An Application Review of Fiber-Reinforced Geopolymer Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Relevant Sources for Literature Review

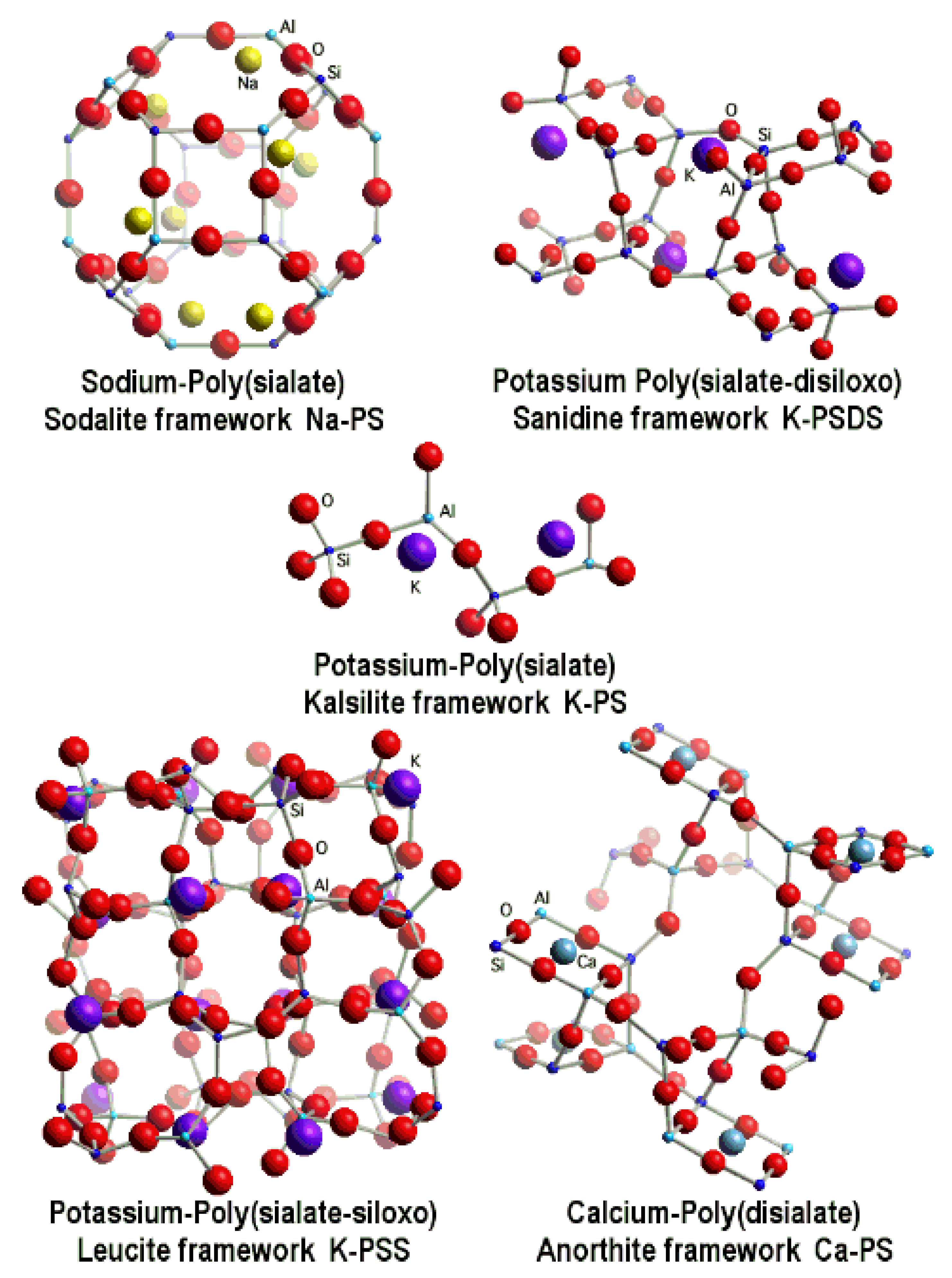

2.2. Geopolymer Matrix and Its Various Types

2.3. Inorganic Synthetic Fiber Reinforcements in Geopolymer Matrix Composites

2.4. Organic Synthetic Fibers Reinforcements in the Geopolymer Matrix Composites

2.5. Bio-Fibers Reinforced Geopolymer Composite

2.6. Steel Fiber Reinforced Geopolymer Composites

2.7. Short and Hybrid Fiber-Reinforced Geopolymer Composites

2.8. Methods for Composite’s Fabrication

3. The Physical, Chemical, and Mechanical Domains of Geopolymer-Based Composite

3.1. Chemical Structure of Geopolymer Matrix

3.2. The Domain of Composites in Various Fields

4. Characterization of Pure Geopolymer and Fiber-Reinforced Composite

4.1. Characterization of Pure Geopolymer

4.2. Fiber-Reinforced Geopolymer Characterization

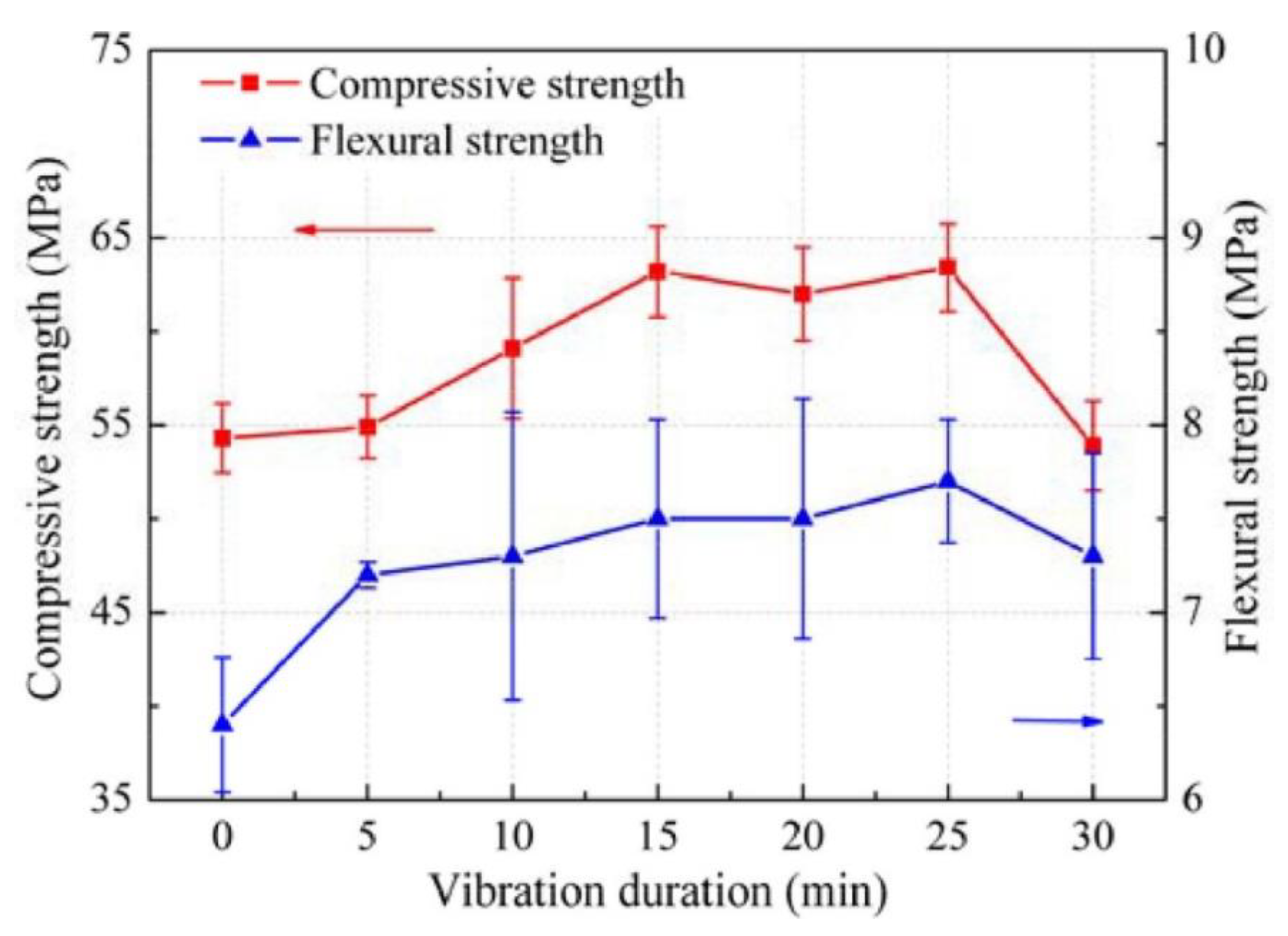

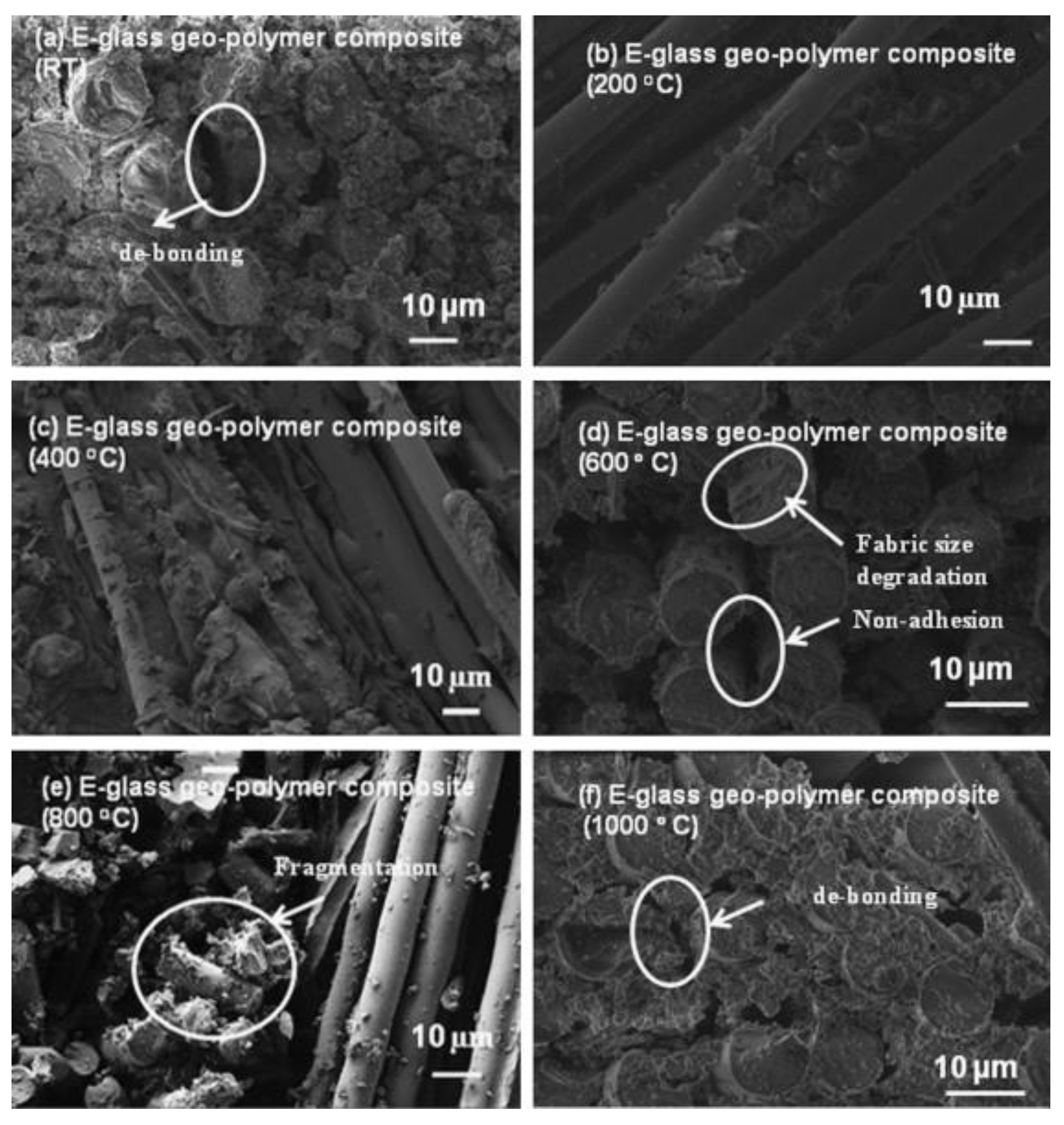

4.2.1. Synthetic Fibers Such as Carbon, E-glass, and Basalt Fiber-Reinforced Geopolymer Composites

4.2.2. Durability on Impact of Fiber-Reinforced Composite

4.2.3. Natural Fibers Such as Cotton, Flax, Jute Fiber Reinforced Geopolymer Composites

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Samal, S. Effect of High temperature on the microstructural evolution of fiber-reinforced geopolymer composite. Heliyon 2019, 5, e01779. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Samal, S.; Thanh, N.P.; Petríková, I.; Marvalová, B.; Vallons, K.A.M.; Lomov, S.V. Correlation of microstructure and mechanical properties of various fabric reinforced geo-polymer composites after exposure to elevated temperature. Ceram. Int. 2015, 41, 12115–12129. [Google Scholar] [CrossRef]

- Samal, S.; Thanh, N.P.; Petríková, I.; Marvalová, B. Improved mechanical properties of various fabric-reinforced geocomposite at elevated temperature. JOM 2015, 67, 1478–1485. [Google Scholar] [CrossRef]

- Samal, S.; Thanh, N.P.; Marvalová, B.; Petríková, I. Thermal Characterization of Metakaolin-Based Geopolymer. JOM 2017, 69, 2480–2484. [Google Scholar] [CrossRef]

- Samal, S.; Marvalová, B.; Petríková, I.; Vallons, K.A.M.; Lomov, S.V.; Rahier, H. Impact and post-impact behavior of fabric reinforced geopolymer composite. Constr. Build. Mater. 2016, 127, 111–124. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A review on mixture design methods for geopolymer concrete. Compos. Part B Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Blanco, I.; Dal Poggetto, G.; Morrone, B.; Tranquillo, E.; Barrino, F.; Catauro, M. Fly Ash Filled Geopolymers: Preparation and Thermal Study. Macromol. Symp. 2020, 389, 1900052. [Google Scholar] [CrossRef]

- Blanco, I.; Cicala, G.; Tosto, C.; Recca, G.; Dal Poggetto, G.; Catauro, M. Kinetic Study of the Thermal Dehydration of Fly Ash Filled Geopolymers. Macromol. Symp. 2021, 395, 2000225. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; Institut Géopolymère, Geopolymer Institute: Saint-Quentin, France, 2020; ISBN 9782954453118. [Google Scholar]

- Samal, S.; Stuchlík, M.; Petrikova, I. Thermal behavior of flax and jute reinforced in matrix acrylic composite. J. Therm. Anal. Calorim. 2018, 131, 1035–1040. [Google Scholar] [CrossRef]

- Samal, S.; Kolinova, M.; Rahier, H.; Dal Poggetto, G.; Blanco, I. Investigation of the Internal Structure of Fiber Reinforced Geopolymer Composite under Mechanical Impact: A Micro Computed Tomography (µCT) Study. Appl. Sci. 2019, 9, 516. [Google Scholar] [CrossRef] [Green Version]

- Temuujin, J.; Minjigmaa, A.; Rickard, W.; Van Riessen, A. Thermal properties of spray-coated geopolymer-type compositions. J. Therm. Anal. Calorim. 2012, 107, 287–292. [Google Scholar] [CrossRef]

- Rashad, A.M.; Ouda, A.S. Thermal resistance of alkali-activated metakaolin pastes containing nano-silica particles. J. Therm. Anal. Calorim. 2019, 136, 609–620. [Google Scholar] [CrossRef]

- Catauro, M.; Tranquillo, E.; Barrino, F.; Dal Poggetto, G.; Blanco, I.; Cicala, G.; Ognibene, G.; Recca, G. Mechanical and thermal properties of fly ash-filled geopolymers. J. Therm. Anal. Calorim. 2019, 138, 3267–3276. [Google Scholar] [CrossRef]

- Samal, S. Effect of shape and size of filler particle on the aggregation and sedimentation behavior of the polymer composite. Powder Technol. 2020, 366, 43–51. [Google Scholar] [CrossRef]

- Bai, T.; Liu, B.; Wu, Y.; Huang, W.; Xia, Z. Mechanical properties of metakaolin-based geopolymer with glass fiber reinforcement and vibration preparation. J. Non Cryst. Solids 2020, 544, 120173. [Google Scholar] [CrossRef]

- Alomayri, T.; Low, I.M. Synthesis, and characterization of mechanical properties in cotton fiber-reinforced geopolymer composites. J. Asian Ceram. Soc. 2013, 1, 30–34. [Google Scholar] [CrossRef] [Green Version]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Effect of fabric orientation on mechanical properties of cotton fabric reinforced geopolymer composites. Mater. Des. 2014, 57, 360–365. [Google Scholar] [CrossRef]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Saxena, S.K.; Kumar, M.; Singh, N.B. Fire Resistant Properties of Alumino Silicate Geopolymer cement Mortars. Mater. Today Proc. 2017, 4, 5605–5612. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Yavna, V.; Mischinenko, V.; Kukharskii, A.; Kruglikov, A.; Kolodina, A.; Yalovega, G. Effect of pre-treatment of flax tows on mechanical properties and microstructure of natural fiber reinforced geopolymer composites. Environ. Technol. Innov. 2020, 20, 101105. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Lin, T.; Jia, D.; He, P.; Wang, M. In situ crack growth observation and fracture behavior of short carbon fiber reinforced geopolymer matrix composites. Mater. Sci. Eng. A 2010, 527, 2404–2407. [Google Scholar] [CrossRef]

- Silva Alves, L.C.; Reis Ferreira, R.A.; Bellini Machado, L.; Castro Motta, L.A. Optimization of metakaolin-based geopolymer reinforced with sisal fibers using response surface methodology. Ind. Crops Prod. 2019, 139, 111551. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Korniejenko, K.; Lin, W.-T.; Šimonová, H. Mechanical Properties of Short Polymer Fiber-Reinforced Geopolymer Composites. J. Compos. Sci. 2020, 4, 128. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-Reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Deepa Raj, S. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. High ductile behavior of a polyethylene fiber-reinforced one-part geopolymer composite: A micromechanics-based investigation. Arch. Civ. Mech. Eng. 2017, 17, 555–563. [Google Scholar] [CrossRef]

- Khan, M.Z.N.; Hao, Y.; Hao, H.; Shaikh, F.U.A. Mechanical properties of ambient cured high strength hybrid steel and synthetic fibers reinforced geopolymer composites. Cem. Concr. Compos. 2018, 85, 133–152. [Google Scholar] [CrossRef]

- Du, F.-P.; Xie, S.-S.; Zhang, F.; Tang, C.-Y.; Chen, L.; Law, W.-C.; Tsui, C.-P. Microstructure and compressive properties of silicon carbide reinforced geopolymer. Compos. B Eng. 2016, 105, 93–100. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Li, H.; Yan, F. Synthesis and tribological behavior of metakaolinite-based geopolymer composites. Mater. Lett. 2005, 59, 3976–3981. [Google Scholar] [CrossRef]

- Łach, M.; Korniejenko, K.; Mikuáa, J. Thermal insulation and thermally resistant materials made of geopolymer foams. Procedia Eng. 2016, 151, 410–416. [Google Scholar] [CrossRef] [Green Version]

- Novais, R.M.; Pullar, R.C.; Labrincha, J.A. Geopolymer foams: An overview of recent advancements. Prog. Mater. Sci. 2020, 109, 100621. [Google Scholar] [CrossRef]

- Hwalla, J.; Saba, M.; Assaad, J.J. Suitability of metakaolin-based geopolymers for underwater applications. Mater. Struct. 2020, 53, 119. [Google Scholar] [CrossRef]

- Khalid, H.R.; Ha, S.K.; Park, S.M.; Lee, H.K. Interfacial bond behavior of FRP fabrics bonded to fiber-reinforced geopolymer mortar. Compos. Struct. 2015, 134, 353–368. [Google Scholar] [CrossRef]

- Karvanis, K.; Rusnáková, S.; Krejčí, O.; Žaludek, M. Preparation, Thermal Analysis, and Mechanical Properties of Basalt Fiber/Epoxy Composites. Polymers 2020, 12, 1785. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Khan, M.Z.N.; Hao, Y.; Hao, H.; Shaikh, F.U.A.; Liu, K. Mechanical properties of ambient cured high-strength plain and hybrid fiber reinforced geopolymer composites from triaxial compressive tests. Constr. Build. Mat. 2018, 185, 338–353. [Google Scholar] [CrossRef]

- Zanotti, C.; Borges, P.H.R.; Bhutta, A.; Banthia, N. Bond strength between concrete substrate and metakaolin geopolymer repair mortar: Effect of curing regime and PVA fiber reinforcement. Cem. Concr. Compos. 2017, 80, 307–316. [Google Scholar] [CrossRef]

- Junaid, M.T.; Elbana, A.; Altoubat, S. Flexural response of geopolymer and fiber-reinforced geopolymer concrete beams reinforced with GFRP bars and strengthened using CFRP sheets. Structures 2020, 24, 666–677. [Google Scholar] [CrossRef]

- Punurai, W.; Kroehong, W.; Saptamongkol, A.; Chindaprasirt, P. Mechanical properties, microstructure and drying shrinkage of hybrid fly ash-basalt fiber geopolymer paste. Constr. Build. Mat. 2018, 186, 62–70. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Y.; Dai, J.-G. Flexural behavior and microstructure of hybrid basalt textile and steel fiber reinforced alkali-activated slag panels exposed to elevated temperatures. Constr. Build. Mater. 2017, 152, 651–660. [Google Scholar] [CrossRef]

- Ribeiro, R.A.S.; Ribeiro, M.G.S.; Sankar, K.; Kriven, W.M. Geopolymer-bamboo composite–A novel sustainable construction material. Constr. Build. Mater. 2016, 123, 501–507. [Google Scholar] [CrossRef]

- Silva, F.J.; Thaumaturgo, C. Fibre reinforcement and fracture response in geopolymeric mortars. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 167–172. [Google Scholar] [CrossRef]

- Le, V.S.; Szczypinski, M.M.; Hájková, P.; Kovacic, V.; Bakalova, T.; Volesky, L.; Hiep, L.I.; Louda, P. Mechanical properties of geopolymer foam at high temperature. Sci. Eng. Compos. Mater. 2020, 27, 129–138. [Google Scholar] [CrossRef]

- Frydrych, M.; Hýsek, Š.; Fridrichová, L.; Le Van, S.; Herclík, M.; Pechočiaková, M.; Le Chi, H.; Louda, P. Impact of Flax and Basalt Fibre Reinforcement on Selected Properties of Geopolymer Composites. Sustainability 2020, 12, 118. [Google Scholar] [CrossRef] [Green Version]

- Samal, S.; Reichmann, D.; Petríková, I.; Marvalova, B. Low Velocity Impact on Fiber Reinforced Geocomposites. Appl. Mech. Mater. 2016, 827, 145–148. [Google Scholar] [CrossRef]

- Camargo, M.M.; Adefrs Taye, E.; Roether, J.A.; Tilahun Redda, D.; Boccaccini, A.R. A Review on Natural Fiber-Reinforced Geopolymer and Cement-Based Composites. Materials 2020, 13, 4603. [Google Scholar] [CrossRef] [PubMed]

- Junaedi, H.; Baig, M.; Dawood, A.; Albahkali, E.; Almajid, A. Mechanical and Physical Properties of Short Carbon Fiber and Nanofiller-Reinforced Polypropylene Hybrid Nanocomposites. Polymers 2020, 12, 2851. [Google Scholar] [CrossRef]

- Samal, S.; Vlach, J.; Kolinova, M.; Kavan, P. Micro-computed tomography characterization of isotropic filler distribution in magnetorheological elastomeric composites. In Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials; Ohji, T., Singh, M., Halbig, M., Moon, K., Eds.; The American Ceramic Society: Westerville, OH, USA; Wiley: Hoboken, NJ, USA, 2016; pp. 57–69. [Google Scholar] [CrossRef]

- Rashad, A.M. Effect of steel fibers on geopolymer properties—The best synopsis for civil engineer. Constr. Build. Mat. 2020, 246, 118534. [Google Scholar] [CrossRef]

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13, 5548. [Google Scholar] [CrossRef]

- Samal, S.; Vlach, J.; Kavan, P. Improved mechanical properties of magneto rheological elastomeric composite with isotropic iron filler distribution. Ciênc. Tecnol. Mater. 2016, 28, 155–161. [Google Scholar] [CrossRef]

- Kriven, W.M. Geopolymer based composites. Compr. Compos. Mater. II 2018, 5, 269–280. [Google Scholar] [CrossRef]

- Hung, T.D.; Louda, P.; Kroisova, D.; Bortnovsky, O.; Xiem, N.T. New generation of geopolymer composite for fire-resistance. In Advances in Composite Materials—Analysis of Natural and Man-Made Materials; Tesinova, P., Ed.; InTech: London, UK, 2011; pp. 73–94. [Google Scholar]

- Mills-Brown, J.; Potter, K.; Foster, S.; Batho, T. The development of a high temperature tensile testing rig for composite laminates. Compos. A 2013, 52, 99–105. [Google Scholar] [CrossRef] [Green Version]

- Alzeer, M.; MacKenzie, K.J.D. Synthesis and mechanical properties of new fiber-reinforced composites of inorganic polymers with natural wool fibers. J. Mater. Sci. 2012, 47, 6958–6965. [Google Scholar] [CrossRef]

- Giancaspro, J.W.; Balaguru, P.N.; Lyon, R.E. Fire protection of flammable materials utilizing geopolymer. SAMPE J. 2004, 40, 42–49. [Google Scholar]

- Ribero, D.; Kriven, W.M. Properties of Geopolymer Composites Reinforced with Basalt Chopped Strand Mat or Woven Fabric. J. Am. Ceram. Soc. 2016, 99, 1192–1199. [Google Scholar] [CrossRef]

- Tran, D.H.; Kroisová, D.; Louda, P.; Bortnovsky, O.; Bezucha, P. Effect of curing temperature on flexural properties of silica-based geopolymer-carbon reinforced composite. J. Achiev. Mater. Manuf. Eng. 2009, 37, 492–497. Available online: http://jamme.acmsse.h2.pl/papers_vol37_2/37238.pdf (accessed on 1 April 2021).

- Welter, M.; Schmücker, M.; MacKenzie, K.J.D. Evolution of the Fibre-Matrix Interactions in Basalt-Fibre-Reinforced Geopolymer-Matrix Composites after Heating. J. Ceram. Sci. Technol. 2015, 6, 17–24. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Li, Z.; Zhou, X.; Chau, C. Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr. Build. Mater. 2008, 22, 370–383. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Y.; Wang, X.; Wu, D. Fabrication, mechanical performance and tribological behaviors of polyacetal-fiber-reinforced metakaolin-based geopolymeric composites. Ceram. Int. 2016, 42, 6329–6341. [Google Scholar] [CrossRef]

- Okada, K.; Imase, A.; Isobe, T.; Nakajima, A. Capillary rise properties of porous geopolymers prepared by an extrusion method using polylactic acid (PLA) fibers as the pore formers. J. Eur. Ceram. Soc. 2011, 31, 461–467. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Metselaar, H.S.C.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Yogesha, B. Study on Mechanical Properties of Natural—Glass Fibre Reinforced Polymer Hybrid Composites: A Review. Mater. Today Proc. 2015, 2, 2959–2967. [Google Scholar] [CrossRef]

- Samal, S.; Tyc, O.; Heller, L.; Šittner, P.; Malik, M.; Poddar, P.; Catauro, M.; Blanco, I. Study of Interfacial Adhesion between Nickel-Titanium Shape Memory Alloy and a Polymer Matrix by Laser Surface Pattern. Appl. Sci. 2020, 10, 2172. [Google Scholar] [CrossRef] [Green Version]

- Ganesh, A.C.; Muthukannan, M. Development of High Performance Sustainable Optimized Fiber Reinforced Geopolymer Concrete and Prediction of Compressive Strength. J. Clean. Prod. 2020, 124543. [Google Scholar] [CrossRef]

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in construction—Recent developments. Constr. Build. Mat. 2020, 260, 120472. [Google Scholar] [CrossRef]

- Sarkar, M.; Dana, K. Partial replacement of metakaolin with red ceramic waste in geopolymer. Ceram. Int. 2021, 47, 3473–3483. [Google Scholar] [CrossRef]

- Samal, S.; Škodová, M.; Abate, L.; Blanco, I. Magneto-Rheological Elastomer Composites. A Review. Appl. Sci. 2020, 10, 4899. [Google Scholar] [CrossRef]

- Zakka, W.P.; Lim, N.H.A.S.; Khun, M.C. A scientometric review of geopolymer concrete. J. Clean. Prod. 2021, 280, 124353. [Google Scholar] [CrossRef]

- Gu, G.; Xu, F.; Huang, X.; Ruan, S.; Peng, C.; Lin, J. Foamed geopolymer: The relationship between rheological properties of geopolymer paste and pore-formation mechanism. J. Clean. Prod. 2020, 277, 123238. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M. Geopolymers reinforced by short and long fibres—Innovative materials for additive manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 167–172. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Shaikh, F.U.A. Comparative deflection hardening behavior of short fiber reinforced geopolymer composites. Constr. Build. Mater. 2014, 70, 54–64. [Google Scholar] [CrossRef]

- Wang, Y.; Aslani, F.; Valizadeh, A. An investigation into the mechanical behaviour of fibre-reinforced geopolymer concrete incorporating NiTi shape memory alloy, steel and polypropylene fibres. Constr. Build. Mater. 2020, 259, 119765. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Hao, H. Effect of hybrid fibers on shear behaviour of geopolymer concrete beams reinforced by basalt fiber reinforced polymer (BFRP) bars without stirrups. Compos. Struct. 2020, 243, 112236. [Google Scholar] [CrossRef]

- Alshaaer, M. Synthesis and characterization of self-healing geopolymer composite. Constr. Build. Mater. 2020, 245, 118432. [Google Scholar] [CrossRef]

- Chu, S.H.; Ye, H.; Huang, L.; Li, L.G. Carbon fiber reinforced geopolymer (FRG) mix design based on liquid film thickness. Constr. Build. Mater. 2020, 121278. [Google Scholar] [CrossRef]

| Geopolymer | Bulk Density (g/cm3) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Compression |

|---|---|---|---|---|

| Matrix | 2.0± 0.1 | 27.8 ± 0.1 | 18.5 ± 0.1 | 11.7± 0.1 |

| Fibers | Bulk density (g/cm3) | Tensile strength (MPa) | Elastic Modulus (GPa) | Ultimate Elongation (%) |

| Steel | 7.65–7.85 | 345–2850 | 200–210 | 0.5–3.5 |

| Carbon fiber, carbon nanotube | 1.4–2.2 | 500–3500 | 35–1800 | 0.3–2.5 |

| Synthetic Polymers | ||||

| PVA | 1.2–1.3 | 800–2500 | 29–42 | 5.7–7 |

| PP | 0.9–0.95 | 240–760 | 1.5–10 | 15–80 |

| PE | 0.92–0.97 | 80–3500 | 5–113 | 3–100 |

| Aramid | 1.38–1.47 | 2300–3500 | 63–120 | 2–4.5 |

| Acrylic | 1.16–1.18 | 270–1000 | 13.8–19.3 | - |

| Polyester | 1.22–1.38 | 580–1100 | 15 | 35 |

| Nylon | 1.13–1.41 | 440–1000 | 4.1–5.2 | 16–20 |

| PET | 1.3–1.4 | 420–450 | 3.1–10 | 11.2 |

| Natural Fiber | ||||

| Jute | 1.3–1.5 | 250–350 | 26–32 | 1.5–1.9 |

| Sisal | 1.34–1.45 | 280–750 | 13–26 | 3.0–5.0 |

| Coconut | 0.87–1.4 | 120–200 | 19–26 | 10.0–25.0 |

| Bamboo | 0.6–1.1 | 140–800 | 11–32 | 2.5–3.7 |

| Cotton | 1.5–1.6 | 390–600 | 5.8–11 | 6.0–10.0 |

| Palm | 1.3–1.46 | 21–60 | 0.6 | - |

| Wool | 1.3 | 160 | 3.5 | - |

| Hemp | 1.4–1.5 | 270–900 | 23.5–90 | 1–3.5 |

| Kenaf | 1.4 | 223–930 | 14.5–53 | 1.5–2.7 |

| Coir | 1.15–1.46 | 95–230 | 2.8–6 | 15–51.4 |

| Banana | 1.4 | 500 | 12.0 | 1.5–9 |

| Flax fabric | 1.5 | 500–1500 | 50–70 | 1.1 |

| Bagasse | 1.3 | 222–290 | 17–27 | - |

| Inorganic fibers | ||||

| E-Glass | 2.5–2.62 | 3100–3800 | 72.4 | 4.8 |

| S-Glass | 2.46–2.49 | 4020–4650 | 86.9 | 5.4 |

| C-glass | 2.6 | 3310 | 69 | 4.8 |

| AR-glass | 2.7 | 3240 | 73 | 4.4 |

| Basalt | 2.65–2.80 | 3000–4840 | 89–110 | 3.00–3.15 |

| Asbestos | 2.55 | 620 | 160 | - |

| Alumina | 3.3–3.95 | 1700–2000 | 300–380 | 0.4 |

| Alumina-silica | 3.4 | 1590–2550 | 200–248 | 0.8–1 |

| SiN | - | 2500–4800 | 195–300 | - |

| SiC | 2.5–2.7 | 2200–3450 | 221–250 | - |

| BN | 7.65–7.85 | 2100 | 345 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samal, S.; Blanco, I. An Application Review of Fiber-Reinforced Geopolymer Composite. Fibers 2021, 9, 23. https://doi.org/10.3390/fib9040023

Samal S, Blanco I. An Application Review of Fiber-Reinforced Geopolymer Composite. Fibers. 2021; 9(4):23. https://doi.org/10.3390/fib9040023

Chicago/Turabian StyleSamal, Sneha, and Ignazio Blanco. 2021. "An Application Review of Fiber-Reinforced Geopolymer Composite" Fibers 9, no. 4: 23. https://doi.org/10.3390/fib9040023