Modernizing Small and Medium-Sized Enterprises: A Lean Audit Model for Digital Integration

Abstract

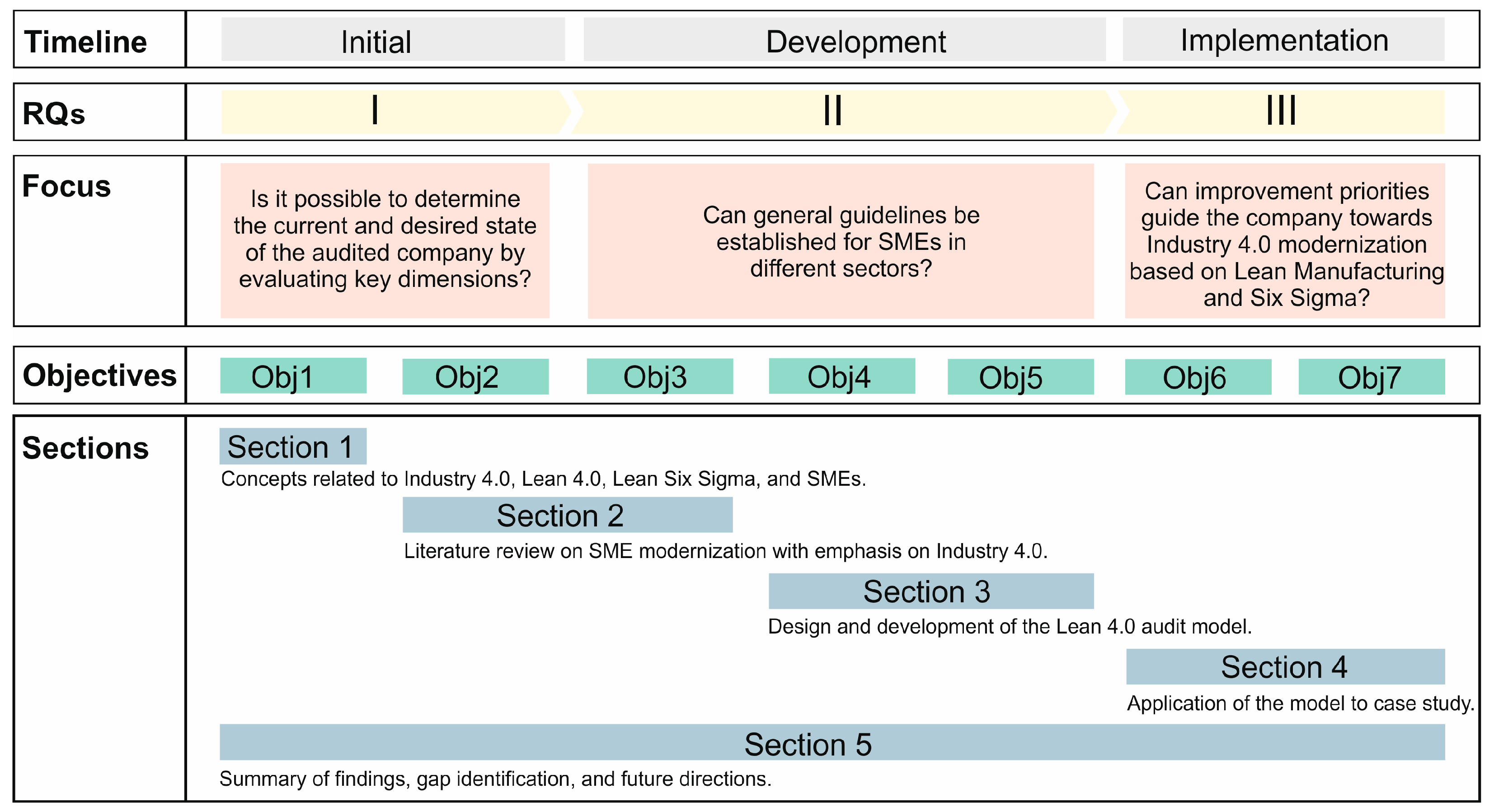

1. Introduction

2. Literature Review

3. Methodology

- Phase I: Readiness Assessment The first phase focuses on evaluating the company’s readiness for the project and adopting corrective measures if necessary. This initial diagnosis is crucial for identifying existing technological capabilities, organizational culture, and operational competencies [37]. Tools such as the “Readiness Assessment Model” by Schumacher et al. [36] can be used to measure the company’s readiness in terms of multiple dimensions.

- Phase II: Implementation of Lean Thinking/Manufacturing/Management: In this phase, the company should implement Lean Thinking, Lean Manufacturing, and Lean Management principles as much as possible. This involves adopting techniques such as waste elimination, continuous improvement (kaizen), just-in-time, and using tools like value-added analysis and value stream mapping [6,41]. The literature suggests that a solid Lean foundation can facilitate the integration of Industry 4.0 technologies by improving operational efficiency and reducing variabilities [9].

- Phase III: Gradual Introduction of Technologies: Once Lean principles are established, the gradual introduction of technologies follows, prioritizing those that offer the greatest efficiency. These technologies include real-time information sharing with suppliers and customers, the use of Radio Frequency Identification (RFID) tags on products and machinery, sensors for monitoring production, automation of processes, and information distribution through integrated systems [42,43]. These technologies are fundamental to creating an intelligent and connected production environment [3].

- Phase IV: Maturation and Introduction of Advanced Technologies: The final phase focuses on maturing the technologies and capabilities introduced in the previous phase and gradually incorporating more complex technologies such as additive manufacturing, augmented reality, artificial intelligence, machine learning, big data, and collaborative robots [4,21]. The integration of these technologies should be carried out to varying degrees based on availability, cost, and the ability to integrate them quickly and efficiently into the existing system [44].

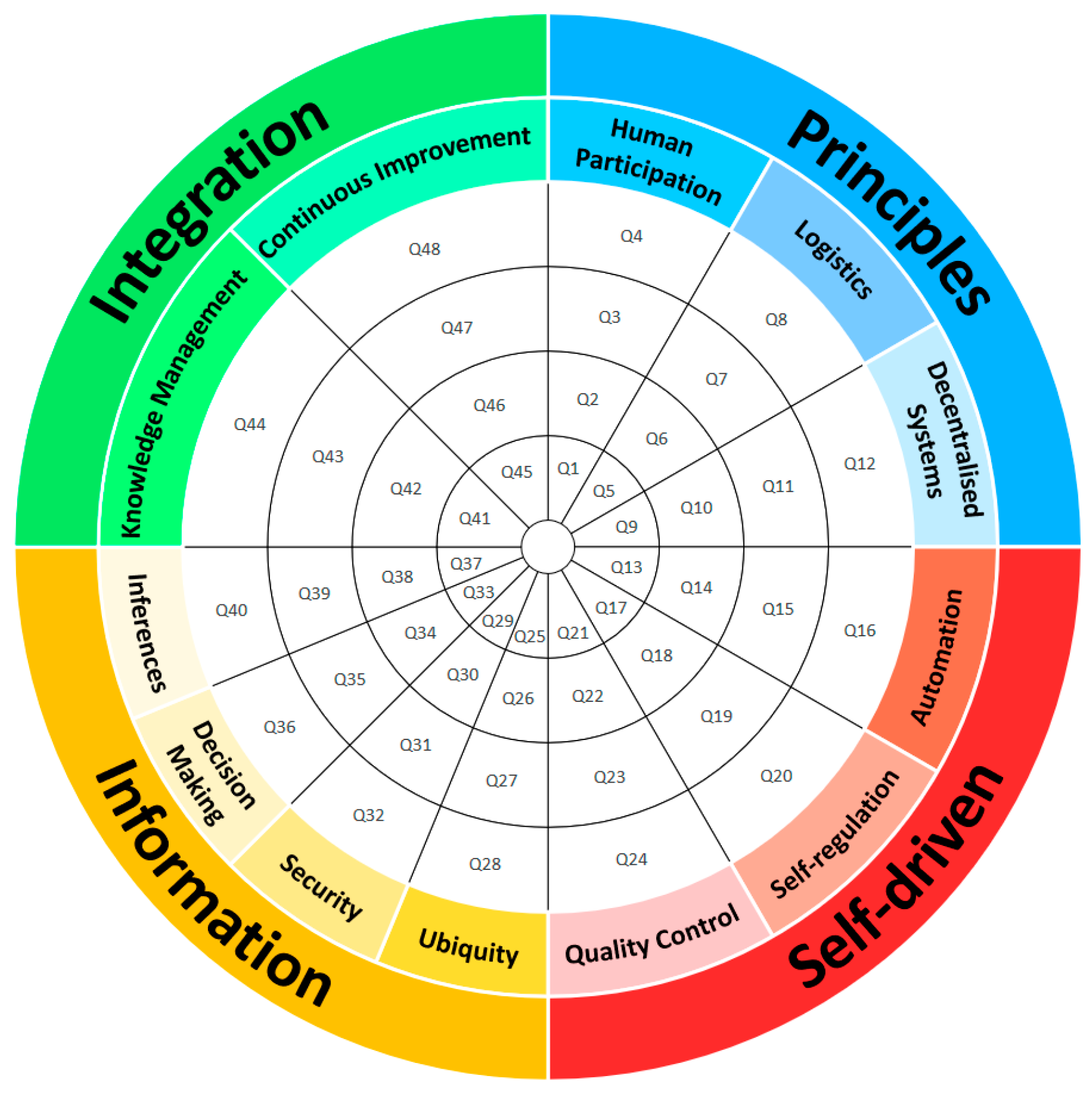

3.1. Lean 4.0 Audit Proposal

3.1.1. Type of Audits

3.1.2. Audit Criteria

3.1.3. Audit Methods

- The Factors Balance Method for Concurrent Engineering proposed by Carter and Baker [51] will provide the application phases and the way to analyze the information collected during the audit. This method is crucial for coordinating design and development activities in a concurrent manufacturing environment, which is essential for implementing Lean 4.0.

3.2. Factors Balancing Approach Method for Lean 4.0

- Human Participation: Ensuring the manufacturing system focuses on customer satisfaction and considers employee input from all levels, including technical staff and management.

- Logistics: Enhancing the organization of movements of raw materials, parts, subassemblies, and finished products within the plant, and improving their reception from suppliers or delivery to customers through LM techniques and Industry 4.0 technological integration.

- Decentralized Systems: Supporting flexible mass manufacturing that maintains high efficiency and effectiveness. This involves lines and work cells capable of reorganization and the production of modular, resilient, and highly customizable products. The Smart Factory operates as a decentralized system within a business environment that interacts digitally.

- Automation: Striving to minimize human intervention in manufacturing processes.

- Self-Regulation: Ensuring a constant flow of value generation and efficient operation with minimal external intervention.

- Quality Control: Maintaining and improving quality control systems to ensure product quality and efficiency, even as the company gains flexibility.

- Ubiquity: Ensuring access and collaboration anytime and anywhere through remote and synchronized communication technologies, promoting operational continuity and team efficiency.

- Security: Protecting digital assets and data with Cybersecurity measures to ensure confidentiality, integrity, and availability, preventing attacks and mitigating risks.

- Decision Making: Enhancing task, project, and company management through Lean Management techniques, both traditional and modern, to improve results and accelerate modernization.

- Inferences: Assisting experts in handling large amounts of information with statistical analyses or processing technologies.

- Knowledge Management: Enhancing pre-existing expert knowledge with technical and organizational knowledge gained during the transition, offering a chance to rethink management practices.

- Continuous Improvement: Emphasizing continuous process improvement in line with Six Sigma principles to avoid digitizing inefficiencies.

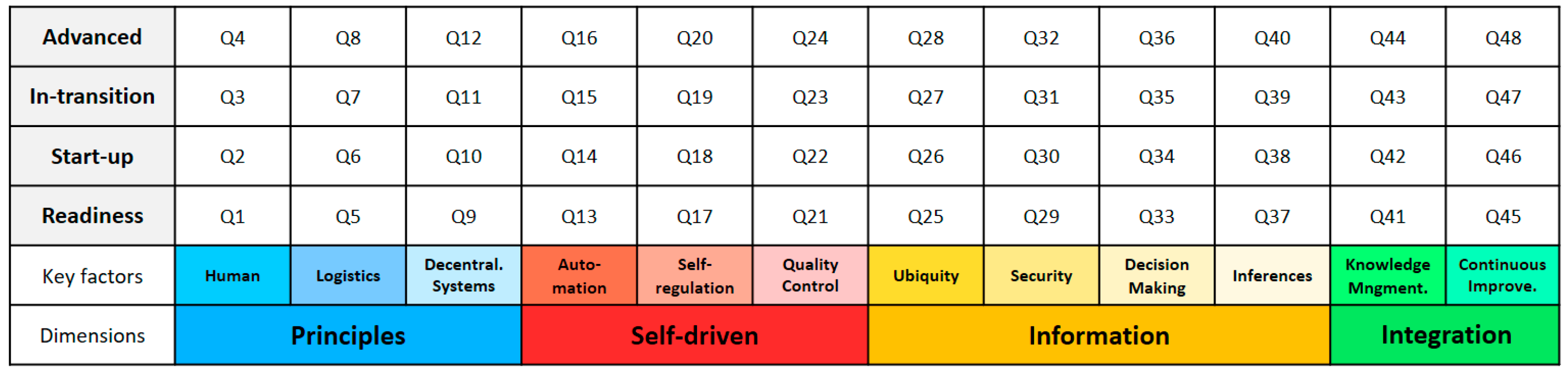

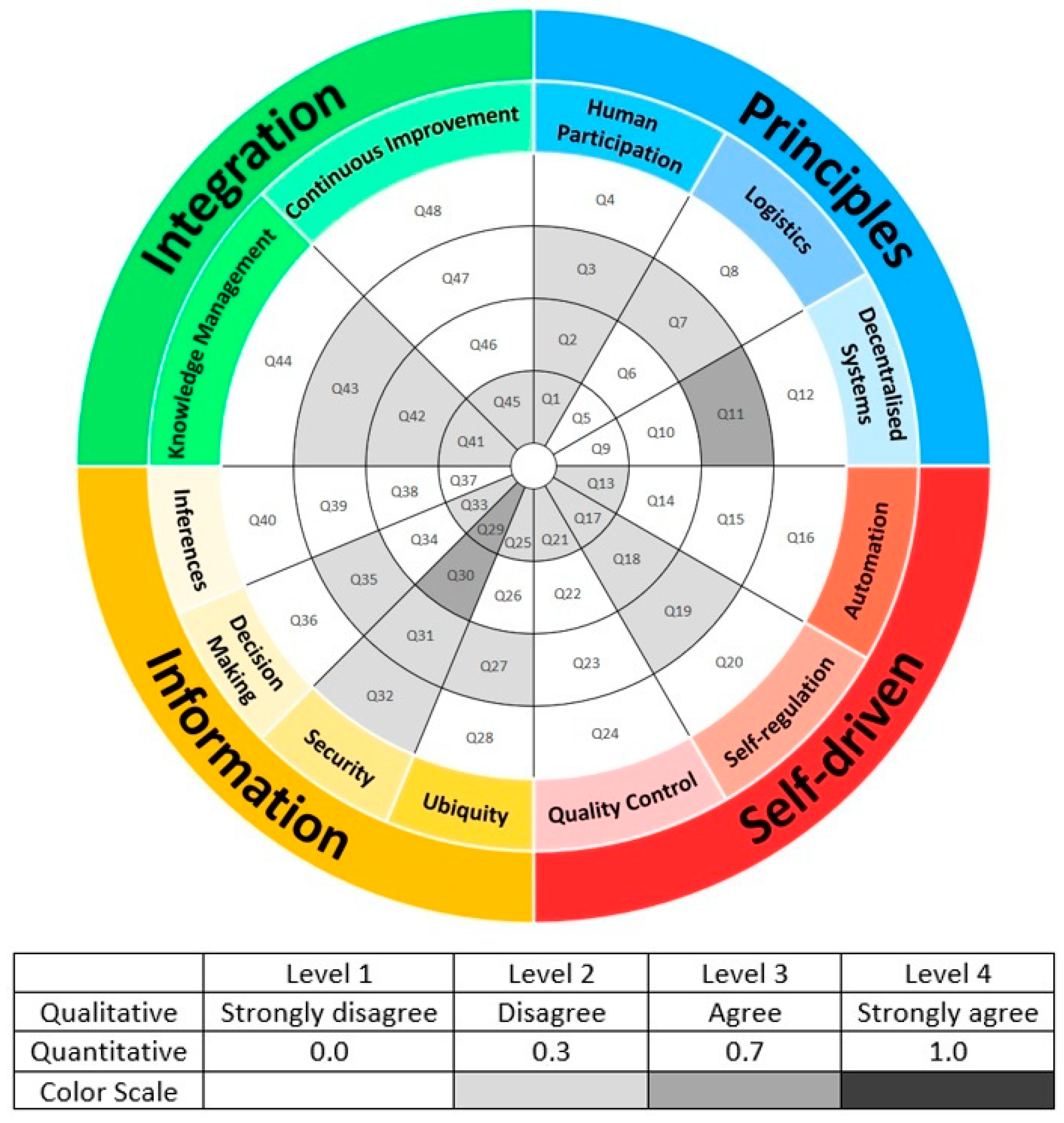

3.2.1. Phase 1: Assessment Questionnaire

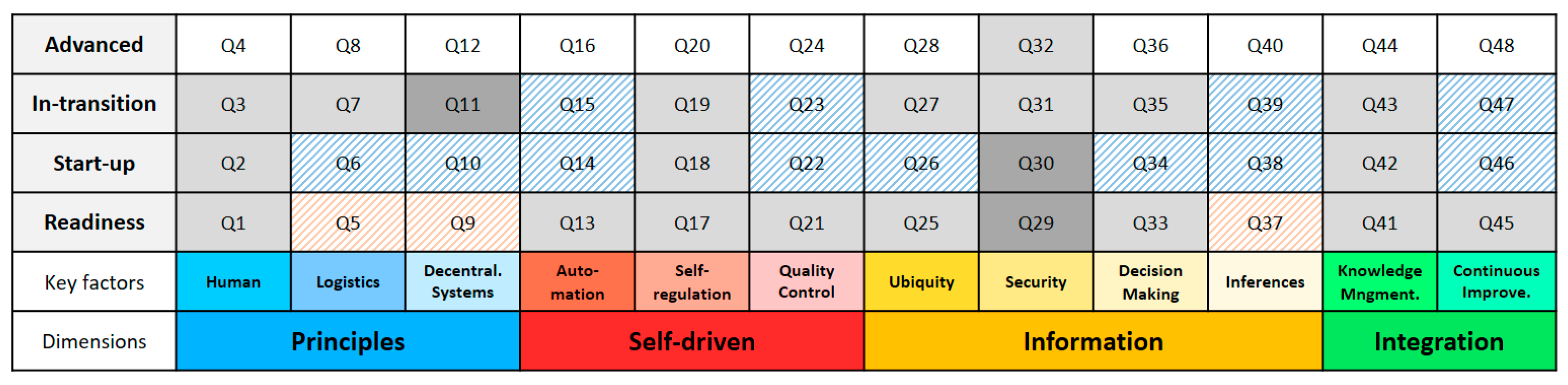

3.2.2. Phase 2: Method Matrix

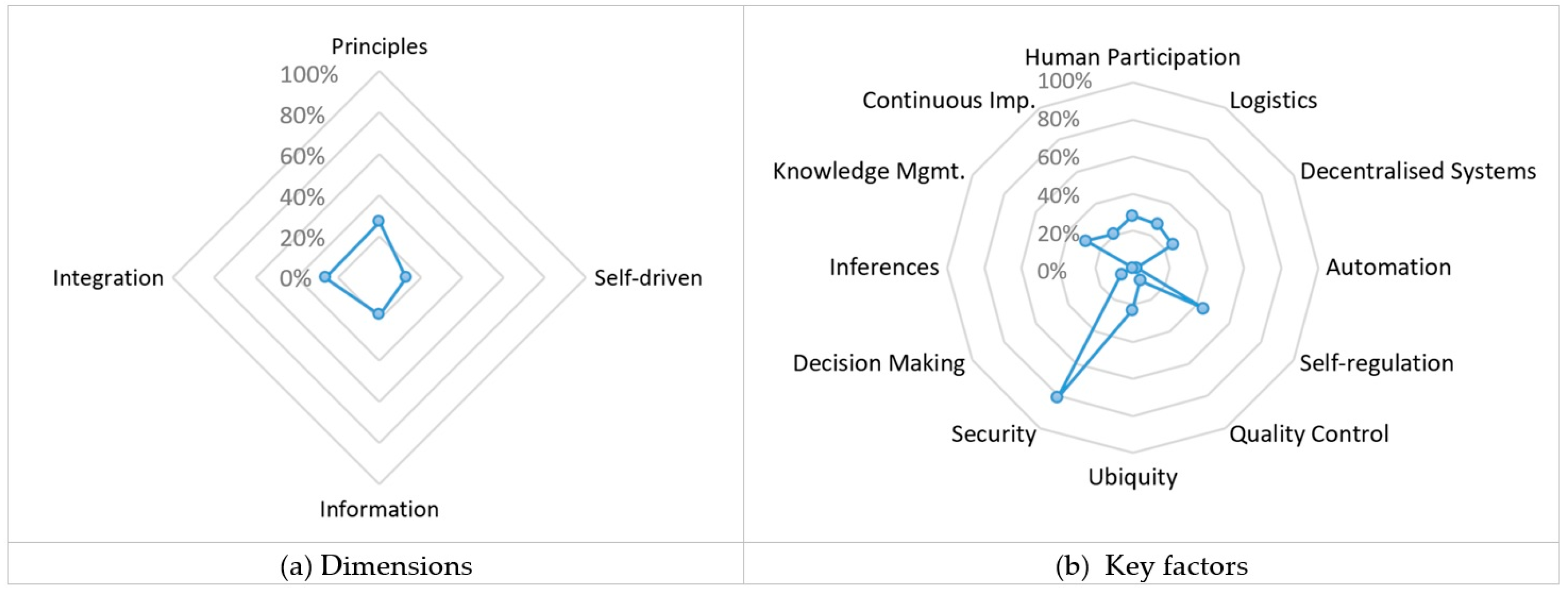

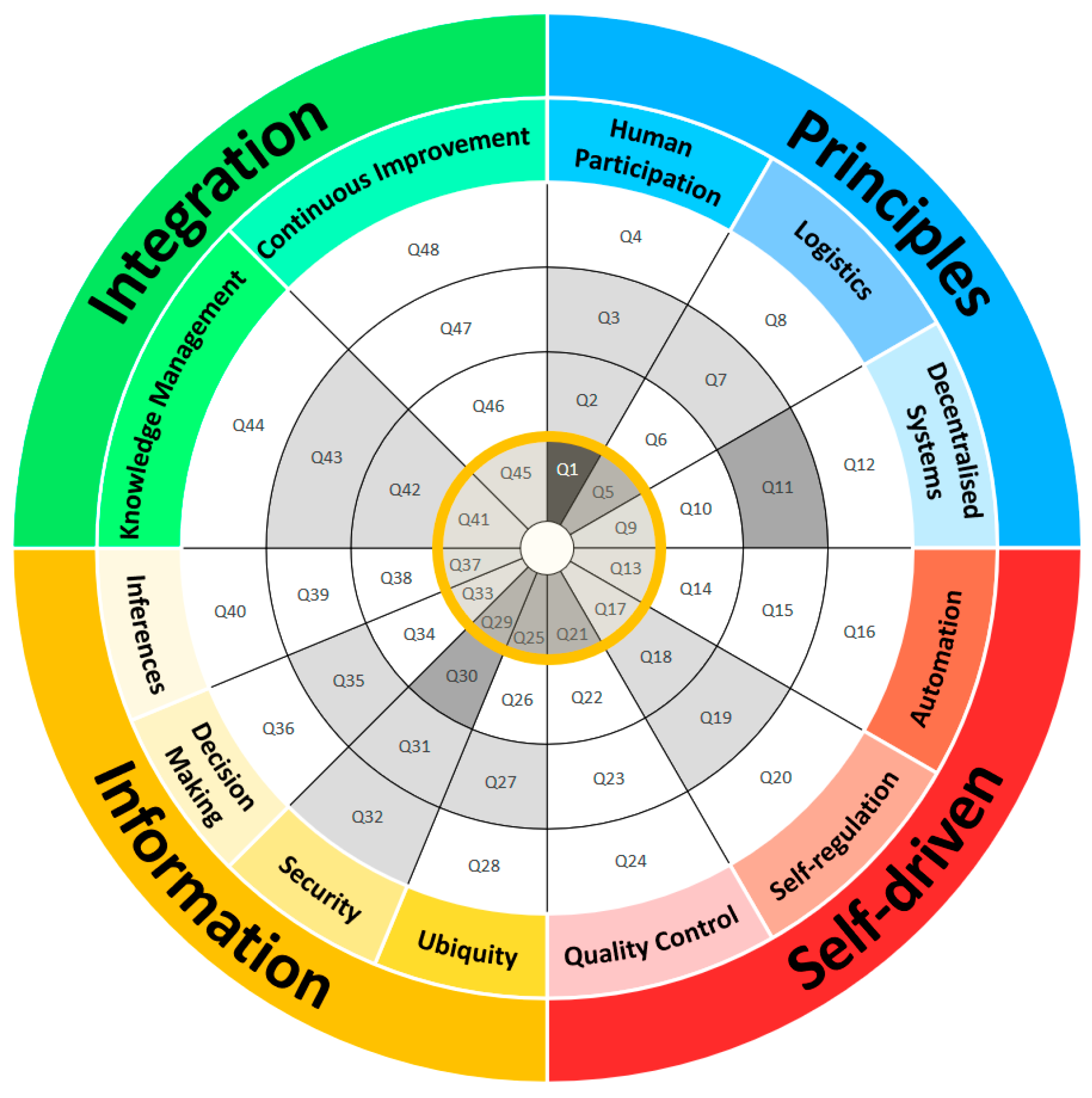

3.2.3. Phase 3: Dimension Map

3.2.4. Phase 4: Improvement Priority Setting

4. Results: Case Study Analysis

4.1. Lean 4.0 Audit Model

- Calculation of the System Implementation Percentage: Based on the “Evaluation of the Demerit Points System” [58], this approach requires translating the demerit scale to the Likert scale used in the surveys.

- Data Processing Based on Starzyńska et al. [60]: This approach involves an audit questionnaire based on a five-value scale and the calculation of assessment indicators. The indicators proposed are defined within each perspective or approach in each audit area. The formula used is shown in (1):

4.2. Analysis of Audit Results

- Basic parameters (input, output) for production aspects are determined. Real-time information on product status, completed orders, orders in process, and pending orders is available.

- There are no sensors to monitor any part of the production process.

- Digital interfaces for data visualization and interaction exist at some workstations. Typically, area managers have access to PCs connected to the data and information management platform.

- Augmented reality devices or other wearables are not used for real-time information visualization.

4.3. Lean 4.0 Implementation

4.4. Digital Enablers for Industry 4.0

5. Conclusions

Future Works

- The model’s validation and generalization in diverse contexts warrant further investigation. While the application of the model in a single case study is valuable, it suggests the necessity to validate its effectiveness and adaptability in a more extensive and heterogeneous sample of SMEs. These SMEs should represent various industrial sectors and possess different operational characteristics and levels of digital maturity. This would allow for the refinement of the model, the identification of possible adaptations needed for specific contexts, and the increase in generalizability of its findings.

- Longitudinal studies on long-term impact. Conducting longitudinal studies on SMEs that have implemented the audit model and the derived action plans would be a fruitful avenue of research. This would facilitate the assessment of the sustainability of the implemented improvements, the genuine impact on operational efficiency and competitiveness over time, and the progression through the maturity stages towards Industry 4.0.

- The refinement of dimensions, key factors, and questionnaires is imperative. As the model is applied in more contexts, feedback could be collected from users and experts to refine the strategic dimensions, key factors, and evaluation questionnaire questions. This approach would ensure the model’s relevance, accuracy, and comprehensiveness in addressing the evolving needs of SMEs.

- In addition, in-depth analysis of the implementation of specific enabling technologies could be a fruitful avenue for future research. This analysis could entail a detailed examination of the implementation and impact of specific Industry 4.0 enabling technologies (e.g., IoT, AI, collaborative robotics, Big Data, and predictive analytics) within the framework of the Lean 4.0 audit model. This would provide more specific and practical guidelines on how SMEs can adopt these technologies effectively and aligned with their Lean objectives.

- The consideration of human factors and organizational culture is imperative for a comprehensive understanding of the implementation process. While the "Human Involvement" factor is incorporated into the model, further analysis is warranted on how human factors and organizational culture influence the adoption of Lean 5.0 in SMEs. The development of modules or tools that are complementary to the model is recommended. These modules or tools could assess cultural readiness and change management. They could also propose strategies to foster a culture of continuous improvement and collaboration.

- Extend the model to the supply chain. The current model’s primary focus on the internal operations of SMEs necessitates extension to encompass external factors. The model’s scope could be expanded to encompass the integration of Lean 4.0 principles and digital technologies throughout the supply chain. This would involve analysing opportunities for collaboration and enhancement with suppliers and customers.

- A relevant future line of research could be to assess how the adoption of Lean 4.0 in SMEs, guided by the proposed audit model, affects their performance in terms of sustainability (reduction of resource consumption, waste minimization, improvement of working conditions, etc.).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| I4.0 | Industry 4.0 |

| ICT | Information and Communications Technology |

| IoT | Internet of Things |

| KPIs | Key performance indicators |

| LM | Lean Manufacturing |

| Obj. | Objectives |

| Q | Question |

| RFID | Radio Frequency Identification |

| RQ | Research question |

| SME | Small and Medium-Sized Enterprise |

| VSM | Value stream mapping |

Appendix A

Appendix A.1

| No. | Question | Response |

|---|---|---|

| Q1 | There is a system for collecting feedback from customers/employees. | N/A 1 2 3 4 |

| Q2 | There are systems to take customer/employee feedback into account. | N/A 1 2 3 4 |

| Q3 | There are systems that allow customers to customize products. | N/A 1 2 3 4 |

| Q4 | There are systems to anticipate customer needs. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q5 | There is a Lean Manufacturing technique applied to logistics. | N/A 1 2 3 4 |

| Q6 | There are several Lean Manufacturing techniques applied to logistics. | N/A 1 2 3 4 |

| Q7 | Some movement of parts/products is automated, and RFID-type identifiers are used to some extent. | N/A 1 2 3 4 |

| Q8 | Most movements are automated, and RFID-type identifiers are widely used. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q9 | Techniques for optimizing manufacturing processes are used. | N/A 1 2 3 4 |

| Q10 | There are multidisciplinary teams and automated processes. | N/A 1 2 3 4 |

| Q11 | There is the capability to quickly manufacture small batches. | N/A 1 2 3 4 |

| Q12 | There are multiple manufacturing cells with the ability to quickly reorganize. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q13 | There is an automated manufacturing process. | N/A 1 2 3 4 |

| Q14 | There are multiple automated manufacturing processes. | N/A 1 2 3 4 |

| Q15 | Most manufacturing processes are automated. | N/A 1 2 3 4 |

| Q16 | All manufacturing processes are automated. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q17 | Techniques are used to plan and schedule tasks regularly. | N/A 1 2 3 4 |

| Q18 | The Kanban technique from Lean Manufacturing is implemented. | N/A 1 2 3 4 |

| Q19 | An e-Kanban platform has been implemented. | N/A 1 2 3 4 |

| Q20 | e-Kanban, SCADA, and ERP platforms are used together. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q21 | There is a total quality control system. | N/A 1 2 3 4 |

| Q22 | Some tests are performed using specialized machines. | N/A 1 2 3 4 |

| Q23 | Not all tests are conducted by people, but they are supervised by them. | N/A 1 2 3 4 |

| Q24 | Preventive and AI-assisted control techniques are used. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q25 | Parameters have been determined to measure aspects of production. | N/A 1 2 3 4 |

| Q26 | Sensors exist to monitor parts of the production. | N/A 1 2 3 4 |

| Q27 | Digital interfaces and sensors exist on most machines. | N/A 1 2 3 4 |

| Q28 | Augmented Reality devices are used to visualize real-time information. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q29 | Access to the company and its various areas is controlled. | N/A 1 2 3 4 |

| Q30 | Information is stored on physical local servers. | N/A 1 2 3 4 |

| Q31 | A cloud service is used to manage information. | N/A 1 2 3 4 |

| Q32 | Some cybersecurity technology, such as Blockchain, is used. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q33 | There is a Lean Management technique for decision-making. | N/A 1 2 3 4 |

| Q34 | There is an intelligent tool for decision-making. | N/A 1 2 3 4 |

| Q35 | There are self-directed work teams. | N/A 1 2 3 4 |

| Q36 | AI or Machine Learning is used for decision-making. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q37 | There is a statistical technique for making inferences. | N/A 1 2 3 4 |

| Q38 | There is a digital platform for statistical data processing and inference generation. | N/A 1 2 3 4 |

| Q39 | There is a connected digital platform for real-time statistical data processing and inference generation. | N/A 1 2 3 4 |

| Q40 | Big Data Analytics technologies are available. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q41 | There are company-specific process manuals. | N/A 1 2 3 4 |

| Q42 | There are regular activities for knowledge dissemination. | N/A 1 2 3 4 |

| Q43 | Knowledge is made available to suppliers/customers. | N/A 1 2 3 4 |

| Q44 | There is a company Knowledge-Based System. | N/A 1 2 3 4 |

| No. | Question | Response |

|---|---|---|

| Q45 | A traditional Lean Management tool is used. | N/A 1 2 3 4 |

| Q46 | Several traditional Lean Management tools are used. | N/A 1 2 3 4 |

| Q47 | A modern Lean Management tool is used. | N/A 1 2 3 4 |

| Q48 | Several modern Lean Management tools are used. | N/A 1 2 3 4 |

Appendix A.2

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | There is no system for collecting feedback from employees or customers. | There are no channels to inform the responsible parties of feedback provided by customers. | There are no systems for allowing customers to customize products or services. | There are no systems capable of predicting and anticipating customer needs. |

| 2 (0.3) | There is some system for collecting feedback from customers or employees through oral means (communication, face-to-face, phone). | The responsible parties are informed of the feedback provided by customers through oral means (face-to-face communication, phone, etc.). | Traditional systems (face-to-face, phone, order sheet) exist for customers to customize aesthetic aspects of the product. | Non-expert systems exist that can predict and anticipate basic customer needs (number of orders). |

| 3 (0.7) | Physical systems for collecting feedback from employees and/or customers exist. | The responsible parties are informed of customer feedback through physical means (panel, order sheets, etc.). | Digital systems (web, app, platform) exist for customers to customize basic aspects of the product. | Expert systems exist that can predict and anticipate basic customer needs (number of orders). |

| 4 (1.0) | Digital systems for collecting feedback from employees and customers exist. | The responsible parties are informed of customer feedback through digital means (email, chat, digital platform, etc.). | Digital systems (web, app, platform) exist for customers to customize aesthetic, dimensional, technical, and functional aspects of the product. | Expert systems, adapted to the company, exist that can predict and anticipate customer needs (number of orders, price, aesthetic and technological trends, functionality). |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | There is no LM technique applied to logistics. | There is no LM technique applied to logistics. | There are no automated movements, and no identifiers are used for raw materials, components, sub-assemblies, and products. | There are no automated movements, and no identifiers are used for raw materials, components, sub-assemblies, and products. |

| 2 (0.3) | A LM technique is applied to external logistics. | Several traditional LM techniques are applied to external and/or internal logistics. | There are no automated movements, but basic or traditional identification exists for raw materials and/or components and/or sub-assemblies and/or products. | Some movements are semi-automated (require personnel), and basic or traditional identification exists for raw materials, components, sub-assemblies, and products. |

| 3 (0.7) | A LM technique is applied to internal logistics. | Several modern LM techniques are applied to external and/or internal logistics. | Some movements are semi-automated (require personnel), and digital identifiers are used for raw materials and/or components and/or sub-assemblies and/or products. | Some movements are automated using AGVs, and digital RFID identifiers are used for raw materials and/or components and/or sub-assemblies and/or products. |

| 4 (1.0) | A LM technique is applied to both external and internal logistics. | Multiple modern LM techniques are applied to both external and internal logistics. | Some movements are automated using AGVs, and digital RFID identifiers are used for raw materials, components, sub-assemblies, and products. | Most movements are automated using AGVs, and digital RFID identifiers are used for raw materials, components, sub-assemblies, and products. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No technique is used for optimizing manufacturing processes. | There are no multidisciplinary work teams, and there are no automated manufacturing processes. | There is no capability to quickly manufacture small batches. | There are no manufacturing cells with the ability to reorganize. |

| 2 (0.3) | A basic technique (not from Process Engineering) is used to optimize some manufacturing process. | There is a multidisciplinary work team, but there are no automated manufacturing processes. | There is the ability to manufacture small batches with high restrictions and without customization. | Some manufacturing cells have the ability to reorganize. |

| 3 (0.7) | Basic techniques from Process Engineering are used to optimize manufacturing processes. | Multidisciplinary work teams exist in some departments, and there are automated manufacturing processes that require human intervention. | There is the capability to manufacture small batches of customized products. | There are multiple manufacturing cells that can reorganize as needed. |

| 4 (1.0) | Adapted and digitized techniques from Process Engineering are used to optimize multiple manufacturing processes. | Multidisciplinary work teams exist in all departments, and there are automated manufacturing processes. | There is the capability to quickly manufacture small batches of customized products through multidisciplinary teams, the use of robots, and automated processes. | There are multiple manufacturing cells with multidisciplinary teams and flexible collaborative machinery that can quickly reorganize as required. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | There is no automated process. | There is no automated process. | There is no automated process. | There is no automated process. |

| 2 (0.3) | There is an automated process with high human intervention in internal or external processes. | There is some (<25%) automated process for execution, regulation, and control in internal and/or external processes. | There is some (<50%) automated process for execution, regulation, and control in internal and/or external processes. | All (100%) manufacturing processes are automated in execution, regulation, and control in external processes. |

| 3 (0.7) | There is an automated process with minimal human intervention in internal and external processes. | There are several (<50%) automated processes for execution, regulation, and control in internal and external processes. | There are multiple (>50%) automated processes for execution, regulation, and control in internal and external processes. | All (100%) manufacturing processes are automated in execution, regulation, and control in internal processes. |

| 4 (1.0) | There is an automated process for execution, regulation, and control in internal and external processes. | There are multiple (>50%) automated processes for execution, regulation, and control in both internal and external processes. | The majority (>80%) of processes are automated in execution, regulation, and control in both internal and external processes. | All (100%) manufacturing processes are automated in execution, regulation, and control in both internal and external processes. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No techniques are used to plan or schedule tasks. | The Kanban technique or similar is not used. | Digital e-Kanban platforms or similar are not used. | Digital e-Kanban platforms, SCADA, ERP, or similar are not used. |

| 2 (0.3) | A technique is used to plan and/or schedule tasks. | Alternative systems to Kanban (other information systems and/or card systems) are used. | Alternative/similar systems to a digital e-Kanban platform are used. | Alternative/similar digital platforms to e-Kanban, SCADA, ERP are used in some process of some department. ERP is used in some dimension of the company. |

| 3 (0.7) | Lean Manufacturing techniques are used to plan and schedule tasks only in specific cases. | Kanban is used in some manufacturing process. | Digital e-Kanban platforms are used in some process of some department. | Standard digital platforms of e-Kanban, SCADA, ERP are used together in some processes of some department. ERP is used in some dimension of the company. |

| 4 (1.0) | Lean Manufacturing techniques are used to plan and schedule tasks frequently. | Kanban is used in most manufacturing processes. | Digital e-Kanban platforms are used in most processes and in several departments. | Adapted digital platforms of e-Kanban, SCADA, ERP are used together in most processes and in several departments. ERP is used in most dimensions of the company. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | There is no total quality control system. | There is no quality control system, and no testing is carried out. | There is no quality control system, and no testing is carried out. | Preventive control techniques are not used. |

| 2 (0.3) | There is some quality control system in external processes. | There is some quality control system, and external testing is carried out. | There is some quality control system, and testing is carried out sporadically with high human supervision. | A basic (qualitative) preventive control technique is used with high human intervention. |

| 3 (0.7) | There is some quality control system in external and/or internal processes at some point in the process. | There is a quality control system, and external and/or internal testing is carried out with high human intervention. | There is a quality control system, and automated testing is carried out sporadically with human supervision. | Preventive control techniques (qualitative and quantitative) are used with human intervention. |

| 4 (1.0) | There is a total quality control system for most internal and external processes throughout the entire process. | There is a quality control system, and some external and internal testing is carried out by specialized machines with minimal human intervention. | There is a quality control system, and automated testing is frequently carried out with minimal human supervision. | Preventive control techniques (qualitative and quantitative) are used with AI assistance. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No parameters are determined to measure production aspects. | No sensors exist to monitor any part of production. | No digital interfaces or sensors exist in the workstations. | Augmented reality devices are not used to visualize real-time information. |

| 2 (0.3) | Some basic parameters (input, output) are determined for production aspects | Some sensors exist to monitor parts of production. | Digital visualization and/or data interaction interfaces exist in some workstations. | Classical devices are used to visualize asynchronous information. |

| 3 (0.7) | Some parameters are determined to measure some aspects of production (input, processes, output). | Sensors exist to monitor several production lines. | Digital visualization and/or data interaction interfaces and sensors exist in some workstations. | Digital devices (screens, wearables, etc.) are used to visualize real-time information. |

| 4 (1.0) | Several parameters are determined to measure most aspects of production (input, processes, output). | Smart sensors of various types exist to monitor most production lines and centers. | Digital visualization and interaction interfaces and smart sensors exist in most machines. | Augmented reality devices are used to visualize real-time information. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No access control is performed for the company or its different areas. | Information is not stored on servers. | Cloud services are not used to manage information. | No cybersecurity technology is used. |

| 2 (0.3) | Basic access control to the company (door and lock) is performed. | Some information is stored on virtual servers sporadically (weekly, monthly) with human intervention. | Information is managed virtually, but cloud services are not used. | Basic cybersecurity technology (software) such as antivirus and firewalls is used. There is no expert personnel. |

| 3 (0.7) | Access control is performed for the company and some areas using classic systems and/or credentials. | All information is stored on virtual and/or physical servers frequently (hourly, daily) with human intervention. | Cloud services (Software: SaaS) are used to manage most of the information. | Advanced cybersecurity technology (software and hardware) such as MDR services, PKI, VPN, Proxies is used. There is no expert personnel. |

| 4 (1.0) | Access control is performed for the company and most areas using digital credentials. | All information is stored on physical local servers frequently (hourly, daily) automatically. | Private cloud services (infrastructure: IaaS, Platform: PaaS) are used to manage most of the information. | Advanced cybersecurity technology (software and hardware) such as blockchain is used, and expert personnel is available. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No decision-making techniques are applied. | There are no intelligent tools for decision-making. | There are no self-managed teams for decision-making. | AI and/or Machine Learning are not used in decision-making. |

| 2 (0.3) | Qualitative techniques are applied for single-criterion and/or multi-criteria decision-making. | Non-intelligent tools exist for making some decisions. | Self-managed teams exist for managing basic tasks. | Intelligent systems are used for some basic decision-making. |

| 3 (0.7) | Quantitative techniques are applied for single-criterion and/or multi-criteria decision-making. | Intelligent tools exist for making some decisions in some departments. | Self-managed teams with low independence and leadership exist in some departments for decision-making and managing tasks, projects, and programs. | AI and/or Machine Learning are used in basic decision-making and managing some tasks. |

| 4 (1.0) | Lean Manufacturing techniques are applied for multi-criteria decision-making. | Intelligent tools exist for making most decisions (financial, production, suppliers…) in most departments. | Self-managed teams exist in most departments for decision-making and managing tasks, projects, and programs. | AI and/or Machine Learning are used in advanced decision-making and managing tasks, projects, and programs. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No statistical techniques are used for making inferences. | No digital platform exists for statistical data processing and making inferences. | No connected digital platform exists for real-time data processing. | No Big Data Analytics technologies exist for making inferences. |

| 2 (0.3) | Some non-computer-assisted statistical technique is used for making inferences. | An external digital platform exists for making basic inferences. | A digital platform exists for processing asynchronous information. | Computer-assisted digital technologies are used for making inferences in some departments. |

| 3 (0.7) | Basic computer-assisted statistical techniques are used for making multiple inferences. | An external digital platform exists for statistical data processing and making inferences. | A connected internal and/or external digital platform exists for processing basic real-time information. | Small Data Analytics technologies exist for making inferences in some departments. |

| 4 (1.0) | Advanced computer-assisted statistical techniques are used for making multiple inferences. | An internal and/or external digital platform exists for advanced statistical data processing and making personalized inferences. | A connected internal digital platform exists for advanced processing of personalized real-time information. | Big Data and Data Mining technologies exist for making advanced inferences in most departments. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | There are no company process manuals. | There are no activities for knowledge dissemination. | No knowledge is made available to suppliers and customers. | There is no knowledge-based system in the company. |

| 2 (0.3) | Physical manuals exist for some internal and/or external company processes. | Sporadic activities take place for knowledge dissemination to specific personnel. | Some basic knowledge is made available to suppliers and/or internal customers upon request through traditional means. | An alternative system (not a knowledge-based system) exists for solving simple problems. |

| 3 (0.7) | Physical and digital manuals exist for most internal and/or external company processes. | Sporadic activities take place for knowledge dissemination aimed at all personnel. | Some operational or technical knowledge is made available to suppliers and customers (both external and internal) upon request via digital registration. | A knowledge-based system exists in the company for solving simple problems. |

| 4 (1.0) | Digital manuals exist for most internal and external company processes. | Regular activities take place for knowledge dissemination aimed at all personnel. | Operational, technical, and organizational knowledge is made available to suppliers and customers (both external and internal) upon request via digital registration. | A knowledge-based system exists in the company for solving complex problems. |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No traditional LM tool is used. | No traditional LM tool is used. | No modern LM tool is used. | No modern LM tool is used. |

| 2 (0.3) | Some traditional management tool that does not belong to LM is used. | Several traditional management tools that do not belong to LM are used. | Some modern management tool that does not belong to LM is used. | Several modern management tools that do not belong to LM are used. |

| 3 (0.7) | Some traditional LM tool is used sporadically in some departments. | Several traditional LM tools are used sporadically in some departments. | Some modern LM tool is used sporadically in some departments. | Several modern LM tools are used sporadically in some departments. |

| 4 (1.0) | Some traditional LM tool is used regularly in most departments. Expert personnel is available. | Several traditional LM tools are used regularly in most departments. Expert personnel is available. | Some modern LM tool is used regularly in most departments. Expert personnel is available. | Several modern LM tools are used regularly in most departments. Expert personnel is available. |

References

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0; acatech—National Academy of Science and Engineering: Munich, Germany, 2013. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios: A Literature Review. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and Developing Measures of Lean Production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World. Bus. Horiz. 2008, 352, 81–82. [Google Scholar] [CrossRef]

- Saad, S.M.; Bahadori, R.; Bhovar, C.; Zhang, H. Industry 4.0 and Lean Manufacturing—A Systematic Review of the State-of-the-Art Literature and Key Recommendations for Future Research. Int. J. Lean Six Sigma 2023. ahead of print. [Google Scholar] [CrossRef]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Kolberg, D.; Zühlke, D. Lean Automation Enabled by Industry 4.0 Technologies. IFAC-PapersOnLine 2015, 28, 1870–1875. [Google Scholar] [CrossRef]

- Narula, S.; Prakash, S.; Dwivedy, M.; Talwar, V.; Tiwari, S.P. Industry 4.0 Adoption Key Factors: An Empirical Study on Manufacturing Industry. J. Adv. Manag. Res. 2020, 17, 697–725. [Google Scholar] [CrossRef]

- Hughes, L.; Dwivedi, Y.K.; Rana, N.P.; Williams, M.D.; Raghavan, V. Perspectives on the Future of Manufacturing within the Industry 4.0 Era. Prod. Plan. Control 2022, 33, 138–158. [Google Scholar] [CrossRef]

- Vinodh, S.; Joy, D. Structural Equation Modelling of Lean Manufacturing Practices. Int. J. Prod. Res. 2012, 50, 1598–1607. [Google Scholar] [CrossRef]

- Patel, S.; Desai, D.A.; Narkhede, B.E.; Maddulety, K.; Raut, R. Lean Six Sigma: Literature Review and Implementation Roadmap for Manufacturing Industries. Int. J. Bus. Excell. 2019, 19, 447–472. [Google Scholar] [CrossRef]

- Snee, R.D. Lean Six Sigma—Getting Better All the Time. Int. J. Lean Six Sigma 2010, 1, 9–29. [Google Scholar] [CrossRef]

- Singh, M.; Rathi, R. A Structured Review of Lean Six Sigma in Various Industrial Sectors. Int. J. Lean Six Sigma 2019, 10, 622–664. [Google Scholar] [CrossRef]

- Antony, J. Six Sigma for Service Processes. Bus. Process Manag. J. 2006, 12, 234–248. [Google Scholar] [CrossRef]

- Chiarini, A.; Kumar, M. Lean Six Sigma and Industry 4.0 Integration for Operational Excellence: Evidence from Italian Manufacturing Companies. Prod. Plan. Control 2021, 32, 1084–1101. [Google Scholar] [CrossRef]

- Ben Slimane, S.; Coeurderoy, R.; Mhenni, H. Digital Transformation of Small and Medium Enterprises: A Systematic Literature Review and an Integrative Framework. Int. Stud. Manag. Organ. 2022, 52, 96–120. [Google Scholar] [CrossRef]

- Sommer, L.; Sommer, L. Industrial Revolution—Industry 4.0: Are German Manufacturing SMEs the First Victims of This Revolution? J. Ind. Eng. Manag. 2015, 8, 1512–1532. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The Industrial Management of SMEs in the Era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1372647. [Google Scholar] [CrossRef]

- Agostini, L.; Nosella, A. The Adoption of Industry 4.0 Technologies in SMEs: Results of an International Study. Manag. Decis. 2020, 58, 625–643. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune Favors the Prepared: How SMEs Approach Business Model Innovations in Industry 4.0. Technol. Forecast. Soc. Change 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Lepore, D.; Vecciolini, C.; Micozzi, A.; Spigarelli, F. Developing Technological Capabilities for Industry 4.0 Adoption: An Analysis of the Role of Inbound Open Innovation in Small and Medium-Sized Enterprises. Creat. Innov. Manag. 2023, 32, 249–265. [Google Scholar] [CrossRef]

- Rosário De Carvalho, G. Industry 4.0 for SME; Instituto Superior de Estatística e Gestão de Informação, Universidade Nova de Lisboa: Lisboa, Portugal, 2022. [Google Scholar]

- Addo-Tenkorang, R.; Møller, C.; Chen, K.L. Digital Transformation Roadmap for Danish SME Smart Factories: Benefits and Future Research. Commun. Comput. Inf. Sci. 2024, 2132, 41–60. [Google Scholar] [CrossRef]

- Roy, M.A.; Abdul-Nour, G.; Gamache, S. Implementation of an Industry 4.0 Strategy Adapted to Manufacturing SMEs: Simulation and Case Study. Sustainability 2023, 15, 15423. [Google Scholar] [CrossRef]

- Semeraro, C.; Alyousuf, N.; Kedir, N.I.; Lail, E.A. A Maturity Model for Evaluating the Impact of Industry 4.0 Technologies and Principles in SMEs. Manuf. Lett. 2023, 37, 61–65. [Google Scholar] [CrossRef]

- Mayer, P. Guidelines for Writing a Review Article; Zurich-Basel Plant Science Center: Zürich, Switzerland, 2009; Volume 82. [Google Scholar]

- Squires, J.E.; Estabrooks, C.A.; Gustavsson, P.; Wallin, L. Individual Determinants of Research Utilization by Nurses: A Systematic Review Update. Implement. Sci. 2011, 6, 1. [Google Scholar] [CrossRef]

- Denzin, N.K.; Lincoln, Y.S. The Sage Handbook of Qualitative Research [El Manual SAGE de Investigación Cualitativa]; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2004; 968p. [Google Scholar]

- Weng, J.; Wei, F.; Jaiswal, A.; Noche, B. A Review of Industry 4.0 on National Level and A Concept of Industry 4.0 Stages Based on Technical Level. In Proceedings of the 17th Annual International Conference on Distributed Computing in Sensor Systems, DCOS, Pafos, Cyprus, 14–16 July 2021; pp. 252–258. [Google Scholar] [CrossRef]

- Pacchini, A.P.T.; Lucato, W.C.; Facchini, F.; Mummolo, G. The Degree of Readiness for the Implementation of Industry 4.0. Comput. Ind. 2019, 113, 103125. [Google Scholar] [CrossRef]

- Ortt, R.; Stolwijk, C.; Punter, M. Implementing Industry 4.0: Assessing the Current State. J. Manuf. Technol. Manag. 2020, 31, 825–836. [Google Scholar] [CrossRef]

- Cifone, F.D.; Hoberg, K.; Holweg, M.; Staudacher, A.P. ‘Lean 4.0’: How Can Digital Technologies Support Lean Practices? Int. J. Prod. Econ. 2021, 241, 108258. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A Critical Review of Smart Manufacturing & Industry 4.0 Maturity Models: Implications for Small and Medium-Sized Enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- De Carolis, A.; Macchi, M.; Negri, E.; Terzi, S. A Maturity Model for Assessing the Digital Readiness of Manufacturing Companies. In Proceedings of the IFIP Advances in Information and Communication Technology, Hamburg, Germany, 3–7 September 2017; Volume 513. [Google Scholar]

- Grufman, N.; Lyons, S.; Sneiders, E. Exploring Readiness of SMEs for Industry 4.0. Complex Syst. Inform. Model. Q. 2020, 2020, 54–86. [Google Scholar] [CrossRef]

- Ávila-Gutiérrez, M.J.; Córdoba-Roldán, A.; Morato-Huerta, P.; Lama-Ruiz, J.R. Revisión Sistemática de Lean 4.0 Para El Desarrollo de Auditorías En Las PYMES Andaluzas. In Proceedings of the 27th International Congress on Project Management and Engineering, Donostia-San Sebastián, Spain, 10–13 July 2023; pp. 3–14. [Google Scholar] [CrossRef]

- Liker, J. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer, 2nd ed.; Taylor & Francis: Abingdon, UK, 2021. [Google Scholar]

- Haddud, A.; DeSouza, A.; Khare, A.; Lee, H. Examining Potential Benefits and Challenges Associated with the Internet of Things Integration in Supply Chains. J. Manuf. Technol. Manag. 2017, 28, 1055–1085. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 Implies Lean Manufacturing: Research Activities in Industry 4.0 Function as Enablers for Lean Manufacturing. J. Ind. Eng. Manag. (JIEM) 2016, 9, 811–833. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- UNE-EN ISO 19011; Asociación Española de Normalización UNE-EN ISO 19011 Directrices Para La Auditoría de Los Sistemas de Gestión. Asociación Española de Normalización: Madrid, Spain, 2018.

- Sepeng, T.D.; Lourens, A.; Van der Merwe, K.; Gerber, R. Certification Bodies’ Interpretation and Application of the ISO 19011 Audit Process Guidelines. Int. J. Qual. Reliab. Manag. 2024, 42, 339–355. [Google Scholar] [CrossRef]

- Abuazza, O.A.; Labib, A.; Savage, B.M. Development of a Conceptual Auditing Framework by Integrating ISO 9001 Principles within Auditing. Int. J. Qual. Reliab. Manag. 2020, 37, 411–427. [Google Scholar] [CrossRef]

- UNE-EN ISO 9001; Asociación Española de Normalización UNE-EN ISO 9001: Sistemas de Gestión de La Calidad. Asociación Española de Normalización: Madrid, Spain, 2015.

- Gitlow, H.S.; Melnyck, R.J.; Levine, D.M. A Guide to Six Sigma and Process Improvement for Practitioners and Students: Foundations, DMAIC, Tools, Cases, and Certification; Pearson FT Press: Hoboken, NJ, USA, 2015; ISBN 0133925366. [Google Scholar]

- Tjahjono, B.; Ball, P.; Vitanov, V.I.; Scorzafave, C.; Nogueira, J.; Calleja, J.; Minguet, M.; Narasimha, L.; Rivas, A.; Srivastava, A.; et al. Six Sigma: A Literature Review. Int. J. Lean Six Sigma 2010, 1, 216–233. [Google Scholar] [CrossRef]

- Carter, D.E.; Baker, B.S. Concurrent Engineering: The Product Development Environment for the 1990s; Addison-Wesley: Boston, MA, USA, 1992; ISBN 0201563495. [Google Scholar]

- Sajid, M.; Wasim, A.; Hussain, S.; Raza, M.H.; Jahanzaib, M. Application of Set-Based Concurrent Engineering Methodology to the Development of Cost Modeling System for Metal Casting Process. Syst. Eng. 2023, 26, 162–176. [Google Scholar] [CrossRef]

- Trubetskaya, A.; McDermott, O.; Durand, P.; Powell, D.J. Improving Value Chain Data Lifecycle Management Utilising Design for Lean Six Sigma Methods. TQM J. 2024, 36, 136–154. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Giglio, R.; van Dun, D.H. Industry 4.0 Adoption as a Moderator of the Impact of Lean Production Practices on Operational Performance Improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Likert, R. A Technique for the Measurement of Attitudes. Arch. Psychol. 1932, 140, 55. [Google Scholar]

- Joshi, A.; Kale, S.; Chandel, S.; Pal, D. Likert Scale: Explored and Explained. Br. J. Appl. Sci. Technol. 2015, 7, 396. [Google Scholar] [CrossRef]

- Allen, I.E.; Seaman, C.A. Likert Scales and Data Analyses. Qual. Prog. 2007, 40, 64–65. [Google Scholar]

- Al-ansari, H.; Mahdi, P. Assess Quality Level of the Final Product by Using Demerit System: A Case Study in One Industry of General Company for Electronic Industries. Res. Invent. Int. J. Eng. Sci. 2016, 6, 2319–6483. [Google Scholar]

- Brito, M.F.; Ramos, A.L.; Carneiro, P.; Gonçalves, M.A. A Continuous Improvement Assessment Tool, Considering Lean, Safety and Ergonomics. Int. J. Lean Six Sigma 2020, 11, 879–902. [Google Scholar] [CrossRef]

- Starzyńska, B.; Bryke, M.; Diakun, J. Human Lean Green Method—A New Approach toward Auditing Manufacturing & Service Companies. Sustainability 2021, 13, 10789. [Google Scholar] [CrossRef]

- Hussain, D.; Figueiredo, M.C. Improving the Time-Based Performance of the Preparatory Stage in Textile Manufacturing Process with Value Stream Mapping. Bus. Process Manag. J. 2023, 29, 801–837. [Google Scholar] [CrossRef]

- Gupta, S.; Jain, S.K. An Application of 5S Concept to Organize the Workplace at a Scientific Instruments Manufacturing Company. Int. J. Lean Six Sigma 2015, 6, 73–88. [Google Scholar] [CrossRef]

| Dimensions | Key Factors |

|---|---|

| Principles | Human Participation Logistics Decentralized Systems |

| Self-driven | Automation Self-Regulation Quality Control |

| Information | Ubiquity Security Decision Making Inferences |

| Integration | Knowledge Management Continuous Improvement |

| No. | Question | Response |

|---|---|---|

| Q25 | Parameters have been determined to measure aspects of production. | N/A 1 2 3 4 |

| Q26 | Sensors exist to monitor parts of the production. | N/A 1 2 3 4 |

| Q27 | Digital interfaces and sensors exist on most machines. | N/A 1 2 3 4 |

| Q28 | Augmented reality devices are used to visualize real-time information. | N/A 1 2 3 4 |

| Level 1 | Level 2 | Level 3 | Level 4 | |

|---|---|---|---|---|

| Qualitative | Strongly disagree | Disagree | Agree | Strongly agree |

| Quantitative | 0.0 | 0.3 | 0.7 | 1.0 |

| Levels | Readiness | Maturity: Start-Up | Maturity: In-Transition | Maturity: Advanced |

|---|---|---|---|---|

| 1 (0.0) | No parameters are determined to measure production aspects. | No sensors exist to monitor any part of production. | No digital interfaces or sensors exist in the workstations. | Augmented reality devices are not used to visualize real-time information. |

| 2 (0.3) | Some basic parameters (input, output) are determined for production aspects | Some sensors exist to monitor parts of production. | Digital visualization and/or data interaction interfaces exist in some workstations. | Classical devices are used to visualize asynchronous information. |

| 3 (0.7) | Some parameters are determined to measure some aspects of production (input, processes, output). | Sensors exist to monitor several production lines. | Digital visualization and/or data interaction interfaces and sensors exist in some workstations. | Digital devices (screens, wearables, etc.) are used to visualize real-time information. |

| 4 (1.0) | Several parameters are determined to measure most aspects of production (input, processes, output). | Smart sensors of various types exist to monitor most production lines and centers. | Digital visualization and interaction interfaces and smart sensors exist in most machines. | Augmented reality devices are used to visualize real-time information. |

| Criterion | Value | Percentage |

|---|---|---|

| Strongly disagree | 1 | 0% |

| Disagree | 2 | 30% |

| Agree | 3 | 70% |

| Strongly agree | 4 | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ávila-Gutiérrez, M.J.; Córdoba-Roldán, A.; Morato-Huerta, P.; Lama-Ruiz, J.R. Modernizing Small and Medium-Sized Enterprises: A Lean Audit Model for Digital Integration. Systems 2025, 13, 304. https://doi.org/10.3390/systems13040304

Ávila-Gutiérrez MJ, Córdoba-Roldán A, Morato-Huerta P, Lama-Ruiz JR. Modernizing Small and Medium-Sized Enterprises: A Lean Audit Model for Digital Integration. Systems. 2025; 13(4):304. https://doi.org/10.3390/systems13040304

Chicago/Turabian StyleÁvila-Gutiérrez, María Jesús, Antonio Córdoba-Roldán, Pablo Morato-Huerta, and Juan Ramón Lama-Ruiz. 2025. "Modernizing Small and Medium-Sized Enterprises: A Lean Audit Model for Digital Integration" Systems 13, no. 4: 304. https://doi.org/10.3390/systems13040304

APA StyleÁvila-Gutiérrez, M. J., Córdoba-Roldán, A., Morato-Huerta, P., & Lama-Ruiz, J. R. (2025). Modernizing Small and Medium-Sized Enterprises: A Lean Audit Model for Digital Integration. Systems, 13(4), 304. https://doi.org/10.3390/systems13040304