Abstract

A thermodynamic approach based on exergy use has been suggested as a measure for the use of resources in Life Cycle Assessment and other sustainability assessment methods. It is a relevant approach since it can capture energy resources, as well as metal ores and other materials that have a chemical exergy expressed in the same units. The aim of this paper is to illustrate the use of the thermodynamic approach in case studies and to compare the results with other approaches, and thus contribute to the discussion of how to measure resource use. The two case studies are the recycling of ferrous waste and the production and use of a laptop. The results show that the different methods produce strikingly different results when applied to case studies, which indicates the need to further discuss methods for assessing resource use. The study also demonstrates the feasibility of the thermodynamic approach. It identifies the importance of both energy resources, as well as metals. We argue that the thermodynamic approach is developed from a solid scientific basis and produces results that are relevant for decision-making. The exergy approach captures most resources that are considered important by other methods. Furthermore, the composition of the ores is shown to have an influence on the results. The thermodynamic approach could also be further developed for assessing a broader range of biotic and abiotic resources, including land and water.

1. Introduction

A more efficient utilization of resources, from, e.g., improved waste treatment, is an important part of a more circular economy, which is arguably a prerequisite for a sustainable society. Life Cycle Thinking (LCT) and Life Cycle Assessment (LCA) have received prominent positions in European waste policy, for example in the Waste Framework Directive, as an approach and tool, respectively, for assessing the environmental impacts and resource use associated with alternative waste management strategies [1].

LCA is a tool to assess the potential environmental impacts and resources used throughout a product’s life cycle, i.e., from raw material extraction, via production and use phases, to waste management [2,3,4]. The term “product” includes both goods and services, for example waste management. The unique feature of LCA is the focus on a life-cycle perspective. This implies that system boundaries should be so wide that inputs to the life-cycle system should be resources as we find them in nature, and outputs should be emissions to nature.

There are four phases in an LCA study: Goal and Scope Definition, Life Cycle Inventory Analysis (LCI), Life Cycle Impact Assessment (LCIA), and Interpretation. The result from the LCI is a compilation of the inputs (resources) and the outputs (emissions) from the product over its life cycle. The ISO standards [4] further define Life Cycle Impact Assessment (LCIA) as the phase of an LCA study that involves classification and characterization of substances, and optionally normalization and weighting. In the classification the LCI, results on resources and emissions are classified into impact categories of environmental relevance (e.g., kg CO2 emissions into Global Warming). In the characterization part of the LCIA, the contributions of different inputs and outputs to impact categories are modeled quantitatively and expressed as an impact score in a unit common to all contributions within the impact category [2]. The relative contribution of a substance to an impact category is estimated with characterization models (e.g., 1 kg of CH4 contributes around 30 times as much to cumulative radiating forcing as 1 kg of CO2). Normalization and weighting are optionally used in order to enable comparison of results across impacts (e.g., global warming against resource depletion).

The ISO standard for LCA [4] states that “resource use” is one of the categories of environmental impacts needing consideration. In the LCA literature, “resource depletion” (including minerals, fossil and renewable energy resources and water) is often described as one impact category that should be included in an LCA study. In principle, the terms “resource use”, “resource consumption” and “resource depletion” should mean different things (resource use can lead to consumption (implying destruction of the resource) which could lead to depletion of the stock or fund resource). In practice, however, many scholars and practitioners are using the terms interchangeably, leading to a mixed use of the terms.

The characterization of the use of abiotic resources—such as minerals and non-renewable fuels—is one of the most frequently discussed impact categories and consequently there is a wide variety of methods available for characterizing contributions to this category (e.g., [2,5,6,7,8]). Essentially, four different groups of approaches can be distinguished [9,10]:

- The impact of the present use of resources is modeled as that of the future use of resources. The rationale for this approach is that the current use of non-renewable resources implies that more effort (e.g., energy) to extract the same amount will be required by future generations, assuming that ore grades decrease with greater extraction, and that technology remains the same. Alternatively, we can adopt other resources that substitute for the ones being assessed as proxies, so that current impacts can be measured in terms of the future impacts. This has been the basis for several LCIA methods for resources, for example Eco-indicator 99 [11] and ReCiPe [12]. However, it has been argued that if current resource use leads to changes in the environmental interventions of future extractions, this should be modeled in the Inventory Analysis, and not in the LCIA [2,13].

- There are methods related to some measure of available resources or reserves and extraction rates. Different approaches exist based on different measures of the reserves, e.g., technically and economically available reserves [14] or ultimately available reserves, as in the CML approach [15,16], and extraction rates. For example, the CML approach uses antimonium (Sb) as the reference of resource extraction rate–to-reserve ratio, such that:where [15]:

- ADPi Abiotic Depletion Potential of resource i (dimensionless);

- Ri ultimate reserve of resource i (kg);

- DRi extraction rate of resource i

- Rsb ultimate reserve of antimonium (i.e., the reference resource (kg));

- Dsb extraction rate of antimonium Rsb (i.e., the reference resource

- There are thermodynamic methods based on exergy decrease or entropy increase. Exergy is a measure of available energy. Entropy can be interpreted in many ways, e.g., as a measure of disorder but also as a measure for the dispersal of energy. In contrast to energy, exergy is destroyed in all real world processes as entropy is produced [17]. The exergy decrease and the entropy increase mirror each other. Methods and data based on this approach have been developed for LCA [18,19,20,21,22,23]. The exergy content of the resources can be assumed to be used through incineration, other chemical reactions and dissipation [18]. Although it may be claimed that all the approaches rely on thermodynamics, this group will be called the thermodynamic approach in this paper.

- The last approach is the aggregation of the total use of energy as in the Cumulative Energy Demand (CED) [24].

All LCIA methods across all approaches above have in common that they result in characterization factors CFi that can be used for calculating the indicator for the use of abiotic resources according to Equation (2) (e.g., [3,9]):

where I is the indicator result and mi is the use of the abiotic resource i in the system under study.

I = Σ CFi mi

The aim of this paper is to contribute to the discussion on different approaches to measure the use of abiotic natural resources (such as non-renewable fuels and mineral resources) in LCA and other methods. This is done by illustrating the application of the thermodynamic approach to case studies, and by comparing the results with other approaches. The focus is on the thermodynamic approach which is discussed in more detail.

2. Materials and Methods

Two case studies were chosen to illustrate the use of different methods: one on the recycling of ferrous waste and one on the production and use of a laptop computer. Since one purpose of recycling is to save resources, a simple recycling case was chosen to see if the methods would capture this concern. A laptop was chosen to illustrate a more complex product, which includes many different types of metals and plastics made from fossil fuels, and which uses significant amounts of electricity during the use phase. For both cases, data were taken from the Ecoinvent database [25] as implemented in the SimaPro software (Pré, Amersfoort, the Netherlands, www.pre.nl).

2.1. Ferrous Waste Recycling

This case is based on the Ecoinvent 2 dataset “Steel, electric, un- and low-alloyed, at plant/RER” [26] with the addition of avoided virgin production (1 kg of steel, low-alloyed per every 1.1 kg of material recycled), with removal of steel scrap input. Direct use of electricity has been replaced by the Swedish electricity mix [27]. The system studied represents an average of different processes of secondary steel production with EU technology and includes transportation of scrap metal and other input materials to the electric arc furnace, steel-making process and casting.

2.2. Production and Use of a Laptop

The case is based on the Ecoinvent 2 dataset “Use, computer, laptop, office use/RER” [28]. The system studied includes laptop production and disposal, transportation to the user and energy consumption during use, the latter considered over a lifespan of four years and taking into account different use modes for office use. The functional unit of the assessment was 1 laptop.

The process for laptop production includes raw material extraction and processing, manufacturing of all components, energy and water use required for various processes, transportation for input materials (ship, rail and road), packaging, final disposal of the laptop, and infrastructure required (factory). The dataset is global and describes the manufacturing of a typical laptop computer during the years 2002–2005. The final disposal is represented by a mixture of manual and mechanical WEEE treatment in Switzerland. The benefit of material recovery is not accounted for. Rail and road transportation is used for the delivery to a user. For the use phase Swedish electricity is used [27]. The office use is calculated according to the share between active (5.5 h/day), standby (2 h/day) and off (16.5 h/day) modes.

2.3. Characterization Methods

Two versions of the thermodynamic approach were applied here. The first is called Exergy F & Ö, where the exergy data were taken from [18]. These data were calculated from information on the chemical composition of the material, the basic thermodynamic data and the reference state developed by Szargut et al. [29] which is made to be similar to the natural environment, including common components of the atmosphere, sea and crust of the earth. For fossil fuels, the exergy is close to the lower heating value. For metals, the whole metal ore was considered as an input to the technical system in line with the life-cycle approach [18]. The second version of the thermodynamic approach was the Cumulative Exergy Demand (CExD) method [19], which uses other data for the ore compositions (see below) and an updated version of the reference state including, for example, more recent data on concentrations of trace elements in sea water (the reader is referred to the references for more details). De Meester et al. [30] have shown that an updated reference state in most cases has only a minor influence on the results. For some specific minerals, the differences can, however, be larger.

In addition, several other often-used LCIA methods were included, e.g., Cumulative Energy Demand (CEnD), CML, Eco-indicator 99 and ReCiPe for minerals and fossil fuels, all as implemented in Simapro. All of these are intended to be used as methods for characterization of the use of abiotic resources in LCA and are in that sense comparable. Although different terms may be used in the literature when describing the methods (e.g., resource use, resource consumption or resource depletion), they are intended and used for this same purpose. All use information about the used amounts of the abiotic resources from the LCIA. The system boundaries for the Ecoindicator 99 and ReCiPe methods are expanded compared to the other methods since they include also future resource extraction. This is because information on impacts from future resource extraction is used for the indicator on the impacts of the current resource use. The methods also differ in the age of underlying data (the readers are referred to the specific methods for details). It is, however, likely that the difference in age has a minor influence in the comparisons since the differences in approaches are large and large parts of the data (e.g., on thermodynamic properties) are not expected to change significantly with time. Many of them are also used on a routine basis by LCA practitioners.

3. Results and Discussion

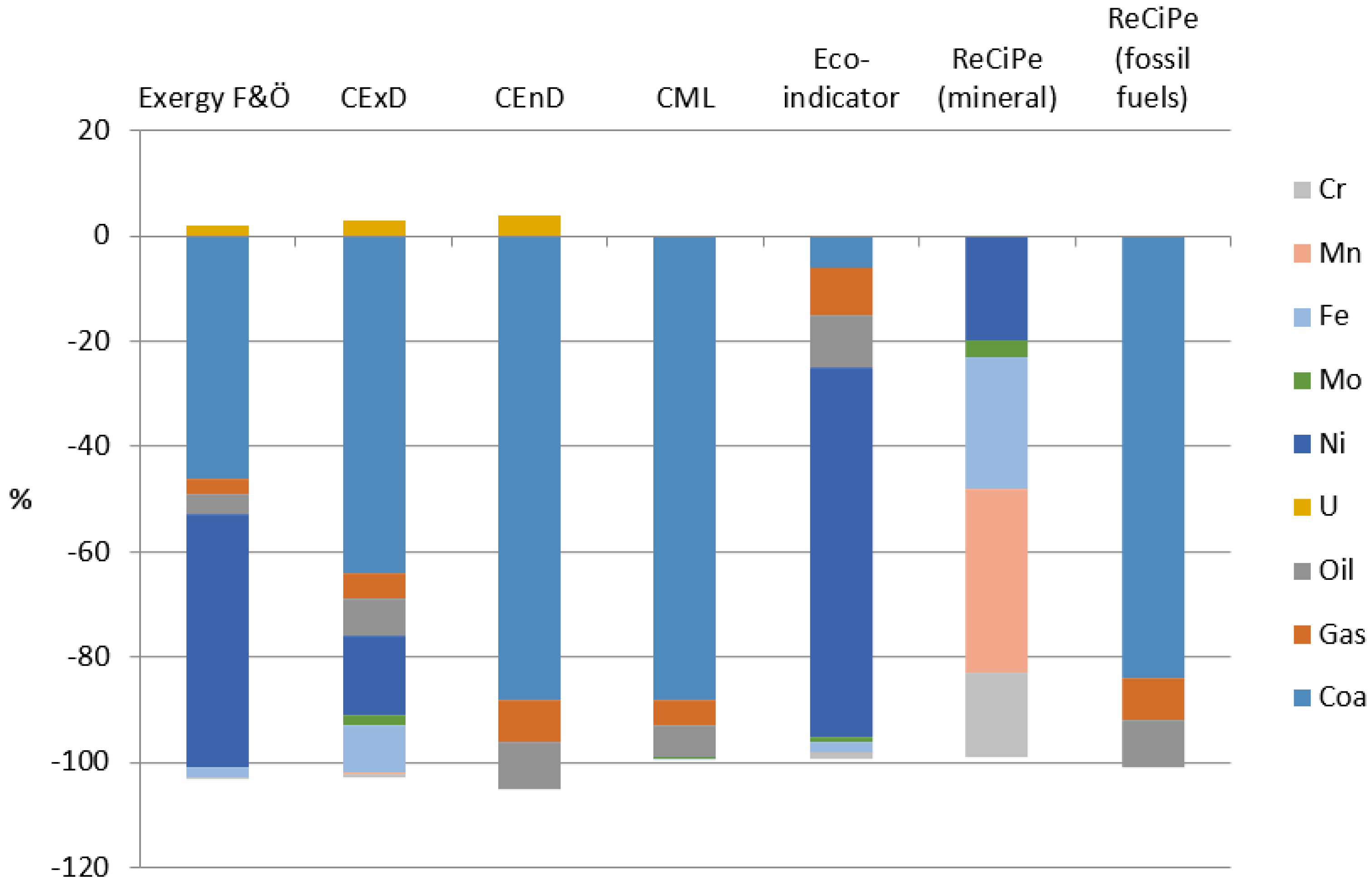

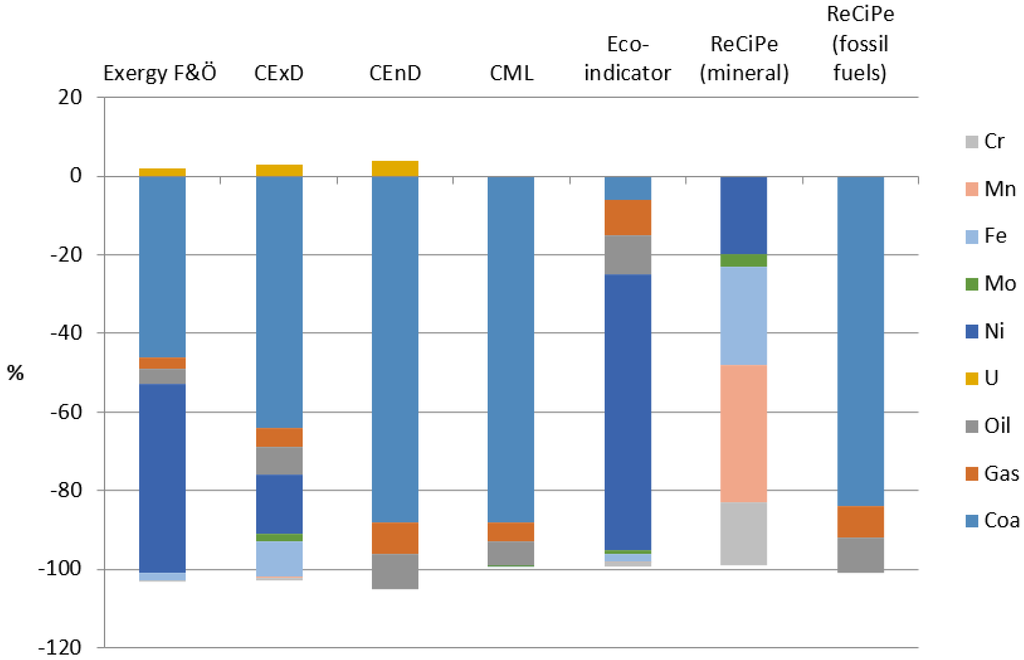

The results for ferrous recycling are presented in Table 1 and Figure 1. The results are in most cases negative, indicating that recycling saves resources. The exception is uranium, which is used for the production of nuclear power. The results thus show that although the total use of abiotic resources decreases, the electricity use is increased.

Table 1.

Characterization of most important non-renewable resources for ferrous recycling in percentage of the total result (only resources that contribute to more than 1% of total result according to at least one method are included; “0” means less than 0.1% and n/a means that no characterization factor for this input was available).

Figure 1.

Characterization of most important non-renewable resources for ferrous recycling in percentage of the total result.

Table 2.

Characterization of most important non-renewable resources for production and use of a laptop in percentage of the total result (only resources that contribute to more than 1% of total result according to at least one method are included; “0” means less than 0.1% and n/a means that no characterization factor for this input was available).

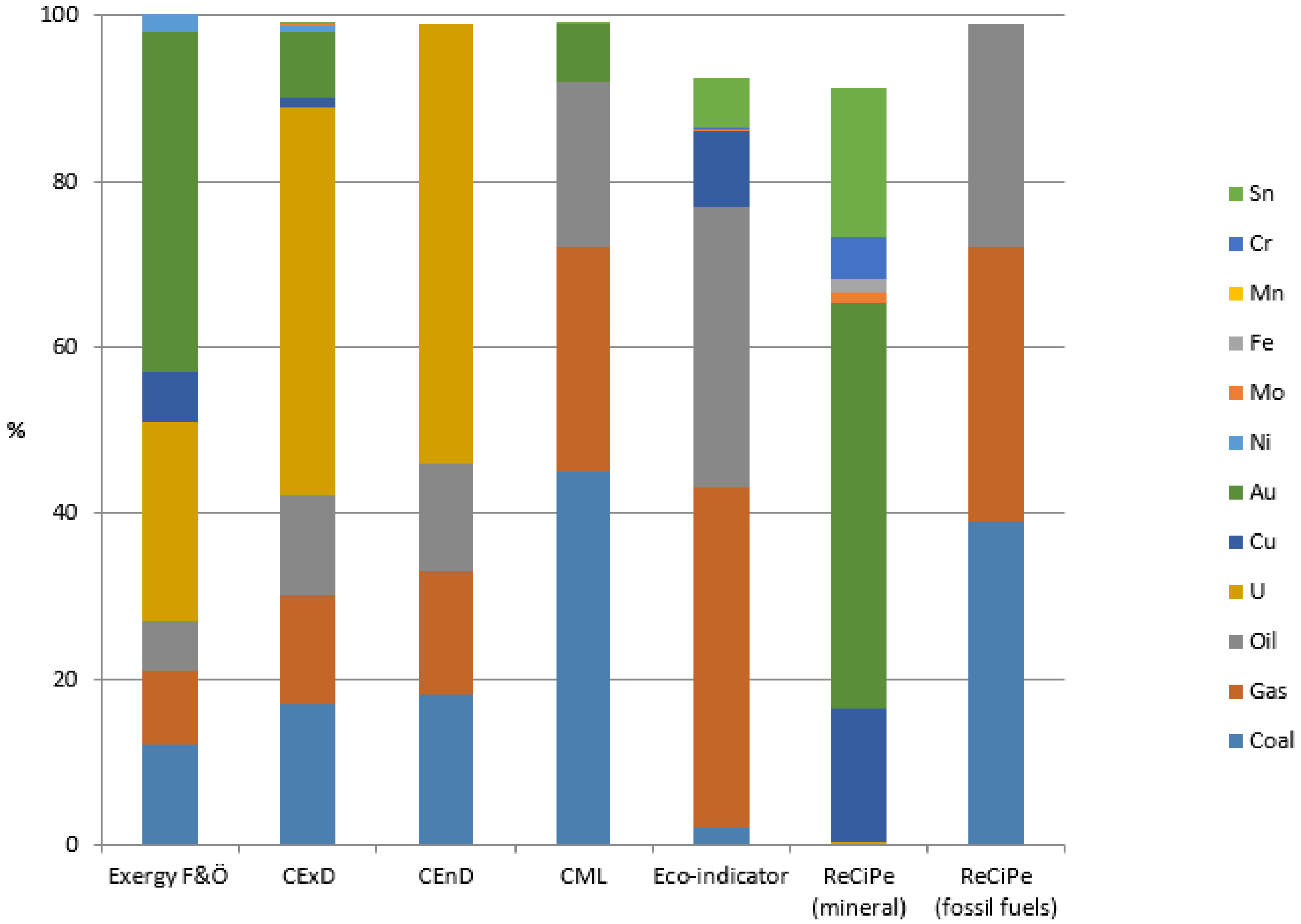

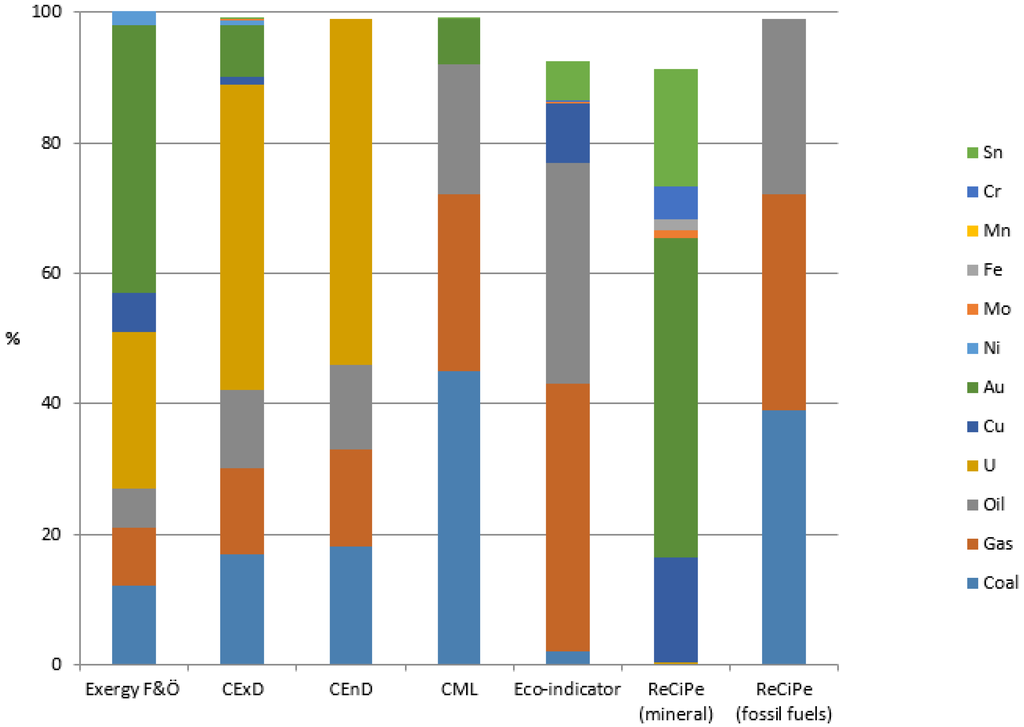

Figure 2.

Characterization of most important non-renewable resources for the production and use of a laptop in percentage of the total result.

The Exergy F & Ö method and CExD give similar results for traditional energy resources, but partly different results for metals. The CEnD naturally only gives results for energy resources, and the CML method gives the result that energy resources are, in practice, the most important resources, especially in the case of ferrous recycling. Conversely, Eco-indicator 99 suggests that metals are more important than energy resources in this case. The Exergy F & Ö and CExD methods give weight to both energy and metal resources.

For metals, the Exergy F & Ö and CExD methods give different results. The Exergy F & Ö method gives higher results than CExD for some metals (e.g., Ni in the case of ferrous recycling and Au in the laptop case). This is because the two methods have modeled the metal ores in different ways. The Exergy F & Ö method has data for sulphidic ores for some metals (copper, gold and nickel) with a high chemical exergy whereas the CExD method uses a generic average ore matrix with a lower chemical exergy. The exergy of the generic ore used in the CExD method [19] was the average of the ores in [18]. It can therefore be argued that the ore composition adopted in the Exergy F & Ö method is more specific and relevant for the metal in question. On the other hand, the ore-generic data may be considered more generally applicable. The ore-specific data used in the Exergy F & Ö method can possibly be compared with site-dependent data, which is sometimes used in LCIA (cf. [2]). However, both methods are consistent in identifying the same metals as being the most important ones. This is partly in contrast to the Ecoindicator 99 and ReCiPe methods, which highlight other metals, partly because of data gaps. It also interesting to note that U is highlighted in the laptop case by the CEnD, CExD and the Exergy F & Ö methods, but hardly at all by the other methods.

Since different methods produce different answers, it is important to discuss and evaluate different approaches. Important questions then are: How can a choice be made between different methods and when is a specific method more adequate? Unfortunately, there is no simple way of determining this. There is no method by which it can be shown that one characterization method is the “correct” one (cf. [31]). Instead, theoretical reasoning must be applied and underlying assumptions should be discussed. Examples of questions that can be raised include: Is the problem defined in a relevant way? Does the quantification method adequately and reliably quantify the contribution to the problem? Are there any logical contradictions? Does the method produce reasonable results and can we in any sense judge which results are reasonable?

In the thermodynamic approach, resource use is measured in terms of exergy use (indicated by the exergy content of the resources) or entropy production. Several ways of thinking can lead to the conclusion that exergy is a relevant measure:

- The energetic argument claims that useful energy (i.e., exergy) is the ultimate limiting and scarce resource because every material resource has an energy cost associated with extracting it, which limits its scale [32]. Given sufficient amounts, a society can divert exergy, within the current technical possibilities, to the acquisition of whatever material that is in short supply. Exergy, rather than energy, is used in this context since consideration is given to the quality of the energy (i.e., the ability to do work) as well as the chemical exergy of traditionally non-energetic raw materials [18]. As ore grades become lower, more exergy will be needed to extract the resource. This is for two reasons. One is because more energy is needed to extract larger amounts of ore (which will have lower grade/concentrations of the resource). The other one is because the amount of chemical exergy that comes with the ore will increase (assuming a constant amount of exergy per kg of ore) since more ore will be needed to produce a certain product.

- The usability argument starts with the question: When we discuss resource depletion or consumption, what is actually depleted or consumed? [18]. It is neither matter, since matter cannot be destroyed or consumed (except for nuclear reactions), nor energy. A reasonable answer may be that it is the usable energy and matter that is consumed and depleted and transformed to less usable energy and matter. This happens in all real world processes. It could therefore be relevant to have the use of usable energy and matter as an indicator for resource consumption. A measure of useful energy is exergy. For a material to be useful it must normally be ordered, i.e., structured and concentrated. A well-known scientific measure that is often interpreted as a measure of the disorder of a system is entropy. If a material is to be useful, it must normally have lower entropy than the surroundings, here defined as the reference state. This implies that the material is structured and concentrated, i.e., has a higher order. An example is an ore which has a higher concentration and typically a lower entropy than the average crust defined in the reference state used in the methods applied here. Another example is fresh water which has lower entropy than seawater (which is part of the reference state). Societies and technical systems can be described as systems feeding on low-entropy matter and energy and converting them into high-entropy matter and energy. The entropy production may therefore be considered a relevant measure of resource consumption (cf. [33]). Since entropy is increased as exergy is decreased according to Ek 3 (where is the decrease of exergy, is the temperature of the surroundings and is the sum of the entropy increased), exergy can be used instead of entropy [29].

- The reversibility argument starts with the assumption that a relevant measure of resource consumption may be the costs required to restore the resource. The exergy of a resource is the theoretical minimum energy required to produce this resource from the defined reference state. It may thus be seen as measure of the minimum costs associated with the resource.

Are the results provided by the thermodynamic method reasonable? When applied in practice, it can be noted that the thermodynamic approach as used here can highlight both energetic resources (both fossil fuels and nuclear fuels) as well as metal resources. This is in contrast to some of the other methods which either only include energetic or metal resources (such as ReCiPe) or in practice highlight only one of them (such as the CML method) or have significant data gaps (such as Ecoindicator). We believe that that is an indication that the results are relevant to decision-makers and useful. This is because both energy and metal resources are on the policy agenda. The method can thus provide support for decision-making when, for example, different products using different types of resources are compared.

However, despite exergy being a feature that is common to both energy and non-energy resources, it is limited in capturing the scarcity of a material, as no indication of abundance and extraction rates of the material is included therein (e.g., [5,10]). Instead the thermodynamic approach is based on the assumption that different resources can substitute for each other and that the limited and scarce resource is exergy. So instead of capturing the scarcity of materials, it is focused on the scarcity of exergy. This is relevant since physical scarcity of materials can be overcome with exergy. If there is enough exergy, materials can be extracted from low-grade ores and seawater.

The thermodynamic approach (or the other methods discussed here) does, however, not capture all resource aspects that are on the political agenda. For example, geopolitical aspects, which are a part of resource criticality assessments (e.g., [34]), are not included. However, there is currently no common and clear picture of how to describe the problem of resource use and which aspects should be included and valued (cf. [35]). Since different methods for the characterization of abiotic resources capture different aspects, they can also be seen as complementary.

The thermodynamic approach can be further developed. Different types of metal ores have different exergies [18] and the databases should therefore be improved to reflect this variability. This is especially relevant if changing ore grades also leads to changes in the composition of the ores. This is the case for many metals typically found in sulphide ores at higher ore grades (e.g., copper), but in oxide ores at lower ore grades with corresponding changes in the exergy of the ore [18]. The possibilities of using exergy consumption not only as measure of abiotic resources but also for other types of resources such as biotic resources, water and land [20] is also an interesting development. This could involve further complexities related, for example, to time for replenishing fund resources, local scarcity of water, etc. The advantage is, however, the possibility to integrate different types of resources in a common framework.

Although characterization methods for the use of abiotic resources have been discussed extensively, there are only a limited number of published studies where comparisons including the thermodynamic approach were made (notable exceptions include [6,7,8] but these were limited in different ways). The comparisons made have also focused on the Cad data [19] and not the Exergy F & Ö data [18], although we show here that they can give different results. Since different case studies illustrate different aspects, new learnings can be made and further studies would be useful. In addition to showing the differences between alternative methods, the case studies here illustrate that the thermodynamic approach can show the importance of both energy and material resources, and that the two datasets used here give similar but not identical results illustrating the importance of the ore composition.

LCA and exergy analysis can be linked in many ways, (cf. [21]). Here, the focus has been on exergy as measure of resource use in the characterization part of the LCIA. In a number of case studies (e.g., [36,37,38]), exergy analysis is used as a characterization method or as a method for broadening LCA [39]. It can be used in these ways for both attributional (or accounting) LCA, as well as consequential LCA (cf. [2]). Others have suggested that LCA and exergy analysis complement each other (e.g., [40,41,42,43]. Exergy analysis can also be used as a stand-alone assessment tool, e.g., [29,44,45,46,47], or linked to other environmental systems analysis tools, such as Strategic Environmental Assessment [48], besides its use as an engineering tool for analyzing and optimizing different types of processes [29,49]. This non-exhaustive list indicates that the applications of exergy analysis are numerous and that it is an established method in many areas. It could therefore also be used with confidence as a characterization method in LCA.

4. Conclusions

There are a number of different methods available for characterizing non-renewable resources and they give strikingly different results. The thermodynamic approach is developed from a solid scientific basis and it is currently operational with, for example, the CExD method with an extensive database. The approach is used by different groups and it produces relevant results. It can be noted that it captures most abiotic resources that are considered important by other methods. For the case studies on the recycling of ferrous waste and the production and use of a laptop, both energy resources and metals are of importance. Results for the thermodynamic approach depend on the composition of the ore; more ore-specific data should be developed and their importance evaluated (in parallel to site-specific data for emissions and impacts). Possibilities for using thermodynamic data for other resources (renewable materials and energy, water and land) should also be explored further.

Revisiting the questions raised above, we draw the conclusions that the thermodynamic approach used here is developed from an established scientific basis, based on a discussion on why exergy is a relevant measure. It is relevant as an indicator both for resource use and resource depletion since it is a measure of something that is actually consumed. We also argue that the results are relevant for decision-making. The calculations can be made in a reliable way and the data necessary is robust and time-independent, except for the composition of the ores which may change with time as the ore grades and types of ores used change.

Acknowledgments

Funding from Vinnova and partners of CESC (Center for Sustainable Communication) at KTH is appreciated. Comments from anonymous reviewers are also gratefully acknowledged.

Author Contributions

G.F. designed the research, Y.A. made the calculations, G.F. drafted the paper with contributions from Y.A. and M.B.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lazarevic, D.; Buclet, N.; Brandt, N. The application of life cycle thinking in the context of European waste policy. J. Clean. Product. 2012, 29–30, 199–207. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Curran, M.A. (Ed.) Life Cycle Assessment Student Handbook; Wiley-Scivener: Hoboken, NJ, USA; Salen, MA, USA, 2015.

- Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040:2006; ISO Standard: Geneva, Switzerland, 1997.

- Klinglmair, M.; Sala, S.; Brandão, M. Assessing resource depletion in LCA: A review of methods and methodological issues. Int. J. Life Cycle Assess. 2014, 19, 580–592. [Google Scholar] [CrossRef]

- Rørbech, J.T.; Vadenbo, C.; Hellweg, S.; Aastrup, T.F. Impact assessment of abiotic resources in LCA: Quantitative comparison of selected characterization models. Environ. Sci. Technol. 2014, 48, 11072–11081. [Google Scholar] [CrossRef] [PubMed]

- Van Caneghem, J.; Vermeulen, I.; Block, C.; Cramm, P.; Mortier, R.; Vandercasteele, C. Abiotic depletion due to resource consumption in a steelwork assessed by five different methods. Resour. Conserv. Recycl. 2010, 54, 1067–1073. [Google Scholar] [CrossRef]

- Alvarenga, R.A.F.; de Oliveira Lins, I.; de Almeida Net, J.A. Evaluation of abiotic resource LCIA methods. Resources 2016, 5. [Google Scholar] [CrossRef]

- Finnveden, G. “Resources” and related impact categories. In Towards a Methodology for Life Cycle Impact Assessment; Udo de Haes, H.A., Ed.; SETAC-Europe: Brussels, Belgium, 1996; pp. 39–48. [Google Scholar]

- European Commission-Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook-Recommendations for Life Cycle Impact Assessment in the European Context, 1st ed.; EUR 24571 EN; Publications Office of the European Union: Luxemburg, Luxemburg, 2011. [Google Scholar]

- Goedkoop, M.; Spriensma, R. The Eco-indicator 99—A Damage-oriented Method for Life Cycle Impact Assessment. Methodology Report, 2nd ed.; Pré Consultants, B.V.: Amersfoort, The Netherlands, 2000. [Google Scholar]

- Goedkoop, M.J.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008, A life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level, First edition Report I: Characterisation. Available online: http://www.lcia-recipe.net (accessed on 15 June 2016).

- Weidema, B.P.; Finnveden, G.; Stewart, M. Impacts from Resource Use—A common position paper. Int. J. Life Cycle Assess. 2005, 10, 382. [Google Scholar] [CrossRef]

- Wenzel, H.; Hauschild, M.Z.; Alting, L. Methodology, Tools, Techniques and Case Studies. In Environmental Assessment of Products; Chapman & Hall: United Kingdom, UK; Kluwer Academic Publishers: Hingham, MA, USA, 1997; Volume 1, p. 544. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Sleeswijk, A.W.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Schneider, L.; Berger, M.; Finkbeiner, M. Abiotic resource depletion in LCA—Background and update of the anthropogenic stock extended abiotic depletion potential (AADP) model. Int. J. Life Cycle Assess. 2015, 20, 709–721. [Google Scholar] [CrossRef]

- Szargut, J. International progress in second law analysis. Energy 1979, 5, 709–718. [Google Scholar] [CrossRef]

- Finnveden, G.; Östlund, P. Exergies of Natural Resources in Life Cycle Assessment and Other Applications. Energy 1997, 22, 923–931. [Google Scholar] [CrossRef]

- Bösch, M.E.; Hellweg, S.; Huijbregts, M.; Frischknecht, R. Applying cumulative exergy demand (CExD) indicators to the ecoinvent database. Int. J. Life Cycle Assess. 2007, 12, 181–190. [Google Scholar] [CrossRef]

- Dewulf, J.; Bösch, M.E.; De Meester, B.; Van der Vorst, G.; Van Langenhove, H.; Hellweg, S.; Huijbregts, M.A.J. Cumulative Exergy Extraction from the Natural Environment (CEENE): A comprehensive Life Cycle Impact Assessment method for resource accounting. Environ. Sci. Technol. 2007, 41, 8477–8483. [Google Scholar] [CrossRef] [PubMed]

- Ayres, R.U.; Ayres, L.W.; Martinas, K. Exergy, waste accounting and life-cycle analysis. Energy 1998, 23, 355–363. [Google Scholar] [CrossRef]

- Gössling-Reisemann, S. Combining LCA with thermodynamics. In Information Technologies in Environmental Engineering; Marx Gomez, J., Sonnenschein, M., Müller, M., Welsch, H., Rautenstrauch, C., Eds.; Springer: Heidelberg, Germany, 2007; pp. 387–396. [Google Scholar]

- Valero, A. From grave to cradle. A thermodynamic approach for accounting for abiotic resource depletion. J. Ind. Ecol. 2013, 17, 43–52. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: the energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Hischier, R.; Hellweg, S.; Nemecek, T.; Rebitzer, G.; Spielman, M. Overview and Methodology; Final report ecoinvent data v 2.0, No. 1; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Classen, M.; Althaus, H.-J.; Blaser, S.; Scharnhorst, W.; Jungbluth, N.; Tuchschmid, M.; Faist Emmenegger, M. Life Cycle Inventories of Metals; Final report ecoinvent data v2.1; Swiss Centre for LCI, Empa—TSL: Dübendorf, Switzerland, 2009; Volume 10. [Google Scholar]

- Frischknecht, R.; Tuchschmid, M.; Faist Emmenegger, M.; Bauer, C.; Dones, R. Strommix und Stromnetz Sachbilanzen von Energiesystemen; Final report No. 6 ecoinvent data v2.0; Dones, R., Ed.; Swiss Centre for LCI, PSI: Dübendorf/Villigen, Switzerland, 2007; Volume 6. [Google Scholar]

- Hischier, R.; Classen, M.; Lehmann, M.; Scharnhorst, W. Life Cycle Inventories of Electric and Electronic Equipment—Production, Use & Final report ecoinvent Data v2.0; Swiss Centre for LCI, Empa—TSL: Duebendorf/St. Gallen, Switzerland, 2007; Volume 18. [Google Scholar]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical and Metallurgical Processes; Hemisphere: New York, NY, USA, 1988. [Google Scholar]

- De Meester, B.; Dewulf, J.; Janssens, A.; van Langenhove, H. An improved calculation of the exergy of natural resources for exergetic life cycle assessment (ELCA). Environ. Sci. Technol. 2006, 40, 6844–6851. [Google Scholar] [CrossRef] [PubMed]

- Finnveden, G. On the Limitations of Life Cycle Assessment and Environmental Systems Analysis Tools in General. Int. J. Life Cycle Assess. 2000, 5, 229–238. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Cleveland, C.J.; Kaufman, R. Energy and Resource Quality: The Ecology of the Economic Process; Wiley-Interscience: New York, NY, USA, 1986. [Google Scholar]

- Gössling-Reisemann, S. What is resource consumption and how can it be measured? J. Ind. Ecol. 2008, 12, 10–25. [Google Scholar] [CrossRef]

- Sonnemann, G.; Gemuchu, E.D.; Adibi, N.; De Bruille, V.; Bulle, C. From a critical review to a conceptual framework for integrating the criticality of resources into Life Cycle Sustainability Assessment. J. Clean. Product. 2015, 94, 20–34. [Google Scholar] [CrossRef]

- Isacs, L.; Finnveden, G.; Håkansson, C.; Steen, B.; Tekie, H.; Rydberg, T.; Widerberg, A.; Wikström, A. Valuation of abiotic resources in impact assessment. Res. Conserv. Recycl. 2015. Submitted. [Google Scholar]

- Achachlouei, M.A.; Moberg, Å.; Hochschorner, E. Life Cycle Assessment of a magazine, part I: Tablet edition in emerging and mature states. J. Ind. Ecol. 2015, 19, 575–589. [Google Scholar] [CrossRef]

- Alanya, S.; Dewulf, J.; Duran, M. Comparison of overall resource consumption of biosolids management system processes using exergetic life cycle assessment. Environ. Sci. Technol. 2015, 49, 9996–10006. [Google Scholar] [CrossRef] [PubMed]

- Reuter, M.A.; von Schalk, A.; Gediga, J. Simulation-based design for resource efficiency of metal production and recycling systems: Cases—Copper production and recycling, e-waste (LED lamps) and nickel pig iron. Int. J. Life Cycle Assess. 2015, 20, 671–693. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Azapagic, A.; Schepelmann, P.; Ritthof, M. Options for broadening and deepening the LCA approaches. J. Clean. Product. 2010, 18, 120–127. [Google Scholar] [CrossRef]

- Portha, J.-F.; Louret, S.; Pons, M.-N.; Jaubert, J.-N. Estimation of the environmental impact of a petrochemical process using coupled LCA and exergy analysis. Resour. Conserv. Recycl. 2010, 54, 291–298. [Google Scholar] [CrossRef]

- Hiraki, T.; Akiyama, T. Exergetic life cycle assessment of new waste aluminium treatment system with co-production of pressurized hydrogen and aluminium hydroxide. Int. J. Hydrog. Energy 2009, 34, 153–161. [Google Scholar] [CrossRef]

- Yang, L.; Zmeureanu, R.; Rivard, H. Comparison of environmental impacts of two residential heating systems. Build. Environ. 2008, 43, 1072–1081. [Google Scholar] [CrossRef]

- De Meester, B.; Dewulf, J.; Verbeke, S.; Janssens, A.; van Langenhove, H. Exergetic life-cycle assessment (ELCA) for resource consumption evaluation in the built environment. Build. Environ. 2009, 44, 11–17. [Google Scholar] [CrossRef]

- Wall, G. Exergy conversion of the Swedish society. Resour. Energy 1987, 9, 55–73. [Google Scholar] [CrossRef]

- Chen, G.Q.; Qi, Z.H. Systems account of societal exergy utlilization: China 2003. Ecol. Model. 2007, 208, 102–118. [Google Scholar] [CrossRef]

- Dewulf, J.; van Langenhove, H.; Muys, B.; Bruers, S.; Bakshi, B.R.; Grubb, G.F.; Paulus, D.M.; Sciubba, E. Exergy: Its potential and limitations in environmental science and technology. Environ. Sci. Technol. 2008, 42, 2221–2232. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.; Heijungs, R.; Huppes, G. Thermodynamic analysis of human-environment systems: A review focused on industrial ecology. Ecol. Model. 2012, 228, 76–88. [Google Scholar] [CrossRef]

- Finnveden, G.; Nilsson, M.; Johansson, J.; Persson, Å.; Moberg, Å.; Carlsson, T. Strategic Environmental Assessment Methodologies—Applications within the energy sector. Environ. Impact Assess. Rev. 2003, 23, 91–123. [Google Scholar] [CrossRef]

- Szargut, J.; Morris, D.R. Cumulative exergy consumption and cumulative degree of perfection of chemical processes. Int. J. Energy Res. 1987, 11, 245–261. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).