System Modelling and Analysis to Support Economic Assessment of Product-Service Systems †

Abstract

:1. Introduction

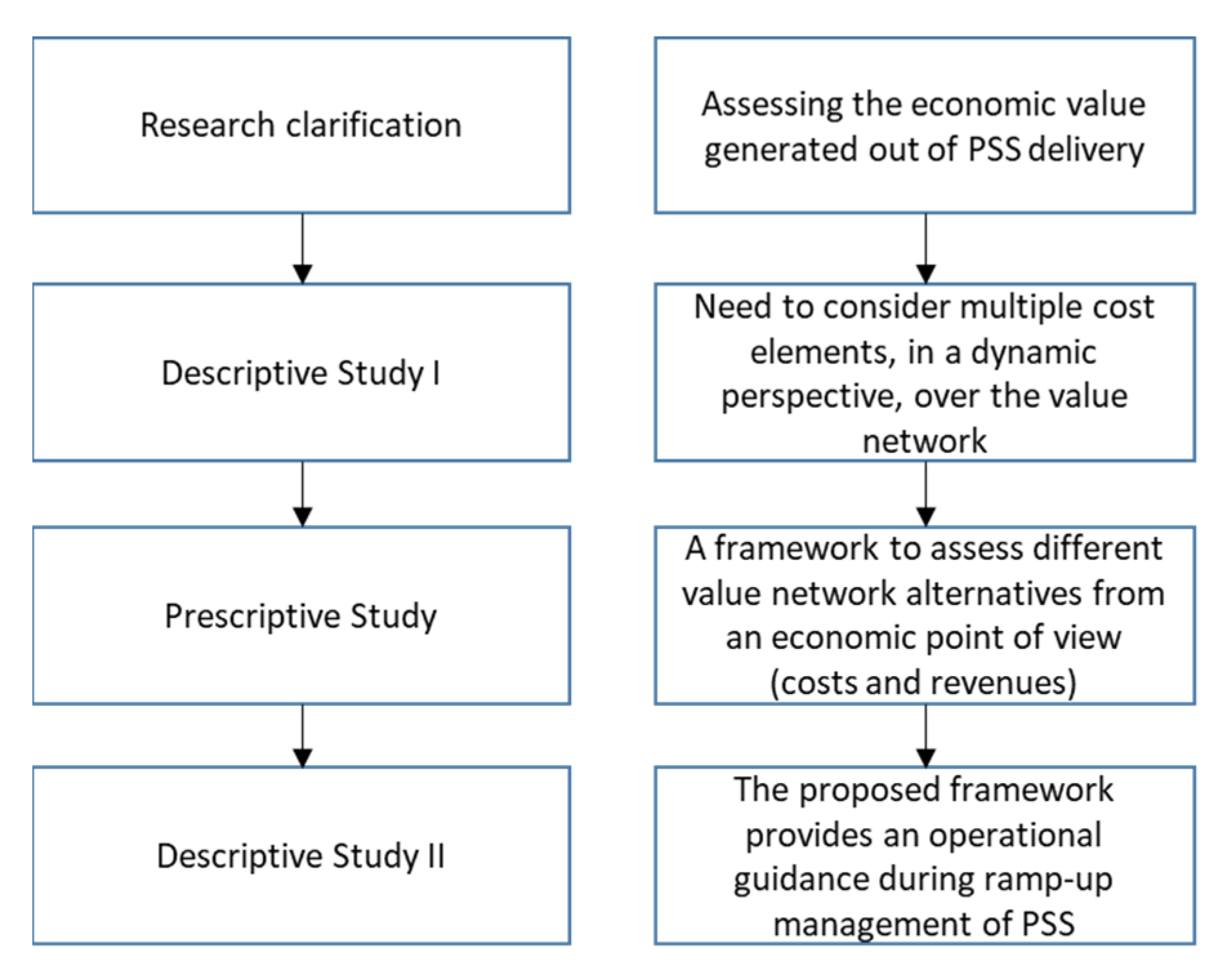

2. Methodology

3. Literature Review

3.1. Multi-Actor and Life Cycle Dimensions in PSS Assessment

3.2. Economic Assessment and Costing Models for PSS

- Comprehensiveness: PSS costing methodologies should involve multiple cost elements from a dynamic perspective (activity-oriented).

- Life cycle: The scope of PSS costing should be inter-temporal, considering a whole offer lifecycle.

- Collaboration: PSS costing should consider the collaborative relationships taking place within the actor value network across the offer lifecycle.

4. A Method for PSS Economic Assessment

4.1. Framework Design

4.2. System Modelling

4.3. System Analysis

4.4. Implementation

5. Case Study

5.1. Overview and Scenario Definition

5.2. Simulation Setting and Economic Results

5.3. Identification of Economic Drivers

6. Discussion and Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beuren, F.H.; Ferreira, M.G.G.; Miguel, P.A.C. Product-service systems: A literature review on integrated products and services. J. Clean. Prod. 2013, 47, 222–231. [Google Scholar] [CrossRef]

- Goedkoop, M.J.; van Halen, C.J.G.; Riele, H.R.M.; Rommens, P.J.M. Product Service Systems, Ecological And Economic Basics. Report for Dutch Ministries of Environment (Vrom) And Economic Affairs. 1999, pp. 1–122. Available online: https://simapro.com/wp-content/uploads/2016/05/Product-Service-Systems-main-report.pdf (accessed on 20 November 2020).

- Cavalieri, S.; Pezzotta, G. Product–Service Systems Engineering: State of the art and research challenges. Comput. Ind. 2012, 63, 278–288. [Google Scholar] [CrossRef]

- Aurich, J.; Mannweiler, C.; Schweitzer, E. How to design and offer services successfully. CIRP J. Manuf. Sci. Technol. 2010, 2, 136–143. [Google Scholar] [CrossRef]

- Becker, J.; Beverungen, D.; Knackstedt, R. The challenge of conceptual modeling for product–service systems: Status-quo and perspectives for reference models and modeling languages. Inf. Syst. e-Bus. Manag. 2009, 8, 33–66. [Google Scholar] [CrossRef]

- Geng, X.; Chu, X.; Xue, D.; Zhang, Z. A systematic decision-making approach for the optimal product–service system planning. Expert Syst. Appl. 2011, 38, 11849–11858. [Google Scholar] [CrossRef]

- Bertoni, A.; Bertoni, M.; Isaksson, O. Value visualization in Product Service Systems preliminary design. J. Clean. Prod. 2013, 53, 103–117. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez, A.E.; Pezzotta, G.; Pinto, R.; Romero, D. A comprehensive description of the Product-Service Systems’ cost estimation process: An integrative review. Int. J. Prod. Econ. 2020, 221, 107481. [Google Scholar] [CrossRef]

- Meier, H.; Roy, R.; Seliger, G. Industrial Product-Service Systems—IPS 2. CIRP Ann. 2010, 59, 607–627. [Google Scholar] [CrossRef]

- Medini, K.; Boucher, X. Configuration of Product-Service Systems value networks—Evidence from an innovative sector for sludge treatment. CIRP J. Manuf. Sci. Technol. 2016, 12, 14–24. [Google Scholar] [CrossRef]

- Vezzoli, C.; Kohtala, C.; Srinivasan, A. Product-Service System Design for Sustainability; Routledge: Abingdon-on-Thames, UK, 2014. [Google Scholar]

- Chen, Y.-T.; Chiu, M.-C. A case-based method for service-oriented value chain and sustainable network design. Adv. Eng. Inform. 2015, 29, 269–294. [Google Scholar] [CrossRef]

- Baldassarre, B.; Calabretta, G.; Bocken, N.; Jaskiewicz, T. Bridging sustainable business model innovation and user-driven innovation: A process for sustainable value proposition design. J. Clean. Prod. 2017, 147, 175–186. [Google Scholar] [CrossRef] [Green Version]

- Bertoni, A.; Bertoni, M.; Panarotto, M.; Johansson, C.; Larsson, A. Value-driven product service systems development: Methods and industrial applications. CIRP J. Manuf. Sci. Technol. 2016, 15, 42–55. [Google Scholar] [CrossRef] [Green Version]

- Hagen, S.; Schoormann, T.; Jannaber, S.; Knackstedt, R.; Thomas, O. Towards an Integrated Approach for Modelling Product- ServiceSystems: Status Quo and Future Challenges. In Workshops der INFORMATIK 2018-Architekturen, Prozesse, Sicherheit und Nachhaltigkeit; Köllen Druck+ Verlag GmbH: Bonn, Germany, 2018; pp. 59–71. [Google Scholar]

- Blessing, L.T.M.; Chakrabarti, A. DRM, a Design Research Methodology; Springer: London, UK, 2009. [Google Scholar]

- Peffers, K.; Tuunanen, T.; Rothenberger, M.A.; Chatterjee, S. A Design Science Research Methodology for Information Systems Research A Design Science Research Methodology for Information Systems Research. MIS Q. 2014, 1222. [Google Scholar] [CrossRef]

- Datta, P.P.; Roy, R. Cost modelling techniques for availability type service support contracts: A literature review and empirical study. CIRP J. Manuf. Sci. Technol. 2010, 3, 142–157. [Google Scholar] [CrossRef] [Green Version]

- Pawar, K.S.; Beltagui, A.; Riedel, J.C. The PSO triangle: Designing product, service and organisation to create value. Int. J. Oper. Prod. Manag. 2009, 29, 468–493. [Google Scholar] [CrossRef]

- McAloone, T.C. Teaching and Implementation Models for Sustainable PSS Development. Motivations, activities and experiences. In Sustainable Consumption and Production: Opportunities and Threats; Sustainable Consumption Research Exchange (SCORE!) Network: Wuppertal, Germany, 2006; pp. 23–25. [Google Scholar]

- Brax, S.A.; Visintin, F. Meta-model of servitization: The integrative profiling approach. Ind. Mark. Manag. 2017, 60, 17–32. [Google Scholar] [CrossRef]

- Polova, O.; Thomas, C. How to perform collaborative servitization innovation projects: The role of servitization maturity. Ind. Mark. Manag. 2020, 90, 231–251. [Google Scholar] [CrossRef]

- Bey, N.; McAloone, T.C. From LCA to PSS–Making leaps towards sustainability by applying product/service-system thinking in product development. In Proceedings of the 13th CIRP International Conference Life Cycle Engineering LCE2006-Towards a Closed Loop Econ, 13, Leuven, Belgium, 31 May–2 June 2006; pp. 571–576. [Google Scholar]

- Bertoni, A.; Bertoni, M. PSS cost engineering: A model-based approach for concept design. CIRP J. Manuf. Sci. Technol. 2020, 29, 176–190. [Google Scholar] [CrossRef] [Green Version]

- Settanni, E.; Newnes, L.B.; Thenent, N.E.; Parry, G.; Goh, Y.M. A through-life costing methodology for use in product–service-systems. Int. J. Prod. Econ. 2014, 153, 161–177. [Google Scholar] [CrossRef] [Green Version]

- Azevedo, A.; Sholiha, M. Innovative Costing System Framework in Industrial Product-service System Environment. Procedia Manuf. 2015, 4, 224–230. [Google Scholar] [CrossRef] [Green Version]

- Sakao, T.; Lindahl, M. A method to improve integrated product service offerings based on life cycle costing. CIRP Ann. 2015, 64, 33–36. [Google Scholar] [CrossRef] [Green Version]

- Medini, K.; Boucher, X.; Peillon, S.; Vaillant, H. Economic Assessment of PSS Value Networks—An Algorithmic Approach. In Proceedings of the IFIP International Conference on Advances in Production Management Systems (APMS), Seoul, Korea, 26–30 August 2018; pp. 141–149. [Google Scholar] [CrossRef]

- Murillo, C.; Boucher, X.; Medini, K.; Gonzalez-feliu, J. Simulation-based approach to apply uncertainty evaluation framework for PSS economic models. In Proceedings of the 11th CIRP Conference on Industrial Product-Service Systems (CIRP IPS2 2019), Hong Kong, China, 29–31 May 2019; pp. 29–31. [Google Scholar]

- Kim, K.-J.; Lim, C.-H.; Heo, J.-Y.; Lee, D.-H.; Hong, Y.-S.; Park, K. An evaluation scheme for product–service system models: Development of evaluation criteria and case studies. Serv. Bus. 2015, 10, 507–530. [Google Scholar] [CrossRef]

- Sholihah, M.; Mitake, Y.; Nakada, T.; Shimomura, Y. Innovative design method for a valuable product-service system: Concretizing multi-stakeholder requirements. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strat. Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Kambanou, M.L.; Lindahl, M. A Literature Review of Life Cycle Costing in the Product-Service System Context. Procedia CIRP 2016, 47, 186–191. [Google Scholar] [CrossRef] [Green Version]

- Estrada, A.; Romero, D. Towards a Cost Engineering Method for Product-Service Systems Based on a System Cost Uncertainty Analysis. Procedia CIRP 2016, 47, 84–89. [Google Scholar] [CrossRef] [Green Version]

- Mourtzis, D.; Doukas, M.; Fotia, S. Classification and Mapping of PSS Evaluation Approaches. IFAC-PapersOnLine 2016, 49, 1555–1560. [Google Scholar] [CrossRef]

- Shen, J.; Erkoyuncu, J.A.; Roy, R.; Wu, B. A framework for cost evaluation in product service system configuration. Int. J. Prod. Res. 2017, 55, 6120–6144. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Lee, J. Optimal Cost Estimation for Improvement of Product Design. Int. J. Ind. Eng. 2011, 18, 232–243. [Google Scholar]

- Sebokwiki.org. SEboK: Guide to the Systems Engineering Body of Knowledge. 2020. Available online: www.sebokwiki.org/wiki/Guide_to_the_Systems_Engineering_Body_of_Knowledge_(SEBoK) (accessed on 20 November 2020).

- Lugnet, J.; Ericson, Å.; Larsson, A. Design of Product–Service Systems: Toward an Updated Discourse. Systems 2020, 8, 45. [Google Scholar] [CrossRef]

- Muller, G. System Modeling and Analysis—A Practical Approach; University of South-Eastern Norway-NISE: Kongsberg, Norway, 2013; Volume 1, p. 128. [Google Scholar]

- Medini, K.; Pierné, A.; Erkoyuncu, J.A.; Cornet, C. A Model for Cost-Benefit Analysis of Production Ramp-up Strategies. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Novi Sad, Serbia, 30 August–3 September 2020. [Google Scholar]

| Actors | Product Oriented PSS | Use Oriented PSS | Result Oriented PSS |

|---|---|---|---|

| Solution provider | Sells the robot and services to Customer | Provides the robot and services on an availability basis | Takes over the cleaning of Customer fridges |

| Battery provider | Sells the battery system to Solution provider | Sells the battery system to Solution provider | Sells the battery system to Solution provider |

| Customer | Purchases and uses the robot for cleaning the fridges | Purchases and uses the robot for cleaning the fridges | Pays for the cleaning service |

| Service Group | Unit Cost Estimates (EUR) |

|---|---|

| Customer co-design | 700 |

| Installation services | 1200 |

| Equipment cleaning | 400 |

| Maintenance | 900 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medini, K.; Peillon, S.; Orellano, M.; Wiesner, S.; Liu, A. System Modelling and Analysis to Support Economic Assessment of Product-Service Systems. Systems 2021, 9, 6. https://doi.org/10.3390/systems9010006

Medini K, Peillon S, Orellano M, Wiesner S, Liu A. System Modelling and Analysis to Support Economic Assessment of Product-Service Systems. Systems. 2021; 9(1):6. https://doi.org/10.3390/systems9010006

Chicago/Turabian StyleMedini, Khaled, Sophie Peillon, Martha Orellano, Stefan Wiesner, and Ang Liu. 2021. "System Modelling and Analysis to Support Economic Assessment of Product-Service Systems" Systems 9, no. 1: 6. https://doi.org/10.3390/systems9010006

APA StyleMedini, K., Peillon, S., Orellano, M., Wiesner, S., & Liu, A. (2021). System Modelling and Analysis to Support Economic Assessment of Product-Service Systems. Systems, 9(1), 6. https://doi.org/10.3390/systems9010006