Abstract

The purpose of this study was to investigate the effects of solar drying and oven drying methods on the quality parameters of dried basil (Ocimum basilicum L.) leaves. The dried basil leaves were dehydrated at three different levels of temperature (T1, T2, and T3 = 50 °C, 55 °C, and 60 °C) using a solar tunnel dryer and an electrical oven dryer. Drying time, energy consumption, dehydration ratio, rehydration ratio, pH, and reducing sugar were observed after drying the basil leaves. The results showed that solar drying at 55 °C required the least energy (0.431 kWh) and took the shortest amount of time (110 min) to complete, whereas oven drying consumed more energy. Additionally, oven drying maintained a low pH (4.30) and reducing sugar level (2.24), extending the shelf life of the dried basil leaves, compared to solar drying. Based on energy consumption, drying time, and mineral contents, the solar drying using a solar tunnel dryer was deemed more suitable than oven drying. The best temperature for drying was determined to be 55 °C, which provided a short drying time, the least energy consumption and a statistically non-significant loss of mineral contents and dehydration ratio. Moreover, solar drying demonstrated a significantly higher speed, with a 6.7-times higher drying rate compared to oven drying, with significantly less energy consumption.

1. Introduction

Basil, also known as Ocimum basilicum L., is a well-known herb from the family La-miaccae which is either an annual or perennial. It is native to Africa, India, and Asia, and has around 150 different varieties, grown in temperate climates worldwide. In India and Pakistan, it is referred to as “Tulsi”, and it holds religious significance in the Greek, Serbian, and Macedonian Orthodox churches, as well as the Hindu religion. Lamiaceae family plants’ extracts have been found to contain several phenolic compounds with potent antioxidant activity, as identified in studies by Nadeem et al. [1] and Nguyen et al. [2].

Basil, in its fresh form, is a popular ingredient in Mediterranean cuisine, commonly used in dishes such as tomato-based products, salads, vegetables, pizza, soups, meat, and seafood. The essential oils present in basil, such as linalool and methyl chavicol, contribute to its unique taste profile [3]. The overall flavor can be described as herbaceous with a hint of anise, making it a popular ingredient in various culinary dishes, especially in Mediterranean and Asian cuisines. Dried and ground basil leaves are also used as a spice in bakery products, confectionery, ice creams, vinegars, and meat products, providing a unique and distinct flavor. Calderón Bravo et al. [4] have documented these uses of basil in their research.

Basil has a multitude of uses, ranging from traditional medicine to culinary purposes, and is a well-known source of flavoring agents, according to Calderón Bravo, Vera Céspedes, Zura-Bravo, and Muñoz [4]. The cosmetic industry also utilizes basil in various products such as soaps, shampoos, lotions, oils, and perfumes. The oil derived from basil has many uses in aromatherapy and is known to be effective in treating stress, migraines, colds, and hay fever [5]. Basil tea is believed to aid digestion through its potential to relax the muscles of the gastrointestinal tract. Compounds, like eugenol, found in basil have been suggested to have anti-inflammatory and antimicrobial properties which may help soothe digestive issues. Additionally, basil may stimulate the production of digestive enzymes, promoting a more efficient digestive process and potentially relieving symptoms like gas, stomach cramps, constipation, diarrhea, and vomiting. It is also believed to have positive effects on mental fatigue and nervous conditions, while hyssop is used as a cough remedy. Thai basil oil obtained from the aerial parts of Ocimum basilicum L. and Ocimum amricana L. has been employed in traditional medicine for various tropical applications, such as poultices or salves for insect bites and ringworms, since ancient times. In addition, seed extract from basil has been found to possess antibacterial properties. The presence of anti-oxidative and antimicrobial constituents in the tissues of many plant species and herbs, including basil, indicates their potential as preservatives, as highlighted in studies by Kamelnia et al. [6] and Sharifi-Rad et al. [7].

Basil leaves and flowers are frequently used in raw or cooked form as a flavoring agent in dishes like tomato-based preparations, pasta sauces, and beans. Historically, basil was utilized as a strewing herb, according to Kumar et al. [8]. To preserve basil leaves, various methods can be employed, but dehydration is the most widely used and effective approach. This method enhances the shelf life of basil leaves by preventing the growth of microbes and hindering the oxidation process that could alter the organoleptic and nutritious properties of the dried leaves. It is crucial to perform drying with care to maintain the aroma, look, and nutritious characteristics of the raw herbs as much as possible [9,10]. The drying process may result in the loss of volatiles or the formation of new volatiles due to oxidation or esterification reactions [7,11].

Dehydration techniques using solar drying are currently extensively utilized. There are several types, designs, and modes of operation of solar dryers that aim to reduce drying times and costs. For instance, Vijayan et al. [12] mentioned the use of indirect forced convection, while Srinivasan and Muthukumar [13] discussed the greenhouse solar dryers. Other methods include the use of an indirect natural convection solar dryer with chimney, a solar dryer with a greenhouse as a collector, a solar tunnel dryer (air collector), and a hybrid solar dryer assisted by evacuated tube collectors, as mentioned by Margarita et al. [14]. Shaw et al. [15] recommended the hot-air drying of herbs at 40–60 °C. Calín-Sánchez et al. [16], in a study, demonstrated that increasing the drying temperature from 40 to 60 °C enhances the spicy, hay-like, sweet, earthy, and woody flavors in dried basil leaves, although it may result in a lower content of total volatiles and a less fresh-herb aroma. Asnaz and Dolcek [17] mentioned that overall, solar drying is regarded as the most hygienic drying method.

Drying basil leaves using conventional oven drying is another controlled method, but the high temperatures employed may damage the color and cause the loss of heat-sensitive nutrients [16,18,19]. The drying process involves the addition of heat and the removal of moisture from the leaves; high moisture levels in leaves, fruits, and other foods provide a suitable environment for microorganism growth, which can cause spoilage and waste. Different drying methods have different impacts on the quality of dried products [18,20] and can affect the nutrient content of food, increasing the availability of some nutrients and reducing the concentration of others [21].

Therefore, it is necessary to find the optimum drying conditions to be used to dehydrate the basil leaves while achieving quality retention. In this study, solar drying and oven drying methods were investigated, using three temperatures, to study their effects on the quality parameters of dried basil leaves; these parameters include dehydration ratio, rehydration ratio, pH, reducing sugar, and mineral contents. The utilization of solar drying techniques in the production of dried basil leaves aligns with key objectives outlined in the United Nations Sustainable Development Goals (SDGs), particularly those related to affordable and clean energy, responsible consumption and production, and climate action.

2. Materials and Methods

It is recommended that the hot-air drying of herbs be carried out at 40–60 °C [15]. Studies have shown that increasing the drying temperature from 40 to 60 °C results in a lower content of total volatiles, a less fresh-herb aroma, and an increase in spicy, hay-like, sweet, earthy, and woody flavors in dried basil leaves [16]. In the current study, the basil leaves underwent washing to eliminate dirt, dust, and foreign matter. They were then subjected to dehydration at three different temperature levels (T1, T2, and T3 = 50 ± 1 °C, 55 ± 1 °C, and 60 ± 1 °C) using solar drying and oven drying methods to identify the ideal drying temperature.

2.1. Drying of Basil Leaves

The indigenous solar tunnel dryer is composed of five main components, including a solar collector with a black plate that absorbs solar energy and transforms it into heat. The heated air is then blown over the product to be dried, which reduces the humidity. The incoming sunlight evaporates the moisture content from the food, and a blower powered by a photovoltaic module maintains the temperature inside the dryer [22].

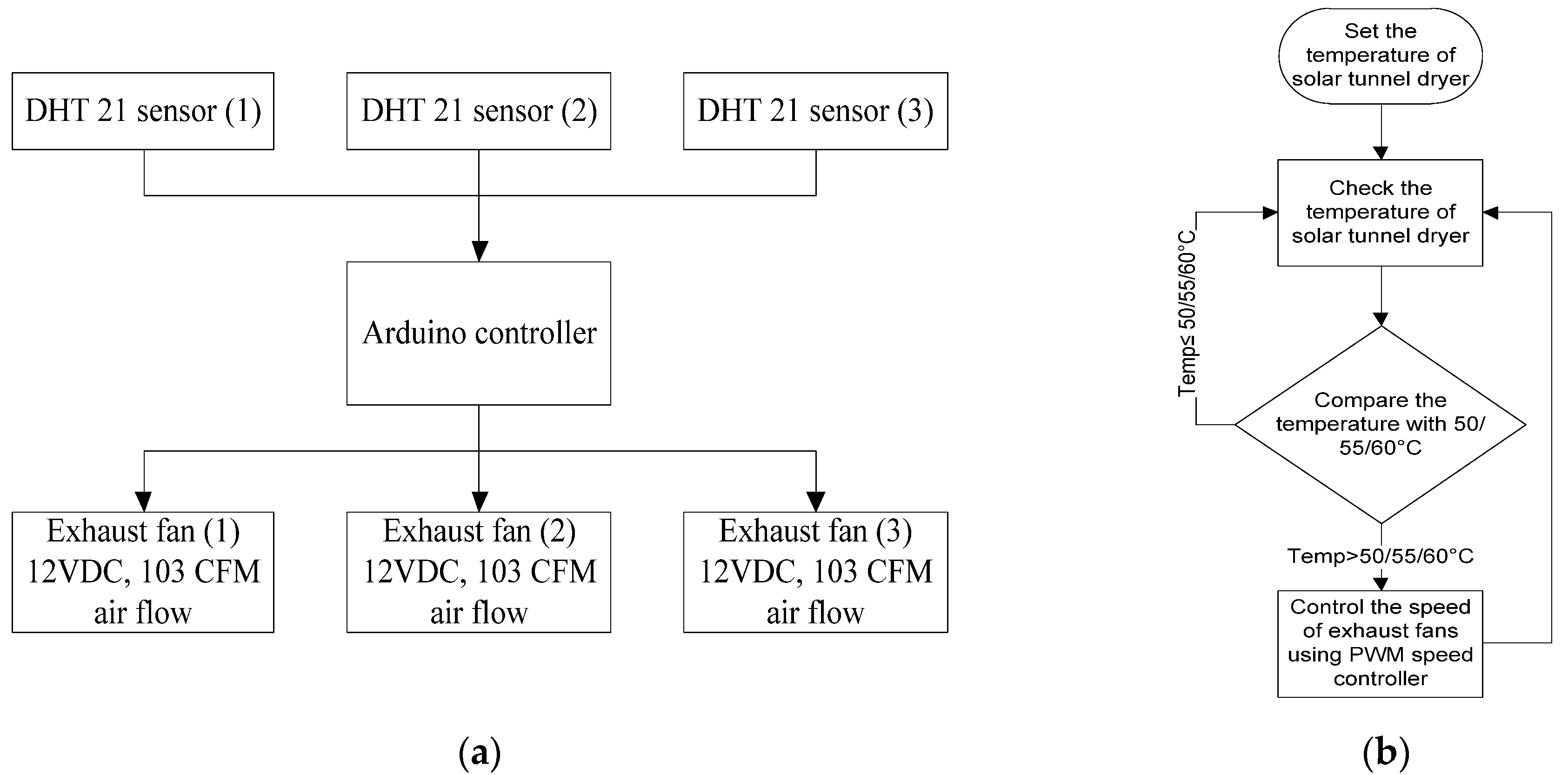

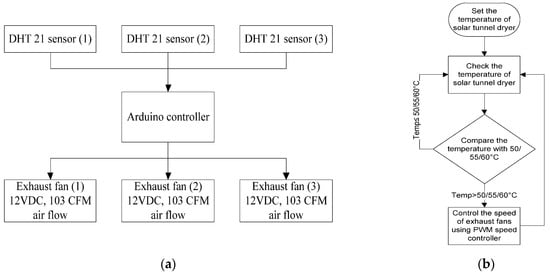

Figure 1a shows the control system of a solar tunnel dryer. It is based on an Arduino controller which takes the temperature and humidity values from three DHT 21 sensors variously installed at the air inlet, the middle of the dryer, and the exhaust-air end of the dryer. Three exhaust fans were used at the exhaust-air end of dryer; these were operated in combinations by the controller to control the inside temperature through the flow of air. The controller turns on/off the fans and adjusts the speed using pulse-width modulation (PWM) speed controller to maintain the dryer temperature (Figure 1b).

Figure 1.

(a) Control system and (b) operational procedure of the solar tunnel dryer.

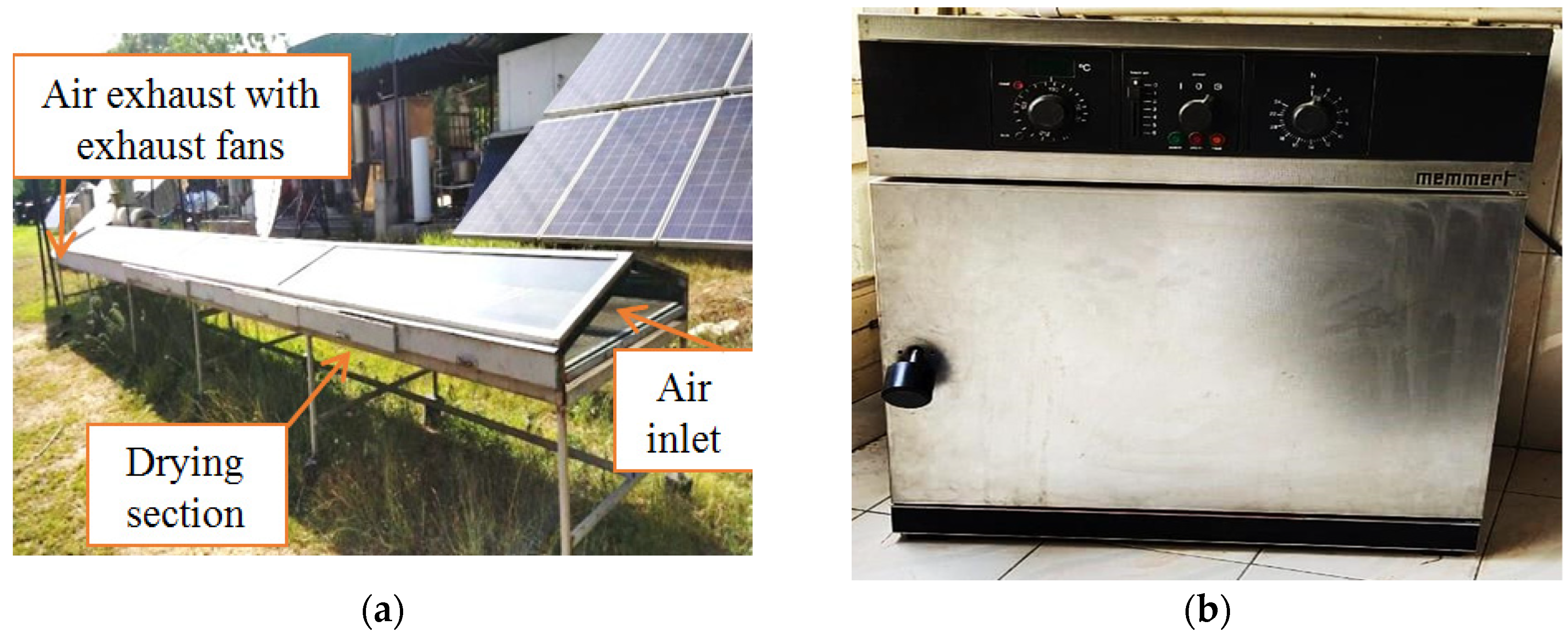

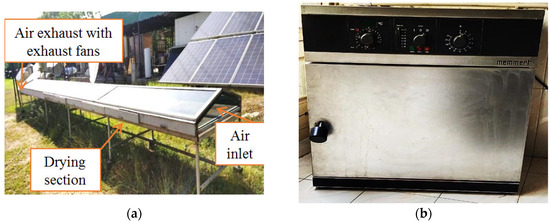

As a comparison, an electrical oven was used as a conventional dryer to determine the best temperature for drying basil leaves using the ASAE (American Society of Agricultural Engineers) procedure of drying, as described in Equation (1). Basil leaves were dried in the solar tunnel dryer (Figure 2a) at three different temperature levels (T1, T2, and T3 = 50 ± 1 °C, 55 ± 1 °C, and 60 ± 1 °C) and 29–36% relative humidity to observe the drying rate and energy consumption [22]. To provide a comparison, an electrical oven (Figure 2b) was used as a conventional dryer to determine the best temperature among (T1, T2, and T3 = 50 ± 1 °C, 55 ± 1 °C, and 60 ± 1 °C) for drying the basil leaves using the ASAE procedure and Equation (1). Basil leaves were dried in both the solar tunnel dryer and the oven dryer to observe the drying rate and energy consumption using a pyranometer (Meteon SP Lite 2, Delft, The Netherlands) and an energy meter (BRii SM2731, Wenzhou, Zhejiang, China).

where Wa is the weight of matter after drying (kg) and Wb is the weight of matter before drying (kg).

Figure 2.

Different type of dryers for drying the basil (Ocimum basilicum L.) leaves at 50, 55, and 60 °C: (a) solar tunnel dryer and (b) electric oven dryer with a 2000 W capacity.

2.2. Physiochemical Analysis

Different physicochemical analyses were conducted on dehydrated basil leaves to assess the impacts of drying on the quality attributes of the final products. The moisture content of fresh and dehydrated basil leaves was determined using the method described by Yilmaz and Alibas [23], using the ASAE procedure. For moisture determination, samples were dried in the oven at 130 °C for 60 min. The dehydration ratio, rehydration ratio, pH, and reducing sugar levels were also measured using the respective methods. The dehydration and rehydration ratios of basil leaves were calculated using Equations (2) and (3), respectively, as reported by [24].

where Wa is the weight of matter after dehydration (kg) and Wb is the weight of matter before dehydration (kg).

where Wa is the weight of matter after rehydration (kg) and Wb is the weight of matter before rehydration (kg).

The pH of the dried leaves was measured by use of a pH scale (Model pH N81, Tacussel Electronque, Barby, France) according to method No. 945.27 of the AOAC [25]. Reducing sugar was measured according to the Lane and Eynon method, No. 925.36 as described by the AOAC [25]. An atomic absorption spectrophotometer (Model: 969, Unicam Limited, Cambridge, UK) was used to analyze the minerals, such as Ca, Cu, K, Fe, and Mg, in all treatments. AOAC [25] method No. 985.35 was implemented, and commercially prepared certified AA standard stock solutions were used for mineral determination. The working settings for each mineral were adjusted on the atomic absorption spectrophotometer as shown in Table 1.

Table 1.

The working settings for each mineral, as adjusted on the atomic absorption spectrophotometer.

2.3. Sensory Assessment

The sensory assessment of the dried basil leaves for qualities like color, taste, and aroma was conducted by a skilled taste panel of 20 postgraduate students using a hedonic score system (1 to 10) as defined by Meilgaard et al. [26], for up to two months, fortnightly.

2.4. Statistical Analysis

The effects of the two different dryers on the quality of basil leaves dried at three different temperatures (50 ± 1 °C, 55 ± 1 °C, and 60 ± 1 °C) and 29–36% relative humidity were observed. For this purpose, a two factors factorial (2 × 3) experiment under CRD (Complete Randomized Design) was set with two drying methods, three temperature levels, and three replications in order to observe the dehydration ratio, rehydration ratio, pH, reducing sugar, and mineral contents (Fe, Ca, Cu, K, and Mg). The basil leaves’ powder was stored in an airtight packing of Biaxially Oriented Polypropylene (BOPP) at room temperature (25 °C). A three factors factorial (2 × 3 × 5) experiment under CRD was set with two drying methods, three temperature levels and five days (0, 15, 30, 45, and 60) to observe the color, taste and aroma. The data were analyzed using SAS version 9.1 at a significance level of p ≤ 0.05.

3. Results

3.1. Drying Rates in the Solar and Oven Drying of Basil Leaves

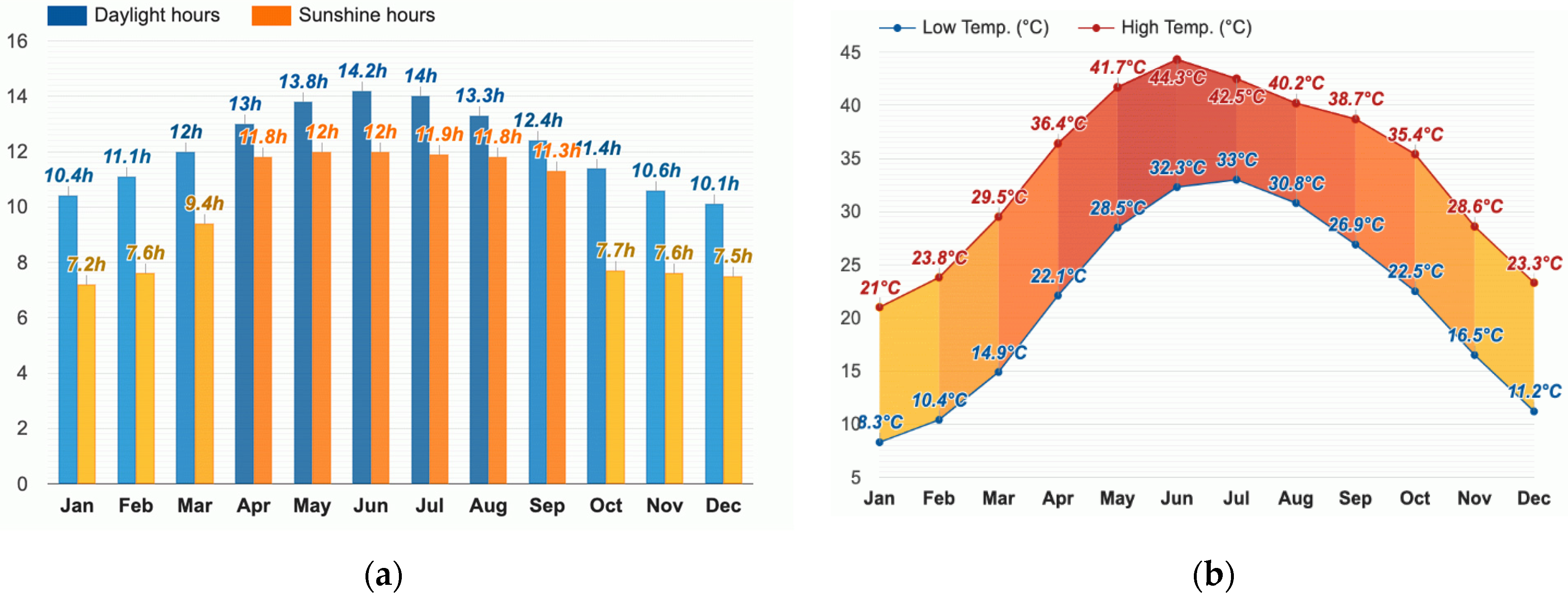

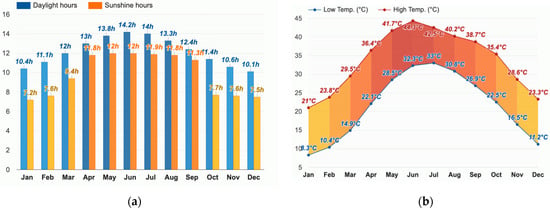

The basil leaves were dried from May–July 2023 in Faisalabad, Pakistan. Figure 3 shows the monthly average daylight/sunshine hours and temperature of Faisalabad, Pakistan for year 2023.

Figure 3.

Monthly average (a) daylight/sunshine hours and (b) temperature of Faisalabad, Pakistan for 2023 (Source: www.weather-atlas.com accessed on 03 May 2024).

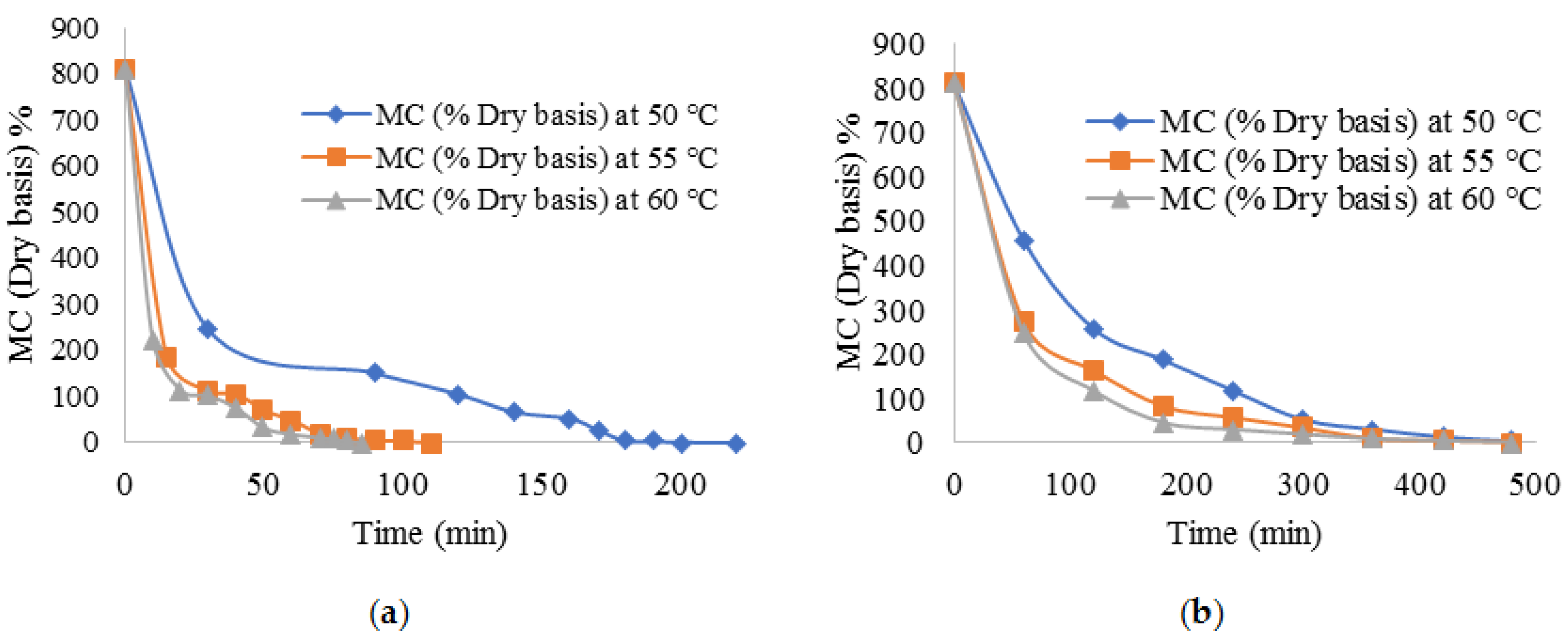

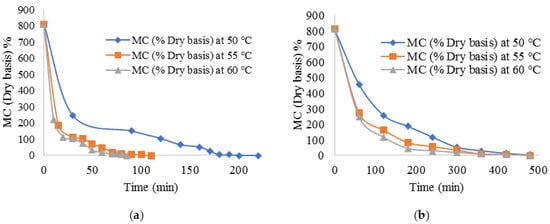

During the months of May, June, and July, average hours of sunlight of 12 h, 12 h, and 11.9 h were recorded with solar irradiation levels of 680–905 W/m2 and high temperatures of 41.7, 44.3, and 42.5 °C, respectively. Relative humidity ranged between 16 and 23%, which helped to speed up the solar drying process. In Figure 4a, it can be seen that in solar drying at 50 °C, the moisture content (d.b) in basil leaves was reduced from 809% to 1.62% in 220 min, while at 55 °C, the moisture content (d.b) was reduced from 809% to 3.6% in 110 min. At 60 °C, the moisture content (d.b) was reduced from 809% to 3.3% in just 85 min. This shows that increased temperature helps to dry the basil leaves more quickly. Figure 4b describes the finding that, in the electrical oven and drying at 50 °C, 55 °C, and 60 °C, the moisture content (d.b) levels in basil leaves were reduced from 809% to 3.1, 4.2, and 4%, respectively, in about 480 min.

Figure 4.

Moisture content of basil leaves at drying temperatures of 50 °C, 55 °C, and 60 °C: (a) in the solar tunnel dryer; and (b) in the electrical oven dryer.

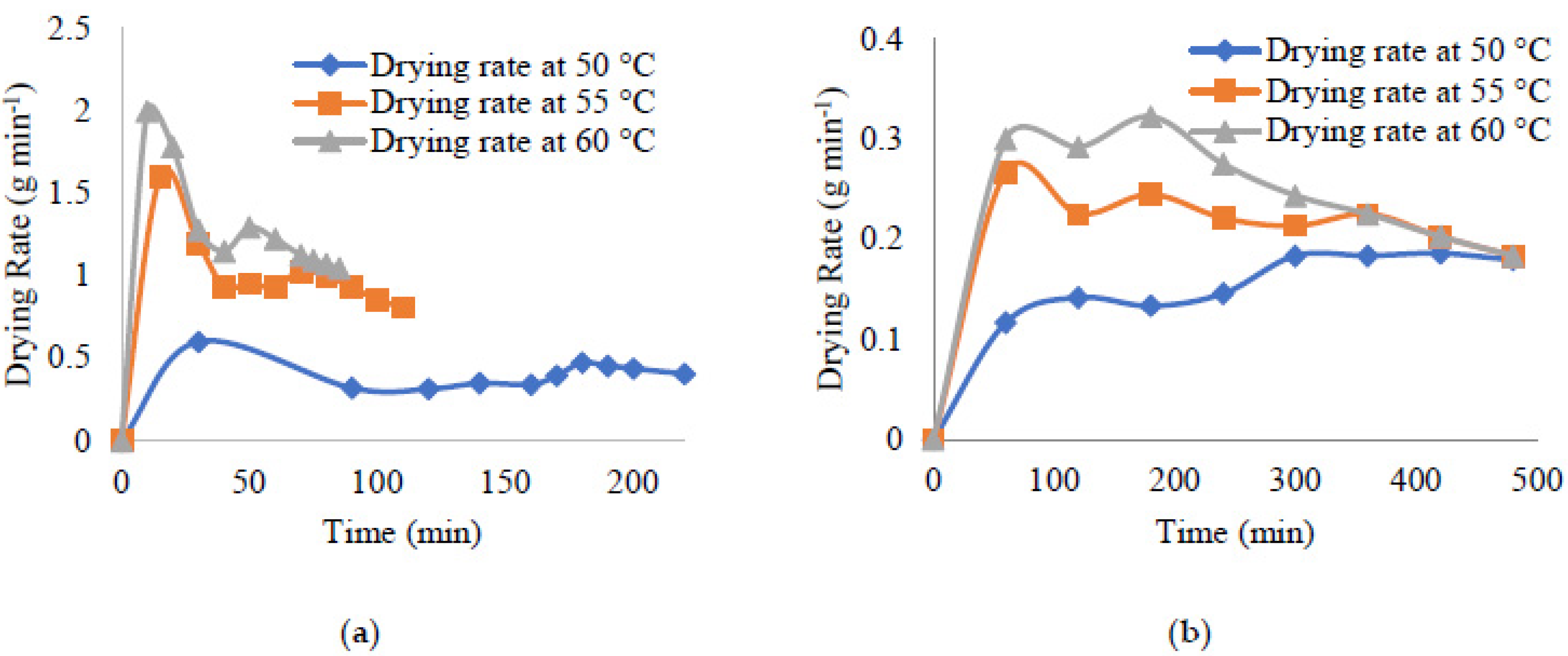

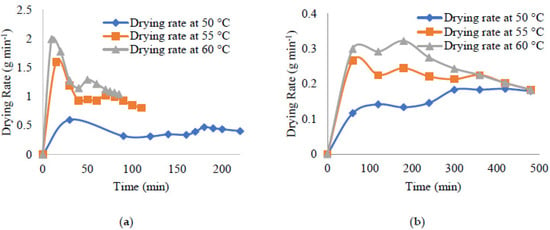

At 50 °C in the solar dryer, the drying rate of basil leaves increased from 0 to 0.6 g min−1 within the interval from 0 to 30 min, and after that point, started to decline, reaching 0.31 in the time interval from 30 to 120 min (Figure 5a). The trend then again changed and started to increase up to 0.45 g min−1 in the time interval from 120 to 190 min. Subsequently, the drying rate started to decrease, reaching 0.4 g min−1 within the time interval from 190 to 220 min. This trend indicates the changing psychrometric characteristics of air passing through the solar tunnel dryer.

Figure 5.

Drying rates of basil leaves at the temperatures of 50 °C, 55 °C, and 60 °C: (a) in the solar tunnel dryer; and (b) in the electrical oven dryer.

At 55 °C in the solar dryer, the drying rate increased from 0 to 1.6 g min−1 within the interval from 0 to 15 min, and after that it declined to 0.94 g min−1 in the time interval from 15 to 40 min. It climbed to 1.03 g min−1 in the time interval from 40 to 70 min, then declined to 0.8 g min−1 within the time interval from 70 to 110 min. At 60 °C in the solar dryer, the drying rate climbed from 0 to 2.0 g min−1 within the interval from 0 to 10 min, and after that it started to decline to 1.15 g min−1 in the time interval from 10 to 40 min. Subsequently, it increased up to 1.29 within the time interval from 40 to 50 min. Between 50 and 85 min, the drying rate declined to 1.04 g min−1. It was found that the higher moisture content in the basil leaves and the low environmental humidity at the start of the drying was the main reason for the initially high drying rate, which tended to decline with the passage of time during drying process.

In oven drying at 50 °C, the drying rate was increasing, rising from 0 to 0.141 g min−1, within the time interval of 0 to 120 min, and after that, a declining trend started, as the values declined from 0.141 to 0.133 g min−1 within the time interval from 120 to 180 min (Figure 5b). Next, from 180 to 420 min, the drying rate increased from 0.133 to 0.186 g min−1, which led to another decline, from 0.186 to 0.179 g min−1, within the interval of time from 420 to 480 min. The observed pattern in the drying rate during oven drying at 50 °C was attributed to the changing moisture content and the influence of factors such as temperature, airflow, and moisture gradient within the basil leaves. At 55 °C, within the time interval of 0 to 60 min, the drying rate increased from 0 to 0.267 g min−1, and after that, a declining trend began, reaching 0.225 g min−1 within the time interval of 60 to 120 min. Further trends in the drying rate started with an increase from 0.225 to 0.244 g min−1 at the time interval of 120 to 180 min; it then declined from 0.244 to 0.183 g min−1 within the time interval of 180 to 480 min.

At 60 °C, the drying rate was increased from 0 to 0.30 g min−1 within the time interval of 0 to 60 min, while from 60 to 120 min, a declining trend lowered values from 0.30 to 0.29 g min−1. A slight incremental increase to 0.322 g min−1 was recorded in the time interval of 120 to 180 min, but values again declined, to 0.183 g min−1, by 480 min.

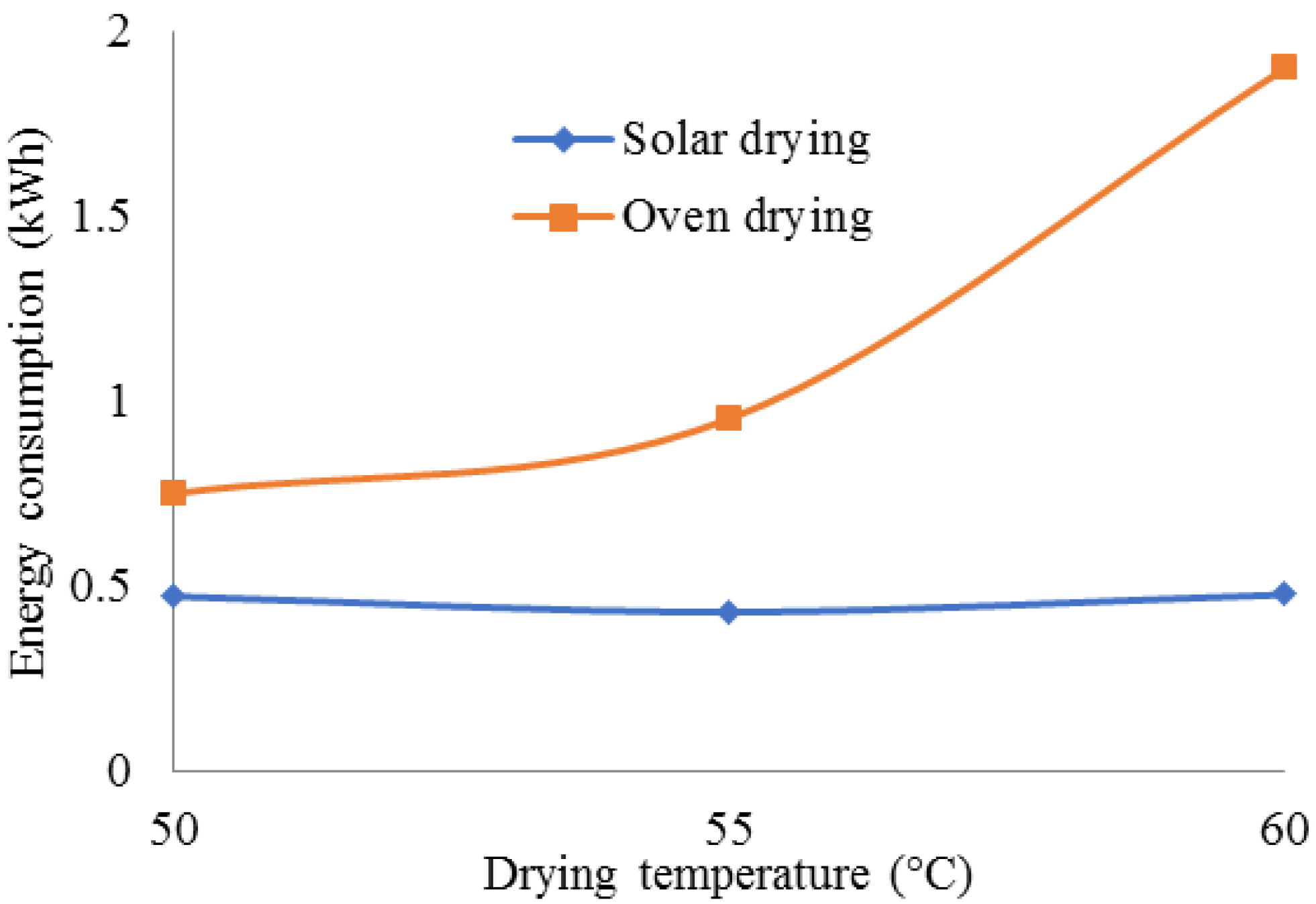

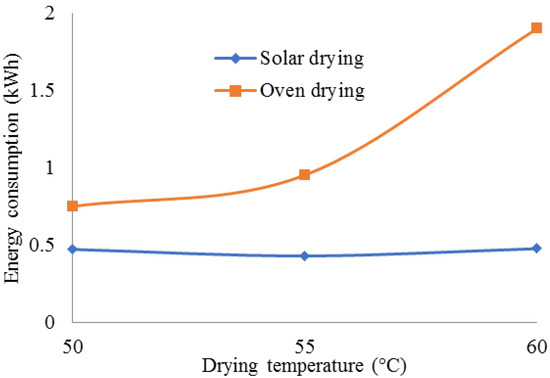

3.2. Energy Consumption in Solar and Oven Drying of Basil Leaves

Figure 6 shows the energy consumption involved in the solar and oven drying of basil leaves at 50 °C, 55 °C, and 60 °C. The energy consumption at 50 °C in solar drying was 0.473 kWh, while at 55 °C, it was found to be 0.431 kWh. At 60 °C, the energy consumption was 0.478 kWh, showing that trend of energy consumption in the solar tunnel dryer between 50 °C to 60 °C was almost constant. It was found that energy consumed in solar drying was greatly dependent on solar radiation (0.453, 0.824, and 1.183 kW m−2) and the air blown through the fan in the solar tunnel dryer. In oven drying, the energy consumption at 50 °C, 55 °C, and 60 °C was 0.751, 0.953, and 1.9 kWh, respectively, showing an increasing trend at higher temperatures.

Figure 6.

Energy consumption of solar tunnel dryer and electrical oven dryer while drying the basil leaves at the temperatures of 50 °C, 55 °C, and 60 °C.

3.3. Quality Analysis of Dried Basil Leaves

Table 2 shows the effects of drying method and temperature on dehydration ratio. The maximum dehydration ratio (9.11) was found at 60 °C in solar drying while a minimum dehydration ratio of 7.12 was found at 50 °C in oven drying. Solar drying at high temperature was found to be effective in showing a high rehydration ratio.

Table 2.

Effects of solar and oven drying on the dehydration ratios of dried basil leaves at the temperatures of 50 °C, 55 °C, and 60 °C.

Table 3 demonstrates the impacts of drying method and temperature on the rehydration ratio. A maximum rehydration ratio of 6.05 ± 0.07 was found for the basil leaves dried at 50 °C in the solar tunnel dryer, and a minimum rehydration ratio of 3.93 ± 0.14 was found for the basil leaves dried at 60 °C in the oven.

Table 3.

Effects of solar and oven drying on the rehydration ratios of dried basil leaves at the temperatures of 50 °C, 55 °C, and 60 °C.

The pH of basil leaves is affected by the drying method and temperature during the drying process, as shown in Table 4. A maximum pH of 6.9 was observed in the basil leaves dried at 50 °C in the solar tunnel dryer, and a pH of 4.3 was found for the basil leaves dried at 60 °C in the oven.

Table 4.

Effects of solar and oven drying on the pH of dried basil leaves at the temperatures of 50 ± 1 °C, 55 °C, and 60 °C.

The effects of drying method and temperature on reducing sugar are presented in Table 5. The highest level of reducing sugar (4.11) was observed in the basil leaves dried at 50 °C in the solar tunnel dryer, which had a low acidic nature (Table 4 and Table 5). On the other hand, the lowest level of reducing sugar (2.24) was found in the basil leaves dried at 60 °C in the oven, due to higher acidic nature (low pH), as shown in Table 4 and Table 5.

Table 5.

Effects of solar and oven drying on the reducing sugar of dried basil leaves at the temperatures of 50 °C, 55 °C, and 60 °C.

3.4. Effects of Drying Temperature on the Mineral Contents of Basil Leaves

Table 6 shows that drying methods and temperatures had no significant effect on the mineral contents of basil leaves at drying temperatures of 50 °C, 55 °C, and 60 °C.

Table 6.

Effects of solar and oven drying on mineral contents of dried basil leaves at the temperatures of 50 °C, 55 °C, and 60 °C.

Across different drying methods and temperatures, the Fe content remains nearly consistent, with minimal variation. The Fe content was recorded as 89.51 mg/100 g in solar-dried basil and 89.56 mg/100 g in oven-dried basil. The slight differences in Fe content between the two drying methods at each temperature level (50 °C, 55 °C, and 60 °C) show no significant effect of the drying method on iron content.

The Ca content in basil leaves ranged from 2240.4 mg/100 g in the solar dryer to 2254.2 mg/100 g in the oven dryer. Again, the differences in calcium content across the different temperatures and methods are negligible. This suggests that drying temperature and method do not significantly affect the calcium content of the basil leaves. Copper levels also remained consistent across the different drying methods and temperatures, with the solar dryer yielding an average Cu content of 2.097 mg/100 g and the oven dryer yielding 2.12 mg/100 g. The similarity in copper content further supports the conclusion that drying temperature and method do not significantly impact copper content in basil leaves.

Potassium content showed minimal variation across different drying methods and temperatures. The solar-dried leaves had a K content of 2696.5 mg/100 g, while oven-dried leaves had a K content of 2697.0 mg/100 g. The minor differences between the two drying methods reinforce the observation that drying temperature does not significantly alter the potassium content. The magnesium content was also not significantly affected by the drying method or temperature. The Mg content in the solar-dried basil was 710.94 mg/100 g, compared to 712.22 mg/100 g in the oven-dried basil. The overall results suggest that the drying temperature, when within the range of 50 °C to 60 °C, does not significantly influence the mineral content of basil leaves.

3.5. Sensory Evaluation for Storage Stability of Dried Basil Leaves

The sensory evaluation of dried basil leaves over a 60-day storage period assessed the effects of oven drying and solar drying at different temperatures (50 °C, 55 °C, and 60 °C) on color, taste, and aroma (Table 7). The results show distinct trends across the storage period, with solar drying at 50 °C consistently outperforming oven drying in all sensory parameters by the end of 60 days.

Table 7.

Mean values of sensory parameters (score: 1–10) observing the effects of drying methods and temperatures on storage stability of dried basil leaves.

At the start of the storage period, oven drying and solar drying methods displayed similar sensory qualities across all temperatures. For color, the initial scores were highest in the solar-dried samples at 50 °C (7.98), with oven drying at 50 °C following closely (7.90). Taste and aroma scores were also close between the two drying methods, with solar drying at 50 °C scoring 7.28 for taste and 6.98 for aroma, slightly higher than the oven-dried samples.

After 15 days, the color, taste, and aroma of the basil leaves remained stable across both drying methods and temperatures, showing minimal differences. The scores for color, taste, and aroma slightly decreased but remained high, with solar drying at 50 °C retaining better sensory properties overall compared to oven drying.

By day 30, the sensory attributes of the basil leaves began to show more distinct differences between the two drying methods. Although the reduction in scores was marginal, solar drying at 50 °C still exhibited superior color retention (7.88), taste (7.18), and aroma (6.88) compared to the oven-dried samples. This indicates that solar drying may be more effective in preserving the sensory qualities of basil leaves over time.

After 45 days, the gap between the two drying methods widened further. Solar drying at 50 °C achieved higher scores in all sensory parameters, with color at 7.85, taste at 7.16, and aroma at 6.86. In contrast, oven-dried samples, especially at 60 °C, showed more noticeable declines in sensory quality. This suggests that solar drying is better at maintaining sensory properties as storage time progresses.

By the end of the 60-day period, solar drying at 50 °C consistently retained the highest sensory scores, with color at 7.87, taste at 7.07, and aroma at 6.77. Oven-dried samples, particularly at higher temperatures, showed declines in sensory quality which were more significant, with color dropping to 7.66, taste to 6.96, and aroma to 6.66. This highlights the superior performance of solar drying in preserving the sensory quality of basil leaves over a prolonged storage period.

Across the 60-day storage period, solar drying at 50 °C consistently outperformed oven drying in terms of color, taste, and aroma retention. While both methods showed minor declines in sensory quality over time, the decline was more pronounced in oven-dried samples, particularly at higher temperatures. Solar drying at 50 °C proved to be the most effective method as to preserving the sensory qualities of basil leaves over time, making it a preferable option for long-term storage stability.

4. Discussion

The results showed that solar drying is much faster than the oven drying due to the fresh-air circulation employed, which takes on the moisture of basil leaves and then exits the dryer. In the case of the oven dryer, fresh air is unavailable and the air in the oven reaches the saturation point, making the drying process slow. Gulcimen et al. [27] conducted a similar study, in which microwave and convective drying techniques were used to dry the basil leaves. The scientists were able to dry the basil leaves from an initial moisture content of 990% (d.b) to a final acceptable moisture content of 9% (d.b). In comparison, Altay et al. [28], in a research study, concluded that the energy efficiency of microwave oven drying was found to be superior to other methods such as solar drying because the former allows for precise control of drying parameters such as temperature and duration, resulting in faster and more uniform drying with reduced energy consumption compared to the variable and weather-dependent conditions of simple solar drying. But microwave drying is less suitable for herbs and leaves as it destroys the heat-sensitive compounds [29].

Further, comparing the solar drying with the oven drying reveals that in solar drying, the drying rate approached a maximum of 2 g min−1 in just 0 to 10 min, while only a 0.30 g min−1 maximum drying rate was achieved in 0–60 min. This showed that solar drying has a 6.7-times higher drying rate compared to oven drying. Ultimately, solar drying takes much less time compared to the oven drying, as shown in Figure 5a,b. Shalaby et al. [30], in a study, found the direct mode forced convection solar dryer to be superior, with a higher drying rate compared to natural-air drying. Gulcimen, Karakaya, and Durmus [27] reached a similar conclusion in their comparative study of microwave and convective drying techniques.

At 50 °C, the energy consumption in the oven dryer was 1.59 times more than that of the solar tunnel dryer, while at 55 °C, the energy consumption in the oven dryer was 2.21 times more than that of the solar dryer. At 60 °C, it was 3.97 times greater compared to the solar tunnel dryer. Hence it was concluded that solar drying consumes significantly less energy, compared to the oven dryer. This conclusion is in line with the study of Ali et al. [31] and Kadam et al. [32] who investigated the energy requirement for the drying of food crops. In addition, Kadam, Goyal, and Gupta [32] also calculated the activation energy using the Arrhenius relation for dried basil leaves, which varied from 9.03 to 33.21 kJ mol−1.

Solar drying at 60 °C achieved the highest dehydration ratio (9.11), indicating a more efficient moisture removal. This supports previous research that suggests higher temperatures in solar drying enhance dehydration efficiency [33,34]. In contrast, oven drying at 50 °C had the lowest dehydration ratio (7.12), which is consistent with findings that controlled environments may lead to slower moisture loss [35].

Solar drying also resulted in superior rehydration ratios, particularly at 50 °C (6.05), compared to oven drying. Previous studies have shown that solar drying better preserves the structural integrity of plant tissues, allowing enhanced water absorption during rehydration [36]. In contrast, oven drying at 60 °C exhibited the lowest rehydration ratio (3.93), which is consistent with research indicating that high temperatures in oven drying can cause excessive tissue damage, reducing rehydration capacity [37].

The decrease in the pH of basil leaves in the oven drying at the same temperatures used in the solar drying may be due to differences in drying kinetics and environmental conditions. The drying process in controlled environment of the electrical oven could lead to increased enzymatic and chemical reactions, resulting in the production of acidic compounds and a lower pH in the dried basil leaves [38,39]. Low pH in dried basil leaves may help to extend the shelf life [40].

Solar drying also preserved higher reducing sugar content, particularly at 50 °C (4.11), which is consistent with earlier studies that associated lower drying temperatures with better sugar retention [41]. The lower reducing sugar levels observed in oven-dried samples, especially at 60 °C (2.24), correlate with higher acidity, which may contribute to the degradation of sugars [42].

This indicates that the nutritional quality, in terms of mineral content, remains stable regardless of the mentioned drying method or temperature used within this range. In the research studies of Sharma et al. [43] and Pachkore and Markandeya [44], lower mineral contents were found in basil leaves during open sun drying compared to the microwave oven drying. Generally, open sun drying is less efficient and has a negative impact on the quality of basil leaves, compared to the oven and solar tunnel dryer.

On the topic of sensory evaluation, solar drying at 50 °C yielded the highest color score after 60 days, followed closely by the oven drying, along with better taste and aroma retention. Color, taste and aroma retention depends on the reduced degradation of available volatile compounds with the passage of time [45]. These results of current study are consistent with the findings of Sarkar et al. [46] and Abd EL-All et al. [47], who worked on the drying of meat and basil in powder form and found that vacuum packaging reduces water activity, retaining the better taste and aroma for long time. Additionally, a study on purple basil leaves investigated various drying methods (sun-drying, freeze-drying, and convective oven and microwave oven drying), with effective moisture diffusivity values found for dried purple basil leaves [28]. Overall, solar drying appeared to be advantageous for preserving color, taste, and aroma in dried basil leaves.

Emphasizing the energy-efficient and hygienic nature of solar drying, this research not only contributes to the preservation of basil’s unique characteristics but also aligns with global efforts toward sustainable and eco-friendly practices.

5. Conclusions

The quality of dried basil leaves depends on the drying method and temperature utilized. It was found that solar drying at 55 °C consumed the least energy, 0.431 kWh, and was completed in a short time, 110 min. This happened due to the availability of abundant solar radiation in Pakistan. Further, the drying rate was enhanced due to low levels of relative humidity (29–36%) in the air. Comparatively, oven drying consumed higher levels of energy. Further, oven drying maintained the low pH (acidic) and low reducing sugar, enhancing the shelf life of dried basil leaves, compared to the solar drying. The decision-making factors of energy consumption, drying time, and mineral contents distinctly favor solar drying through a solar tunnel dryer. This method, particularly at 55 °C, showcased superior performance with minimal energy usage, as well as a suitable rehydration ratio, pH, and reducing sugar levels. However, statistically non-significant variations in dehydration ratio, and mineral contents were found for this temperature. On the topic of the sensory evaluation of dried basil leaves, solar drying at 50 °C yielded the highest color score (7.87) and showed better taste and aroma retention in the dried basil leaves after 60 days, outperforming oven drying. This method proves to be the more effective for preserving sensory qualities, which is consistent with previous studies on basil leaves. This study not only underscores the technical advantages of solar drying but also aligns with crucial aspects of environmental sustainability. By harnessing abundant solar radiation, this approach significantly reduces the reliance on conventional energy sources, contributing to a more sustainable and eco-friendly drying process. It is important to note that the efficiency of the solar drying process depends on seasonal variations. Since this study was conducted during the summer season, it should be noted that drying efficiency and physicochemical properties may differ during winter, when generally, the air temperature in Pakistan does not exceed 25 °C. Therefore, further research is needed to explore the effects of seasonal changes on solar drying performance and to develop optimized drying strategies for different climate conditions.

Author Contributions

Conceptualization, F.N.A., S.M., G.M.-u.-d. and M.Y.; Data curation, F.N.A. and M.Y.; Formal analysis, S.M., G.M.-u.-d. and M.A.M.; Investigation, F.N.A. and M.Y.; Methodology, F.N.A. and M.Y.; Project administration, F.N.A.; Resources, M.Y.; Software, F.N.A.; Supervision, S.M., G.M.-u.-d. and M.A.M.; Validation, F.N.A. and M.Y.; Visualization, F.N.A.; Writing—original draft, F.N.A. and M.Y.; Writing—review and editing, S.M., G.M.-u.-d. and M.A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data are available on demand.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nadeem, H.R.; Akhtar, S.; Sestili, P.; Ismail, T.; Neugart, S.; Qamar, M.; Esatbeyoglu, T. Toxicity, antioxidant activity, and phytochemicals of basil (Ocimum basilicum L.) leaves cultivated in Southern Punjab, Pakistan. Foods 2022, 11, 1239. [Google Scholar] [CrossRef]

- Nguyen, V.; Nguyen, N.; Thi, N.; Thi, C.; Truc, T.; Nghi, P. Studies on chemical, polyphenol content, flavonoid content, and antioxidant activity of sweet basil leaves (Ocimum basilicum L.). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1092, 012083. [Google Scholar] [CrossRef]

- Senthoorraja, R.; Subaharan, K.; Manjunath, S.; Pragadheesh, V.S.; Bakthavatsalam, N.; Mohan, M.G.; Senthil-Nathan, S.; Basavarajappa, S. Electrophysiological, behavioural and biochemical effect of Ocimum basilicum oil and its constituents methyl chavicol and linalool on Musca domestica L. Environ. Sci. Pollut. Res. 2021, 28, 50565–50578. [Google Scholar] [CrossRef]

- Calderón Bravo, H.; Vera Céspedes, N.; Zura-Bravo, L.; Muñoz, L.A. Basil seeds as a novel food, source of nutrients and functional ingredients with beneficial properties: A review. Foods 2021, 10, 1467. [Google Scholar] [CrossRef] [PubMed]

- Shahrajabian, M.H.; Sun, W. Five important seeds in traditional medicine, and pharmacological benefits. Seeds 2023, 2, 290–308. [Google Scholar] [CrossRef]

- Kamelnia, E.; Mohebbati, R.; Kamelnia, R.; El-Seedi, H.R.; Boskabady, M.H. Anti-inflammatory, immunomodulatory and anti-oxidant effects of Ocimum basilicum L. and its main constituents: A review. Iran. J. Basic Med. Sci. 2023, 26, 617. [Google Scholar] [PubMed]

- Sharifi-Rad, J.; Adetunji, C.O.; Olaniyan, O.T.; Ojo, S.K.; Samuel, M.O.; Temitayo, B.T.; Roli, O.I.; Nimota, O.O.; Oluwabunmi, B.T.; Adetunji, J.B. Antimicrobial, antioxidant and other pharmacological activities of Ocimum Species: Potential to be used as food preservatives and functional ingredients. Food Rev. Int. 2023, 39, 1547–1577. [Google Scholar] [CrossRef]

- Kumar, K.; Dasgupta, C.N.; Das, D. Cell growth kinetics of Chlorella sorokiniana and nutritional values of its biomass. Bioresour. Technol. 2014, 167, 358–366. [Google Scholar] [CrossRef]

- De Martino, L.; Caputo, L.; Amato, G.; Iannone, M.; Barba, A.A.; De Feo, V. Postharvest Microwave Drying of Basil (Ocimum basilicum L.): The Influence of Treatments on the Quality of Dried Products. Foods 2022, 11, 1029. [Google Scholar] [CrossRef]

- Crivelli, S.; Eskow, E.; Bader, B.; Lamberti, V.; Byrd, R.; Schnabel, R.; Head-Gordon, T. A physical approach to protein structure prediction. Biophys. J. 2002, 82, 36–49. [Google Scholar] [CrossRef]

- Díaz-Maroto, M.; Pérez-Coello, M.; Cabezudo, M. Effect of different drying methods on the volatile components of parsley (Petroselinum crispum L.). Eur. Food Res. Technol. 2002, 215, 227–230. [Google Scholar]

- Vijayan, S.; Arjunan, T.; Kumar, A. Exergo-environmental analysis of an indirect forced convection solar dryer for drying bitter gourd slices. Renew. Energy 2020, 146, 2210–2223. [Google Scholar] [CrossRef]

- Srinivasan, G.; Muthukumar, P. A review on solar greenhouse dryer: Design, thermal modelling, energy, economic and environmental aspects. Sol. Energy 2021, 229, 3–21. [Google Scholar] [CrossRef]

- Margarita, C.T.; Erika, C.T.B.M.M.; Carlos, O.S.J. Technical and experimental study of the solar dehydration of the moringa leaf and its potential integration to the sustainable agricultural industry. Eur. J. Sustain. Dev. 2018, 7, 65. [Google Scholar] [CrossRef]

- Shaw, M.; Meda, V.; Tabil, L., Jr.; Opoku, A., Jr. Drying and color characteristics of coriander foliage using convective thin-layer and microwave drying. J. Microw. Power Electromagn. Energy 2006, 41, 56–65. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Lipan, L.; Cano-Lamadrid, M.; Kharaghani, A.; Masztalerz, K.; Carbonell-Barrachina, Á.A.; Figiel, A. Comparison of traditional and novel drying techniques and its effect on quality of fruits, vegetables and aromatic herbs. Foods 2020, 9, 1261. [Google Scholar] [CrossRef]

- Asnaz, M.S.K.; Dolcek, A.O. Comparative performance study of different types of solar dryers towards sustainable agriculture. Energy Rep. 2021, 7, 6107–6118. [Google Scholar] [CrossRef]

- Nurhaslina, C.; Bacho, S.A.; Mustapa, A. Review on drying methods for herbal plants. Mater. Today Proc. 2022, 63, S122–S139. [Google Scholar] [CrossRef]

- Kırca, A.; Özkan, M.; Cemeroğlu, B. Effects of temperature, solid content and pH on the stability of black carrot anthocyanins. Food Chem. 2007, 101, 212–218. [Google Scholar] [CrossRef]

- Kapoor, S.; Aggarwal, P. Drying method affects bioactive compounds and antioxidant activity of carrot. Int. J. Veg. Sci. 2015, 21, 467–481. [Google Scholar] [CrossRef]

- Oni, M.O.; Ogungbite, O.C.; Akindele, A.K. The effect of different drying methods on some common Nigerian edible botanicals. Int. J. Adv. Res. Bot. 2015, 1, 15–22. [Google Scholar]

- Anum, R.; Ghafoor, A.; Munir, A. Study of the drying behavior and performance evaluation of gas fired hybrid solar dryer. J. Food Process. Eng. 2017, 40, e12351. [Google Scholar] [CrossRef]

- Yilmaz, A.; Alibas, I. The impact of drying methods on quality parameters of purple basil leaves. J. Food Process. Preserv. 2021, 45, e15638. [Google Scholar] [CrossRef]

- Doymaz, I. Drying kinetics and rehydration characteristics of convective hot-air dried white button mushroom slices. J. Chem. 2014, 2014, 453175. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 22nd ed.; Oxford University Press: Oxford, UK, 2023. [Google Scholar]

- Meilgaard, M.; Civille, G.; Carr, B. The spectrum descriptive analysis method. Sens. Eval. Tech. 2007, 49, 2376–2377. [Google Scholar]

- Gulcimen, F.; Karakaya, H.; Durmus, A. Drying of sweet basil with solar air collectors. Renew. Energy 2016, 93, 77–86. [Google Scholar] [CrossRef]

- Altay, K.; Hayaloglu, A.A.; Dirim, S.N. Determination of the drying kinetics and energy efficiency of purple basil (Ocimum basilicum L.) leaves using different drying methods. Heat Mass Transf. 2019, 55, 2173–2184. [Google Scholar] [CrossRef]

- Iranshahi, K.; Rubinetti, D.; Onwude, D.I.; Psarianos, M.; Schlüter, O.K.; Defraeye, T. Electrohydrodynamic drying versus conventional drying methods: A comparison of key performance indicators. Energy Convers. Manag. 2023, 279, 116661. [Google Scholar] [CrossRef]

- Shalaby, S.; Darwesh, M.; Ghoname, M.; Salah, S.E.; Nehela, Y.; Fetouh, M. The effect of drying sweet basil in an indirect solar dryer integrated with phase change material on essential oil valuable components. Energy Rep. 2020, 6, 43–50. [Google Scholar] [CrossRef]

- Ali, M.; Niazi, F.; Siddiqui, M.A.; Saleem, M. Comparative Study on Oven and Solar Drying of Agricultural Residues and Food Crops. Int. J. Renew. Energy Dev. 2022, 11, 1165. [Google Scholar] [CrossRef]

- Kadam, D.; Goyal, R.; Gupta, M. Mathematical modeling of convective thin layer drying of basil leaves. J. Med. Plants Res. 2011, 5, 4721–4730. [Google Scholar]

- Mazza, G. Dehydration of carrots. Effects of pre-drying treatments on moisture transport and product quality. Int. J. Food Sci. Technol. 1983, 18, 113–123. [Google Scholar] [CrossRef]

- Kingsly, R.P.; Goyal, R.K.; Manikantan, M.R.; Ilyas, S.M. Effects of pretreatments and drying air temperature on drying behaviour of peach slice. Int. J. Food Sci. Technol. 2007, 42, 65–69. [Google Scholar] [CrossRef]

- Ratti, C. Hot air and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Demiray, E.; Seker, A.; Tulek, Y. Drying kinetics of onion (Allium cepa L.) slices with convective and microwave drying. Heat Mass Transf. 2017, 53, 1817–1827. [Google Scholar] [CrossRef]

- Zhang, M.; Tang, J.; Mujumdar, A.; Wang, S. Trends in microwave-related drying of fruits and vegetables. Trends Food Sci. Technol. 2006, 17, 524–534. [Google Scholar] [CrossRef]

- Sagar, V.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.-Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.-H.; Wang, J.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes–a comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1408–1432. [Google Scholar] [CrossRef]

- Alp, D.; Bulantekin, Ö. The microbiological quality of various foods dried by applying different drying methods: A review. Eur. Food Res. Technol. 2021, 247, 1333–1343. [Google Scholar] [CrossRef]

- Sharma, G.; Prasad, S. Optimization of process parameters for microwave drying of garlic cloves. J. Food Eng. 2006, 75, 441–446. [Google Scholar] [CrossRef]

- Danso-Boateng, E. Effect of drying methods on nutrient quality of basil (Ocimum viride) leaves cultivated in Ghana. Int. Food Res. J. 2013, 20, 1569–1573. [Google Scholar]

- Sharma, R.; Bhatia, S.; Kaur, P. Effect of drying methods on biochemical quality of basil leaf. Agric. Res. J. 2018, 5, 331–335. [Google Scholar] [CrossRef]

- Pachkore, G.; Markandeya, S. Effect of Drying on the Essential Oil and the Mineral Contents of Basil (Ocimum basilicum L.). IUP J. Life Sci. 2010, 4, 39. [Google Scholar]

- Saifullah, M.; Shishir, M.R.I.; Ferdowsi, R.; Rahman, M.R.T.; Van Vuong, Q. Micro and nano encapsulation, retention and controlled release of flavor and aroma compounds: A critical review. Trends Food Sci. Technol. 2019, 86, 230–251. [Google Scholar] [CrossRef]

- Sarkar, B.; Hazarika, M.; Laskar, S.; Das, A.; Upadhyay, S.; Gogoi, P.; Choudhury, S.; Deuri, D. Proximate, microbiological and sensory evaluation of solar and oven dried spent hen meat powder incorporated with phytoingredients. J. Entomol. Zool. Stud. 2020, 8, 12–23. [Google Scholar]

- Abd EL-All, M.H.; Khater, E.G.; Bhansawi, A.H. Basil quality as affected by drying system, drying temperature and plant layer thickness. Misr J. Agric. Eng. 2023, 40, 45–58. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).