1. Introduction

Our planet endures extreme environmental events, ranging from potent hurricanes and prolonged droughts to catastrophic floods and severe wildfires. The consensus among climate scientists attributes these events primarily to global warming and anthropogenic climate change [

1]. The global mean surface temperature (GMST) emerges as a critical metric in this context [

2,

3]. Studies have shown that the GMST has increased by an average of 0.15–0.20 °C per decade since the Industrial Revolution in 1750 [

4]. This trajectory suggests that if decisive actions are not taken to significantly reduce greenhouse gas emissions, most notably, carbon dioxide (CO

2), we are likely to see a continuation of this alarming trend [

5,

6].

In the realm of agriculture, fruit crop production is an area that has been significantly impacted by climatic change. The open-field nature of most fruit farming makes these crops especially susceptible to changes in environmental conditions. A variety of factors, including temperature, humidity, soil pH, and precipitation, play pivotal roles in determining the health and yield of these crops. As global temperatures continue to rise, both the geographic areas suitable for the production of these crops and their yield rates are being adversely affected. This, in turn, has a domino effect that necessitates comprehensive adjustments throughout the entire supply chain network of the agricultural sector.

The complex interplay between climate change and agriculture is more than a mere academic concern; it has profound implications for food security, economic stability, and even geopolitical peace. Traditional supply chain models, which were designed under the assumption of relatively stable environmental conditions, are no longer adequate. There is an urgent need for new models that are robust and flexible enough to adapt to rapidly changing climatic conditions [

7].

This urgency transcends the need for immediate, reactive measures. It calls for proactive, long-term strategic planning to ensure that the fruit crop industry—and by extension, the global agricultural sector—can sustainably adapt to an uncertain future characterized by climate volatility [

8]. Reliance on static supply chain models in this dynamic landscape is fraught with risks, including economic inefficiencies and vulnerabilities [

9]. The development of dynamic supply chains, built on data-driven insights and featuring agile transportation networks, offers a path towards greater resilience and sustainability [

10].

In response to the diverse challenges brought about by climate change to agriculture, we propose an advanced mathematical model designed to optimize distribution facility locations and adapt supply chain network design over numerous periods. Using the U.S. apple industry as a case in point, we have integrated climate change projections from the Intergovernmental Panel on Climate Change (IPCC)’s fifth assessment report [

5]. Drawing from historical datasets, our system employs detailed regression analyses to project the U.S. apple supply and demand. The core advantage of our model lies in its all-encompassing grasp of agricultural supply chains, covering aspects from the shifting dynamics of demand to the intricacies of fluctuating production capacities [

11]. Beyond its theoretical foundation, our model stands as a roadmap for industry stakeholders, offering practical strategies to navigate the uncertainties of a climate-affected future.

The rest of this manuscript is structured as follows:

Section 2 delves into the existing literature relevant to this study;

Section 3 elaborates on the mathematical model we have developed;

Section 4 applies this model to a case study in the U.S. apple industry;

Section 5 and

Section 6 present our findings and conclusion, respectively; and

Section 7 discusses their broader implications.

2. Research Backgrounds

2.1. Fruit Crop Production under Climate Change

Historically, research has focused on examining fruit crop production under various environmental conditions and identifying the optimal living conditions for fruit crops. With the emergence of climate change issues in recent years, studies concentrating on its impact on fruit crop production have taken center stage [

12,

13].

The repercussions of climate change for fruit crops are intricate and multifaceted [

13,

14]. A widely accepted finding, as proposed by Nelson et al., is that while climate change predominantly reduces crop yields, certain crops in specific regions might experience productivity enhancements [

15].

Such diversity and complexity are observed between subtropical and temperate fruit crops. While warmer weather can bolster subtropical fruit production, it can be detrimental to temperate fruit crops [

16,

17]. Elevated temperatures can induce early blooming, subjecting temperate fruit crops to increased risks of unexpected frost damage and potential chilling deficiencies, this being crucial for bud development before germination [

18]. Furthermore, the magnitude of these impacts often varies based on the fruit crop species and their cultivation regions, leading most researchers to target specific fruits or regions.

Based on the consensus regarding the diverse climate change impact on fruit crops, studies focusing on fruit crop yield are abundant, including but not limited to studies like the one conducted by Lar et al., who have shown that rising temperatures can diminish pollen moisture, resulting in a drop in fruit crop production [

19]. Rajan’s research revealed that a mere 0.2 °C increase in temperature could drastically alter areas conducive to the color development of red guava [

20]. Jones and Brennan devised a preliminary protocol to gauge the chill requirements for berry fruit crops, like blackcurrants, which face developmental challenges due to progressively warmer UK winters [

21]. In a similar vein, Crepinsek and Kajfez determined that a 1 °C air temperature elevation could advance apple leaf appearance for ripening by 2 days, with a 3 °C rise leading to a 4–5 day acceleration in Slovenia [

22]. Warrick et al.’s comprehensive study on New Zealand’s apple production, utilizing the CLIMPACTS system, posited that despite projections suggesting earlier apple bloom and maturity, significant changes in apple production in New Zealand are unlikely to occur until 2050 [

23].

The majority of these studies delved into the tangible effects of climate change on fruit crop production and quality using historical data. Yet, projections concerning future fruit crop cultivation areas or potential production quantities remain scant, largely due to the unpredictability stemming from intertwined uncertainties [

24]. Notably, a study conducted by Li et al. ventured into this territory, forecasting apple yield variations in China’s Shaanxi Province using scenarios from the IPCC [

5]. This research stands out for its utilization of future meteorological data, sourced from regional climate models, to predict apple yield variations [

25]. Kaukoranta et al. explored a similar avenue, focusing on apple cultivation projections for Finland by 2040 [

26].

Even with the advancements in the forecasting of future fruit crop yield variations, the scope of this research remains restricted to specific regions. Furthermore, such studies often neglect the resulting changes in supply chains, especially concerning distribution facility locations and transportation strategies, which are the core subjects of our research.

2.2. Fruit Crop Supply Chain Management (SCM) under Climate Change

It is undeniable that climate change profoundly impacts global food production and its subsequent supply chain management (SCM) [

27]. While direct research on the influence of climate change on the fruit crop supply chain is limited, a plethora of studies have examined the broader implications of climate change for SCM. Owen and Daskin, for instance, shed light on how climate-induced shifts are necessitating a reimagining of traditional production and distribution models [

11]. In a comprehensive review, Ghadge et al. examined 90 pertinent articles in 2019, concluding that climate change adversely impacts supply chain operations [

27].

Contrasting the wealth of general SCM research related to climate change, only a handful of studies have specifically addressed facility location or transportation issues resulting from climate change. Recognizing the pivotal role of facility location in effective SCM, Barahona and Jensen identified evolving patterns in optimal plant facility locations due to climate shifts [

28]. They emphasized the need for adaptive decision making in these contexts [

28]. Similarly, Ge et al. highlighted the pressing need for forward-thinking facility location strategies for fresh produce in the U.S., given the changing agricultural landscape [

29]. The current literature underscores the multifaceted influence of climate change on food SCM, emphasizing the pressing need for innovative, resilient strategies for the sector’s future. Additionally, Schwarz et al. detailed potential challenges in transportation, a cornerstone of SCM, stemming from climate-induced weather changes [

30].

In the context of today’s intricate global food supply chains, a nuanced understanding of their dynamic responses to climate change, fortified by quantitative analyses, is indispensable. Davis et al. highlighted this in their seminal research on supply chain resilience to environmental shocks [

31]. Expanding this discourse, D’Odorico et al. examined the interconnected systems, specifically the food–water–energy nexus, within which these supply chains operate [

32].

Despite the wealth of research available, the nuanced effects of climate change on specific supply chain components, like optimal distribution facility locations and transportation strategies, remain under-explored. This knowledge gap is widening, especially with observed shifts in ideal fruit crop production locales, underscoring the need for a comprehensive approach to address evolving climate scenarios.

Our proposed mathematical modeling serves as a linchpin for informed decision making in both the industry and policy sectors. This model is especially pertinent given the challenges of SCM, where priorities like food security and environmental sustainability must be harmonized. Our model is distinct, offering an integrated approach that provides a panoramic view of the system over extended periods. Furthermore, the model’s application to a case study, projecting supply and demand in the U.S. apple industry, underscores the significance of our research.

3. Model Description

3.1. Mathematical Model Formulation

The main goal of our research is to introduce a dynamic model that aids in optimal decision making for fruit crops, considering the complexities introduced by climate change. The agricultural sector, notably the apple industry that our proposed model has chosen for a case study, faces profound challenges stemming from climatic fluctuations. Traditionally, capacitated facility location problems (CFLP) have been instrumental in determining optimal facility locations, primarily based on stable data inputs [

28]. However, given the evolving complexities associated with climate change, these conventional models require significant enhancements to maintain their relevance [

33].

To address these challenges and achieve our primary objective, we present the Capacitated Facility Location Problems with Multi-period (CFLP-MP) framework. This model, designed to incorporate temporal dynamics, is adept at adapting to the shifting scenarios in sectors vulnerable to environmental variations. One of the primary aims of this innovation is to equip decision-makers with a nuanced tool that enables more effective responses to the uncertainties and variabilities in production scenarios.

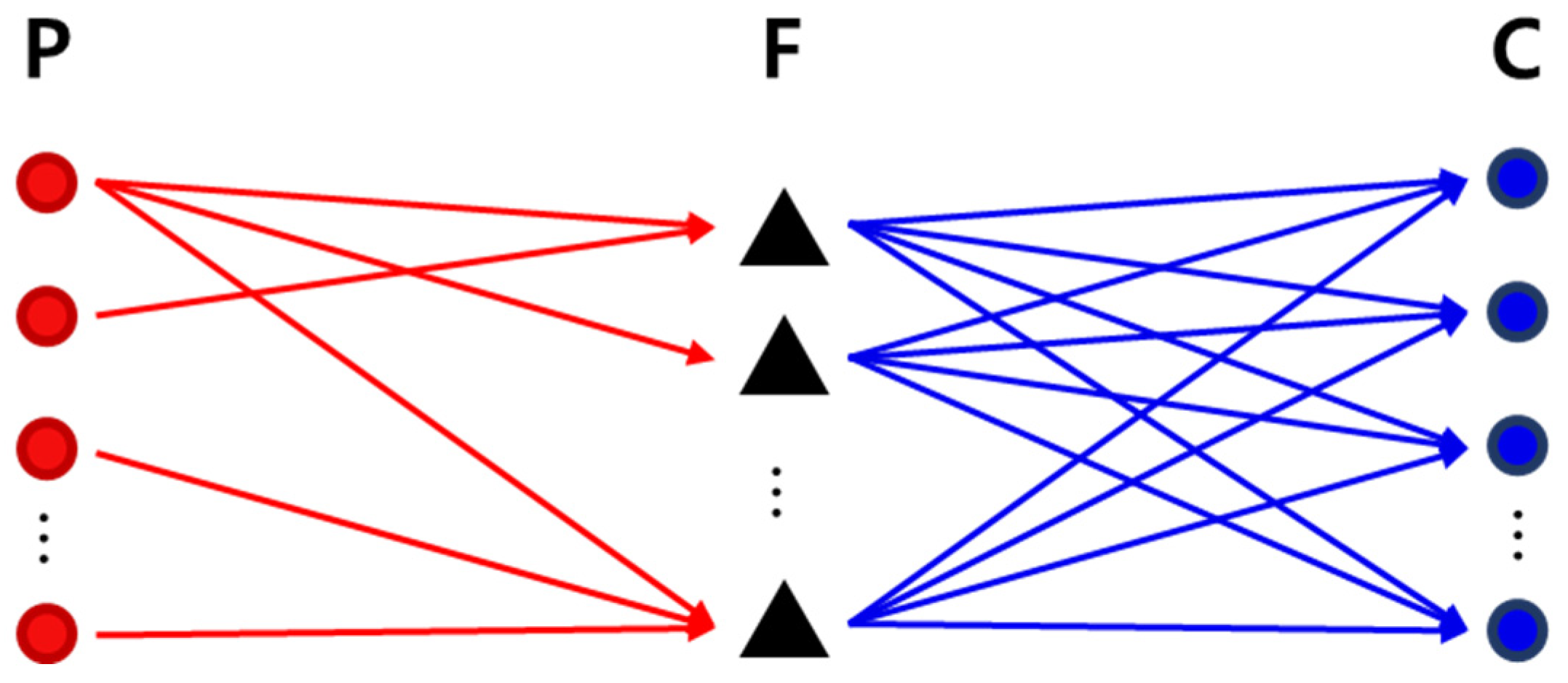

The essence of the CFLP-MP framework is its focus on coordinating intricate supply chain interactions, especially evident in sector like the apple industry. The model effectively coordinates potential facility locations, denoted as F—places where apples are stored or undergo preliminary processing—with their associated levels, represented by L—which account for variations in storage or processing capacities. In parallel, there are production nodes, represented by P—apple farms or orchards where apples are grown. Additionally, customer nodes, indicated as C, act as the distribution points, such as markets or stores, where the apples are finally made available to consumers. These interactions are spread across distinct time intervals, labeled as T.

Figure 1 offers a simple visual depiction of the supply chain flow, illustrating the progression from production to facilities and onward to consumers. It is essential to note that for each time frame, while the facility location remains anchored, the supply channels between

P and

F and between

F and

C are subject to dynamic shifts.

Central to our research, the CFLP-MP framework’s primary objective is to strategically minimize overall costs throughout the supply chain. This encompasses expenses linked to setting up storage facilities, daily operations, apple transportation, and potential losses during the entire process. [

34].

3.2. Notations and Definitions of Decision Variables

Key variables of the model encompass:

| System variables |

| P | : | Set of production nodes. |

| F | : | Set of potential facility nodes. |

| C | : | Set of customer nodes. |

| T | : | Set of time periods. |

| L | : | Set of facility levels. |

| Cost parameters |

| Cl f0 | : | Facility initial cost of installing a level l. (l ∈ L) [USD] |

| Cl f1 | : | Facility marginal cost for a level l, representing the incremental cost incurred when processing a single unit of a product at facility level l. (l ∈ L) [USD] |

| Cs | : | Shipping cost incurred per unit, per mile when products have been transferred between nodes. [USD] |

| Operational parameters |

| δ | : | Shrinkage factor, a coefficient quantifying the percentage loss of the product during the shipping process. |

| Htp | : | Product availability at production node p at a given time t, representing the quantity of product generated at that production node. (p ∈ P, t ∈ T) [lb] |

| Dtc | : | Demand quantity at demand node c at a given time t. (c ∈ C, t ∈ T) [lb] |

| dpf | : | Distance variable, representing the travel distance between a production node p and a facility node f. (p ∈ P, f ∈ F) [miles] |

| dfc | : | Distance variable, representing the travel distance from a facility node f to a demand node c. (f ∈ F, c ∈ C) [miles] |

| Dmax | : | Maximum allowable travel distance for shipments. [miles] |

| Qlmax | : | Maximum quantity that can be processed at a facility with level l. [lb] |

| Qlmin | : | Minimum quantity that can be processed at a facility with level l. [lb] |

| Decision variables |

| xfl | : | Binary decision variable, equal to 1 if a facility has been installed at location f with level l, otherwise 0. (f ∈ F, l ∈ L) |

| ytpfl | : | Integer decision variable, representing the quantity of shipment from production node p to facility f with level l during time t, otherwise 0. (p ∈ P, f ∈ F, l ∈ L, t ∈ T) [lb] |

| ztfcl | : | Integer decision variable, representing the quantity of shipment from facility f to demand c with level l during time t (f ∈ F, c ∈ C, l ∈ L, t ∈ T) [lb] |

At the core of this model lie decision variables, which denote whether a facility is active at a specific location and the quantity of products shipped across different nodes within the supply chain. The variable xfl represents the binary decision of activating a facility f with level l, and this decision is made to be consistent across all considered time periods. Meanwhile, the variables ytpfl and ztfcl, originally defined as integers, capture the intricate flow of goods from production nodes to facilities, and then from these facilities to the final customer nodes, across different time periods. While these variables are defined as integers to ensure precision, scenarios prioritizing computational efficiency may consider them as continuous, acknowledging the trade-offs with solution exactness.

Central to ensuring the efficiency and feasibility of this model are certain constraints. Firstly, the single level selection constraint ensures that only one facility level is uniquely instantiated for each potential facility location, preventing logistical redundancies as depicted in constraint (1).

Ensuring that all products are directed from their respective production nodes to the facilities is another pivotal aspect. This is manifested through the constraint that bounds the product flow based on the activation status of the facility in constraint (2). To further enrich this, a flow balance constraint is instituted, which mandates that the net product flow, adjusted for any shrinkage losses, remains consistent from the production nodes through the facilities and finally to the customer nodes in constraint (3).

Furthermore, the crux of any supply chain model, the demand satisfaction, is addressed by constraint (4), ensuring that the aggregated shipments to each customer node equate to the demand of that node.

Constraints (5) and (6) define capacity boundaries. These constraints not only restrict the inbound quantities at each operational facility but also determine the appropriate facility level.

A quintessential element are the shipping limitations, which are meticulously crafted to ensure shipments do not breach predefined limits in constraints (7) and (8). In light of possible shrinkage during transit, this constraint embodies both the maximum allowable shipment quantity and potential reductions due to shrinkage.

Lastly, the objective of the MILP model seeks to optimize costs across multiple fronts. From the expense of setting up facilities to the logistical costs of shipping products and the inevitable losses due to shrinkage, the model aims at an economically judicious balance.

In summation, this MILP formulation offers a structured yet adaptive framework, capable of deciphering and navigating the intricate maze of supply chain challenges exacerbated by climate change. In conclusion, the essence of our research lies in providing an effective tool to navigate the uncertainties introduced by climate change in the fruit crops industry. We believe that, through its application, our model can offer invaluable insights and guide stakeholders towards informed decisions even in the face of climatic uncertainties.

4. Model Implementation

4.1. A Case Study on Apple in the U.S.

Apple is an important fruit crop throughout the world both from a dietary and economic perspective. It is produced in more than 125 countries, and its world production in 2022 was approximately 192 billion pounds, which accounted for slightly less than 10% of the world fresh fruit crop production in that year [

35]. Because of its wide distribution and high production volume, it is considered as one of the important cash crops in many regions of the world [

36]. Changes both in production area and consequent supply chain under a volatile climate would significantly impact the economy of producers. For this reason, apple is chosen as a case fruit crop for this research.

Apple is classified as a temperate fruit crop, and it shows the best production yields in moderate climates. Temperate fruit crops are unique in that they require a certain number of ‘chilling hours’—defined as sustained periods of low temperature—for the healthy development of buds before the onset of the spring growing season [

37]. Elevated surface temperatures, a direct consequence of global warming, are reducing the length of these chilling hours, thereby inhibiting bud development and compromising crop yields [

38,

39]. Apple requires 1000 to 1500 h (about 2 months) of chilling temperature, normally below 7 °C [

40]. Another temperature-related condition for apple cultivation is the growing temperature, in which apple normally shows the best ripening, maturing, and harvesting. Past research suggests that the optimal growing temperature for apple ranges between 10 °C and 25 °C [

26,

37]. Given the significance of temperature in apple cultivation, this research focuses solely on temperature in examining apple production yield, neglecting all other environmental factors mentioned in

Section 1.

The U.S. is selected as a case study region (country) because its continental area is wide; thus, it is suitable for observing spatial changes in apple cultivation depending on the temperature variations triggered by climate change. The production volume and economic value of the apple industry in the U.S. are also high enough for a case study. The U.S. produced 10.1 billion pounds of apple, representing the second largest yield and over 5% of the global production, in 2022, and the revenues from over 26,000 producers were around 3.2 billion U.S. dollars [

41,

42].

Although the continental area is wide and its production level is high, only limited regions in the U.S. are suitable for apple production because of the temperature conditions explained above [

43]. For this reason, usually, the top five states in the United States produce more than 90% of the apple yield every year. The current apple production map based on the bearing acreage of apple trees in 2017 is shown in

Figure 2 [

44]. It is assumed that counties with a larger bearing acreage of apple trees (highlighted with darker red colors) have a higher production yield. The major apple production areas are mainly distributed in the western area and northeast region of the United States, which have enough chilling hours and an optimal growing temperature.

Against this background, this study aims to observe the changes in the apple production map depending on temperature change and the consequent optimal supply chain system when applying a mathematical model. In the following subsections, we introduce the ways in which this study projects the future supply of, and demand for, apple in the U.S., and the assumptions needed when applying the mathematical model proposed in

Section 3.

4.2. Assumptions

Facility locations play a pivotal role in refining the apple production industry’s supply chain dynamics. This research explores the apple industry across 48 contiguous U.S. states, covering 3142 counties. Alaska and Hawaii are excluded to maintain focus. The study also prioritizes the top 90% of apple production and demand across the United States to emphasize the primary tendencies and streamline the dataset.

4.2.1. Production and Demand Data

Apple Production: The data source for apple production is the United States Department of Agriculture (USDA) Agriculture Census of 2017, facilitating a comprehensive review of apple production at the county level [

44].

Domestic Apple Demand: A key methodology aspect involves aligning apple production with domestic demand, reflecting a market-clearing condition. This alignment ensures an accurate representation of the apple market, inspired by Barahona and Jensen [

28]. Demand is integrated at the county level using population datasets from the U.S. Department of Commerce, Bureau of the Census [

45]. This not only fortifies the study’s empirical foundation but also highlights regional consumption patterns.

4.2.2. Geospatial Representation

Production and Demand—County Level: Both production and demand are mapped to the central longitude and latitude coordinates of the respective counties, in line with methodologies proposed by Bixby and Anbil [

46].

Facility—State Level: Facilities at the state level are positioned based on the central coordinates of the respective states, adhering to methodologies by Bixby and Anbil [

46].

4.2.3. Facility Level and Cost Analysis

Facility Establishment Level: Navigating the intricate landscape of establishment costs, this study builds upon insights extracted from prior research, particularly Etemadnia et al. and Canning et al. [

47,

48]. These insights equip our model to categorize costs meticulously into fixed and variable segments. Such a categorization not only bolsters the model’s granularity but also encapsulates cost dynamics contingent on operational scales. Grounded in the insights of Ge et al., our model embraces three distinct establishment levels, each marked by specific capacities and cost structures [

29].

Facility Costs: The nuances of fixed costs and marginal costs, and the inherent methodologies are derived and contextualized from Ge et al., with the capacity levels harmonized with the market-clearing condition, echoing the formula of multiply 5 to the total supply and divide by the number of facilities.

Shipping Cost: Exploring the logistics component, shipping costs are derived from the industry benchmarks of C.H. Robinson’s North America Freight Insights and data from the Federal Reserve Bank of St. Louis [

49,

50]. These sources suggest that truck rates typically range between USD 1.50 and USD 2.50 per mile [

49,

50]. Moreover, the nuances of trucking capacities, averaging between 40,000 and 45,000 pounds, are gleaned from recent industry findings, particularly Schwarz et al. [

30].

4.2.4. Shrinkage Analysis

Lastly, the intricate dynamics of shrinkage, pivotal to the CFLP-MP, are meticulously delineated from empirical datasets. Comprehensive data suggest that apples undergo an average transit of 1760 miles en route to U.S. terminal markets [

51]. Further cumulative analyses, anchored in USDA’s repositories, indicate that apples witness a 23.2% reduction from farm to consumer, translating into a shrinkage coefficient [

52].

Table 1 consolidates the key parameters driving our mathematical model, reflecting our commitment to methodological rigor. The table categorizes facility-related costs across three distinct levels, each with its own cost structure and capacity. Additionally, shipping-related parameters are meticulously detailed, capturing aspects like travel distances and industry-standard trucking capacities.

4.3. Current and Future Apple Production in the U.S.

The current and future apple productions in the U.S. necessary for model input are explained in this subsection. Future crop fruit production is hard to predict mainly because of weather variation, especially under a longer time frame, and apple is no exception. Since the temporal period covered in this research is approximately 70 years (2015–2085), the accurate prediction of apple production is impossible. For this reason, we propose a simple statistical scheme to predict apple production in the future using the required temperature conditions for apple growth discussed in

Section 4.1.

In this apple production prediction scheme, the smallest apple-producible unit is the U.S. county, and its producibility is based on the temperature conditions discussed in

Section 4.1. Only the U.S. counties that meet both conditions are considered as apple-producible counties. For this binary scheme, monthly average temperatures for all the contiguous U.S. counties from 2006 to 2015 are obtained from the National Oceanic and Atmospheric Administration (NOAA) database, and future monthly temperatures for years 2050 and 2085 are extrapolated based on them. With the temperature data for 35-year intervals (2015, 2050, and 2085), counties that have average temperatures of 0–7 °C for two consecutive months from November to March are first filtered as those meeting the chilling hour conditions. Then, counties that have average temperatures of 10–25 °C for five months in the remaining months are additionally filtered to capture optimal growing temperature conditions. The counties meeting both of these conditions are assumed to have apple production in the designated years.

The amount of apples produced in these counties is calculated based on the area in which apple trees are cultivated on average in the United States. According to the data from the National Agricultural Statistics Service (NASS), the average apple (non)bearing acreage in the U.S. occupies approximately 0.03% of the entire acreage of the counties in which apples are produced. Additionally, the amount of apples produced in these lands was determined to be 32,169 pounds per acreage in 2017. These two numbers are multiplied according to the land acreage for each county which meets the two temperature conditions, and thus, each county is filtered for its potential for apple production. Through this approach, apple production maps, demonstrating the distribution of the production amount, are prepared for 2015, 2050, and 2070.

4.4. Current and Future Apple Demand in the U.S.

The current and future apple demands in the U.S. necessary for model input are explained in this subsection. In our approach, apple demand is assumed to be directly proportional to population size. To integrate this into our mathematical model for determining optimal facility locations and transportation strategies, we derive the demand by multiplying the production amount by the population ratio, ultimately resulting in a reduced sum of around 10 percent. This adjusted demand figure is used to match the production amount derived from the previous subsection (

Section 4.3).

Since we set the current apple production amount as that in 2015 for the sake of data availability, the apple demand in 2015 is also needed. For this purpose, the county population for 2015 is calculated by interpolating two numbers, which are based on the U.S. county population census for 2010 and 2020. The population ratio for each county is obtained by dividing the county population with the U.S. total population. This population ratio is multiplied with the total apple production amount for 2015 to determine the apple demand in each county for 2015.

A more complex scheme is applied for the future apple demand calculations. To avoid discrepancies between the U.S. national and county-level populations, the future county population is calculated using a bottom-up approach. First, the population compound annual growth rate (CAGR) for the past 30 years (1990–2020) for an individual county is calculated. The relative county CAGR is calculated by multiplying the 30-year county CAGR with the county population ratio relative to the entire state population, and they are then summed up to determine the state CAGR. Dividing the relative county CAGR with the state CAGR leads us to obtain the contribution ratio of each county to the state CAGR. This is subsequently used to determine the county population.

Since the state CAGR does not reflect the state population ratio relative to the U.S. population, it is multiplied with the state population ratio relative to the U.S. population in order to determine the relative state CAGR. The entire U.S. population CAGR for the past 30 years is obtained by adding up all the relative state CAGRs for each state. This bottom-up approach leads us to propose that the U.S. population CAGR for the past 30 years is 1.11%. This figure is compared with the actual U.S. population CAGR (0.96%), which is obtained using the U.S. population for 1990 and 2020, confirming that the gap is in a reasonable range for this research purpose. In addition, the contribution ratio of each state to the U.S. CAGR is calculated by dividing the relative state CAGR by the entire U.S. CAGR.

Now, the entire U.S. population in the target year can be obtained using the population in 2020 and the U.S. population CAGR. The difference in the U.S. entire population between the two years (the target year and 2020) is allocated to each state proportional to the contribution ratio of each state to the U.S. CAGR. Then, finally, the difference in the state population between the two years (the target year and 2020) is also proportionally allocated to each county depending on the value of the contribution ratio of each county relative to the state CAGR.

In this way, the county populations in the target years (2050 and 2085) and their relative ratios to the entire U.S. population in each year are calculated. Subsequently, the apple demand in each county is determined by multiplying these relative ratios by the total apple production amount.

4.5. Scenario Description

In 2014, the fifth assessment report of the IPCC suggested four representative concentration pathways (RCPs) [

5]. The scenarios capture possible future greenhouse gas concentration trajectories as the result of future activities. The RCP scenarios range from RCP 2.6 to RCP 8.5, and the numerical values in these scenarios represent the approximate radiative forcing level (amount of energy trapped in the atmosphere, W/m

2) expected to occur by 2100 compared to the pre-industrial era [

5]. These scenarios are commonly used in research which observes changes in specific phenomena influenced by climate change.

This study aims to identify shifts in apple production maps, distribution facility location/scale changes, and transportation schemes depending on temperature changes. For these purposes, three RCP scenarios are adopted in this research, and they are described below. Among the three scenarios, the current emissions track close to RCP 8.5, and the temperature increase is high; thus, adaptation to this scenario will involve high costs.

RCP 2.6: High effort to curb emissions and 1.0 °C temperature increase by 2100

RCP 4.5: Medium effort to curb emissions and 1.8 °C temperature increase by 2100

RCP 8.5: Low effort to curb emissions and 3.7 °C temperature increase by 2100

The expected temperature increases presented in each RCP scenario are global average values; thus, temperature changes in specific regions may vary depending on geographical, environmental and/or industrial circumstances. In the context of the United States, the fourth National Climate Assessment (NCA4) report published by the U.S. Global Change Research Program (USGCRP) in 2018 breaks down the U.S. territories into seven regions and proposes temperature increases for each region depending on the RCP scenarios. The projected temperature changes for each region in 2050 and 2085 based on different scenarios are presented in

Table 2 [

53]. Since the NCA4 report does not deal with the RCP 2.6 scenario, the global average value for temperature increase in 2085 is used for this scenario, and its interpolated value is applied to 2050.

The values in

Table 2 are added to the projected future temperature (in

Section 4.3) for each corresponding county depending on the scenario to be analyzed.

5. Results

In the subsequent analysis, we present the outcomes of the proposed CFLP-MP model, obtained utilizing the Gurobi optimization 10.0 commercial solver for optimal solutions [

54]. Computations were executed on a multi-core infrastructure with 16 threads, powered by an AMD Ryzen 9 5950X 3.40 GHz processor. This processor is a product of Advanced Micro Devices, Inc. (AMD), a semiconductor company headquartered in Santa Clara, CA, USA. The computational setup also included 96.0 GB of RAM. Given that our model’s data draw on future predictions, our analysis emphasizes the identification of significant trends over a range of specific numerical results.

5.1. Change in the U.S. Producible Apple Amount Map

Figure 3 depicts the counties expected to produce apples in 2050 and 2085 across three distinct RCP scenarios. Darker red shades mark counties with a higher projected apple production, while lighter hues indicate reduced apple yields. The variations in the apple production map are subtle in the RCP 2.6 scenario, attributed to the consistent 0.5 °C temperature increments anticipated each year. This level of accrual does not impact apple production regions. However, the RCP 4.5 and RCP 8.5 scenarios forecast more pronounced changes in apple yields. For instance, in RCP 4.5, the Midwest regions, including states like Illinois and Indiana, may see reduced apple production, whereas the Northeast remains relatively stable. The RCP 8.5 scenario predicts even more striking shifts, largely due to minimal efforts in carbon emission reduction, leading to higher temperature rises. For this reason, a remarkable number of areas are projected to be lost from the apple-producible counties in 2085, although they are marked as producible counties in 2050. This trend indicates that if we do not make efforts to curb carbon emissions, as the RCP 8.5 scenario shows, the producible apple areas in the U.S. will be discernably reduced.

Table 3 provides a detailed breakdown of the production amounts derived from our mathematical model. If carbon emission reductions are effective and we adhere to the RCP 2.6 scenario, it is expected that apple production will remain relatively stable in the coming years. However, in the RCP 8.5 scenario, we might see a decline of up to 35.8% in the current apple production, attributed to the shrinking viable production areas in the United States. While the figures presented here are specific to this case study, the observed trends in apple production areas and yields have significant wider implications.

5.2. Change in Distribution Facility Locations

Facility locations were determined using the developed mathematical model, which simultaneously considers apple production and demand across U.S. counties over a 70-year period. In total, 23–25 facilities were determined to be necessary under the current cost parameters. Since the RCP 2.6 scenario has the highest producible apple amount, it requires 25 distribution facilities, and the other two scenarios require 23 facilities.

The locations of the facilities are very similar overall, although there are some discrepancies among the scenarios. The facility locations are almost the same in the western half of the U.S. territory, since the area of each county is large enough, and the producible areas do not change with time in any of the scenarios. The most notable differences are observed in the eastern half of the United States. Although both the RCP 4.5 and 8.5 scenarios necessitate 23 facilities, their locations differ slightly due to variations in production and demand. It is noticeable that two independent distribution facilities (yellow) are required in the states of Illinois and Missouri in scenario RCP 4.5. In contrast, four distinct facilities (green) are needed in the East Coast areas in the RCP 8.5 scenario (

Figure 4).

This facility location decision captures the changes in both production and demand over 70 years (2015–2085). For this reason, the result may become more meaningful if the observation time frame were to be shortened. As we will discuss later (

Section 7), the temperature increase triggered by climate change would be higher than expected unless we made efforts to curb carbon emissions. If this comes to pass, we may face a situation much more serious than that projected in this study, and the overall decision regarding facility location would become more relevant.

5.3. Apple Transportation in Different Scenarios

Figure 5 provides a comprehensive visualization of aggregation and distribution patterns across counties within the optimized supply chain network for 2015, 2050, and 2085, each parsed under the diverse climate scenarios of RCP 2.6, RCP 4.5, and RCP 8.5. The black triangular symbols represent the locations of the designated facilities. The red solid lines indicate shipments from apple production nodes to these facilities, while the blue lines highlight the shipments from the facilities to the demand locations.

Primarily, the western territorial expanse, where apple production appears to be abundant, displays minimal transportation engagements. This elucidates an inherent regional propensity for self-sufficiency, obviating the need for an extensive external supply influx. Conversely, in the central to eastern regions, the apple yields are relatively modest, indicating a reliance on external supply conduits. A dominant feature emerging from this analysis is a strategic trend of channeling apples from the more productive northern territories to the consumption-dense southern locales.

Diving deeper into scenario-specific variances, the RCP 2.6 scenario, which exhibits the most stable apple production pattern, shows minimal noticeable changes in the supply chain from 2015 to 2085. However, the RCP 4.5 and RCP 8.5 scenarios, characterized by pronounced shifts in apple production patterns, reveal stark transformations in their supply chain dynamics. In 2015, we can observe a discernible horizontal transportation trend. As we progress to 2085, driven by temperature-induced shifts, the major apple production regions migrate northward. This migration leads to an increased vertical logistic movement, indicating a profound pivot in the supply chain orientation towards the vertical axis. These changes are especially conspicuous in the RCP 8.5 scenario, which represents the most significant variation in apple production patterns.

Coupled with the northward migration of apple production regions, we can also observe that the average shipment distances tend to increase. Given that the changes in population distribution remain relatively marginal in comparison to the shifts in apple production locales, the lengthier shipments from facilities to customers become more apparent.

Table 4 demonstrates the costs for the variables obtained based on the optimal decisions in each scenario. Interestingly, despite the distinct production and demand parameters for each scenario, the optimal total costs fail to exhibit a clear trend. For example, even though RCP 2.6 has the largest production volume, its total cost is closely aligned with that of RCP 8.5, which has the lowest apple production. This suggests that, despite the varying production volume and demand, the model demonstrates resilience in maintaining operational efficiency, thereby offering a solution to the initial challenge of creating an adaptive agricultural supply chain network. This adaptability is further manifested in the model’s economic justification for additional facility installations, thereby minimizing transportation costs when larger product volumes are involved. Additionally, because the optimal decision is made after simultaneously considering all the costs in a multi-time frame, no discernible temporal trend is observable in either the marginal or shipping costs. These insights imply that each scenario dictates its own unique set of optimal supply chain decisions.

6. Conclusions

In the middle of the intricate impacts of climate change, our research offers crucial insights into the dynamics of supply chain operations, focusing specifically on the USA’s apple supply chain. Through the deployment of the CFLP-MP model, we validate its effectiveness in forecasting optimal facility locations and transportation strategies across various climate scenarios. Given the rapid pace of environmental changes, the relevance of such predictive tools is evident, highlighting the pressing need for adaptable decision-making frameworks.

Our analysis indicates potential changes in the apple production landscape in the USA due to varying climate conditions. Some regions may see a decline in apple production capacities, while others could emerge as new production hubs. These expected changes call for prompt adjustments in broader supply chain strategies and long-term facility location planning. By using the RCP scenarios, our study offers a practical approach, guiding decision makers in addressing potential challenges based on these climatic projections.

To conclude, our research emphasizes the critical role of incorporating climate change considerations into core business and supply chain strategies. As industries adapt to the challenges of a changing environment, our findings aim to provide clear guidance for informed and sustainable decision making.

7. Discussion and Future Research Directions

Although this study shows time series integrated supply chain decision in the USA apple market under climate change, there remain areas for discussion and improvement in future research.

First, as discussed in earlier sections, our research emphasizes the role of temperature in fruit crop production. However, it is crucial to recognize that fruit crops, including apples, are influenced by a myriad of factors. Beyond temperature, elements like precipitation, soil properties, and light intensity play a significant role [

16,

34]. Our model focuses on temperature’s impact on apple yields, but a more holistic approach incorporating these variables could offer a broader perspective. Future research, perhaps leveraging system dynamics modeling, could delve deeper into these interdependencies, paving the way for a more comprehensive understanding of fruit crop production.

Second, the proposed model, CFLP-MP, is tailored to the agricultural sector, particularly the fruit crop industry, but its foundational mechanisms are adaptable and hold promise for broader applications in diverse supply chain systems. Thus, it is conceivable that future research could expand this model to cater to different sectors, where the production nodes and consumer demands are influenced by variables other than climate change. Furthermore, while the current model leans heavily towards quantitative metrics, we recognize the profound influence of qualitative elements such as labor dynamics, domain-specific expertise, and the regulatory landscape on supply chain dynamics. Additionally, while the current approach maintains fixed facility locations across time periods, we recognize the potential benefits of dynamic facility location models. Thus, we are open to exploring dynamic FLP models in subsequent studies.

Third, while the model’s case study in this research focuses on the U.S. domestic apple industry, the geographical applicability of the model is not confined solely to the U.S. Since the proposed model has demonstrated resilience in maintaining operational efficiencies under variated input conditions, its applicability can be expanded to other geographical regions even in the global perspective. Since apple is produced in more than 125 countries and traded internationally [

55], the model may be applied to find the optimal supply chain network, in terms of facility locations and trading routes, upon obtaining the temperature and demand projection data of each country. However, as Davis et al. pointed out in their study, the global supply chain is dynamically shifting under the current climate change and thus observing the real-time change of the supply chain is also valuable to study [

31]. From this perspective, the mathematical model proposed in this research has limitations because it suggests the optimal solution after considering all changes occurring within a specific time frame. A simulation methodology, such as agent-based modeling, would be an alternative approach to capture the real-time dynamics of the supply chain and consequent decisions of each agent belonging in the system, which will be a future research direction.

Climate change is no longer a special or intermittent event but is becoming the new normal. Consequently, we argue that surface temperature change has transitioned from being a variable to being a constant. According to the 6th Assessment Report from the Intergovernmental Panel on Climate Change (IPCC), global surface temperature in 2011–2020 has increased by 1.1 °C compared to 1850–1900, and this increment is 0.11 °C higher than the increase observed in 2001–2020 compared to 1850–1900. Moreover, the rate of surface temperature rise since 1970 has been more rapid than in any other 50-year span over the last 2000 years [

56]. Now, the issue is how much it increases and how soon we will face significant impacts triggered by the temperature change. With the accelerated temperature rise speed, CO

2 concentration in 2020 has increased by 47% compared to 1750 and reached 410 ppm [

56]. Based on these data, the IPCC projects that temperatures will rise by 1.8 °C, 2.7 °C, and 4.4 °C by 2100 under the RCP 2.6, 4.5, and 8.5 scenarios, respectively. These increments are about 0.8 °C higher for all scenarios than the temperature increment projected in the IPCC’s previous report in 2014, which are adopted in this research [

56]. For this reason, it would not be surprising if we faced these changes in a much shorter time-period than this study sets. Fruit crop production variation triggered by temperature change in a shorter time-frame would require more holistic decisions concerning supply chain adaptation and we believe that this research is meaningful in this respect.