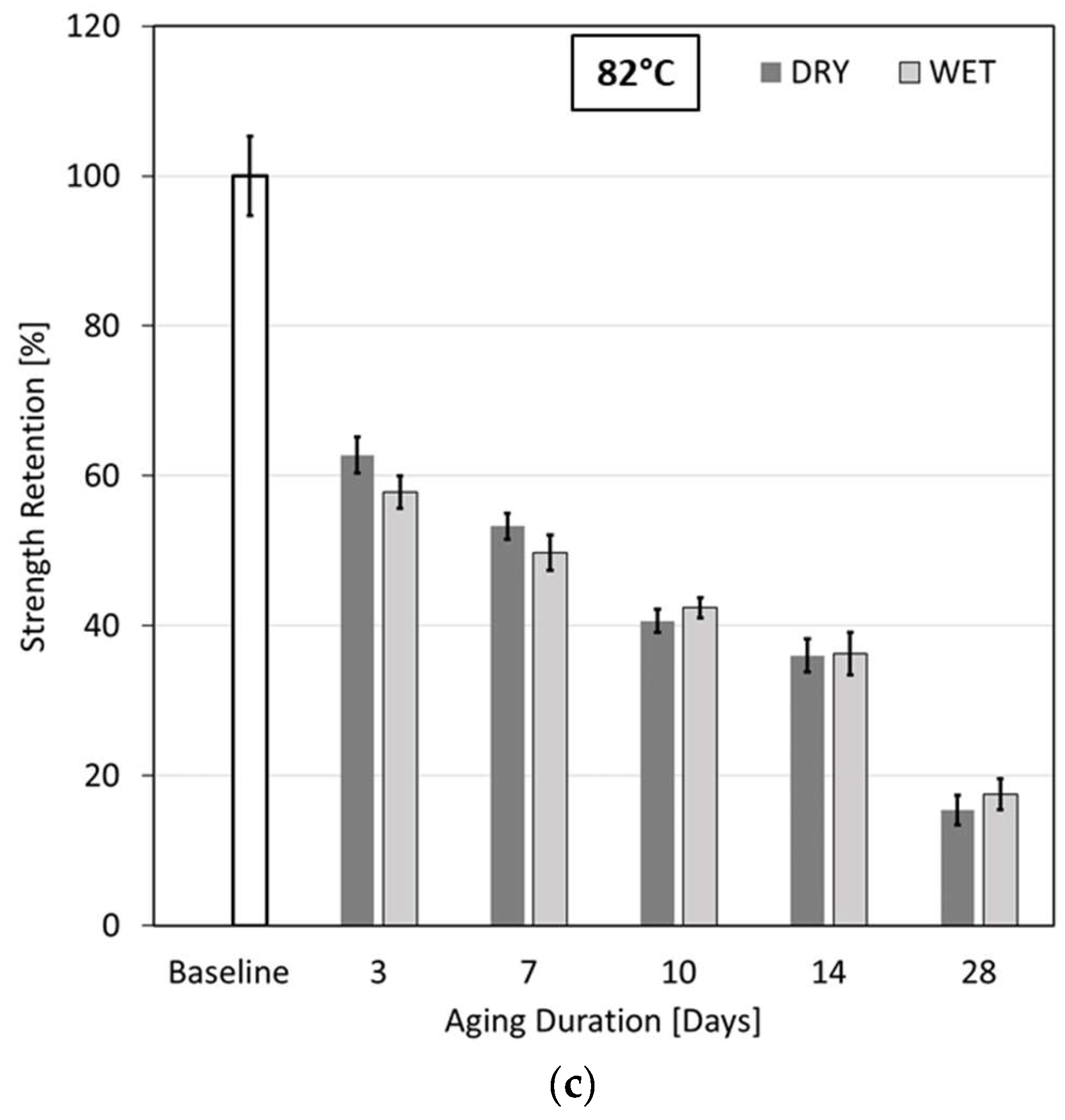

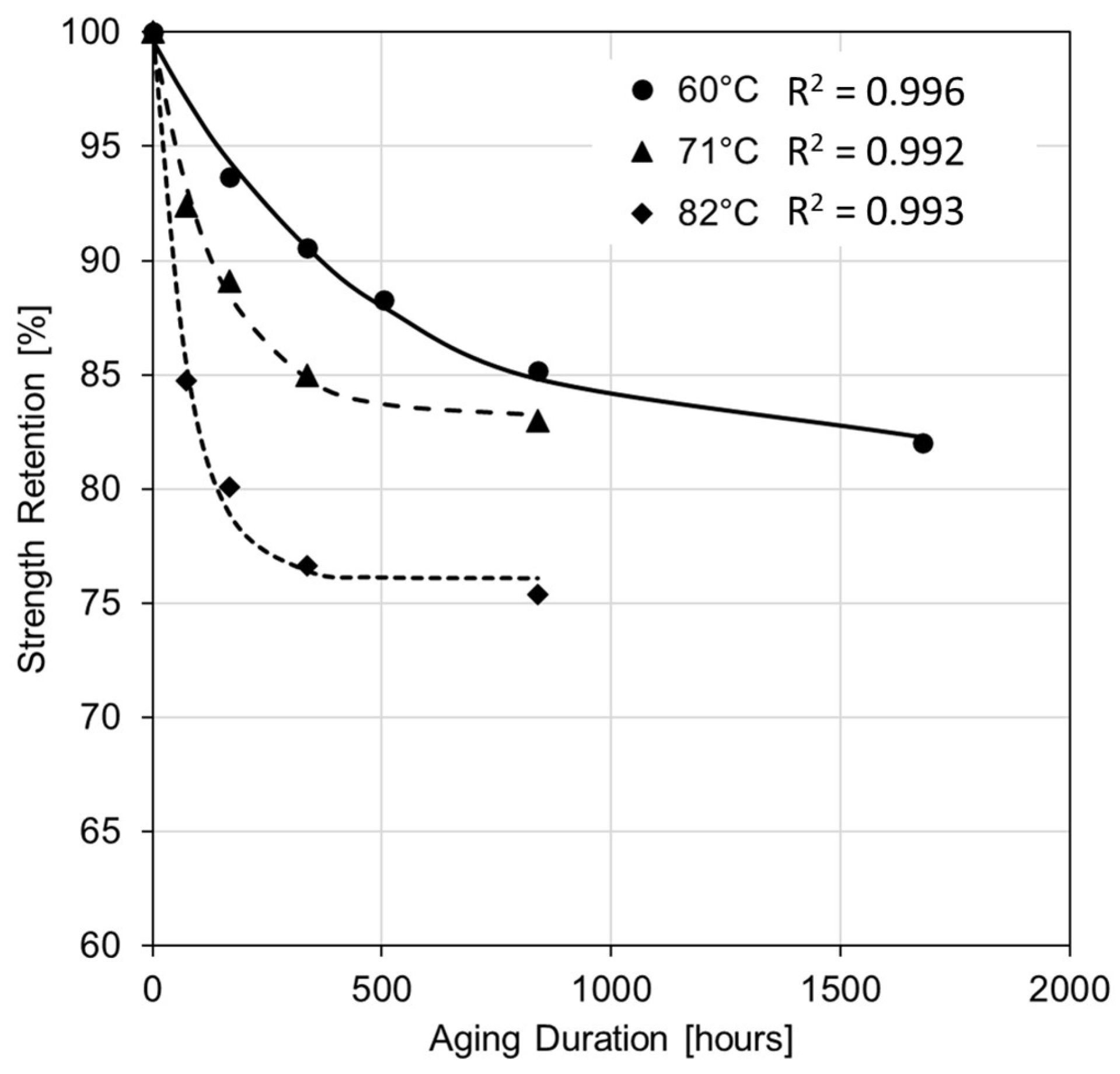

3.1.1. Strength Variations for Basalt Fibers

3.1.2. Strength Variations for Carbon Fibers

3.2. Prediction of Tensile Strength

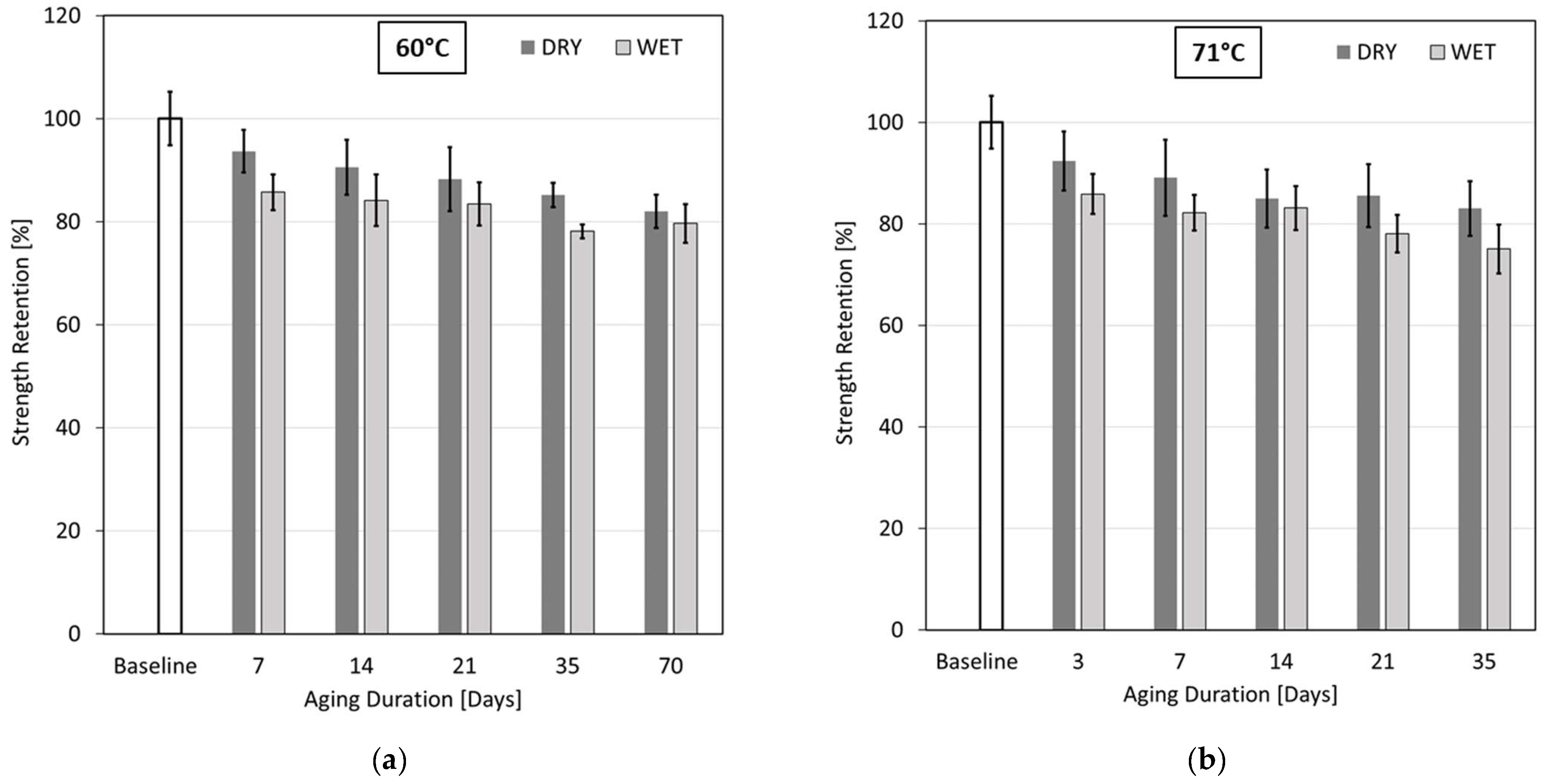

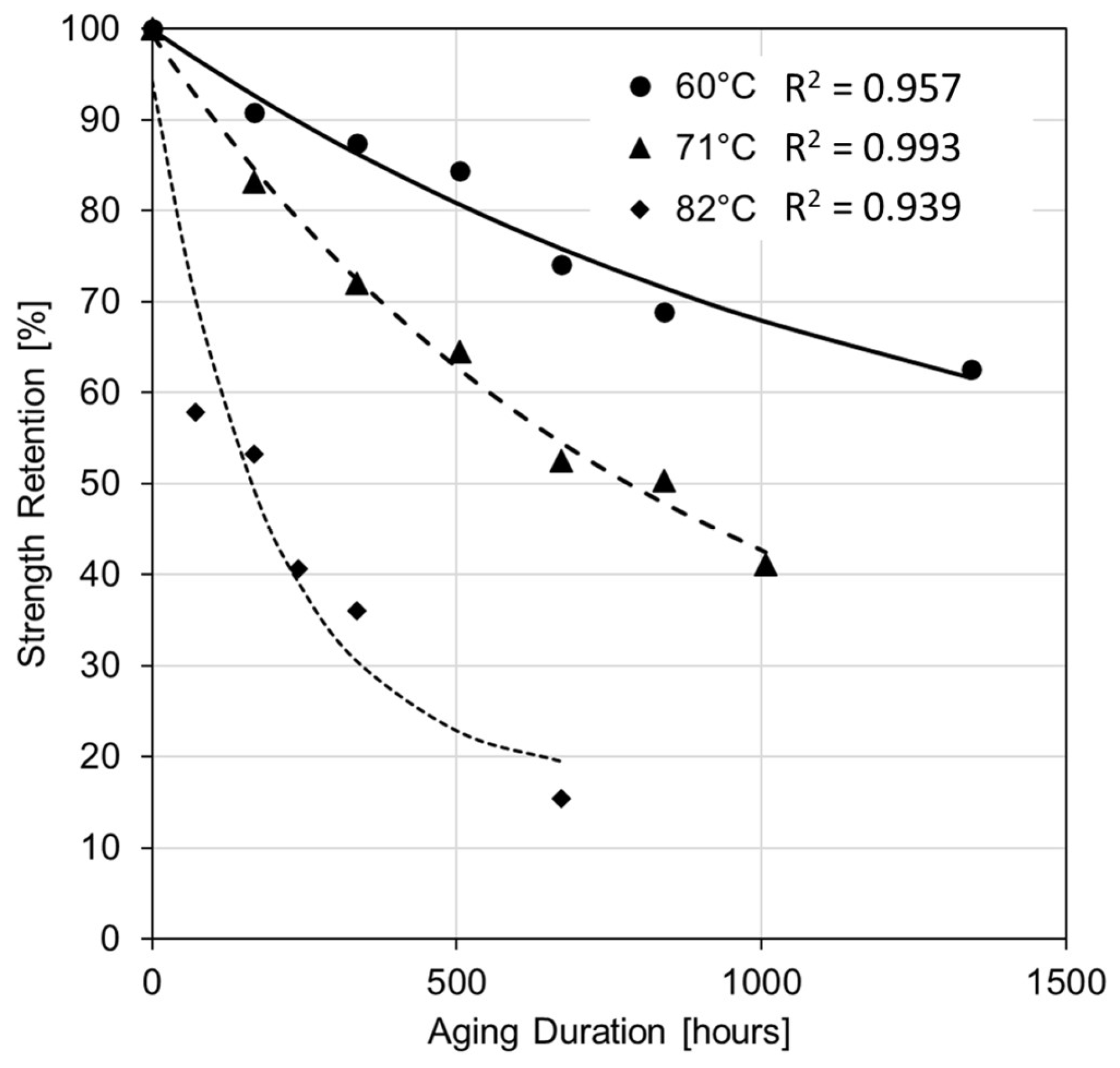

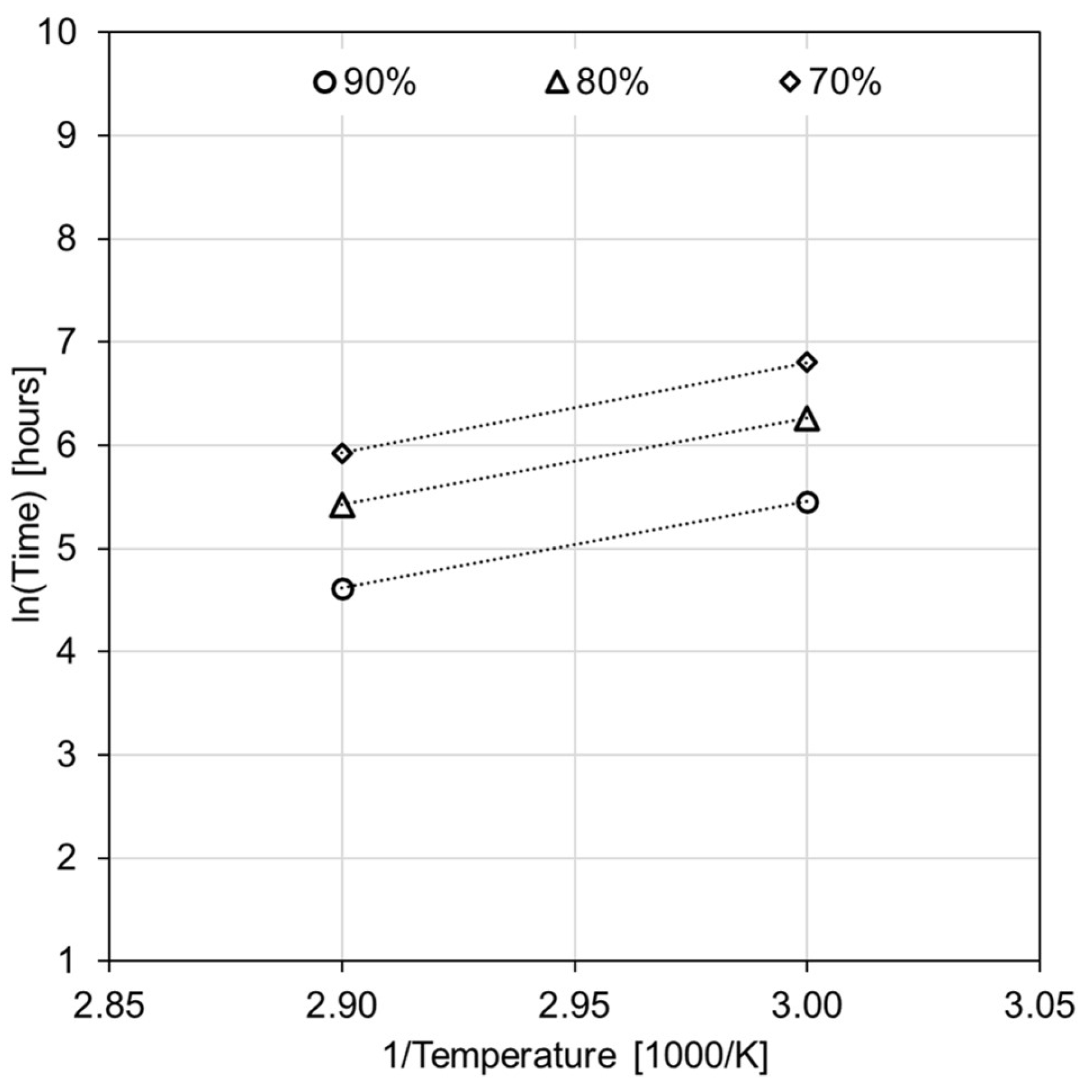

3.2.1. Basalt Fibers

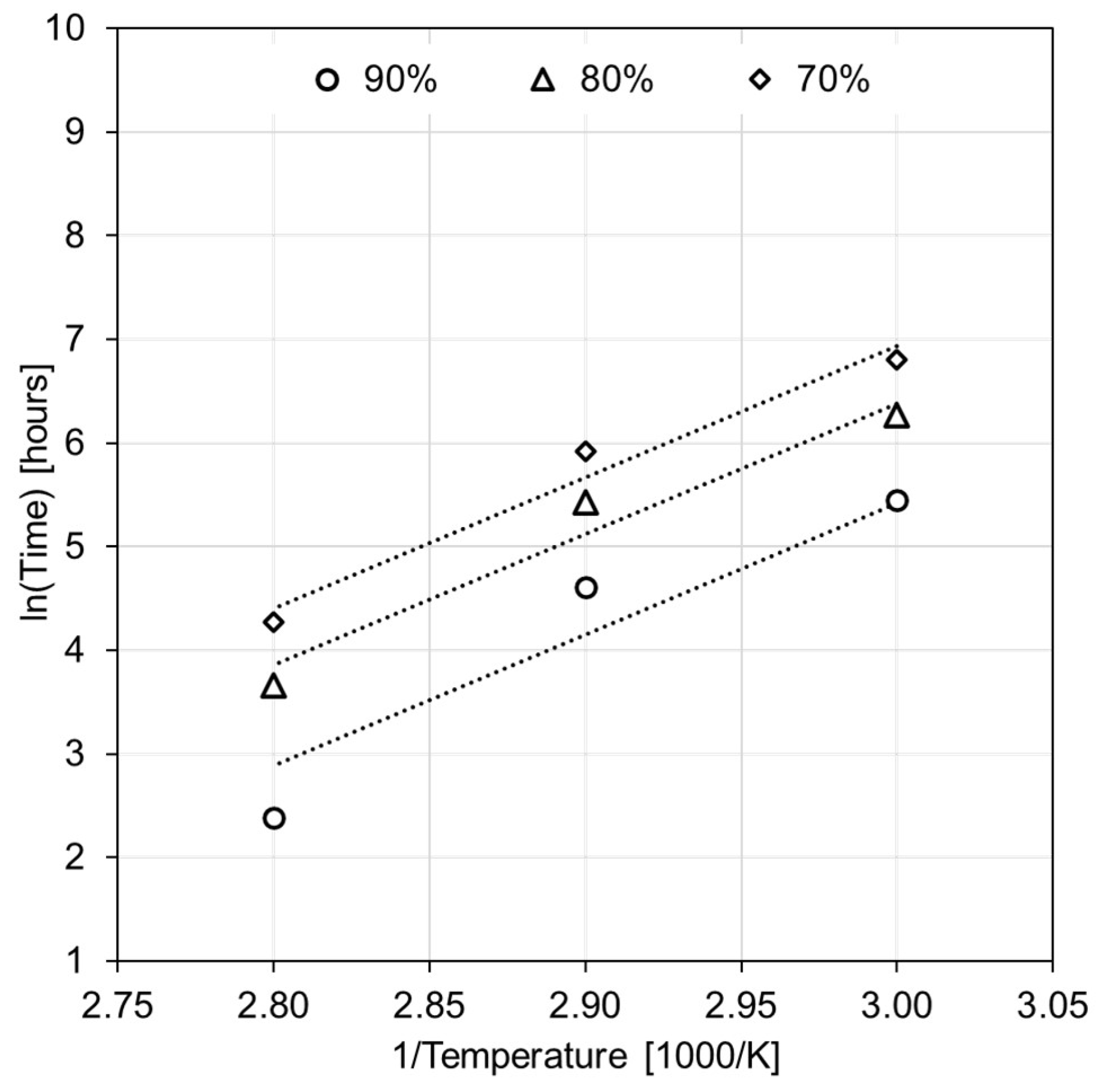

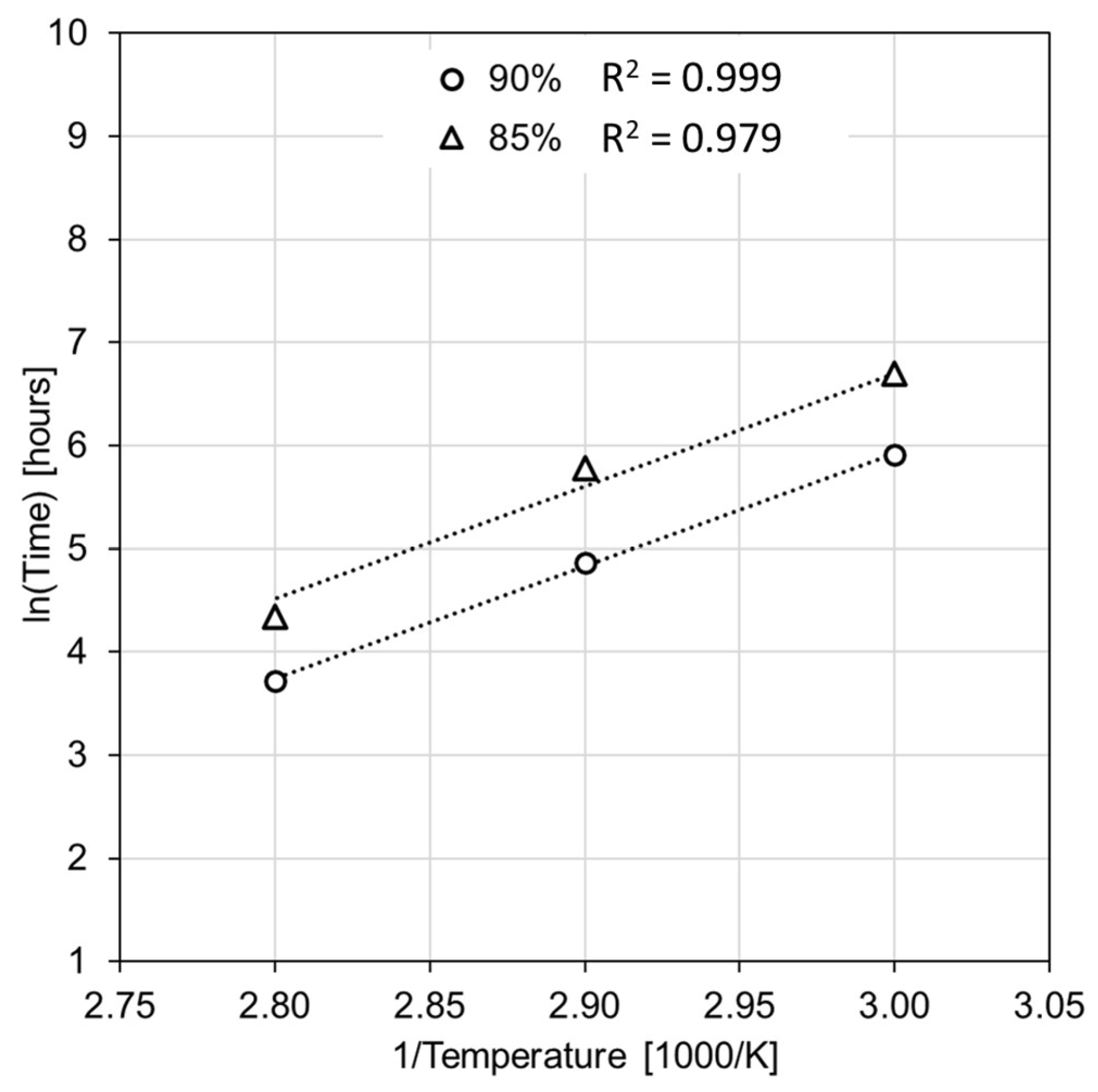

3.2.2. Carbon Fibers

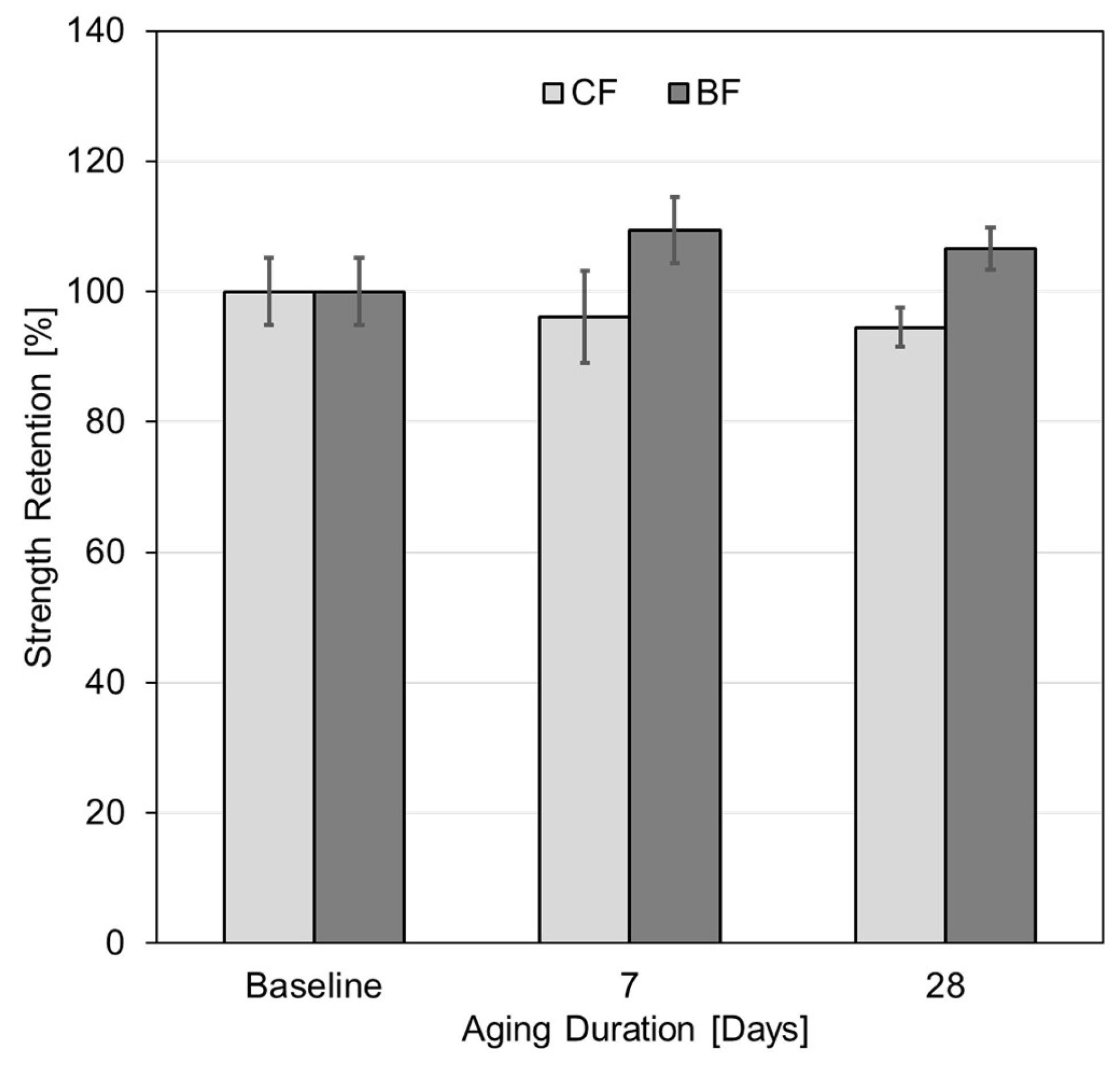

3.3. Variation in Tensile Strength after Exposure to Humidity

3.4. Mass Dissolution Tests

3.4.1. Basalt Fibers

3.4.2. Carbon Fibers

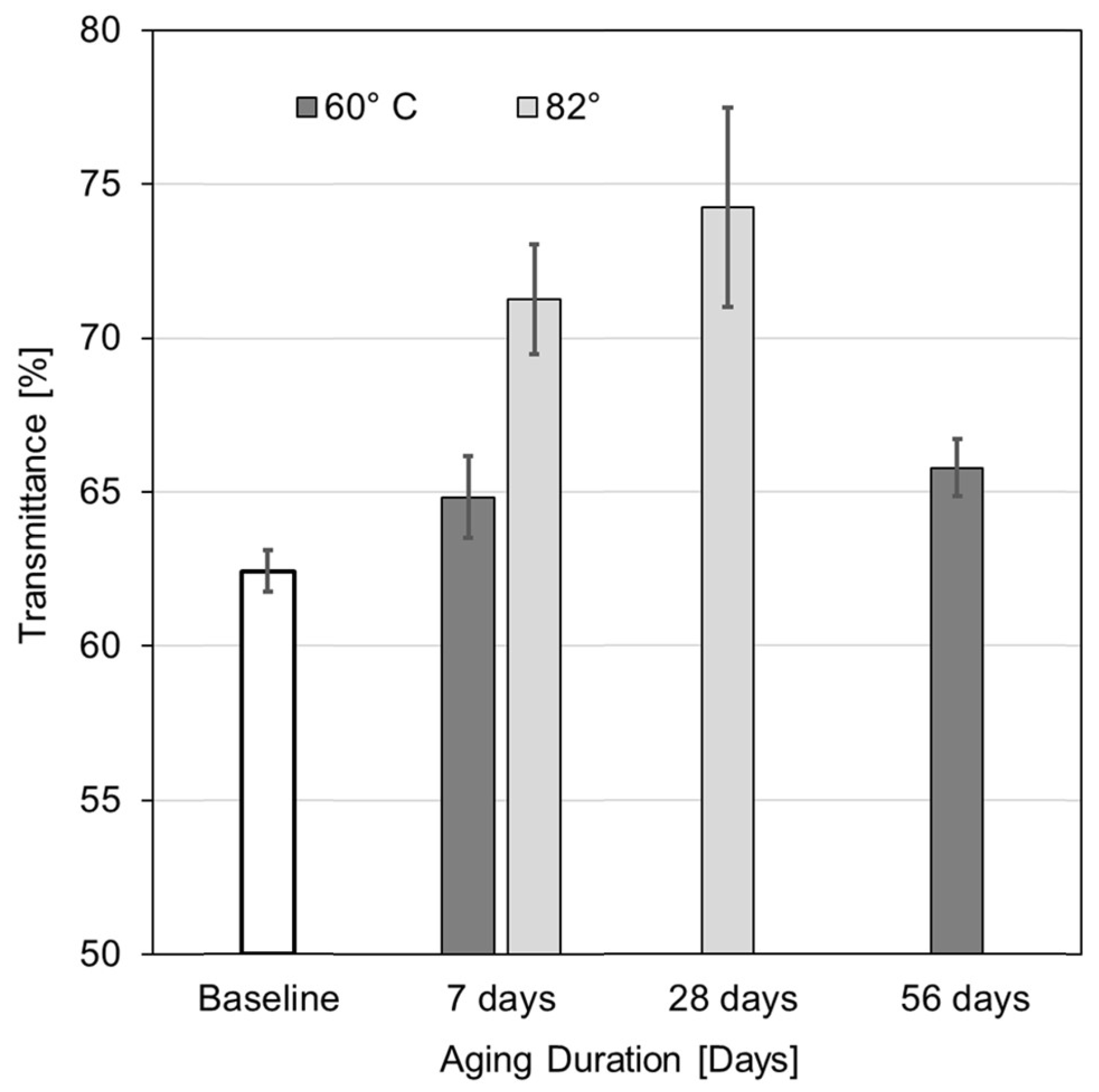

3.5. FTIR Results

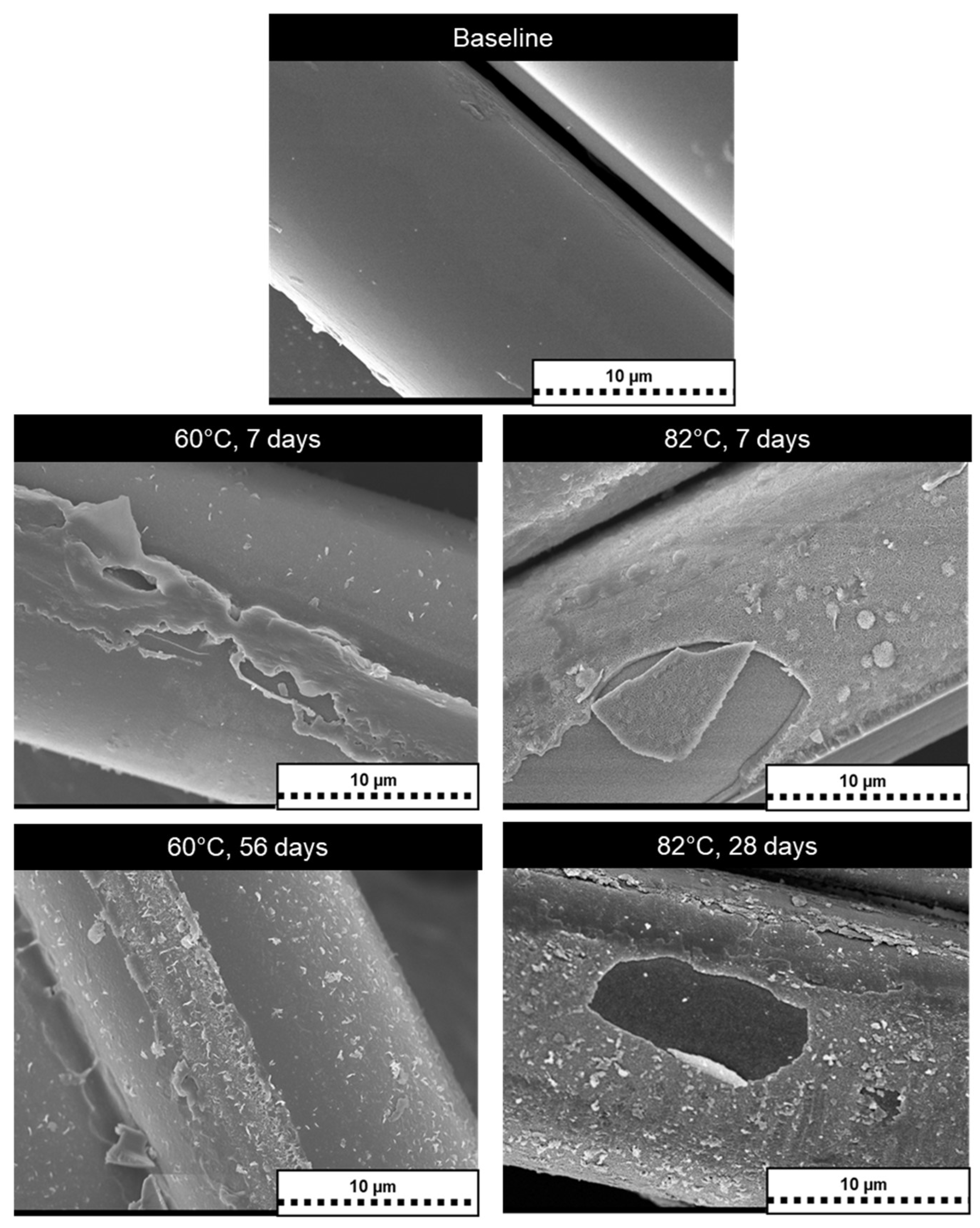

3.6. Morphological Changes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krauklis, A.E. Modular Paradigm for Composites: Modeling Hydrothermal Degradation of Glass Fibers. Fibers 2021, 9, 83. [Google Scholar] [CrossRef]

- Krauklis, A.E. Environmental Aging of Constituent Materials in Fiber Reinforced Polymer Composites. Ph.D. Thesis, NTNU, Trondheim, Norway, July 2019. [Google Scholar]

- Feih, S.; Wei, J.; Kingshott, P.; Sorensen, B. The influence of fibre sizing on the strength and fracture toughness of glass fibre composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 245–255. [Google Scholar] [CrossRef]

- Cousin, P.; Hassan, M.; Vijay, P.; Robert, M.; Benmokrane, B. Chemical resistance of carbon, basalt, and glass fibers used in FRP reinforcing bars. J. Compos. Mater. 2019, 53, 3651–3670. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Tensile behavior contrast of basalt and glass fibers after chemical treatment. Mater. Des. 2010, 31, 4244–4250. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Grabovac, I.; Whittaker, D. Application of bonded composites in the repair of ships structures—A 15-year service experience. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1381–1398. [Google Scholar] [CrossRef]

- Robert, M.; Roy, R.; Benmokrane, B. Environmental effects on glass fiber reinforced polypropylene thermoplastic composite laminate for structural applications. Polym. Compos. 2010, 31, 604–611. [Google Scholar] [CrossRef]

- Kuram, E. Thermal and water ageing effect on mechanical, rheological and morphological properties of glass-fibre-reinforced poly (oxymethylene) composite. Proc. Inst. Mech. Eng. E J. Process Mech. Eng. 2019, 233, 211–224. [Google Scholar] [CrossRef]

- Borges, C.; Akhavan-Safar, A.; Marques, E.; Carbas, R.; Ueffing, C.; Weißgraeber, P.; da Silva, L. Effect of water ingress on the mechanical and chemical properties of polybutylene terephthalate reinforced with glass fibers. Materials 2021, 14, 1261. [Google Scholar] [CrossRef]

- Messana, A.; Airale, A.; Ferraris, A.; Sisca, L.; Carello, M. Correlation between thermo-mechanical properties and chemical composition of aged thermoplastic and thermosetting fiber reinforced plastic materials. Mater. Werkst. 2017, 48, 447–455. [Google Scholar] [CrossRef]

- Silva, M.; da Fonseca, B.; Biscaia, H. On estimates of durability of FRP based on accelerated tests. Compos. Struct. 2014, 116, 377–387. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Ggani, A.; Echtermeyer, A. Long-term hydrolytic degradation of the sizing-rich composite interphase. Coatings 2019, 9, 263. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.; Gagani, A.; Jørgensen, J. Composite material recycling technology—State-of-the-art and sustainable development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Kasper, A. Recycling composites: FAQs. Reinf. Plast. 2008, 52, 39. [Google Scholar] [CrossRef]

- Fang, M.; Zhang, N.; Huang, M.; Lu, B.; Lamnawar, K.; Liu, C.; Shen, C. Effects of hydrothermal aging of carbon fiber reinforced polycarbonate composites on mechanical performance and sand erosion resistance. Polymers 2020, 12, 2453. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, P.; Guo, R.; Li, C.; Xian, G. Durability study of glass fiber reinforced polypropylene sheet under simulated seawater sea sand concrete environment. J. Mater. Res. Technol. 2022, 20, 1079–1092. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Gagani, A.; Vegere, K.; Kalnina, I.; Klavins, M.; Echtermeyer, A. Dissolution Kinetics of R-Glass Fibers: Influence of Water Acidity, Temperature, and Stress Corrosion. Fibers 2019, 7, 22. [Google Scholar] [CrossRef]

- Davalos, J.; Chen, Y.; Ray, I. Long-term durability prediction models for GFRP bars in concrete environment. J. Compos. Mater. 2012, 46, 1899–1914. [Google Scholar] [CrossRef]

- Kececi, E.; Asmatulu, R. Effects of moisture ingressions on mechanical properties of honeycomb-structured fiber composite for aerospace applications. Int. J. Adv. Manuf. Technol. 2017, 88, 459–470. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, J.; Zhou, L.; Lu, M.; Liang, W.; Wang, Z. Effect of fiber surface modification on water absorption and hydrothermal aging behaviors of GF/pCBT composites. Compos. B Eng. 2015, 82, 84–91. [Google Scholar] [CrossRef]

- Zhang, Y.; Mi, C. Improved hydrothermal aging performance of glass fiber-reinforced polymer composites via silica nanoparticle coating. J. Appl. Polym. Sci. 2020, 137, 19. [Google Scholar] [CrossRef]

- Jiang, D.; Xing, L.; Liu, L.; Sun, S.; Zhang, Q.; Wu, Z.; Yan, X.; Guo, J.; Huang, Y.; Guo, Z. Enhanced mechanical properties and anti-hydrothermal ageing behaviors of unsaturated polyester composites by carbon fibers interfaced with POSS. Compos. Sci. Technol. 2015, 117, 168–175. [Google Scholar] [CrossRef]

- Echtermeyer, A.; Krauklis, A.; Gagani, A.; Sæter, E. Zero Stress Aging of Glass and Carbon Fibers in Water and Oil—Strength Reduction Explained by Dissolution Kinetics. Fibers 2019, 7, 107. [Google Scholar] [CrossRef]

- Sunny, J.; Palacios Moreno, J.; Nazaripoor, H.; Mertiny, P. Accelerated Zero-Stress Hydrothermal Aging of Dry E-Glass Fibers and Service Life Prediction Using Arrhenius Model. Fibers 2023, 11, 70. [Google Scholar] [CrossRef]

- Sunny, J.; Palacios Moreno, J.; Nazaripoor, H.; Mertiny, P. Accelerated zero stress aging of glass, basalt and carbon fibers-strength reduction explained by chemical and morphological analysis. In Proceedings of the 2023 Canadian Society for Mechanical Engineering International Conference, Sherbrooke, QC, Canada, 28–31 May 2023. [Google Scholar]

- Hexcel Carbon Fiber Technical Datasheet. Available online: https://www.hexcel.com/user_area/content_media/raw/IM2A_HexTow_DataSheet.pdf (accessed on 5 September 2022).

- Basalt Fiber Technical Data Sheet. Available online: https://www.mafic.com/product-lines (accessed on 5 September 2022).

- Zhu, J.; Deng, Y.; Chen, P.; Wang, G.; Min, H.; Fang, W. Prediction of long-term tensile properties of glass fiber reinforced composites under acid-base and salt environments. Polymers 2022, 14, 3031. [Google Scholar] [CrossRef] [PubMed]

- ASTM D2256M-10; Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D2343-17; Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics. ASTM International: West Conshohocken, PA, USA, 2009.

- ISO 11346; Rubber, Vulcanized or Thermoplastic Estimation of Life Time and Maximum Temperature of Use. International Organization for Standardization: Geneva, Switzerland, 2014.

- Starkova, O.; Gagani, A.; Karl, C.; Rocha, I.; Burlakovs, J.; Krauklis, A. Modelling of environmental ageing of polymers and polymer composites-durability prediction metholds. Polymers 2022, 14, 907. [Google Scholar] [CrossRef] [PubMed]

- Krauklis, A.E.; Echtermeyer, A. Long-term dissolution of glass fibers in water described by dissolving cylinder zero-order kinetic model: Mass loss and radius reduction. Open Chem. 2018, 16, 1189–1199. [Google Scholar] [CrossRef]

- Pusch, J.; Wohlmann, B. Carbon fibers. In Inorganic and Composite Fibers: Production, Properties, and Applications; Woodhead Publishing: Oxford, UK, 2018; pp. 31–51. [Google Scholar] [CrossRef]

- Liu, J.; Chen, M.; Yang, J.; Wu, Z. Study on mechanical properties of basalt fibers superior to E-glass fibers. J. Nat. Fibers 2022, 19, 882–894. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. Development of sustainable microwave-based approach to recover glass fibers for wind turbine blades composite waste. Resour. Conserv. Recycl. 2022, 179, 106107. [Google Scholar] [CrossRef]

- Abidi, N. FTIR Microspectroscopy: Selected Emergency Applications; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–134. [Google Scholar]

| Aging Temperature [°C] | A1 [N] | τ [hour] | Y0 [N] | [K] |

|---|---|---|---|---|

| 60 | 58.65 | 1268.7 | 41.26 | 8410 |

| 71 | 81.11 | 837.5 | 18.16 | 8410 |

| 82 | 77.20 | 190.9 | 17.25 | 8410 |

| Aging Temperature [°C] | A1 [N] | τ [hour] | Y0 [N] | [K] |

|---|---|---|---|---|

| 60 | 17.89 | 477.18 | 81.76 | 10,940 |

| 71 | 16.51 | 146.75 | 83.18 | 10,940 |

| 82 | 23.72 | 78.36 | 76.11 | 10,940 |

| Element | Si | Ca | Al | Na | Mg | K |

|---|---|---|---|---|---|---|

| Concentration at 60 °C [mg/L] | 3.15 | 0.38 | 0.7 | 0.51 | 0.23 | 0.21 |

| Concentration at 82 °C [mg/L] | 12.49 | 1.54 | 4.12 | 1.36 | 1.16 | 0.67 |

| Element | C | N |

|---|---|---|

| Concentration at 60 °C [mg/L] | 30.52 | 0.27 |

| Concentration at 82 °C [mg/L] | 34.79 | 0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sunny, J.; Palacios Moreno, J.; Nazaripoor, H.; Mertiny, P. Hydrothermal Aging and Humidity Exposure of Carbon and Basalt Fibers and Life Time Prediction. Fibers 2024, 12, 58. https://doi.org/10.3390/fib12070058

Sunny J, Palacios Moreno J, Nazaripoor H, Mertiny P. Hydrothermal Aging and Humidity Exposure of Carbon and Basalt Fibers and Life Time Prediction. Fibers. 2024; 12(7):58. https://doi.org/10.3390/fib12070058

Chicago/Turabian StyleSunny, John, Jorge Palacios Moreno, Hadi Nazaripoor, and Pierre Mertiny. 2024. "Hydrothermal Aging and Humidity Exposure of Carbon and Basalt Fibers and Life Time Prediction" Fibers 12, no. 7: 58. https://doi.org/10.3390/fib12070058