The Secrets of Beautiful Hair: Why is it Flexible and Elastic?

Abstract

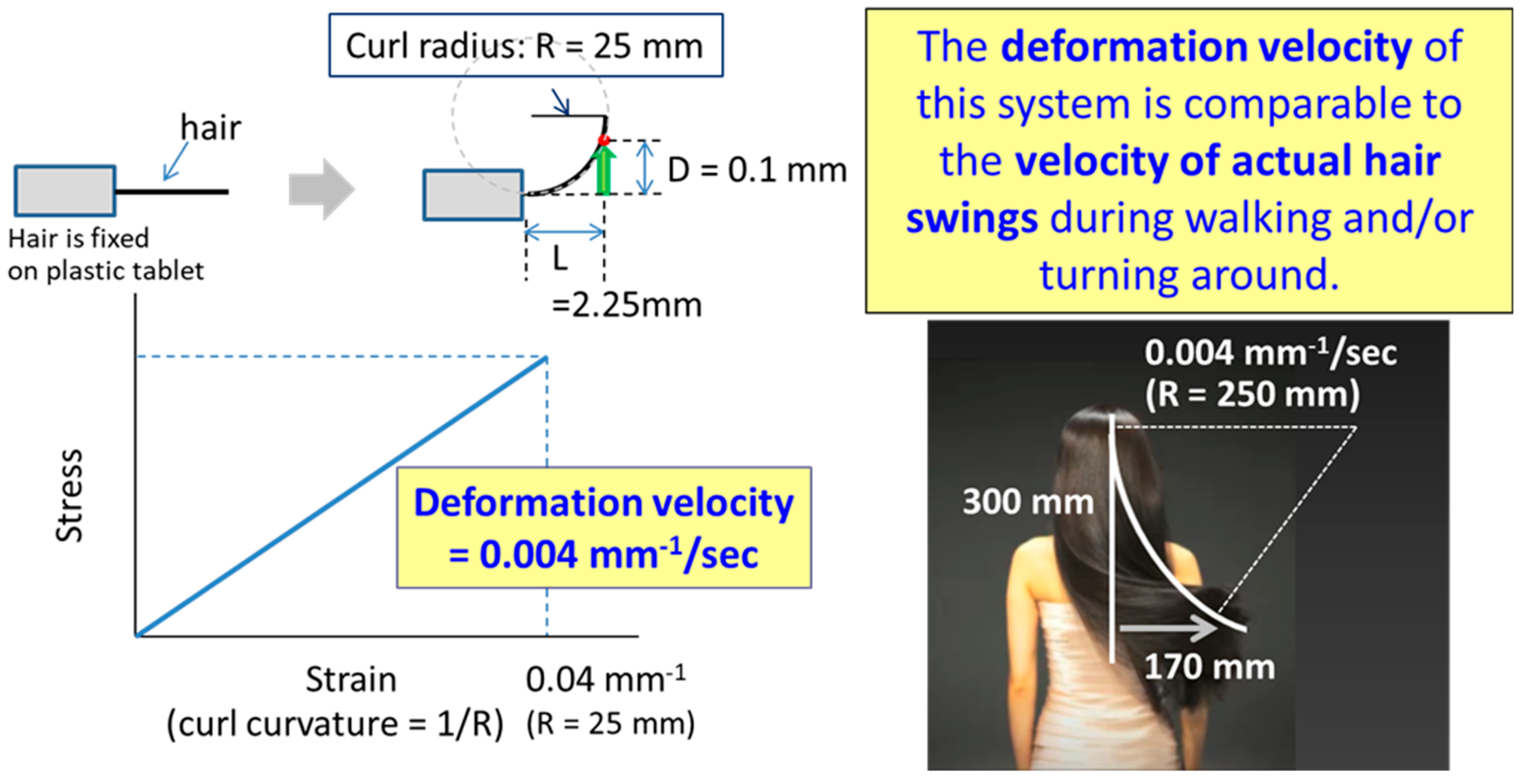

:1. Introduction

2. Materials and Methods

2.1. Hair Samples

2.1.1. Selection of Hair Samples

2.1.2. Chemical Treated Hair

2.1.3. Caucasian Hair

2.2. Preparation of the Hair Sample

2.2.1. Preparation of the Model Damaged Hair

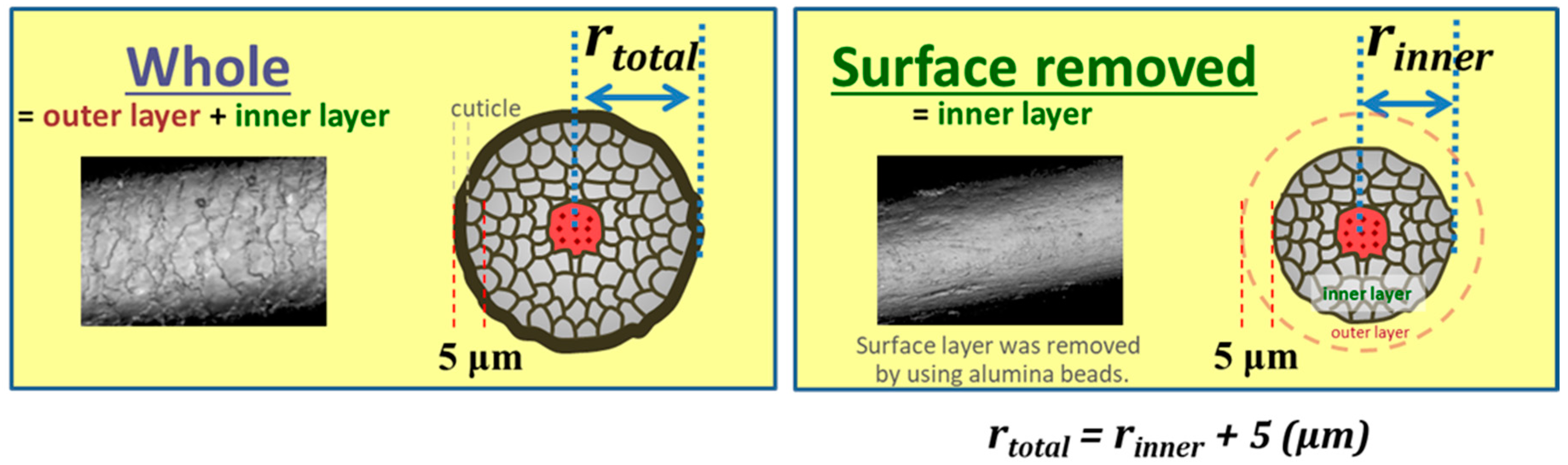

2.2.2. Preparation of the Surface-Removed Hair

2.2.3. Treatment with Succinic Acid

2.2.4. The Three-Step Treatment System

2.3. Microscopic Observation Of Hair Cross-Sections

2.3.1. Transmission Electron Microscopy (TEM)

2.3.2. Fluorescent Light Microscope (FLM)

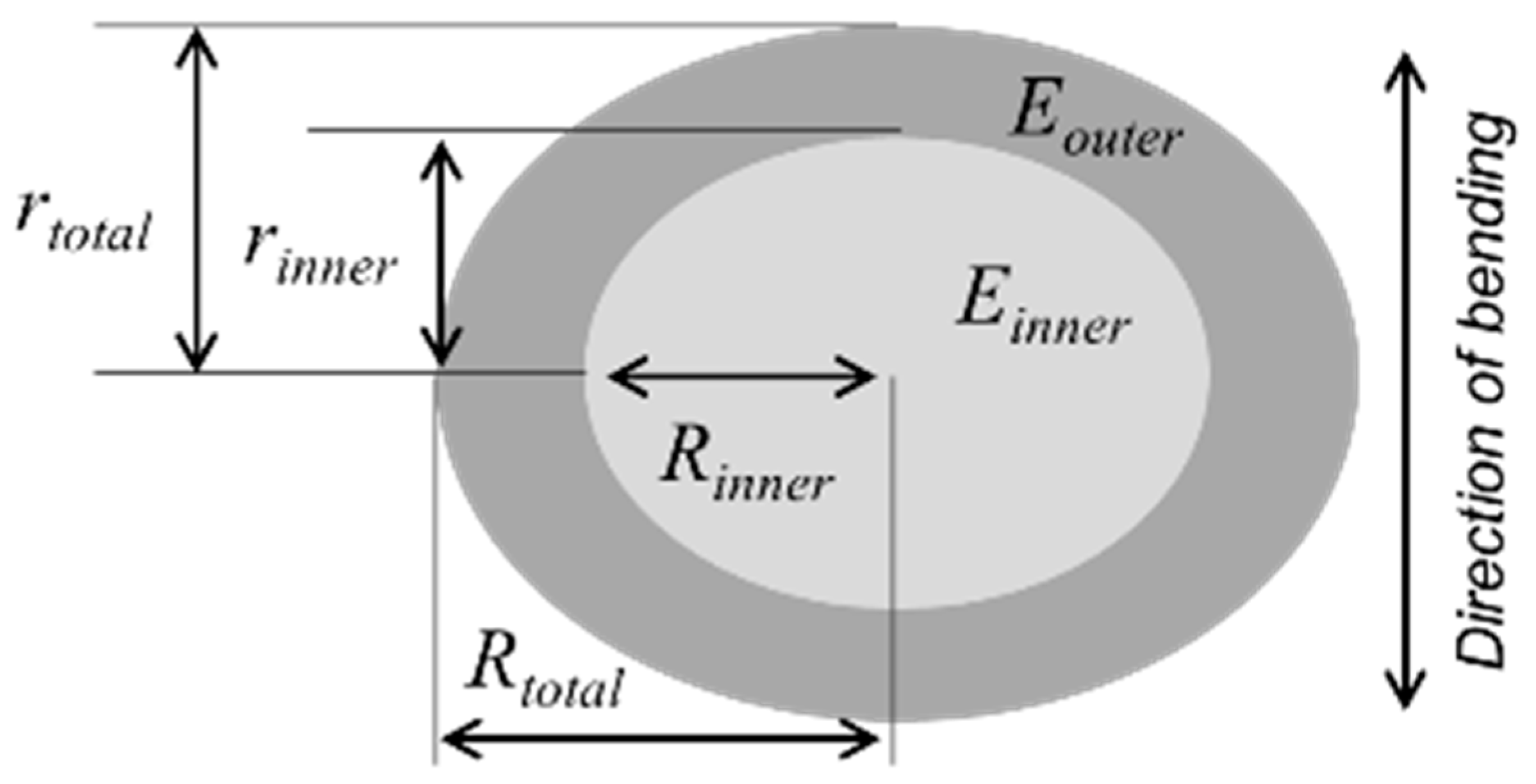

2.4. Measurement of Bending Elasticity in the Outer and Inner Layers

2.5. Atomic Force Microscopy (AFM)

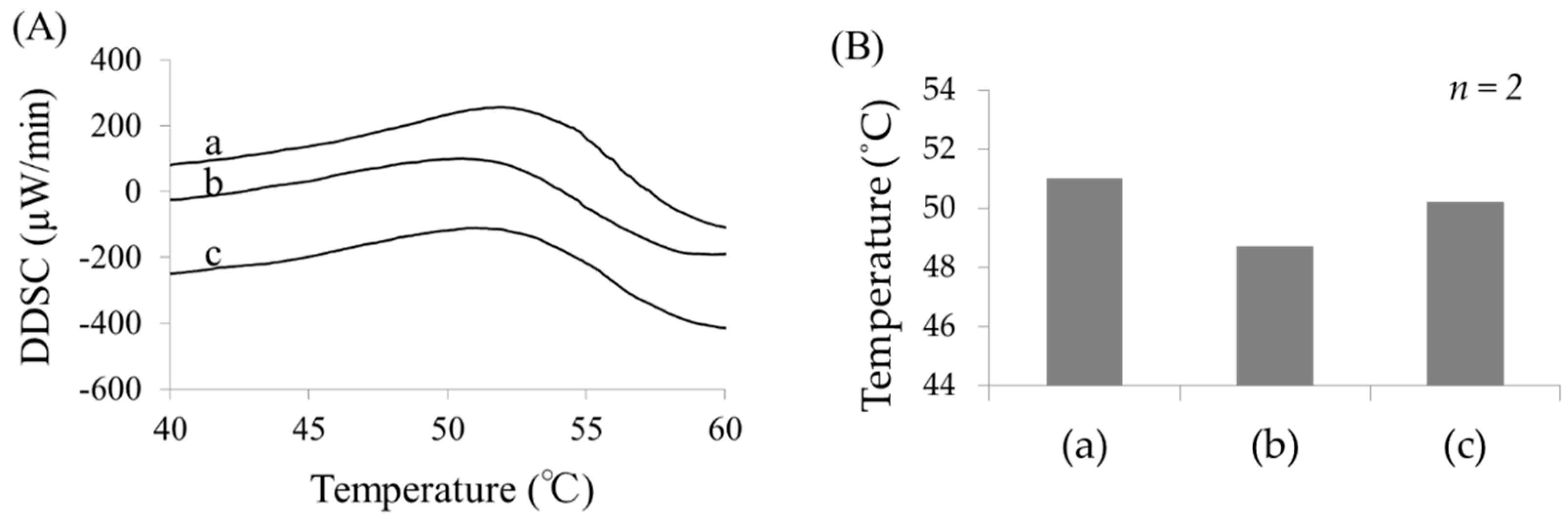

2.6. Differential Scanning Calorimetry (DSC)

3. Results

3.1. Distribution of Cortical Cells

3.1.1. TEM Observation of Hair Cross-Sections

3.1.2. FLM Observation of Hair Cross-Sections

3.2. Distribution of Hair Mechanical Properties

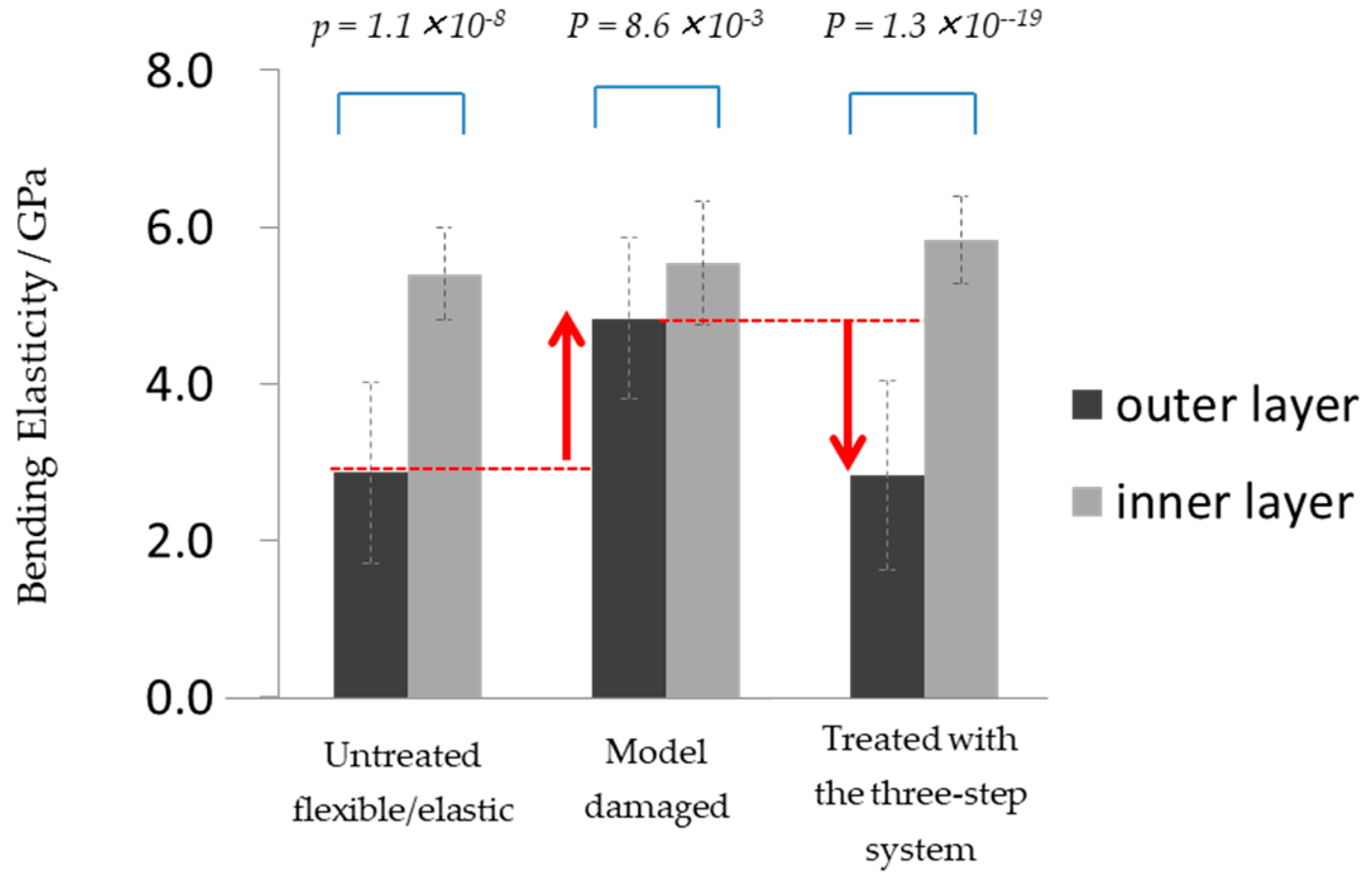

3.2.1. Bending Elasticity of Outer and Inner Layers

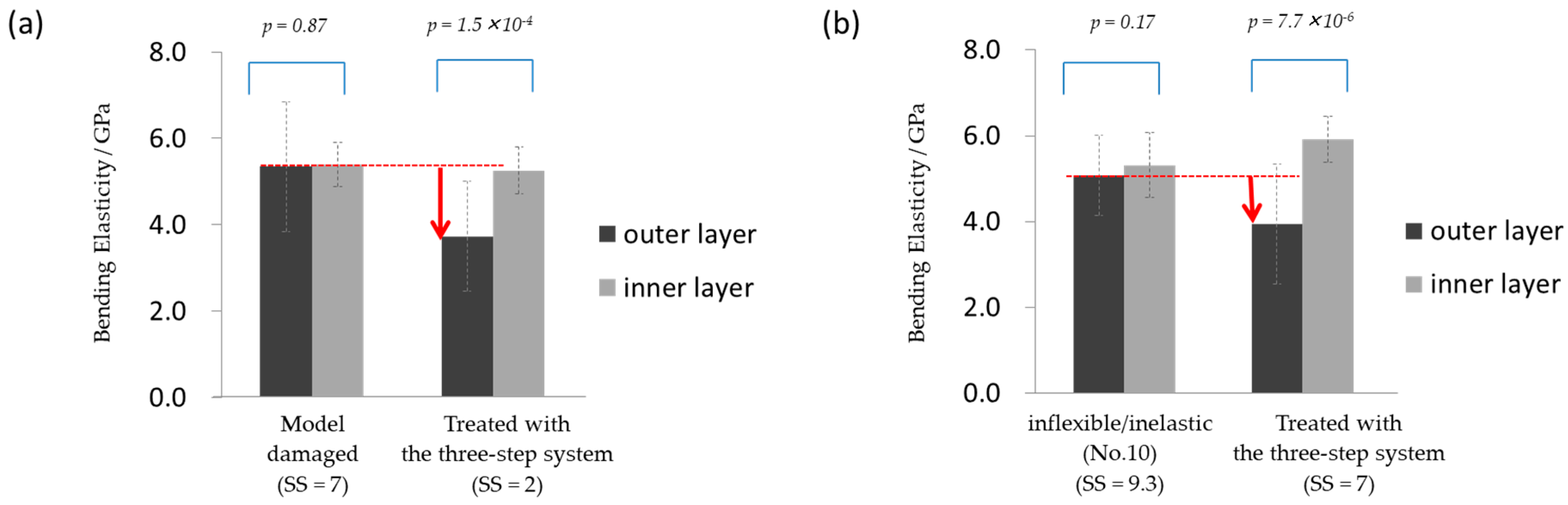

3.2.2. Influence by Hair Damage

3.3. Modification of the Mechanical Properties

3.3.1. Treatment with Succinic Acid

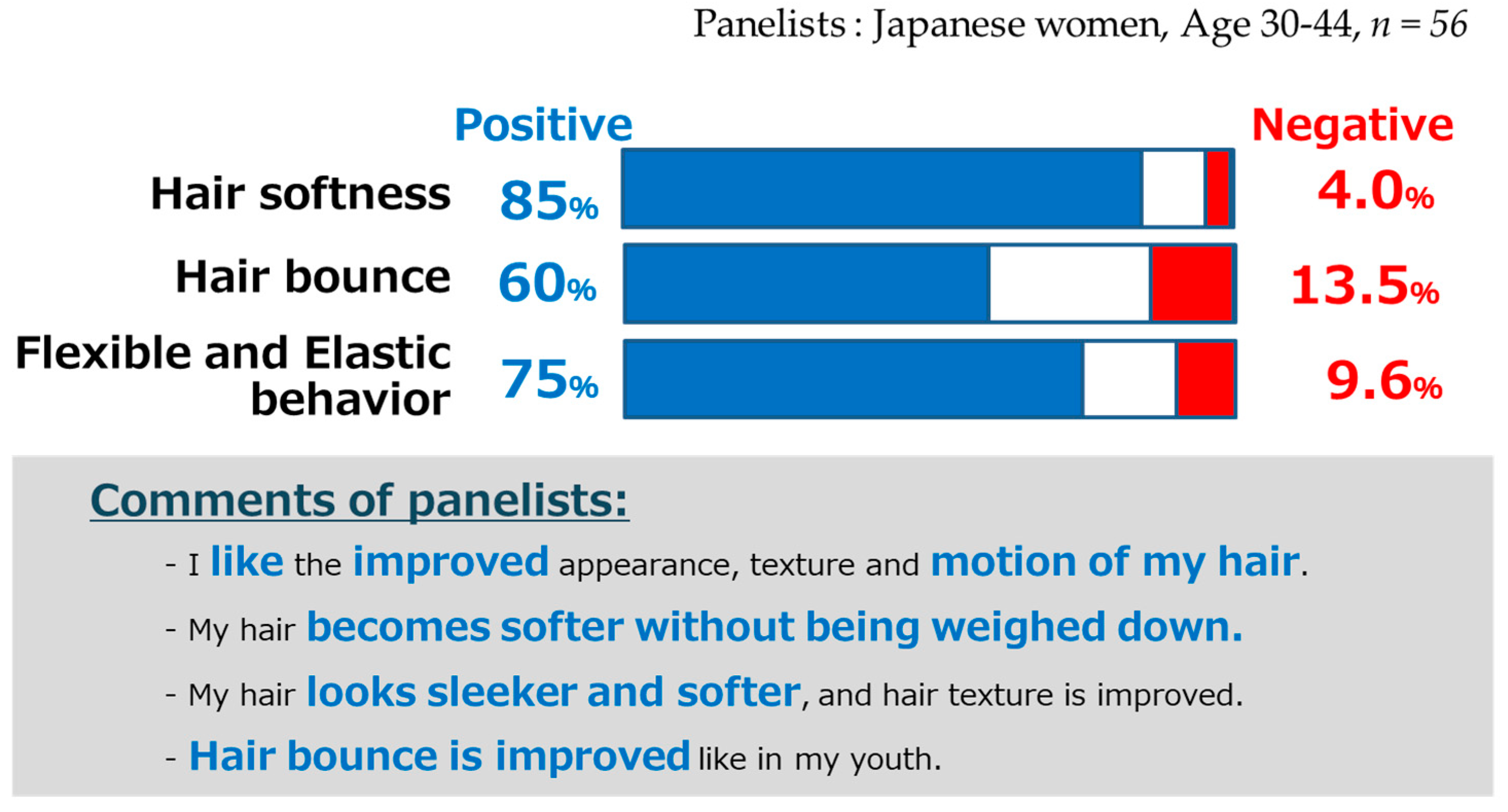

3.3.2. Treatment with the Three-Step Treatment System

3.3.3. Application to Caucasian hair

4. Discussion

4.1. Characteristic Structural Pattern

4.2. Characteristics of Bending Elasticities

4.3. Modification of the Mechanical Properties

4.3.1. Effect of Succinic Acid

4.3.2. The Three-Step Treatment System

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nagase, S.; Satoh, N.; Nakamura, K. Influence of internal structure of hair fiber on hair appearance. 2. Consideration of the visual perception mechanism of hair appearance. J. Cosmet. Sci. 2002, 53, 387–402. [Google Scholar] [PubMed]

- Tanamachi, H.; Inoue, S.; Tanji, N.; Tsujimura, H.; Oguri, M.; Ishita, M.; Tokunaga, S.; Sazanami, F. Deposition of 18-MEA onto alkaline-color-treated weathered hair to form a persistent hydrophobicity. J. Cosmet. Sci. 2009, 60, 31–44. [Google Scholar] [CrossRef] [PubMed]

- Okamoto, M.; Yakawa, R.; Mamada, A.; Inoue, S.; Nagase, S.; Shibuichi, S.; Kariya, E.; Satoh, N. Influence of internal structures of hair fiber on hair appearance. 3. Generation of light-scattering factors in hair cuticles and the influence on hair shine. J. Cosmet. Sci. 2003, 54, 353–366. [Google Scholar] [PubMed]

- Breakspear, S.; Fukuhara, M.; Itou, T.; Hirano, Y.; Nojiri, M.; Kiyomine, A.; Inoue, S. Alignment control and softness creation in hair with glycylglycine. J. Cosmet. Sci. 2014, 64, 19–33. [Google Scholar]

- Nagase, S.; Shibuichi, S.; Ando, K.; Kariya, E.; Okamoto, M.; Yakawa, R.; Mamada, A.; Satoh, N. Light-Scattering Control at Medulla Enhances Human Hair Shine. Internal Structures of Hair Fiber and Its Shine (1). In Proceedings of the 21th IFSCC Congress, Berlin, Germany, 11–14 September 2000. [Google Scholar]

- Okamoto, M.; Mamada, A.; Yakawa, R.; Inoue, S.; Nagase, S.; Shibuichi, S.; Satoh, N. Hole Generation Mechanisms in Hair Medulla and Its Repairing Technique. Internal Structures of Hair Fiber and its Shine (3). In Proceedings of the 21th IFSCC Congress, Berlin, Germany, 11–14 September 2000. [Google Scholar]

- Nojiri, M.; Itou, T.; Asami, M.; Ueyama, K.; Nakamura, K. A novel technolory for improving hair setting ability and its mechanism. J. Cosmet. Sci. 2004, 55, 151–153. [Google Scholar]

- Itou, T.; Nojiri, M.; Ootsuka, Y.; Nakamura, K. Study of interaction between hair protein and organic acid that improves hair-set durability by near-infrared spectroscopy. J. Cosmet. Sci. 2006, 57, 139–151. [Google Scholar]

- Galliano, A.; Lheur, M.; Santoprete, R. Analysing the movement of a hair swatch using vdeo and image analysis: Apromibing technique for exploring the dynamic properties of hair. J. Cosmet. Sci. 2015, 37, 56–62. [Google Scholar] [CrossRef] [PubMed]

- Hindley, M.C.; Yap, M.; Ugail, H. Measurement of Hair Dynamics via video image Analysis. In Proceedings of the 27th IFSCC Congress, Seoul, Korea, 23–25 October 2017; p. 167. [Google Scholar]

- Wiesche, E.S.; Focht, N.; Wortmann, F.J. The Swinging Behaviour of Human Hair—A Novel Method to Quantify Hair Collective Movements. In Proceedings of the 23rd IFSCC Conference, Zurich, Switzerland, 21–23 September 2015; p. 123. [Google Scholar]

- Obataya, E.; Kitin, P.; Yamauchi, H. Bending characteristics of bamboo (Phyllostachys pubescens) with respect to its fiber–foam composite structure. Wood Sci. Technol. 2007, 41, 385–400. [Google Scholar] [CrossRef]

- Balfour, H. Structure and affinities of the composite bow. J. Anthr. Inst. Great Br. Irel. 1890, 19, 220–250. [Google Scholar] [CrossRef]

- Bryson, W.G.; Harland, D.P.; Caldwell, J.P.; Vernon, J.A.; Walls, R.J.; Woods, J.L.; Nagase, S.; Itou, T.; Koike, K. Cortical cell types and intermediate filament arrangements correlate with fiber curvature in Japanese human hair. J. Struct. Biol. 2009, 166, 46–58. [Google Scholar] [CrossRef]

- Kajiura, Y.; Watanabe, S.; Itou, T.; Nakamura, K.; Iida, A.; Inoue, K.; Yagi, N.; Shinohara, Y.; Amemiya, Y. Structural analysis of human hair single fibers by scanning microbeam SAXS. J. Struct. Biol. 2006, 155, 438–444. [Google Scholar] [CrossRef] [PubMed]

- Nagase, S.; Tsuchiya, M.; Matsui, T.; Shibuichi, S.; Tsujimura, H.; Masukawa, Y.; Satoh, N.; Itou, T.; Koike, K.; Tsujii, K. Characterization of curved hair of Japanese women with reference to internal structures and amino acid composition. J. Cosmet. Sci. 2008, 59, 317–332. [Google Scholar] [PubMed]

- Nagase, S.; Kajiura, Y.; Mamada, A.; Abe, H.; Shibuichi, S.; Satoh, N.; Itou, T.; Shinohara, Y.; Amemiya, Y. Changes in structure and geometric properties of human hair by aging. J. Cosmet. Sci. 2009, 60, 637–648. [Google Scholar] [CrossRef] [PubMed]

- Nishita, Y.; Ezure, M.; Tanji, N.; Mizooku, T.; Nagase, S.; Osumi, T. Physical Properties of Shinayaka Hair and Fine Technology to Control Internal Hair Properties. J. Soc. Cosmet. Jpn. 2017, 51, 126–133. [Google Scholar] [CrossRef]

- Breakspear, S.; Mamada, A.; Itou, T.; Noecker, B. Contribution of the cuticle to the stiffness hair: Significant or minor? IFSCC Mag. 2015, 1, 25–34. [Google Scholar]

- Swift, J.A. Some simple theoretical considerations on the bending stiffness of human hair. Int. J. Cos. Sci. 1995, 17, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Bucciarelli, L.L. Engineering Mechanics for Structures; Dover Publications, INC: Mineola, NY, USA, 2009; pp. 263–271. [Google Scholar]

- Sogabe, A.; Yasuda, M.; Noda, A. Physical properties of human hair 1. Evaluation of bending stress by measuring the major and the minor axis of human hair. J. Soc. Cosmet. Chem. Jpn. 2002, 36, 207–215. [Google Scholar] [CrossRef]

- Nakajima, K.; Fujinami, S.; Nukaga, H.; Watabe, H.; Kitano, H.; Ono, N.; Endoh, K.; Kaneko, M.; Nishi, T. Nanorheology mapping by atomic force microsdopy. Kobunshi Ronbunshu 2005, 63, 476–487. [Google Scholar] [CrossRef]

- Caldwell, J.P.; Bryson, W.G. Elastic modulus mapping of the wool fibre cellular structure by atomic force microscopy. In Proceedings of the 11th International Wool Research Conference, Leeds, UK, 4–9 September 2005; p. 89FWS. [Google Scholar]

- Ezawa, Y.; Nagase, S.; Mamada, A.; Inoue, S.; Koike, K.; Itou, T. Stiffness of human hair correlates with the fractions of cortical cell types. Cosmetics 2019, 6, 24. [Google Scholar] [CrossRef]

- Wortmann, F.J.; Stapels, M.; Elliott, R.; Chandra, L. The effect of water on the glass transition of human hair. Biopolymers 2006, 81, 371–375. [Google Scholar] [CrossRef]

- Gao, T. Evaluation of hair humidity resistance/moisturization from hair elasticity. J. Cosmet. Sci. 2007, 58, 393–404. [Google Scholar] [PubMed]

- Scott, G.V.; Robbins, C.R. Stiffness of human hair fibers. J. Soc. Cosmet. Chem. 1978, 29, 469–485. [Google Scholar]

| Sample No. | Sensory Score (SS) | Evaluation |

|---|---|---|

| 1 | 1.6 | flexible/elastic |

| 2 | 1.8 | flexible/elastic |

| 3 | 3.1 | flexible/elastic |

| 4 | 4.2 | somewhat flexible/elastic |

| 5 | 4.3 | somewhat flexible/elastic |

| 6 | 4.5 | somewhat flexible/elastic |

| 7 | 7.1 | inflexible/inelastic |

| 8 | 8.5 | inflexible/inelastic |

| 9 | 9.0 | inflexible/inelastic |

| 10 | 9.3 | inflexible/inelastic |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ezure, M.; Tanji, N.; Nishita, Y.; Mizooku, T.; Nagase, S.; Osumi, T. The Secrets of Beautiful Hair: Why is it Flexible and Elastic? Cosmetics 2019, 6, 40. https://doi.org/10.3390/cosmetics6030040

Ezure M, Tanji N, Nishita Y, Mizooku T, Nagase S, Osumi T. The Secrets of Beautiful Hair: Why is it Flexible and Elastic? Cosmetics. 2019; 6(3):40. https://doi.org/10.3390/cosmetics6030040

Chicago/Turabian StyleEzure, Mikako, Noriyuki Tanji, Yukari Nishita, Takashi Mizooku, Shinobu Nagase, and Takahiro Osumi. 2019. "The Secrets of Beautiful Hair: Why is it Flexible and Elastic?" Cosmetics 6, no. 3: 40. https://doi.org/10.3390/cosmetics6030040

APA StyleEzure, M., Tanji, N., Nishita, Y., Mizooku, T., Nagase, S., & Osumi, T. (2019). The Secrets of Beautiful Hair: Why is it Flexible and Elastic? Cosmetics, 6(3), 40. https://doi.org/10.3390/cosmetics6030040