The Emerging Role of Plant-Based Building Materials in the Construction Industry—A Bibliometric Analysis

Abstract

:1. Introduction

- What kind of research is being conducted worldwide regarding green and biobased building materials, and what current trends are prevailing?

- What are the most studied biobased—primarily plant-based—raw materials?

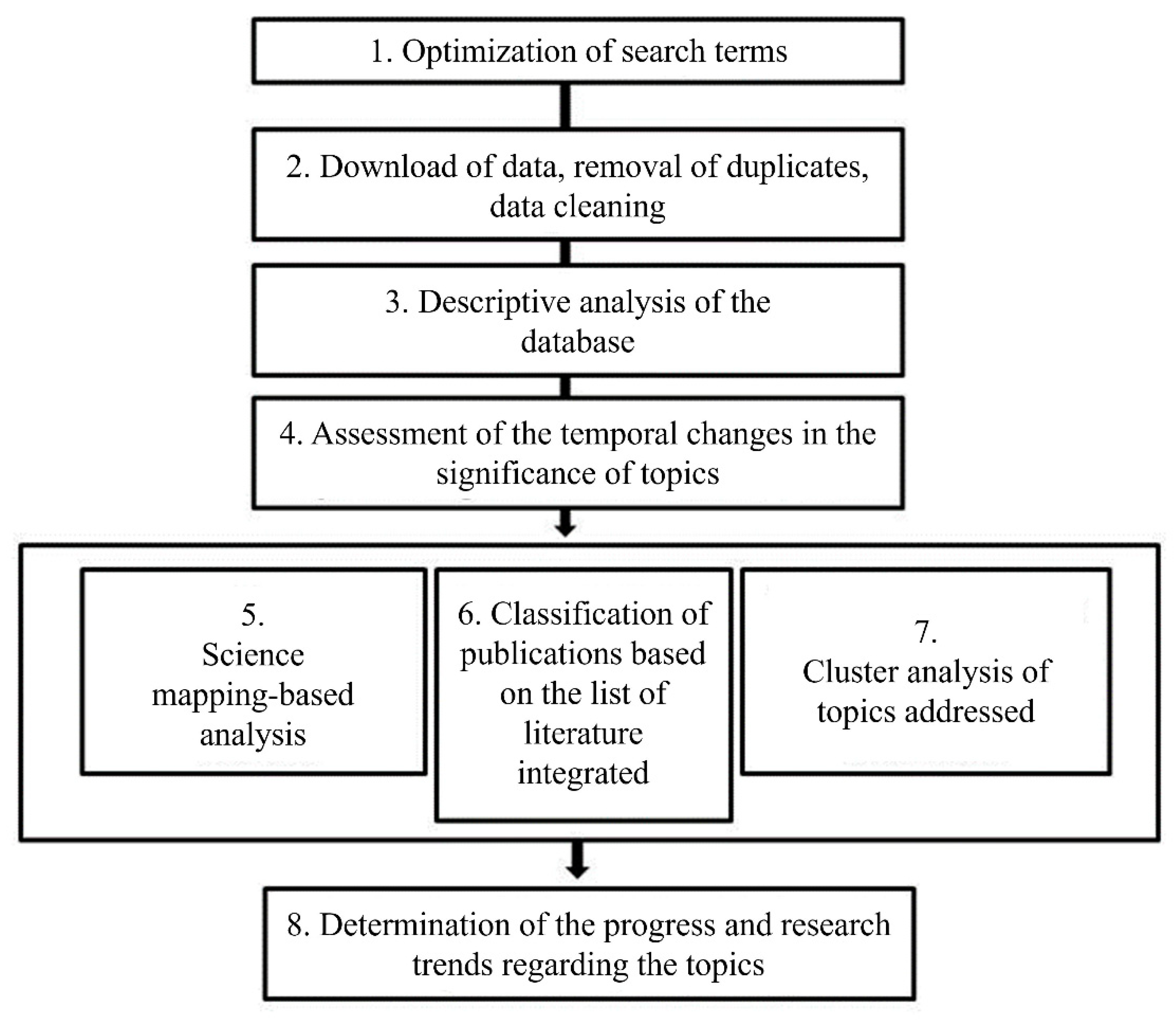

2. Material and Methods

3. Results and Discussion

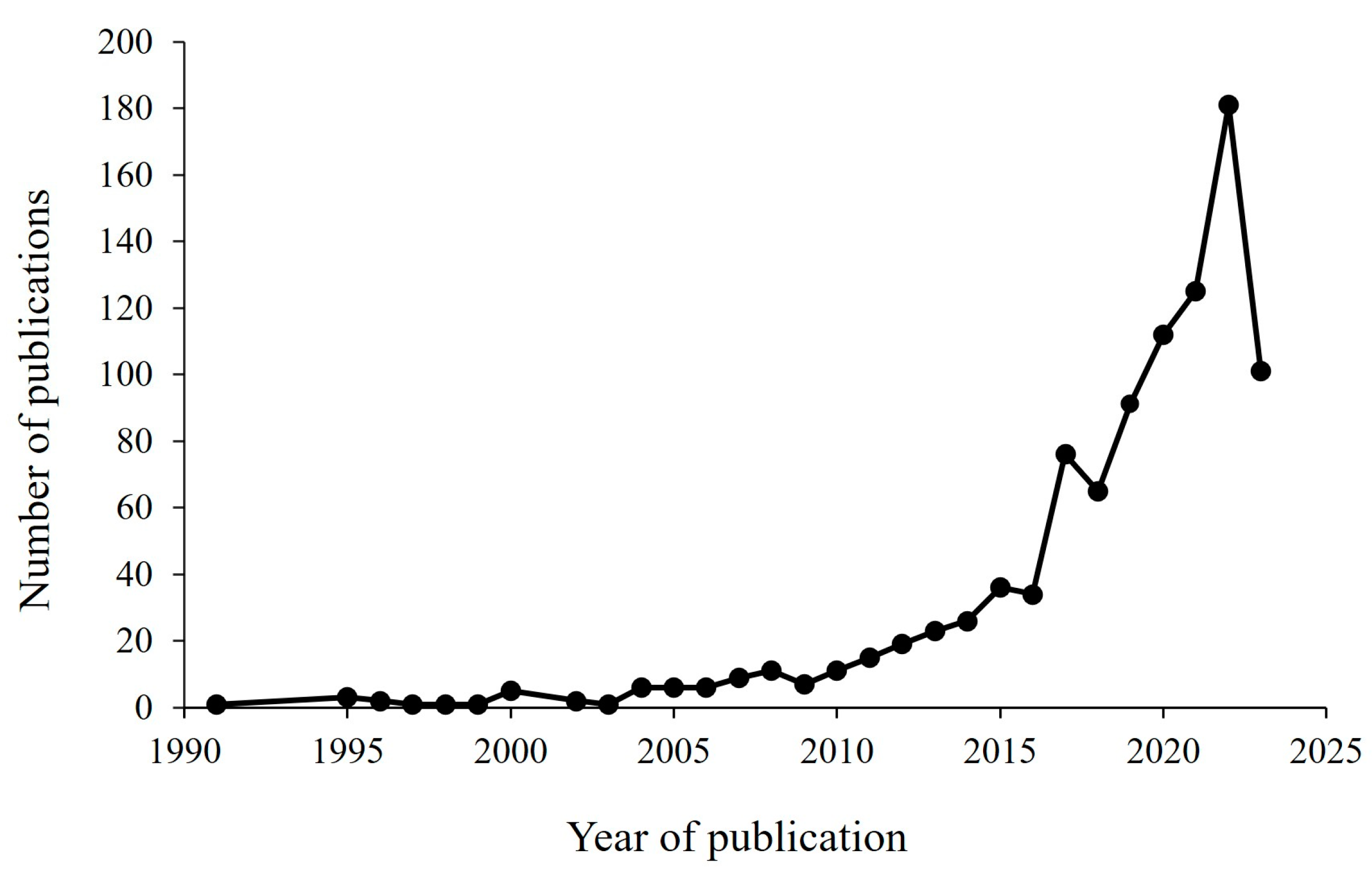

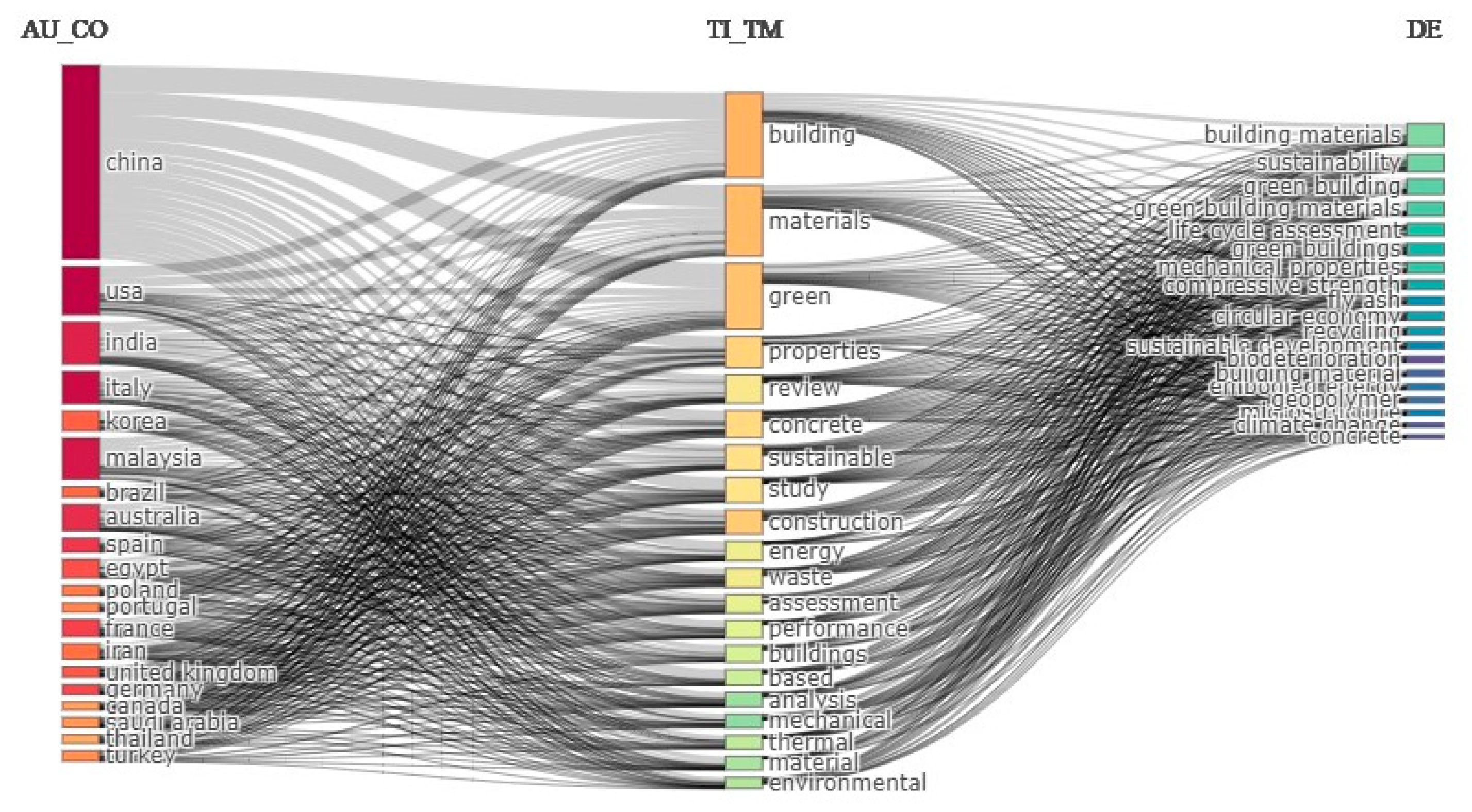

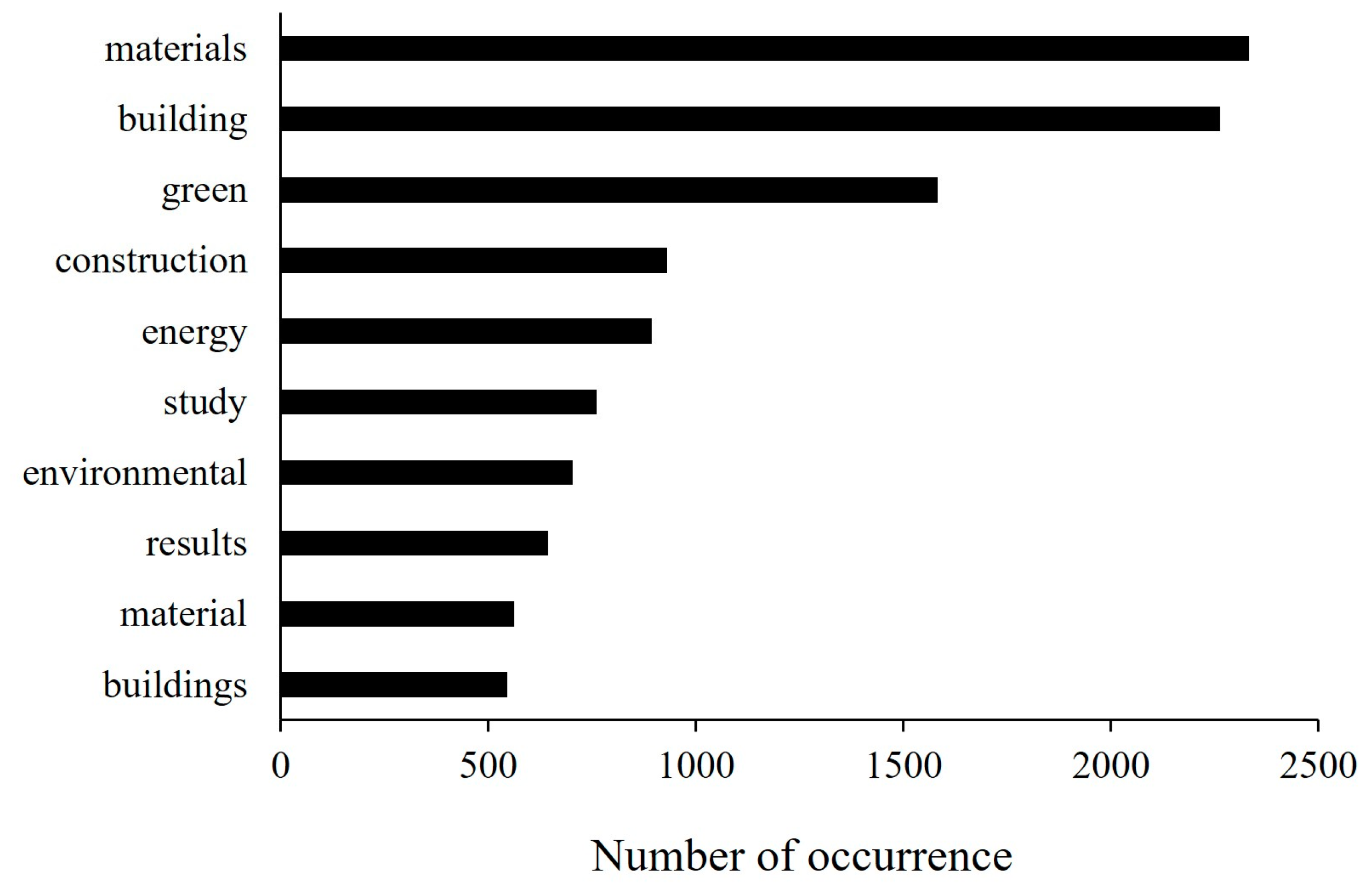

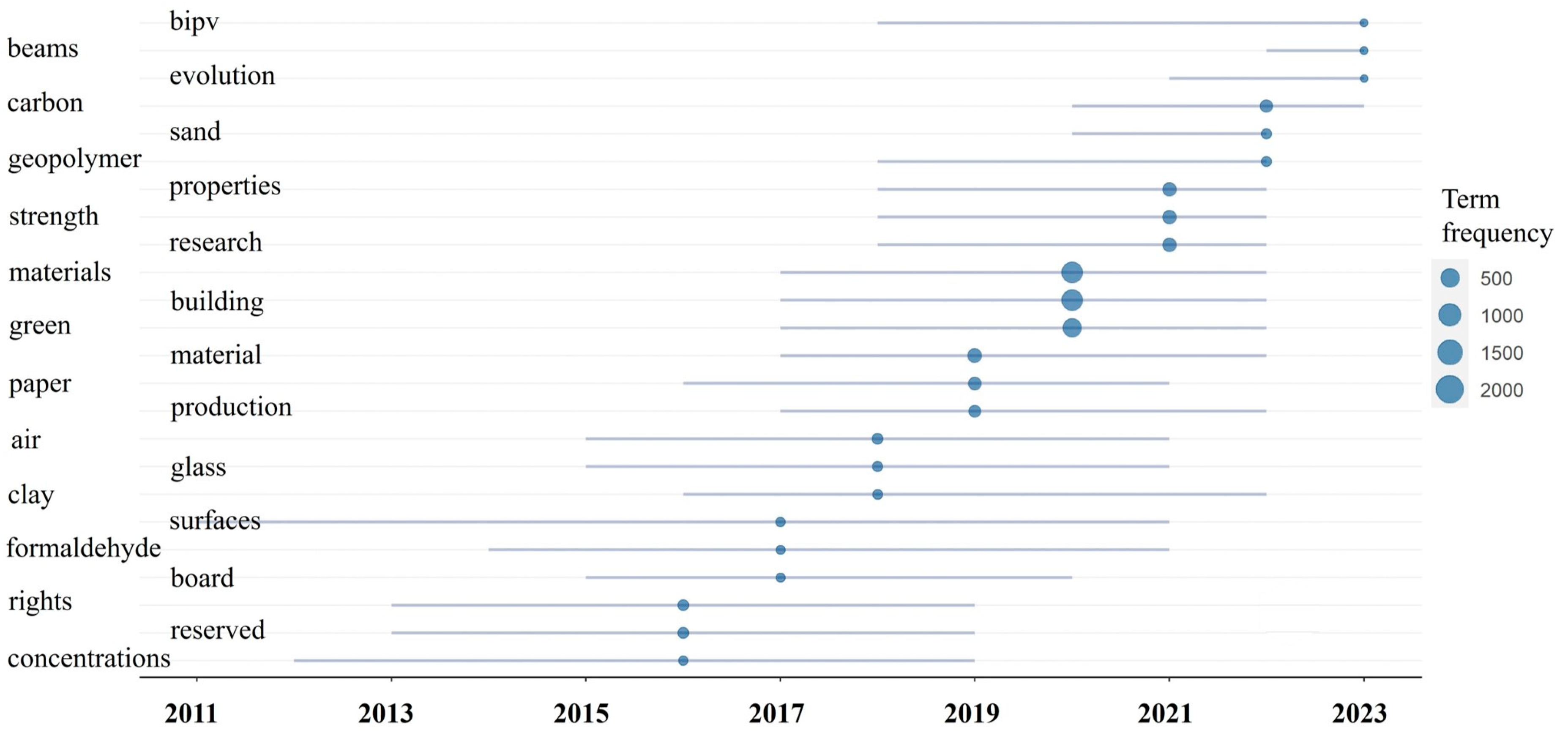

3.1. Green and Biobased Building Materials in the Literature

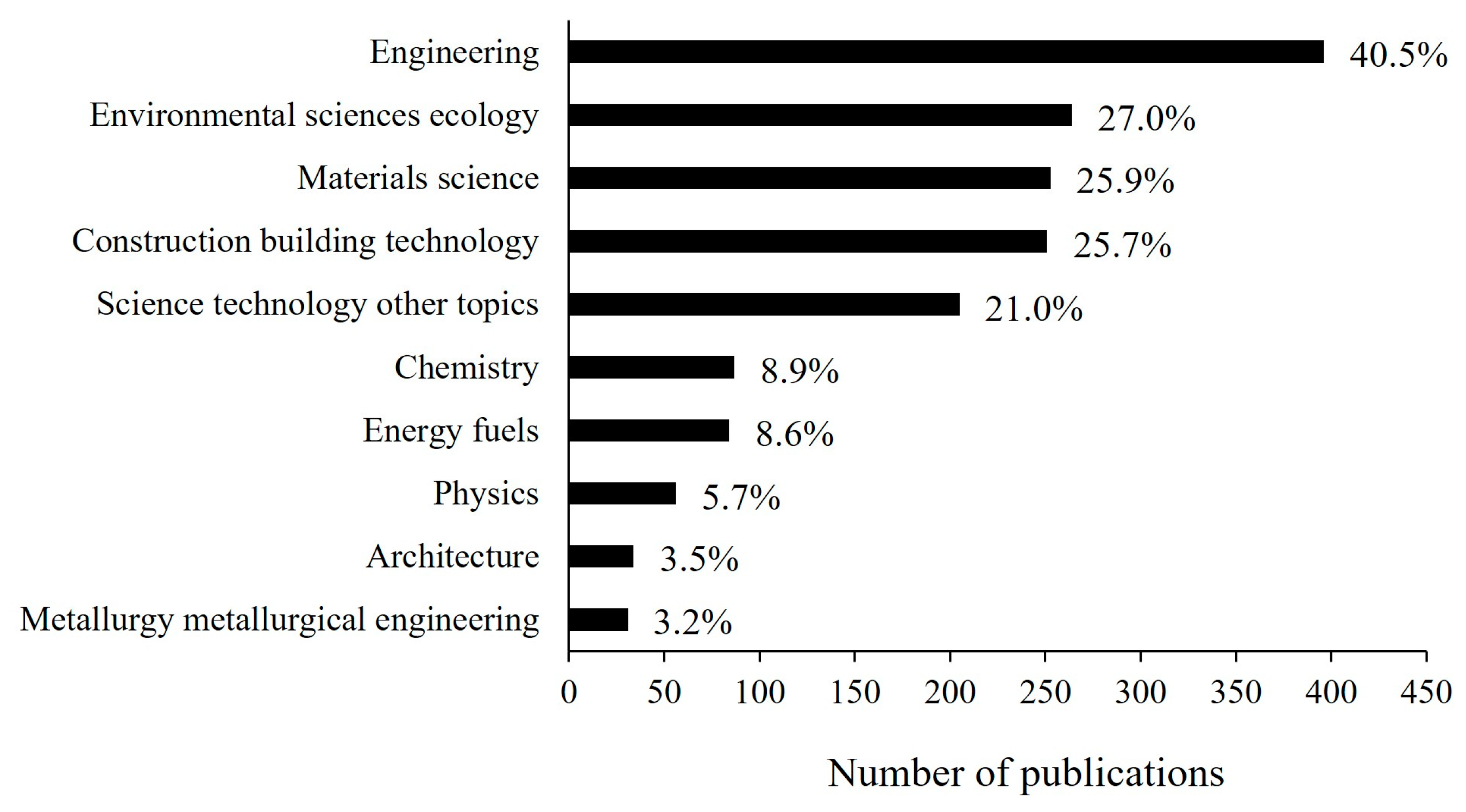

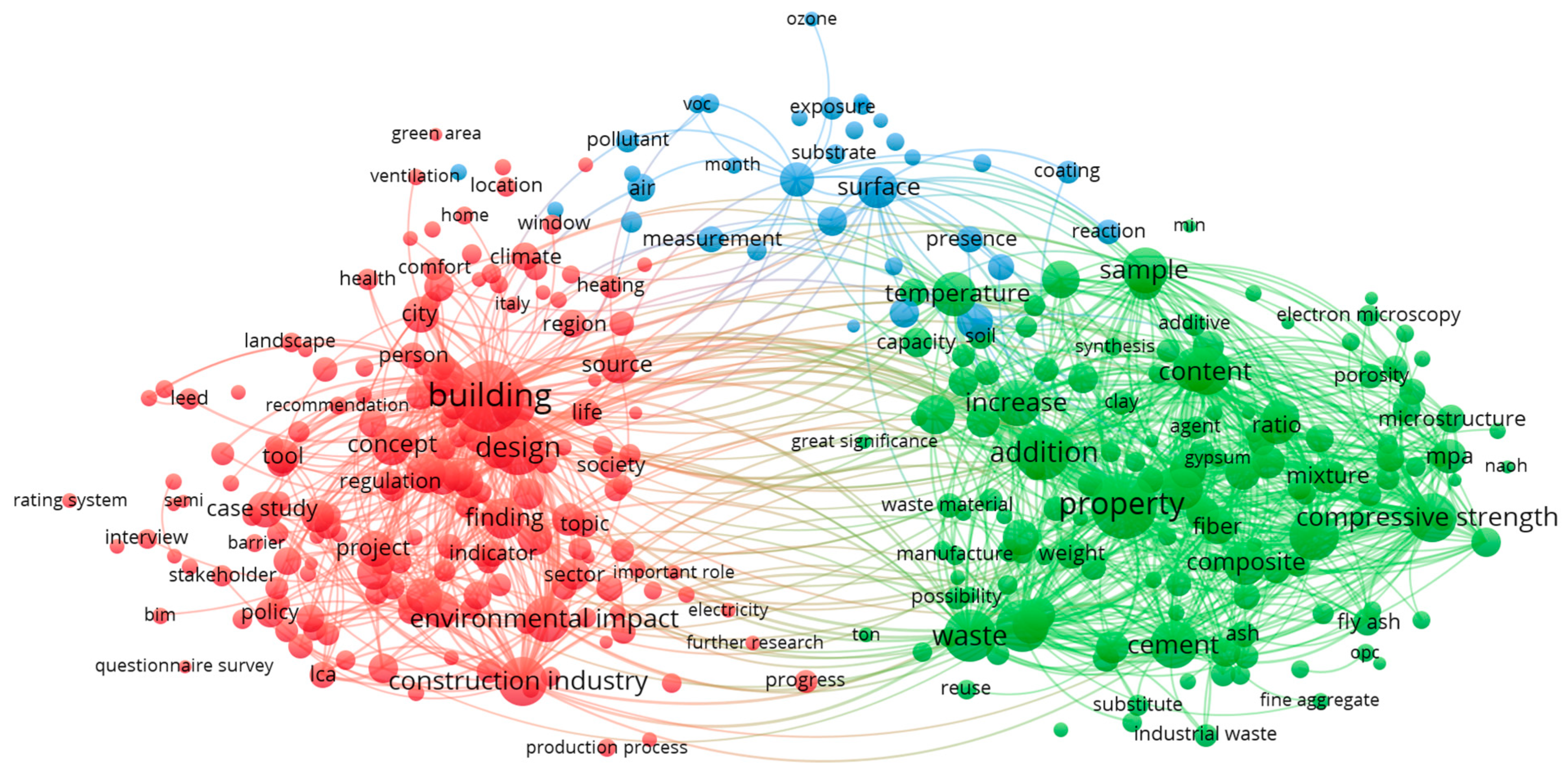

3.2. The Context of Green and Biobased Building Materials

3.3. Plant-Based Resources for a Sustainable Construction Industry

- (a)

- A significant part of research involves utilizing biological resources that differ from their original, widely known nature. These methods try to exploit the specific properties (e.g., tensile strength, absorbency, porosity) developed in nature over thousands of years, by which it becomes possible to create entirely new biobased or natural construction materials that were not used before. Some of these have similar or better characteristics than existing building materials. Biobased transparent wood, for example, is a biocomposite that combines a porous wood reinforcement with a polymer matrix phase [36]. According to Montanari et al. [37], the heat storage function of this material contributes to reducing energy consumption in buildings, and its transparency contributes to the reduction in artificial lighting. Researchers have achieved similarly outstanding results with cellulose, which is found in large quantities in the cell walls of plants. In addition to its importance in the construction industry, it is an excellent substitute for petroleum-synthesized plastics [38,39].

- (b)

- Another aspect is research that handles biological resources as aggregates. While developing green building materials for such purposes, additives and aggregates of natural origin with lower environmental impact are added to the base composites, thus replacing the original aggregate with a higher environmental impact. For example, composites made from hemp are characterized by low production costs, adequate insulation performance and vapor permeability, and low thermal conductivity [40,41]. Further, much research exists on plant fibers’ role in improving composites’ mechanical properties. According to Ramamoorthy et al. [42], plant fibers can be classified into different groups: straw, seed, bast, wood, grass, and leaf. These are particularly important in construction research to increase reinforced concrete structures’ compressive and flexural strength. Missio et al. [43] highlight that foamed green and sustainable foams made using nanocellulose are stronger, lighter, and fire resistant, have better compressive strength, and are less wettable than formaldehyde crosslinked foams. Researchers also reported that it is possible to develop lightweight cementitious products with lignocellulose of reed and coconut, which improve mechanical properties, such as insulation performance. At the same time, the panels designed in this way also showed better resistance to wet environments [44]. Sapuan et al. [45] highlighted that banana fiber improves the structure of polyester tar.

- (c)

- A leading research direction focuses on how adding plant-based materials can improve specific properties of the building material. Ordinary Portland cement (OPC) has significant CO2 emissions during manufacturing, accounting for 63% of global CO2 emissions [46,47]. Therefore, research in the literature is widely devoted to offsetting the harmful effects of cement production [48]. For example, according to Amin et al. [49], the compressive and flexural strength of cementitious composites reinforced with plant fibers increased by up to 43% and 67%, respectively, compared to the original reference composites. The researchers also found that the plant fibers most commonly incorporated into various composites are coconut, flax, jute, hemp and wheat straw, and sugar palm. Similarly, the integration of oil palm shells can also be found in the literature, which is available in large quantities in Malaysia, Indonesia, and Thailand [46]. These initiatives making specific processes more sustainable can be identified in concrete production: research suggests that in concrete construction, eucalyptus fiber improves cracking and shrinkage properties [50].Concrete research targeting self-healing concrete production is also of primary importance. It is well known that concrete is a low-tensile and brittle material that is highly susceptible to cracking [51], against which Vijay et al. [52] proposed using bacteria as suitable agents for repairing cracks in the matrix. Additionally, Dewi et al. [53] found that using bamboo fibers in concrete increased the tensile strength of concrete and improved its characteristics regarding microcrack formation and plasticity. Menor et al. [54] investigated the role of cork in concrete production. They observed that the material has a high absorption value and can be used as a light additive for internal hardening of concrete. Klapiszewski et al. [55] developed hybrid materials containing lignin, resulting in low porosity and improved mechanical strength parameter values.Similarly, several projects have concerned the application of plant-based materials to wooden structures. Ercan et al. [56] investigated the burning properties of wood elements in green building composite panels. The researchers have shown that slow-burning materials can delay the risk of collapse in the event of a fire in a building. Research suggests that coating with the addition of peanut shells reduced burning time and increased combustion temperature compared to control conditions. Charai et al. [57] developed an Alpha drywall roofing building material using alfa grass (Stipa tenacissima L.) fibers from the eastern Moroccan region. The material significantly improved the thermal insulation quality of the roof and reduced its heat transfer value, and based on simulations, the research suggests that retrofitting the 40 mm thick Alfa drywall reduced the energy demand of residential buildings by 4%. Aouba et al. [58] investigated the significance of adding olive flour and wheat straw residues in brick production to improve heat performance while maintaining carrying capacity.

- (d)

- As an additional group, research on the construction use of waste from an agri-food sector, including agricultural and livestock farms, can be named. Ryłko-Polak et al. [47] highlighted that lignin and its derivatives are also used in construction, mainly as additives in cement composites and bitumen substitutes [59]. Tawasil et al. [60] studied the production of fiberboard made from waste coconut shells and found that the higher the composition of coconut fiber in the coconut fiber sawdust sheets was, the better the physical and mechanical performance became; the percentage of water absorption decreased, and the bending modulus of the plate also increased. Maximino et al. [61] evaluated the applicability of sustainable building materials from waste with mycelium binders in the construction industry. The authors found that the average compressive strength of bricks made of sawdust and rice bran mixed with mycelium increased compared to non-mycelium bricks. Romano et al. [62] assessed ten biobased waste insulation materials and recognized sawdust and wool as the most promising green materials.

- (e)

- Biobased building material research is often conducted at the compound (molecule) level, which has given new impetus to the development of green chemistry [63]. The behavior of fibers from natural ingredients (e.g., coconut, flax, hemp, etc.) depends mainly on the pre-treatment of the fibers. For example, Khalid et al. [64] concluded that higher concentrations of chemicals and longer soaking times in fibers tend to improve mechanical properties. According to Khoshnava et al. [65], the polluting nature of conventional building materials (CBMs) that are extracted from non-renewable resources can be offset by non-toxic green building materials containing natural and organic compounds. In this regard, biocomposites can be an environmentally friendly solution to reduce indoor and outdoor impacts on human health. For example, Mija et al. [66], describing the role of humines in construction, found that these compounds play an essential role in the evolvement of new classes of thermosetting materials and composites, as well as in the green processes of wood impregnation.

- (f)

- Green architectural structures also appear in the focus of recent research. This group includes green roofs consisting of planted vegetation, growing medium, filter layer, drainage and storage layers, protective and storage wool, and waterproof layers [67,68]. A specific type of this is vertical green belt systems, which are usually implemented on the façade of buildings [69].

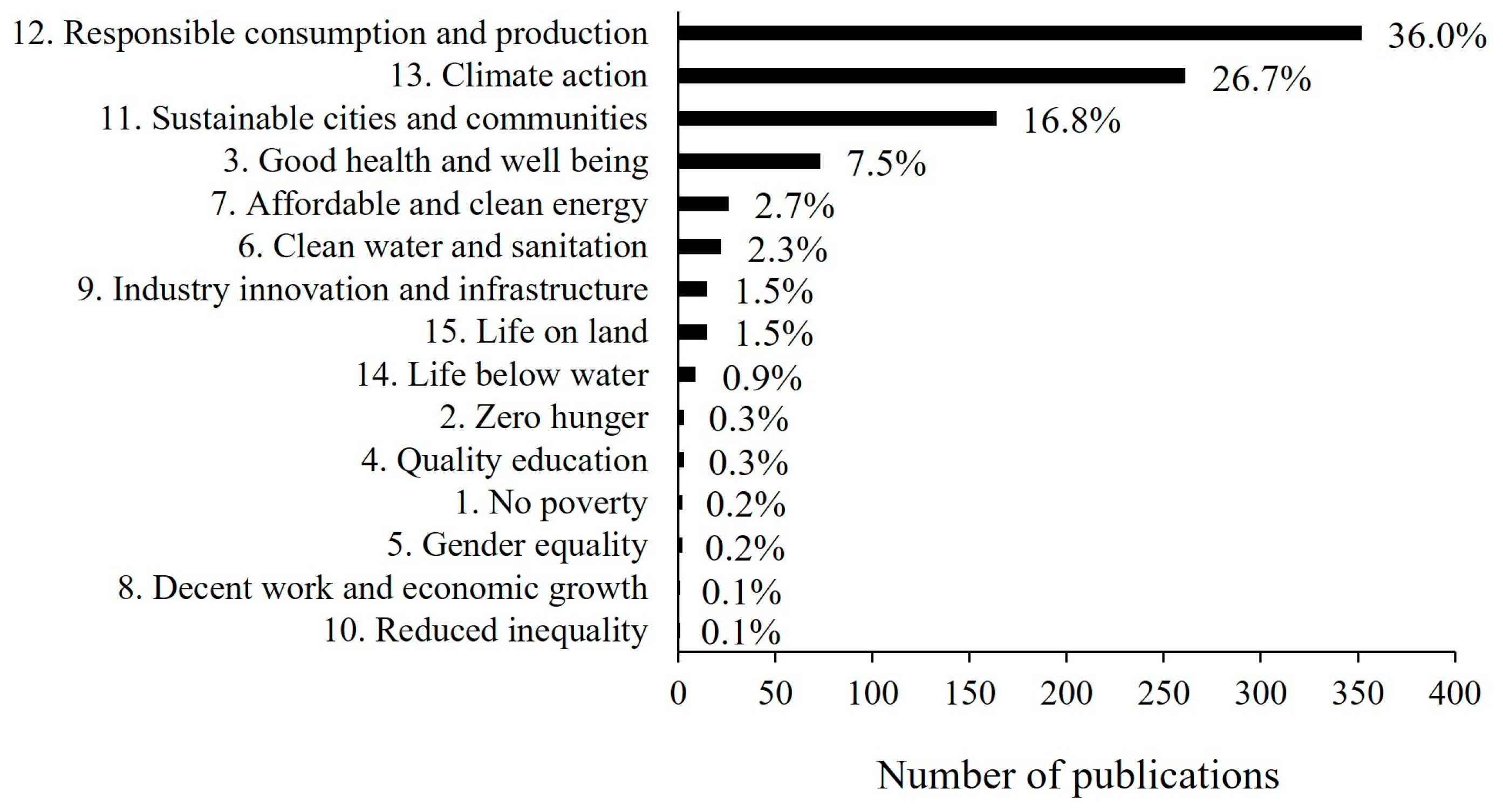

3.4. The Use of Plant-Based Green Building Materials

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tippu, J.; Saravanasankar, S.; Sankaranarayanan, B.; Ali, S.M.; Qarnain, S.S.; Karuppiah, K. Towards sustainability: Analysis of energy efficiency factors in buildings of smart cities using an integrated framework. J. Inst. Eng. India Ser. A. 2023, 104, 223–235. [Google Scholar] [CrossRef]

- Chileshe, N.; Kavishe, N.; Edwards, D.J. Identification of critical capacity building challenges in public-private partnerships (PPPs) projects: The case of Tanzania. Int. J. Construct. Manage. 2023, 23, 495–504. [Google Scholar] [CrossRef]

- Scherz, M.; Hoxha, E.; Maierhofer, D.; Kreiner, H.; Passer, A. Strategies to improve building environmental and economic performance: An exploratory study on 37 residential building scenarios. Int. J. Life Cycle Assess. 2023, 28, 828–842. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Embodied carbon mitigation and reduction in the built environment–What does the evidence say? J. Environ. Manage. 2016, 181, 687–700. [Google Scholar] [CrossRef] [PubMed]

- Pomponi, F.; Stephan, A. Water, energy, and carbon dioxide footprints of the construction sector: A case study on developed and developing economies. Water Res. 2021, 194, 116935. [Google Scholar] [CrossRef] [PubMed]

- Hamada, H.M.; Thomas, B.S.; Yahaya, F.M.; Muthusamy, K.; Yang, J.; Abdalla, J.A.; Hawileh, R.A. Sustainable use of palm oil fuel ash as a supplementary cementitious material: A comprehensive review. J. Build. Eng. 2021, 40, 102286. [Google Scholar] [CrossRef]

- Tokede, O.O.; Rodgers, G.; Waschl, B.; Salter, J.; Ashraf, M. Harmonising life cycle sustainability thinking in material substitution for buildings. Resour. Conserv. Recycl. 2022, 185, 106468. [Google Scholar] [CrossRef]

- Esch, T.; Brzoska, E.; Dech, S.; Leutner, B.; Palacios-Lopez, D.; Metz-Marconcini, A.; Marconcini, M.; Roth, A.; Zeidler, J. World Settlement Footprint 3D—A first three-dimensional survey of the global building stock. Remote Sens. Environ. 2022, 270, 112877. [Google Scholar] [CrossRef]

- Abergel, T.; Dean, B.; Dulac, J.; Hamilton, I.; Wheeler, T. Global Status Report. Towards a Zero-Emission, Efficient, And Resilient Buildings and Construction Sector. Global Alliance for Buildings and Construction. 2018. Available online: https://worldgbc.org/wp-content/uploads/2022/03/2018-GlobalABC-Global-Status-Report.pdf (accessed on 4 September 2023).

- United Nations. World Population Prospects 2019 Highlights. 2019. Available online: https://population.un.org/wpp/Publications/Files/WPP2019_Highlights.pdf (accessed on 4 September 2023).

- Eberhardt, L.C.M.; Birgisdottir, H.; Birkved, M. Potential of circular economy in sustainable buildings. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 092051. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; do Carmo Duarte Freitas, M.; Tavaras, S.F. Circular economy in the construction industry: A systematic literature review. J. Cleaner Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Ghufran, M.; Khan, K.I.A.; Ullah, F.; Nasir, A.R.; Al Alahmadi, A.A.; Alzaed, A.N.; Alwetaishi, M. Circular Economy in the Construction Industry: A Step towards Sustainable Development. Buildings 2022, 12, 1004. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- Krausmann, F.; Wiedenhofer, D.; Lauk, C.; Haas, W.; Tanikawa, H.; Fishman, T.; Haberl, H. Global socioeconomic material stocks rise 23-fold over the 20th century and require half of annual resource use. Proc. Natl. Acad. Sci. USA 2017, 114, 1880–1885. [Google Scholar] [CrossRef]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How circular is the global economy? An assessment of material flows, waste production, and recycling in the European Union and the world in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Hu, M.; van der Voet, E.; Huppes, G. Dynamic material flow analysis for strategic construction and demolition waste management in Beijing. J. Ind. Ecol. 2010, 14, 440–456. [Google Scholar] [CrossRef]

- Gasparri, E.; Arasteh, S.; Kuru, A.; Stracchi, P.; Brambilla, A. Circular economy in construction: A systematic review of knowledge gaps towards a novel research framework. Front. Built Environ. 2023, 9, 1239757. [Google Scholar] [CrossRef]

- Farooq, S.A.; Indhu, B.; Jagannathan, P. Impact of covid-19 on supply chain management in construction industry in Kashmir. Asian J. Civ. Eng. 2023, 24, 429–438. [Google Scholar] [CrossRef]

- De Luca, P.; Carbone, I.; Nagy, J.B. Green building materials: A review of state of the art studies of innovative materials. J. Green Build. 2017, 12, 141–161. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Cascione, V.; Walker, P. Upscaling bio-based construction: Challenges and opportunities. Build. Res. Inf. 2023, 51, 764–782. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on Biobased Building Material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. CitNetExplorer: A new software tool for analyzing and visualizing citation networks. J. Informetr. 2014, 8, 802–823. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2021, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Saiz-Jiménez, C.; Hermosin, B.; Ortega-Calvo, J.J.; Gomez-Alarcon, G. Applications of analytical pyrolysis to the study of stony cultural properties. J. Anal. Appl. Pyrolysis 1991, 20, 239–251. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://www.refworld.org/docid/57b6e3e44.html (accessed on 2 September 2023).

- Pearlmutter, D.; Theochari, D.; Nehls, T.; Pinho, P.; Piro, P.; Korolova, A.; Papaefthimiou, S.; Garcia Mateo, M.C.; Calheiros, C.; Zluwa, I.; et al. Enhancing the circular economy with nature-based solutions in the built urban environment: Green building materials, systems and sites. Blue-Green Syst. 2020, 2, 46–72. [Google Scholar] [CrossRef]

- Le, D.L.; Salomone, R.; Nguyen, Q.T. Circular bio-based building materials: A literature review of case studies and sustainability assessment methods. Build. Environ. 2023, 244, 110774. [Google Scholar] [CrossRef]

- Bourbia, S.; Kazeoui, H.; Belarbi, R. A review on recent research on bio-based building materials and their applications. Mater. Renew. Sustain. Energy 2023, 12, 117–139. [Google Scholar] [CrossRef]

- Wang, J.; Euring, M.; Ostendorf, K.; Zhang, K. Biobased materials for food packaging. J. Bioresour. Bioprod. 2022, 7, 1–13. [Google Scholar] [CrossRef]

- Yadav, M.; Agarwal, M. Biobased building materials for sustainable future: An overview. Mater. Today Proc. 2021, 43, 2895–2902. [Google Scholar] [CrossRef]

- Vagtholm, R.; Matteo, A.; Vand, B.; Tupenaite, L. Evolution and Current State of Building Materials, Construction Methods, and Building Regulations in the U.K.: Implications for Sustainable Building Practices. Buildings 2023, 13, 1480. [Google Scholar] [CrossRef]

- Sahlol, D.G.; Elbeltagi, E.; Elzoughiby, M.; Abd Elrahman, M. Sustainable building materials assessment and selection using system dynamics. J. Build. Eng. 2021, 35, 101978. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Karthik Selvakumar, K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar] [CrossRef]

- Hai, L.V.; Muthoke, R.M.; Panicker, P.S.; Agumba, D.O.; Pham, H.D.; Kim, J. All-biobased transparent-wood: A new approach and its environmental-friendly packaging application. Carbohydr. Polym. 2021, 264, 118012. [Google Scholar] [CrossRef] [PubMed]

- Montanari, C.; Chen, H.; Lidfeldt, M.; Gunnarsson, J.; Olsén, P.; Berglund, L.A. Sustainable Thermal Energy Batteries from Fully Bio-Based Transparent Wood. Small. 2023, 19, 2301262. [Google Scholar] [CrossRef] [PubMed]

- Tu, H.; Zhu, M.; Duan, B.; Zhang, L. Recent progress in high-strength and robust regenerated cellulose materials. Adv. Mater. 2021, 33, 2000682. [Google Scholar] [CrossRef]

- Rasheed, M.; Jawaid, M.; Karim, Z.; Abdullah, L.C. Morphological, physiochemical and thermal properties of microcrystalline cellulose (MCC) extracted from bamboo fiber. Molecules 2020, 25, 2824. [Google Scholar] [CrossRef]

- Elkhaoulani, A.; Arrakhiz, F.Z.; Benmoussa, K.; Bouhfid, R.; Qaiss, A. Mechanical and thermal properties of polymer composite based on natural fibers: Moroccan hemp fibers/polypropylene. Mater. Des. 2013, 49, 203–208. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Missio, A.L.; Otoni, C.G.; Zhao, B.; Beaumont, M.; Khakalo, A.; Kämäräinen, T.; Silva, S.H.F.; Mattos, B.D.; Rojas, O.J. Nanocellulose removes the need for chemical crosslinking in tannin-based rigid foams and enhances their strength and fire retardancy. ACS Sustain. Chem. Eng. 2020, 10, 10303–10310. [Google Scholar] [CrossRef]

- Mucsi, Z.M.; Hasan, K.F.; Horváth, P.G.; Bak, M.; Kóczán, Z.; Alpár, T. Semi-dry technology mediated lignocellulosic coconut and energy reed straw reinforced cementitious insulation panels. J. Build. Eng. 2022, 57, 104825. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Leenie, A.; Harimi, M.; Beng, Y.K. Mechanical properties of woven banana fibre reinforced epoxy composites. Mater. Des. 2006, 27, 689–693. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, K.; Cui, N.; Cheng, X.; Ren, K.; Hou, P.; Feng, L.; Zhou, Z.; Xie, N. Green and durable lightweight aggregate concrete: The role of waste and recycled materials. Materials 2020, 13, 3041. [Google Scholar] [CrossRef] [PubMed]

- Ryłko-Polak, I.; Komala, W.; Białowiec, A. The Reuse of Biomass and Industrial Waste in Biocomposite Construction Materials for Decreasing Natural Resource Use and Mitigating the Environmental Impact of the Construction Industry: A Review. Materials 2022, 15, 4078. [Google Scholar] [CrossRef] [PubMed]

- Zailan, S.N.; Mahmed, N.; Abdullah, M.M.A.B.; Rahim, S.Z.A.; Halin, D.S.C.; Sandu, A.V.; Vizureanu, P.; Yahya, Z. Potential Applications of Geopolymer Cement-Based Composite as Self-Cleaning Coating: A Review. Coatings 2022, 12, 133. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. A comprehensive review of types, properties, treatment methods and application of plant fibers in construction and building materials. Materials 2022, 15, 4362. [Google Scholar] [CrossRef]

- Jongvisuttisun, P.; Negrello, C.; Kurtis, K.E. Effect of processing variables on efficiency of eucalyptus pulps for internal curing. Cem. Concr. Compos. 2013, 37, 126–135. [Google Scholar] [CrossRef]

- Coppola, L.; Beretta, S.; Bignozzi, M.C.; Bolzoni, F.; Brenna, A.; Cabrini, M.; Candamano, S.; Caputo, D.; Carsana, M.; Cioffi, R.; et al. The Improvement of Durability of Reinforced Concretes for Sustainable Structures: A Review on Different Approaches. Materials 2022, 15, 2728. [Google Scholar] [CrossRef]

- Vijay, K.; Murmu, M.; Deo, S.V. Bacteria based self healing concrete—A review. Constr. Build. Mater. 2017, 152, 1008–1014. [Google Scholar] [CrossRef]

- Dewi, S.M.; Wijaya, M.N. The use of bamboo fiber in reinforced concrete beam to reduce crack. AIP Conf. Proc. 2017, 1887, 020003. [Google Scholar] [CrossRef]

- Menor, M.C.P.; Ros, P.S.; García, A.M.; Caballero, M.J.A. Granulated cork with bark characterised as environment-friendly lightweight aggregate for cement-based materials. J. Clean. Prod. 2019, 229, 358–373. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Klapiszewska, I.; Ślosarczyk, A.; Jesionowski, T. Lignin-based hybrid admixtures and their role in cement composite fabrication. Molecules 2019, 24, 3544. [Google Scholar] [CrossRef]

- Ercan, E.; Atar, M.; Kucuktuvek, M.; Keskin, H. Characterization of formaldehyde emission and combustion properties of peanut (Arachis Hypogaea) husk-based green composite panels for building applications. Drv. Ind. 2022, 73, 139–149. [Google Scholar] [CrossRef]

- Charai, M.; Mezrhab, A.; Karkri, M.; Moga, L. Thermal performance study of plaster reinforced with Alfa fibers. AIP Conf. Proc. 2021, 2429, 020005. [Google Scholar] [CrossRef]

- Aouba, L.; Bories, C.; Coutand, M.; Perrin, B.; Lemercier, H. Properties of fired clay bricks with incorporated biomasses: Cases of olive stone flour and wheat straw residues. Constr. Build. Mater. 2016, 102, 7–13. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Zhang, Y.; Liu, C.; Yu, G.; Li, B.; Mu, X.; Peng, H. Preparation of concrete water reducer via fractionation and modification of lignin extracted from pine wood by formic acid. ACS Sustain. Chem. Eng. 2017, 5, 4214–4222. [Google Scholar] [CrossRef]

- Tawasil, D.N.B.; Aminudin, E.; Abdul Shukor Lim, N.H.; Nik Soh, N.M.Z.; Leng, P.C.; Ling, G.H.T.; Ahmad, M.H. Coconut fibre and sawdust as green building materials: A laboratory assessment on physical and mechanical properties of particleboards. Buildings 2021, 11, 256. [Google Scholar] [CrossRef]

- Maximino, C.; Ongpeng, J.; Inciong, E.; Sendo, V.; Soliman, C.; Siggaoat, A. Using waste in producing bio-composite mycelium bricks. Appl. Sci. 2020, 10, 5303. [Google Scholar] [CrossRef]

- Romano, A.; Bras, A.; Grammatikos, S.; Shaw, A.; Riley, M. Dynamic behaviour of bio-based and recycled materials for indoor environmental comfort. Constr. Build. Mater. 2019, 211, 730–743. [Google Scholar] [CrossRef]

- Kobayashi, T.; Nakajima, L. Sustainable development goals for advanced materials provided by industrial wastes and biomass sources. Curr. Opin. Green Sustain. Chem. 2021, 28, 100439. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Imran, R.; Arif, Z.U.; Akram, N.; Arshad, H.; Al Rashid, A.; García Márquez, F.P. Developments in Chemical Treatments, Manufacturing Techniques and Potential Applications of Natural-Fibers-Based Biodegradable Composites. Coatings 2021, 11, 293. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Mohamad Zin, R.; Štreimikienė, D.; Mardani, A.; Ismail, M. The role of green building materials in reducing environmental and human health impacts. Int. J. Environ. Res. Public. Health 2020, 17, 2589. [Google Scholar] [CrossRef] [PubMed]

- Mija, A.; van der Waal, J.C.; Pin, J.M.; Guigo, N.; de Jong, E. Humins as promising material for producing sustainable carbohydrate-derived building materials. Constr. Build. Mater. 2017, 139, 594–601. [Google Scholar] [CrossRef]

- Weiler, S.; Scholz-Barth, K. Green Roof Systems: A Guide to the Planning, Design, and Construction of Landscapes Over Structure, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Grant, G.; Gedge, D. Living Roofs and Walls from Policy to Practice, 10 Years of Urban Greening in London and beyond. Blanche Cameron of the Bartlett UCL. 2019. Available online: https://livingroofs.org/wp-content/uploads/2019/04/LONDON-LIVING-ROOFS-WALLS-REPORT-2019.pdf (accessed on 25 August 2023).

- Hachoumi, I.; Pucher, B.; De Vito-Francesco, E.; Prenner, F.; Ertl, T.; Langergraber, G.; Fürhacker, M.; Allabashi, R. Impact of Green Roofs and Vertical Greenery Systems on Surface Runoff Quality. Water 2021, 13, 2609. [Google Scholar] [CrossRef]

- Iskandar, M.J.; Baharum, A.; Anuar, F.H.; Othaman, R. Palm oil industry in South East Asia and the effluent treatment technology—A review. Environ. Technol. Innov. 2018, 9, 169–185. [Google Scholar] [CrossRef]

- Luca, B.I.; Panțiru, A.; Timu, A.; Bărbuță, M.; Diaconu, L.I.; Rujanu, M.; Diaconu, A.C. Eco-concrete for obtaining “green” construction elements. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1283, 012007. [Google Scholar] [CrossRef]

- Liu, D.; Yao, Q.; Jia, Y. Experimental study of vegetable fiber-mortar composites in ecological and energy-saving composite wall. J. Beijing Jiaotong Univ. 2011, 35, 34–38. [Google Scholar]

- Hasan, K.F.; Horváth, P.G.; Bak, M.; Le, D.H.A.; Mucsi, Z.M.; Alpar, T. Rice straw and energy reed fibers reinforced phenol formaldehyde resin polymeric biocomposites. Cellulose 2021, 28, 7859–7875. [Google Scholar] [CrossRef]

- Çomak, B.; Bideci, A.; Bideci, Ö.S. Effects of hemp fibers on characteristics of cement-based mortar. Constr. Build. Mater. 2018, 169, 794–799. [Google Scholar] [CrossRef]

- Bayapureddy, Y.; Muniraj, K.; Mutukuru, M.R.G. Sugarcane bagasse ash as supplementary cementitious material in cement composites: Strength, durability, and microstructural analysis. J. Korean Ceram. Soc. 2020, 57, 513–519. [Google Scholar] [CrossRef]

- Guirguis, M.N.; Farahat, Z.; Micheal, A. Developing an interior cladding fiberboard by utilizing sugarcane bagasse as a local agro-waste in Egypt. Sci. Rep. 2023, 13, 12870. [Google Scholar] [CrossRef] [PubMed]

- Alengaram, U.J.; Al Muhit, B.A.; bin Jumaat, M.Z. Utilization of oil palm kernel shell as lightweight aggregate in concrete—A review. Constr. Build. Mater. 2013, 38, 161–172. [Google Scholar] [CrossRef]

- Rai, A.; Joshi, Y.P. Applications and properties of fibre reinforced concrete. Int. J. Eng. Res. Appl. 2014, 4, 123–131. [Google Scholar]

- Ramli, M.; Kwan, W.H.; Abas, N.F. Strength and durability of coconut-fiber-reinforced concrete in aggressive environments. Constr. Build. Mater. 2013, 38, 554–566. [Google Scholar] [CrossRef]

- Arrakhiz, F.Z.; Elachaby, M.; Bouhfid, R.; Vaudreuil, S.; Essassi, M.; Qaiss, A. Mechanical and thermal properties of polypropylene reinforced with Alfa fiber under different chemical treatment. Mater. Des. 2012, 35, 318–322. [Google Scholar] [CrossRef]

- Sodangi, M.; Kazmi, Z.A. Integrated evaluation of the impediments to the adoption of coconut palm wood as a sustainable material for building construction. Sustainability 2020, 12, 7676. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- Stohl, L.; Manninger, T.; von Werder, J.; Dehn, F.; Gorbushina, A.; Meng, B. Bioreceptivity of concrete: A review. J. Build. Eng. 2023, 76, 107201. [Google Scholar] [CrossRef]

- Nazmul, R.T.; Sainsbury, B.A.; Al-Deen, S.; Garcez, E.O.; Ashraf, M. An Experimental Evaluation of Hemp as an Internal Curing Agent in Concrete Materials. Materials 2023, 16, 3993. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.P.; Durán-Suárez, J.A.; Castro-Gomes, J. Improving the Behaviour of Green Concrete Geopolymers Using Different HEMP Preservation Conditions (Fresh and Wet). Minerals 2022, 12, 1530. [Google Scholar] [CrossRef]

- Zhou, X.; Saini, H.; Kastiukas, G. Engineering properties of treated natural hemp fiber-reinforced concrete. Front. Built Environ. 2017, 3, 33. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Prétot, S.; Lanos, C. Hemp-straw composites: Gluing study and multi-physical characterizations. Materials 2019, 12, 1199. [Google Scholar] [CrossRef]

- Kumar, G. Review on Feasibility of Bamboo in Modern Construction. Int. J. Pf. Civ. Eng. SSRG-IJCE 2015, 2, 66–70. [Google Scholar]

- Ede, A.N.; Olofinnade, O.M.; Joshua, O.; Nduka, D.O.; Oshogbunu, O.A. Influence of bamboo fiber and limestone powder on the properties of self-compacting concrete. Cogent Eng. 2020, 7, 1721410. [Google Scholar] [CrossRef]

- Bittner, C.M.; Oettel, V. Fiber Reinforced Concrete with Natural Plant Fibers—Investigations on the Application of Bamboo Fibers in Ultra-High Performance Concrete. Sustainability 2020, 14, 12011. [Google Scholar] [CrossRef]

- Kundu, S.P.; Chakraborty, S.; Chakraborty, S. Effectiveness of the surface modified jute fibre as fibre reinforcement in controlling the physical and mechanical properties of concrete paver blocks. Constr. Build. Mater. 2018, 191, 554–563. [Google Scholar] [CrossRef]

- Krishna, T.S.V.; Yadav, B.M. A comparative study of jute fiber reinforced concrete with plain cement concrete. Int. J. Res. Eng. Technol. 2016, 5, 111–116. [Google Scholar]

- Ali, A.; Nasir, M.A.; Khalid, M.Y.; Nauman, S.; Shaker, K.; Khushnood, S.; Altaf, K.; Zeeshan, M.; Hussain, A. Experimental and numerical characterization of mechanical properties of carbon/jute fabric reinforced epoxy hybrid composites. J. Mech. Sci. Technol. 2019, 33, 4217–4226. [Google Scholar] [CrossRef]

- Abirami, R.; Vijayan, D.S.; John, S.J.; Albert, A.; Alex, A.K. Experimental study on concrete properties using pineapple leaf fiber. Int. J. Adv. Res. Technol. 2020, 11, 913–920. [Google Scholar] [CrossRef]

- Yaremko, C. Durability of flax fibre reinforced concrete. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2012. [Google Scholar]

- Öztürk, T.; Bayrakl, M. The possibilities of using tobacco wastes in producing lightweight concrete. Agric. Eng. Int. CIGR J. 2005, 7, BC05006. [Google Scholar]

- Juan, S.; Zhi, Z. Preparation and study of resin translucent concrete products. Adv. Civ. Eng. 2019, 2019, 8196967. [Google Scholar] [CrossRef]

- Kausar, A. Scientific potential of chitosan blending with different polymeric materials: A review. J. Plast. Film. Sheeting 2017, 33, 384–412. [Google Scholar] [CrossRef]

- Tran-Ly, A.N.; Heeb, M.; Kalac, T.; Schwarze, F.W. Antimicrobial effect of fungal melanin in combination with plant oils for the treatment of wood. Front. Mater. 2022, 9, 915607. [Google Scholar] [CrossRef]

- Almusaed, A.; Almssad, A.; Alasadi, A.; Yitmen, I.; Al-Samaraee, S. Assessing the Role and Efficiency of Thermal Insulation by the “BIO-GREEN PANEL” in Enhancing Sustainability in a Built Environment. Sustainability 2023, 15, 10418. [Google Scholar] [CrossRef]

- Nagdeve, S.S.; Manchanda, S.; Dewan, A. Thermal performance of indirect green façade in composite climate of India. Build. Environ. 2023, 230, 109998. [Google Scholar] [CrossRef]

- Omar, M.F.; Abdullah, M.A.H.; Rashid, N.A.; Abdul Rani, A.L.; Illias, N.A. The Application of Coconut Fiber as Insulation Ceiling Board in Building Construction. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864, 012196. [Google Scholar] [CrossRef]

- Manohar, K.; Ramlakhan, D.; Kochhar, G.; Haldar, S. Biodegradable fibrous thermal insulation. J. Braz. Soc. Mech. Sci. Eng. 2006, 28, 45–47. [Google Scholar] [CrossRef]

- Yli-Halla, M.; Lötjönen, T.; Kekkonen, J.; Virtanen, S.; Marttila, H.; Liimatainen, M.; Saari, M.; Mikkola, J.; Suomela, R.; Joki-Tokola, E. Thickness of peat influences the leaching of substances and greenhouse gas emissions from a cultivated organic soil. Sci. Total Environ. 2022, 806, 150499. [Google Scholar] [CrossRef]

- Bakatovich, A.; Gaspar, F. Composite material for thermal insulation based on moss raw material. Constr. Build. Mater. 2019, 228, 116699. [Google Scholar] [CrossRef]

- Zou, S.; Li, H.; Wang, S.; Jiang, R.; Zou, J.; Zhang, X.; Liu, L.; Zhang, G. Experimental research on an innovative sawdust biomass-based insulation material for buildings. J. Clean. Prod. 2020, 260, 121029. [Google Scholar] [CrossRef]

- Kain, G.; Tudor, E.M.; Barbu, M.C. Bark thermal insulation panels: An explorative study on the effects of bark species. Polymers 2020, 12, 2140. [Google Scholar] [CrossRef] [PubMed]

- Karaky, H.; Maalouf, C.; Bliard, C.; Gacoin, A.; Lachi, M.; El Wakil, N.; Polidori, G. Characterization of beet-pulp fiber reinforced potato starch biopolymer composites for building applications. Constr. Build. Mater. 2019, 203, 711–721. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Martellotta, F. Performance characterization of broad band sustainable sound absorbers made of almond skins. Materials 2020, 13, 5474. [Google Scholar] [CrossRef] [PubMed]

- La Scalia, G.; Saeli, M.; Miglietta, P.P.; Micale, R. Coffee biowaste valorization within circular economy: Evaluation method of spent coffee grounds potentials for mortar production. Int. J. Life Cycle Assess. 2021, 26, 1805–1815. [Google Scholar] [CrossRef] [PubMed]

| Source | Number of Published Articles |

|---|---|

| Construction and Building Materials | 68 |

| Sustainability | 48 |

| Journal of Cleaner Production | 43 |

| Materials | 26 |

| Building and Environment | 23 |

| Journal of Building Engineering | 23 |

| Energy and Buildings | 19 |

| Buildings | 17 |

| Science of the Total Environment | 13 |

| Journal of Green Building | 12 |

| Building Material/Procedure | Plant-Based Material | Products Created after Plant-Based Material Use | Related Publication(s) |

|---|---|---|---|

| Cement production | agricultural palm waste | cement composites | [47,70] |

| mixed plant-based agricultural waste | biocomposites as reinforcers, plasticizers, and insulators | [47,71] | |

| rice and reed fiber | reinforced cementitious panels and biocomposites with increased compressive strength | [72,73] | |

| hemp fiber | cement-based mortar with increased compressive and flexural strength | [74] | |

| sugarcane bagasse ash | cement-based products with increased compressive strength | [75,76] | |

| Concrete production | palm kernel shell | lightweight concrete aggregate | [46,77] |

| mixed plant fibers | reinforced concrete | [78] | |

| coconut fiber | high-strength reinforced concrete with increased compressive and bending strength | [46,49,79,80,81,82] | |

| biofilm with microorganisms | concrete with increased bioreceptivity | [83] | |

| hemp | concrete with reinforced internal structure and increased self-healing ability | [84,85,86,87] | |

| bamboo fiber | agent treating concrete cracks, high-performance concrete with decreased shrinkage | [53,88,89,90] | |

| juta fiber | reinforced concrete | [91,92,93] | |

| pineapple leaf fiber | reinforced concrete | [94] | |

| flax fiber | reinforced concrete with increased compressive strength | [49,95] | |

| granulated cork | concrete and mortar with increased insulating property | [54] | |

| tobacco waste | lightweight concrete | [96] | |

| resins from different origin | translucent concrete | [97] | |

| Brick production | building waste materials with mycelium | bio-composite mycelium bricks | [61] |

| Wood-based products | delignified, succinylated birch wood | transparent wood | [37] |

| chitosan | wooden surfaces with increased flame resistance | [98] | |

| fungal melanin, linseed, and tree tea oil | wooden materials with increased antibacterial effects and water resistance | [99] | |

| peanut husk | green composite panels with increased flame resistance | [56] | |

| Sealing and insulation materials | nanocellulose | performance improvement of tannin-based foams | [43] |

| various plant species | bio-green insulation panels | [100,101] | |

| coconut fiber | insulation ceiling board, fibrous thermal insulation | [102,103] | |

| peat | thermal insulation material | [104,105] | |

| sawdust | green insulation panels | [106] | |

| arch, pine, spruce, fir, and oak tree bark resins | insulation panels | [107] | |

| beet-pulp fiber with potato starch | biopolymer composites with increased insulation property | [108] | |

| almond skin | sound absorber materials | [109] | |

| Other | spent coffee grounds | mortar with increased technical and sustainability performance | [110] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boros, A.; Tőzsér, D. The Emerging Role of Plant-Based Building Materials in the Construction Industry—A Bibliometric Analysis. Resources 2023, 12, 124. https://doi.org/10.3390/resources12100124

Boros A, Tőzsér D. The Emerging Role of Plant-Based Building Materials in the Construction Industry—A Bibliometric Analysis. Resources. 2023; 12(10):124. https://doi.org/10.3390/resources12100124

Chicago/Turabian StyleBoros, Anita, and Dávid Tőzsér. 2023. "The Emerging Role of Plant-Based Building Materials in the Construction Industry—A Bibliometric Analysis" Resources 12, no. 10: 124. https://doi.org/10.3390/resources12100124

APA StyleBoros, A., & Tőzsér, D. (2023). The Emerging Role of Plant-Based Building Materials in the Construction Industry—A Bibliometric Analysis. Resources, 12(10), 124. https://doi.org/10.3390/resources12100124