A Review of Human–Robot Collaboration Safety in Construction

Abstract

1. Introduction

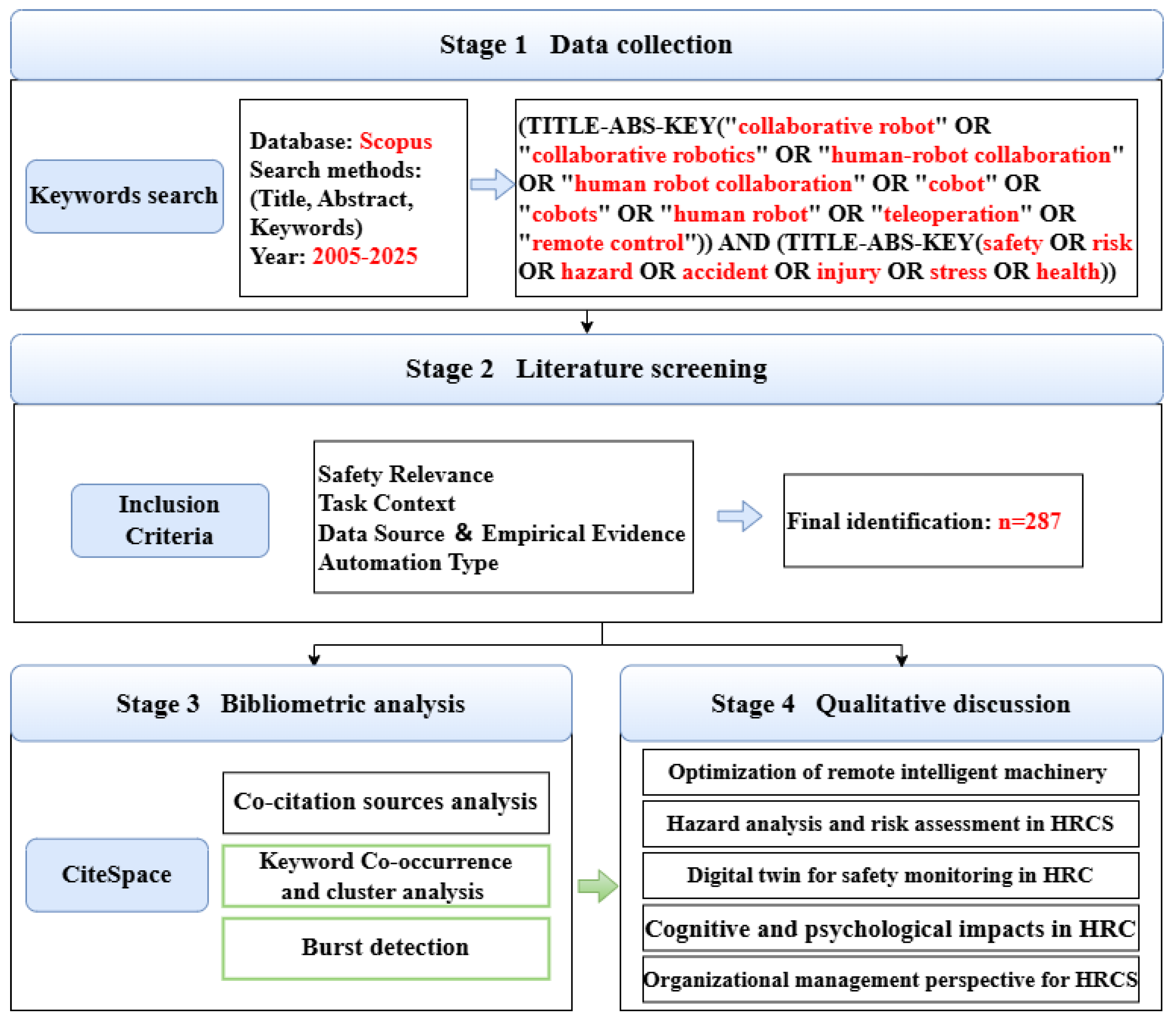

2. Methodology

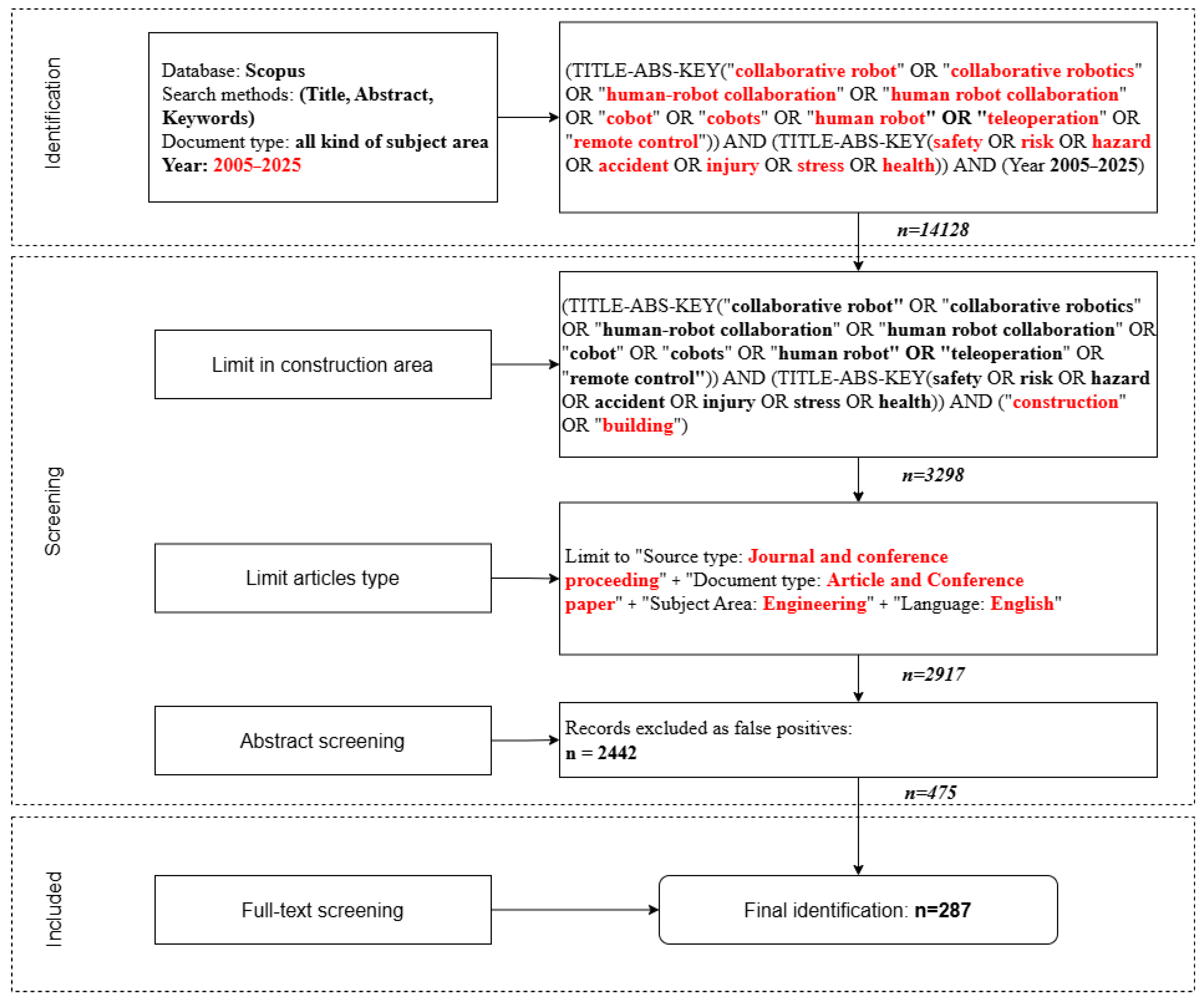

2.1. Data Collection

2.2. Literature Screening

2.3. Bibliometric Analysis

2.4. Qualitative Discussion

3. Bibliometric Analysis

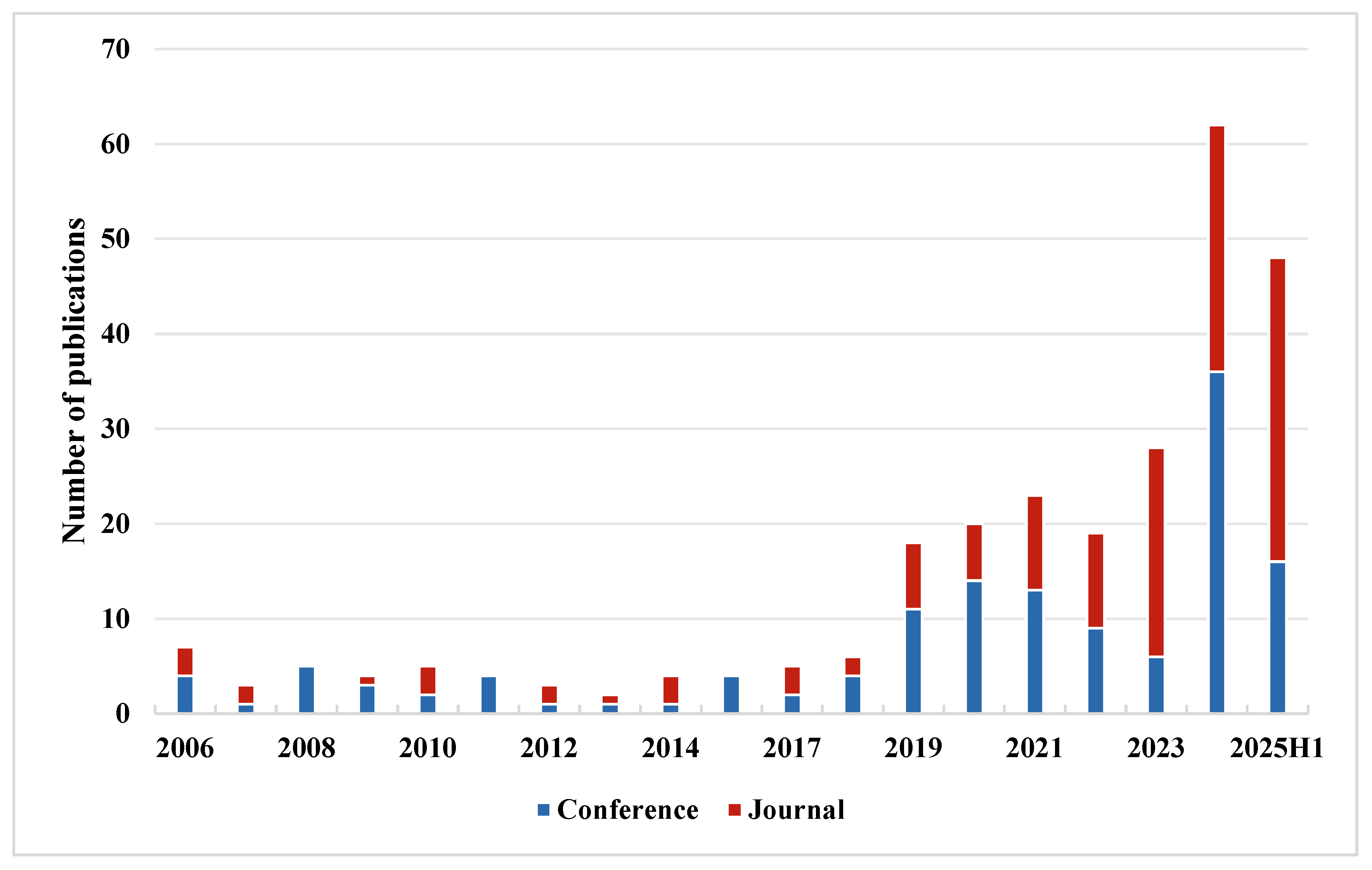

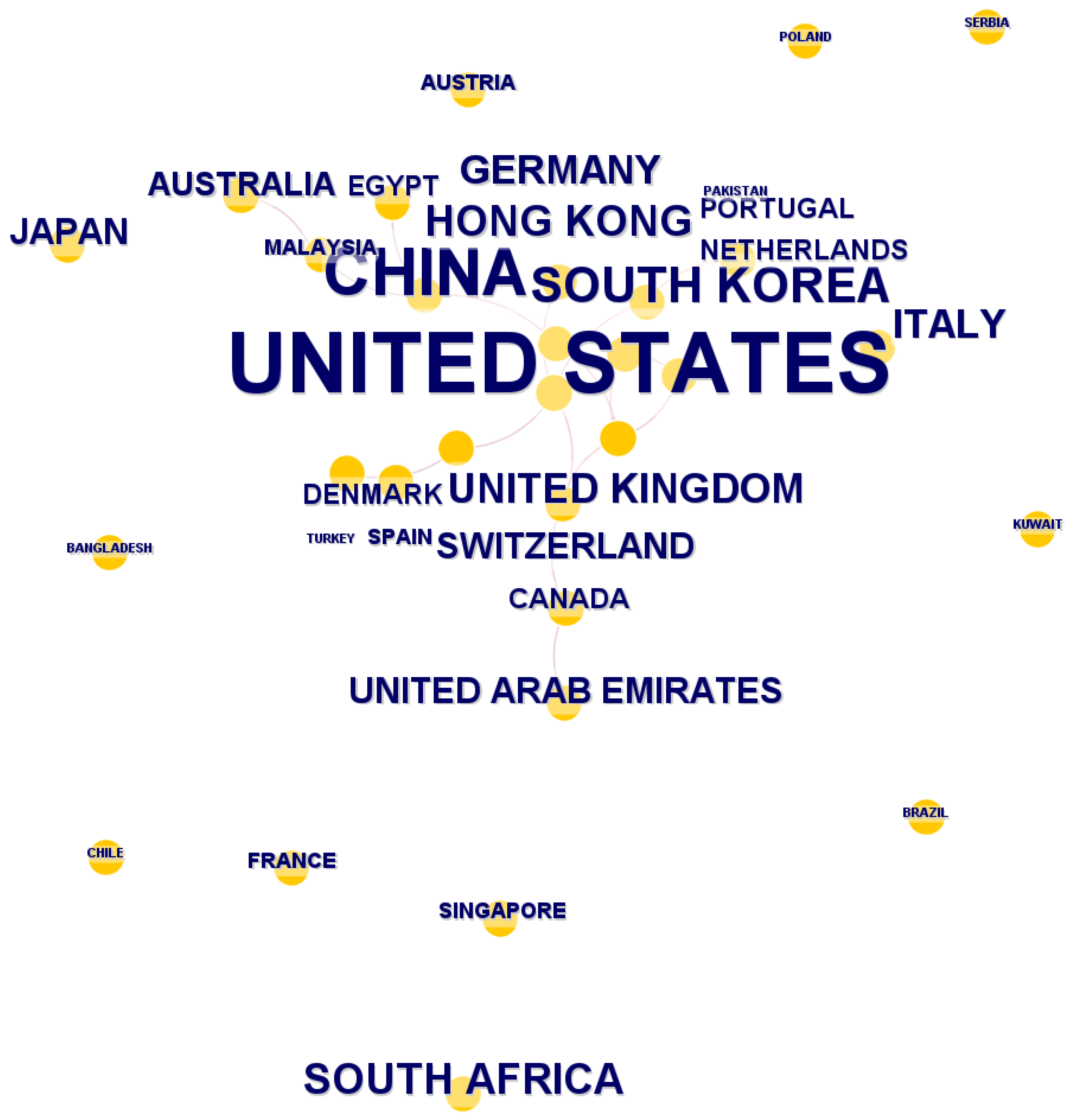

3.1. Quantitative Analysis

3.2. Knowledge Mapping

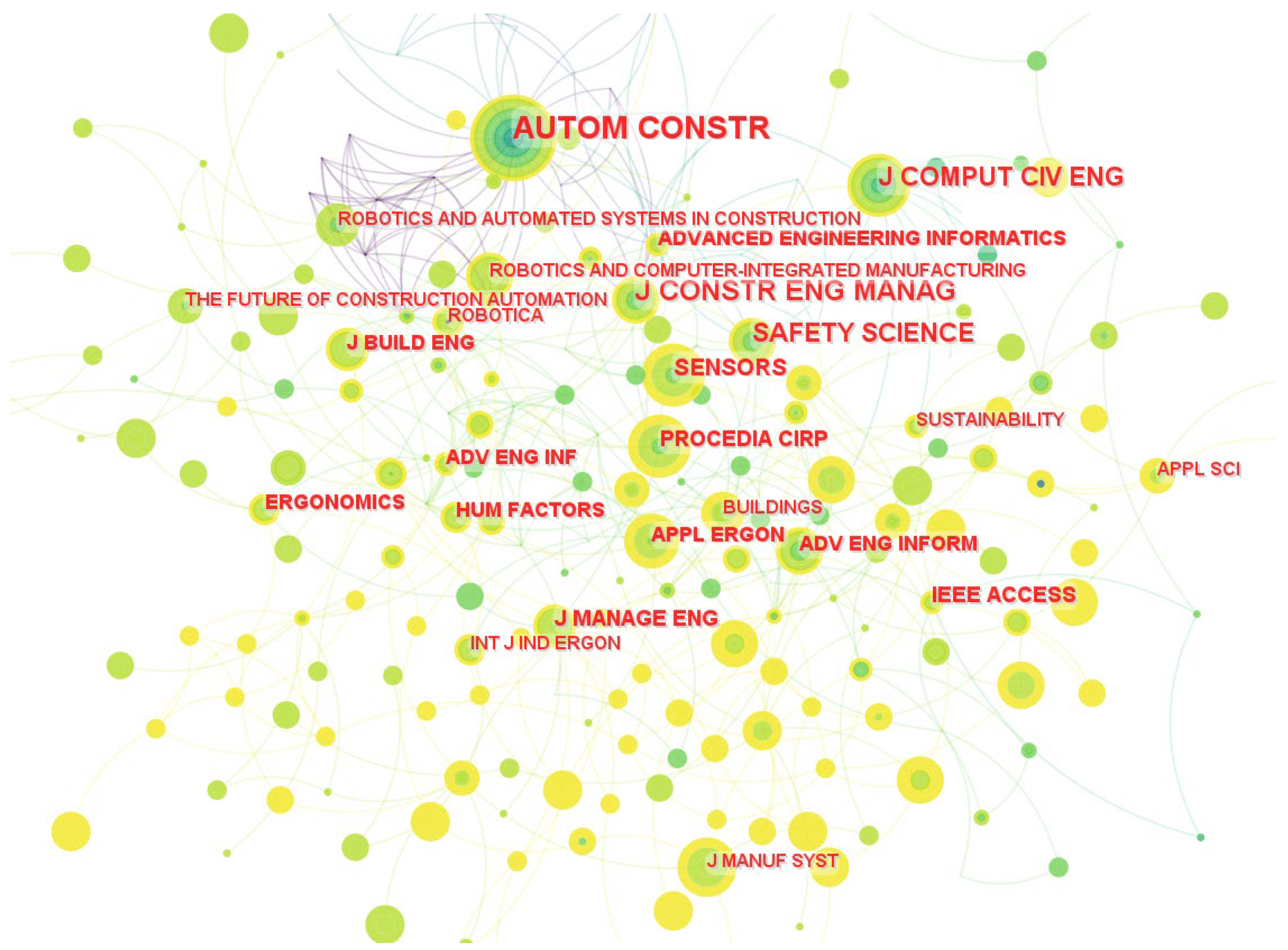

3.2.1. Co-Citation Sources Analysis

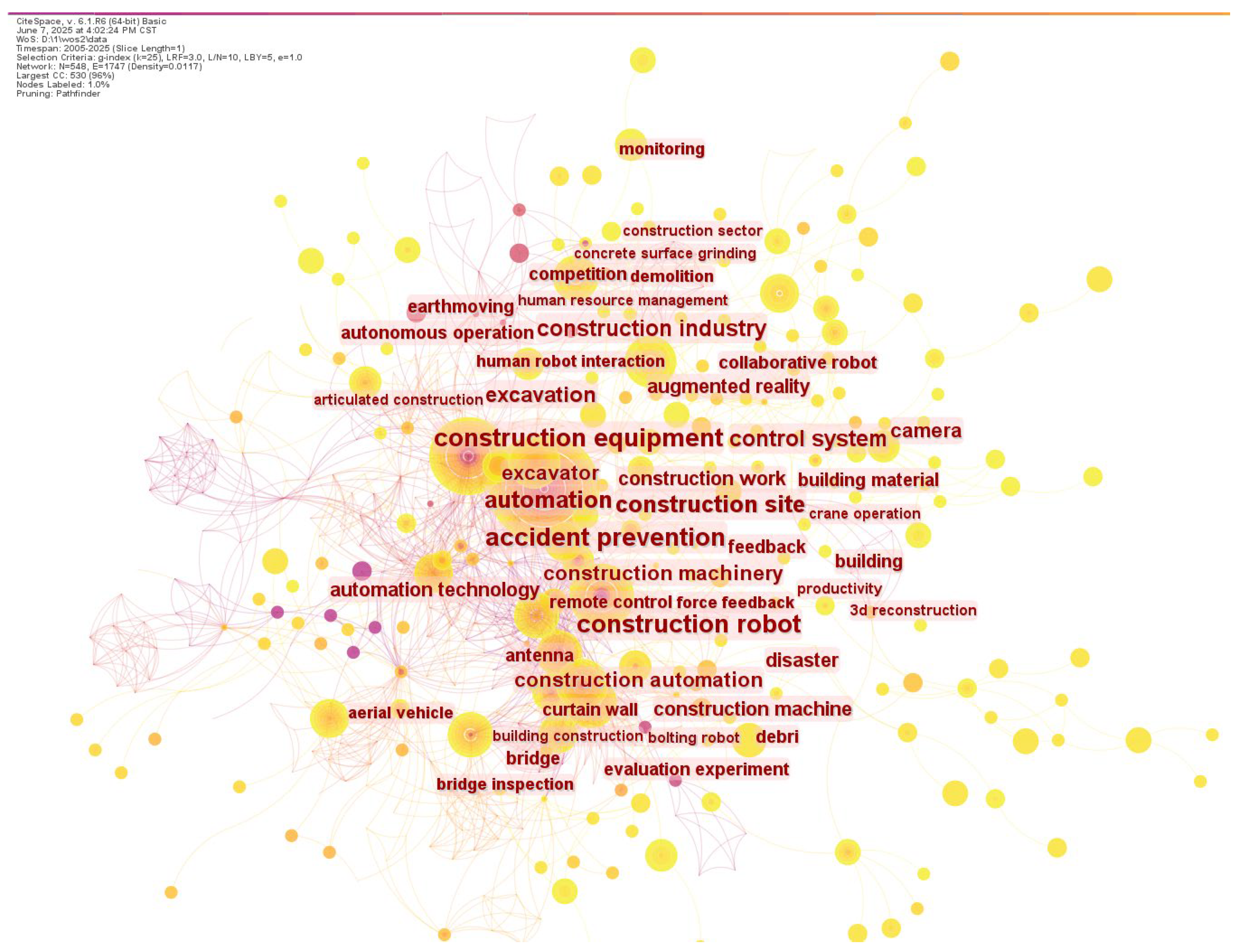

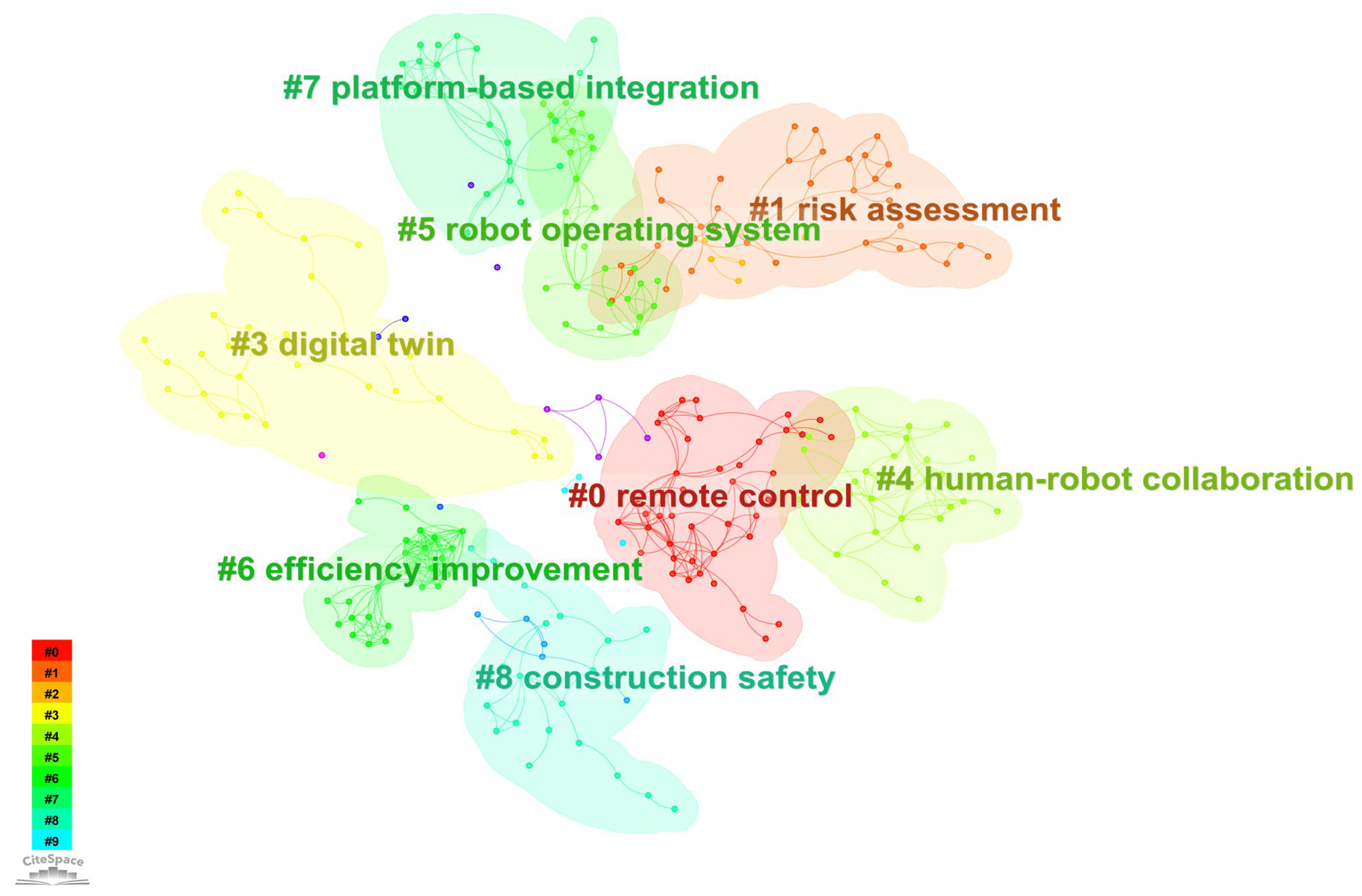

3.2.2. Keyword Co-Occurrence and Cluster Analysis

- Cluster #0: Remote control

- 2.

- Cluster #5: Robot Operating System (ROS)

- 3.

- Cluster #6: Efficiency Improvement and Cluster #8: Construction Safety

- 4.

- Cluster #7: Platform-based Incorporation

3.2.3. Burst Detection

4. Discussion of Qualitative Review Findings in Construction HRCS

4.1. Optimization of Remote Intelligent Machinery

4.2. Hazard Analysis and Risk Assessment in HRCS

4.3. Digital Twin for Safety Monitoring in HRC

4.4. Cognitive and Psychological Impacts in HRC

4.5. Organizational Management Perspective for HRCS

5. Conclusions

Supplementary Materials

Funding

Data Availability Statements

Conflicts of Interest

Appendix A

| Year | Number of Publications | |

| Conference | Journal | |

| 2005 | 1 | 0 |

| 2006 | 4 | 3 |

| 2007 | 1 | 2 |

| 2008 | 5 | 0 |

| 2009 | 3 | 1 |

| 2010 | 2 | 3 |

| 2011 | 4 | 0 |

| 2012 | 1 | 2 |

| 2013 | 1 | 1 |

| 2014 | 1 | 3 |

| 2015 | 4 | 0 |

| 2017 | 2 | 3 |

| 2018 | 4 | 2 |

| 2019 | 11 | 7 |

| 2020 | 14 | 6 |

| 2021 | 13 | 10 |

| 2022 | 9 | 10 |

| 2023 | 6 | 22 |

| 2024 | 36 | 26 |

| 2025H1 | 16 | 32 |

References

- OSHA (Occupational Safety and Health Administration); OSHA Technical Manual (OTM). Chapter—Industrial Robot Systems and Industrial Robot System Safety; OSHA Directive TED; OSHA: Washington, DC, USA, 2021.

- Davila Delgado, J.M.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and Automated Systems in Construction: Understanding Industry-Specific Challenges for Adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Bock, T. Construction Robotics. Auton. Robots 2007, 22, 201–209. [Google Scholar] [CrossRef]

- Kim, S.; Peavy, M.; Huang, P.-C.; Kim, K. Development of BIM-Integrated Construction Robot Task Planning and Simulation System. Autom. Constr. 2021, 127, 103720. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, R.; Wu, H.; Pan, J.; Luo, X. Human-Robot Collaboration for on-Site Construction. Autom. Constr. 2023, 150, 104812. [Google Scholar] [CrossRef]

- Brosque, C.; Skeie, G.; Fischer, M. Comparative Analysis of Manual and Robotic Concrete Drilling for Installation Hangers. J. Constr. Eng. Manag. 2021, 147, 05021001. [Google Scholar] [CrossRef]

- Lee, J.S.; Ham, Y.; Park, H.; Kim, J. Challenges, Tasks, and Opportunities in Teleoperation of Excavator toward Human-in-the-Loop Construction Automation. Autom. Constr. 2022, 135, 104119. [Google Scholar] [CrossRef]

- Li, S.; Zheng, P.; Liu, S.; Wang, Z.; Wang, X.V.; Zheng, L.; Wang, L. Proactive Human–Robot Collaboration: Mutual-Cognitive, Predictable, and Self-Organising Perspectives. Robot. Comput.-Integr. Manuf. 2023, 81, 102510. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on Human–Robot Collaboration in Industrial Settings: Safety, Intuitive Interfaces and Applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Liang, C.-J.; Wang, X.; Kamat, V.R.; Menassa, C.C. Human-Robot Collaboration in Construction: Classification and Research Trends. J. Constr. Eng. Manag. 2021, 147, 03121006. [Google Scholar] [CrossRef]

- Sun, Y.; Jeelani, I.; Gheisari, M. Safe Human-Robot Collaboration in Construction: A Conceptual Perspective. J. Saf. Res. 2023, 86, 39–51. [Google Scholar] [CrossRef]

- Robla-Gómez, S.; Becerra, V.M.; Llata, J.R.; González-Sarabia, E.; Torre-Ferrero, C.; Pérez-Oria, J. Working Together: A Review on Safe Human-Robot Collaboration in Industrial Environments. IEEE Access 2017, 5, 26754–26773. [Google Scholar] [CrossRef]

- Li, W.; Hu, Y.; Zhou, Y.; Pham, D.T. Safe Human–Robot Collaboration for Industrial Settings: A Survey. J. Intell. Manuf. 2024, 35, 2235–2261. [Google Scholar] [CrossRef]

- Okpala, I.; Nnaji, C.; Gambatese, J. Assessment Tool for Human–Robot Interaction Safety Risks during Construction Operations. J. Constr. Eng. Manag. 2023, 149, 04022145. [Google Scholar] [CrossRef]

- Gervasi, R.; Mastrogiacomo, L.; Franceschini, F. A Conceptual Framework to Evaluate Human-Robot Collaboration. Int. J. Adv. Manuf. Technol. 2020, 108, 841–865. [Google Scholar] [CrossRef]

- Ohueri, C.C.; Masrom, M.A.N.; Noguchi, M. Human-Robot Collaboration for Building Deconstruction in the Context of Construction 5.0. Autom. Constr. 2024, 167, 105723. [Google Scholar] [CrossRef]

- Xiao, B.; Chen, C.; Yin, X. Recent Advancements of Robotics in Construction. Autom. Constr. 2022, 144, 104591. [Google Scholar] [CrossRef]

- Jin, R.; Zou, P.X.W.; Piroozfar, P.; Wood, H.; Yang, Y.; Yan, L.; Han, Y. A Science Mapping Approach Based Review of Construction Safety Research. Saf. Sci. 2019, 113, 285–297. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H.; Kang, S.-C.; Al-Hussein, M. Virtual Reality Applications for the Built Environment: Research Trends and Opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical Evaluation of Off-Site Construction Research: A Scientometric Analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The Journal Coverage of Web of Science and Scopus: A Comparative Analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and Analysis of Safety Management Studies in the Construction Industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Ann. Intern. Med. 2009, 151, 4. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting System-atic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Small, H. Visualizing Science by Citation Mapping. J. Am. Soc. Inf. Sci. 1999, 50, 799–813. [Google Scholar] [CrossRef]

- Chen, C. ENTERING 2014. Int. Surg. 2014, 99, 1. [Google Scholar] [CrossRef]

- Cui, K.; Li, W.; Wang, M.; He, Z. The Impacts of Electric Vehicle Scale-up Development on Emission Reduction: Mapping the Field and Providing a Research Agenda. Pol. J. Environ. Stud. 2023, 32, 4639–4651. [Google Scholar] [CrossRef]

- Ye, Q.; Zhou, R.; Asmi, F. Evaluating the Impact of the Pandemic Crisis on the Aviation Industry. Transp. Res. Rec. 2022, 2677. [Google Scholar] [CrossRef]

- Ding, Y.; Ma, J.; Luo, X. Applications of Natural Language Processing in Construction. Autom. Constr. 2022, 136, 104169. [Google Scholar] [CrossRef]

- Wen, Q.-J.; Ren, Z.-J.; Lu, H.; Wu, J.-F. The Progress and Trend of BIM Research: A Bibliometrics-Based Visualization Analysis. Autom. Constr. 2021, 124, 103558. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace II: Detecting and Visualizing Emerging Trends and Transient Patterns in Scientific Literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef]

- Kim, M.C.; Zhu, Y.; Chen, C. How Are They Different? A Quantitative Domain Comparison of Information Visualization and Data Visualization (2000–2014). Scientometrics 2016, 107, 123–165. [Google Scholar] [CrossRef]

- Lin, G.-X.; Chen, C.-M.; Rui, G.; Hu, B.-S. Research Relating to Three-Dimensional (3D) Printing in Spine Surgery: A Bibliometric Analysis. Eur. Spine J. 2023, 32, 395–407. [Google Scholar] [CrossRef]

- Sasaki, T.; Nagai, T.; Kawashima, K. Remote Control of Backhoe for Rescue Activities Using Pneumatic Robot System. In Proceedings of the ICRA 2006, Orlando, FL, USA, 15–19 May 2006; Volume 2006, pp. 3177–3182. [Google Scholar]

- Sasaki, T.; Kawashima, K. Development of a Remote Control System for Construction Machinery for Rescue Activities with a Pneumatic Robot. Adv. Robot. 2006, 20, 213–232. [Google Scholar] [CrossRef]

- Top, F.; Krottenthaler, J.; Fottner, J. Evaluation of Remote Crane Operation with an Intuitive Tablet Interface and Boom Tip Control; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2020; Volume 2020, pp. 3275–3282. [Google Scholar]

- Lee, S.; Yu, S.; Yu, S.; Han, C. An Improved Multipurpose Field Robot for Installing Construction Materials. Robotica 2010, 28, 945–957. [Google Scholar] [CrossRef]

- Le, Q.H.; Bae, J.-I.; Jeong, Y.-M.; Nguyen, C.T.; Yang, S.-Y. Development of the Flexible Observation System for a Virtual Reality Excavator Using the Head Tracking System; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2015; pp. 841–846. [Google Scholar]

- Chen, Y.-C.; Chi, H.-L.; Kang, S.-C.; Hsieh, S.-H. Attention-Based User Interface Design for a Tele-Operated Crane. J. Comput. Civ. Eng. 2016, 30, 04015030. [Google Scholar] [CrossRef]

- Kim, D.; Kim, J.; Lee, K.; Park, C.; Song, J.; Kang, D. Excavator Tele-Operation System Using a Human Arm. Autom. Constr. 2009, 18, 173–182. [Google Scholar] [CrossRef]

- Nagano, H.; Takenouchi, H.; Cao, N.; Konyo, M.; Tadokoro, S. Tactile Feedback System of High-Frequency Vibration Signals for Supporting Delicate Teleoperation of Construction Robots. Adv. Robot. 2020, 34, 730–743. [Google Scholar] [CrossRef]

- Szabolcsi, R.; Molnár, G.; Wuhrl, T. Conceptual Design of a UAV-UGV Autonomous Collaborative Robot System; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024; pp. 207–211. [Google Scholar]

- Lee, J.S.; Oh, S.; Park, H.; Ham, Y. Feedback System for Enhancing Human-Robot Interaction Performance in Construction Robots; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2024; Volume 1, pp. 79–88. [Google Scholar]

- Cai, J.; Du, A.; Liang, X.; Li, S. Prediction-Based Path Planning for Safe and Efficient Human-Robot Collaboration in Construction via Deep Reinforcement Learning. J. Comput. Civ. Eng. 2023, 37, 04022046. [Google Scholar] [CrossRef]

- Ito, M.; Raima, C.; Saiki, S.; Yamazaki, Y.; Kurita, Y. Effects of Machine Instability Feedback on Safety during Digging Operation in Teleoperated Excavators. IEEE Access 2021, 9, 28987–28998. [Google Scholar] [CrossRef]

- Lv, M.; Feng, Z.; Yang, X.; Liu, B. A Method for Human–Robot Complementary Collaborative Assembly Based on Knowledge Graph. CCF Trans. Pervasive Comput. Interact. 2025, 7, 70–86. [Google Scholar] [CrossRef]

- Wu, M.; Lin, J.-R.; Zhang, X.-H. How Human-Robot Collaboration Impacts Construction Productivity: An Agent-Based Multi-Fidelity Modeling Approach. Adv. Eng. Inform. 2022, 52, 101589. [Google Scholar] [CrossRef]

- Lin, J.; Li, Q.; Zhu, R.; Cai, Y.; You, L.; Zou, L.; Liu, S. Coupled Risk Assessment of Construction Workers’ Unsafe Behaviors in Human-Robot Interactions; International Association for Automation and Robotics in Construction (IAARC): Oulu, Finland, 2024; pp. 585–592. [Google Scholar]

- Cheng, M.H.; Liang, C.-J.; Dominguez, E.G. Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites; International Association for Automation and Robotics in Construction (IAARC): Oulu, Finland, 2024; pp. 9–16. [Google Scholar]

- Ojha, A.; Liu, Y.; Shayesteh, S.; Jebelli, H.; Sitzabee, W.E. Affordable Multiagent Robotic System for Same-Level Fall Hazard Detection in Indoor Construction Environments. J. Comput. Civ. Eng. 2023, 37, 04022042. [Google Scholar] [CrossRef]

- Kim, H.-G.; Park, J.-H.; Kim, J.-C.; Hwang, J.-H.; Park, J.-W.; Park, I.-G.; Lee, H.-J.; Noh, K.; Choi, Y.-H.; Suh, J.-H. Development of a Multi-Robot System for Pier Construction. Machines 2024, 12, 385. [Google Scholar] [CrossRef]

- Im, H.; Lee, C.-E.; Cho, Y.-J. Radio Mapping Scheme Using Collective Intelligent Robots for Teleoperation in Unstructured Environments. In Proceedings of the The 23rd IEEE International Symposium on Robot and Human Interactive Communication, Edinburgh, UK, 25–29 August 2014; pp. 856–861. [Google Scholar]

- Wei, H.-H.; Zhang, Y.; Sun, X.; Chen, J.; Li, S. Intelligent Robots and Human-Robot Collaboration in the Construction Industry: A Review. J. Intell. Constr. 2023, 1, 1–12. [Google Scholar] [CrossRef]

- Kleinberg, J. Bursty and Hierarchical Structure in Streams. Data Min. Knowl. Discov. 2003, 7, 373–397. [Google Scholar] [CrossRef]

- You, S.; Kim, J.-H.; Lee, S.; Kamat, V.; Robert, L.P. Enhancing Perceived Safety in Human–Robot Collaborative Construction Using Immersive Virtual Environments. Autom. Constr. 2018, 96, 161–170. [Google Scholar] [CrossRef]

- Akbar, A.; Song, J.; Kwon, S.W. Remote Monitoring System and Controller for the Construction Machinery Using AR Smart Glasses; International Association for Automation and Robotics in Construction (IAARC): Oulu, Finland, 2021; Volume 2021, pp. 475–482. [Google Scholar]

- Liu, Y.; Habibnezhad, M.; Jebelli, H.; Monga, V. Worker-in-the-Loop Cyber-Physical System for Safe Human-Robot Collaboration in Construction; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2021; pp. 1075–1083. [Google Scholar]

- Senk, V.; Ghazanfari, M.; Rasoulzadeh, S.; Vasylevska, K.; Kovacs, B.I.; Mortezapoor, S.; Vonach, E.; Kovacic, I.; Füssl, J.; Kaufmann, H.; et al. HeXA: Haptic-Enhanced eXtended Reality Framework for Material-Informed Architectural Design. J. Build. Eng. 2025, 108, 112707. [Google Scholar] [CrossRef]

- Yang, T.; Arashpour, M.; Abdi, E. Critical Review of Load Handover in Construction Cranes. J. Archit. Eng. 2025, 31, 03125001. [Google Scholar] [CrossRef]

- Le, Q.H.; Lee, J.W.; Yang, S.Y. Remote Control of Excavator Using Head Tracking and Flexible Monitoring Method. Autom. Constr. 2017, 81, 99–111. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Wang, Y.; Gu, B.; Li, B.; Fang, D. Comprehensive Lifecycle Safety Risk Assessment for Construction Robotics Using T-S Fault Tree Analysis and Bayesian Network. Autom. Constr. 2025, 172, 106041. [Google Scholar] [CrossRef]

- Nnaji, C.; Okpala, I.; Gambatese, J.; Jin, Z. Controlling Safety and Health Challenges Intrinsic in Exoskeleton Use in Construction. Saf. Sci. 2023, 157, 105943. [Google Scholar] [CrossRef]

- Lin, X.; Guo, Z.; Jin, X.; Guo, H. Digital Twin-Enabled Safety Monitoring System for Seamless Worker-Robot Collaboration in Construction. Autom. Constr. 2025, 174, 106147. [Google Scholar] [CrossRef]

- Wang, X.; Liang, C.-J.; Menassa, C.C.; Kamat, V.R. Interactive and Immersive Process-Level Digital Twin for Collaborative Human–Robot Construction Work. J. Comput. Civ. Eng. 2021, 35, 04021023. [Google Scholar] [CrossRef]

- Lu, L.; Xie, Z.; Wang, H.; Li, L.; Xu, X. Mental Stress and Safety Awareness during Human-Robot Collaboration—Review. Appl. Ergon. 2022, 105, 103832. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Ham, Y. The Effect of Time Pressure on Human-Robot Interaction Performance During Excavator Teleoperation; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2024; pp. 505–512. [Google Scholar]

- Liu, Y.; Habibnezhad, M.; Jebelli, H. Brainwave-Driven Human-Robot Collaboration in Construction. Autom. Constr. 2021, 124, 103556. [Google Scholar] [CrossRef]

- Baek, F.; Kim, D.; Lee, G.; Choi, B.; Lee, S. Effect of Human Emotional Responses on Human-Robot Team Pty in Construction. Autom. Constr. 2024, 166, 105608. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.; Masoud, N.; Krishnan, M.S.; Li, V.C. Digital Twin-Driven Deep Reinforcement Learning for Adaptive Task Allocation in Robotic Construction. Adv. Eng. Inform. 2022, 53, 101710. [Google Scholar] [CrossRef]

- Adami, P.; Rodrigues, P.B.; Woods, P.J.; Becerik-Gerber, B.; Soibelman, L.; Copur-Gencturk, Y.; Lucas, G. Effectiveness of VR-Based Training on Improving Construction Workers’ Knowledge, Skills, and Safety Behavior in Robotic Teleoperation. Adv. Eng. Inform. 2021, 50, 101431. [Google Scholar] [CrossRef]

- Shayesteh, S.; Ojha, A.; Liu, Y.; Jebelli, H. Human-Robot Teaming in Construction: Evaluative Safety Training through the Integration of Immersive Technologies and Wearable Physiological Sensing. Saf. Sci. 2023, 159, 106019. [Google Scholar] [CrossRef]

- Yamamoto, H.; Ishimatsu, Y.; Ageishi, S.; Ikeda, N.; Endo, K.; Masuda, M.; Uchida, M.; Yamaguchi, H. Example of Experimental Use of 3D Measurement System for Construction Robot Based on Component Design Concept. Int. Symp. Autom. Robot. Constr. ISARC Proc. 2006, 252–257. [Google Scholar] [CrossRef]

- Roldán, J.J.; Peña-Tapia, E.; Garzón-Ramos, D.; de León, J.; Garzón, M.; del Cerro, J.; Barrientos, A. Multi-Robot Systems, Virtual Reality and ROS: Developing a New Generation of Operator Interfaces. In Robot Operating System (ROS); Springer: Cham, Switzerland, 2019; pp. 29–64. ISBN 978-3-319-91590-6. [Google Scholar]

- Hashimoto, S.; Ishida, A.; Inami, M.; Igarashi, T. Touchme: An Augmented Reality Based Remote Robot Manipulation. In Proceedings of the ICAT2011, Osaka, Japan, 28–30 November 2011. [Google Scholar]

- Gil, M.S.; Kang, M.S.; Lee, S.H.; Kim, D.; Kim, B.; Han, C.S. Proposal of Installation Method of Heavy Duty Glass Using Intuitive Manipulation Device. Int. Symp. Autom. Robot. Constr. ISARC Proc. 2011, 82–88. [Google Scholar] [CrossRef]

- Kurien, M.; Kim, M.-K.; Kopsida, M.; Brilakis, I. Real-Time Simulation of Construction Workers Using Combined Human Body and Hand Tracking for Robotic Construction Worker System. Autom. Constr. 2018, 86, 125–137. [Google Scholar] [CrossRef]

- Hirabayashi, T.; Akizono, J.; Yamamoto, T.; Sakai, H.; Yano, H. Teleoperation of Construction Machines with Haptic Information for Underwater Applications. Autom. Constr. 2006, 15, 563–570. [Google Scholar] [CrossRef]

- Oh, K.W.; Kim, D.; Hong, D.; Park, J.-H.; Hong, S. Design of a Haptic Device for Excavator Equipped with Crusher; Vilnius Gediminas Technical University: Vilnius, Lithuania, 2008; pp. 202–208. [Google Scholar]

- Franklin, C.S.; Dominguez, E.G.; Fryman, J.D.; Lewandowski, M.L. Collaborative Robotics: New Era of Human–Robot Cooperation in the Workplace. J. Saf. Res. 2020, 74, 153–160. [Google Scholar] [CrossRef]

- ISO ISO/TS 15066; Robots and Robotic Devices—Collaborative Robots. ISO: Geneva, Switzerland, 2016.

- Wang, X.V.; Kemény, Z.; Váncza, J.; Wang, L. Human–Robot Collaborative Assembly in Cyber-Physical Production: Classification Framework and Implementation. CIRP Ann. 2017, 66, 5–8. [Google Scholar] [CrossRef]

- Deng, M.; Menassa, C.C.; Kamat, V.R. Kamat From BIM to Digital Twins: A Systematic Review of the Evolution of Intelligent Building Representations in the AEC-FM Industry. J. Inf. Technol. Constr. 2021, 26, 58–83. [Google Scholar] [CrossRef]

- Meissner, A.; Trübswetter, A.; Conti-Kufner, A.S.; Schmidtler, J. Friend or Foe? Understanding Assembly Workers’ Acceptance of Human-Robot Collaboration. J. Hum.-Robot Interact. 2020, 10, 1–30. [Google Scholar] [CrossRef]

- Zorzenon, R.; Lizarelli, F.L.; de A. Moura, D.B.A. What Is the Potential Impact of Industry 4.0 on Health and Safety at Work? Saf. Sci. 2022, 153, 105802. [Google Scholar] [CrossRef]

- Bartneck, C.; Kulić, D.; Croft, E.; Zoghbi, S. Measurement Instruments for the Anthropomorphism, Animacy, Likeability, Perceived Intelligence, and Perceived Safety of Robots. Int. J. Soc. Robot. 2009, 1, 71–81. [Google Scholar] [CrossRef]

- Chuan Tan, J.T.; Duan, F.; Zhang, Y.; Kato, R.; Arai, T. Safety Design and Development of Human-Robot Collaboration in Cellular Manufacturing. In Proceedings of the 2009 IEEE International Conference on Automation Science and Engineering, Bangalore, India, 22–25 August 2009; pp. 537–542. [Google Scholar]

- Jeelani, I.; Gheisari, M. Safety Challenges of Human-Drone Interactions on Construction Jobsites. In Automation and Robotics in the Architecture, Engineering, and Construction Industry; Jebelli, H., Habibnezhad, M., Shayesteh, S., Asadi, S., Lee, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 143–164. ISBN 978-3-030-77163-8. [Google Scholar]

- Sarvghadi, H.; Reinhardt, A.; Semmelhack, E.A. A Survey of Wearable Devices to Capture Human Factors for Human-Robot Collaboration. Pervasive Mob. Comput. 2025, 110, 102048. [Google Scholar] [CrossRef]

- Carvalho, L.; Rezeck, P.; Lima, M.V.; Pinto, L.; Freitas, G.; Nascimento, E.R.; MacHaret, D.G.; Chaimowicz, L.; Pessin, G.; Campos, M.F.M. On the Evaluation of Force Feedback Augmented Teleoperation of Excavator-like Mobile Manipulators; IEEE Computer Society: Washington, DC, USA, 2020; Volume 2020, pp. 1401–1407. [Google Scholar]

- Liau, Y.Y.; Ryu, K. Genetic Algorithm-Based Task Allocation in Multiple Modes of Human–Robot Collaboration Systems with Two Cobots. Int. J. Adv. Manuf. Technol. 2022, 119, 7291–7309. [Google Scholar] [CrossRef]

- Adami, P.; Becerik-Gerber, B.; Soibelman, L.; Doleck, T.; Copur-Gencturk, Y.; Lucas, G. An Immersive Virtual Learning Environment for Worker-Robot Collaboration on Construction Sites; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2020; Volume 2020, pp. 2400–2411. [Google Scholar]

- Adami, P.; Rodrigues, P.B.; Woods, P.J.; Becerik-Gerber, B.; Soibelman, L.; Copur-Gencturk, Y.; Lucas, G. Impact of VR-Based Training on Human–Robot Interaction for Remote Operating Construction Robots. J. Comput. Civ. Eng. 2022, 36, 04022006. [Google Scholar] [CrossRef]

- Onososen, A.; Musonda, I. VR-BASED TRAINING METHODS IN ENHANCING COMMUNICATION WITHIN HUMAN-ROBOT TEAMS IN CONSTRUCTION; Association of Researchers in Construction Management: London, UK, 2024; pp. 121–128. [Google Scholar]

| Journal Sources | Count |

|---|---|

| Automation in Construction | 144 |

| Journal of Construction Engineering and Management | 71 |

| Journal of Computing in Civil Engineering | 60 |

| Advanced Engineering Informatics | 55 |

| Safety Science | 48 |

| Sensors | 38 |

| IEEE Access | 27 |

| Journal of management in engineering | 26 |

| Journal of Building Engineering | 21 |

| Applied Ergonomics | 21 |

| Ergonomics | 18 |

| Human factors | 17 |

| Buildings | 16 |

| Sustainability | 16 |

| Applied Ergonomics | 2 |

| Applied Sciences (Switzerland) | 2 |

| Buildings | 2 |

| Cluster Number | Cluster Quantity | Literature Average Year | Silhouette Value | Cluster Label (LLR)LSI |

|---|---|---|---|---|

| 0 | 41 | 2015 | 1 | remote control; fifth-generation mobile communication, construction machinery, VR; human computer; force feedback; unmanned ground vehicle; environmental measurement. |

| 1 | 35 | 2022 | 1 | risk assessment: wearable robots, hazard assessment, risk mitigation strategies, construction safety, unsafe behavior, mental workload. |

| 2 | 29 | 2013 | 0.952 | human robot; human–robot interaction. |

| 3 | 29 | 2023 | 1 | digital twin; virtual reality; monitoring; workstation design, robotic manipulation, robot operating system, robot–environment interaction. |

| 4 | 28 | 2024 | 1 | human–robot collaboration; collaborative robots; robot speed. |

| 5 | 27 | 2011 | 0.993 | robot operating system; integrated design; machine design; motion planning; path. |

| 6 | 25 | 2015 | 0.986 | efficiency improvement: automation; organizational structure; human–robot team; intelligent construction system, improving remote operability, situational awareness, MR. |

| 7 | 22 | 2014 | 0.993 | platform-based incorporation; project-based integration; digital fabrication; construction automation; tele-operated excavation system; sensor-based estimation; robot manipulator efficiency improvement. |

| 8 | 20 | 2021 | 0.956 | construction safety: smart protection helmet, wearable devices; situational awareness; mental workload. |

| Linked Qualitative Dimension | Bibliometric Evidence | Representative References | |

|---|---|---|---|

| Clusters | Bursts | ||

| (1) Remote intelligent machinery | #0 “Remote control | “camera”; “excavator”; “teleoperation system”; “feedback”; “augmented reality”; “end effector”; “construction machinery” | Lee, Ham et al., 2022 [7]; Chen et al., 2016 [39]; Le et al., 2017 [60]; Kim et al., 2009 [40]; Nagano et al., 2020) [41] |

| (2) Hazard analysis and risk assessment | #1 “Risk assessment” | “safety risk”, “monitoring” | Okpala et al., 2023 [14]; Zhang et al., 2023 [5]; Wang et al., 2025 [61]; Sun et al., 2023 [11]; Nnaji et al., 2023 [62] |

| (3) Digital twin for safety monitoring | #3 “Digital twin” | “automation”; “monitoring” | Lin et al., 2025 [63]; Wang et al., 2021 [64] |

| (4) Cognitive and psychological impacts | #6 “Efficiency improvement”; #8 “Construction safety-mental workload | “feedback”; “safety risk” | You et al., 2018 [55]; Lu et al., 2022 [65]; Lee and Ham, 2024 [66]; Liu et al., 2021 [67]; Baek et al., 2024 [68] |

| (5) Organizational/management perspective | #6 “Efficiency improvement-organizational structure; human–robot team” | “automation” | Lee, Lee et al., 2022 [69]; Adami et al., 2021 [70]; Shayan Shayesteh et al., 2023 [71] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, P.; Zeng, N.; Li, Q.; Nübel, K. A Review of Human–Robot Collaboration Safety in Construction. Systems 2025, 13, 856. https://doi.org/10.3390/systems13100856

Lin P, Zeng N, Li Q, Nübel K. A Review of Human–Robot Collaboration Safety in Construction. Systems. 2025; 13(10):856. https://doi.org/10.3390/systems13100856

Chicago/Turabian StyleLin, Peng, Ningshuang Zeng, Qiming Li, and Konrad Nübel. 2025. "A Review of Human–Robot Collaboration Safety in Construction" Systems 13, no. 10: 856. https://doi.org/10.3390/systems13100856

APA StyleLin, P., Zeng, N., Li, Q., & Nübel, K. (2025). A Review of Human–Robot Collaboration Safety in Construction. Systems, 13(10), 856. https://doi.org/10.3390/systems13100856