Separation of Cellulose from Wastewater and Valorisation via Pyrolysis: A Case Study in the Czech Republic

Abstract

1. Introduction

2. Materials and Methods

2.1. Cellulose Separation

2.2. Pyrolytic Tests

2.3. Analytical Methods

2.4. Evaluation of the Scenarios

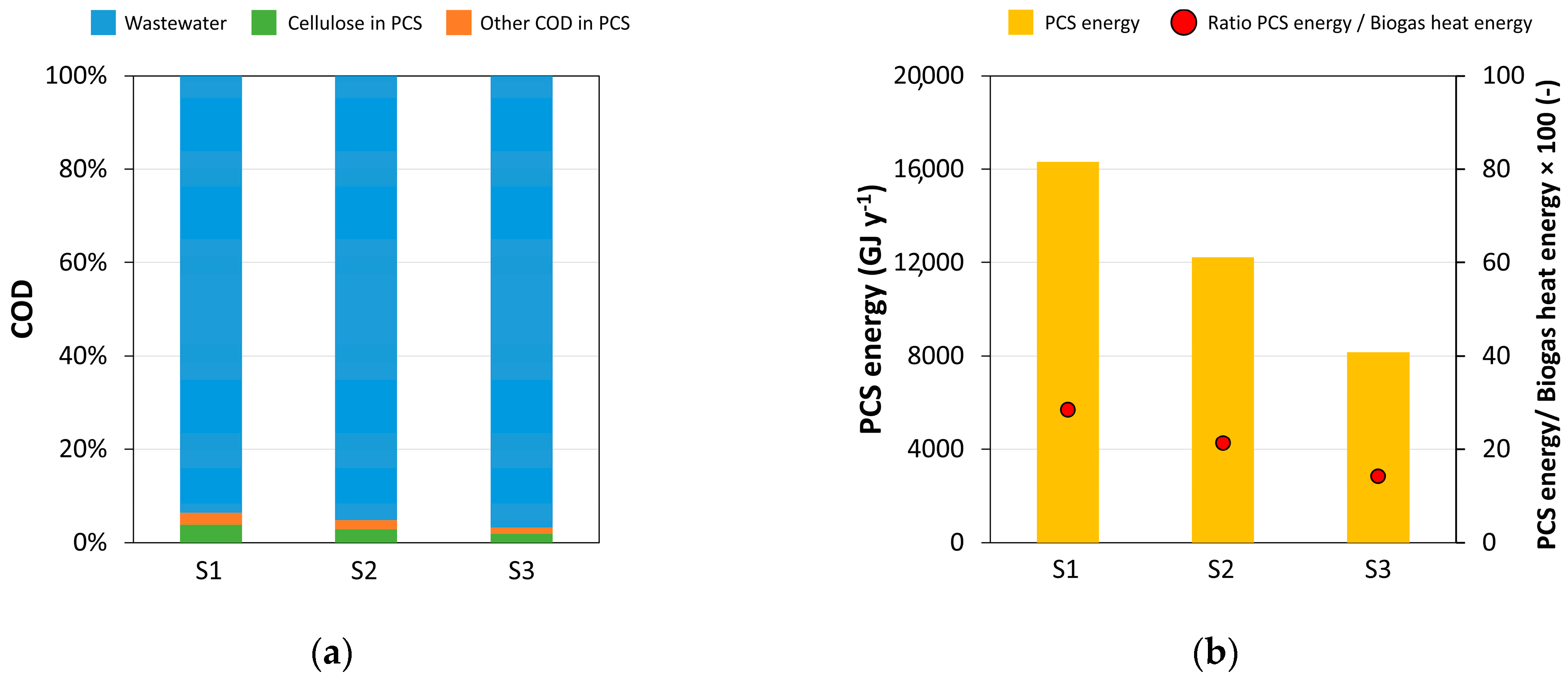

- Scenario 1 (S1): 100% of the cellulose is recovered. Given the application of a multiple-stage mechanical separation system, the cellulose separation from WW flux in this study is assumed to be close to complete.

- Scenario 2 (S2): 75% of the cellulose in the WW is separated and recovered.

- Scenario 3 (S3): Only 50% of the cellulose in the WW is separated and recovered.

3. Results and Discussion

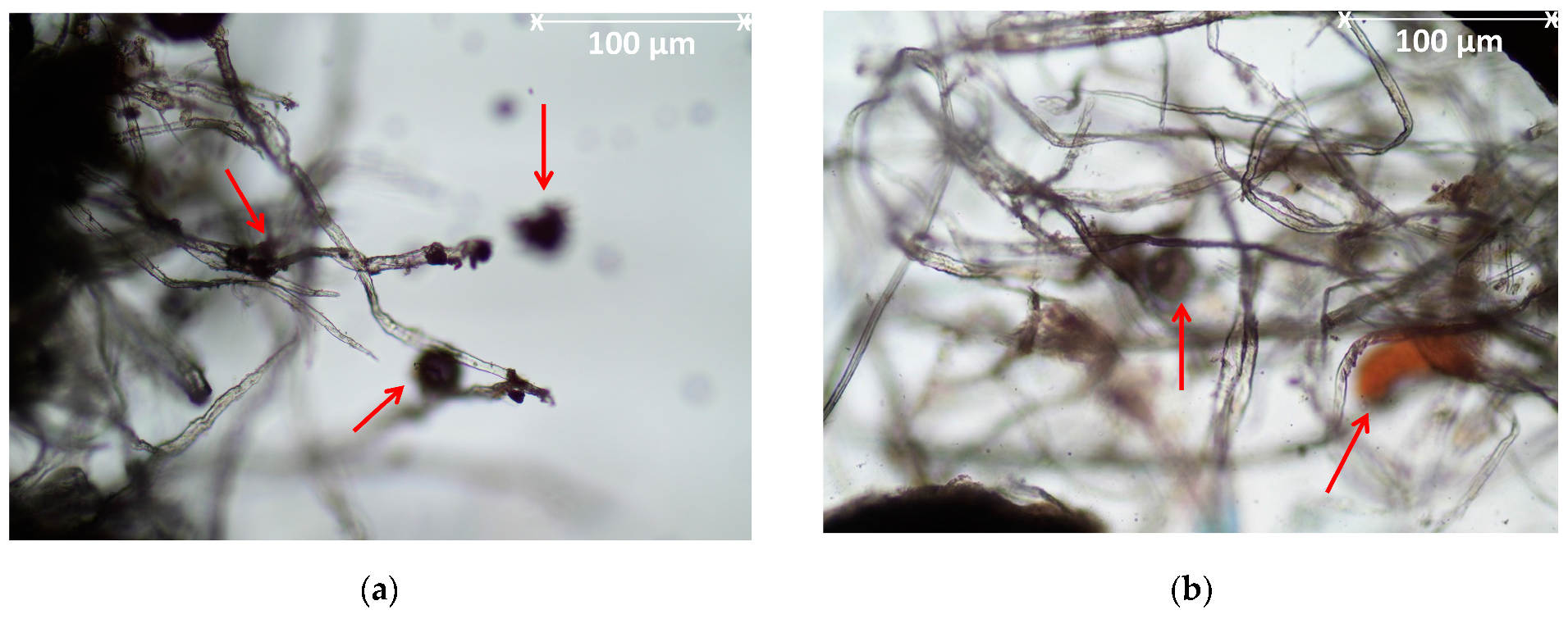

3.1. Cellulose Separation and Characterization

3.2. Production of Carbon-Based Material from Medium-Temperature Pyrolysis

3.3. Production of D-PCS and P-PCS: Estimation in the Case Study

3.4. Impact of Cellulose Separation on the Operation of the WWTP

3.4.1. COD Fluxes

3.4.2. Energy Content

3.5. Limitations of the Study and “Open Questions”

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fernández-Arévalo, T.; Lizarralde, I.; Fdz-Polanco, F.; Pérez-Elvira, S.I.; Garrido, J.M.; Puig, S.; Poch, M.; Grau, P.; Ayesa, E. Quantitative Assessment of Energy and Resource Recovery in Wastewater Treatment Plants Based on Plant-Wide Simulations. Water Res. 2017, 118, 272–288. [Google Scholar] [CrossRef] [PubMed]

- Maktabifard, M.; Zaborowska, E.; Makinia, J. Achieving Energy Neutrality in Wastewater Treatment Plants through Energy Savings and Enhancing Renewable Energy Production. Rev. Environ. Sci. Biotechnol. 2018, 17, 655–689. [Google Scholar] [CrossRef]

- Awe, O.W.; Liu, R.; Zhao, Y. Analysis of Energy Consumption and Saving in Wastewater Treatment Plant: Case Study from Ireland. J. Water Sustain. 2016, 6, 63–76. [Google Scholar] [CrossRef]

- Djordjevićová, D.; Carnevale Miino, M.; Raček, J.; Hlavínek, P.; Chorazy, T.; Rajaković-Ognjanović, V.; Cvijetić, N. Influence of Cellulose on the Anoxic Treatment of Domestic Wastewater in Septic Tanks: Statistical Analysis of the Chemical and Physico-Chemical Parameters. Sustainability 2023, 15, 7990. [Google Scholar] [CrossRef]

- Statista Toilet Paper—Worldwide. Available online: https://www.statista.com/outlook/cmo/tissue-hygiene-paper/toilet-paper/worldwide?currency=usd (accessed on 7 July 2023).

- Chen, R.; Nie, Y.; Kato, H.; Wu, J.; Utashiro, T.; Lu, J.; Yue, S.; Jiang, H.; Zhang, L.; Li, Y.-Y. Methanogenic Degradation of Toilet-Paper Cellulose upon Sewage Treatment in an Anaerobic Membrane Bioreactor at Room Temperature. Bioresour. Technol. 2017, 228, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Crutchik, D.; Frison, N.; Eusebi, A.L.; Fatone, F. Biorefinery of Cellulosic Primary Sludge towards Targeted Short Chain Fatty Acids, Phosphorus and Methane Recovery. Water Res. 2018, 136, 112–119. [Google Scholar] [CrossRef]

- Ghasimi, D. Bio-Methanation of Fine Sieved Fraction Sequestered from Raw Municipal Sewage; Technische Universiteit Delft: Delft, The Netherlands, 2016. [Google Scholar]

- Tsavkelova, E.A.; Netrusov, A.I. Biogas Production from Cellulose-Containing Substrates: A Review. Appl. Biochem. Microbiol. 2012, 48, 421–433. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H.; Öz, C. Progress in Bioethanol Processing. Prog. Energy Combust. Sci. 2008, 34, 551–573. [Google Scholar] [CrossRef]

- Pirraglia, A.; Gonzalez, R.; Saloni, D.; Denig, J. Technical and Economic Assessment for the Production of Torrefied Ligno-Cellulosic Biomass Pellets in the US. Energy Convers. Manag. 2013, 66, 153–164. [Google Scholar] [CrossRef]

- Si, Y.; Hu, J.; Wang, X.; Yang, H.; Chen, Y.; Shao, J.; Chen, H. Effect of Carboxymethyl Cellulose Binder on the Quality of Biomass Pellets. Energy Fuels 2016, 30, 5799–5808. [Google Scholar] [CrossRef]

- Cipolletta, G.; Eusebi, A.L.; Palmieri, S.; Giosuè, C.; Tittarelli, F.; Frison, N.; Pastore, C.; Foglia, A.; Fatone, F. Toilet Paper Recovery from Municipal Wastewater and Application in Building Sector. IOP Conf. Ser. Earth Environ. Sci. 2019, 296, 012024. [Google Scholar] [CrossRef]

- Akyol, Ç.; Eusebi, A.L.; Cipolletta, G.; Bruni, C.; Foglia, A.; Giosuè, C.; Frison, N.; Tittarelli, F.; Canestrari, F.; Fatone, F. Cellulosic Materials Recovery from Municipal Wastewater: From Treatment Plants to the Market. In Clean Energy and Resource Recovery; Elsevier: Amsterdam, The Netherlands, 2022; pp. 125–136. [Google Scholar]

- Akyol, Ç.; Foglia, A.; Ozbayram, E.G.; Frison, N.; Katsou, E.; Eusebi, A.L.; Fatone, F. Validated Innovative Approaches for Energy-Efficient Resource Recovery and Re-Use from Municipal Wastewater: From Anaerobic Treatment Systems to a Biorefinery Concept. Crit. Rev. Environ. Sci. Technol. 2020, 50, 869–902. [Google Scholar] [CrossRef]

- Thakur, V.K. (Ed.) Lignocellulosic Polymer Composites; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; ISBN 9781118773949. [Google Scholar]

- Hu, F.; Zeng, J.; Cheng, Z.; Wang, X.; Wang, B.; Zeng, Z.; Chen, K. Cellulose Nanofibrils (CNFs) Produced by Different Mechanical Methods to Improve Mechanical Properties of Recycled Paper. Carbohydr. Polym. 2021, 254, 117474. [Google Scholar] [CrossRef] [PubMed]

- Chen, H. Biotechnology of Lignocellulose; Springer: Dordrecht, The Netherlands, 2014; ISBN 978-94-007-6897-0. [Google Scholar]

- Kim, D.; Park, K.Y.; Yoshikawa, K. Conversion of Municipal Solid Wastes into Biochar through Hydrothermal Carbonization. In Engineering Applications of Biochar; IntechOpen: Rijeka, Croatia, 2017. [Google Scholar]

- Zhang, C.; Chao, L.; Zhang, Z.; Zhang, L.; Li, Q.; Fan, H.; Zhang, S.; Liu, Q.; Qiao, Y.; Tian, Y.; et al. Pyrolysis of Cellulose: Evolution of Functionalities and Structure of Bio-Char versus Temperature. Renew. Sustain. Energy Rev. 2021, 135, 110416. [Google Scholar] [CrossRef]

- Raček, J.; Sevcik, J.; Chorazy, T.; Kucerik, J.; Hlavínek, P. Biochar—Recovery Material from Pyrolysis of Sewage Sludge: A Review. Waste Biomass Valorization 2020, 11, 3677–3709. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A. Feedstock and Process Influence on Biodiesel Produced from Waste Sewage Sludge. J. Environ. Manag. 2018, 216, 176–182. [Google Scholar] [CrossRef]

- Novotný, M.; Marković, M.; Raček, J.; Šipka, M.; Chorazy, T.; Tošić, I.; Hlavínek, P. The Use of Biochar Made from Biomass and Biosolids as a Substrate for Green Infrastructure: A Review. Sustain. Chem. Pharm. 2023, 32, 100999. [Google Scholar] [CrossRef]

- Petreje, M.; Sněhota, M.; Chorazy, T.; Novotný, M.; Rybová, B.; Hečková, P. Performance Study of an Innovative Concept of Hybrid Constructed Wetland-Extensive Green Roof with Growing Media Amended with Recycled Materials. J. Environ. Manag. 2023, 331, 117151. [Google Scholar] [CrossRef]

- Chen, L.; Liao, Y.; Guo, Z.; Cao, Y.; Ma, X. Products Distribution and Generation Pathway of Cellulose Pyrolysis. J. Clean. Prod. 2019, 232, 1309–1320. [Google Scholar] [CrossRef]

- Ahmed, A.S.; Khalil, A.; Ito, Y.; van Loosdrecht, M.C.M.; Santoro, D.; Rosso, D.; Nakhla, G. Dynamic Impact of Cellulose and Readily Biodegradable Substrate on Oxygen Transfer Efficiency in Sequencing Batch Reactors. Water Res. 2021, 190, 116724. [Google Scholar] [CrossRef]

- Liu, R.; Li, Y.; Zhang, M.; Hao, X.; Liu, J. Review on the Fate and Recovery of Cellulose in Wastewater Treatment. Resour. Conserv. Recycl. 2022, 184, 106354. [Google Scholar] [CrossRef]

- Ruiken, C.J.; Breuer, G.; Klaversma, E.; Santiago, T.; van Loosdrecht, M.C.M. Sieving Wastewater—Cellulose Recovery, Economic and Energy Evaluation. Water Res. 2013, 47, 43–48. [Google Scholar] [CrossRef] [PubMed]

- American Public Health Association. APHA Standard Methods for the Examination of Water and Wastewater; American Public Health Association (APHA): Washington, DC, USA, 2012; Volume 10. [Google Scholar]

- ČSN ČSN EN ISO 1716 (730883); Testing the Reaction of Products to Fire—Determination of Heat of Combustion (Caloric Values). Czech Standardization Agency (ČSN): Prague, Czech Republic, 1999. Available online: https://www.technicke-normy-csn.cz/csn-en-iso-1716-730883-222197.html (accessed on 19 May 2023). (In Czech)

- ČSN EN ISO 11885 (757387); Water Quality—Determination of 33 Elements by Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP AES). Czech Standardization Agency (ČSN): Prague, Czech Republic, 1999. (In Czech)

- ČSN EN 13657 (838015); Characterization of Waste—Digestion for Subsequent Determination of Aqua Regia Soluble Portion of Elements. Czech Standardization Agency (ČSN): Prague, Czech Republic, 2003. (In Czech)

- ČSN 46 5735 (465735); Industrial Composts. Czech Standardization Agency (ČSN): Prague, Czech Republic, 1991. (In Czech)

- ČSN EN 12879 (758005); Characterization of Sludges—Determination of the Loss on Ignition of Dry Mass. Czech Standardization Agency (ČSN): Prague, Czech Republic, 2001. (In Czech)

- ČSN EN 12880 (758006); Characterization of Sludges—Determination of Dry Residue and Water Content. Czech Standardization Agency (ČSN): Prague, Czech Republic, 2001. (In Czech)

- ČSN EN 12176 (758010); Characterization of Sludge—Determination of PH-Value. Czech Standardization Agency (ČSN): Prague, Czech Republic, 1999. (In Czech)

- Raček, J.; Doskočil, B.; Ševčík, J.; Chorazy, T.; Hlavínek, P. Drying Sewage Sludge for the Conditions of the Czech Republic. Vodovod Info 2018, 2018, 14. (In Czech) [Google Scholar]

- Kim, D.; Yoshikawa, K.; Park, K. Characteristics of Biochar Obtained by Hydrothermal Carbonization of Cellulose for Renewable Energy. Energies 2015, 8, 14040–14048. [Google Scholar] [CrossRef]

- Chen, R.; Nie, Y.; Tanaka, N.; Niu, Q.; Li, Q.; Li, Y.-Y. Enhanced Methanogenic Degradation of Cellulose-Containing Sewage via Fungi-Methanogens Syntrophic Association in an Anaerobic Membrane Bioreactor. Bioresour. Technol. 2017, 245, 810–818. [Google Scholar] [CrossRef]

- BVK Annual Report 2020; Brněnské vodárny a kanalizace: Brno, Czech Republic, 2020. (In Czech)

| Parameter (u.m.) | Value |

|---|---|

| Flow (m3 d−1) | 76,400–98,000 |

| BOD5 (mg L−1) | 285–395 |

| COD (mg L−1) | 620–900 |

| TSS (mg L−1) | 290–480 |

| TDS (mg L−1) | 820–926 |

| pH (-) | 7.6–7.7 |

| EC (µS cm−1) | 1313–1444 |

| N-NH4+ (mg L−1) | 41–50 |

| N-NO3− (mg L−1) | <0.05 |

| N-NO2− (mg L−1) | <0.01 |

| Ntot (mg L−1) | 61.7–68 |

| Ptot (mg L−1) | 7.06–8.71 |

| AOX (mg L−1) | 0.3–0.4 |

| Tmin (°C) | 15–20 |

| Tmax (°C) | 26.1–34.9 |

| PCS (±SD) [n = 5] | T-PCS (±SD) [n = 3] | |

|---|---|---|

| Physicochemical parameters | ||

| DM (%) | 14.6 ± 1.5 | 21.7 ± 1.3 |

| pH (-) | 7.4 ± 0.2 | n.e. |

| ROI (%DM) | n.e. | 16.8 ± 0.8 |

| LOI (%DM) | 94.5 ± 9.5 | 83.2 ± 4.2 |

| Chemical parameters | ||

| Total P (mg kg−1DM) | 3670 ± 734 | n.e. |

| As (mg kg−1DM) | 6.30 ± 1.30 | 0.68 ± 0.14 |

| Cd (mg kg−1DM) | ˂0.50 | ˂0.40 |

| Cr (mg kg−1DM) | 26.1 ± 5.2 | n.e. |

| Pb (mg kg−1DM) | 16.1 ± 3.2 | 15.6 ± 3.1 |

| Cu (mg kg−1DM) | n.e. | 102 ± 20.4 |

| Ni (mg kg−1DM) | 10.5 ± 2.1 | 15.2 ± 3 |

| Hg (mg kg−1DM) | 0.6 ± 0.1 | 0.5 ± 0.1 |

| Zn (mg kg−1DM) | 350 ± 70 | 503 ± 100.1 |

| V (mg kg−1DM) | n.e. | 6.5 ± 1.3 |

| Scenario 1 | Scenario 2 | Scenario 3 | |

|---|---|---|---|

| CODD-PCS (kg y−1) | 1,485,833 | 1,114,375 | 742,917 |

| CH4 production (Mm3 y−1) | 0.51 | 0.38 | 0.25 |

| Biogas production (Mm3 y−1) | 0.72 | 0.54 | 0.36 |

| Ratio with current scenario (%) | 14.80 | 11.10 | 7.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Djordjevićová, D.; Carnevale Miino, M.; Raček, J.; Chorazy, T.; Hlavínek, P.; Vranayova, Z. Separation of Cellulose from Wastewater and Valorisation via Pyrolysis: A Case Study in the Czech Republic. Resources 2024, 13, 51. https://doi.org/10.3390/resources13040051

Djordjevićová D, Carnevale Miino M, Raček J, Chorazy T, Hlavínek P, Vranayova Z. Separation of Cellulose from Wastewater and Valorisation via Pyrolysis: A Case Study in the Czech Republic. Resources. 2024; 13(4):51. https://doi.org/10.3390/resources13040051

Chicago/Turabian StyleDjordjevićová, Denisa, Marco Carnevale Miino, Jakub Raček, Tomáš Chorazy, Petr Hlavínek, and Zuzana Vranayova. 2024. "Separation of Cellulose from Wastewater and Valorisation via Pyrolysis: A Case Study in the Czech Republic" Resources 13, no. 4: 51. https://doi.org/10.3390/resources13040051

APA StyleDjordjevićová, D., Carnevale Miino, M., Raček, J., Chorazy, T., Hlavínek, P., & Vranayova, Z. (2024). Separation of Cellulose from Wastewater and Valorisation via Pyrolysis: A Case Study in the Czech Republic. Resources, 13(4), 51. https://doi.org/10.3390/resources13040051