Global Warming Potential and Waste Handling of Pearl Farming in Ago Bay, Mie Prefecture, Japan

Abstract

:1. Introduction

2. Materials and Methods

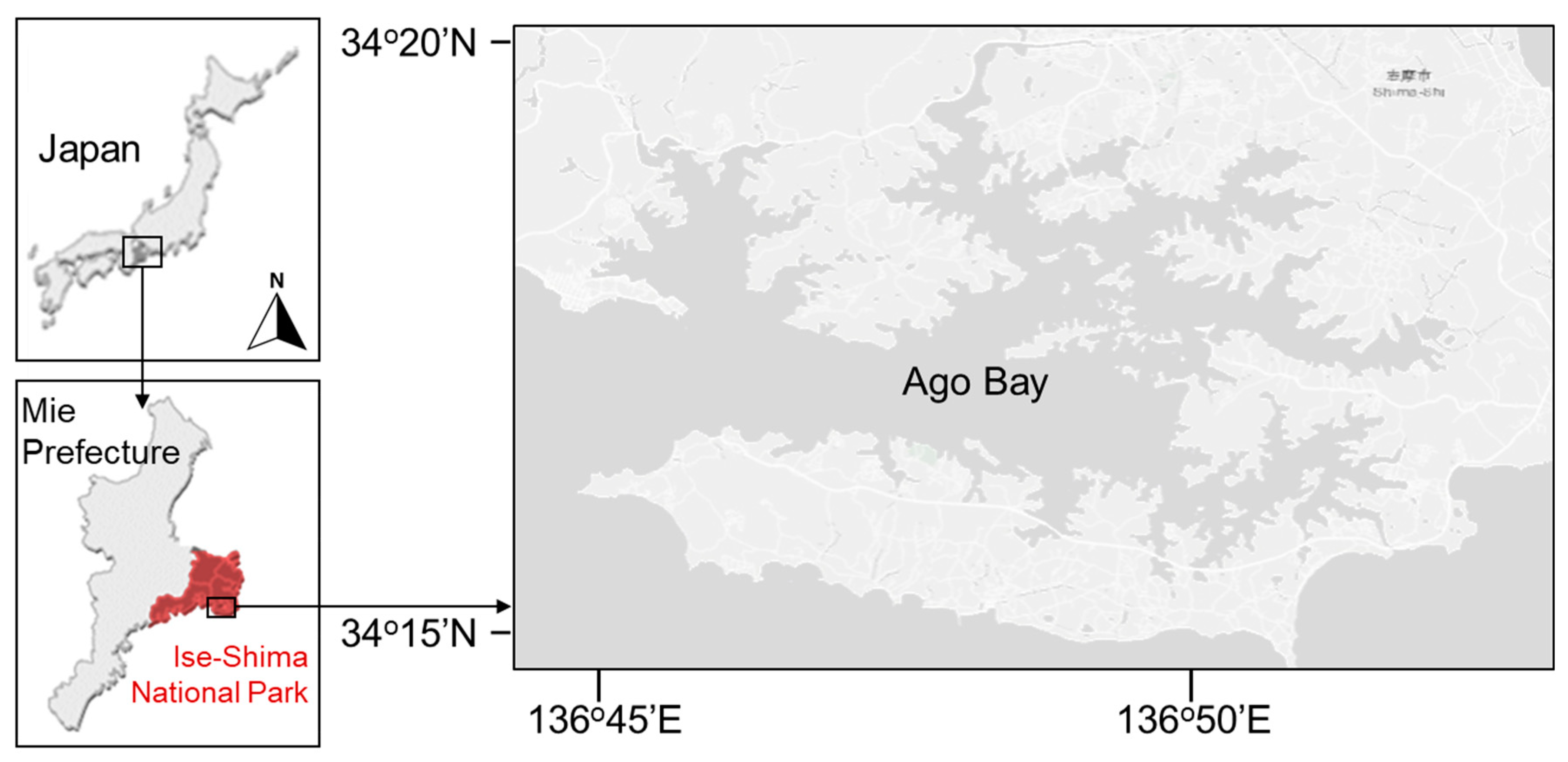

2.1. Study Site

2.2. LCA Framework

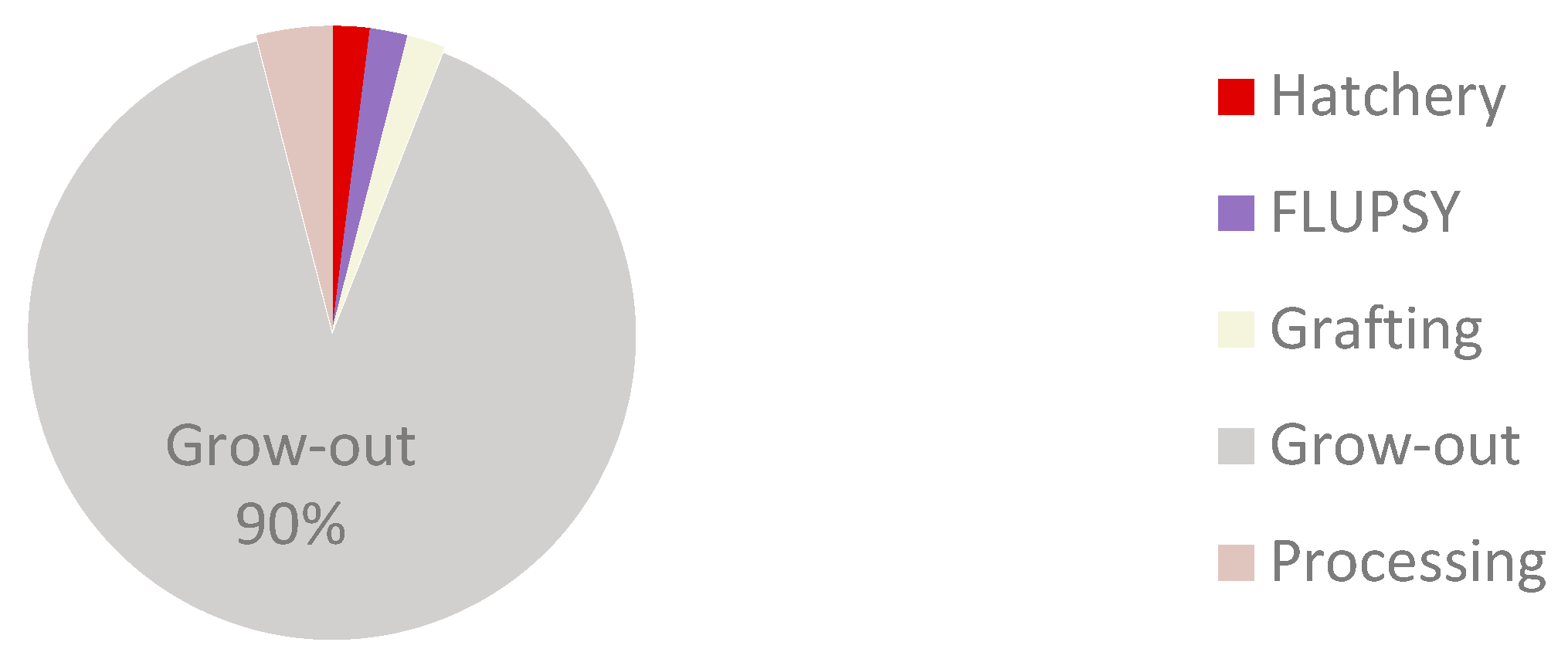

2.2.1. Goal and Scope Definition

2.2.2. Life-Cycle Inventory

2.2.3. Life-Cycle Impact Assessment (LCIA)

3. Results and Discussion

3.1. Life-Cycle Impact Assessment

3.2. Comparing the Global Warming Potential of Pearls with Other Jewelries

3.3. Solid-Waste Handling in Pearl Farming

3.3.1. Defective Pearls

3.3.2. Shell Waste

3.3.3. Plastic Waste

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. The State of World Fisheries and Aquaculture. In Sustainability in Action; FAO: Rome, Italy, 2020; 244p. [Google Scholar] [CrossRef]

- FAO. The State of World Fisheries and Aquaculture. 2018—Meeting the Sustainable Development Goals; FAO: Rome, Italy, 2018; 227p. [Google Scholar]

- Pearls Regain Shine as Japan’s Exports Double. Available online: https://asia.nikkei.com/Business/Markets/Commodities/Pearls-regain-shine-as-Japan-s-exports-double (accessed on 29 April 2023).

- Tisdell, C.A.; Poirine, B. Economics of pearl farming. In The Pearl Oyster, 1st ed.; Southgate, P., Lucas, J., Eds.; Elsevier: Oxford, UK, 2008; pp. 473–495. [Google Scholar] [CrossRef]

- Environment Impact of Extraction of Pearls (Pearl Farming). Available online: https://www.envpk.com/environmental-impact-of-extraction-of-pearls-pearl-farming/#:~:text=Water%20Pollution%3A%20Freshwater%20ecosystems%20are,water%20pollution%20during%20pearl%20farming (accessed on 16 April 2023).

- Pearl Jewelry Market Size, Share, Growth Report 2030. Available online: https://www.zionmarketresearch.com/report/pearl-jewelry-market#:~:text=The%20global%20pearl%20jewelry%20market (accessed on 16 April 2023).

- Zhu, C.; Southgate, P.C.; Li, T. Production of pearls. In Goods and Services of Marine Bivalves, 1st ed.; Smaal, A.C., Ferreira, J.G., Grant, J., Petersen, J.K., Strand, Ø., Eds.; Springer: Cham, Switzerland, 2019; 591p. [Google Scholar] [CrossRef] [Green Version]

- Dirlam, D.M.; Misiorowski, E.B.; Thomas, S.A. Pearl fashion through the ages. Gems Gemmol. 1985, 21, 63–78. [Google Scholar] [CrossRef]

- History of Pearls. Available online: https://www.americangemsociety.org/birthstones/june-birthstones/history-of-pearls/#:~:text=Tudor%20England%20was%20known%20as,and%20clothing%20adorned%20with%20pearls (accessed on 16 April 2023).

- Nagai, K. A history of the cultured pearl industry. Zool. Sci. 2013, 30, 783–793. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sustainable Pearls. Available online: http://www.sustainablepearls.org/pearls/pearl-farming-around-the-world/japan/ (accessed on 16 April 2023).

- O’Connor, W.A.; Gifford, S.P. Environmental impacts of pearl farming. In The Pearl Oyster, 1st ed.; Southgate, P., Lucas, J., Eds.; Elsevier: Oxford, UK, 2008; pp. 497–525. [Google Scholar] [CrossRef]

- Cartier, L.E.; Ali, S.H. China’s pearl industry an indicator of ecological stress. GAHK J. 2013, XXXIV, 18–21. [Google Scholar]

- Yokoyama, H. Impact of fish and pearl farming on the benthic environments in Gokasho Bay: Evaluation from seasonal fluctuations of the macrobenthos. Fish. Sci. 2002, 68, 258–268. [Google Scholar] [CrossRef]

- Akamatsu, S. Pearl culture and the biological environment. Ships Ocean Newsl. 2004, 86, 19–20. Available online: https://www.spf.org/en/opri/newsletter/86_1.html?full=86_1 (accessed on 15 April 2023).

- Gifford, S.; Dunstan, R.H.; O’Connor, W.; Roberts, T.; Toia, R. Pearl aquaculture–profitable environmental remediation? Sci. Total Environ. 2004, 319, 27–37. [Google Scholar] [CrossRef]

- Tamburini, E.; Fano, E.A.; Castaldelli, G.; Turolla, E. Life cycle assessment of oyster farming in the Po Delta, Northern Italy. Resources 2019, 8, 170. [Google Scholar] [CrossRef] [Green Version]

- Turolla, E.; Castaldelli, G.; Fano, E.A.; Tamburini, E. Life cycle assessment (LCA) proves that Manila clam farming (Ruditapes philippinarum) is a fully sustainable aquaculture practice and a carbon sink. Sustainability 2020, 12, 5252. [Google Scholar] [CrossRef]

- Sherry, J.; Koester, J. Life cycle assessment of aquaculture stewardship council certified Atlantic salmon (Salmo salar). Sustainability 2020, 12, 6079. [Google Scholar] [CrossRef]

- Matsuda, O. Recent attempt towards environmental restoration of enclosed coastal seas: Ago Bay Restoration Project based on the new concept of Sato-Umi. Bull. Fragr. 2009, 29, 9–18. Available online: https://www.fra.affrc.go.jp/bulletin/bull/bull29/2.pdf (accessed on 16 April 2023).

- Kokubu, H.; Matsuda, O. Satoumi in Ago Bay: Embracing Integrated Coastal Management. Available online: https://ourworld.unu.edu/en/satoumi-in-ago-bay-embracing-integrated-coastal-management (accessed on 15 April 2023).

- Le Moullac, G.; Schuck, L.; Chabrier, S.; Belliard, C.; Lyonnard, P.; Broustal, F.; Soyez, C.; Saulnier, D.; Brahmi, C.; Ky, C.L.; et al. Influence of temperature and pearl rotation on biomineralization in the pearl oyster, Pinctada margaritifera. J. Exp. Biol. 2018, 221, jeb186858. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oe, H.; Yamaoka, Y. Sustainable coastal business strategies for cultured pearl sectors: Agenda development for cost-area actors’ collection. Coasts 2022, 2, 341–354. [Google Scholar] [CrossRef]

- Toyoshima, J.; Fujii, I.; Maekawa, M.; Tsunoda, T.; Kamada, N.; Hidaka, H.; Tojo, Y.; Ikeda, K. Assessing effectiveness of satoumi activities in Japanese coastal areas from ecological and socioeconomic perspectives. Ocean Coast. Manag. 2022, 230, 106354. [Google Scholar] [CrossRef]

- Murata, H.; Fujii, T.; Yonezawa, C. Evaluating the effect of the incidence angle of ALOS-2 PALSAR-2 on detecting aquaculture facilities for sustainable use of coastal space and resources. PeerJ 2023, 11, e14649. [Google Scholar] [CrossRef]

- ISO14040:2006; Environmental Management–Life Cycle Assessment–Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Consoli, F.; Allen, D.; Bousted, I.; Fava, J.; Franklin, W.; Jensen, A.A.; de Oude, N.; Parrish, R.; Perriman, R.; Postlethwaite, D.; et al. Guidelines for Life-Cycle Assessment: A “Code of Practice”, 1st ed.; Society of Environmental Toxicology and Chemistry (SETAC): Sesimbra, Portugal, 1993; 77p. [Google Scholar]

- Lwin, C.M.; Nogi, A.; Hashimoto, S. Eco-efficiency assessment of material use: The case of phosphorus fertilizer usage in Japan’s rice sector. Sustainability 2017, 9, 1562. [Google Scholar] [CrossRef] [Green Version]

- Cartier, L.E.H. Sustainability and Traceability in Marine Cultured Pearl Production. Ph.D. Dissertation, University of Basel, Basel, Switzerland, 2014. Available online: https://edoc.unibas.ch/34907/1/THESIS%20for%20PRINT%20Laurent%20Cartier.pdf (accessed on 25 April 2023).

- Cartier, L.E.; Ali, S.H. Pearl farming as a sustainable development path. Solut. J. 2012, 4, 30–34. [Google Scholar]

- Wells, F.E.; Jernakoff, P. An assessment of the environmental impact of wild harvest pearl aquaculture (Pinctada maxima) in Western Australia. J. Shellfish Res. 2006, 25, 141–150. [Google Scholar] [CrossRef]

- Bondad-Reantaso, M.G.; McGladdery, S.E.; Berthe, F.C. Pearl Oyster Health Management: A Manual; Food and Agriculture Organization: Rome, Italy, 2007; Volume 503, 119p. [Google Scholar]

- Southgate, P.C.; Lucas, J.S. (Eds.) The Pearl Oyster, 1st ed.; Elsevier: Oxford, UK, 2008; 574p. [Google Scholar]

- Cartier, L.E.; Carpenter, K.E. The influence of pearl oyster farming on reef fish abundance and diversity in Ahe, French Polynesia. Mar. Pollut. Bull. 2014, 78, 43–50. [Google Scholar] [CrossRef]

- Nash, J.; Ginger, C.; Cartier, L. The sustainable luxury contradiction: Evidence from a consumer study of marine-cultured pearl jewellery. J. Corp. Citizsh. 2016, 73–95. [Google Scholar] [CrossRef]

- Oluleye, G. Environmental Impacts of Mined Diamonds; Centre for Environmental Policy, Imperial College London: London, UK, 2021; 30p. [Google Scholar]

- Norgate, T.; Haque, N. Using life cycle assessment to evaluate some environmental impacts of gold production. J. Clean. Prod. 2012, 29–30, 53–63. [Google Scholar] [CrossRef]

- Usapein, P.; Tongcumpou, C. Greenhhouse gas emission in jewelry industry: A case study of silver flat ring. App. Environ. Res. 2016, 38, 11–18. [Google Scholar] [CrossRef]

- Nuss, P.; Eckelman, M.J. Life cycle assessment of metals: A scientific synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef] [PubMed]

- Thammaraksa, C.; Wattanawan, A.; Prapaspongsa, T. Corporate environmental assessment of a large jewelry company: From a life cycle assessment to green industry. J. Clean. Prod. 2017, 164, 485–494. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P.; Lang, C. Impact analysis of gold silver refining processes through life-cycle assessment. J. Clean. Prod. 2019, 228, 867–881. [Google Scholar] [CrossRef]

- Fernandez, J.; Kimas, C. A life cycle assessment of jewelry. De Paul Discov. 2019, 8, 6. Available online: https://via.library.depaul.edu/depaul-disc/vol8/iss1/6 (accessed on 17 April 2023).

- Johnston, W.; Hine, D.; Southgate, P.C. Overview of the development and modern landscape of marine pearl culture in the South Pacific. J. Shellfish Res. 2019, 38, 499–518. [Google Scholar] [CrossRef]

- Johnston, B.; Kishore, P.; Vuibeqa, G.B.; Hine, D.; Southgate, P.C. Economic assessment of community-based pearl oyster spat collection and mabé pearl production in the western Pacific. Aquaculture 2020, 514, 734505. [Google Scholar] [CrossRef]

- Lin, Y.; Sai, N. Ethics and sustainability in the jewellry industry. Front. Bus. Econ. Manag. 2023, 7, 187–193. [Google Scholar] [CrossRef]

- Fong, Q.S.W.; Ellis, S.; Haws, M. Economic feasibility of small-scale black-lipped pearl oyster (Pinctada margaritifera) pearl farming in the central Pacific. Aquac. Econ. Manag. 2005, 9, 347–368. [Google Scholar] [CrossRef]

- Blay, C.; Planes, S.; Ky, C.L. Cultured pearl surface quality profiling by the shell matrix protein gene expression in the biomineralized pearl sac tissue of Pinctada margaritifera. Mar. Biotechnol. 2018, 20, 490–501. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Q.; Hu, W.; Bai, Z. Research trends of development on pearl bivalve mollusks based on a bibliometric network analysis in the past 25 years. Front. Mar. Sci. 2021, 8, 657263. [Google Scholar] [CrossRef]

- Sun, T.; Wang, H.; Hu, H.; Li, J.; Bai, Z. Estimation of non-nucleated pearl quality traits from donor and host mussel-derived genetic parameters in the golden strain of Hyriopsis cumingii. Aquaculture 2022, 560, 738460. [Google Scholar] [CrossRef]

- Chen, H.S.; Chang, J.H.; Wu, J.S.B. Calcium bioavailablity of nanonized pearl powder for adults. J. Food Sci. 2008, 73, H246–H251. [Google Scholar] [CrossRef] [PubMed]

- Loh, X.J.; Young, D.J.; Guo, H.; Tang, L.; Wu, Y.; Zhang, G.; Tang, C.; Ruan, H. Pearl powder—An emerging material for biomedical applications: A review. Materials 2021, 14, 2797. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, H.; Shimomura, N.; Oura, K.; Hasegawa, Y. Nacre extract from pearl oyster shell prevents D-galactose-induced brain and skin aging. Mar. Biotechnol. 2023. online ahead of print. [Google Scholar] [CrossRef]

- Norton, J.H.; Dashorst, M.; Lansky, T.M.; Mayer, R.J. An evaluation of some relaxants for use with pearl oysters. Aquaculture 1996, 144, 39–52. [Google Scholar] [CrossRef]

- de Alvarenga, R.A.F.; Galindro, B.M.; Helpa, C.F.; Soares, S.R. The recycling of oyster shells: An environmental analysis using Life Cycle Assessment. J. Environ. Manag. 2012, 106, 102–109. [Google Scholar] [CrossRef]

- Summa, D.; Lanzoni, M.; Castaldelli, G.; Fano, E.A.; Tamburini, E. Trends and opportunities of bivalve shells’ waste valorization in a prospect of circular blue bioeconomy. Resources 2022, 11, 48. [Google Scholar] [CrossRef]

- Wu, S.-C.; Hsu, H.-C.; Wu, Y.-N.; Ho, W.-F. Hydroxyapatite synthesized from oyster shell powders by ball milling and heat treatment. Mater. Charact. 2011, 62, 1180–1187. [Google Scholar] [CrossRef]

- Luo, H.; Huang, G.; Fu, X.; Liu, X.; Zheng, D.; Peng, J.; Zhang, K.; Huang, B.; Fan, L.; Chen, F.; et al. Waste oyster shell as a kind of active filler to treat the combined wastewater at an estuary. J. Environ. Sci. 2013, 25, 2047–2055. [Google Scholar] [CrossRef]

- Lee, M.; Tsai, W.-S.; Chen, S.-T. Reusing shell waste as a soil conditioner alternative? A comparative study of eggshell and oyster shell using a life cycle assessment approach. J. Clean. Prod. 2020, 265, 121845. [Google Scholar] [CrossRef]

- Goldsborough, W.; Meritt, D. Oyster Gardening for Restoration & Education; University of Maryland Center for Environmental Science: Cambridge, MD, USA, 2001; Available online: https://www.mdsg.umd.edu/sites/default/files/files/Oyster-Gardening-Guide-1.pdf (accessed on 27 April 2023).

- Haws, M. The Basic Methods of Pearl Farming: A Layman’s Manual. Center for Tropica, and Subtropical Aquaculture, Publication No. 127. 2002; University of Hawaii: Hilo, HI, USA, 2002; Available online: https://www.ctsa.org/files/publications/CTSA_1276316728619239483681.pdf (accessed on 26 April 2023).

- Andréfouët, S.; Thomas, Y.; Lo, C. Amount and type of derelict gear from the declining black pearl oyster aquaculture in Ahe atoll lagoon, French Polynesia. Mar. Pollut. Bull. 2014, 83, 224–230. [Google Scholar] [CrossRef] [PubMed]

- Gardon, T.; Reisser, C.; Soyez, C.; Quillien, V.; Le Moullac, G. Microplastics affect energy balance and gametogenesis in the pearl oyster Pinctada margaritifera. Environ. Sci. Technol. 2018, 52, 5277–5286. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gardon, T.; Morvan, L.; Huvet, A.; Quillien, V.; Soyez, C.; Le Moullac, G.; Le Luyer, J. Microplastics induce dose-specific transcriptomic disruptions in energy metabolism and immunity of the pearl oyster Pinctada margaritifera. Environ. Pollut. 2020, 266, 115180. [Google Scholar] [CrossRef] [PubMed]

- D’Eusanio, M.; Serreli, M.; Petti, L. Social life-cycle assessment of a piece of jewellery. Emphasis on the local community. Resources 2019, 8, 158. [Google Scholar] [CrossRef] [Green Version]

| Inputs | Value |

|---|---|

| Materials and fuel | |

| High-density polyethylene (HDPE) | 8 |

| Polyvinyl chloride (PVC) | 0.8 |

| Rubber | 0.1 |

| Concrete (kg) | 0.6 |

| Wood (m3) | 102 |

| Fuel (l) | 45 |

| Engine oil (l) | 0.4 |

| Energy | |

| Electricity (kWh) | 0.5 |

| Resources | |

| Seawater (m3) | 2.12 |

| Freshwater (m3) | 0.1 |

| Greenhouse Gas | Emission Values (kg) | Global Warming Potential Values (kg CO2eq) |

|---|---|---|

| Carbon dioxide (CO2) | 1.1 × 10−1 | 0.10 |

| Methane (CH4) | 5.1 × 10−2 | 1.43 |

| Nitrous oxides (N2O) | 1.3 × 10−2 | 3.45 |

| Total global warming potential | 4.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinka, D.; Matsubae, K. Global Warming Potential and Waste Handling of Pearl Farming in Ago Bay, Mie Prefecture, Japan. Resources 2023, 12, 75. https://doi.org/10.3390/resources12070075

Pinka D, Matsubae K. Global Warming Potential and Waste Handling of Pearl Farming in Ago Bay, Mie Prefecture, Japan. Resources. 2023; 12(7):75. https://doi.org/10.3390/resources12070075

Chicago/Turabian StylePinka, Dheanara, and Kazuyo Matsubae. 2023. "Global Warming Potential and Waste Handling of Pearl Farming in Ago Bay, Mie Prefecture, Japan" Resources 12, no. 7: 75. https://doi.org/10.3390/resources12070075

APA StylePinka, D., & Matsubae, K. (2023). Global Warming Potential and Waste Handling of Pearl Farming in Ago Bay, Mie Prefecture, Japan. Resources, 12(7), 75. https://doi.org/10.3390/resources12070075